The Effect of Low-Temperature Short-Term Annealing on the Microstructure and Properties of Ultrafine-Grained Pure Titanium

Abstract

1. Introduction

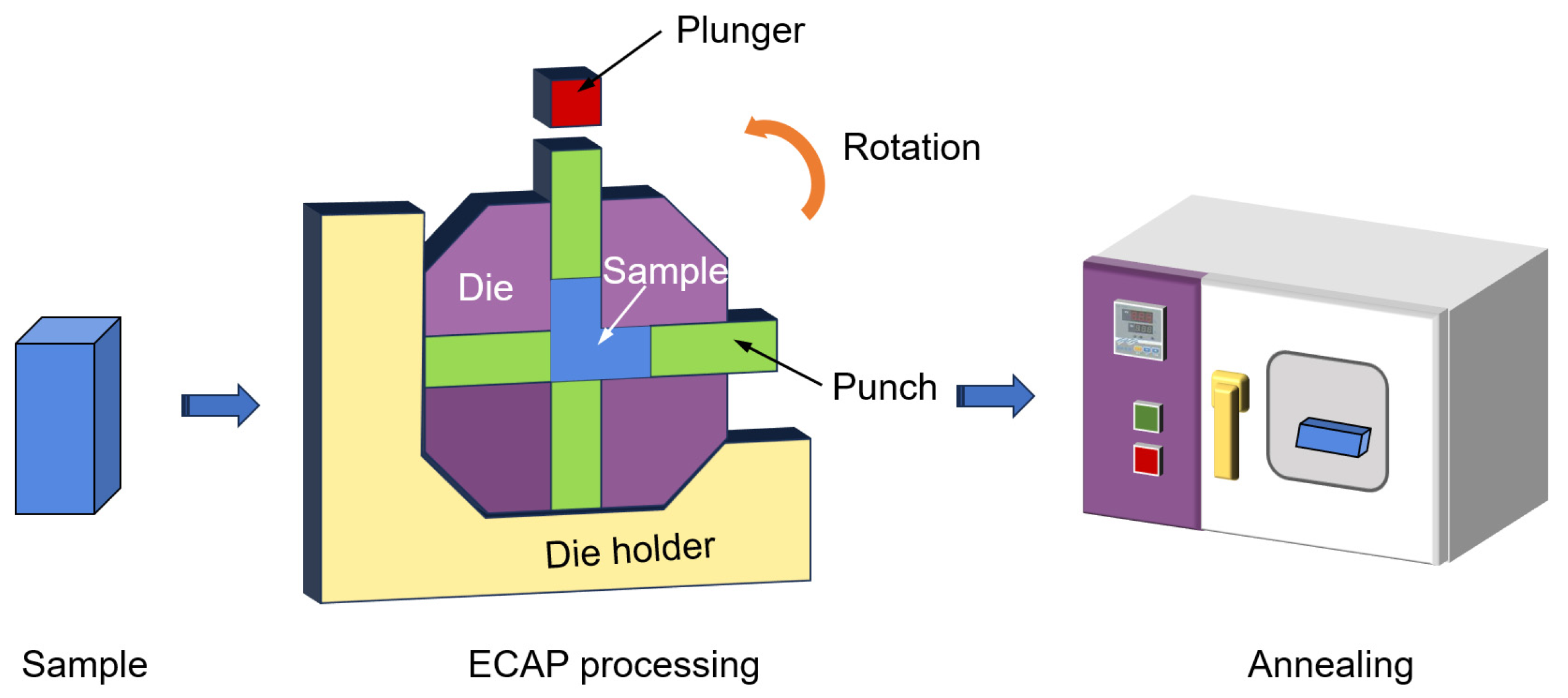

2. Materials and Methods

3. Results and Discussion

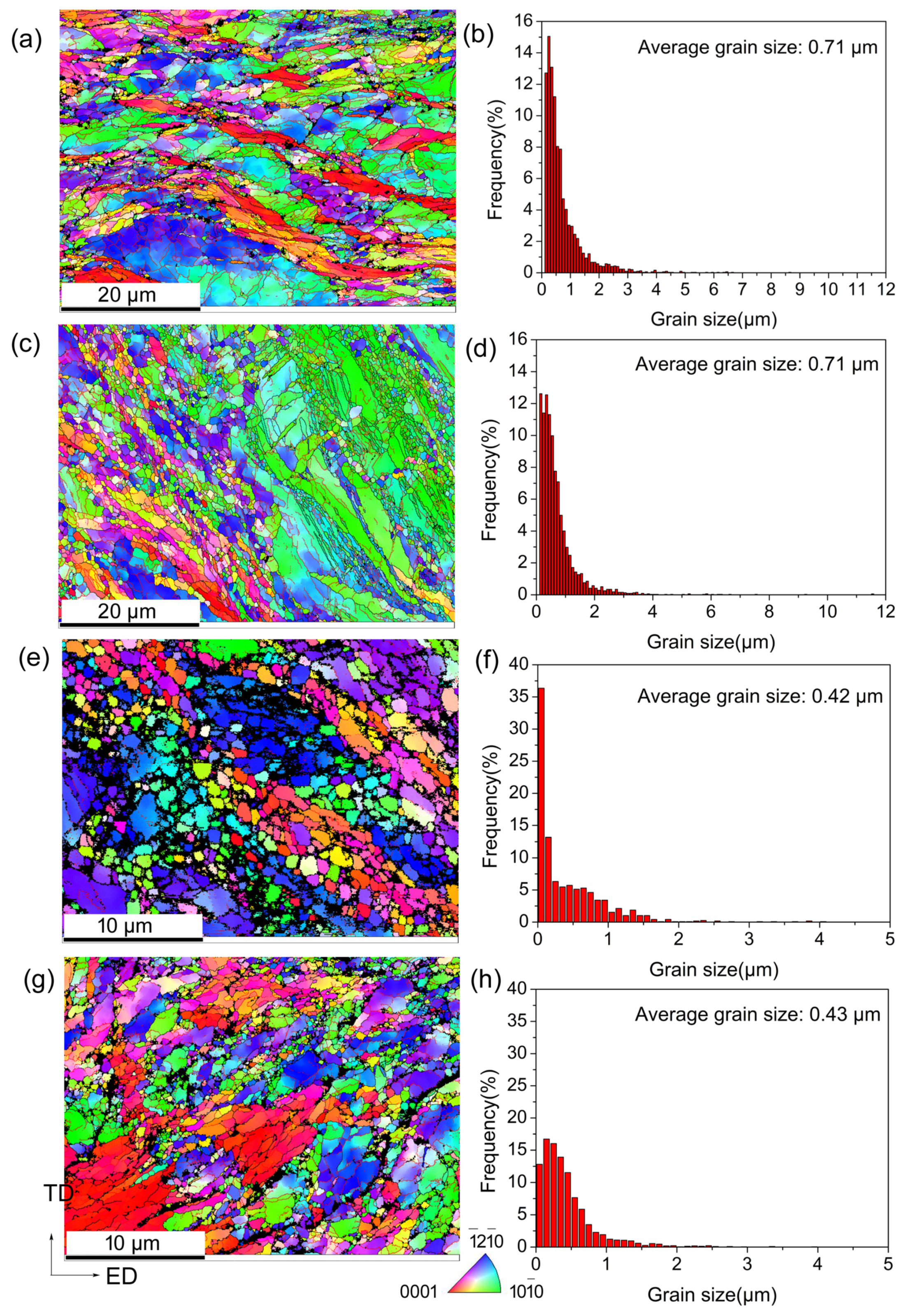

