Study on the Macroscopic Properties and Microstructure of High Fly Ash Content Alkali-Activated Fly Ash Slag Concrete Cured at Room Temperature

Abstract

1. Introduction

2. Raw Materials and Mix Proportions

2.1. Raw Materials

2.2. Mix Proportions

3. Specimen Preparation and Curing

4. Test Procedures

4.1. Compressive Strength Test

4.2. Air Permeability Test

4.3. Water Absorption Test

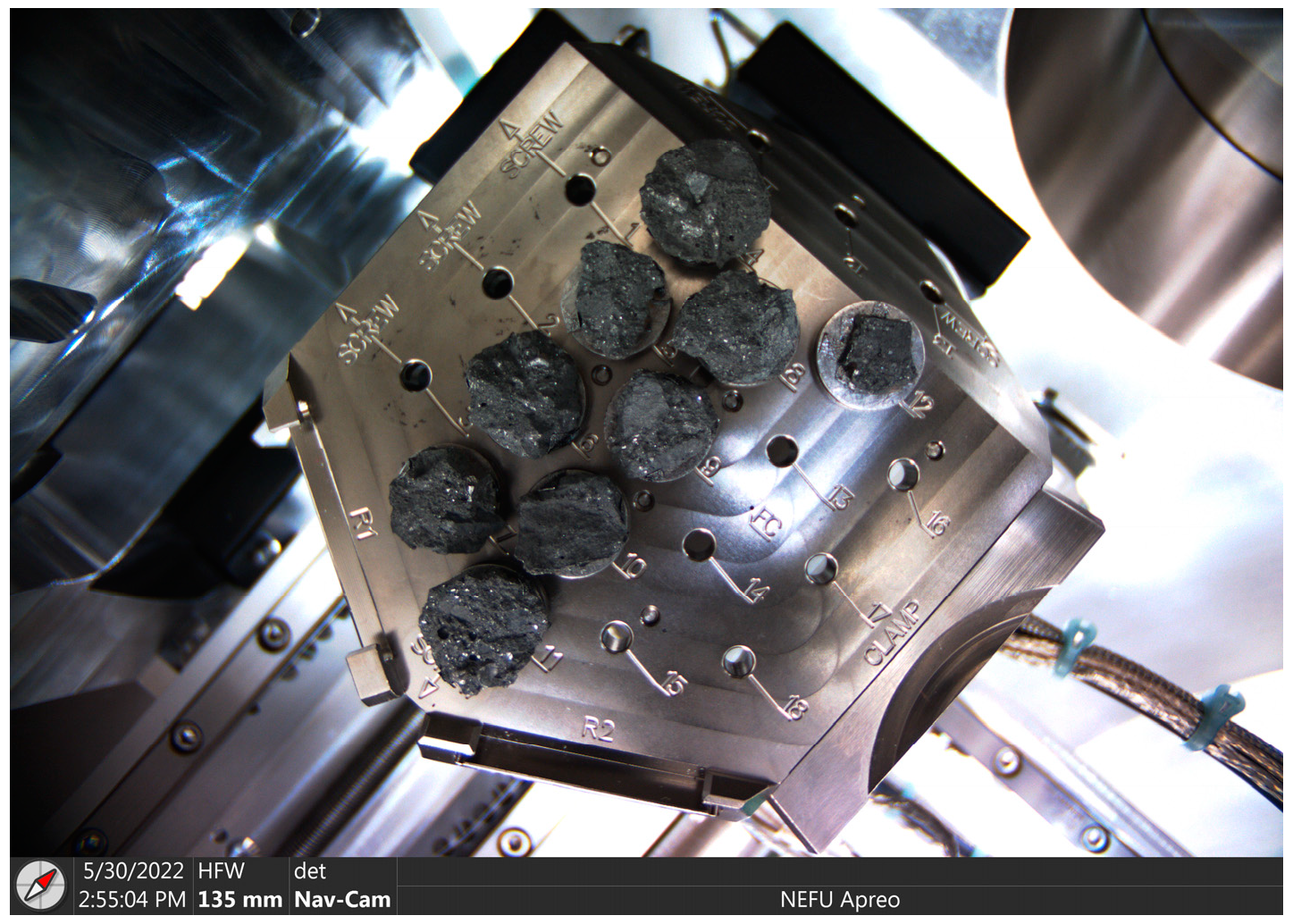

4.4. Microstructure Analysis Experiment

5. Results and Discussion

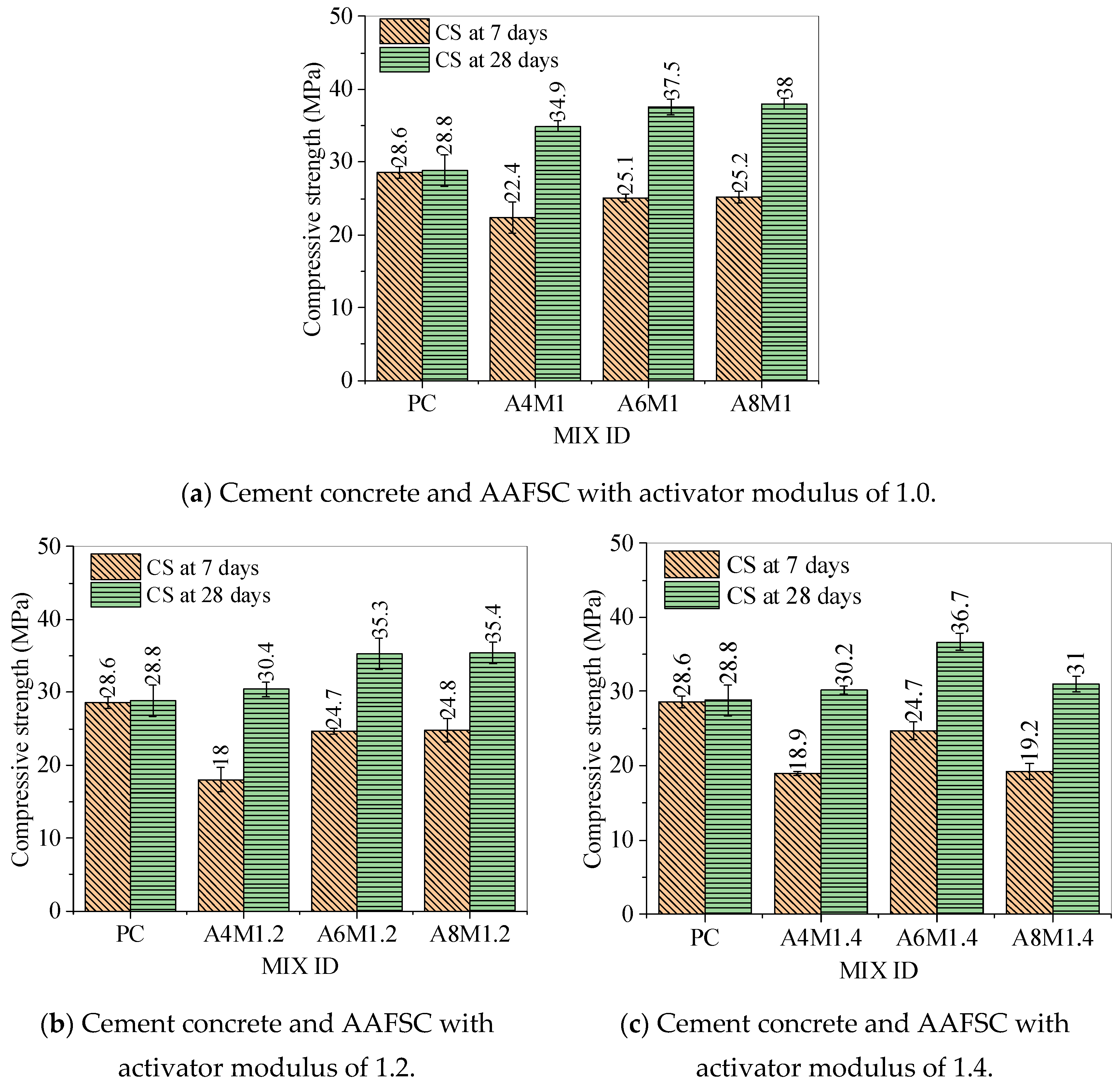

5.1. Compressive Strength

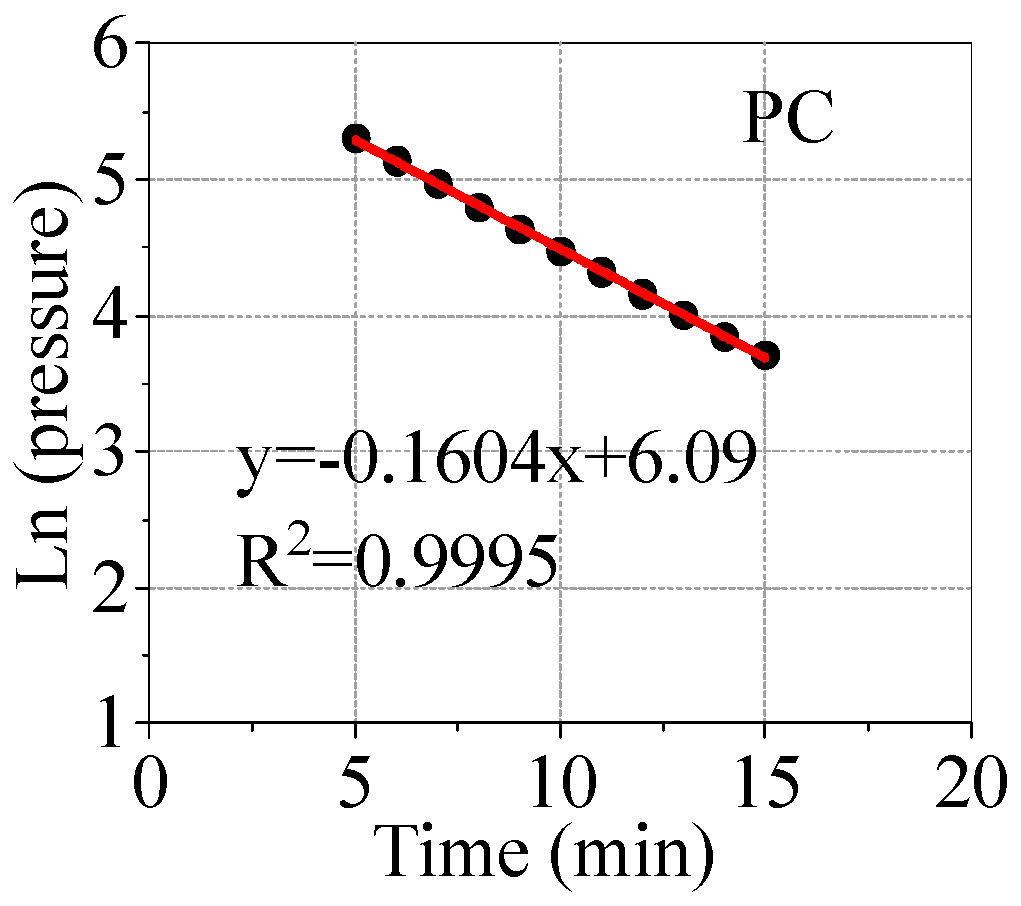

5.2. Air Permeability

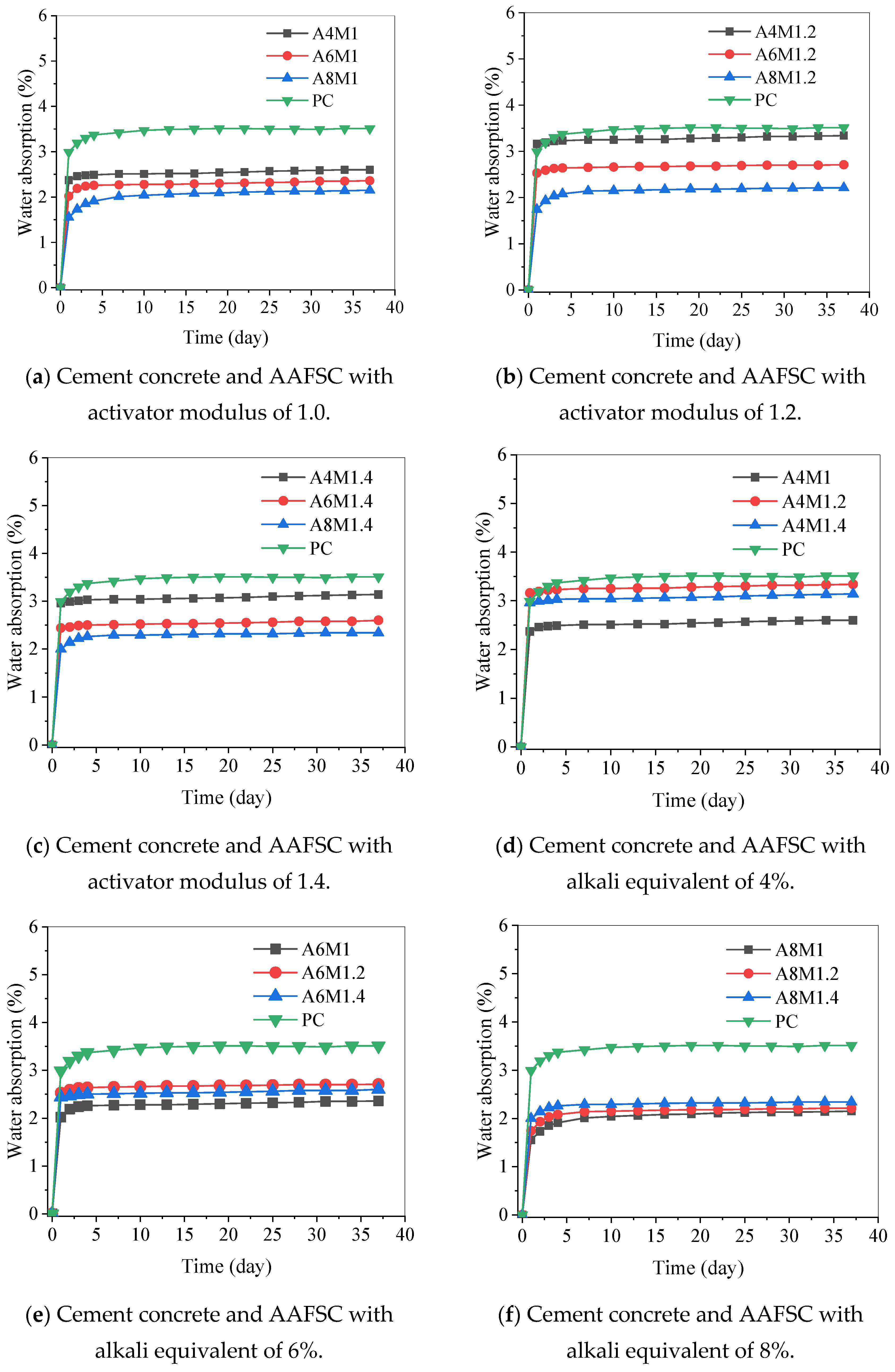

5.3. Water Absorption Analysis

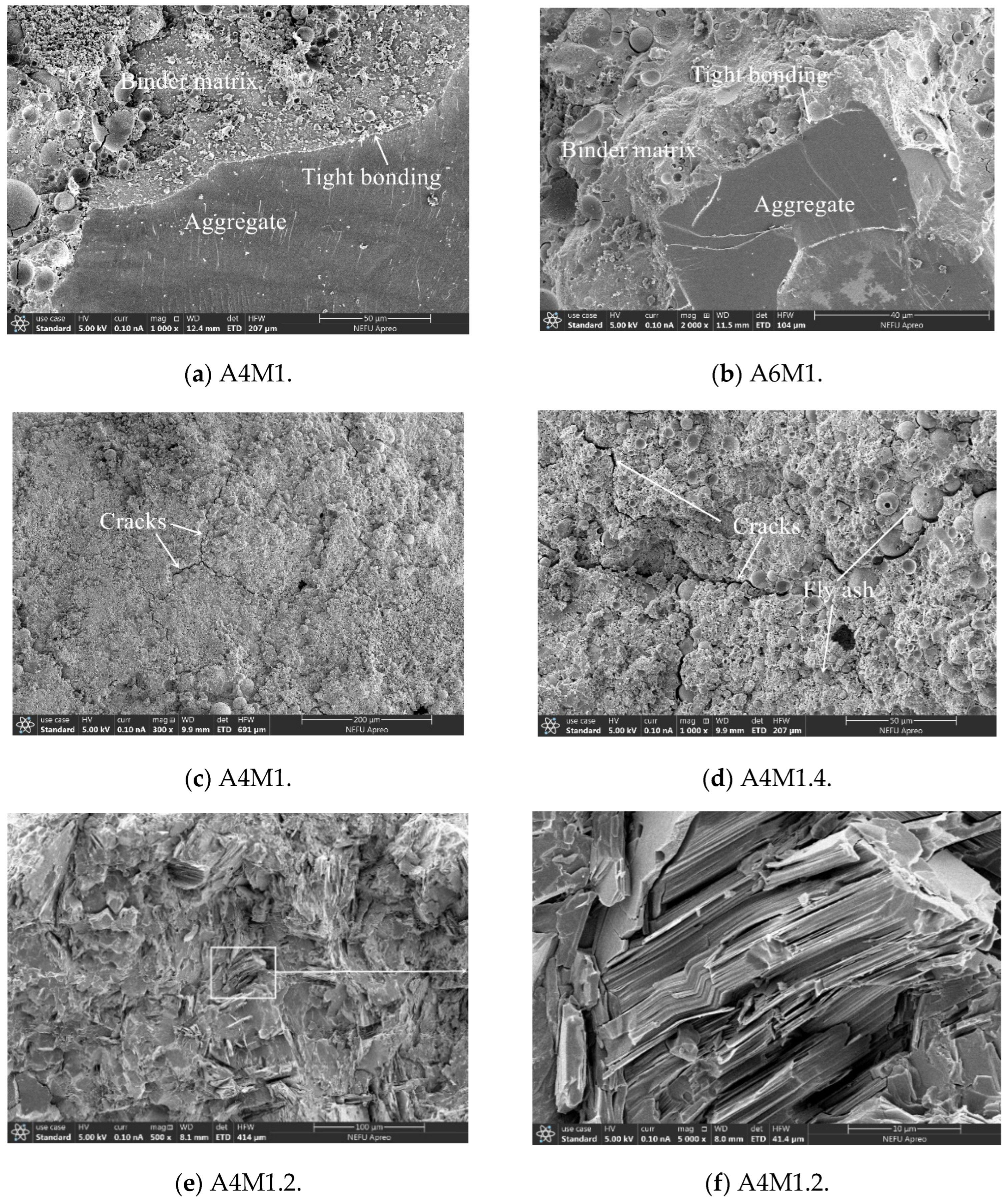

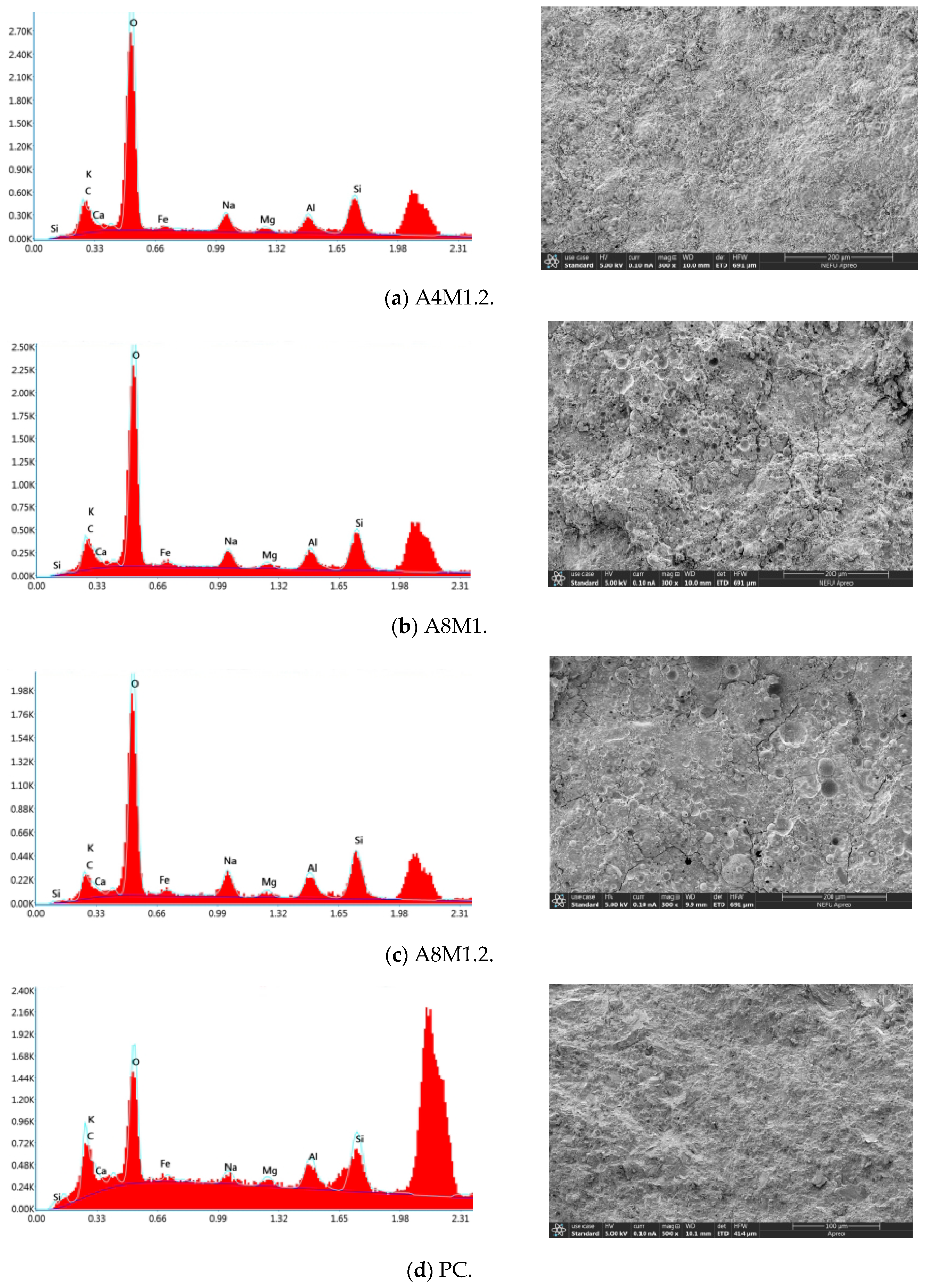

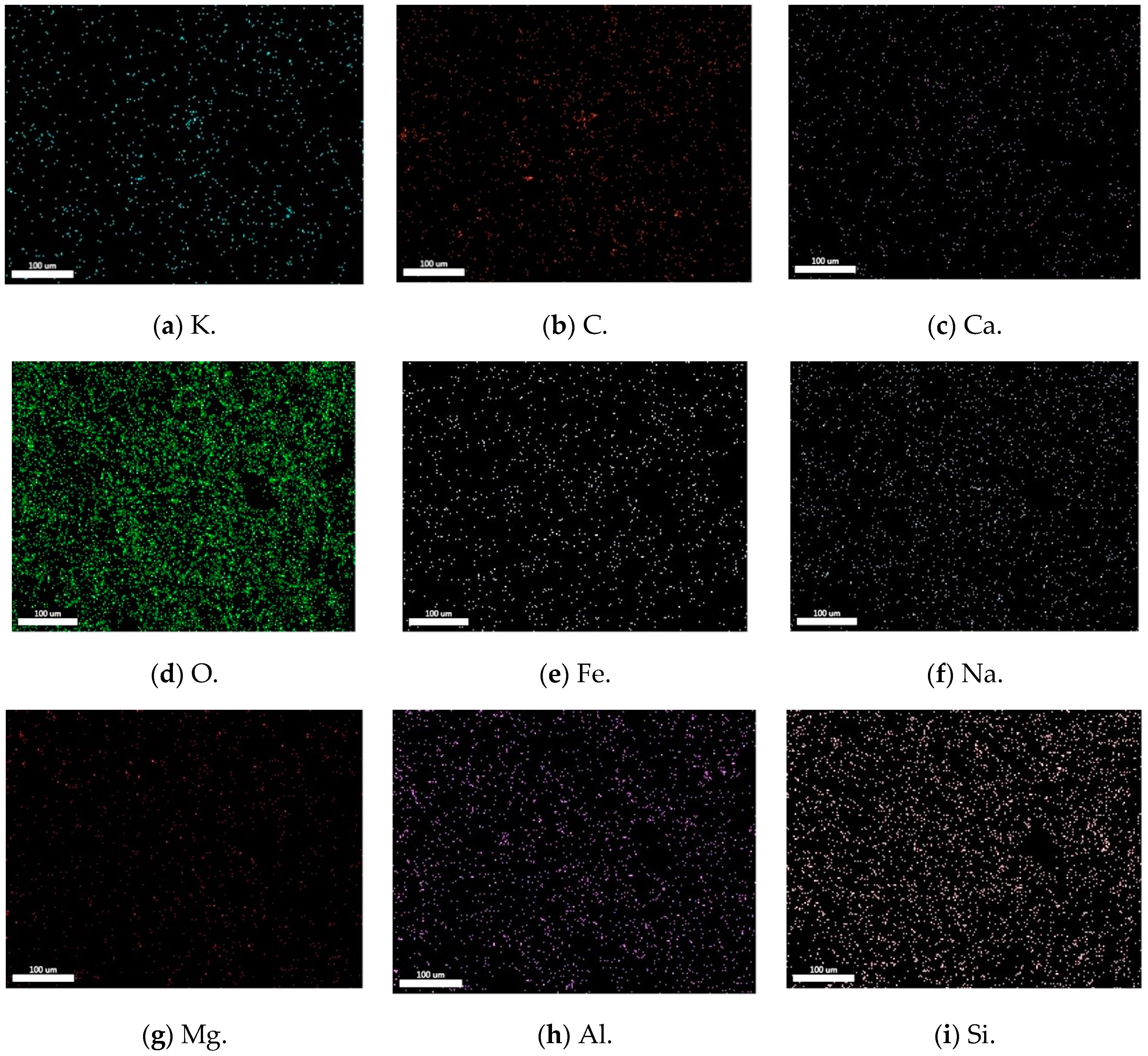

5.4. Microscopic Analysis

6. Conclusions

