A Comprehensive Review of Carbon Capture, Storage, and Reduction Strategies Within the Built Environment

Abstract

1. Introduction

1.1. Background

1.2. Research Gap and Objectives

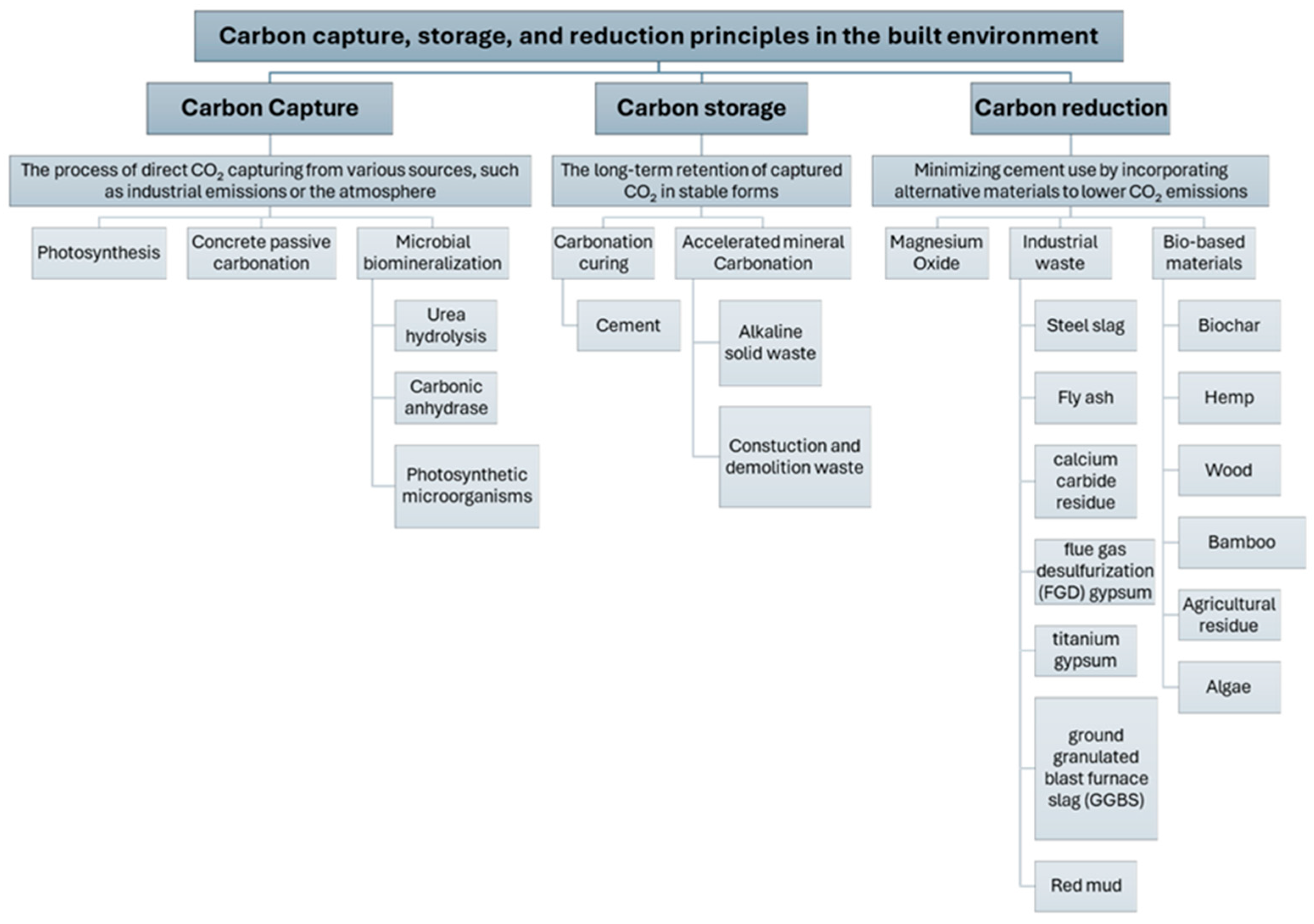

2. Carbon Capture, Storage, and Reduction Principles in the Built Environment

2.1. Carbon Capture

2.1.1. Photosynthesis

2.1.2. Concrete Passive Carbonation

2.1.3. Microbial Biomineralization

Urea Hydrolysis

Carbonic Anhydrase

Photosynthetic Microorganisms

2.2. Carbon Storage