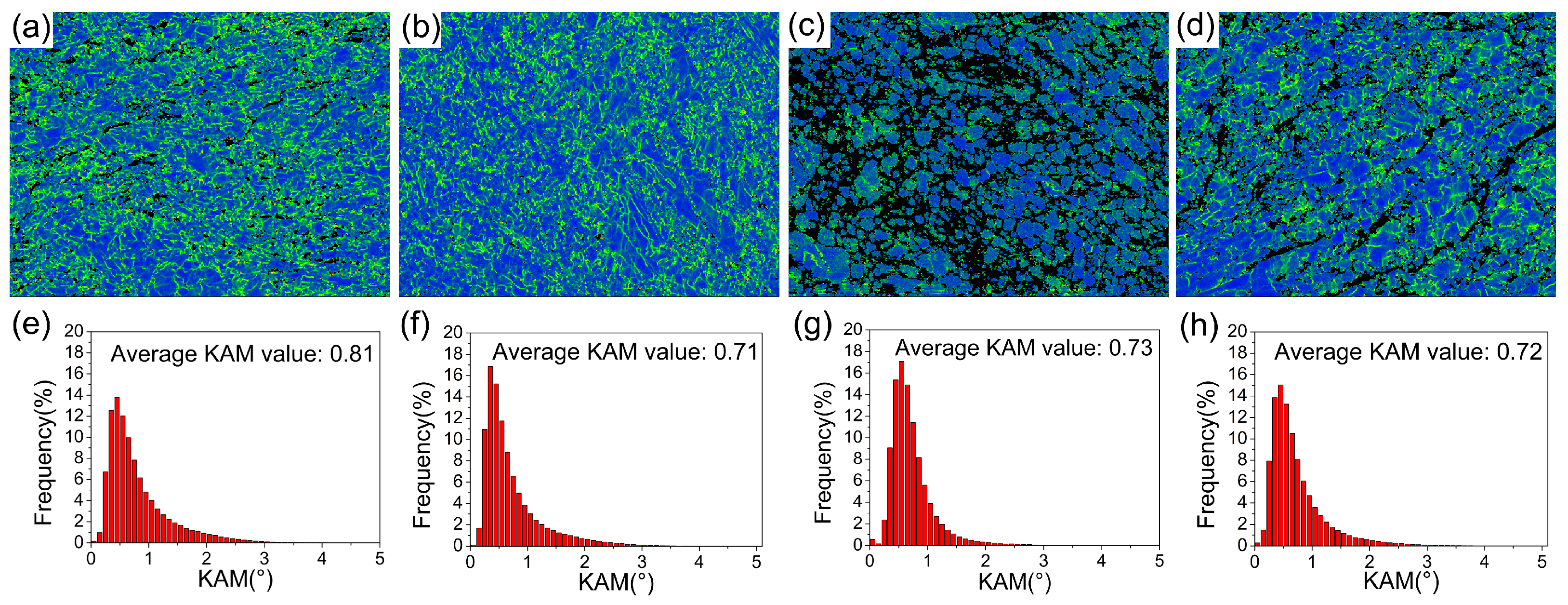

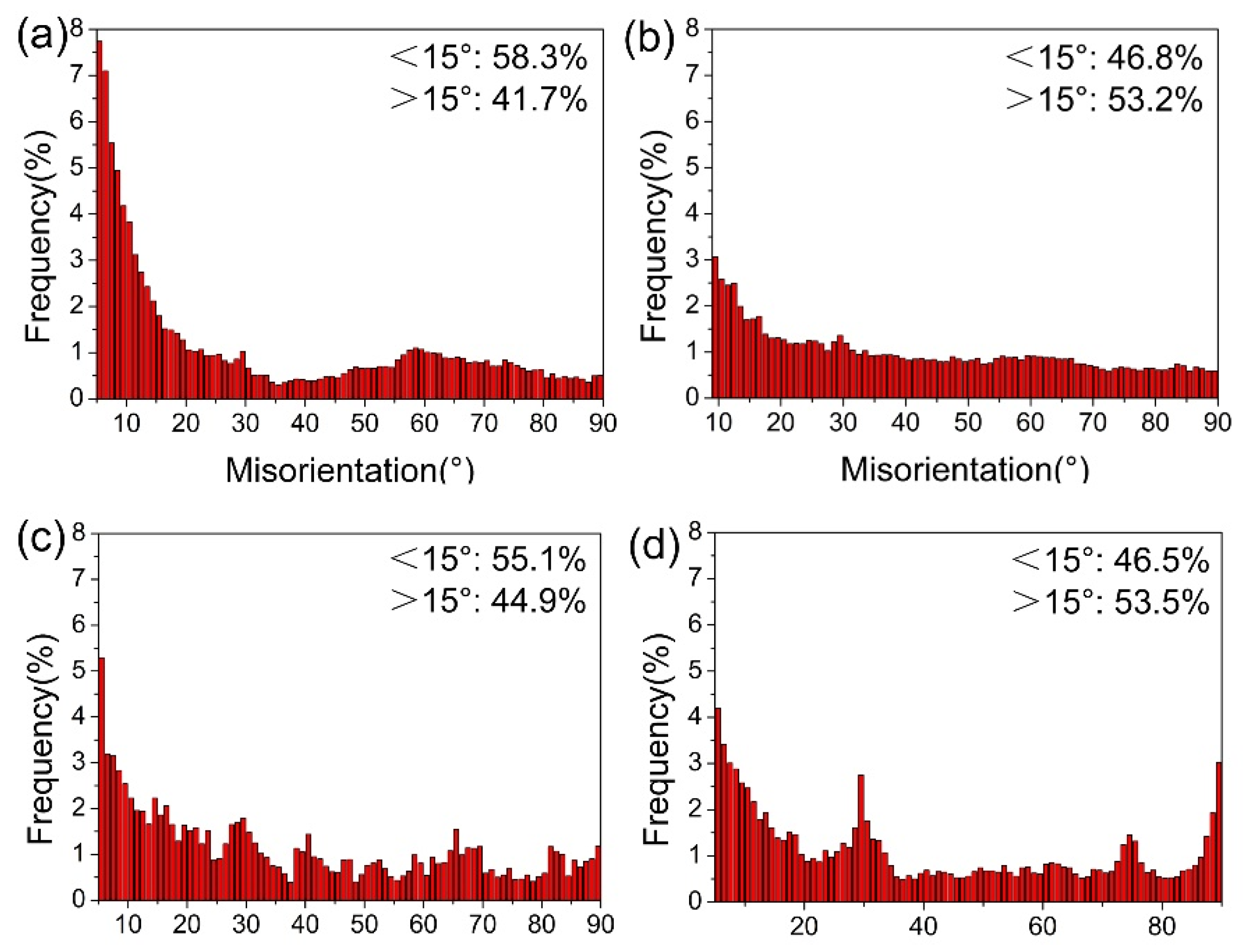

3.1. Microstructure

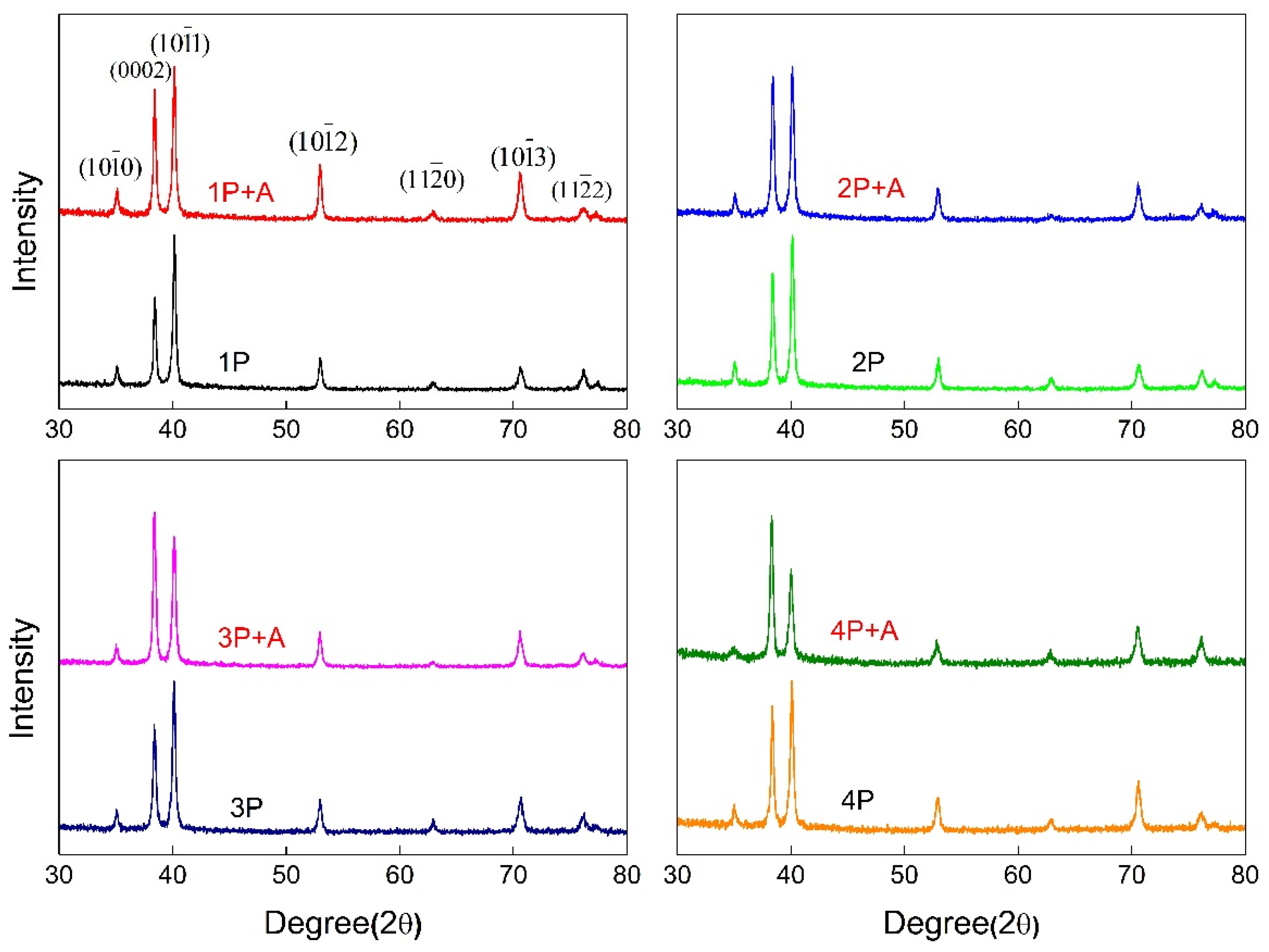

