Impact of the Applied Electrode System on Properties of Electrodeposited Calcium Phosphate Coatings

Abstract

1. Introduction

2. Materials and Methods

2.1. Material

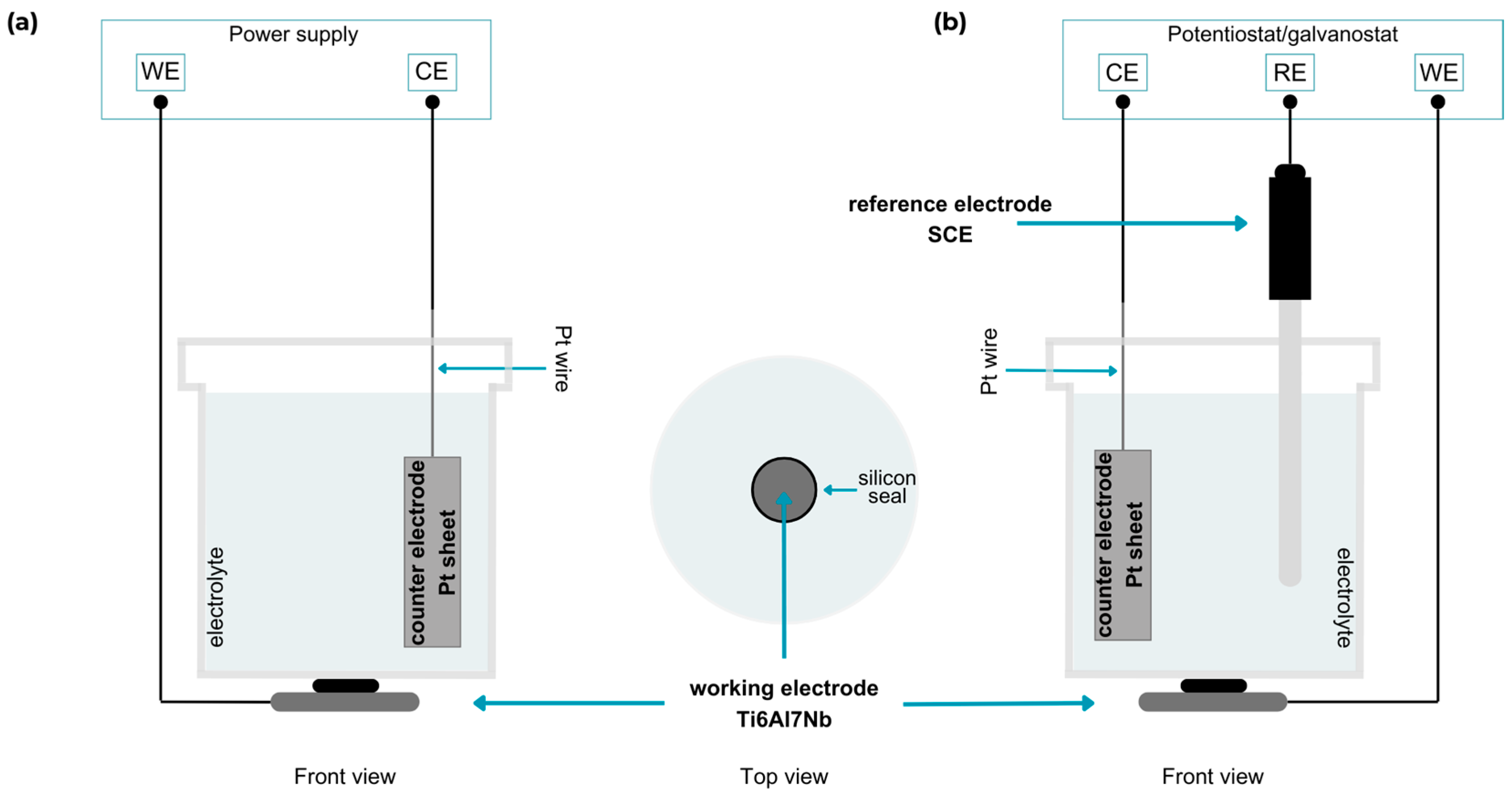

2.2. Electrochemical Coatings Deposition