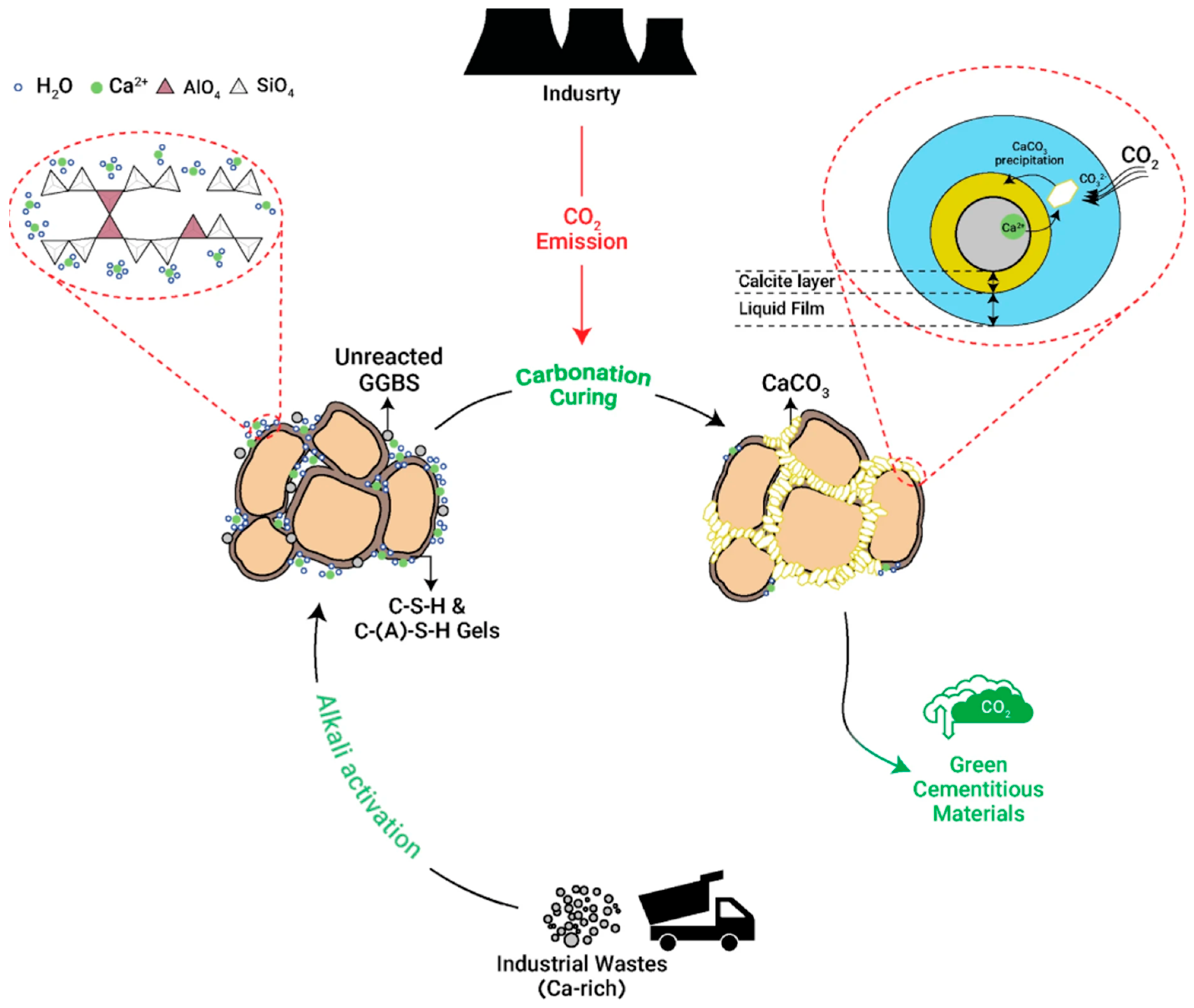

2.2.1. Carbonation Curing

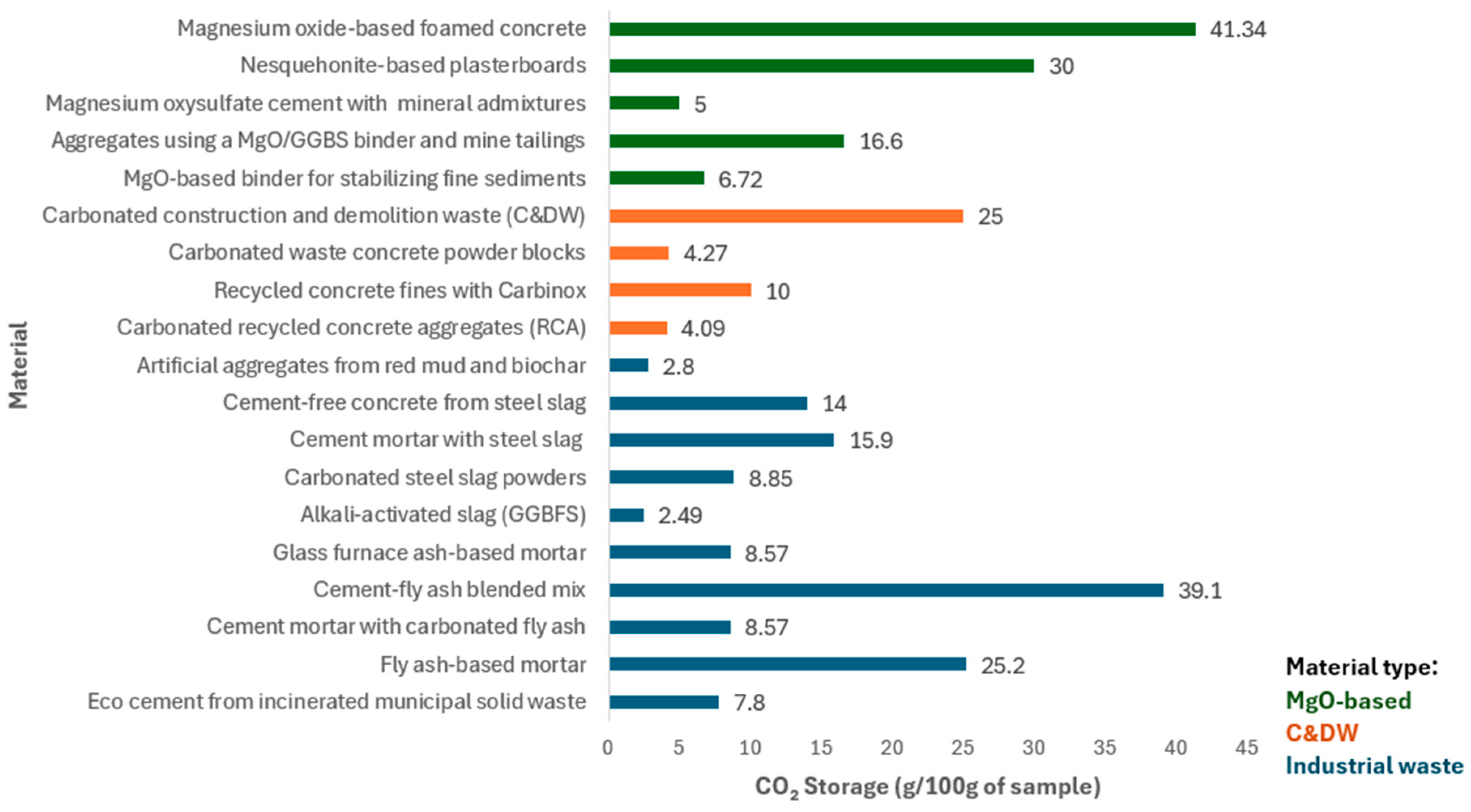

2.2.2. Accelerated Mineral Carbonation

Direct Carbonation

Aqueous Carbonation

Carbonation During Mixing

2.2.3. Construction and Demolition Waste

2.3. Carbon Reduction

2.3.1. Magnesium Oxide

2.3.2. Industrial Waste

2.3.3. Bio-Based Materials

Biochar

| Material Mix | Waste Source | Compressive Strength (MPa) | Carbonation Condition | CO2 Uptake/Reduction | Application | Ref. |