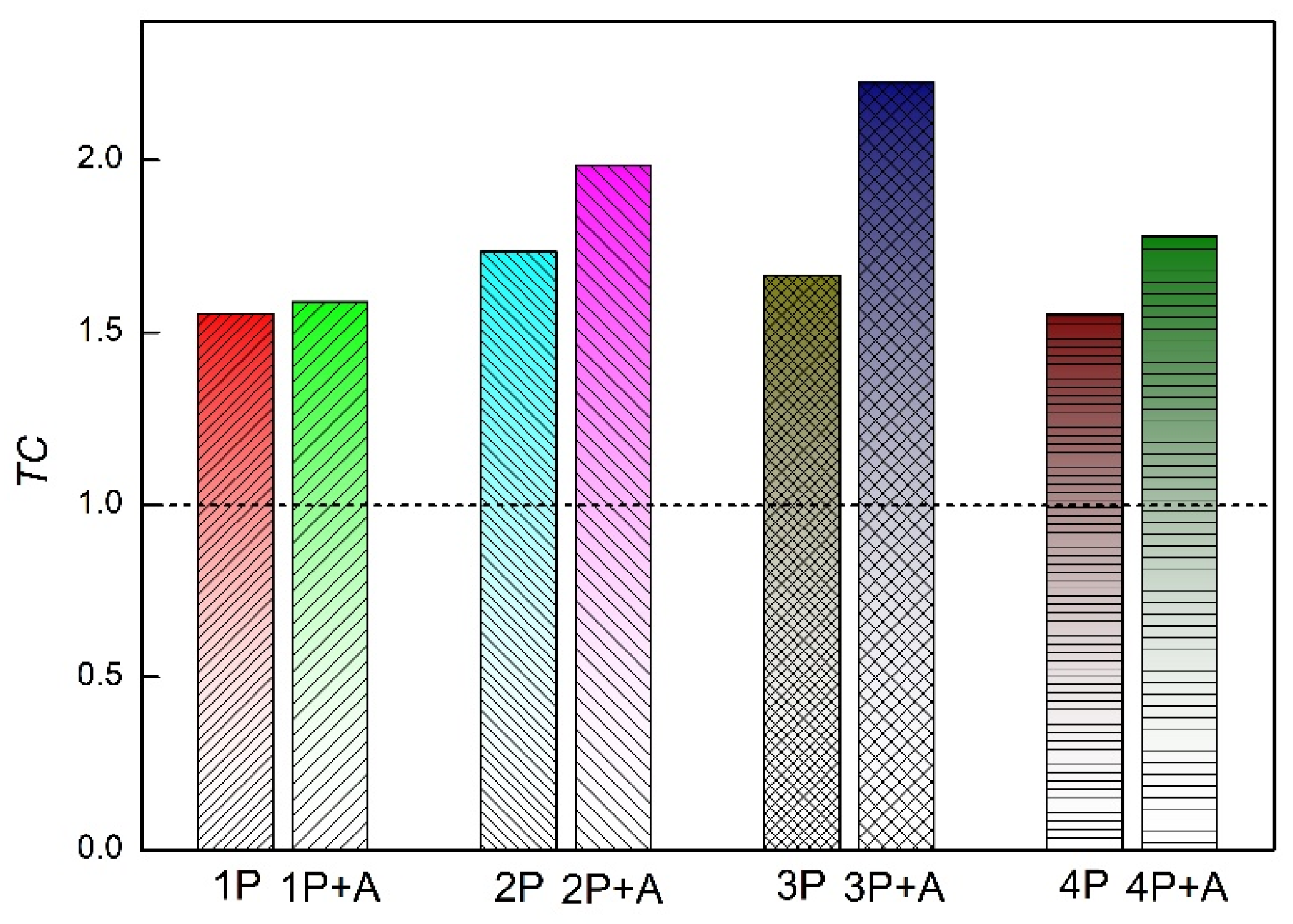

3.2. Texture Evolution

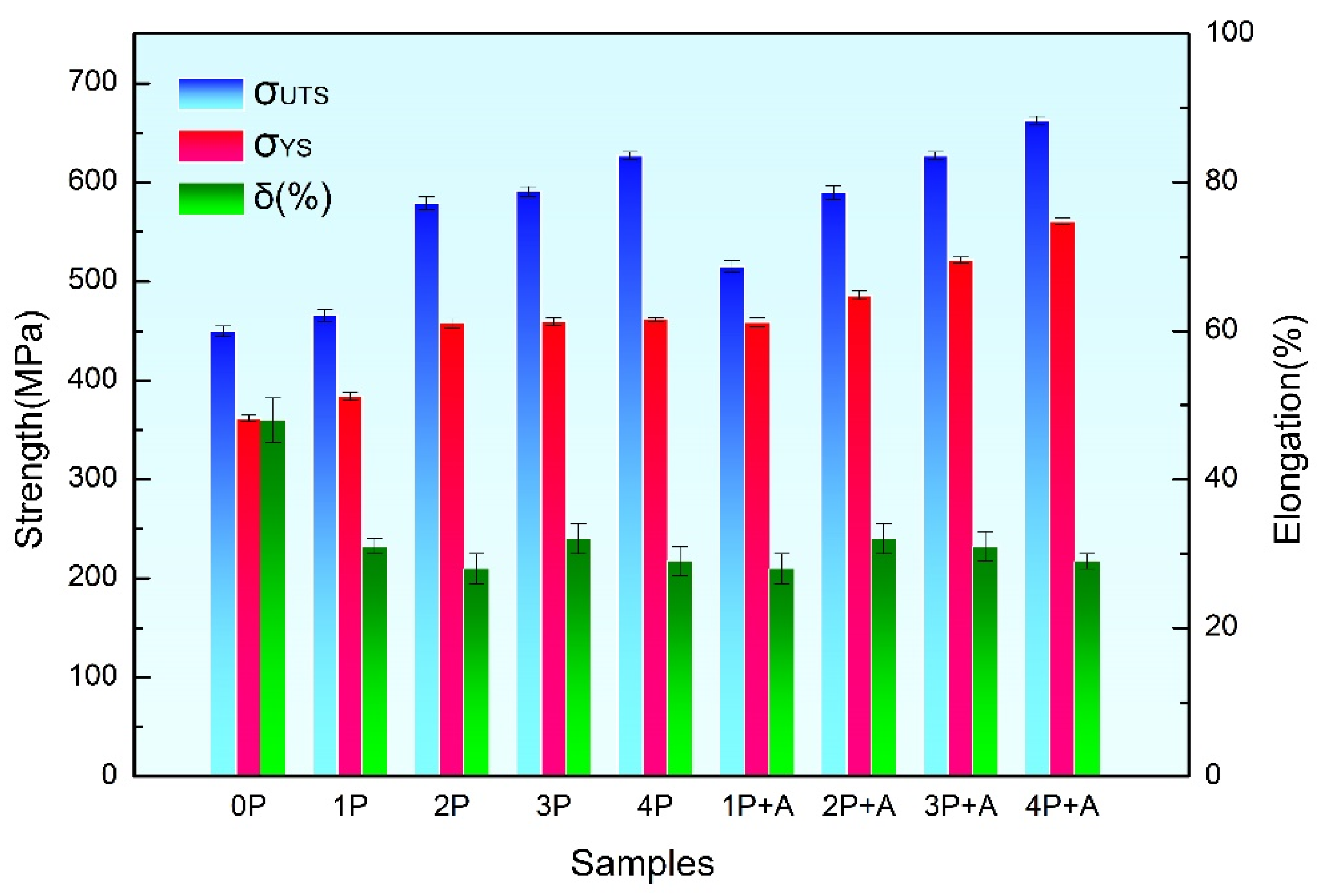

3.3. Mechanical Properties

4. Conclusions

- (1)