- The 7-day compressive strength range of AAFSC was from 18 MPa to 25.2 MPa, all lower than that of cement concrete. The 28-day compressive strength ranged from 30.4 MPa to 38 MPa, all higher than that of the cement concrete. The 28-day compressive strength of A8M1 reached 38 MPa, which was 131.94% of the value of cement concrete.

- In this study, AAFSC exhibited excellent impermeability protection performance. The air permeability coefficient increased first and then decreased with the increase of alkali equivalent, and decreased with the decreasing alkali activator modulus. Among them, the AAFSC with activator modulus of 1.0 had better impermeability than the cement concrete.

- The water absorption curves of AAFSC were entirely below that of cement concrete, indicating a lower water absorption rate. The water absorption rate of AAFSC decreased with the increasing alkali equivalent, and the value of A8M1 was 2.13%, which was only 60.86% of that of cement concrete. The water absorption model established could predict the water absorption capacity of AAFSC at different water absorption stages in this study.

- Through SEM and EDX analysis, it was found that the cementitious matrix of AAFSC was well bonded to the aggregate, and fly ash particles with different degrees of reaction could be seen, indicating that the reaction of fly ash was still ongoing. The Ca/Si value of AAFSC was lower, which may be one of the reasons why the AAFSC had better water absorption and impermeability performance than cement concrete in this study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Joseph, B.; Mathew, G. Influence of aggregate content on the behavior of fly ash based geopolymer concrete. Entia Iran. 2012, 19, 1188–1194. [Google Scholar] [CrossRef]

- Rafeet, A.; Vinai, R.; Soutsos, M.; Sha, W. Effects of slag substitution on physical and mechanical properties of fly ash-based alkali activated binders (AABs). Cem. Concr. Res. 2019, 122, 118–135. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Effect of GGBFS on setting, workability and early strength properties of fly ash geopolymer concrete cured in ambient condition. Constr. Build. Mater. 2014, 66, 163–171. [Google Scholar] [CrossRef]

- Rafeet, A.; Vinai, R.; Soutsos, M.; Sha, W. Guidelines for mix proportioning of fly ash/GGBS based alkali activated concretes. Constr. Build. Mater. 2017, 147, 130–142. [Google Scholar] [CrossRef]

- Deb, P.S.; Nath, P.; Sarker, P.K. The effects of ground granulated blast-furnace slag blending with fly ash and activator content on the workability and strength properties of geopolymer concrete cured at ambient temperature. Mater. Des. 2014, 62, 32–39. [Google Scholar] [CrossRef]

- Athira, V.S.; Bahurudeen, A.; Saljas, M.; Jayachandran, K. Influence of different curing methods on mechanical and durability properties of alkali activated binders. Constr. Build. Mater. 2021, 299, 123963. [Google Scholar] [CrossRef]

- Kim, T.; Kang, C. Investigation of the Effect of Mixing Time on the Mechanical Properties of Alkali-Activated Cement Mixed with Fly Ash and Slag. Materials 2021, 14, 2301. [Google Scholar] [CrossRef]

- Alrefaei, Y.; Wang, Y.S.; Dai, J.G. Effect of mixing method on the performance of alkali-activated fly ash/slag pastes along with polycarboxylate admixture. Cem. Concr. Compos. 2021, 117, 103917. [Google Scholar] [CrossRef]

- Jang, J.G.; Lee, N.K.; Lee, H.K. Fresh and hardened properties of alkali-activated fly ash/slag pastes with superplasticizers. Constr. Build. Mater. 2014, 50, 169–176. [Google Scholar] [CrossRef]

- de Hita, M.J.; Criado, M. Influence of the Fly Ash Content on the Fresh and Hardened Properties of Alkali-Activated Slag Pastes with Admixtures. Materials 2022, 15, 992. [Google Scholar] [CrossRef] [PubMed]

