Numerical and Experimental Approaches for Mechanical Durability Assessment of an EV Battery Pack Case

Abstract

1. Introduction

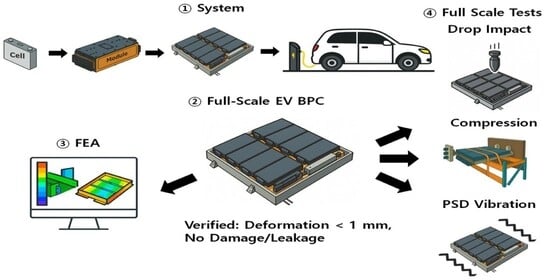

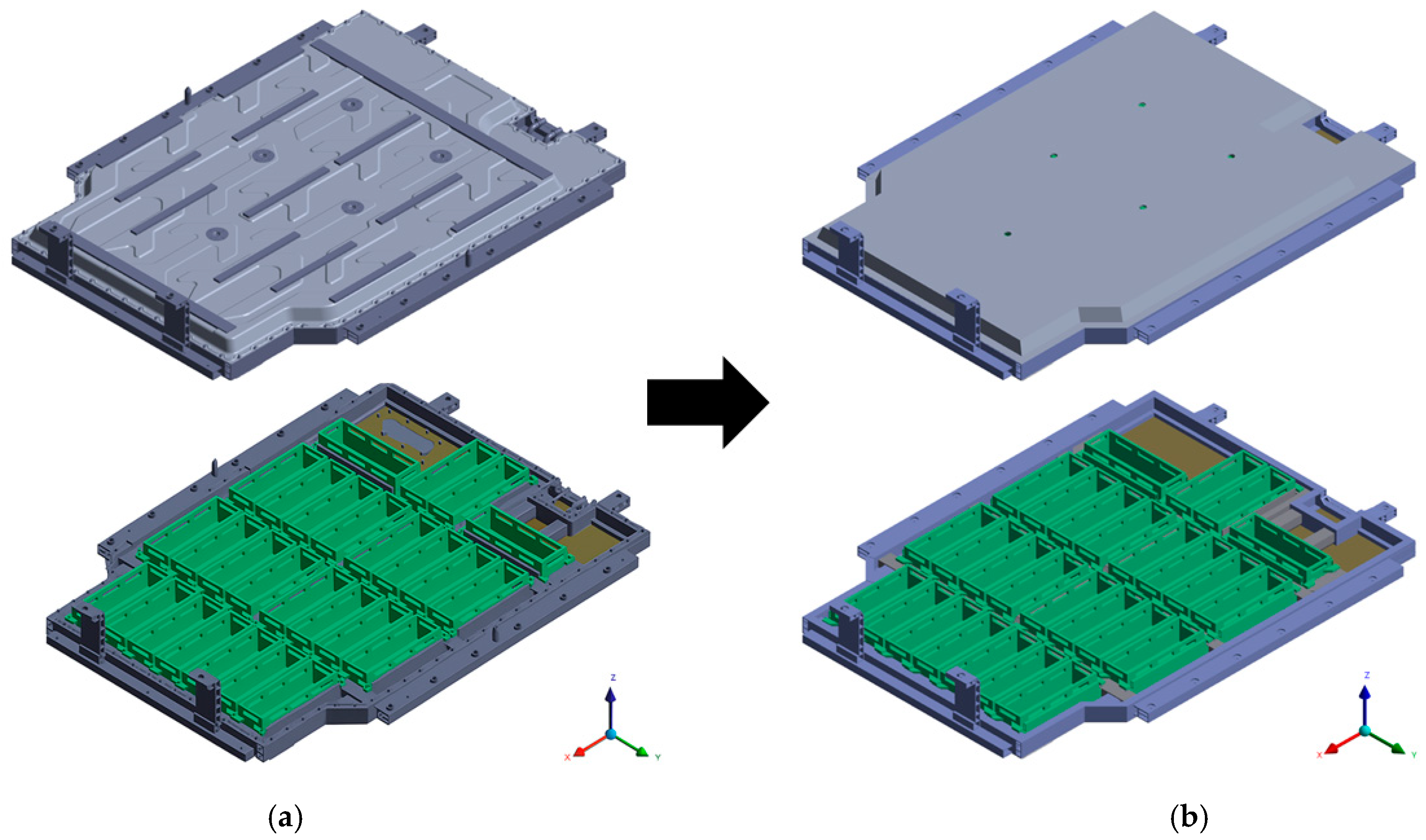

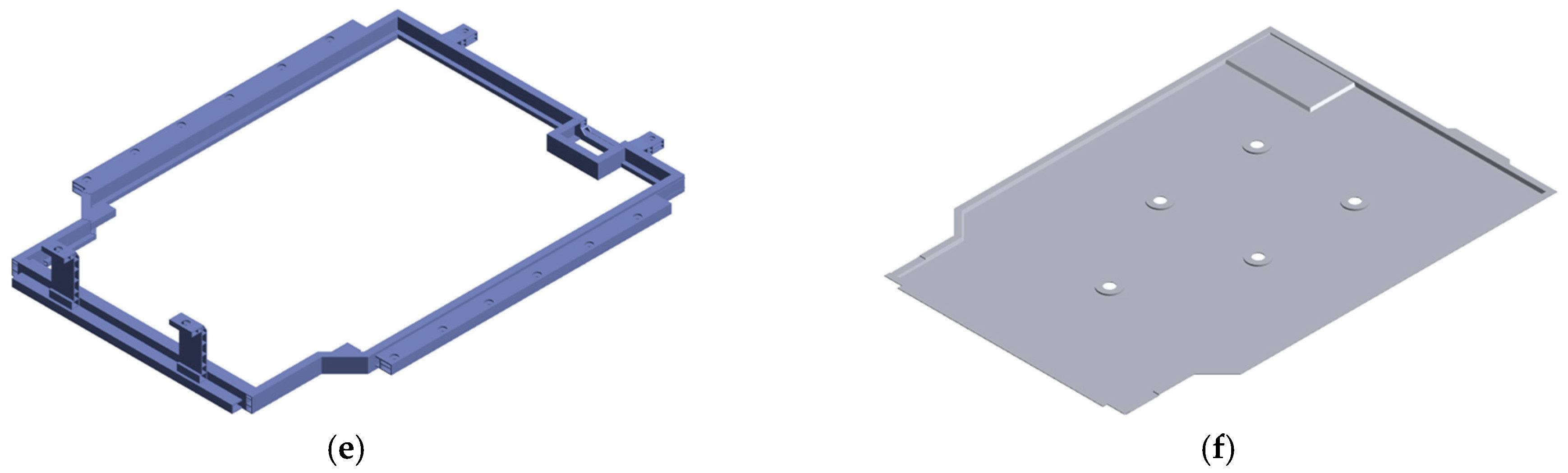

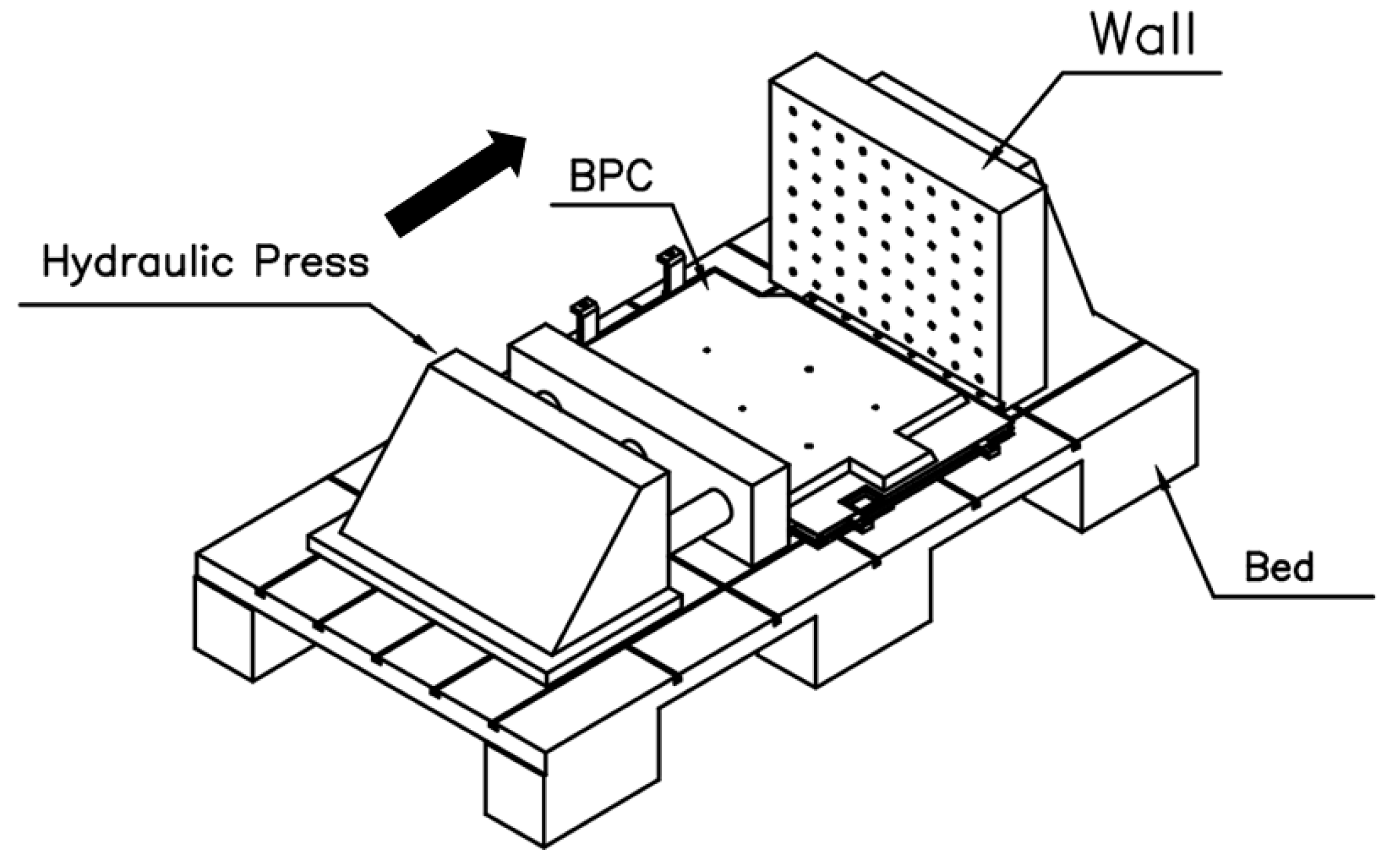

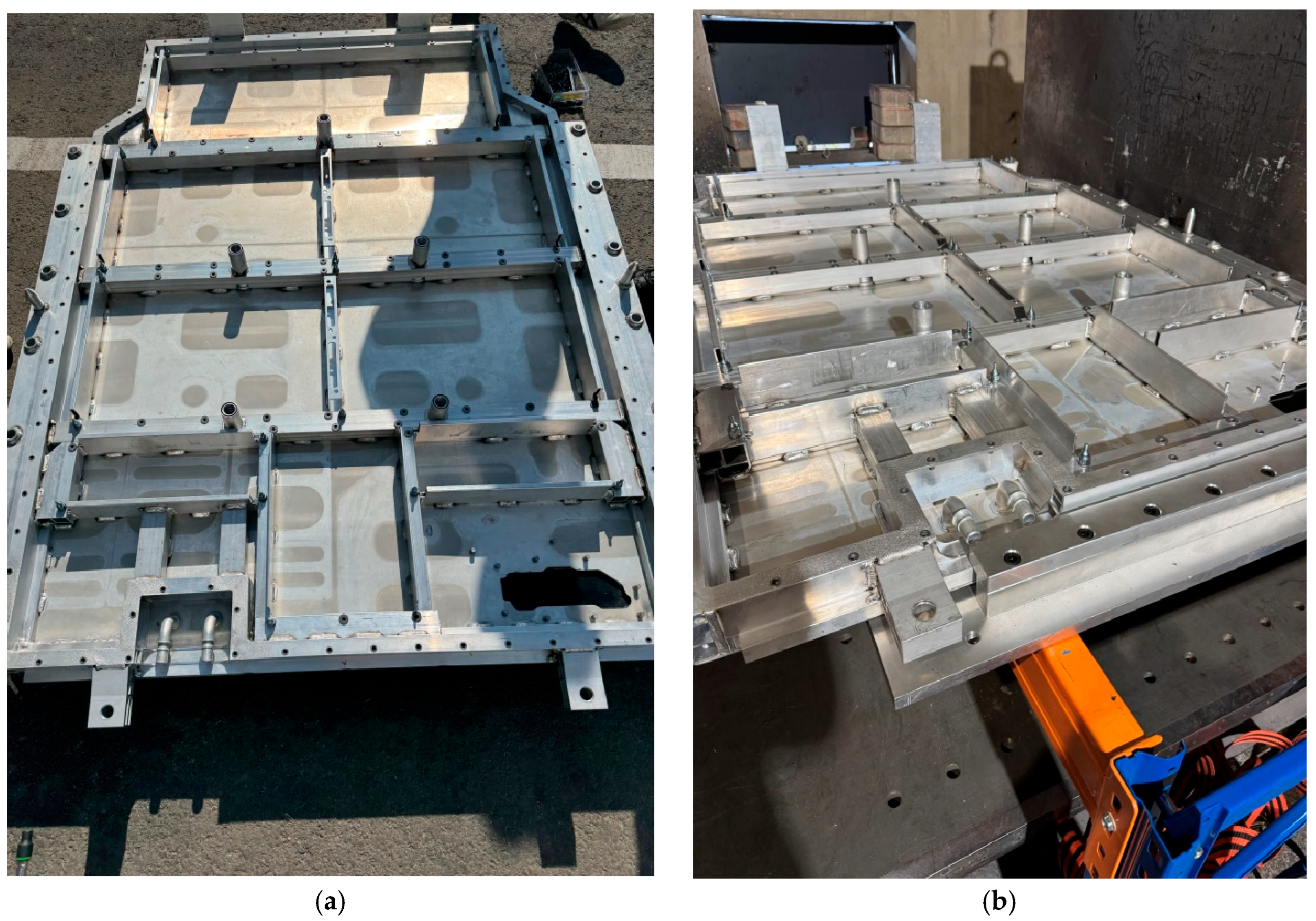

2. FEA Model and Structural Test Setup for the EV BPC

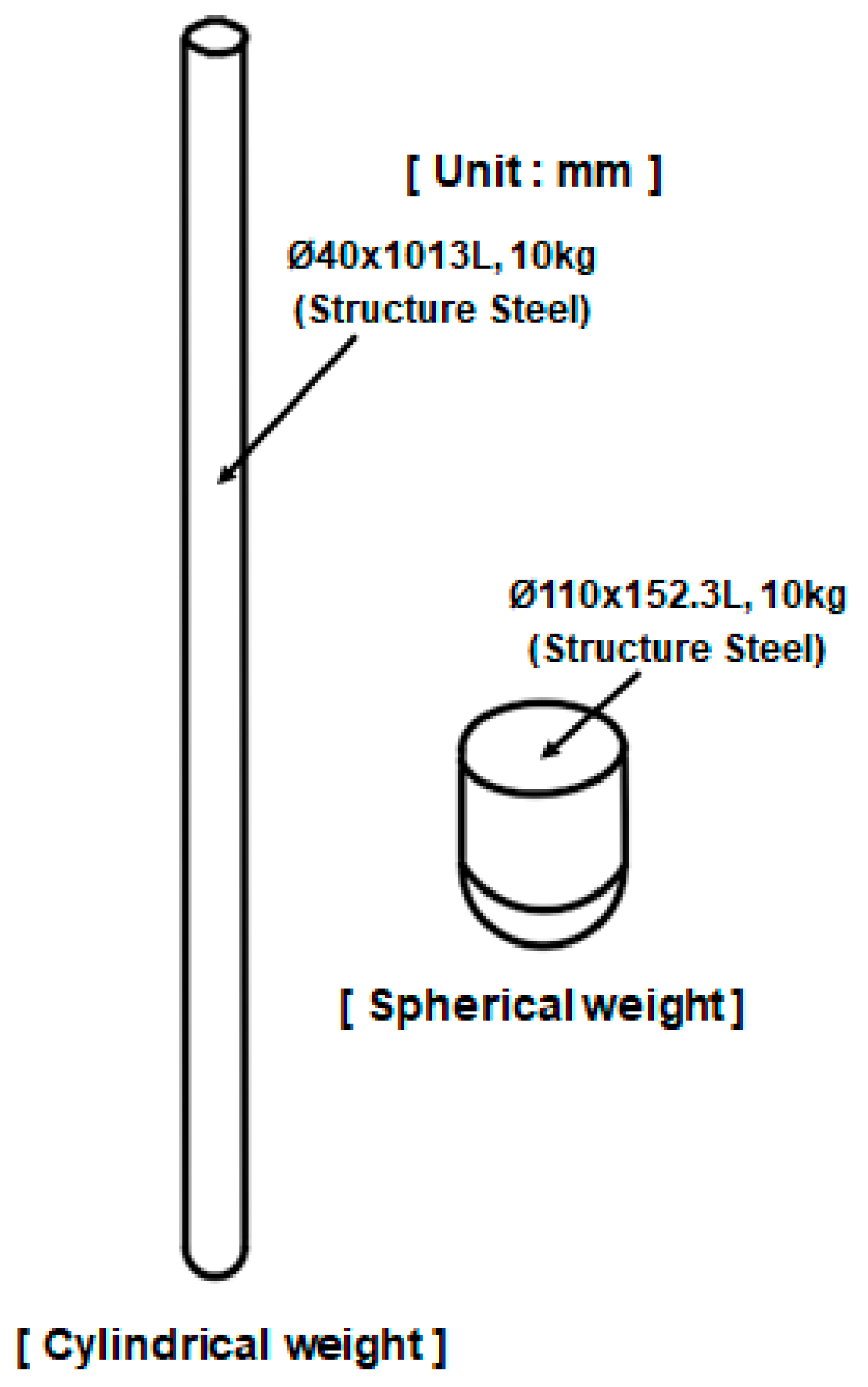

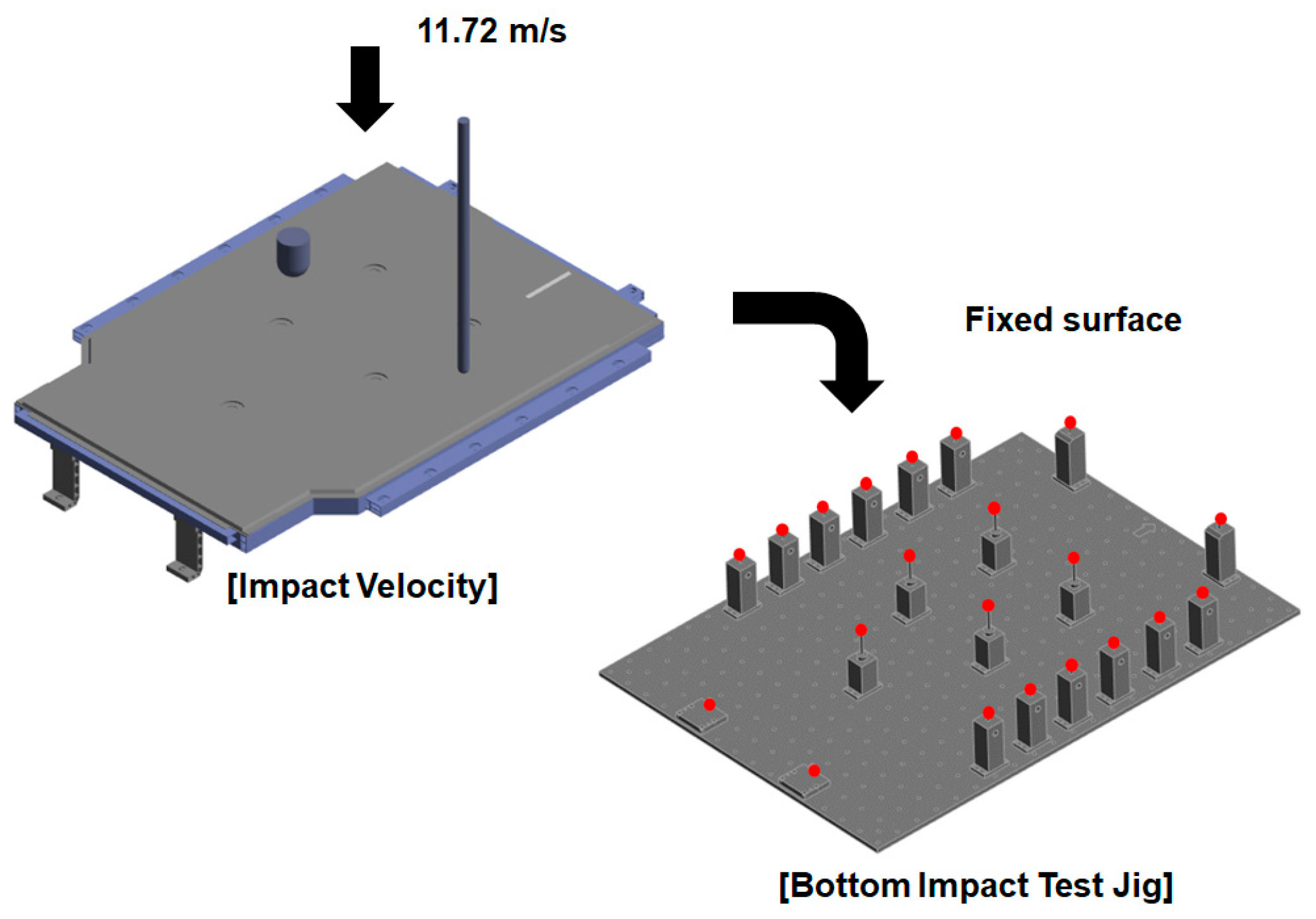

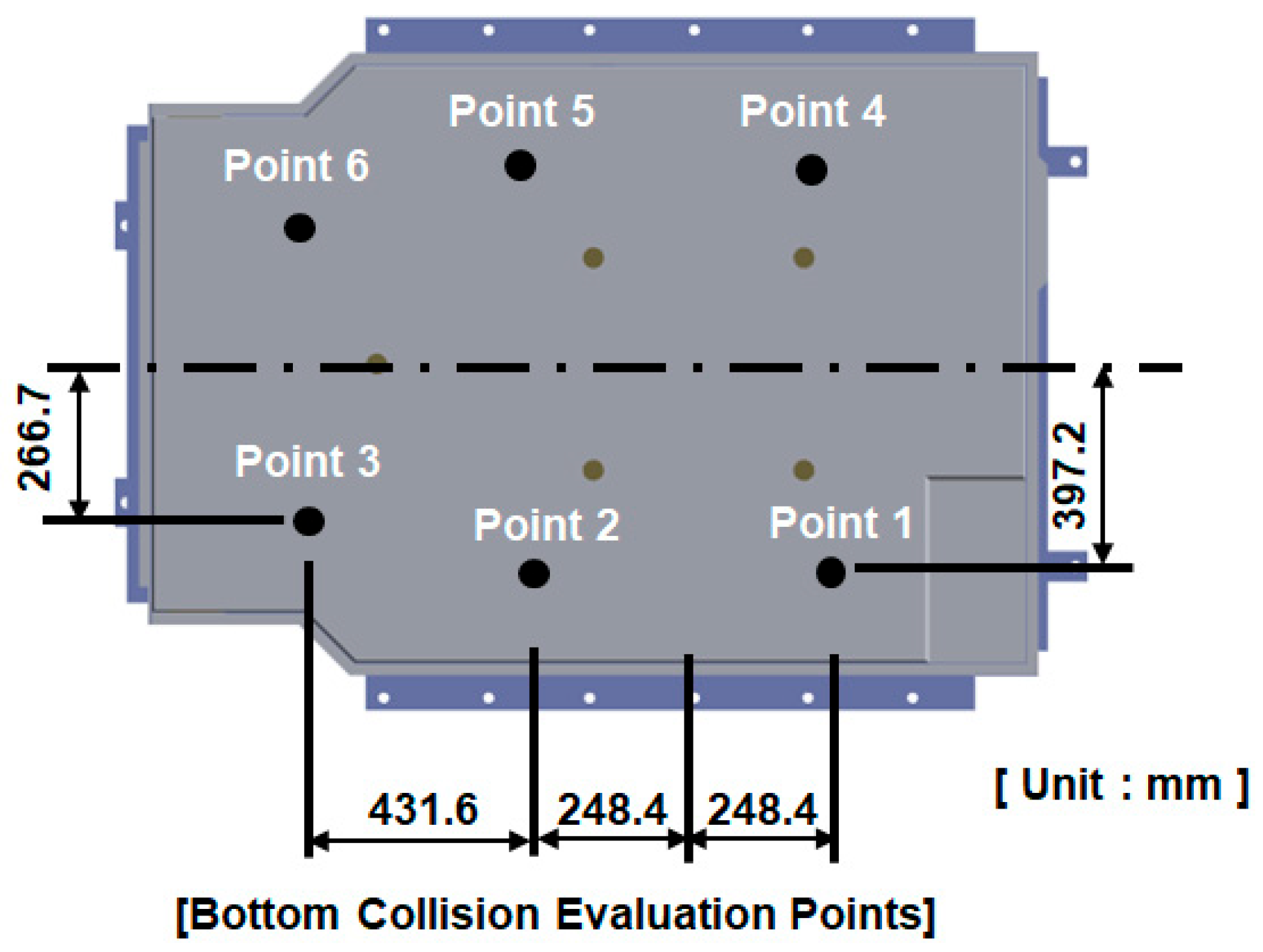

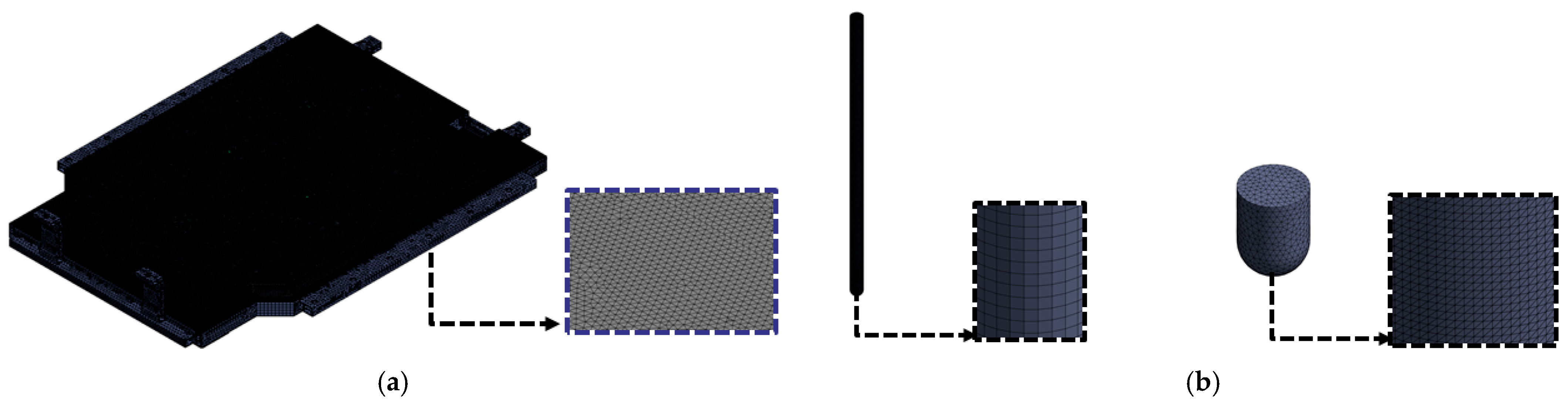

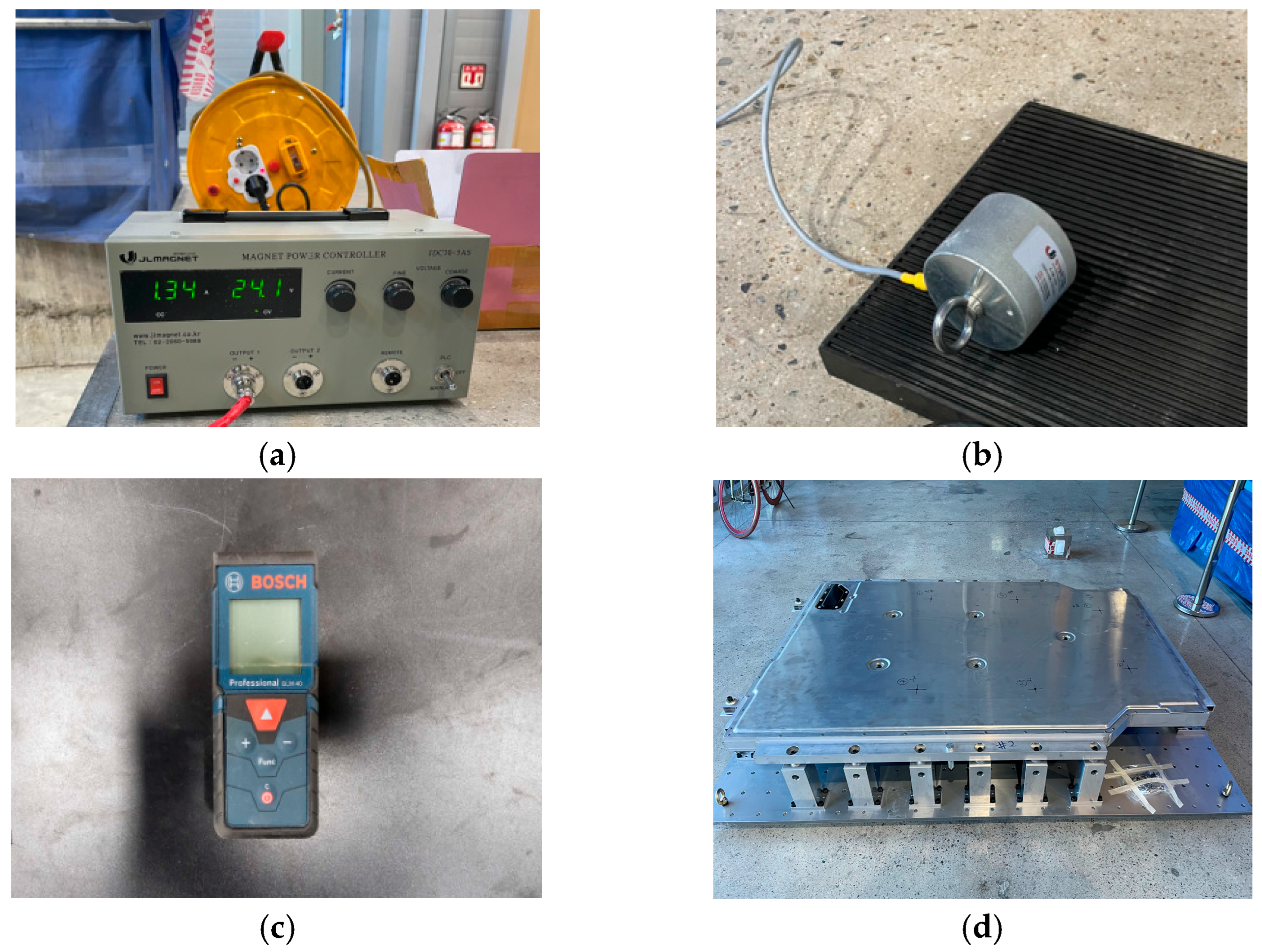

2.1. Analysis and Experimental Conditions for BPC Bottom Impact