|---|---|---|---|---|---|---|

|

| >18 |

|

|

| [71] |

|

|

|

|

| [68] | |

|

|

| Soil stabilization | [65] | ||

|

| 6.1 ± 0.6 |

| Gypsum Panels | [73] | |

|

|

|

| Low carbon Semi-flexible pavement (SFP) | [101] | |

|

| At FA/GGBS ratio 40/60, 6% alkali content, W/B ratio 0.36, and 2% fiber:

|

| Engineering geopolymer composites (EGC) | [89] | |

|

| 1.37 to 1.95 at 28 days |

|

| Artificial lightweight cold-bonded aggregates (ALCBAs) | [72] |

|

|

|

| Alkali-activated slag (AAS) as a Sustainable binder for Pervious Concrete and Structural Plaster | [98] | |

|

|

|

|

| Sustainable alkali-activated slag mortar | [64] |

Eight mortar mixtures:

|

| 94 at 28 days |

| Steel slags as binder compounds and aggregates in alkali-activated systems | [102] | |

|

|

|

|

| SCM | [59] |

|

|

|

|

| [74] | |

|

|

|

|

| Steel slag concrete slabs and pipes | [57] |

|

|

|

| Sustainable concrete repair materials | [97] | |

|

|

|

| Concrete SCM and cement replacement in foam concrete | [90] | |

|

|

|

|

| SCM in concrete | [67] |

|

|

|

| SCM | [60] | |

|

|

|

| SCM in mortar suitable for Freeze–Thaw and sulfate attack | [61] | |

|

|

|

|

| Green Non-Cementitious Binder | [66] |

|

| Up to 31.21 MPa | Ambient CO2 curing at:

|

| SCM in mortars | [69] |

|

|

| SCM in cement paste | [62] | ||

|

|

| Aqueous carbonation process:

|

| SCMs in cement mortar | [63] |

|

|

|

|

| Non-Cementitious Binder | [70] |

|

| 33 MPa at 28 days |

|

| Non-Cementitious concrete blocks | [93] |

Hemp

Wood

Bamboo

Agricultural Residues

Algae

3. Direct CO2 Capturing Materials for the Built Environment

3.1. Liquid Sorbents

3.1.1. Alkaline Hydroxides

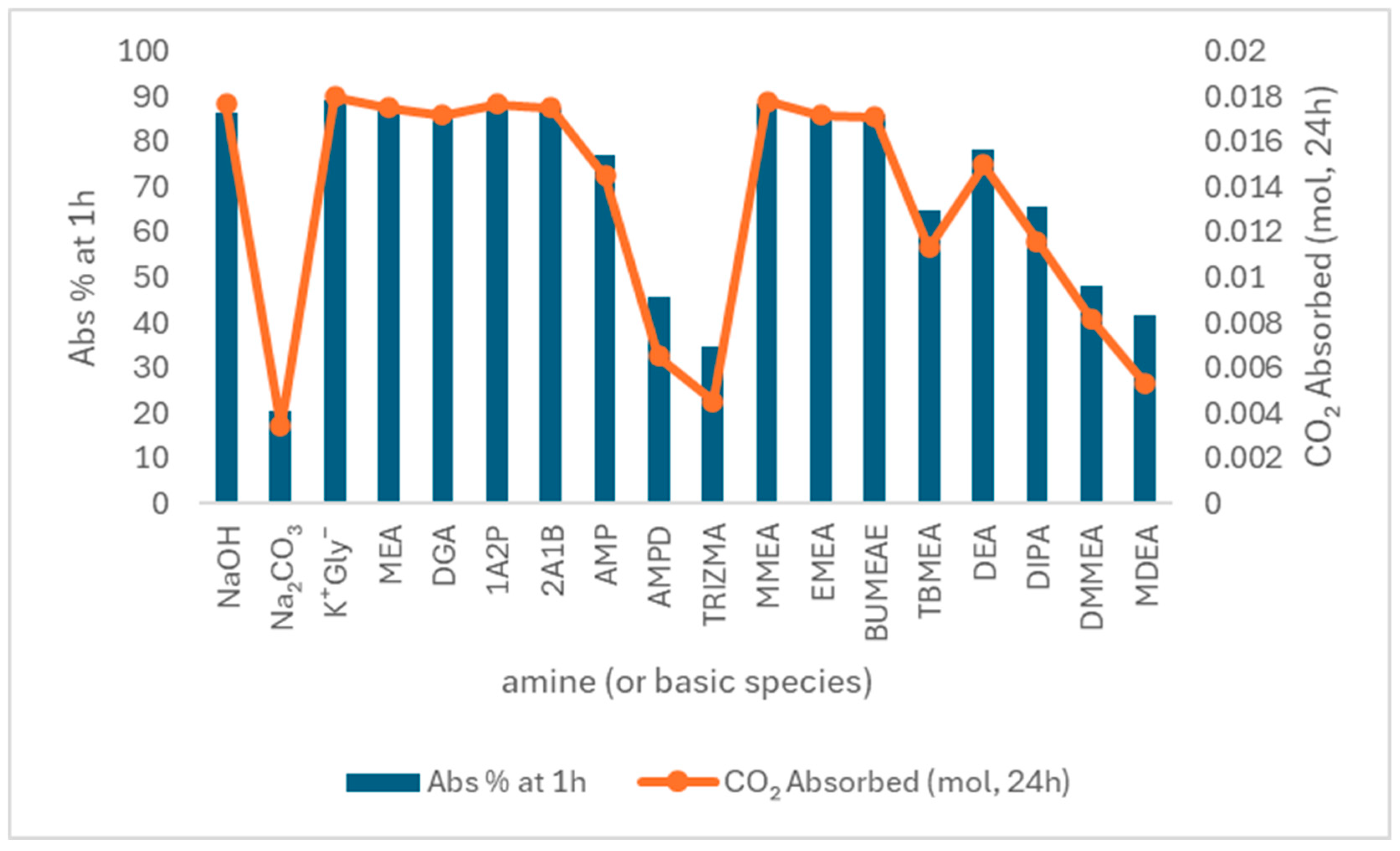

3.1.2. Amines

3.1.3. Ionic Liquids

3.1.4. Low-Regeneration Energy Sorbents

3.2. Solid Sorbents

3.2.1. Chemisorption-Based Sorbents

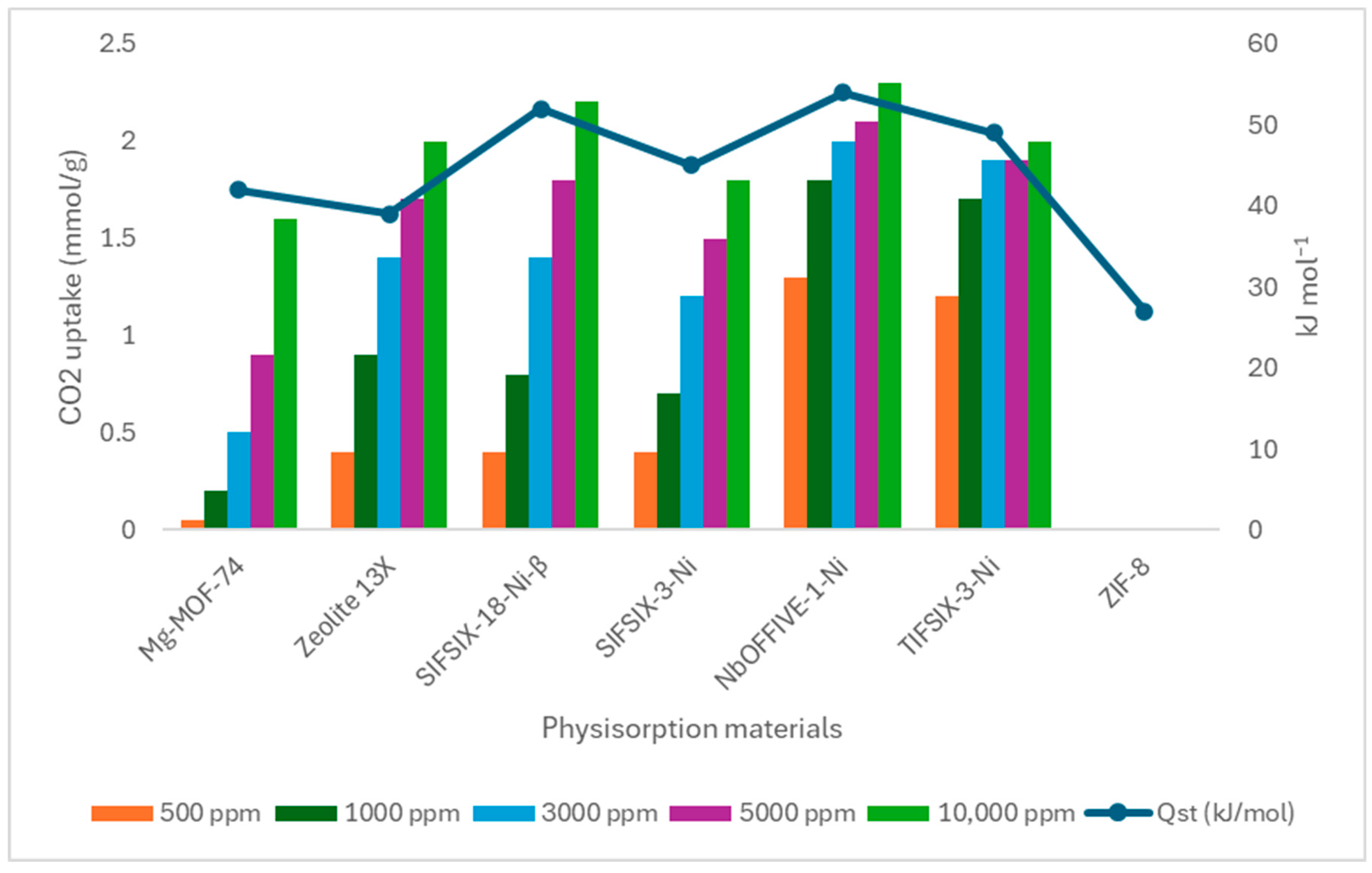

3.2.2. Physisorption-Based Sorbents

3.2.3. Amine-Functionalized Sorbents

4. Future Directions

4.1. Innovative Materials and Technologies

4.2. Synergic Carbon Storage and Circular Economy Approach

4.3. Policy Implementation and Standards

4.4. Life Cycle Assessments and Economic Analysis Integration to Practice

5. Conclusions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Climate Change 2021: The Physical Science Basis|Climate Change 2021: The Physical Science Basis. Available online: https://www.ipcc.ch/report/ar6/wg1/ (accessed on 9 November 2024).

- Yousaf, A.; Al Rashid, A.; Koç, M. 3D printing of alkali-activated geopolymers for sustainable and circular economy advancements. Circ. Econ. 2024, 3, 100101. [Google Scholar] [CrossRef]

- Yousaf, A.; Khan, S.A.; Koç, M. Exploring the potential of construction-compatible materials in structural supercapacitors for energy storage in the built environment. Cem. Concr. Compos. 2025, 155, 105809. [Google Scholar] [CrossRef]

- Built Environment Decarbonization|WBCSD. Available online: https://www.wbcsd.org/actions/built-environment-decarbonization/ (accessed on 31 January 2025).