- After ECAP processing, the microstructure of industrial pure titanium became increasingly refined with the increasing number of passes, resulting in an average grain size of ~420 nm after four passes. Furthermore, the strength of industrial pure titanium was enhanced via ECAP processing, and the tensile strength of the specimens after four passes was improved by 39% compared with that of the sample in the initial state.

- (2)

- Microstructure observation revealed that the grain growth of ECAP-processed samples was very little during short-term annealing. The calculated results of the EBSD analysis demonstrated that the dislocation density was decreased after annealing. Moreover, the proportion of HAGBs was increased by the aging treatment. The XRD observations showed that the basal texture was strengthened after short-term annealing.

- (3)

- The ECAP-processed specimens subjected to annealing treatment at 300 °C for 15 min exhibited increased strength compared with the pre-annealed specimens. This strengthening effect was likely attributable to the fact that the low annealing temperature and short duration prevented substantial grain growth and enhanced basal texture, thereby impeding dislocation movement.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Edalati, K.; Bachmaier, A.; Beloshenko, V.A.; Beygelzimer, Y.; Blank, V.D.; Botta, W.J.; Bryła, K.; Čížek, J.; Divinski, S.; Enikeev, N.A.; et al. Nanomaterials by severe plastic deformation: Review of historical developments and recent advances. Mater. Res. Lett. 2022, 10, 163–256. [Google Scholar] [CrossRef]

- Ovid’ko, I.A.; Valiev, R.Z.; Zhu, Y.T. Review on superior strength and enhanced ductility of metallic nanomaterials. Prog. Mater. Sci. 2018, 94, 462–540. [Google Scholar] [CrossRef]

- Lin, H.-K.; Li, G.Y.; Mortier, S.; Bazarnik, P.; Huang, Y.; Lewandowska, M.; Langdon, T.G. Processing of CP-Ti by high-pressure torsion and the effect of surface modification using a post-HPT laser treatment. J. Alloys Compd. 2019, 784, 653–659. [Google Scholar] [CrossRef]

- Edalati, K.; Ahmed, A.Q.; Akrami, S.; Ameyama, K.; Aptukov, V.; Asfandiyarov, R.N.; Ashida, M.; Astanin, V.; Bachmaier, A.; Beloshenko, V.; et al. Severe plastic deformation for producing superfunctional ultrafine-grained and heterostructured materials: An interdisciplinary review. J. Alloys Compd. 2024, 1002, 174667. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Estrin, Y.; Horita, Z.; Langdon, T.G.; Zehetbauer, M.J.; Zhu, Y. Producing Bulk Ultrafine-Grained Materials by Severe Plastic Deformation: Ten Years Later. JOM 2016, 68, 1216–1226. [Google Scholar] [CrossRef]

- Dyakonov, G.S.; Mironov, S.; Enikeev, N.; Semenova, I.P.; Valiev, R.Z.; Semiatin, S.L. Annealing behavior of severely-deformed titanium Grade 4. Mater. Sci. Eng. A 2019, 742, 89–101. [Google Scholar] [CrossRef]

- Gu, Y.; Jiang, J.; Ma, A.; Lu, L.; Wu, H. Corrosion behavior of pure titanium processed by rotary-die ECAP. J. Mater. Res. Technol. 2021, 15, 1873–1880. [Google Scholar] [CrossRef]

- Mishnaevsky, L.; Levashov, E.; Valiev, R.Z.; Segurado, J.; Sabirov, I.; Enikeev, N.; Prokoshkin, S.; Solov’yov, A.V.; Korotitskiy, A.; Gutmanas, E.; et al. Nanostructured titanium-based materials for medical implants: Modeling and development. Mater. Sci. Eng. R 2014, 81, 1–19. [Google Scholar] [CrossRef]

- Wang, J.L.; Liu, R.L.; Majumdar, T.; Mantri, S.A.; Ravi, V.A.; Banerjee, R.; Birbilis, N. A closer look at the in vitro electrochemical characterisation of titanium alloys for biomedical applications using in-situ methods. Acta Biomater. 2017, 54, 469–478. [Google Scholar] [CrossRef]

- Sotniczuk, A.; Kuczyńska-Zemła, D.; Kwaśniak, P.; Thomas, M.; Garbacz, H. Corrosion behavior of Ti-29Nb-13Ta-4.6Zr and commercially pure Ti under simulated inflammatory conditions—Comparative effect of grain refinement and non-toxic β phase stabilizers. Electrochim. Acta 2019, 312, 369–379. [Google Scholar] [CrossRef]

- Elias, C.N.; Fernandes, D.J.; Souza, F.M.d.; Monteiro, E.d.S.; Biasi, R.S.d. Mechanical and clinical properties of titanium and titanium-based alloys (Ti G2, Ti G4 cold worked nanostructured and Ti G5) for biomedical applications. J. Mater. Res. Technol. 2019, 8, 1060–1069. [Google Scholar] [CrossRef]

- Kaur, M.; Singh, K. Review on titanium and titanium based alloys as biomaterials for orthopaedic applications. Mater. Sci. Eng. C 2019, 102, 844–862. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Fu, L.; Fu, B.; Shan, A. Effects of annealing on microstructure and mechanical properties of nano-grained titanium produced by combination of asymmetric and symmetric rolling. Mater. Sci. Eng. A 2012, 558, 309–318. [Google Scholar] [CrossRef]

- Sheremetyev, V.; Churakova, A.; Derkach, M.; Gunderov, D.; Raab, G.; Prokoshkin, S. Effect of ECAP and annealing on structure and mechanical properties of metastable beta Ti-18Zr-15Nb (at.%) alloy. Mater. Lett. 2021, 305, 130760. [Google Scholar] [CrossRef]