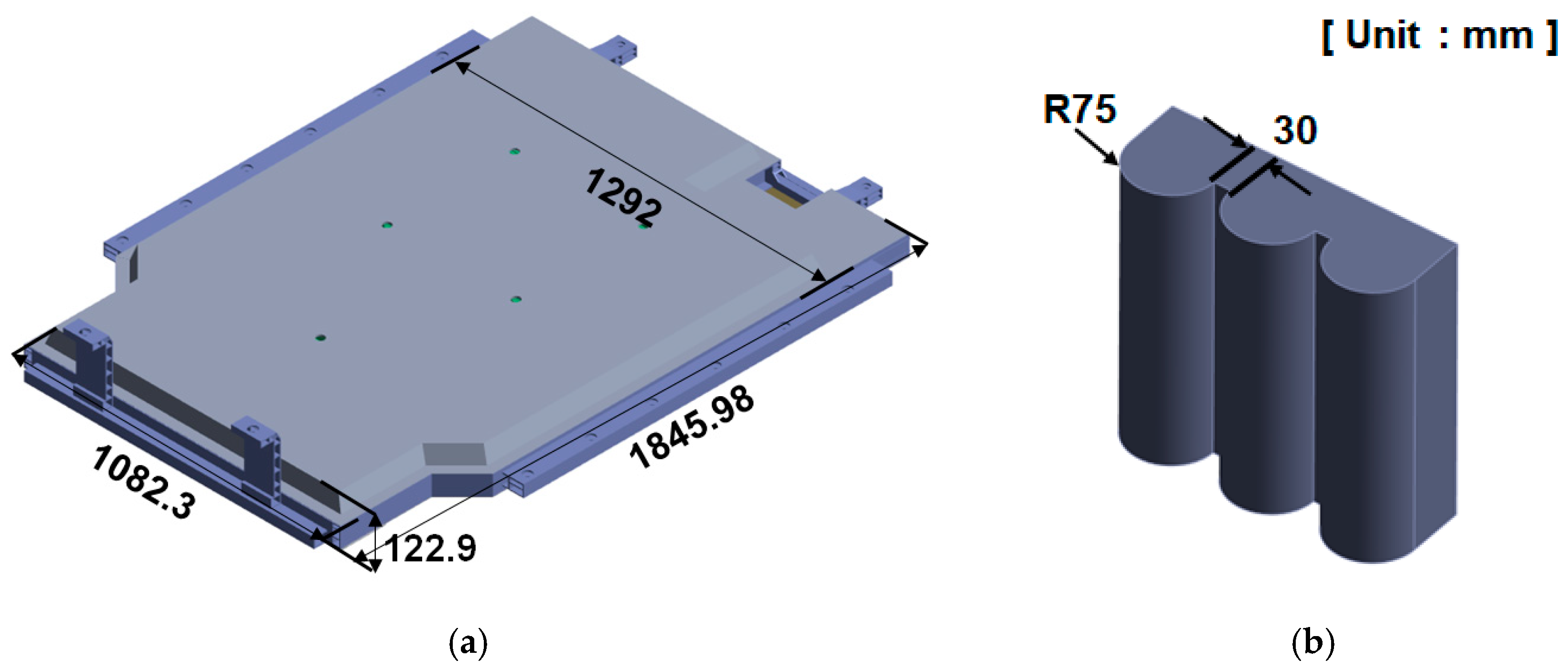

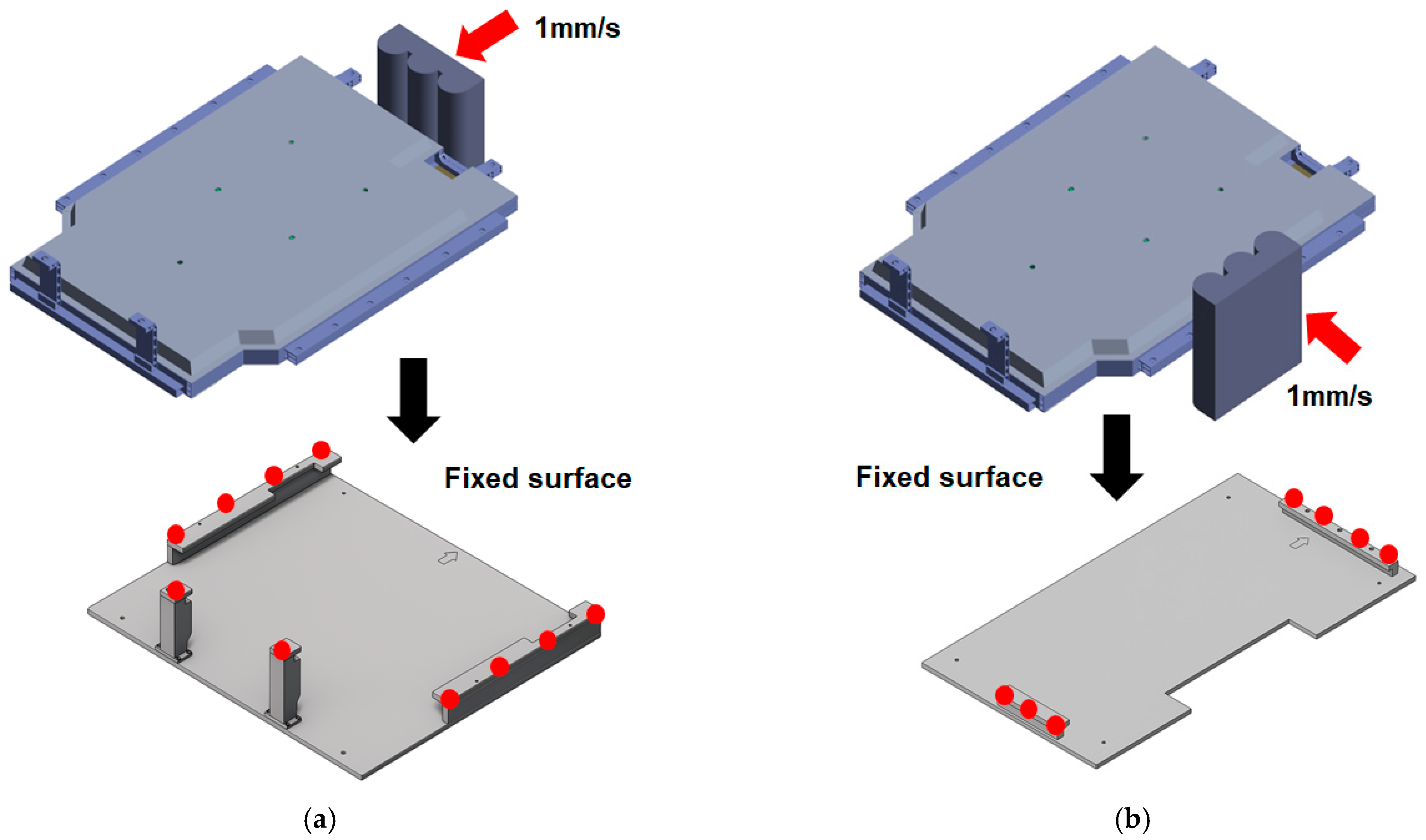

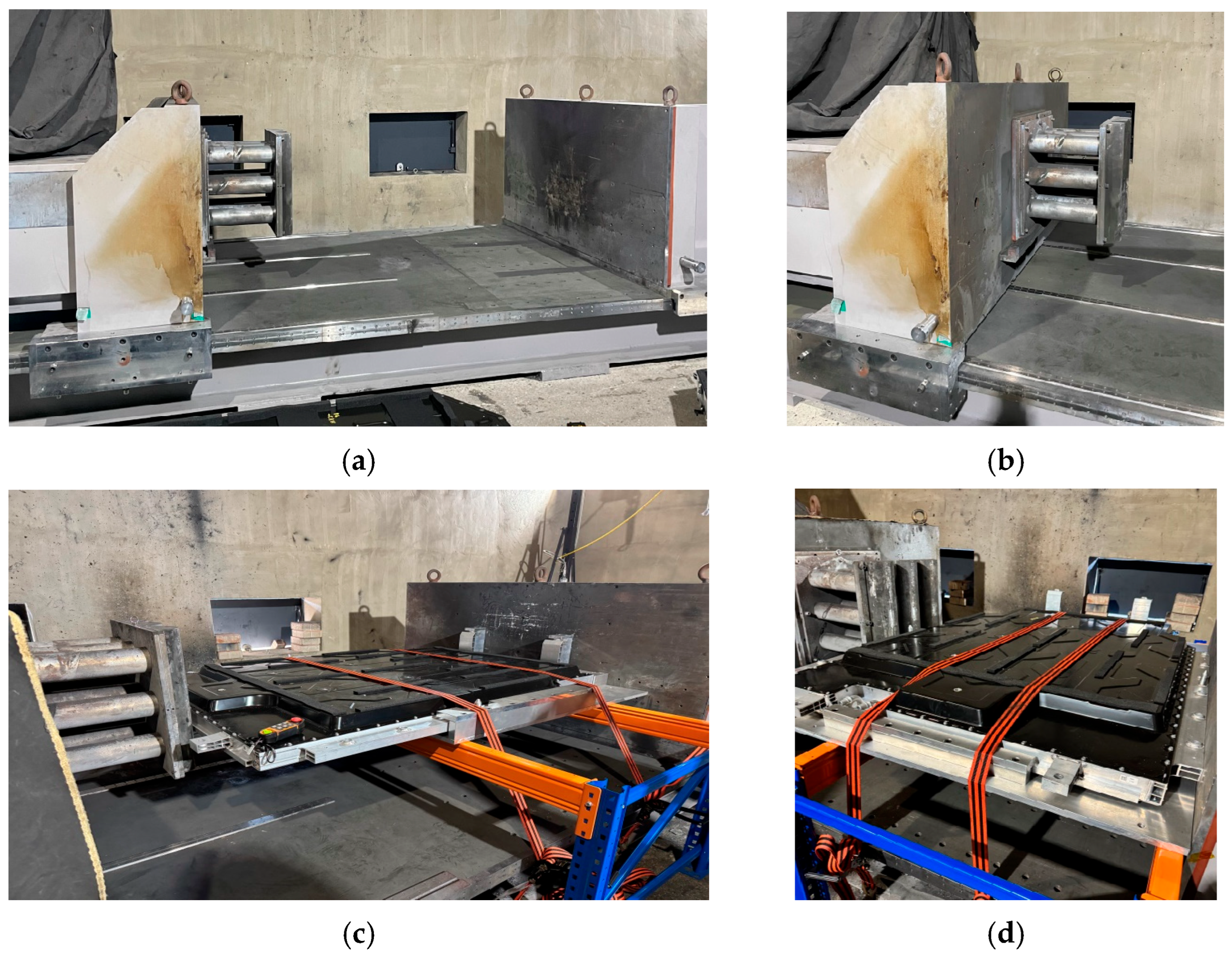

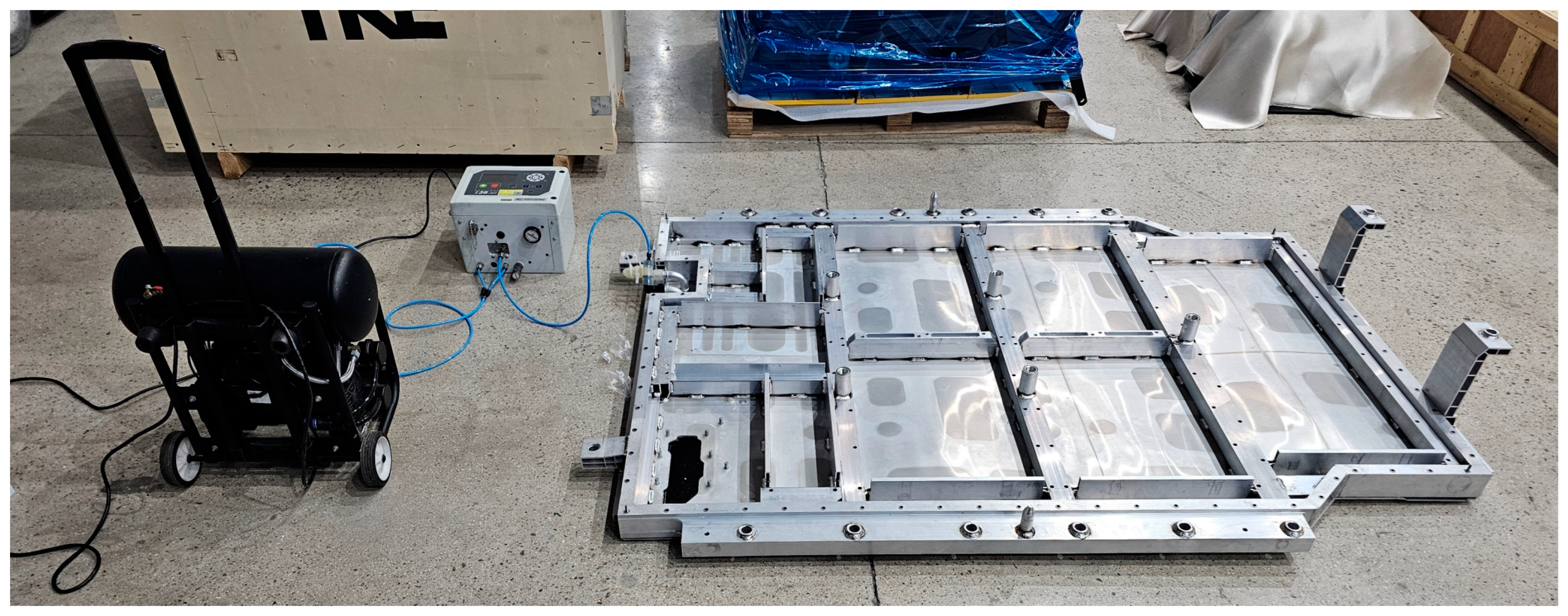

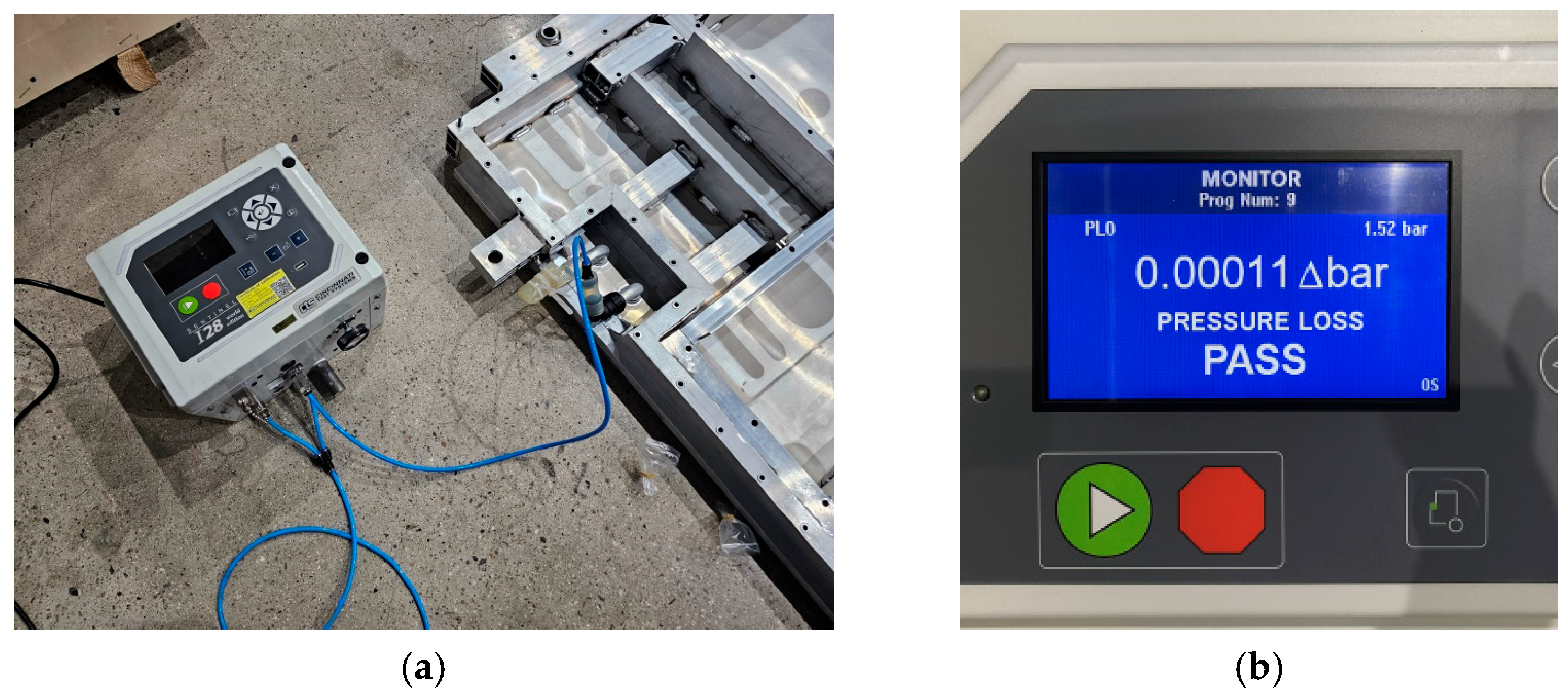

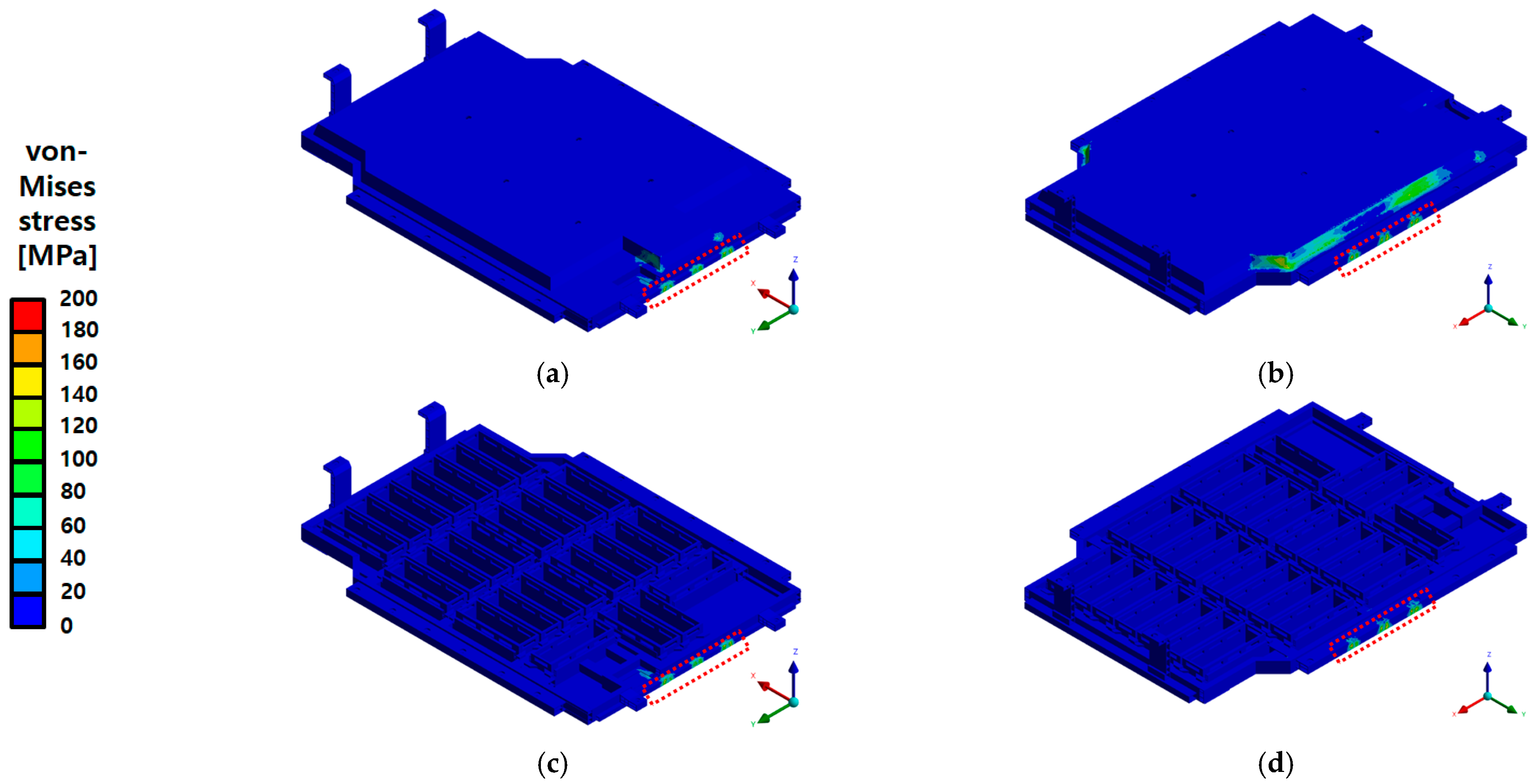

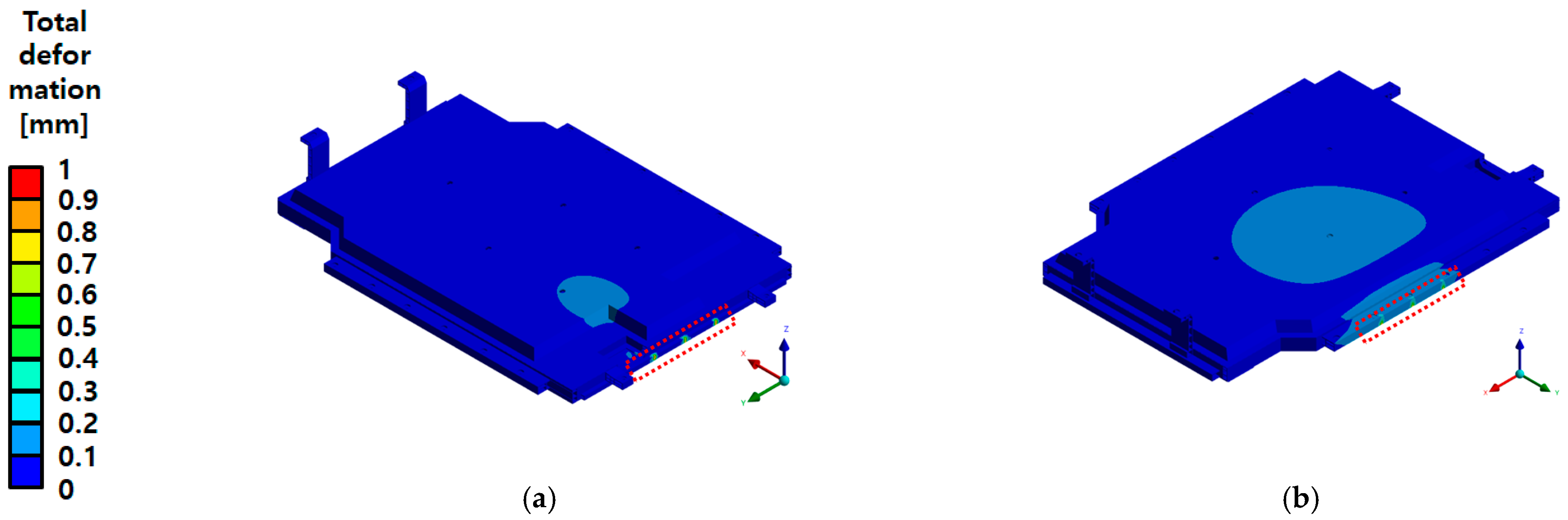

2.2. FEA and Experimental Conditions for BPC Under Compression Load

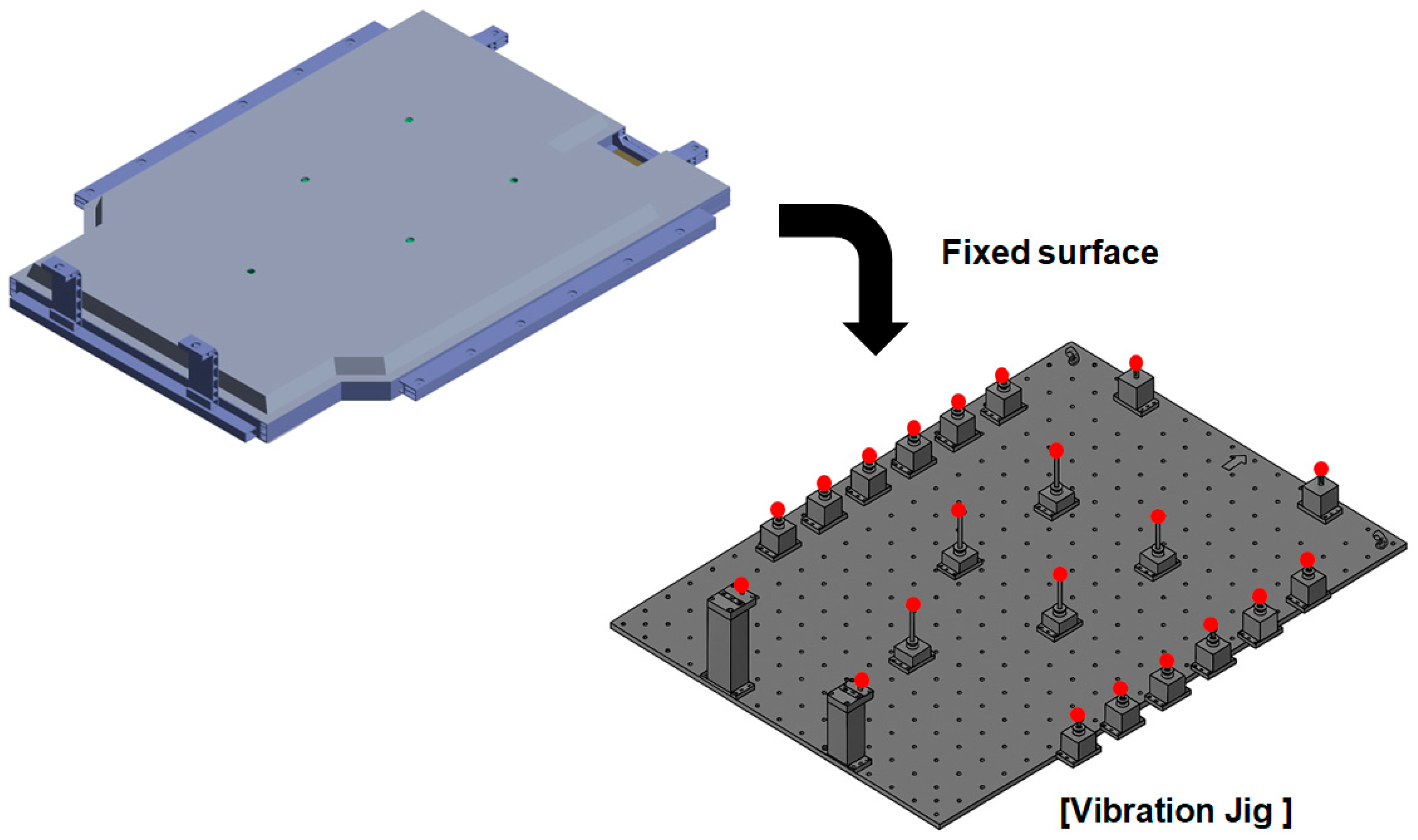

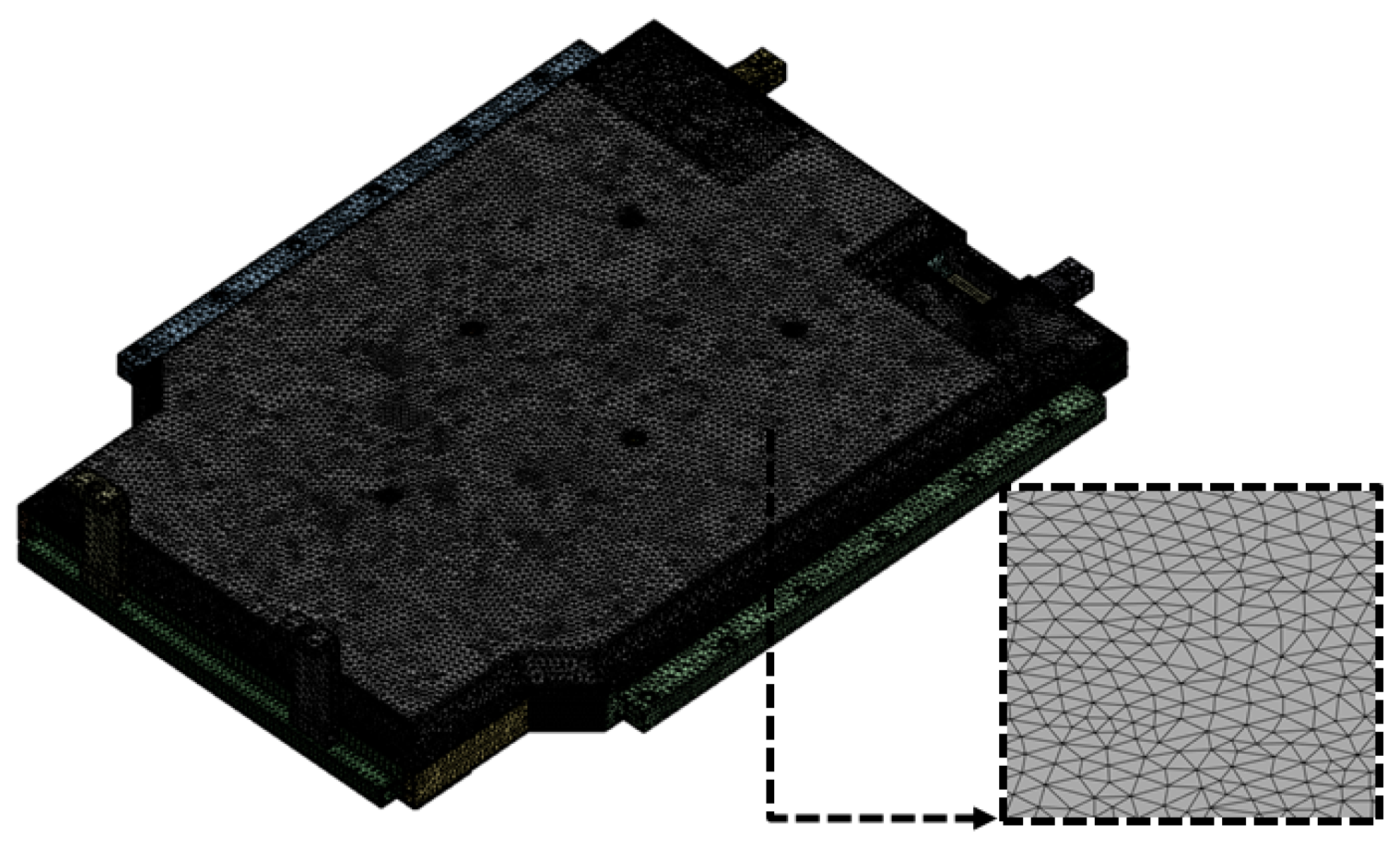

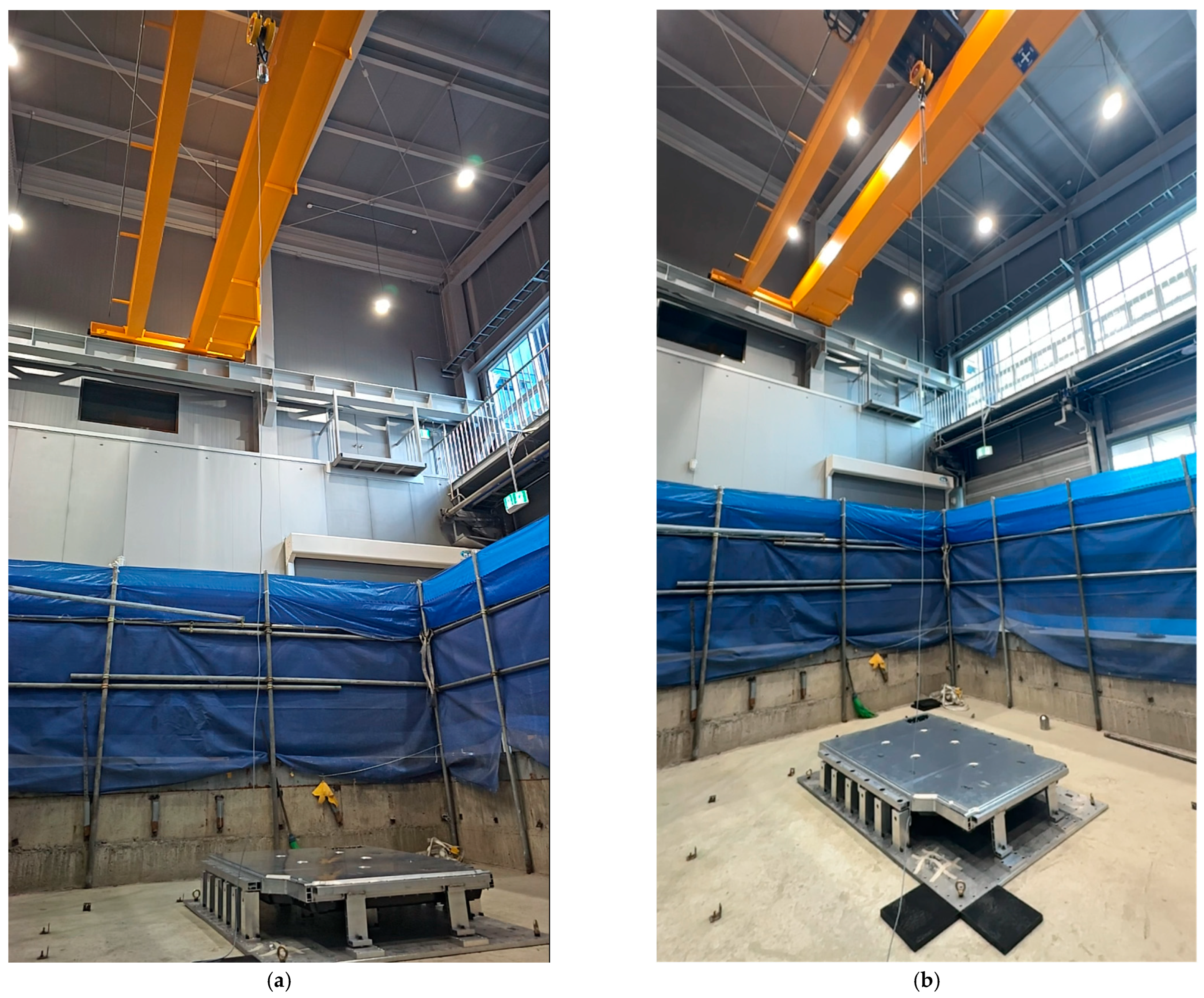

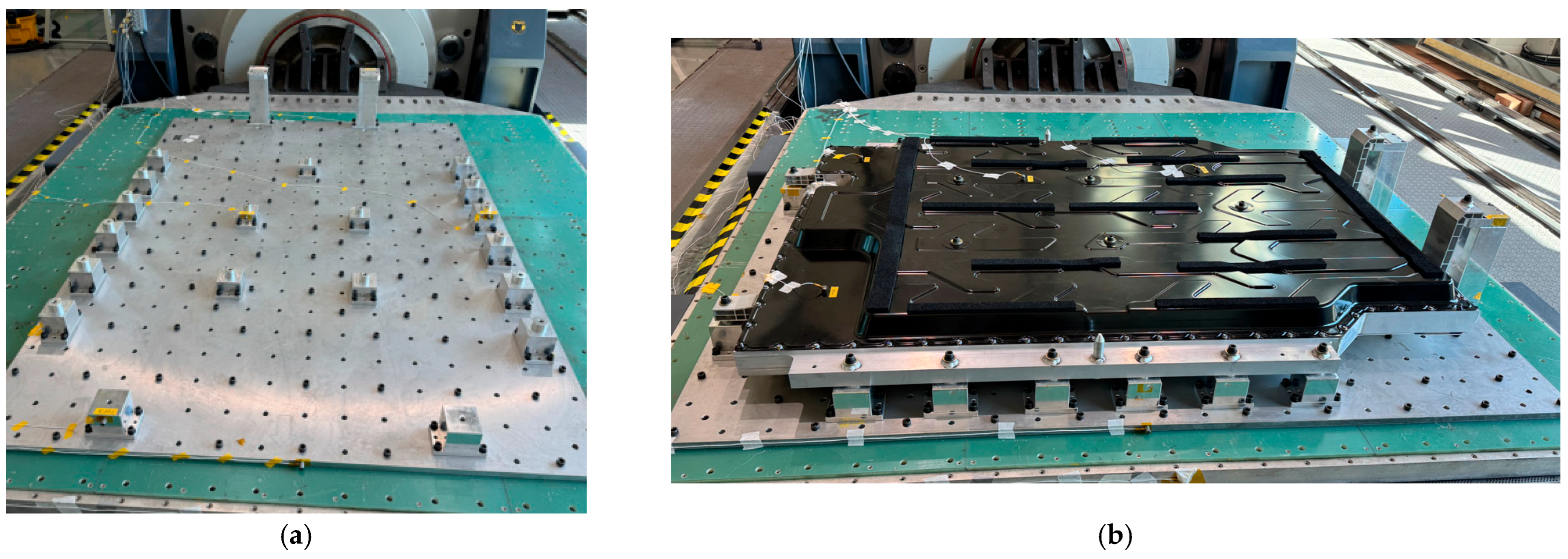

2.3. PSD-Based BPC Random Vibration Analysis and Test Conditions