2.3. Coatings Characterization Methods

3. Results and Discussion

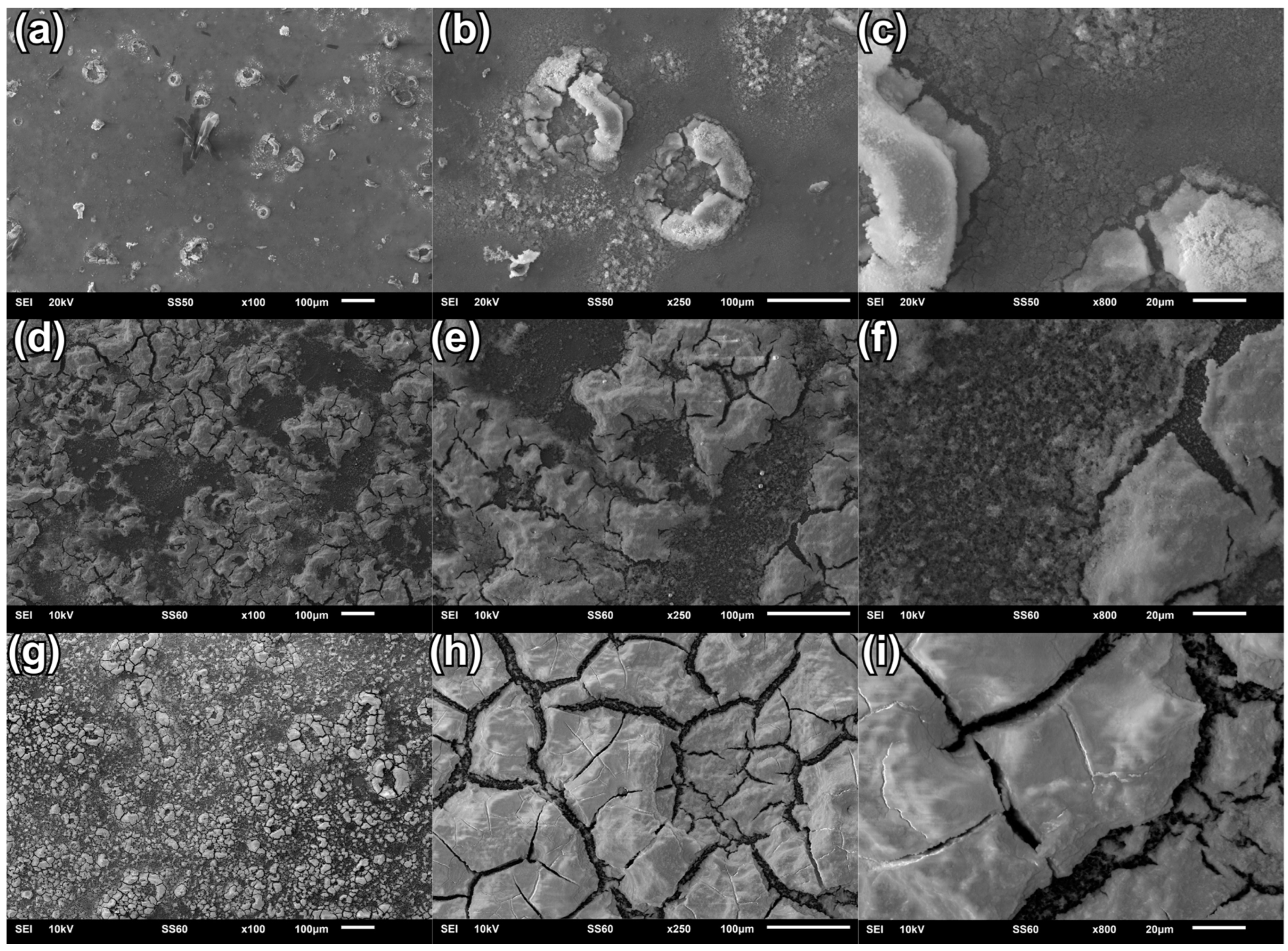

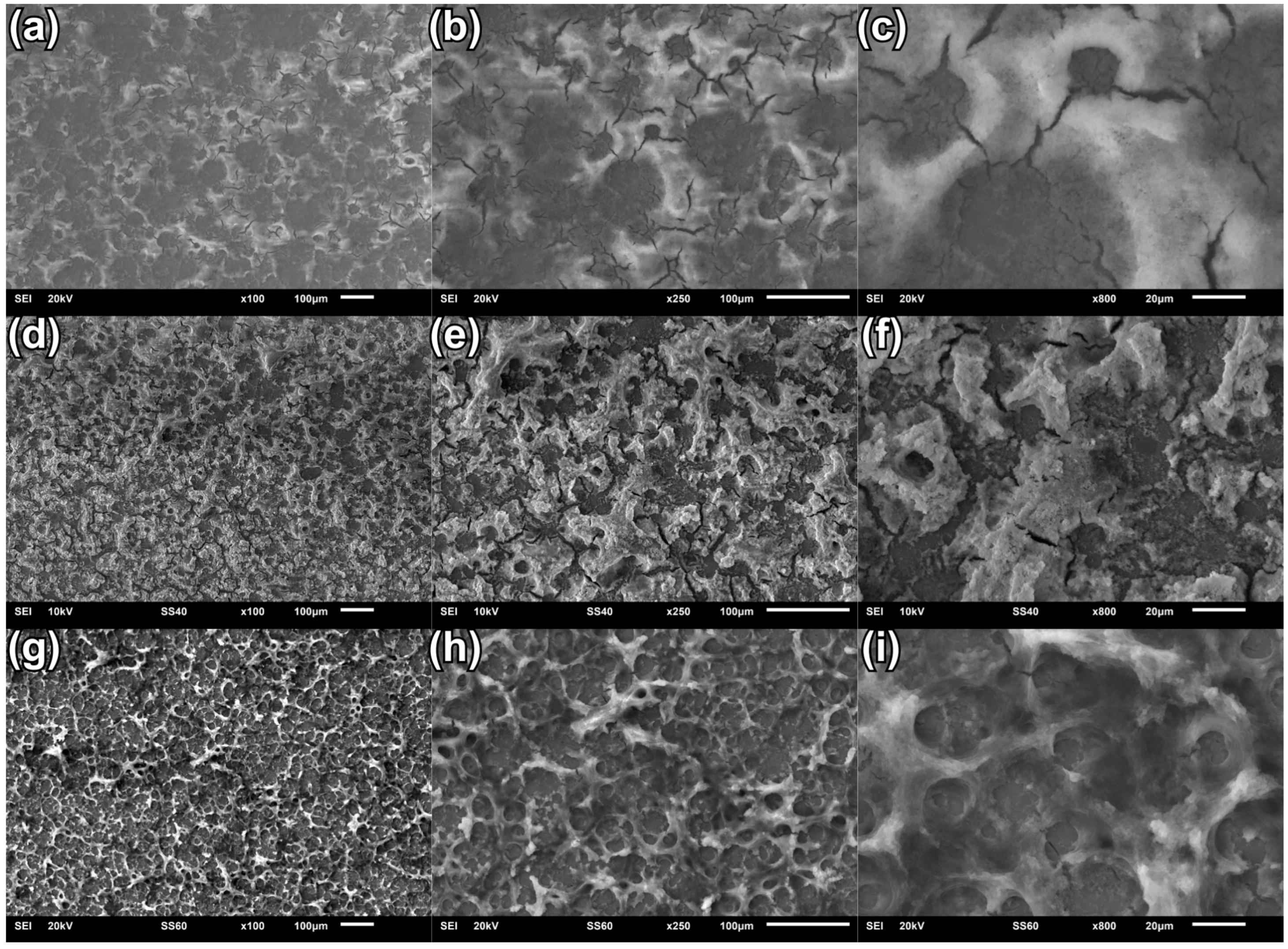

3.1. Scanning Electron Microscopy

3.2. Thickness and Roughness of CaP Coatings

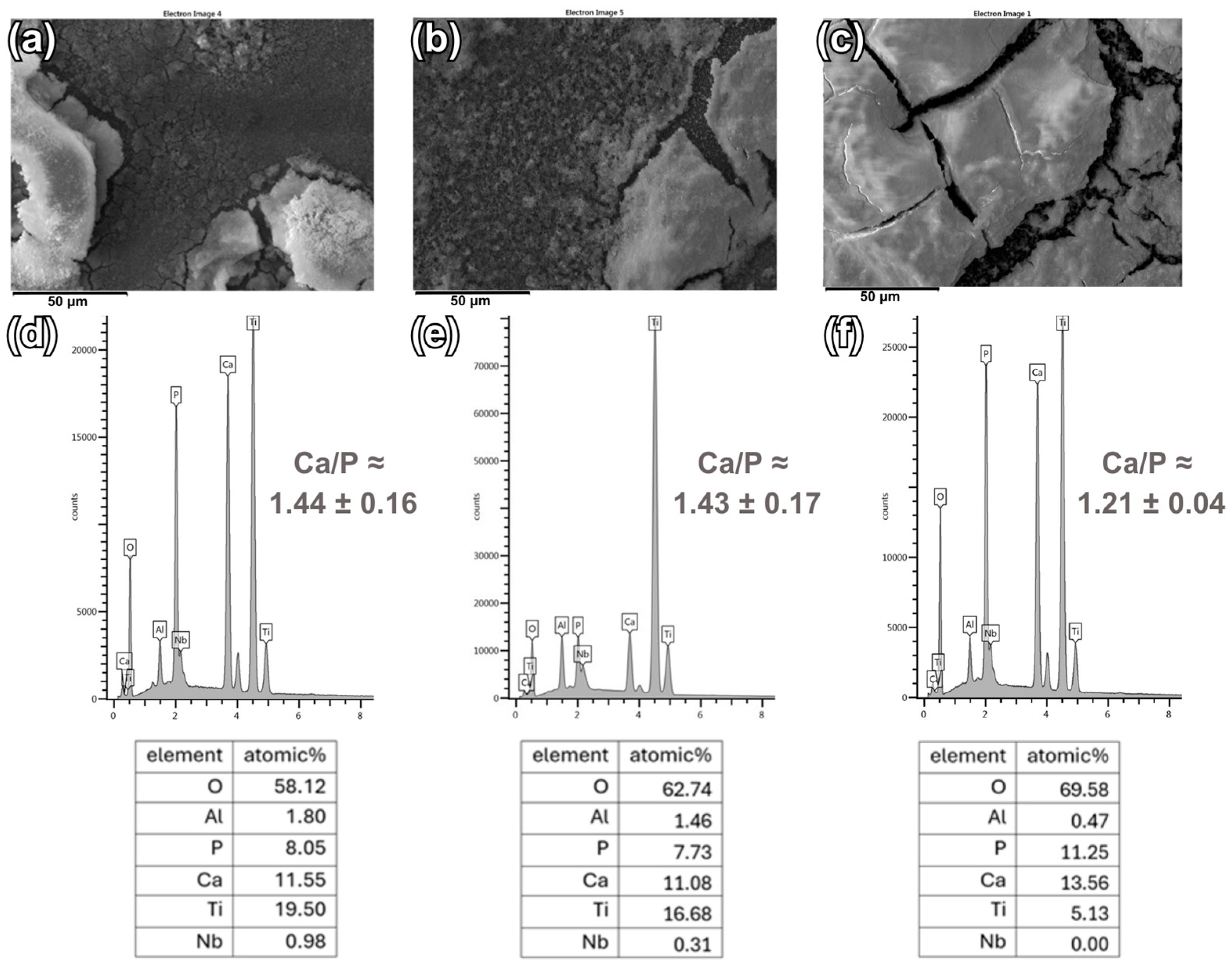