- Nedeljković, M.; Ghiassi, B.; van der Laan, S.; Li, Z.; Ye, G. Effect of curing conditions on the pore solution and carbonation resistance of alkali-activated fly ash and slag pastes. Cem. Concr. Res. 2018, 116, 146–158. [Google Scholar] [CrossRef]

- Yang, T.; Zhu, H.; Zhang, Z.; Gao, X.; Zhang, C.; Wu, Q. Effect of fly ash microsphere on the rheology and microstructure of alkali-activated fly ash/slag pastes. Cem. Concr. Res. 2018, 109, 198–207. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, Y.; Ma, Y.; Xiao, S.; Hu, J.; Wang, H. Fresh and hardened properties of alkali-activated fly ash/slag binders: Effect of fly ash source, surface area, and additives. J. Sustain. Cem.-Based Mater. 2021, 11, 239–262. [Google Scholar] [CrossRef]

- El-Hassan, H.; Shehab, E.; Al-Sallamin, A. Effect of curing regime on the performance and microstructure characteristics of alkali-activated slag-fly ash blended concrete. J. Sustain. Cem.-Based Mater. 2021, 10, 289–317. [Google Scholar] [CrossRef]

- Rodrigue, A.; Duchesne, J.; Fournier, B.; Bissonnette, B. Influence of added water and fly ash content on the characteristics, properties and early-age cracking sensitivity of alkali-activated slag/fly ash concrete cured at ambient temperature. Constr. Build. Mater. 2018, 171, 929–941. [Google Scholar] [CrossRef]

- Aiken, T.A.; Kwasny, J.; Sha, W.; Tong, K.T. Mechanical and durability properties of alkali-activated fly ash concrete with increasing slag content. Constr. Build. Mater. 2021, 301, 124330. [Google Scholar] [CrossRef]

- Bondar, D.; Basheer, M.; Nanukuttan, S. Suitability of alkali activated slag/fly ash (AA-GGBS/FA) concretes for chloride environments: Characterisation based on mix design and compliance testing. Constr. Build. Mater. 2019, 216, 612–621. [Google Scholar] [CrossRef]

- Lee, N.K.; Lee, H.K. Setting and mechanical properties of alkali-activated fly ash/slag concrete manufactured at room temperature. Constr. Build. Mater. 2013, 47, 1201–1209. [Google Scholar] [CrossRef]

- Aliques-Granero, J.; Tognonvi, M.T.; Tagnit-Hamou, A. Durability study of AAMs: Sulfate attack resistance. Constr. Build. Mater. 2019, 229, 117100. [Google Scholar] [CrossRef]

- Mukherjee, S.; Shi, X.; Deng, Y.; Udpa, L. A Hybrid Microwave NDE System for Rapid Inspection of GFRP Composites. Mater. Eval. 2020, 78, 963–975. [Google Scholar] [CrossRef]

- Shi, X.; Olvera, A.; Hamilton, C.; Gao, E.; Li, J.; Utke, L.; Petruska, A.; Yu, Z.; Udpa, L.; Deng, Y.; et al. AI-Enabled Robotic NDE for Structural Damage Assessment and Repair. Mater. Eval. 2021, 79, 1849286. [Google Scholar] [CrossRef]

- Shi, X.; Rathod, V.T.; Mukherjee, S.; Udpa, L.; Deng, Y. Multi-modality strain estimation using a rapid near-field microwave imaging system for dielectric materials. Measurement 2020, 151, 107243. [Google Scholar] [CrossRef]

- Wang, J.; Xie, J.; Wang, C.; Zhao, J.; Liu, F.; Fang, C. Study on the optimum initial curing condition for fly ash and GGBS based geopolymer recycled aggregate concrete. Constr. Build. Mater. 2020, 247, 118540. [Google Scholar] [CrossRef]

- Xie, J.; Wang, J.; Zhang, B.; Fang, C.; Li, L. Physicochemical properties of alkali activated GGBS and fly ash geopolymeric recycled concrete. Constr. Build. Mater. 2019, 204, 384–398. [Google Scholar] [CrossRef]

- Rodrigue, A.; Duchesne, J.; Fournier, B.; Champagne, M.; Bissonnette, B. Alkali-silica reaction in alkali-activated combined slag and fly ash concretes: The tempering effect of fly ash on expansion and cracking. Constr. Build. Mater. 2020, 251, 118968. [Google Scholar] [CrossRef]

- Keulen, A.; Yu, Q.L.; Zhang, S.; Grünewald, S. Effect of admixture on the pore structure refinement and enhanced performance of alkali-activated fly ash-slag concrete. Constr. Build. Mater. 2018, 162, 27–36. [Google Scholar] [CrossRef]

- Yuan, Z.; Jia, Y.; Sun, J.; Zhang, X.; Hu, Y.; Han, X. Study on the Properties of High Fly Ash Content Alkali-Activated Fly Ash Slag Pastes and Fiber-Reinforced Mortar Under Normal Temperature Curing. Materials 2024, 17, 5668. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Z.; Jia, Y. Mechanical properties and microstructure of glass fiber and polypropylene fiber reinforced concrete: An experimental study. Constr. Build. Mater. 2020, 266, 121048. [Google Scholar] [CrossRef]

- Provis, J.L.; Deventer, J. Alkali Activated Materials; Springer: Dordrecht, The Netherlands, 2014. [Google Scholar]

- Escalante García, J.I.; Campos-Venegas, K.; Gorokhovsky, A.; Fernández, A. Cementitious composites of pulverised fuel ash and blast furnace slag activated by sodium silicate: Effect of Na2O concentration and modulus. Adv. Appl. Ceram. 2006, 105, 201–208. [Google Scholar] [CrossRef]

- CS (Chinese Standard) GB/T 50081-2019; Standard for Test Method of Mechanical Properties on Ordinary Concrete. Standardization Administration of China: Beijing, China, 2019. (In Chinese)

- ASTM C642; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete, Annual Book of ASTM Standard. ASTM Standard: West Conshohocken, PA, USA, 2013.

- ASTM C1723; Standard Guide for Examination of Hardened Concrete Using Scanning Electron Microscopy, Annual Book of ASTM Standard. ASTM Standard: West Conshohocken, PA, USA, 2010.