3. Structural Response Evaluation of EV BPC Through Analysis and Experimental Testing

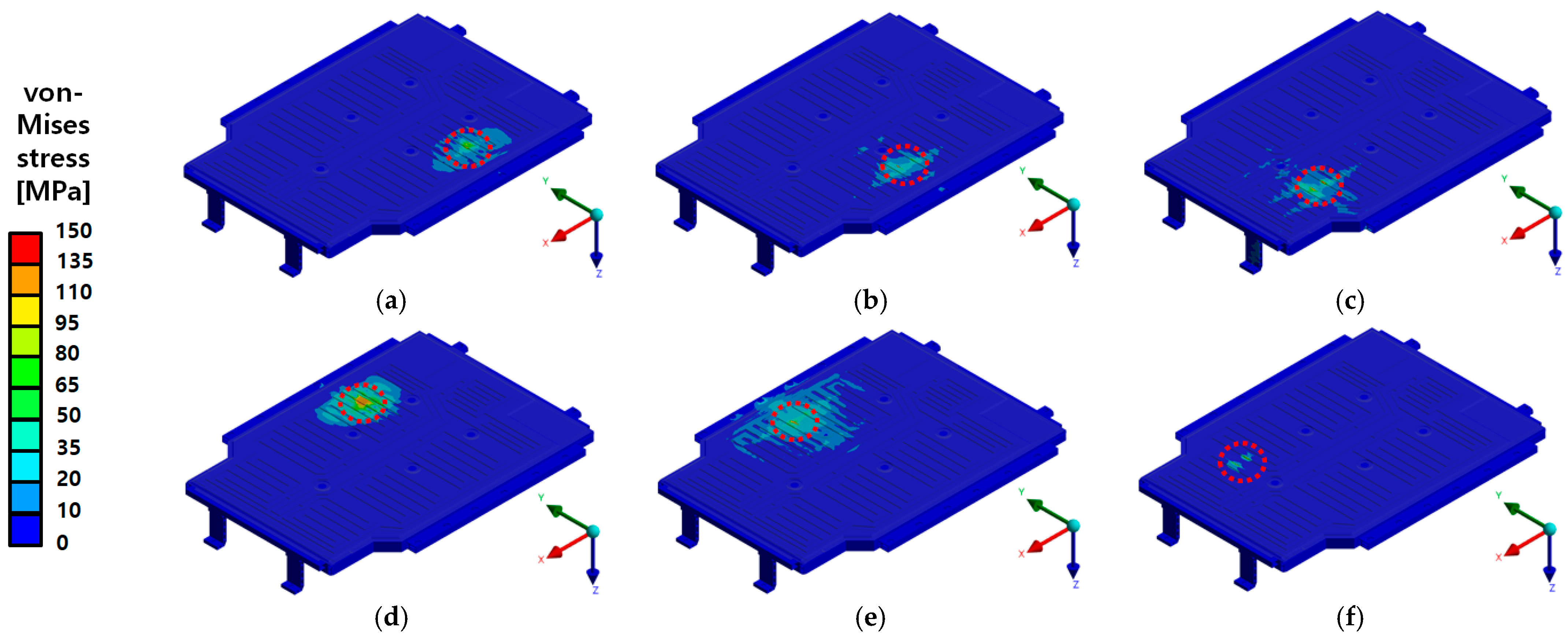

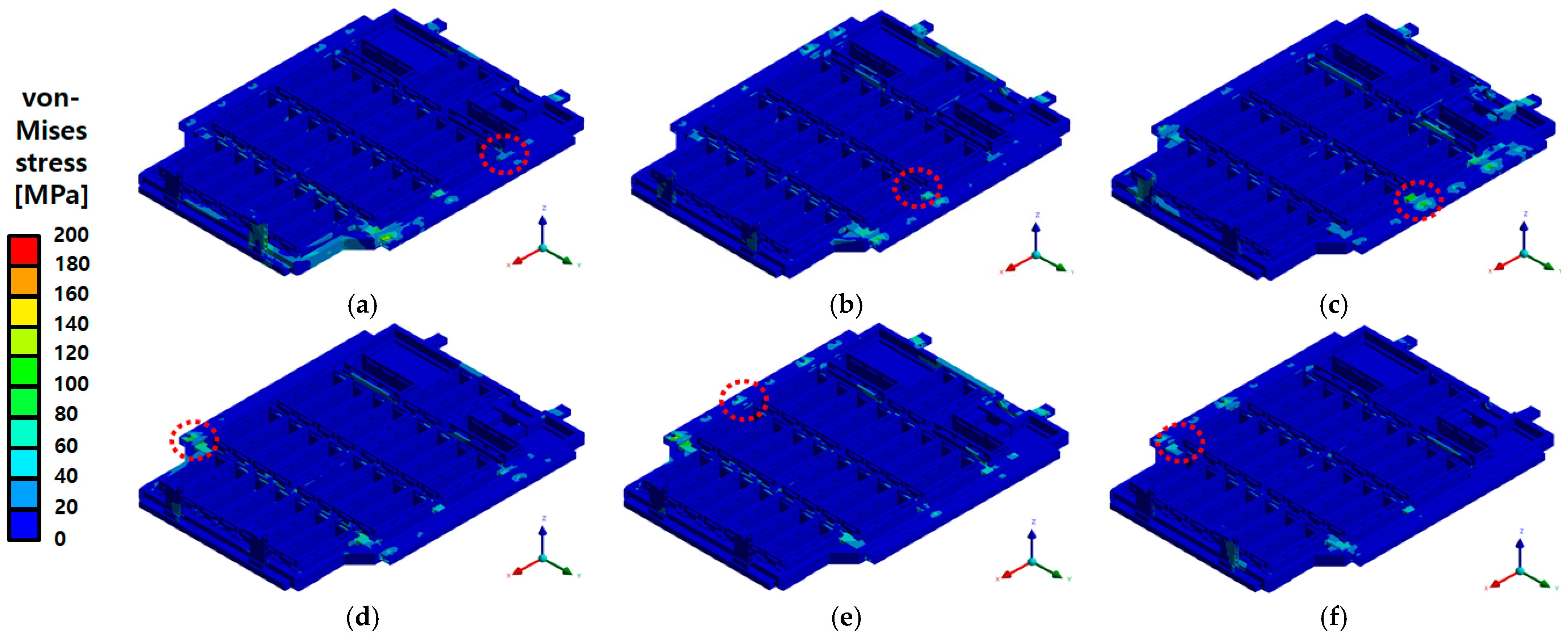

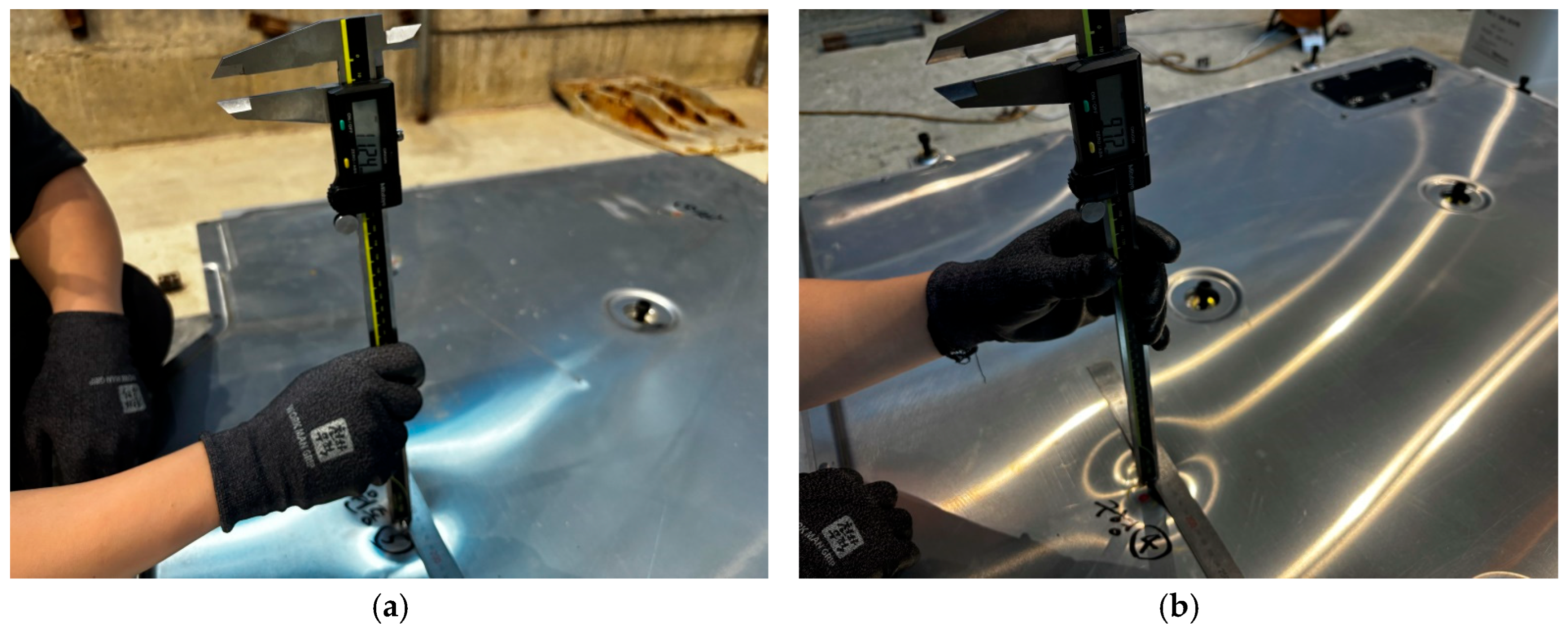

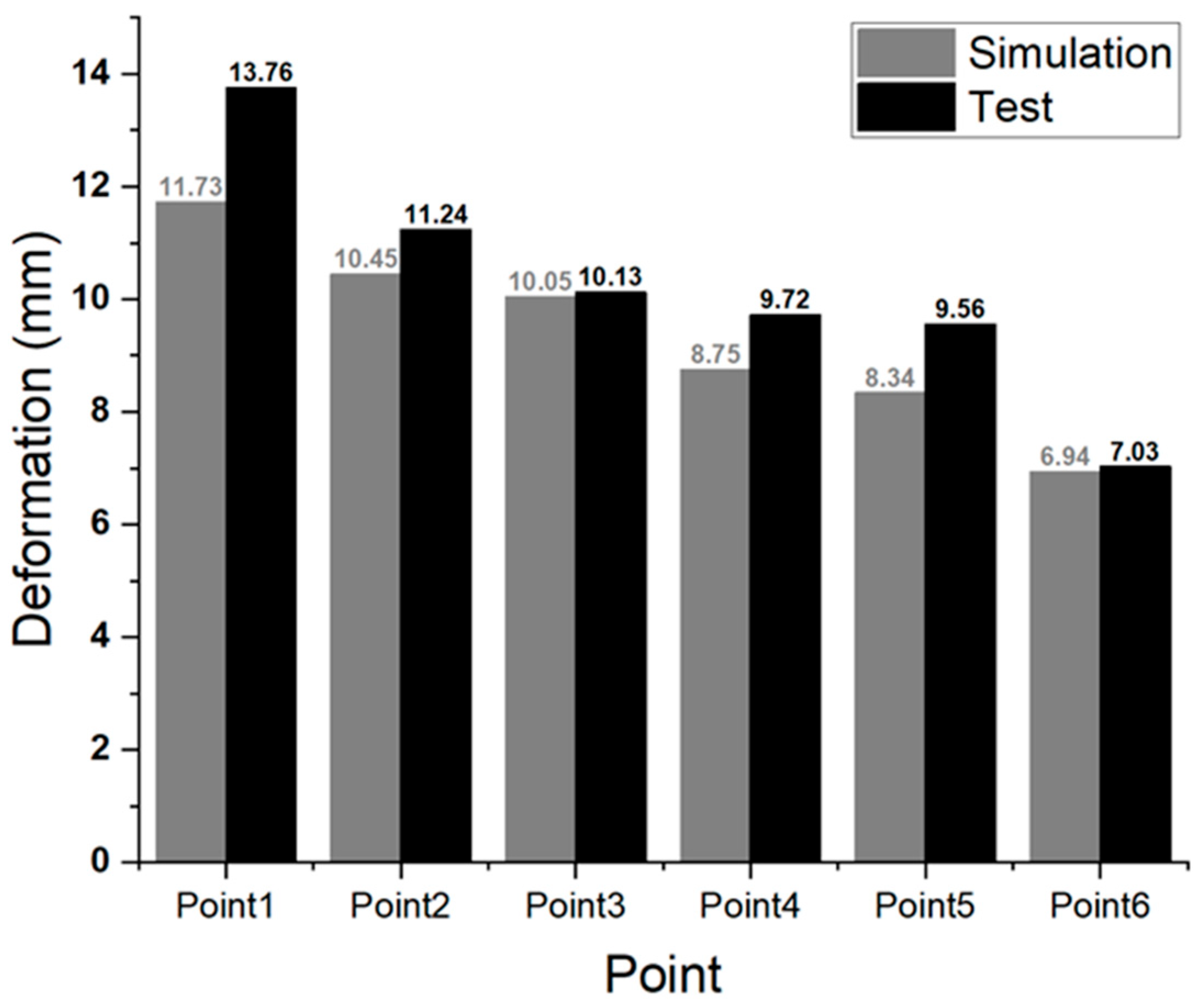

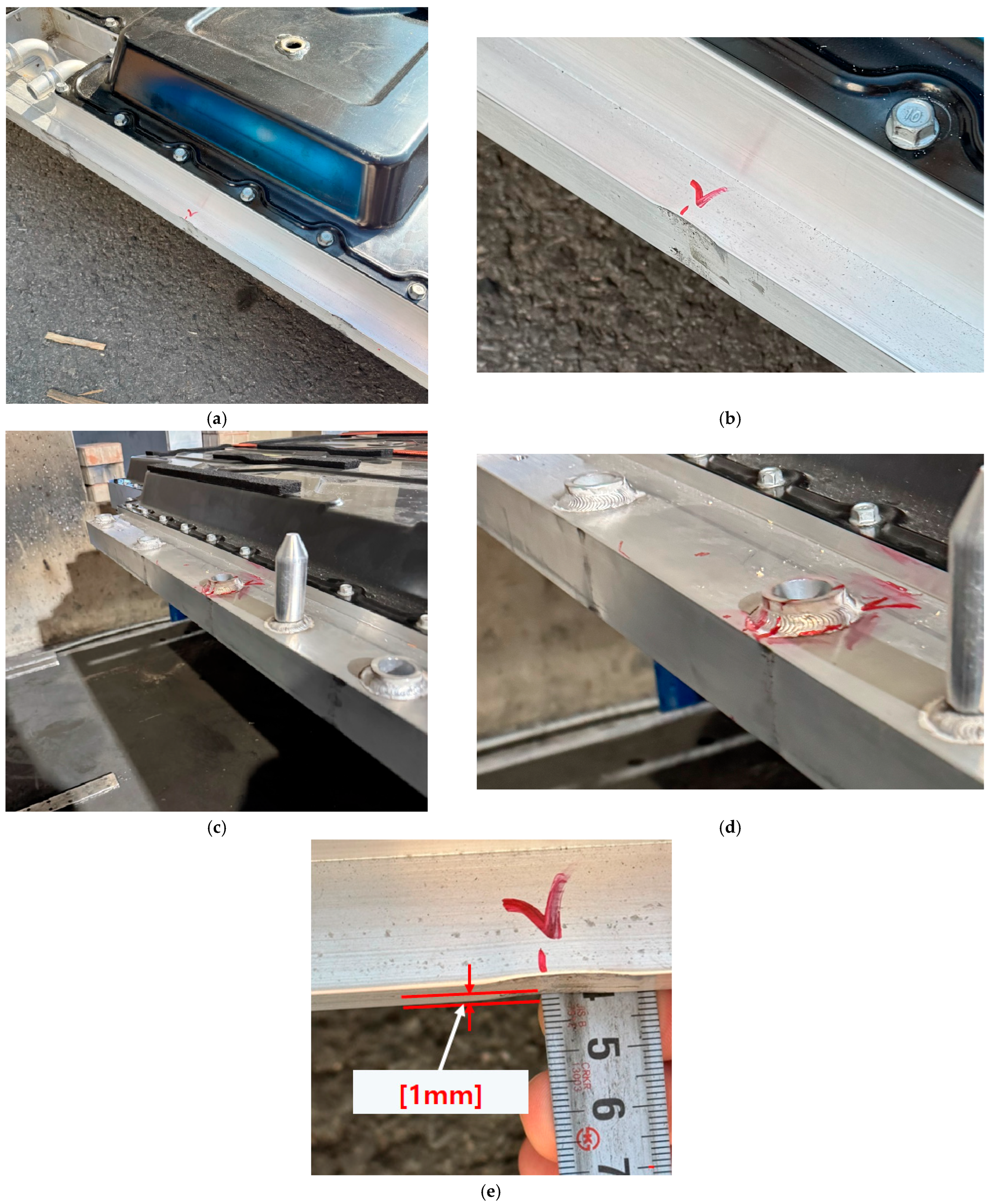

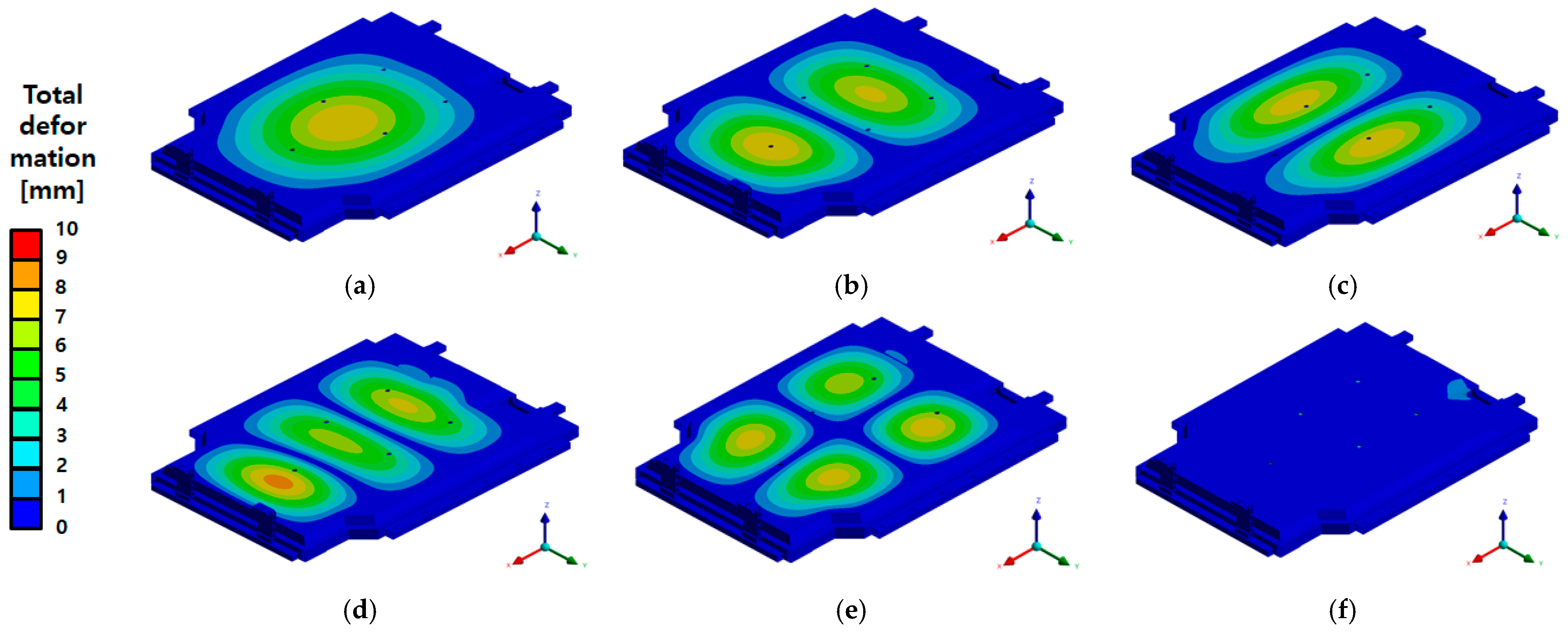

3.1. Bottom Impact Analysis and Experimental Validation of BPC

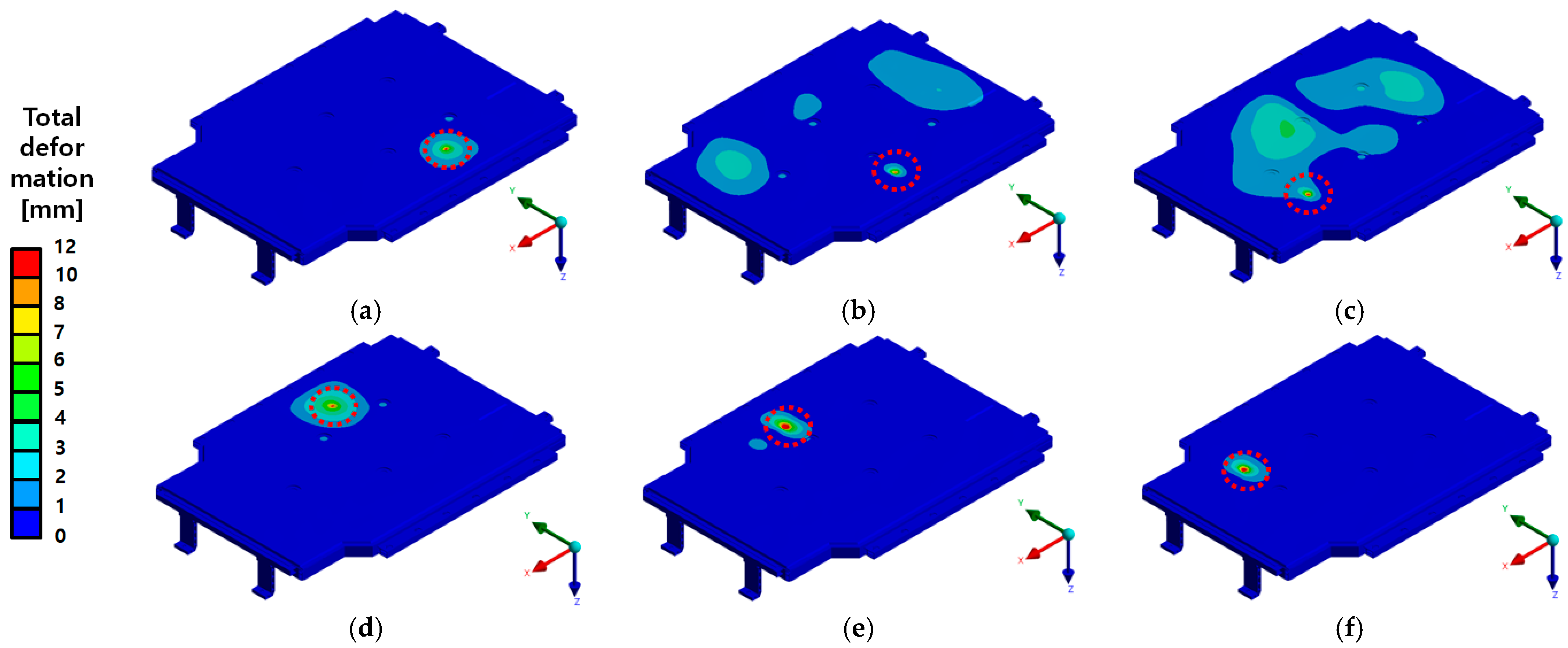

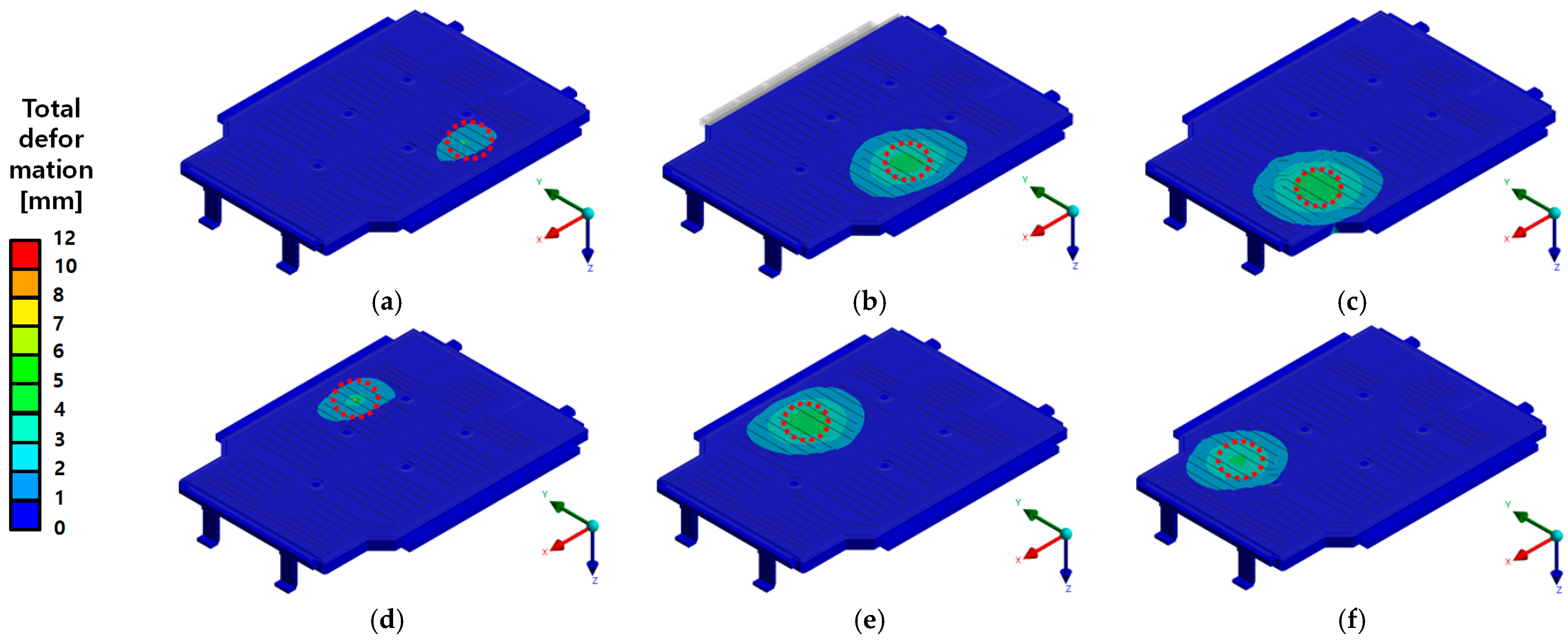

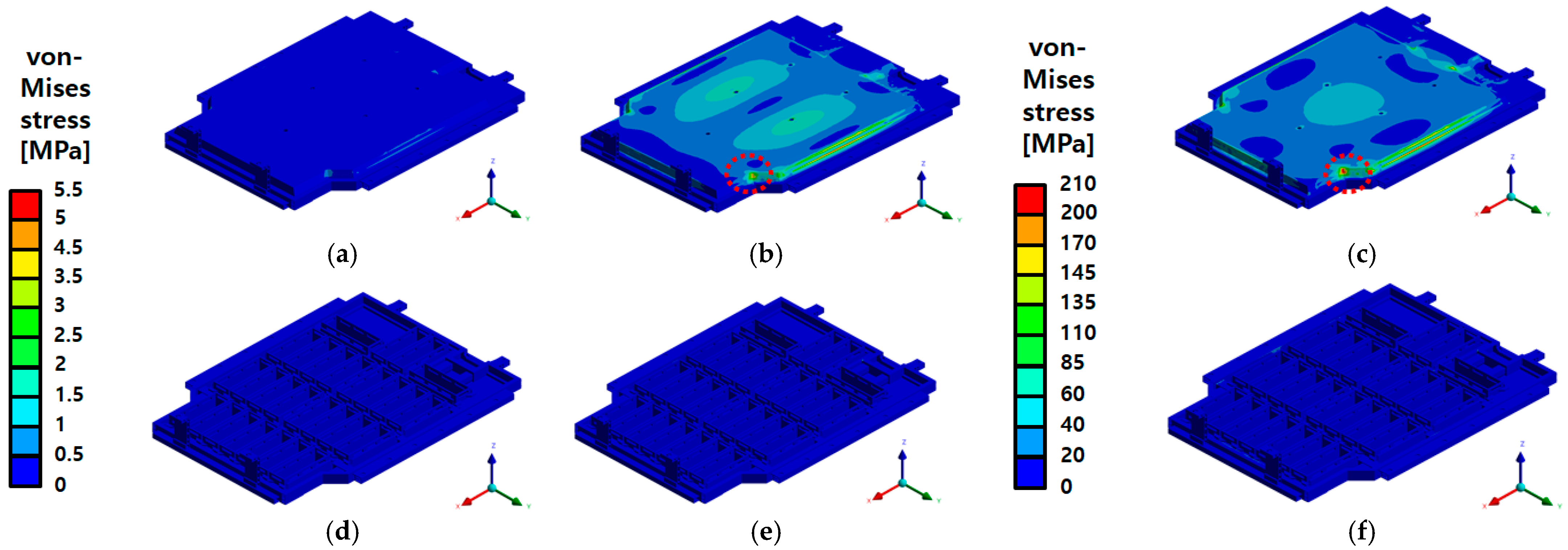

3.2. Compression Analysis and Experimental Validation of BPC

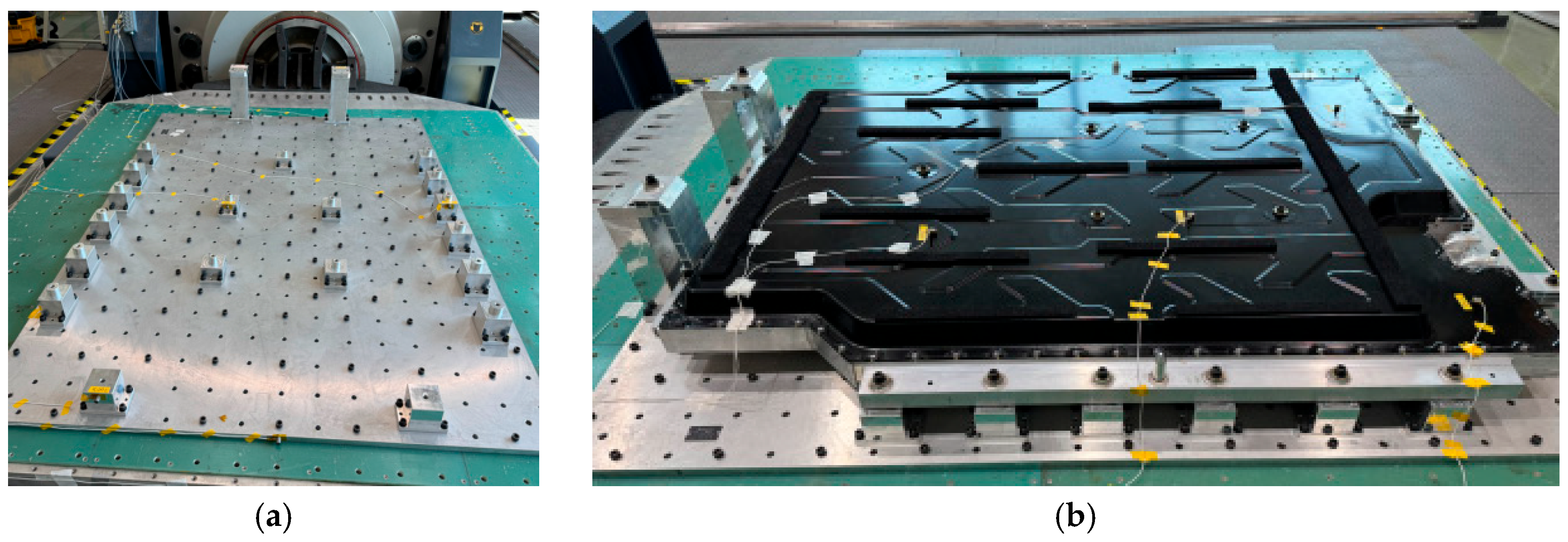

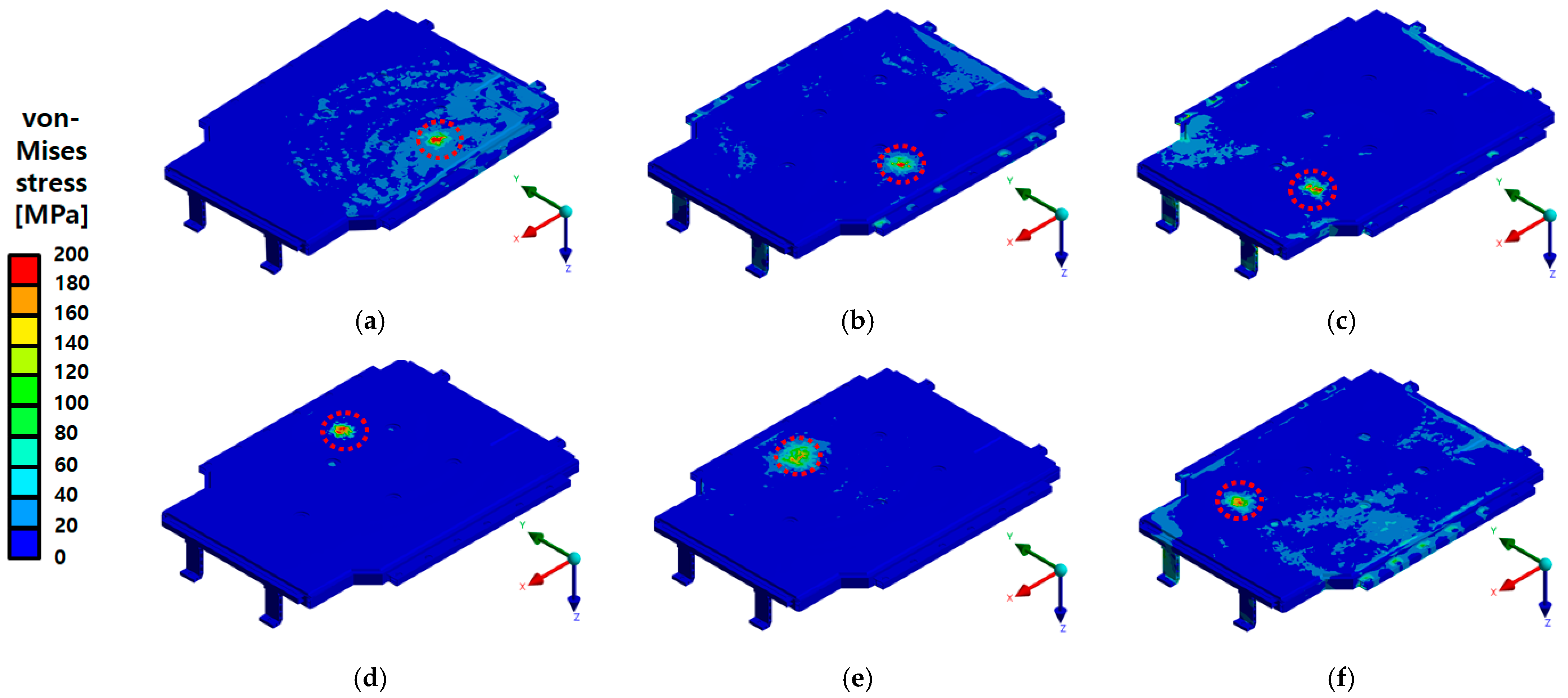