3.3. Energy Dispersive X-Ray Spectroscopy

3.4. Diffraction Measurements

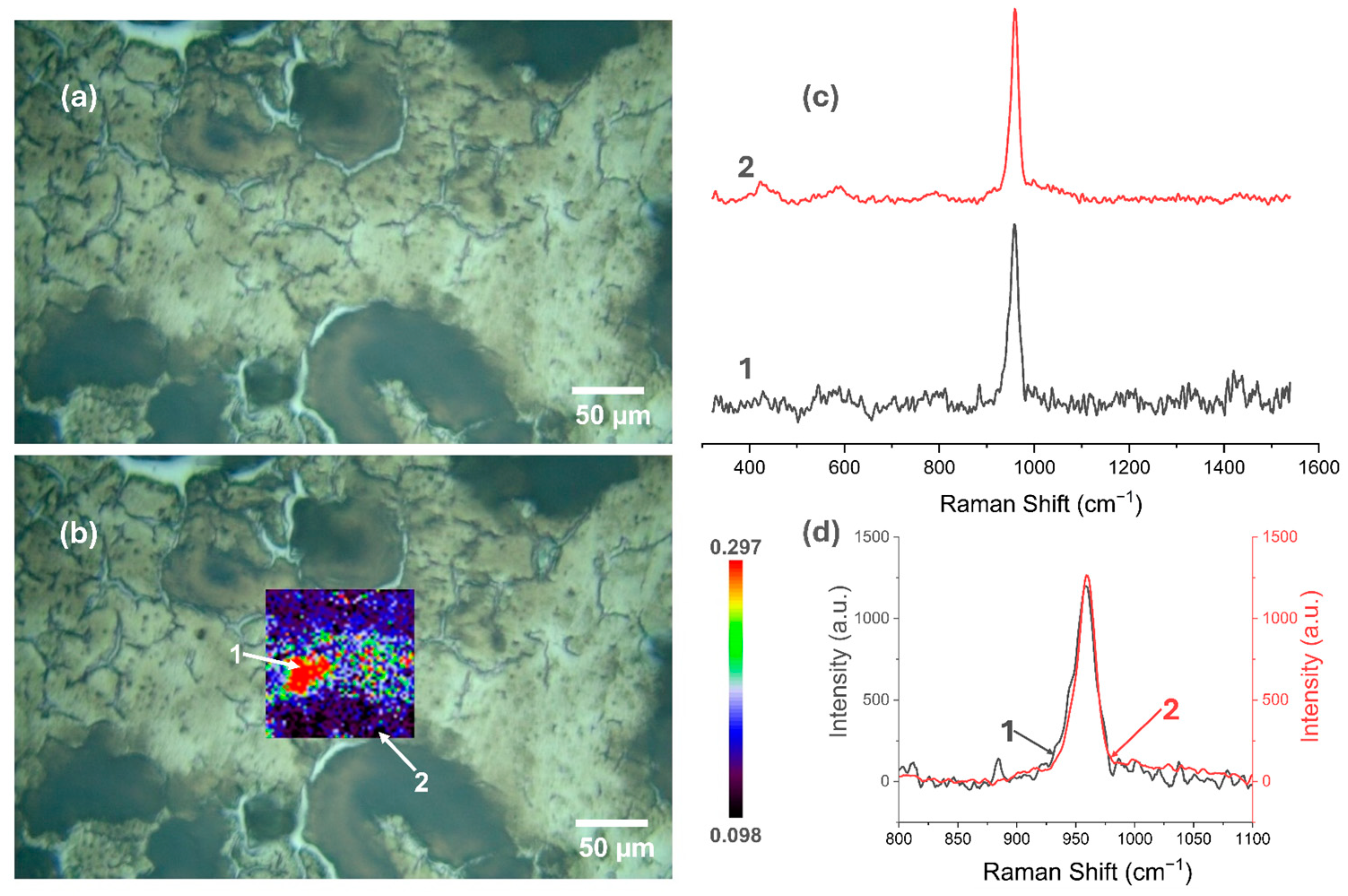

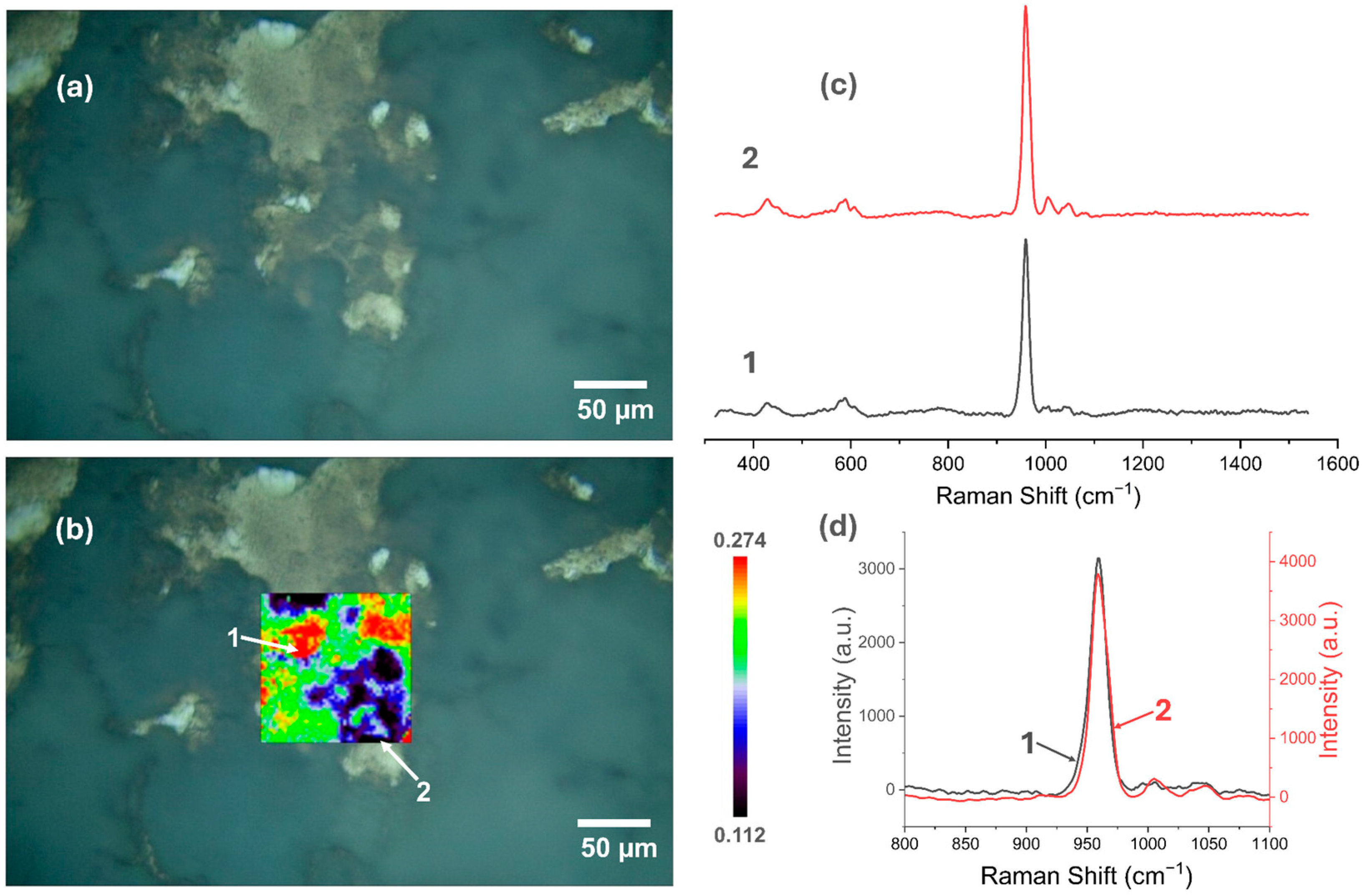

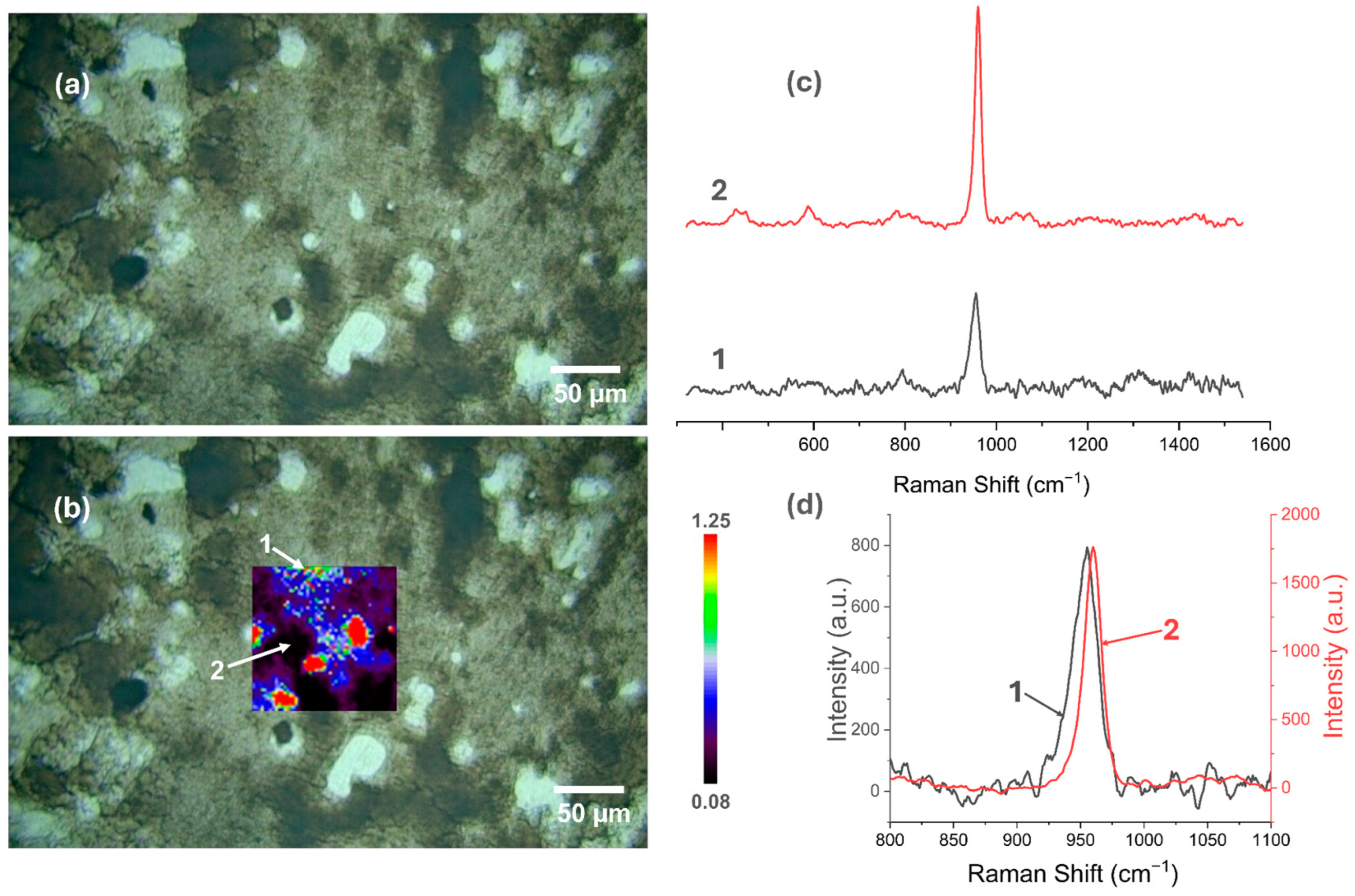

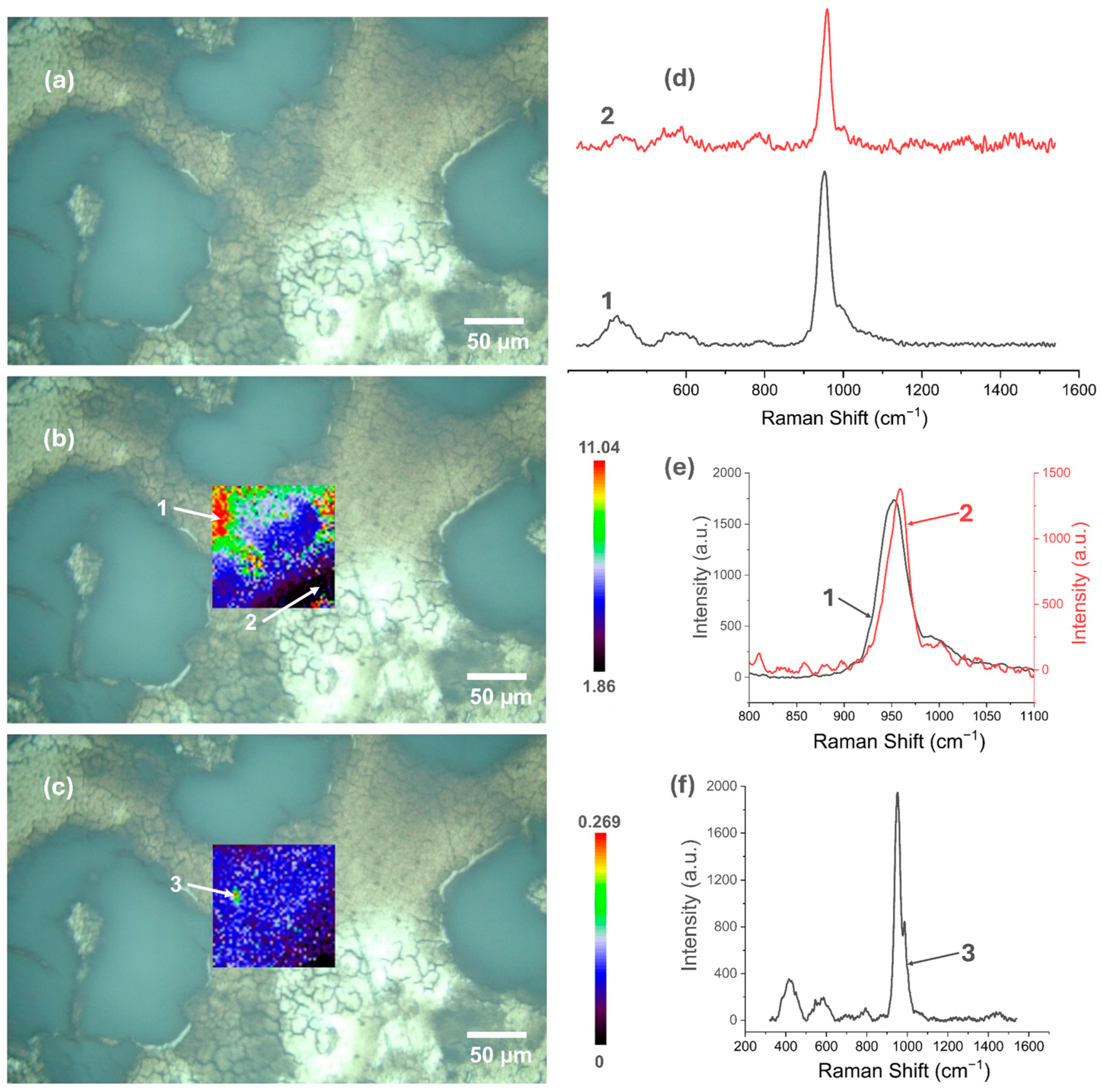

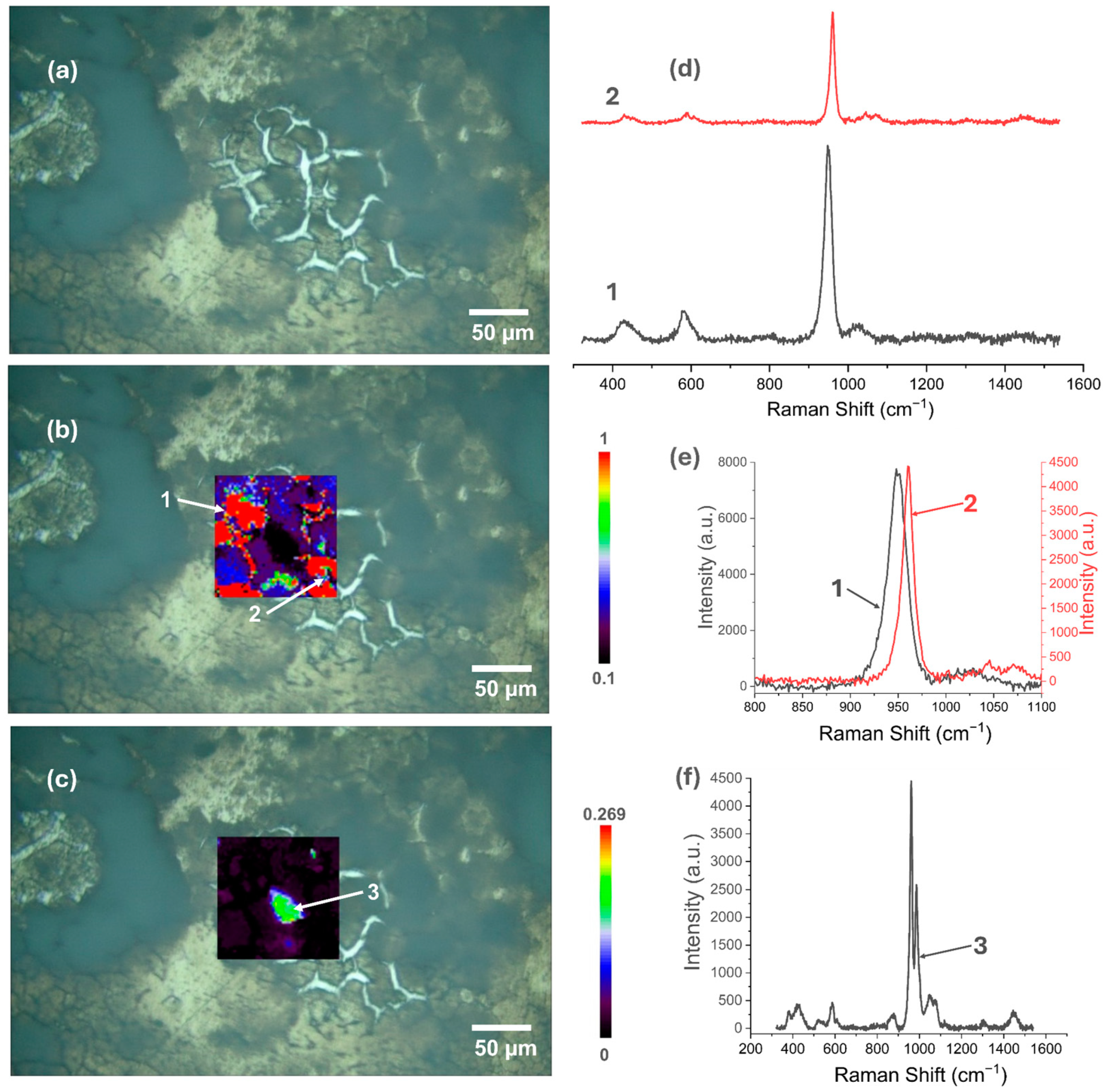