- Yousaf, A.; Khan, S.A.; Koç, M. 3DP for sustainable built environment–Synthesis and thermomechanical characterization of composite materials based on local soil and date palm fiber waste. J. Clean. Prod. 2024, 481, 144050. [Google Scholar] [CrossRef]

- Song, S.; Liu, Z.; Liu, G.; Cui, X.; Sun, J. Application of biochar cement-based materials for carbon sequestration. Constr. Build. Mater. 2023, 405, 133373. [Google Scholar] [CrossRef]

- Hasan, K.; Islam, M.T.; Ferdaus, R.; Yahaya, F.M. Experimental study on environment-friendly concrete production incorporating palm oil clinker and cockle shell powder as cement partial replacement. Mater. Today Proc. 2024, 107, 254–262. [Google Scholar] [CrossRef]

- Arehart, J.H.; Hart, J.; Pomponi, F.; D’Amico, B. Carbon sequestration and storage in the built environment. Sustain. Prod. Consum. 2021, 27, 1047–1063. [Google Scholar] [CrossRef]

- Race to Zero—Climate Champions. Available online: https://climatechampions.unfccc.int/system/race-to-zero/ (accessed on 9 November 2024).

- Net Zero Tracker|Welcome. Available online: https://zerotracker.net/ (accessed on 9 November 2024).

- Bjånesøy, S.; Kinnunen, A.; Einarsdóttir, H.; Heinonen, J. Carbon storage in the built environment: A review. Inst. Phys. 2023, 3, 042003. [Google Scholar] [CrossRef]

- van Straelen, J.; Geuzebroek, F.; Goodchild, N.; Protopapas, G.; Mahony, L. CO2 capture for refineries, a practical approach. Energy Procedia 2009, 1, 179–185. [Google Scholar] [CrossRef]

- Grebner, D.L.; Bettinger, P.; Siry, J.P. Common Forestry Practices. In Introduction to Forestry and Natural Resources; Academic Press: Cambridge, MA, USA, 2013; pp. 255–285. [Google Scholar] [CrossRef]

- Yousaf, A.; Al Rashid, A.; Polat, R.; Koç, M. Potential and challenges of recycled polymer plastics and natural waste materials for additive manufacturing. Sustain. Mater. Technol. 2024, 41, e01103. [Google Scholar] [CrossRef]

- Harris, N.; Cook-Patton, S.; Gibbs, D.; Lister, K. Young Forests Capture Carbon Quicker than Previously Thought. 2020. Available online: https://www.wri.org/insights/young-forests-capture-carbon-quicker-previously-thought (accessed on 31 January 2025).

- Meng, D.; Unluer, C.; Yang, E.H.; Qian, S. Carbon sequestration and utilization in cement-based materials and potential impacts on durability of structural concrete. Constr. Build. Mater. 2022, 361, 129610. [Google Scholar] [CrossRef]

- Kazemian, M.; Shafei, B. Carbon sequestration and storage in concrete: A state-of-the-art review of compositions, methods, and developments. Constr. Build. Mater. 2023, 70, 102443. [Google Scholar] [CrossRef]

- Sangmesh, B.; Patil, N.; Jaiswal, K.K.; Gowrishankar, T.; Selvakumar, K.K.; Jyothi, M.; Jyothilakshmi, R.; Kumar, S. Development of sustainable alternative materials for the construction of green buildings using agricultural residues: A review. Constr. Build. Mater. 2023, 368, 130457. [Google Scholar] [CrossRef]

- Ahmed, S.; Rehman, A.; Amjad, A.; Hasib, M.H.; Hussain, F.; Khan, A.Q.; Khushnood, R.A. Development of multifunctional cementitious composite using biochar. J. Build. Eng. 2024, 96, 110598. [Google Scholar] [CrossRef]

- Zou, S.; Sham, M.L.; Xiao, J.; Leung, L.M.; Lu, J.X.; Poon, C.S. Biochar-enabled carbon negative aggregate designed by core-shell structure: A novel biochar utilizing method in concrete. Constr. Build. Mater. 2024, 449, 138507. [Google Scholar] [CrossRef]

- Rivas-Aybar, D.; John, M.; Biswas, W. Environmental Life Cycle Assessment of a Novel Hemp-Based Building Material. Materials 2023, 16, 7208. [Google Scholar] [CrossRef] [PubMed]

- Chung, I.K.; Beardall, J.; Mehta, S.; Sahoo, D.; Stojkovic, S. Using marine macroalgae for carbon sequestration: A critical appraisal. J. Appl. Phycol. 2011, 23, 877–886. [Google Scholar] [CrossRef]