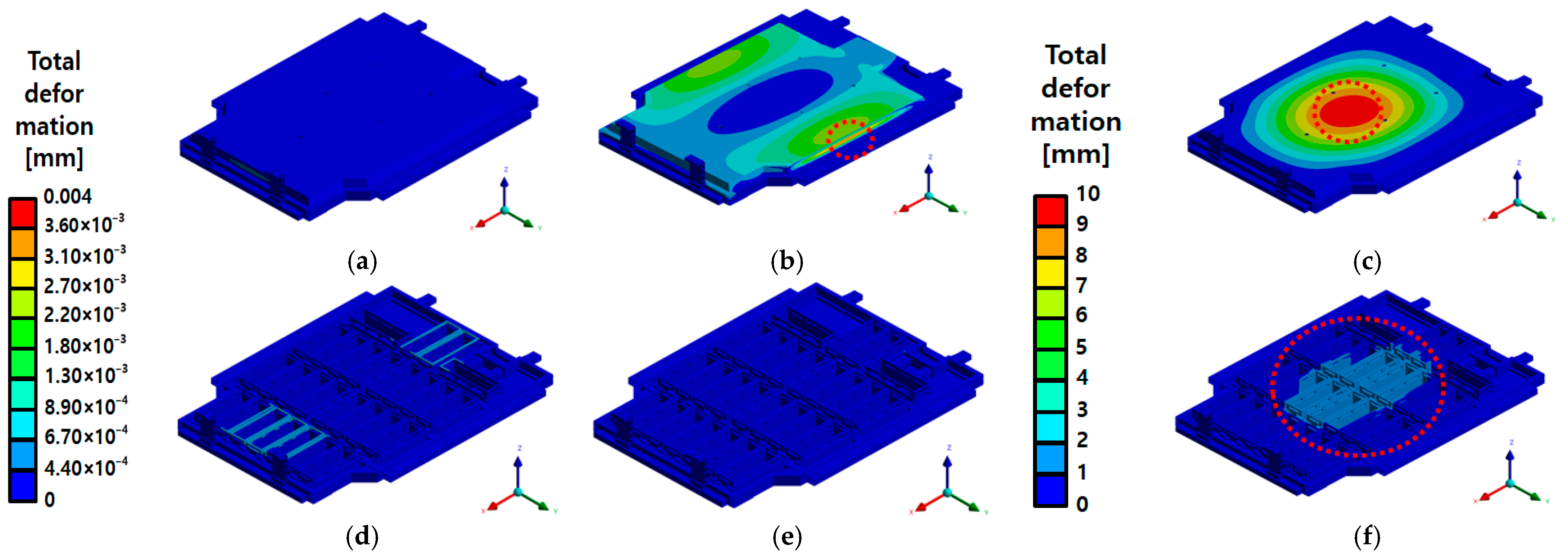

3.3. Vibration Analysis and Experimental Validation of BPC

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lee, S.; Kim, J.; Kim, S.; Lee, C.; Ko, J.; Lee, S. Analysis of the Change in Cooling Performance Depending on the Length of the Coolant Flow Path of the EV Battery Case Using the Finite Element Analysis Technique. In Proceedings of the Korean Society of Automotive Engineers Annual Autumn Conference, Yeosu-si, Republic of Korea, 17–20 November 2021. Paper No. 21AKSAE_P020. [Google Scholar]

- Choi, K.; Choi, H.; Lee, S.; Go, G.; Song, J.; Kim, J. A Study on the Side Impact Analysis of Electric Vehicle