3.5. Raman Spectroscopy

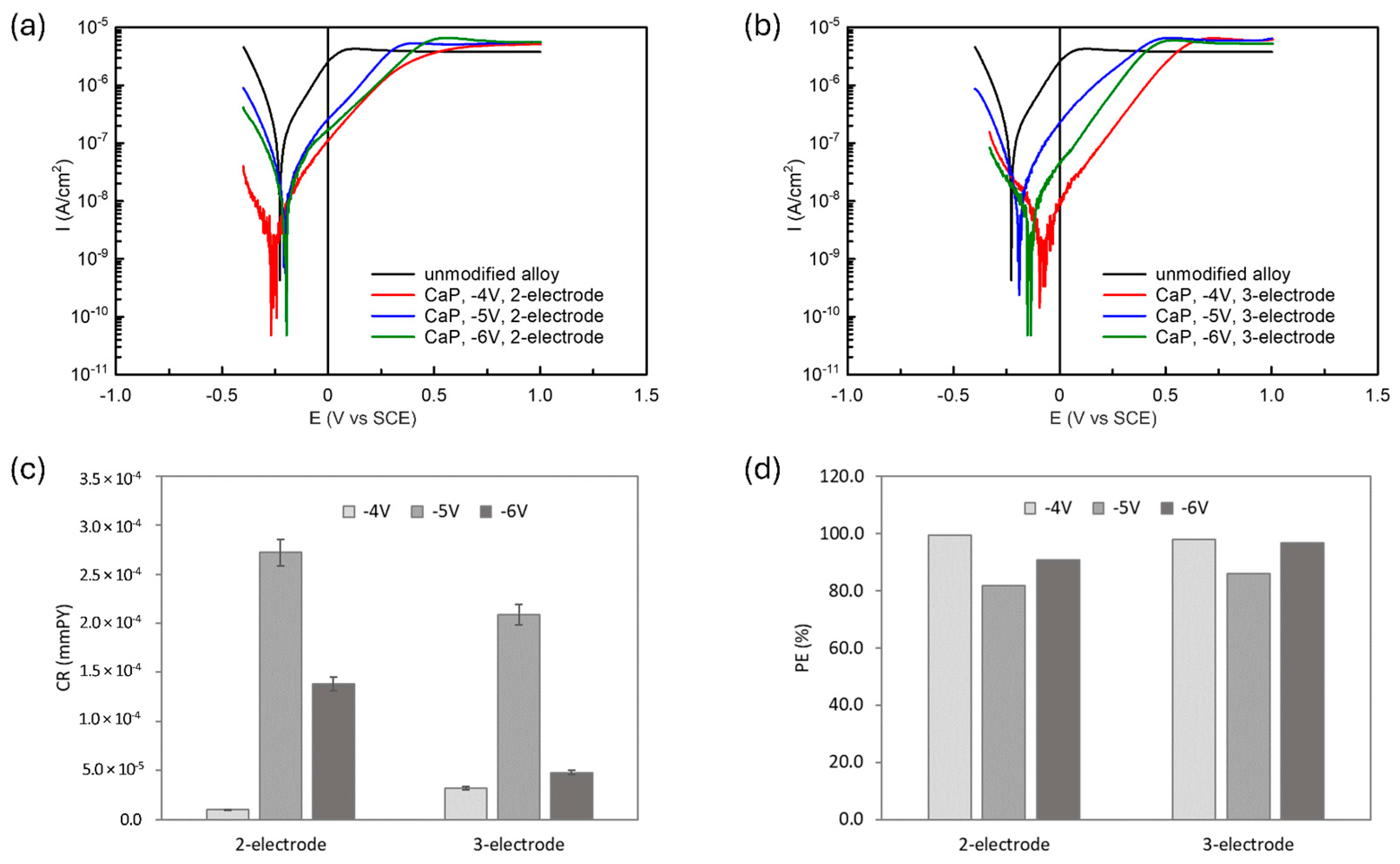

3.6. Corrosion Study

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sarraf, M.; Rezvani Ghomi, E.; Alipour, S.; Ramakrishna, S.; Liana Sukiman, N. A State-of-the-Art Review of the Fabrication and Characteristics of Titanium and Its Alloys for Biomedical Applications. Bio-Des. Manuf. 2022, 5, 371–395. [Google Scholar] [CrossRef]

- Sidambe, A.T. Biocompatibility of Advanced Manufactured Titanium Implants—A Review. Materials 2014, 7, 8168–8188. [Google Scholar] [CrossRef]