- Hannawi, K.; Bian, H.; Prince-Agbodjan, W.; Raghavan, B. Effect of different types of fibers on the microstructure and the mechanical behavior of Ultra-High Performance Fiber-Reinforced Concretes. Compos. Part B 2016, 86, 214–220. [Google Scholar] [CrossRef]

- Yu, Z.; Ni, C.; Tang, M.; Shen, X. Relationship between water permeability and pore structure of Portland cement paste blended with fly ash. Constr. Build. Mater. 2018, 175, 458–466. [Google Scholar] [CrossRef]

- Behfarnia, K.; Behravan, A. Application of high performance polypropylene fibers in concrete lining of water tunnels. Mater. Des. 2014, 55, 274–279. [Google Scholar] [CrossRef]

- Powers, T.C. A working hypothesis for further studies of frost resistance of concrete. J. Am. Concr. Inst. 1945, 16, 245–272. [Google Scholar]

- Izaguirre, A.; Lanas, J.; Alvarez, J. Effect of a polypropylene fibre on the behaviour of aerial lime-based mortars. Constr. Build. Mater. 2010, 25, 992–1000. [Google Scholar] [CrossRef]

- Fallah, S.; Nematzadeh, M. Mechanical properties and durability of high-strength concrete containing macro-polymeric and polypropylene fibers with nano-silica and silica fume. Constr. Build. Mater. 2017, 132, 170–187. [Google Scholar] [CrossRef]

- Yuan, Z.; Jia, Y. Experimental Study on the Mechanical Properties, Water Absorption, and Fiber Degradation of Naturally Aged Glass Fiber and Polypropylene Fiber-Reinforced Concrete. Materials 2022, 15, 3760. [Google Scholar] [CrossRef]

- Afroughsabet, V.; Ozbakkaloglu, T. Mechanical and durability properties of high-strength concrete containing steel and polypropylene fibers. Constr. Build. Mater. 2015, 94, 73–82. [Google Scholar] [CrossRef]

- Radlinska, A.H. Fly ash-slag interaction during alkaline activation: Influence of activators on phase assemblage and microstructure formation. Constr. Build. Mater. 2016, 122, 594–606. [Google Scholar]

- Mehta, A.; Siddique, R.; Ozbakkaloglu, T.; Shaikh, F.U.A.; Belarbi, R. Fly ash and ground granulated blast furnace slag-based alkali-activated concrete: Mechanical, transport and microstructural properties. Constr. Build. Mater. 2020, 257, 119548. [Google Scholar] [CrossRef]

- Celikten, S.; Saridemir, M.; Deneme, I.O. Mechanical and microstructural properties of alkali-activated slag and slag + fly ash mortars exposed to high temperature. Constr. Build. Mater. 2019, 217, 50–61. [Google Scholar] [CrossRef]

- Fang, G.; Zhang, M. The evolution of interfacial transition zone in alkali-activated fly ash-slag concrete. Cem. Concr. Res. 2019, 129, 105963. [Google Scholar] [CrossRef]

- Fang, G.; Wang, Q.; Zhang, M. Micromechanical analysis of interfacial transition zone in alkali-activated fly ash-slag concrete. Cem. Concr. Compos. 2021, 119, 103990. [Google Scholar] [CrossRef]

- Ryu, G.S.; Lee, Y.B.; Koh, K.T.; Chung, Y.S. The mechanical properties of fly ash-based geopolymer concrete with alkaline activators. Constr. Build. Mater. 2013, 47, 409–418. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, R.; Mehrotra, S.P. Influence of granulated blast furnace slag on the reaction, structure and properties of fly ash based geopolymer. J. Mater. Sci. 2010, 45, 607–615. [Google Scholar] [CrossRef]

- Singh, B.; Rahman, M.R.; Paswan, R.; Bhattacharyya, S.K. Effect of activator concentration on the strength, ITZ and drying shrinkage of fly ash/slag geopolymer concrete. Constr. Build. Mater. 2016, 118, 171–179. [Google Scholar] [CrossRef]

- Bernal, S.A.; Provis, J.L.; Walkley, B.; San Nicolas, R.; Gehman, J.D.; Brice, D.G.; Kilcullen, A.R.; Duxson, P.; van Deventer, J.S. Gel nanostructure in alkali-activated binders based on slag and fly ash, and effects of accelerated carbonation. Cem. Concr. Res. 2013, 53, 127–144. [Google Scholar] [CrossRef]

| Chemical Components | Content (wt%) |

|---|---|

| SiO2 | 58.23 |

| Al2O3 | 19.21 |

| Fe2O3 | 8.2 |

| CaO | 7.12 |

| K2O | 2.29 |

| MgO | 1.46 |

| Na2O | 1.32 |

| TiO2 | 0.78 |

| SO3 | 0.54 |

| P2O5 | 0.25 |

| Other Components | 0.6 |

| Chemical Components | Content (wt%) |

|---|---|

| CaO | 40.63 |

| SiO2 | 29.51 |

| Al2O3 | 15.32 |

| MgO | 7.82 |

| SO3 | 2.74 |

| TiO2 | 1.40 |

| Fe2O3 | 0.85 |

| MnO | 0.53 |

| K2O | 0.46 |

| Na2O | 0.41 |

| Other Components | 0.33 |

| MIX ID | Fly Ash (kg/m3) | Slag (kg/m3) | Sand (kg/m3) | Stone (kg/m3) | Sodium Silicate (kg/m3) | Sodium Hydroxide (kg/m3) | Water (kg/m3) | Water Reducer (kg/m3) |