- Raab, G.I.; Kodirov, I.S.; Aksenov, D.A.; Valiev, R.Z. The formation of a high-strength state in martensitic Ti Grade 4 by ECAP. J. Alloys Compd. 2022, 922, 166205. [Google Scholar] [CrossRef]

- Xu, H.Q.; Wei, K.X.; Wei, W.; Dzugan, J.; Alexandrov, I.V.; An, X.L.; Wang, D.D.; Liu, X.K.; Daniel, M.; Hradil, D.; et al. Microstructure and mechanical properties evolution of Ti-13Nb-13Zr alloy processed by ECAP-Conform and rotary swaging. J. Alloys Compd. 2023, 969, 172351. [Google Scholar] [CrossRef]

- Tesař, K.; Koller, M.; Vokoun, D.; Tyc, O.; Čech, J.; Sedlák, P. Texture, elastic anisotropy and thermal stability of commercially pure titanium prepared by room temperature ECAP. Mater. Des. 2023, 226, 111678. [Google Scholar] [CrossRef]

- Yang, X.-R.; Wang, Z.-L.; Dai, Y.; Li, B.-W.; Jin, Z.; Luo, L.; Liu, X.-Y.; Wang, J.-Z. Evolution of microstructure, macrotexture and mechanical properties of high strength biomedical TA4 pure titanium during multi-pass ECAP. J. Mater. Res. Technol. 2024, 28, 3976–3987. [Google Scholar] [CrossRef]

- Fattah-Alhosseini, A.; Imantalab, O.; Ansari, G. The role of grain refinement and film formation potential on the electrochemical behavior of commercial pure titanium in Hank’s physiological solution. Mater. Sci. Eng. C 2017, 71, 827–834. [Google Scholar] [CrossRef] [PubMed]

- Lu, J.; Zhang, Y.; Huo, W.; Zhang, W.; Zhao, Y.; Zhang, Y. Electrochemical corrosion characteristics and biocompatibility of nanostructured titanium for implants. Appl. Surf. Sci. 2018, 434, 63–72. [Google Scholar] [CrossRef]

- Sotniczuk, A.; Chromiński, W.; Adamczyk-Cieślak, B.; Pisarek, M.; Garbacz, H. Corrosion behaviour of biomedical Ti under simulated inflammation: Exploring the relevance of grain refinement and crystallographic texture. Corros. Sci. 2022, 200, 110238. [Google Scholar] [CrossRef]

- Gu, Y.; Ma, A.; Jiang, J.; Yuan, Y.; Wu, H. Microstructure and tensile anisotropy of pure Ti processed by up-scaled RD-ECAP. Mater. Charact. 2020, 168, 110513. [Google Scholar] [CrossRef]

- Gu, Y.; Jiang, J.; Ma, A.; Wu, H.; Lu, L. Enhanced corrosion behavior of ultrafine-grained pure titanium in simulated high-temperature seawater. J. Mater. Res. Technol. 2022, 19, 1–6. [Google Scholar] [CrossRef]

- Agarwal, K.M.; Tyagi, R.K.; Singhal, A.; Bhatia, D. Effect of ECAP on the mechanical properties of titanium and its alloys for biomedical applications. Mater. Sci. Energy. Technol. 2020, 3, 921–927. [Google Scholar] [CrossRef]

- Fintova, S.; Dlhy, P.; Mertova, K.; Chlup, Z.; Duchek, M.; Prochazka, R.; Hutar, P. Fatigue properties of UFG Ti grade 2 dental implant vs. conventionally tested smooth specimens. J. Mech. Behav. Biomed. Mater. 2021, 123, 104715. [Google Scholar] [CrossRef]

- Rezyapova, L.R.; Safargalina, Z.A.; Usmanov, E.I.; Valiev, R.R.; Minasov, T.B.; Valiev, R.Z. Nanostructured Titanium with Ultrafine-Grained Structure as Advanced Engineering Material for Biomedical Application. Adv. Eng. Mater. 2024, 26, 2400394. [Google Scholar] [CrossRef]

- Jiang, Q.-W.; Li, X.-W. Effect of pre-annealing treatment on the compressive deformation and damage behavior of ultrafine-grained copper. Mater. Sci. Eng. A 2012, 546, 59–67. [Google Scholar] [CrossRef]

- Edalati, K.; Hashiguchi, Y.; Iwaoka, H.; Matsunaga, H.; Valiev, R.Z.; Horita, Z. Long-time stability of metals after severe plastic deformation: Softening and hardening by self-annealing versus thermal stability. Mater. Sci. Eng. A 2018, 729, 340–348. [Google Scholar] [CrossRef]

- Mavlyutov, A.M.; Bondarenko, A.S.; Murashkin, M.Y.; Boltynjuk, E.V.; Valiev, R.Z.; Orlova, T.S. Effect of annealing on microhardness and electrical resistivity of nanostructured SPD aluminium. J. Alloys Compd. 2017, 698, 539–546. [Google Scholar] [CrossRef]

- Orlova, T.S.; Latynina, T.A.; Mavlyutov, A.M.; Murashkin, M.Y.; Valiev, R.Z. Effect of annealing on microstructure, strength and electrical conductivity of the pre-aged and HPT-processed Al-0.4Zr alloy. J. Alloys Compd. 2019, 784, 41–48. [Google Scholar] [CrossRef]

- Sotniczuk, A.; Kuczyńska-Zemła, D.; Królikowski, A.; Garbacz, H. Enhancement of the corrosion resistance and mechanical properties of nanocrystalline titanium by low-temperature annealing. Corros. Sci. 2019, 147, 342–349. [Google Scholar] [CrossRef]

- Kim, J.G.; Seol, J.B.; Bae, J.W.; Kim, H.S. On the mechanistic understanding of annealing-induced strength enhancement of ultrafine-grained high-Mn steel. Materialia 2020, 13, 100837. [Google Scholar] [CrossRef]

- Chen, J.; Su, Y.; Zhang, Q.; Sun, J.; Yang, D.; Jiang, J.; Song, D.; Ma, A. Enhancement of strength-ductility synergy in ultrafine-grained Cu-Zn alloy prepared by ECAP and subsequent annealing. J. Mater. Res. Technol. 2022, 17, 433–440. [Google Scholar] [CrossRef]