- Wawrzynski, J.; Gil, J.A.; Goodman, A.D.; Waryasz, G.R. Hypersensitivity to Orthopedic Implants: A Review of the Literature. Rheumatol. Ther. 2017, 4, 45–56. [Google Scholar] [CrossRef] [PubMed]

- Eliaz, N. Corrosion of Metallic Biomaterials: A Review. Materials 2019, 12, 407. [Google Scholar] [CrossRef]

- Amirtharaj Mosas, K.K.; Chandrasekar, A.R.; Dasan, A.; Pakseresht, A.; Galusek, D. Recent Advancements in Materials and Coatings for Biomedical Implants. Gels 2022, 8, 323. [Google Scholar] [CrossRef] [PubMed]

- Challa, V.S.A.; Mali, S.; Misra, R.D.K. Reduced Toxicity and Superior Cellular Response of Preosteoblasts to Ti-6Al-7Nb Alloy and Comparison with Ti-6Al-4V. J. Biomed. Mater. Res. 2013, 101A, 2083–2089. [Google Scholar] [CrossRef]

- Joseph, L.A.; Israel, O.K.; Edet, E.J. Comparative Evaluation of Metal Ions Release from Titanium and Ti-6Al-7Nb into Bio-Fluids. Dent. Res. J. 2009, 6, 7–11. [Google Scholar]

- Black, J.; Sherk, H.; Bonini, J.; Rostoker, W.R.; Schajowicz, F.; Galante, J.O. Metallosis Associated with a Stable Titanium-Alloy Femoral Component in Total Hip Replacement. A Case Report. JBJS 1990, 72, 126. [Google Scholar] [CrossRef]

- Shinohara, R.; Ueda, K.; Watanabe, F. Influence of the Difference between Implant Body and Screw Materials on Abutment Screw Loosening. Dent. Mater. J. 2019, 38, 150–156. [Google Scholar] [CrossRef]

- Apostu, D.; Lucaciu, O.; Berce, C.; Lucaciu, D.; Cosma, D. Current Methods of Preventing Aseptic Loosening and Improving Osseointegration of Titanium Implants in Cementless Total Hip Arthroplasty: A Review. J. Int. Med. Res. 2018, 46, 2104–2119. [Google Scholar] [CrossRef] [PubMed]

- Goharian, A. Chapter 1—Fundamentals in Loosening and Osseointegration of Orthopedic Implants. In Osseointegration of Orthopaedic Implants; Goharian, A., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 1–26. ISBN 978-0-12-813384-2. [Google Scholar]

- Liu, B.; Zhang, X.; Xiao, G.; Lu, Y. Phosphate Chemical Conversion Coatings on Metallic Substrates for Biomedical Application: A Review. Mater. Sci. Eng. C 2015, 47, 97–104. [Google Scholar] [CrossRef]

- Liu, S.; Liu, J.; Tang, Y. Surface Modification Techniques of Titanium and Its Alloys to Functionally Optimize Their Biomedical Properties: Thematic Review. Front. Bioeng. Biotechnol. 2020, 8, 603072. [Google Scholar]

- Choi, A.H.; Karacan, I.; Ben-Nissan, B. Surface Modifications of Titanium Alloy Using Nanobioceramic-Based Coatings to Improve Osseointegration: A Review. Mater. Technol. 2020, 35, 742–751. [Google Scholar] [CrossRef]

- Liu, X.; Chu, P.; Ding, C. Surface Modification of Titanium, Titanium Alloys, and Related Materials for Biomedical Applications. Mater. Sci. Eng. R 2004, 47, 49–121. [Google Scholar] [CrossRef]

- Priyadarshini, B.; Rama, M.; Chetan; Vijayalakshmi, U. Bioactive Coating as a Surface Modification Technique for Biocompatible Metallic Implants: A Review. J. Asian Ceram. Soc. 2019, 7, 397–406. [Google Scholar] [CrossRef]

- Sánchez-Bodón, J.; Andrade Del Olmo, J.; Alonso, J.M.; Moreno-Benítez, I.; Vilas-Vilela, J.L.; Pérez-Álvarez, L. Bioactive Coatings on Titanium: A Review on Hydroxylation, Self-Assembled Monolayers (SAMs) and Surface Modification Strategies. Polymers 2021, 14, 165. [Google Scholar] [CrossRef]

- Świeczko-Żurek, B. Biomateriały; Gdańsk University of Technology: Gdańsk, Poland, 2009; ISBN 978-83-7348-272-2. [Google Scholar]

- Bandyopadhyay, A.; Mitra, I.; Goodman, S.B.; Kumar, M.; Bose, S. Improving Biocompatibility for next Generation of Metallic Implants. Prog. Mater. Sci. 2023, 133, 101053. [Google Scholar] [CrossRef]

- Kazimierczak, P.; Przekora, A. Osteoconductive and Osteoinductive Surface Modifications of Biomaterials for Bone Regeneration: A Concise Review. Coatings 2020, 10, 971. [Google Scholar] [CrossRef]

- Lu, J.; Yu, H.; Chen, C. Biological Properties of Calcium Phosphate Biomaterials for Bone Repair: A Review. RSC Adv. 2018, 8, 2015–2033. [Google Scholar] [CrossRef]

- Awasthi, S.; Pandey, S.K.; Arunan, E.; Srivastava, C. A Review on Hydroxyapatite Coatings for the Biomedical Applications: Experimental and Theoretical Perspectives. J. Mater. Chem. B 2021, 9, 228–249. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Qiao, H.; Nian, X.; Zhang, X.; Zhang, X.; Song, G.; Xu, Z.; Zhang, H.; Han, S. Improving the Bioactivity and Corrosion Resistance Properties of Electrodeposited Hydroxyapatite Coating by Dual Doping of Bivalent Strontium and Manganese Ion. Surf. Coat. Technol. 2016, 291, 205–215. [Google Scholar] [CrossRef]

- Eliaz, N.; Metoki, N. Calcium Phosphate Bioceramics: A Review of Their History, Structure, Properties, Coating Technologies and Biomedical Applications. Materials 2017, 10, 334. [Google Scholar] [CrossRef] [PubMed]

- Gomes, D.S.; Santos, A.M.C.; Neves, G.A.; Menezes, R.R. A Brief Review on Hydroxyapatite Production and Use in Biomedicine. Cerâmica 2019, 65, 282–302. [Google Scholar] [CrossRef]

- Prakasam, M.; Locs, J.; Salma-Ancane, K.; Loca, D.; Largeteau, A.; Berzina-Cimdina, L. Biodegradable Materials and Metallic Implants—A Review. J. Funct. Biomater. 2017, 8, 44. [Google Scholar] [CrossRef]

- Knaack, D.; Goad, M.E.P.; Aiolova, M.; Rey, C.; Tofighi, A.; Chakravarthy, P.; Lee, D.D. Resorbable Calcium Phosphate Bone Substitute. J. Biomed. Mater. Res. 1998, 43, 399–409. [Google Scholar] [CrossRef]

- Habraken, W.; Habibovic, P.; Epple, M.; Bohner, M. Calcium Phosphates in Biomedical Applications: Materials for the Future? Mater. Today 2016, 19, 69–87. [Google Scholar] [CrossRef]

- Dorozhkin, S.V. Calcium Orthophosphate Deposits: Preparation, Properties and Biomedical Applications. Mater. Sci. Eng. C 2015, 55, 272–326. [Google Scholar] [CrossRef]

- Clèries, L.; Martínez, E.; Fernández-Pradas, J.M.; Sardin, G.; Esteve, J.; Morenza, J.L. Mechanical Properties of Calcium Phosphate Coatings Deposited by Laser Ablation. Biomaterials 2000, 21, 967–971. [Google Scholar] [CrossRef]

- Thin Calcium Phosphate Coatings for Medical Implants; León, B., Jansen, J., Eds.; Springer: New York, NY, USA, 2009; ISBN 978-0-387-77718-4. [Google Scholar]