|---|---|---|---|---|---|---|---|---|

| A4M1 | 344 | 86 | 655 | 1165 | 54.5 | 12.3 | 120.4 | 3.01 |

| A6M1 | 344 | 86 | 655 | 1165 | 81.7 | 18.4 | 105.3 | 3.01 |

| A8M1 | 344 | 86 | 655 | 1165 | 109 | 24.6 | 90.2 | 3.01 |

| A4M1.2 | 344 | 86 | 655 | 1165 | 65.4 | 10.3 | 114.3 | 3.01 |

| A6M1.2 | 344 | 86 | 655 | 1165 | 98.1 | 15.5 | 96.2 | 3.01 |

| A8M1.2 | 344 | 86 | 655 | 1165 | 130.8 | 20.6 | 78.2 | 3.01 |

| A4M1.4 | 344 | 86 | 655 | 1165 | 76.3 | 8.3 | 108.3 | 3.01 |

| A6M1.4 | 344 | 86 | 655 | 1165 | 114.4 | 12.5 | 87.2 | 3.01 |

| A8M1.4 | 344 | 86 | 655 | 1165 | 152.6 | 16.7 | 66.1 | 3.01 |

| MIX ID | Cement (kg/m3) | Fly Ash (kg/m3) | Silica Fume (kg/m3) | Slag (kg/m3) | Sand (kg/m3) | Stone (kg/m3) | Water (kg/m3) | Water Reducer (kg/m3) |

|---|---|---|---|---|---|---|---|---|

| PC | 280 | 86 | 22 | 43 | 655 | 1165 | 129 | 6.45 |

| MIX ID | 7-Day Compressive Strength (MPa) | Standard Deviation | 28-Day Compressive Strength (MPa) | Standard Deviation |

|---|---|---|---|---|

| PC | 28.6 | 0.78 | 28.8 | 2.12 |

| A4M1 | 22.4 | 2.16 | 34.9 | 0.72 |

| A6M1 | 25.1 | 0.52 | 37.5 | 1.06 |

| A8M1 | 25.2 | 0.8 | 38 | 0.72 |

| A4M1.2 | 18 | 1.64 | 30.4 | 1.04 |

| A6M1.2 | 24.7 | 0.4 | 35.3 | 2.13 |

| A8M1.2 | 24.8 | 1.63 | 35.4 | 1.51 |

| A4M1.4 | 18.9 | 0.24 | 30.2 | 0.55 |

| A6M1.4 | 24.7 | 1.19 | 36.7 | 1.08 |

| A8M1.4 | 19.2 | 1.13 | 31 | 1.11 |

| MIX ID | Air Permeability Coefficient | Protection Quality Level |

|---|---|---|

| PC | 1.691 × 10−16 | Good |

| A4M1 | 0.957 × 10−16 | Very good |

| A6M1 | 1.471 × 10−16 | Good |

| A8M1 | 1.084 × 10−16 | Very good |

| A4M1.2 | 2.401 × 10−16 | Good |

| A6M1.2 | 3.204 × 10−16 | Good |

| A8M1.2 | 2.181 × 10−16 | Good |

| A4M1.4 | 2.264 × 10−16 | Good |

| A6M1.4 | 3.246 × 10−16 | Good |

| A8M1.4 | 2.229 × 10−16 | Good |

| MIX ID | R2 | ||

|---|---|---|---|

| A4M1 | 2.5388 | 2.6516 | 0.9955 |

| A6M1 | 2.2997 | 2.0327 | 0.9953 |

| A8M1 | 2.0696 | 1.1340 | 0.9728 |

| A4M1.2 | 3.2751 | 3.2962 | 0.9973 |

| A6M1.2 | 2.6705 | 2.8864 | 0.9979 |

| A8M1.2 | 2.1599 | 1.4767 | 0.9889 |

| A4M1.4 | 3.0700 | 3.2757 | 0.9967 |

| A6M1.4 | 2.5386 | 3.1851 | 0.9964 |

| A8M1.4 | 2.3010 | 1.9152 | 0.9941 |

| PC | 3.4595 | 1.8585 | 0.9917 |

| Mix ID | Element (wt%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| O | Si | Al | Fe | Na | Mg | K | C | Ca | Ca/Si | |

| A4M1 | 47 | 14 | 8 | 5 | 8 | 4 | 4 | 5 | 4 | 0.286 |

| A6M1 | 44 | 15 | 10 | 5 | 8 | 4 | 4 | 5 | 4 | 0.267 |

| A8M1 | 45 | 15 | 9 | 5 | 8 | 4 | 4 | 5 | 4 | 0.267 |

| A4M1.2 | 47 | 15 | 8 | 5 | 8 | 4 | 4 | 6 | 4 | 0.267 |

| A6M1.2 | 42 | 17 | 10 | 6 | 8 | 5 | 4 | 5 | 4 | 0.235 |

| A8M1.2 | 45 | 17 | 9 | 5 | 9 | 4 | 3 | 4 | 3 | 0.176 |

| A4M1.4 | 48 | 16 | 8 | 5 | 8 | 4 | 3 | 5 | 4 | 0.250 |

| A6M1.4 | 52 | 15 | 8 | 4 | 8 | 3 | 3 | 4 | 3 | 0.200 |

| A8M1.4 | 48 | 16 | 8 | 5 | 9 | 4 | 3 | 4 | 4 | 0.250 |

| PC | 25 | 17 | 13 | 9 | 9 | 8 | 5 | 7 | 5 | 0.294 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, Z.; Jia, Y.; Xie, X.; Xu, J. Study on the Macroscopic Properties and Microstructure of High Fly Ash Content Alkali-Activated Fly Ash Slag Concrete Cured at Room Temperature. Materials 2025, 18, 547. https://doi.org/10.3390/ma18030547

Yuan Z, Jia Y, Xie X, Xu J. Study on the Macroscopic Properties and Microstructure of High Fly Ash Content Alkali-Activated Fly Ash Slag Concrete Cured at Room Temperature. Materials. 2025; 18(3):547. https://doi.org/10.3390/ma18030547

Chicago/Turabian StyleYuan, Zhu, Yanmin Jia, Xuanben Xie, and Junming Xu. 2025. "Study on the Macroscopic Properties and Microstructure of High Fly Ash Content Alkali-Activated Fly Ash Slag Concrete Cured at Room Temperature" Materials 18, no. 3: 547. https://doi.org/10.3390/ma18030547

APA StyleYuan, Z., Jia, Y., Xie, X., & Xu, J. (2025). Study on the Macroscopic Properties and Microstructure of High Fly Ash Content Alkali-Activated Fly Ash Slag Concrete Cured at Room Temperature. Materials, 18(3), 547. https://doi.org/10.3390/ma18030547