- Sotniczuk, A.; Kuczyńska-Zemła, D.; Majchrowicz, K.; Kijeńska-Gawrońska, E.; Kruszewski, M.; Nikiforow, K.; Pisarek, M.; Swieszkowski, W.; Garbacz, H. Tailoring mechanical and surface properties of UFG CP-Ti by the low-temperature annealing. Appl. Surf. Sci. 2023, 607, 155038. [Google Scholar] [CrossRef]

- Majchrowicz, K.; Sotniczuk, A.; Adamczyk-Cieślak, B.; Chromiński, W.; Jóźwik, P.; Pakieła, Z.; Garbacz, H. The influence of microstructure and texture on the hardening by annealing effect in cold-rolled titanium. J. Alloys Compd. 2023, 948, 169791. [Google Scholar] [CrossRef]

- Renk, O.; Maier-Kiener, V.; Issa, I.; Li, J.H.; Kiener, D.; Pippan, R. Anneal hardening and elevated temperature strain rate sensitivity of nanostructured metals: Their relation to intergranular dislocation accommodation. Acta Mater. 2019, 165, 409–419. [Google Scholar] [CrossRef]

- Semenova, I.; Salimgareeva, G.; Da Costa, G.; Lefebvre, W.; Valiev, R. Enhanced Strength and Ductility of Ultrafine-Grained Ti Processed by Severe Plastic Deformation. Adv. Eng. Mater. 2010, 12, 803–807. [Google Scholar] [CrossRef]

- Huang, X.; Xin, Y.; Cao, Y.; Li, W.; Huang, G.; Zhao, X.; Liu, Q.; Wu, P. Understanding the mechanisms of texture evolution in an Mg-2Zn-1Ca alloy during cold rolling and annealing. Int. J. Plast. 2022, 158, 103412. [Google Scholar] [CrossRef]

- Stolyarov, V.V.; Zeipper, L.; Mingler, B.; Zehetbauer, M. Influence of post-deformation on CP-Ti processed by equal channel angular pressing. Mater. Sci. Eng. A 2008, 476, 98–105. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Sergueeva, A.V.; Mukherjee, A.K. The effect of annealing on tensile deformation behavior of nanostructured SPD titanium. Scr. Mater. 2003, 49, 669–674. [Google Scholar] [CrossRef]

- Gu, Y.; Ma, A.; Jiang, J.; Li, H.; Song, D.; Wu, H.; Yuan, Y. Simultaneously improving mechanical properties and corrosion resistance of pure Ti by continuous ECAP plus short-duration annealing. Mater. Charact. 2018, 138, 38–47. [Google Scholar] [CrossRef]

- Singh, A.V.; Vyas, V.; Salve, T.S.; Cortelli, D.; Dellasega, D.; Podesta, A.; Milani, P.; Gade, W.N. Biofilm formation on nanostructured titanium oxide surfaces and a micro/nanofabrication-based preventive strategy using colloidal lithography. Biofabrication 2012, 4, 025001. [Google Scholar] [CrossRef]

- Yang, Z.; Ma, A.; Xu, B.; Jiang, J.; Wu, H.; Sun, J. Tailoring the microstructure and texture to achieve high strength in a high-Al content Mg alloy by stepless-temperature-reduction ECAP. Mater. Sci. Eng. A 2022, 841, 143023. [Google Scholar] [CrossRef]

- Stylianou, R.; Tkadletz, M.; Schalk, N.; Penoy, M.; Czettl, C.; Mitterer, C. Effects of reference materials on texture coefficients determined for a CVD α-Al2O3 coating. Surf. Coat. Technol. 2019, 359, 314–322. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, W.; Zhang, L. Crystalline Size Effects on Texture Coefficient, Electrical and Optical Properties of Sputter-deposited Ga-doped ZnO Thin Films. J. Mater. Sci. Technol. 2015, 31, 175–181. [Google Scholar] [CrossRef]

- Latysh, V.; Krallics, G.; Alexandrov, I.; Fodor, A. Application of bulk nanostructured materials in medicine. Curr. Appl. Phys. 2006, 6, 262–266. [Google Scholar] [CrossRef]

- Wu, H.; Jiang, J.; Liu, H.; Sun, J.; Gu, Y.; Tang, R.; Zhao, X.; Ma, A. Fabrication of an Ultra-Fine Grained Pure Titanium with High Strength and Good Ductility via ECAP plus Cold Rolling. Metals 2017, 7, 563. [Google Scholar] [CrossRef]

- Huang, X.; Hansen, N.; Tsuji, N. Hardening by annealing and softening by deformation in nanostructured metals. Science 2006, 312, 249–251. [Google Scholar] [CrossRef]

- Huang, X.; Kamikawa, N.; Hansen, N. Increasing the ductility of nanostructured Al and Fe by deformation. Mater. Sci. Eng. A 2008, 493, 184–189. [Google Scholar] [CrossRef]

- Huang, X. Tailoring dislocation structures and mechanical properties of nanostructured metals produced by plastic deformation. Scr. Mater. 2009, 60, 1078–1082. [Google Scholar] [CrossRef]

- Akbari Mousavi, S.A.A.; Bahadori, S.R. The effects of post annealing on the mechanical properties, microstructure and texture evolutions of pure copper deformed by twist extrusion process. Mater. Sci. Eng. A 2011, 528, 1242–1246. [Google Scholar] [CrossRef]

- Zhao, F.X.; Xu, X.C.; Liu, H.Q.; Wang, Y.L. Effect of annealing treatment on the microstructure and mechanical properties of ultrafine-grained aluminum. Mater. Des. 2014, 53, 262–268. [Google Scholar] [CrossRef]

- Volkov, A.Y.; Kliukin, I.V. Improving the mechanical properties of pure magnesium through cold hydrostatic extrusion and low-temperature annealing. Mater. Sci. Eng. A 2015, 627, 56–60. [Google Scholar] [CrossRef]

- Singh, A.V.; Galluzzi, M.; Borghi, F.; Indrieri, M.; Vyas, V.; Podesta, A.; Gade, W.N. Interaction of bacterial cells with cluster-assembled nanostructured titania surfaces: An atomic force microscopy study. J. Nanosci. Nanotechnol. 2013, 13, 77–85. [Google Scholar] [CrossRef]