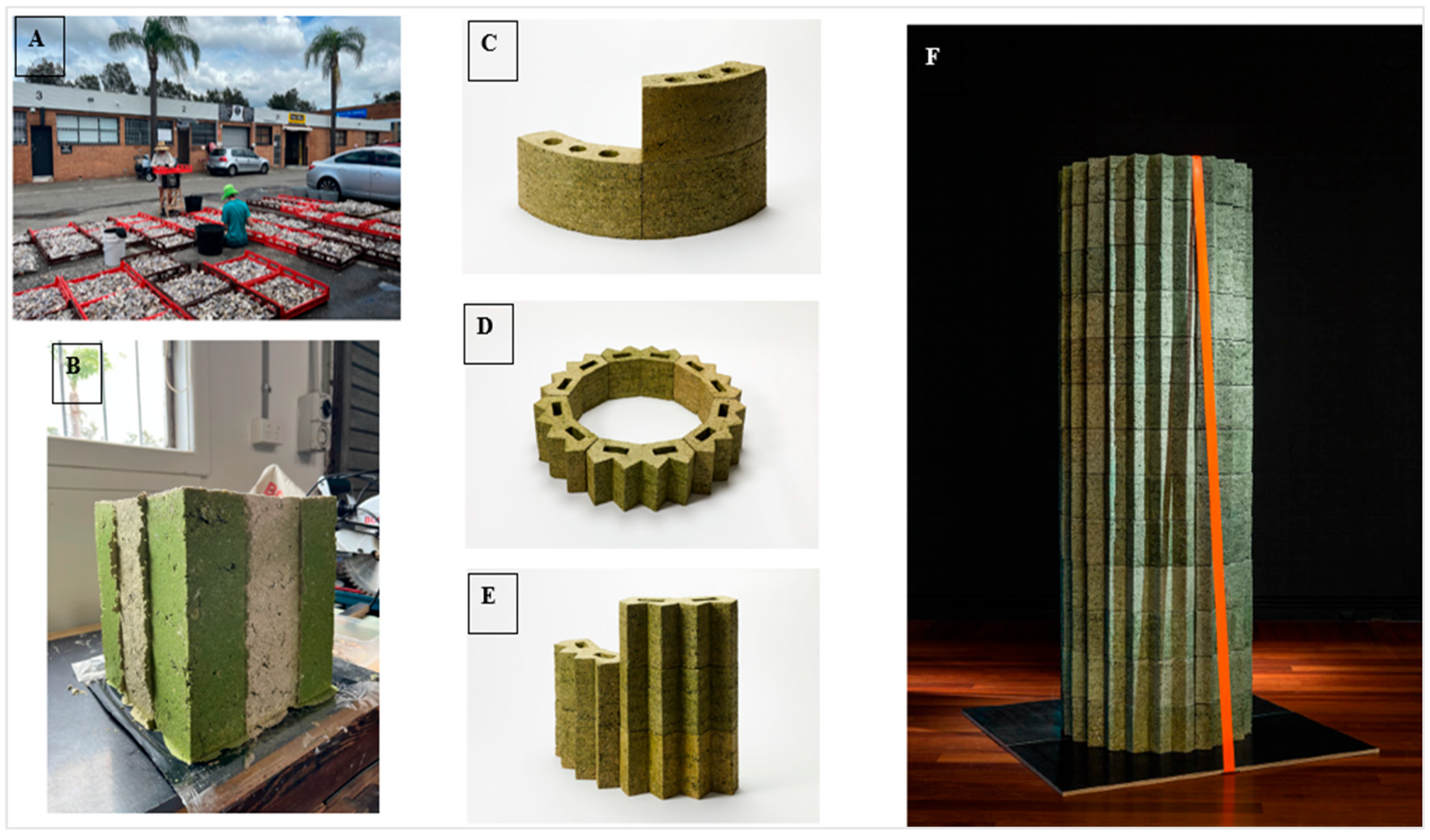

- Scardifield, K.; McLean, N.; Kuzhiumparambil, U.; Ralph, P.J.; Neveux, N.; Isaac, G.; Schork, T. Biomasonry products from macroalgae: A design driven approach to developing biomaterials for carbon storage. J. Appl. Phycol. 2024, 36, 935–950. [Google Scholar] [CrossRef]

- EPD: Straw as Insulation Material—School of Natural Building. Available online: http://schoolofnaturalbuilding.co.uk/epd-straw-as-insulation-material/ (accessed on 4 January 2025).

- Agarwal, R.; Pawar, N.; Supriya; Rawat, P.; Rai, D.; Kumar, R.; Naik B, S. Thermo-mechanical behavior of cementitious material with partial replacement of Class-II biochar with Accelerated Carbonation Curing (ACC). Ind. Crops. Prod. 2023, 204, 117335. [Google Scholar] [CrossRef]

- Miao, B.H.; Headrick, R.J.; Li, Z.; Spanu, L.; Loftus, D.J.; Lepech, M.D. Life cycle assessment and design of LignoBlock: A lignin bound block on the path towards a green transition of the construction industry. J. Clean. Prod. 2024, 474, 143610. [Google Scholar] [CrossRef]

- Pahlavan, F.; Hung, A.M.; Aldagari, S.; Schmidt, A.J.; Valdez, P.J.; Fini, E.H. From biowaste to BioPave: Biological pathways for sequestration of anthropogenic CO2 and enhancing durability of roadway infrastructures. Resour. Conserv. Recycl. 2024, 205, 107515. [Google Scholar] [CrossRef]

- Farooq, M.; Bashir, M.; Gull, U.; Mukhtar, M.; Gani, K.M. Preliminary Investigations on the Performance and Characterization of Municipal Wastewater Sludge-Derived Biochar–Plastic Composites: A Resource-Oriented Solution to Sludge and Plastic Waste. J. Hazard. Toxic Radioact. Waste 2024, 28. [Google Scholar] [CrossRef]

- Di Luigi, M.; Petit, D.; Sarkar, A.; Guo, Z.; Zhou, C.; Ren, S. Tailoring biogenic straw insulation from additive manufacturing. Appl. Mater. Today 2023, 32, 101851. [Google Scholar] [CrossRef]

- Sisman, M.; Teomete, E.; Yanik, J.; Malayoglu, U.; Tac, G.D. The effects of apricot kernel shell nanobiochar on mechanical properties of cement composites. Cem. Wapno Beton 2023, 28, 2–15. [Google Scholar] [CrossRef]

- Bošković, I.; Radivojević, A. Life cycle greenhouse gas emissions of hemp-lime concrete wall constructions in Serbia: The impact of carbon sequestration, transport, waste production and end of life biogenic carbon emission. J. Build. Eng. 2023, 66, 105908. [Google Scholar] [CrossRef]

- García-Troncoso, N.; Hidalgo-Astudillo, S.; Tello-Ayala, K.; Vanegas-Alman, N.; Bompa, D.V. Preparation and performance of sugarcane bagasse ash pavement repair mortars. Case Stud. Constr. Mater. 2023, 19, e02563. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, J.; Wu, Y.; Xie, T.; Bo, L.; Li, Z. Life cycle assessment of steel-glued laminated bamboo (GluBam) hybrid truss in China. Energy Build 2023, 294, 113218. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, Y.; Labianca, C.; Wang, L.; Ruan, S.; Poon, C.S.; Ok, Y.S.; Tsang, D.C.W. Carbon-negative cement-bonded biochar particleboards. Biochar 2022, 4, 58. [Google Scholar] [CrossRef]

- Li, H.; Luo, Z.; Xu, X.; Cang, Y.; Yang, L. Assessing the embodied carbon reduction potential of straw bale rural houses by hybrid life cycle assessment: A four-case study. J. Clean. Prod. 2021, 303, 127002. [Google Scholar] [CrossRef]

- Zhang, Y.; Maierdan, Y.; Guo, T.; Chen, B.; Fang, S.; Zhao, L. Biochar as carbon sequestration material combines with sewage sludge incineration ash to prepare lightweight concrete. Constr. Build. Mater. 2022, 343, 128116. [Google Scholar] [CrossRef]