- Huang, H.; Manga, Y.; Huang, W.-N.; Lin, C.-K.; Tseng, C.-L.; Huang, H.-M.; Wu, C.-Y.; Wu, C.-C. Effect of Hydroxyapatite Formation on Titanium Surface with Bone Morphogenetic Protein-2 Loading through Electrochemical Deposition on MG-63 Cells. Materials 2018, 11, 1897. [Google Scholar] [CrossRef]

- Cotrut, C.M.; Vladescu, A.; Dinu, M.; Vranceanu, D.M. Influence of Deposition Temperature on the Properties of Hydroxyapatite Obtained by Electrochemical Assisted Deposition. Ceram. Int. 2018, 44, 669–677. [Google Scholar] [CrossRef]

- Zhang, Z.; Dunn, M.F.; Xiao, T.D.; Tomsia, A.P.; Saiz, E. Nanostructured Hydroxyapatite Coatings for Improved Adhesion and Corrosion Resistance for Medical Implants. MRS Online Proc. Libr. OPL 2001, 703, V7.5. [Google Scholar] [CrossRef]

- Best, S.M.; Porter, A.E.; Thian, E.S.; Huang, J. Bioceramics: Past, Present and for the Future. J. Eur. Ceram. Soc. 2008, 28, 1319–1327. [Google Scholar] [CrossRef]

- Advances in Calcium Phosphate Biomaterials; Ben-Nissan, B., Ed.; Springer Series in Biomaterials Science and Engineering; Springer: Berlin/Heidelberg, Germany, 2014; Volume 2, ISBN 978-3-642-53979-4. [Google Scholar]

- Meyer, F.; Amaechi, B.T.; Fabritius, H.-O.; Enax, J. Overview of Calcium Phosphates Used in Biomimetic Oral Care. Open Dent. J. 2018, 12, 406–423. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Zhang, X.; Luo, M.; Hu, W.; Zheng, L.; Huang, R.; Greven, J.; Hildebrand, F.; Yuan, F. Plasma Spray vs. Electrochemical Deposition: Toward a Better Osteogenic Effect of Hydroxyapatite Coatings on 3D-Printed Titanium Scaffolds. Front. Bioeng. Biotechnol. 2021, 9, 705774. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Eliaz, N.; Xiang, Z.; Hsu, H.-P.; Spector, M.; Hobbs, L.W. Early Bone Apposition in Vivo on Plasma-Sprayed and Electrochemically Deposited Hydroxyapatite Coatings on Titanium Alloy. Biomaterials 2006, 27, 4192–4203. [Google Scholar] [CrossRef]

- Ong, J.L.; Appleford, M.; Oh, S.; Yang, Y.; Chen, W.-H.; Bumgardner, J.D.; Haggard, W.O. The Characterization and Development of Bioactive Hydroxyapatite Coatings. JOM 2006, 58, 67–69. [Google Scholar] [CrossRef]

- Bøe, B.G.; Röhrl, S.M.; Heier, T.; Snorrason, F.; Nordsletten, L. A Prospective Randomized Study Comparing Electrochemically Deposited Hydroxyapatite and Plasma-Sprayed Hydroxyapatite on Titanium Stems: 55 Hips Followed for 2 Years with RSA and DXA. Acta Orthop. 2011, 82, 13–19. [Google Scholar] [CrossRef]

- Habibovic, P.; Barrère, F.; Van Blitterswijk, C.A.; De Groot, K.; Layrolle, P. Biomimetic Hydroxyapatite Coating on Metal Implants. J. Am. Chem. Soc. 2002, 85, 517–522. [Google Scholar] [CrossRef]

- Kang, A.; Singh, G.; Chawla, V. Some Problems Associated with Thermal Sprayed Ha Coatings: A Review. Int. J. Surf. Eng. Mater. Surf. Eng. Mater. Technol. 2013, 3, 10–20. [Google Scholar]

- Asri, R.I.M.; Harun, W.S.W.; Hassan, M.A.; Ghani, S.A.C.; Buyong, Z. A Review of Hydroxyapatite-Based Coating Techniques: Sol–Gel and Electrochemical Depositions on Biocompatible Metals. J. Mech. Behav. Biomed. Mater. 2016, 57, 95–108. [Google Scholar] [CrossRef]

- Jaafar, A.; Schimpf, C.; Mandel, M.; Hecker, C.; Rafaja, D.; Krüger, L.; Arki, P.; Joseph, Y. Sol–Gel Derived Hydroxyapatite Coating on Titanium Implants: Optimization of Sol–Gel Process and Engineering the Interface. J. Mater. Res. 2022, 37, 2558–2570. [Google Scholar] [CrossRef]

- Kim, H.-W.; Koh, Y.-H.; Li, L.-H.; Lee, S.; Kim, H.-E. Hydroxyapatite Coating on Titanium Substrate with Titania Buffer Layer Processed by Sol–Gel Method. Biomaterials 2004, 25, 2533–2538. [Google Scholar] [CrossRef]

- Djošić, M.; Janković, A.; Mišković-Stanković, V. Electrophoretic Deposition of Biocompatible and Bioactive Hydroxyapatite-Based Coatings on Titanium. Materials 2021, 14, 5391. [Google Scholar] [CrossRef]

- Laska, A. Parameters of the electrophoretic deposition process and its influence on the morphology of hydroxyapatite coatings. Review. Mater. Eng. 2020, 1, 20–25. [Google Scholar] [CrossRef] [PubMed]

- Surmenev, R.A.; Surmeneva, M.A.; Grubova, I.Y.; Chernozem, R.V.; Krause, B.; Baumbach, T.; Loza, K.; Epple, M. RF Magnetron Sputtering of a Hydroxyapatite Target: A Comparison Study on Polytetrafluorethylene and Titanium Substrates. Appl. Surf. Sci. 2017, 414, 335–344. [Google Scholar] [CrossRef]

- Nieh, T.G.; Jankowski, A.F.; Koike, J. Processing and Characterization of Hydroxyapatite Coatings on Titanium Produced by Magnetron Sputtering. J. Mater. Res. 2001, 16, 3238–3245. [Google Scholar] [CrossRef]

- Adamek, G.; Jakubowicz, J. Electrochemical Deposition of the Ca-P Coatings on the Porous Nanocrystalline Ti-6Al-4V Alloy. Solid State Phenom. 2011, 183, 1–8. [Google Scholar] [CrossRef]

- Amirnejad, M.; Rajabi, M.; Jamaati, R. Electrodeposition of Hydroxyapatite Coating on Ti6Al4V Alloy: Mechanistic Investigation of the Substrate Crystallographic Texture Effect. J. Electrochem. Soc. 2022, 169, 072508. [Google Scholar] [CrossRef]

- Awan, N.M.; Manzoor, M.U.; Hussain, F.; Rehman, Z.U.; Ishtiaq, M. A Feasible Route to Produce 30 MPa Adhesion Strength of Electrochemically Deposited Hydroxyapatite (HA) on Titanium (Ti6Al4V) Alloy. Trans. Indian Inst. Met. 2023, 76, 1653–1660. [Google Scholar] [CrossRef]

- Safavi, M.S.; Walsh, F.C.; Surmeneva, M.A.; Surmenev, R.A.; Khalil-Allafi, J. Electrodeposited Hydroxyapatite-Based Biocoatings: Recent Progress and Future Challenges. Coatings 2021, 11, 110. [Google Scholar] [CrossRef]

- Drevet, R.; Benhayoune, H. Electrodeposition of Calcium Phosphate Coatings on Metallic Substrates for Bone Implant Applications: A Review. Coatings 2022, 12, 539. [Google Scholar] [CrossRef]

- Zielinski, A.; Bartmanski, M. Electrodeposited Biocoatings, Their Properties and Fabrication Technologies: A Review. Coatings 2020, 10, 782. [Google Scholar] [CrossRef]

- Łosiewicz, B.; Osak, P.; Maszybrocka, J.; Kubisztal, J.; Bogunia, S.; Ratajczak, P.; Aniołek, K. Effect of Temperature on Electrochemically Assisted Deposition and Bioactivity of CaP Coatings on CpTi Grade 4. Materials 2021, 14, 5081. [Google Scholar] [CrossRef] [PubMed]

- Costa, G.M.D.; Everton, G.O.; Amaral, G.O.; Cruz, G.; Ghosh, A.; De Souza, M.E.P. Brushite/Hydroxyapatite Coatings on H2SO4 Passivated 316LSS by Electrodeposition: In Vitro Corrosion and Anti-Inflammatory Activity. Surf. Coat. Technol. 2024, 476, 130304. [Google Scholar] [CrossRef]

- Dev, P.R.; Anand, C.P.; Michael, D.S.; Wilson, P. Hydroxyapatite Coatings: A Critical Review on Electrodeposition Parametric Variations Influencing Crystal Facet Orientation towards Enhanced Electrochemical Sensing. Mater. Adv. 2022, 3, 7773–7809. [Google Scholar] [CrossRef]

- Canva.Com. Available online: https://www.canva.com/ (accessed on 21 January 2025).