- Nasiri-Abarbekoh, H.; Abbasi, R.; Ekrami, A.; Ziaei-Moayyed, A.A. Notch-texture strengthening mechanism in commercially pure titanium thin sheets. Mater. Des. 2014, 55, 683–689. [Google Scholar] [CrossRef]

- Liu, G.; Yang, Y.; Luo, X.; Huang, B.; Kou, Z.; Li, P. Improving the mechanical properties of titanium films by texture strengthening. Mater. Charact. 2017, 127, 365–370. [Google Scholar] [CrossRef]

- Srinivasan, N.; Velmurugan, R.; Singh, S.K.; Pant, B.; Kumar, R. Texture strengthening and anisotropic hardening of mill annealed Ti-6Al-4V alloy under equi-biaxial tension. Mater. Charact. 2020, 164, 110349. [Google Scholar] [CrossRef]

- Li, R.G.; Li, H.R.; Pan, H.C.; Xie, D.S.; Zhang, J.H.; Fang, D.Q.; Dai, Y.Q.; Zhao, D.Y.; Zhang, H. Achieving exceptionally high strength in binary Mg-13Gd alloy by strong texture and substantial precipitates. Scr. Mater. 2021, 193, 142–146. [Google Scholar] [CrossRef]

- Liu, F.; Liu, Z.Y.; He, G.Y.; Ou, L.N. Dislocation ordering and texture strengthening of naturally aged Al-Cu-Mg alloy. J. Mater. Sci. Technol. 2022, 118, 1–14. [Google Scholar] [CrossRef]

- Wang, S.; Hou, J.P.; Zhang, Z.J.; Gong, B.S.; Qu, Z.; Wang, H.; Zhou, X.H.; Jiang, H.C.; Wang, Q.; Li, X.W.; et al. Grain design in ultra-fine Al wire with remarkable combination of strength and conductivity: Ultra-fine-long grains with super strong <111> texture. Scr. Mater. 2024, 238, 115746. [Google Scholar] [CrossRef]

- Sun, J.; Xu, B.; Yang, Z.; Zhuo, X.; Han, J.; Wu, Y.; Song, D.; Liu, H.; Jiang, J.; Ma, A. Developing an industrial-scale ECAP Mg-Al-Zn alloy with multi-heterostructure for synchronously high strength and good ductility. Mater. Charact. 2020, 164, 110341. [Google Scholar] [CrossRef]

| Fe | C | N | O | Ti |

|---|---|---|---|---|

| 0.06 | 0.02 | 0.01 | 0.06 | Balance |

| Number | Specific Treatment |

|---|---|

| 0P | As-received |

| 1P | ECAP for 1 pass |

| 2P | ECAP for 2 passes |

| 3P | ECAP for 3 passes |

| 4P | ECAP for 4 passes |

| 1P + A | ECAP for 1 pass + 300 °C × 15 min annealing treatment |

| 2P + A | ECAP for 2 passes + 300 °C × 15 min annealing treatment |

| 3P + A | ECAP for 3 passes + 300 °C × 15 min annealing treatment |

| 4P + A | ECAP for 4 passes + 300 °C × 15 min annealing treatment |

| Sample | Texture Coefficient (TC) | ||||

|---|---|---|---|---|---|

| (0002) | |||||

| 1P | 0.52 | 1.55 | 0.76 | 1.29 | 0.49 |

| 2P | 0.55 | 1.73 | 0.69 | 1.17 | 0.63 |

| 3P | 0.52 | 1.66 | 0.68 | 1.31 | 0.68 |

| 4P | 0.49 | 1.55 | 0.55 | 1.11 | 0.60 |

| 1P + A | 0.51 | 1.59 | 0.55 | 1.62 | 0.45 |

| 2P + A | 0.51 | 1.98 | 0.63 | 1.07 | 0.34 |

| 3P + A | 0.43 | 2.22 | 0.56 | 1.23 | 0.30 |

| 4P + A | 0.36 | 1.78 | 0.35 | 0.90 | 0.73 |

| Samples | Tensile Strength σb (MPa) | Yield Strength σs (MPa) | Elongations δ (%) |

|---|---|---|---|

| 0P | 450 ± 5 | 362 ± 3 | 48 ± 3 |

| 1P | 466 ± 6 | 384 ± 4 | 31 ± 1 |

| 2P | 579 ± 7 | 458 ± 5 | 28 ± 2 |

| 3P | 591 ± 5 | 460 ± 4 | 32 ± 2 |

| 4P | 627 ± 4 | 462 ± 3 | 29 ± 2 |

| 1P + A1 | 515 ± 6 | 459 ± 5 | 28 ± 2 |

| 2P + A1 | 590 ± 7 | 486 ± 4 | 32 ± 2 |

| 3P + A1 | 627 ± 4 | 522 ± 3 | 31 ± 2 |

| 4P + A1 | 663 ± 4 | 561 ± 3 | 29 ± 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, Y.; Jiang, J.; Ma, A.; Gu, Y.; Yang, Z.; Wu, H.; Song, C.; Yang, Q.; Ni, C. The Effect of Low-Temperature Short-Term Annealing on the Microstructure and Properties of Ultrafine-Grained Pure Titanium. Materials 2025, 18, 517. https://doi.org/10.3390/ma18030517

Gu Y, Jiang J, Ma A, Gu Y, Yang Z, Wu H, Song C, Yang Q, Ni C. The Effect of Low-Temperature Short-Term Annealing on the Microstructure and Properties of Ultrafine-Grained Pure Titanium. Materials. 2025; 18(3):517. https://doi.org/10.3390/ma18030517

Chicago/Turabian StyleGu, Yanxia, Jinghua Jiang, Aibin Ma, Yaxiao Gu, Zhenquan Yang, Haoran Wu, Chenlong Song, Qingping Yang, and Chaobing Ni. 2025. "The Effect of Low-Temperature Short-Term Annealing on the Microstructure and Properties of Ultrafine-Grained Pure Titanium" Materials 18, no. 3: 517. https://doi.org/10.3390/ma18030517

APA StyleGu, Y., Jiang, J., Ma, A., Gu, Y., Yang, Z., Wu, H., Song, C., Yang, Q., & Ni, C. (2025). The Effect of Low-Temperature Short-Term Annealing on the Microstructure and Properties of Ultrafine-Grained Pure Titanium. Materials, 18(3), 517. https://doi.org/10.3390/ma18030517