Battery Pack Case. In Proceedings of the 2021 Fall Conference of the Korean Society of Automotive Engineers, Gwangju and Honam Branch, Gwangju, Republic of Korea, 16 December 2021. KSAE21-H0038. [Google Scholar]

- Lim, J.; Choi, Y.; Han, Y. Development of Simulation Platform for Crashworthiness and Fire Safety under Dynamic Loading. In Proceedings of the 2023 Spring Conference of the Korean Society of Automotive Engineers, Jeju, Republic of Korea, 24–27 May 2023. 23SKSAE_G001. [Google Scholar]

- Jang, S.; Lee, Y.; Shin, C.; Kim, H.; Ji, W. PSD Vibration Durability Analysis for Plastic Battery Pack Case of Electric Vehicles. In Proceedings of the 2021 Spring Conference of the Korean Society of Automotive Engineers, Online, 23–26 June 2021. 21SKSAE_G005. [Google Scholar]

- Kim, B.; Kim, J.; Kim, Y.; Min, K. Development of cooling system model for electric vehicle battery pack. In Proceedings of the 2023 Fall Conference of the Korean Society of Automotive Engineers, Ulsan, Republic of Korea, 17–18 November 2023. 23AKSAE_P046. [Google Scholar]

- Choi, M.-Y. Necessity of Research to Improve Safety in Case of Collision under EV Battery. In Proceedings of the 2023 Fall Conference of the Korean Society of Automotive Engineers, Ulsan, Republic of Korea, 17–18 November 2023. 23AKSAE_G005. [Google Scholar]

- Choi, K.; Kim, S.; Choi, H.; Lee, S.; Kim, J. Design of the High Stiffness Battery Housing for Electric Vehicle. In Proceedings of the 2021 Spring Conference of the Korean Society of Mechanical Engineers, Daejeon, Republic of Korea, 24–25 June 2021. KSME2021R1011. [Google Scholar]

- Rho, J.; Choi, B.; Kim, Y.; Lee, G. Free Drop Analysis and Experimental Verification for Safety of Battery Pack for Micro Mobility EV. In Proceedings of the 2022 Spring Conference of the Korean Society of Automotive Engineers, Busan, Republic of Korea, 2–4 June 2022; KSAE: Seoul, Republic of Korea, 2022. 22SKSAE_E031. [Google Scholar]