- Chen, T.; Zhao, L.; Gao, X.; Li, L.; Qin, L. Modification of carbonation-cured cement mortar using biochar and its environmental evaluation. Cem. Concr. Compos. 2022, 134, 104764. [Google Scholar] [CrossRef]

- Sikora, P.; Woliński, P.; Chougan, M.; Madraszewski, S.; Węgrzyński, W.; Papis, B.K.; Federowicz, K.; Ghaffar, S.H.; Stephan, D. A systematic experimental study on biochar-cementitious composites: Towards carbon sequestration. Ind. Crops. Prod. 2022, 184, 115103. [Google Scholar] [CrossRef]

- Ohenoja, K.; Rissanen, J.; Kinnunen, P.; Illikainen, M. Direct carbonation of peat-wood fly ash for carbon capture and utilization in construction application. J. CO2 Util. 2020, 40, 101203. [Google Scholar] [CrossRef]

- Heidari, M.D.; Lawrence, M.; Blanchet, P.; Amor, B. Regionalised Life Cycle Assessment of Bio-Based Materials in Construction; the Case of Hemp Shiv Treated with Sol-Gel Coatings. Materials 2019, 12, 2987. [Google Scholar] [CrossRef]

- Dervishaj, A.; Malmqvist, T.; Silfwerbrand, J.; Gudmundsson, K. A digital workflow for assessing lifespan, carbonation, and embodied carbon of reusing concrete in buildings. J. Build. Eng. 2024, 96, 110536. [Google Scholar] [CrossRef]

- Fitzpatrick, D.; Nolan, E.; Richardson, M.G. Sequestration of carbon dioxide by concrete infrastructure: A preliminary investigation in Ireland. J. Sustain. Archit. Civ. Eng. 2015, 10, 66–77. [Google Scholar] [CrossRef]

- Andersson, R.; Fridh, K.; Stripple, H.; Häglund, M. Calculating CO2 uptake for existing concrete structures during and after service life. Environ. Sci. Technol. 2013, 47, 11625–11633. [Google Scholar] [CrossRef]

- Ma, M.; Huang, Z.; Wang, J.; Niu, L.; Zhang, W.; Xu, X.; Xi, F.; Liu, Z. Carbon uptake by cement in China: Estimation and contribution to carbon neutrality goals. Sci. China Earth Sci. 2024, 67, 2056–2067. [Google Scholar] [CrossRef]

- Xi, F.; Davis, S.J.; Ciais, P.; Crawford-Brown, D.; Guan, D.; Pade, C.; Shi, T.; Syddall, M.; Lv, J.; Ji, L.; et al. Substantial global carbon uptake by cement carbonation. Nat. Geosci. 2016, 9, 880–883. [Google Scholar] [CrossRef]

- Guo, R.; Wang, J.; Bing, L.; Tong, D.; Ciais, P.; Davis, S.J.; Andrew, R.M.; Xi, F.; Liu, Z. Global CO2 uptake by cement from 1930 to 2019. Earth Syst. Sci. Data 2021, 13, 1791–1805. [Google Scholar] [CrossRef]

- Dwivedi, A.; Gupta, S. Carbon dioxide sequestration in mortars with excavated soil: Engineering performances and environmental benefits. Sci. Total Environ. 2024, 917, 170285. [Google Scholar] [CrossRef]

- Ma, L.; Pang, A.P.; Luo, Y.; Lu, X.; Lin, F. Beneficial factors for biomineralization by ureolytic bacterium Sporosarcina pasteurii. Microb. Cell Fact. 2020, 19, 12. [Google Scholar] [CrossRef]

- Yu, X.; Meng, Q.; Yang, Y.; Zhang, W.; Cheng, L. Microstructural and Geomechanical Study on Microbial-Carbonized Sand Using Streptomyces Microflavus for Dust Control. Front. Earth Sci. 2022, 10, 875010. [Google Scholar] [CrossRef]

- Kim, H.; Son, H. Utilization of Bio-Mineral Carbonation for Enhancing CO2 Sequestration and Mechanical Properties in Cementitious Materials. Buildings 2022, 12, 744. [Google Scholar] [CrossRef]

- Gilmour, K.A.; Ghimire, P.S.; Wright, J.; Haystead, J.; Dade-Robertson, M.; Zhang, M.; James, P. Microbially induced calcium carbonate precipitation through CO2 sequestration via an engineered Bacillus subtilis. Microb. Cell Fact. 2024, 23, 168. [Google Scholar] [CrossRef] [PubMed]

- Zhu, T.; Paulo, C.; Merroun, M.L.; Dittrich, M. Potential application of biomineralization by Synechococcus PCC8806 for concrete restoration. Ecol. Eng. 2015, 82, 459–468. [Google Scholar] [CrossRef]

- Qian, C.; Ren, L.; Xue, B.; Cao, T. Bio-mineralization on cement-based materials consuming CO2 from atmosphere. Constr. Build. Mater. 2016, 106, 126–132. [Google Scholar] [CrossRef]

- The Atmosphere|National Oceanic and Atmospheric Administration. Available online: https://www.noaa.gov/jetstream/atmosphere (accessed on 1 January 2025).