- Lee, K.; Jeong, Y.-H.; Ko, Y.-M.; Choe, H.-C.; Brantley, W.A. Hydroxyapatite Coating on Micropore-Formed Titanium Alloy Utilizing Electrochemical Deposition. Thin Solid. Films 2013, 549, 154–158. [Google Scholar] [CrossRef]

- Mohammed, M.T.; Khan, Z.A.; Siddiquee, A.N. Surface Modifications of Titanium Materials for Developing Corrosion Behavior in Human Body Environment: A Review. Procedia Mater. Sci. 2014, 6, 1610–1618. [Google Scholar] [CrossRef]

- Dorozhkin, S.V. Calcium Orthophosphates as Bioceramics: State of the Art. J. Funct. Biomater. 2010, 1, 22–107. [Google Scholar] [CrossRef]

- Chakraborty, R.; Seesala, V.S.; Sen, M.; Sengupta, S.; Dhara, S.; Saha, P.; Das, K.; Das, S. MWCNT Reinforced Bone like Calcium Phosphate—Hydroxyapatite Composite Coating Developed through Pulsed Electrodeposition with Varying Amount of Apatite Phase and Crystallinity to Promote Superior Osteoconduction, Cytocompatibility and Corrosion Protection Performance Compared to Bare Metallic Implant Surface. Surf. Coat. Technol. 2017, 325, 496–514. [Google Scholar] [CrossRef]

- Chakraborty, R.; Saha, P. A Comparative Study on Surface Morphology and Electrochemical Behaviour of Hydroxyapatite-Calcium Hydrogen Phosphate Composite Coating Synthesized in-Situ through Electro Chemical Process under Various Deposition Conditions. J. Surf. Interfac. 2018, 12, 160–167. [Google Scholar] [CrossRef]

- Hu, R.; Lin, C.; Shi, H. A Novel Ordered Nano Hydroxyapatite Coating Electrochemically Deposited on Titanium Substrate. J. Biomed. Mater. Res. 2007, 80A, 687–692. [Google Scholar] [CrossRef]

- Santos, A.; Teixeira, J.; Fonzar, C.; Rangel, E.; Cruz, N.; Lisboa-Filho, P.N. A Tribological Investigation of the Titanium Oxide and Calcium Phosphate Coating Electrochemical Deposited on Titanium. Metals 2023, 13, 410. [Google Scholar] [CrossRef]

- Bakin, B.; Koc Delice, T.; Tiric, U.; Birlik, I.; Ak Azem, F. Bioactivity and Corrosion Properties of Magnesium-Substituted CaP Coatings Produced via Electrochemical Deposition. Surf. Coat. Technol. 2016, 301, 29–35. [Google Scholar] [CrossRef]

- Popov, B.N. Corrosion Engineering: Principles and Solved Problems; Elsevier: Amsterdam, The Netherlands; Oxford, UK; Paris, France, 2015; ISBN 978-0-444-62722-3. [Google Scholar]

- ASTM G102-89; Standard Practice for Calculation of Corrosion Rates and Related Information from Electrochemical Measurements 2015. ASTM: West Conshohocken, PA, USA, 2015.

| Voltage/Potential | Deposition Time | |

|---|---|---|

| two-electrode system | −4 V; −5 V; −6 V | 2 h |

| three-electrode system | −4 VSCE; −5 VSCE; −6 VSCE |

| Type of the Electrode System | Applied Voltage/Potential | Thickness (µm) | Average Surface Roughness, Ra (µm) |

|---|---|---|---|

| two-electrode system | −4 V | 3.8 ± 0.5 | 1.19 ± 0.15 |

| −5 V | 1.7 ± 0.3 | 3.22 ± 0.21 | |

| −6 V | 2.5 ± 0.4 | 2.91 ± 0.19 | |

| three-electrode system | −4 VSCE | 17.5 ± 0.6 | 2.66 ± 0.08 |

| −5 VSCE | 7.5 ± 0.5 | 3.30 ± 0.20 | |

| −6 VSCE | 16.7 ± 0.7 | 2.67 ± 0.27 |

| Sample | ba (mV) | bc (mV) | Ecor (V) | Icor (A/cm2) | Rp (MOhm cm2) | CR (mmPY) | PE (%) |

|---|---|---|---|---|---|---|---|

| unmodified alloy | 209 ± 18 | 113 ± 10 | −0.227 ± 0.012 | (1.72 ± 0.09)·10−7 | 0.19 ± 0.01 | (1.50 ± 0.08)·10−3 | - |

| two-electrode set-up | |||||||

| CaP, −4 V | 98 ± 9 | 91 ± 8 | −0.263 ± 0.014 | (1.13 ± 0.06)·10−9 | 18.10 ± 1.17 | (9.87 ± 0.49)·10−6 | 99.3 |

| CaP, −5 V | 247 ± 15 | 121 ± 11 | −0.210 ± 0.018 | (3.12 ± 0.16)·10−8 | 1.13 ± 0.08 | (2.72 ± 0.14)·10−4 | 81.8 |

| CaP, −6 V | 155 ± 10 | 129 ± 12 | −0.197 ± 0.012 | (1.58 ± 0.08)·10−8 | 1.93 ± 0.12 | (1.38 ± 0.07)·10−4 | 90.8 |

| three-electrode set-up | |||||||

| CaP, −4 VSCE | 205 ± 15 | 154 ± 13 | −0.098 ± 0.022 | (3.68 ± 0.18)·10−9 | 10.41 ± 0.75 | (3.21 ± 0.16)·10−5 | 97.9 |

| CaP, −5 VSCE | 198 ± 14 | 121 ± 12 | −0.194 ± 0.015 | (2.40 ± 0.12)·10−8 | 1.36 ± 0.11 | (2.09 ± 0.10)·10−4 | 86.0 |

| CaP, −6 VSCE | 146 ± 9 | 169 ± 12 | −0.140 ± 0.012 | (5.47 ± 0.27)·10−9 | 6.22 ± 0.44 | (4.78 ± 0.24)·10−5 | 96.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iwaniak, K.; Kaczorowski, W.; Burnat, B.; Grabarczyk, J. Impact of the Applied Electrode System on Properties of Electrodeposited Calcium Phosphate Coatings. Materials 2025, 18, 539. https://doi.org/10.3390/ma18030539

Iwaniak K, Kaczorowski W, Burnat B, Grabarczyk J. Impact of the Applied Electrode System on Properties of Electrodeposited Calcium Phosphate Coatings. Materials. 2025; 18(3):539. https://doi.org/10.3390/ma18030539

Chicago/Turabian StyleIwaniak, Klaudia, Witold Kaczorowski, Barbara Burnat, and Jacek Grabarczyk. 2025. "Impact of the Applied Electrode System on Properties of Electrodeposited Calcium Phosphate Coatings" Materials 18, no. 3: 539. https://doi.org/10.3390/ma18030539

APA StyleIwaniak, K., Kaczorowski, W., Burnat, B., & Grabarczyk, J. (2025). Impact of the Applied Electrode System on Properties of Electrodeposited Calcium Phosphate Coatings. Materials, 18(3), 539. https://doi.org/10.3390/ma18030539