- Lee, D.; Lee, S. A Study of Electric Vehicle Battery Case Model with Honeycomb Unit Structure Applied for Impact Absorption. In Proceedings of the 2024 Spring Conference of the Korean Society of Automotive Engineers, Pyeongchang, Republic of Korea, 24–27 May 2024. 24SKSAE_E012. [Google Scholar]

- Lim, H.; Sim, H. A Study on Molding Analysis of Electric Vehicle Battery Cover with SMC Material. In Proceedings of the 2018 Fall Conference of the Korean Society of Automotive Engineers, Jeju, Republic of Korea, 6 November 2018. 18AKSAE_F006. [Google Scholar]

- Lim, H.; Sim, P. A Study on Vibration Fatigue Analysis of Electric Vehicle Battery Cover Using PSD. In Proceedings of the 2018 Fall Conference of the Korean Society of Automotive Engineers, Jeju, Republic of Korea, 6 November 2018. 18AKSAE_F007. [Google Scholar]

- Son, J.; Jeong, H.; Kim, J.; Kang, D. A Study on Validation Techniques of Large Rubber Gaskets (More than 2M) for Electric Vehicle Battery Packs Applying a Direct Vacuum Method and Material Optimization to Secure Sealing Performance (Less than C set 20%). In Proceedings of the KSMPE Autumn Conference 2023, Sacheon, Republic of Korea, 29 November 2023; p. 41. [Google Scholar]

- Song, H.; Choi, J.; Park, D.; Kim, N.; Shin, D. Evaluation of Charging Mileage of Electric Vehicle Using Battery Module. Trans. KSAE 2019, 27, 645–652. [Google Scholar] [CrossRef]

- Choi, G.; Choi, H.; Lee, S.; Park, S.; Kim, J. A Stiffness Analysis for Rear Floor of Light Weight Material. In Proceedings of the 2021 Spring Conference of the Korean Society of Automotive Engineers, Online, 23–26 June 2021. 21SKSAE_E033. [Google Scholar]

- Kim, B.; Lee, D. Optimization Design for Augmentation of Cooling Performance Utilizing Leading-Edge Materials in Electric Vehicle Battery Cells. J. Korean Soc. Precis. Eng. 2020, 37, 529–538. [Google Scholar] [CrossRef]

- Turaka, S.; Obulu, P.; Reddy, K.V.K. Computational Fluid Dynamics and Thermal Analysis of a Lithium-Ion Battery with Different Cooling System for Electric Vehicles. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1136, 012033. [Google Scholar] [CrossRef]

- Jarrett, A.; Kim, I.Y. Design optimization of electric vehicle battery cooling plates for thermal performance. J. Power Sources 2011, 196, 10359–10368. [Google Scholar] [CrossRef]

- Hyun, S.; Kim, S. Numerical Study on Natural Convection Heat Transfer Characteristics inside Battery Pack of Electric Vehicle. KSME J. Fluid Mach. 2022, 25, 19–27. [Google Scholar] [CrossRef]

- Tamaldin, N.; Yamin, A.K.M.; Abdollah, M.F.B.; Amiruddin, H.; Abdullah, M.A. Design Optimization of Thermal Management System for Electric Vehicle Utilizing CFD Analysis, DFMEA and CES. Procedia Eng. 2013, 68, 305–312. [Google Scholar] [CrossRef]

- Falcone, M.; Palka Bayard De Volo, E.; Hellany, A.; Rossi, C.; Pulvirenti, B. Lithium-Ion Battery Thermal Management Systems: A Survey and New CFD Results. Batteries 2021, 7, 86. [Google Scholar] [CrossRef]

- Panchal, S.; Gudlanarva, K.; Tran, M.-K.; Fraser, R.; Fowler, M. High Reynold’s Number Turbulent Model for Micro-Channel Cold Plate Using Reverse Engineering Approach for Water-Cooled Battery in Electric Vehicles. Energies 2020, 13, 1638. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, X.; Wierzbicki, T.; Xia, Y.; Chen, G. Structural Designs for Electric Vehicle Battery Pack against Ground Impact; SAE Technical Paper 2018-01-1438; SAE International: Warrendale, PA, USA, 2018. [Google Scholar] [CrossRef]

- In, J.; Ma, J.; Kim, H. Development of a new electric vehicle post-crash fire safety test in Korea (Proposed for the Korean new car assessment program). World Electr. Veh. J. 2025, 16, 103. [Google Scholar] [CrossRef]

- Muresanu, A.D.; Dudescu, M.C.; Tica, D. Study on the crashworthiness of a battery frame design for an electric vehicle using FEM. World Electr. Veh. J. 2024, 15, 534. [Google Scholar] [CrossRef]

- Ślaski, G.; Spadło, M.; Marcinkiewicz, J.; Konieczny, W. Analysis and experimental tests of potential new mounting techniques for use in vibration testing of electric vehicle battery packs on electromagnetic exciters: Advantages and disadvantages. Appl. Sci. 2024, 14, 2920. [Google Scholar] [CrossRef]

- Nanwatkar, R.; Tonde, S.; Shaikh, A.; Savardekar, P. Crashworthiness and Structural Durability of Lithium-Ion Battery Packs under Impact and Drop Scenarios. Int. J. Adv. Res. Sci. Commun. Technol. 2025, 5, 281–287. [Google Scholar]

- Xiong, Y.; Pan, Y.; Wu, L.; Liu, B. Effective weight-reduction- and crashworthiness-analysis of a vehicle’s battery-pack system via orthogonal experimental design and response surface methodology. Eng. Fail. Anal. 2021, 128, 105635. [Google Scholar] [CrossRef]

- Hong, J.; Wang, Z.; Zhang, X.; Wang, W.; Chen, Y.; Shan, T. Collision-Caused Thermal Runaway Investigation of Li-Ion Battery in Real-World Electric Vehicles. Appl. Therm. Eng. 2024, 236, 121901. [Google Scholar] [CrossRef]

- Choi, Y.; Lee, S.; Hong, J.; Park, J. Experimental and Numerical Studies on the Thermomechanical Deformation of Lithium-Ion Battery Pack Housing under Thermal Runaway Propagation Condition. eTransportation 2025, 25, 100431. [Google Scholar] [CrossRef]

- Navale, A.B.; Chippa, S.P.; Chougule, D.A.; Raut, P.M. Crashworthiness aspects of electric vehicle design. Int. J. Crashworth. 2020, 25, 105–117. [Google Scholar] [CrossRef]

- Pan, Y.; Xiong, Y.; Dai, W.; Diao, K.; Wu, L.; Wang, J. Crush and Crash Analysis of an Automotive Battery-Pack Enclosure for Lightweight Design. Int. J. Crashworth. 2020, 25, 280–292. [Google Scholar] [CrossRef]

- Arora, S.; Shen, W.; Kapoor, A. Review of mechanical design and strategic placement technique of a robust battery pack for electric vehicles. Renew. Sustain. Energy Rev. 2016, 60, 1319–1331. [Google Scholar] [CrossRef]

- Choi, C.; Cho, J.; Kil, Y.; Yoon, Y. Development of Polymer Composite Battery Pack Case for an Electric Vehicle. SAE Int. J. Mater. Manuf. 2013, 6, 663–671. [Google Scholar] [CrossRef]

- Dai, Z.; Miao, Q.; Wu, D. Data Simulation of the Impact of Ball Strikes on the Bottom of Electric Vehicle Battery Packs Based on Finite Element Analysis. Therm. Sci. Eng. Prog. 2024, 53, 102757. [Google Scholar] [CrossRef]

- Jimenez-Martinez, M.; Valencia-Sánchez, J.L.; Torres-Cedillo, S.G.; Cortés-Pérez, J. Battery Housing for Electric Vehicles, a Durability Assessment Review. Designs 2024, 8, 113. [Google Scholar] [CrossRef]

- Hua, X.; Thomas, A. Effect of dynamic loads and vibrations on lithium-ion batteries. J. Low Freq. Noise Vib. Act. Control 2021, 40, 1–8. [Google Scholar] [CrossRef]

- Gilaki, M.; Walsh, R.; Sahraei, E. Model-Based Design of an Electric Bus Lithium-Ion Battery Pack. J. Electrochem. Energy Convers. Storage 2021, 18, 020914. [Google Scholar] [CrossRef]

- Shui, L.; Chen, F.; Garg, A.; Peng, X.; Bao, N.; Zhang, J. Design optimization of battery pack enclosure for electric vehicle. Struct. Multidiscip. Optim. 2018, 58, 331–347. [Google Scholar] [CrossRef]

- Kulkarni, S.; Hale, F.; Taufique, M.; Soulami, A.; Devanathan, R. Investigation of crashworthiness of carbon fiber-based electric vehicle battery enclosure using finite element analysis. Appl. Compos. Mater. 2023, 30, 1689–1715. [Google Scholar] [CrossRef]

- Chidambaram, R.; Pedapati, P.; Kanna, P.; Taler, D.; Sobota, T.; Taler, J. Structural assessment of electric two-wheeler battery enclosure: Thermal and structural study. J. Therm. Anal. Calorim. 2025, 150, 6939–6958. [Google Scholar] [CrossRef]

- Wang, Z.; Shi, S.; Liu, P. Research progress on collision safety of electric vehicles. In Proceedings of the 2011 Third International Conference on Measuring Technology and Mechatronics Automation (ICMTMA), Shanghai, China, 6–7 January 2011; pp. 153–156. [Google Scholar] [CrossRef]

- Lee, D. A Study on the Convective Cooling Performance of the Secondary Battery in Electric Vehicle. J. Korean Soc. Precis. Eng. 2018, 35, 1157–1162. [Google Scholar] [CrossRef]

- Kim, Y.H.; Lee, J.S. Numerical Analysis of Cooling Performance Based on Flow Characteristics of Electric Vehicle Battery Cooling Plates. J. Ind. Technol. Res. 2024, 29, 43–51. [Google Scholar] [CrossRef]

- Ye, B.; Rubel, M.R.H.; Li, H. Design and Optimization of Cooling Plate for Battery Module of an Electric Vehicle. Appl. Sci. 2019, 9, 754. [Google Scholar] [CrossRef]

- Szűrke, S.K.; Kovács, G.; Sysyn, M.; Liu, J.; Fischer, S. Numerical Optimization of Battery Heat Management of Electric Vehicles. J. Appl. Comput. Mech. 2023, 9, 4119. [Google Scholar] [CrossRef]

- Li, H.; Chen, L.; Zuo, H.; Zhang, B.; Jia, G. Performance Enhancement of a Battery Thermal Management System Using Novel Liquid Cold Plates with Micro-Channel Featuring Pin Fins. Energy 2024, 301, 131731. [Google Scholar] [CrossRef]

- Ministry of Land, Infrastructure and Transport (MOLIT). Guidelines for Vehicle Underbody Impact Tests; MOLIT: Sejong, Republic of Korea, 2017. [Google Scholar]

- GB/T 31467.3-2015; Test Specification for Lithium-Ion Traction Battery Packs and Systems—Part 3: Safety Requirements. Standardization Administration of China: Beijing, China, 2015.

- UN 38.3; Recommendations on the Transport of Dangerous Goods—Manual of Tests and Criteria. United Nations: New York, NY, USA, 2017.

- UL 2596; Outline of Investigation for Batteries for Use in Electric Vehicles. Underwriters Laboratories: Northbrook, IL, USA, 2017.

- Lovell, M.R.; Deng, Z. Experimental Investigation of Sliding Friction between Hard and Deformable Surfaces with Application to Manufacturing Processes. Wear 1999, 236, 117–127. [Google Scholar] [CrossRef]

- IEC 62660-2:2018; Secondary Lithium-Ion Cells for the Propulsion of Electric Road Vehicles—Part 2: Reliability and Abuse Testing. International Electrotechnical Commission: Geneva, Switzerland, 2018.

- ISO 12405-3:2014; Electrically Propelled Road Vehicles—Test Specification for Lithium-Ion Traction Battery Packs and Systems—Part 3: Safety Performance Requirements. International Organization for Standardization: Geneva, Switzerland, 2014.

- Kim, M.; Choi, W.; Jeong, K.; Kim, C. Study on Design Process Using CAE of Battery Case. Trans. KSAE 2023, 31, 89–97. [Google Scholar] [CrossRef]

| Material | Density [kg/m3] | Young’s Modulus [GPa] | Yield Strength [MPa] | Poisson’s Ratio |

|---|---|---|---|---|

| SGACUD 60/60 | 7900 | 210 | 142.66 | 0.3 |

| PA6-GF30 | 1360 | 9.7 | 30 | 0.35 |

| A3003-O | 2730 | 68 | 61 | 0.3 |

| A6082S-T6 | 2700 | 68 | 260 | 0.3 |

| A6N01S-T6 | 2700 | 68 | 240 | 0.3 |

| A6061P | 2700 | 68 | 245 | 0.3 |

| Structure Steel | 7850 | 200 | 250 | 0.3 |

| Model | Node | Elements |

|---|---|---|

| BPC model | 852,867 | 1,436,879 |

| Cylindrical weight | 27,600 | 25,074 |

| Spherical weight | 15,865 | 86,443 |

| Model | Node | Elements |

|---|---|---|

| BPC Model | 3,638,393 | 1,453,197 |

| Crush Plate | 17,572 | 5571 |

| X Axis | Y Axis | Z Axis | |||

|---|---|---|---|---|---|

| Frequency (Hz) | PSD (G2/Hz) | Frequency (Hz) | PSD (G2/Hz) | Frequency (Hz) | PSD (G2/Hz) |

| 5 | 0.0125 | 5 | 0.04 | 5 | 0.05 |

| 10 | 0.03 | 10 | 0.04 | 10 | 0.06 |

| 20 | 0.03 | 20 | 0.04 | 20 | 0.06 |

| 200 | 0.00025 | 200 | 0.0008 | 200 | 0.0008 |

| Grms | 0.96 g | Grms | 1.23 g | Grms | 1.44 g |

| Model | Node | Elements |

|---|---|---|

| BPC Model | 3,683,232 | 1,6727,901 |

| Category | Specification |

|---|---|

| Max Force | Sine: 30,000 kgf |

| Random: 24,000 kgf | |

| Shock: 60,000 kgf | |

| Frequency Range | 5–1700 Hz |

| Displacement | ±25.5 mm |

| Acceleration | Up to 980 m/s2 |

| Payload Capacity | Up to 6000 kg |

| Slip Table | Size: 2500 × 2500 mm |

| Hole Type: M8 | |

| Hole Pitch: 100 mm | |

| Control System | 16-channel controller |

| Modes: Sine, Random, Shock, SoR, RoR |

| Classification | Point 1 | Point 2 | Point 3 | Point 4 | Point 5 | Point 6 |

|---|---|---|---|---|---|---|

| Depth (mm) | 13.76 | 11.24 | 10.13 | 9.72 | 9.56 | 7.03 |

| Result | Pass | Pass | Pass | Pass | Pass | Pass |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.S.; Cho, M.; Lee, C.; Kim, J.; Kang, S. Numerical and Experimental Approaches for Mechanical Durability Assessment of an EV Battery Pack Case. Materials 2025, 18, 5683. https://doi.org/10.3390/ma18245683

Kim HS, Cho M, Lee C, Kim J, Kang S. Numerical and Experimental Approaches for Mechanical Durability Assessment of an EV Battery Pack Case. Materials. 2025; 18(24):5683. https://doi.org/10.3390/ma18245683

Chicago/Turabian StyleKim, Hyun Soo, Mingoo Cho, Changyeon Lee, Jaewoong Kim, and Sungwook Kang. 2025. "Numerical and Experimental Approaches for Mechanical Durability Assessment of an EV Battery Pack Case" Materials 18, no. 24: 5683. https://doi.org/10.3390/ma18245683

APA StyleKim, H. S., Cho, M., Lee, C., Kim, J., & Kang, S. (2025). Numerical and Experimental Approaches for Mechanical Durability Assessment of an EV Battery Pack Case. Materials, 18(24), 5683. https://doi.org/10.3390/ma18245683