- Nam, M.S.; Park, D.; Doh, J.H. Performance improvement of cement materials by mineral carbonation accelerated by CO2 microbubble water. Constr. Build. Mater. 2024, 447, 138210. [Google Scholar] [CrossRef]

- Li, L.; Liu, Q.; Wu, M. Properties of Cement Mortars Subject to Varied Carbonation Treatments at Early Ages. J. Mater. Civ. Eng. 2023, 35, 04023462. [Google Scholar] [CrossRef]

- Xian, X.; Mahoutian, M.; Zhang, D.; Shao, Y.; Yu, Z. Carbon capture and utilization using cement-free concrete products via near-ambient pressure carbonation. Int. J. Greenh. Gas Control 2024, 134, 104130. [Google Scholar] [CrossRef]

- Hanifa, M.; Agarwal, R.; Sharma, U.; Thapliyal, P.C.; Singh, L.P. A review on CO2 capture and sequestration in the construction industry: Emerging approaches and commercialised technologies. J. CO2 Util. 2023, 67, 102292. [Google Scholar] [CrossRef]

- Li, H.; Peng, Y.; Xu, M.; Wang, Y.; Ding, J.; Ma, B.; Jin, L.; Lu, S.; Yan, J. Use of municipal solid waste incineration fly ash as a supplementary cementitious material: CO2 mineralization coupled with mechanochemical pretreatment. Environ. Res. 2024, 242, 117799. [Google Scholar] [CrossRef]

- Tiwari, S.K.; Giri, B.S.; Thivaharan, V.; Srivastava, A.K.; Kumar, S.; Singh, R.P.; Kumar, R.; Singh, R.S. Sequestration of simulated carbon dioxide (CO2) using churning cementations waste and fly-ash in a thermo-stable batch reactor (TSBR). Environ. Sci. Pollut. Res. 2020, 27, 27470–27479. [Google Scholar] [CrossRef]

- Su, A.; Chen, T.; Gao, X.; Li, Q.; Qin, L. Effect of carbonation curing on durability of cement mortar incorporating carbonated fly ash subjected to Freeze-Thaw and sulfate attack. Constr. Build. Mater. 2022, 341, 127920. [Google Scholar] [CrossRef]

- Luo, S.; Guo, M.Z.; Ling, T.C. Mechanical and microstructural performances of fly ash blended cement pastes with mixing CO2 during fresh stage. Constr. Build. Mater. 2022, 358, 129444. [Google Scholar] [CrossRef]

- Viet, D.B.; Chan, W.P.; Phua, Z.H.; Ebrahimi, A.; Abbas, A.; Lisak, G. The use of fly ashes from waste-to-energy processes as mineral CO2 sequesters and supplementary cementitious materials. J. Hazard. Mater. 2020, 398, 122906. [Google Scholar] [CrossRef]

- Han, S.H.; Kim, S.M.; Jun, Y.; Han, T.H.; Kim, J.H. Carbon-captured sodium hydroxide solution for sustainable alkali-activated slag. Sustain. Mater. Technol. 2024, 40, e00915. [Google Scholar] [CrossRef]

- Razeghi, H.R.; Safaee, F.; Geranghadr, A.; Ghadir, P.; Javadi, A.A. Investigating accelerated carbonation for alkali activated slag stabilized sandy soil. Geotech. Geol. Eng. 2024, 42, 575–592. [Google Scholar] [CrossRef]

- Balinee, B.; Ranjith, P.G.; Huppert, H.E. A clean and sustainable CO2 storage method in construction materials. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 160. [Google Scholar] [CrossRef]

- Li, X.; Mehdizadeh, H.; Ling, T.C. Environmental, economic and engineering performances of aqueous carbonated steel slag powders as alternative material in cement pastes: Influence of particle size. Sci. Total Environ. 2023, 903, 166210. [Google Scholar] [CrossRef] [PubMed]

- Kravchenko, E.; Qin, C.; Lin, Z.; Ng, C.W.W. Effect of polyvinyl alcohol on the CO2 uptake of carbonated steel slag. Constr. Build. Mater. 2023, 375, 130761. [Google Scholar] [CrossRef]

- Liu, G.; Schollbach, K.; van der Laan, S.; Tang, P.; Florea, M.V.A.; Brouwers, H.J.H. Recycling and utilization of high volume converter steel slag into CO2 activated mortars—The role of slag particle size. Resour. Conserv. Recycl. 2020, 160, 104883. [Google Scholar] [CrossRef]

- Xian, X.; Mahoutian, M.; Zhang, S.; Shao, Y.; Zhang, D.; Liu, J. Converting industrial waste into a value-added cement material through ambient pressure carbonation. J. Environ. Manag. 2023, 325, 116603. [Google Scholar] [CrossRef]

- Li, C.; Li, Y.; Zhu, W.; Zeng, G.; Ouyang, Z.; Cheng, M.; Jiang, Z. Carbon dioxide cured building materials as an approach to decarbonizing the calcium carbide related industry. Renew. Sustain. Energy Rev. 2023, 186, 113688. [Google Scholar] [CrossRef]

- Liu, J.; Li, M.; Jin, H.; Cheng, L.; Xing, F. The role of different ratios of biochar in the artificial lightweight cold-bonded aggregates (ALCBAs) containing high volume of red mud (RM). Constr. Build. Mater. 2024, 422, 135815. [Google Scholar] [CrossRef]

- Moreno, V.; González-Arias, J.; Ruiz-Martinez, J.D.; Balart-Gimeno, R.; Baena-Moreno, F.M.; Leiva, C. FGD-Gypsum Waste to Capture CO2 and to Recycle in Building Materials: Optimal Reaction Yield and Preliminary Mechanical Properties. Materials 2024, 17, 3774. [Google Scholar] [CrossRef] [PubMed]

- Lin, X.; Liu, H.W.; Zhou, Z.X.; Liu, G.G.; Ni, B.J.; Wang, C.Q. Killing three birds with one stone: A novel valorization strategy for comprehensive utilization of waste titanium gypsum. Constr. Build. Mater. 2024, 442, 137680. [Google Scholar] [CrossRef]

- Sahoo, P.; Dwivedi, A.; Tuppad, S.M.; Gupta, S. Sequestration and utilization of carbon dioxide to improve engineering properties of cement-based construction materials with recycled brick powder: A pathway for cleaner construction. Constr. Build. Mater. 2023, 395, 132268. [Google Scholar] [CrossRef]

- Kravchenko, E.; Sauerwein, M.; Besklubova, S.; Ng, C.W.W. A comparative life cycle assessment of recycling waste concrete powder into CO2-Capture products. J. Environ. Manag. 2024, 352, 119947. [Google Scholar] [CrossRef]

- Bergmans, J.; Kamyab, H.K.; Ghosh, D.; Van Mierloo, P.; Carens, H.; Nielsen, P. Carbonation of Recycled Concrete Aggregates for New Concrete and Concrete Fines to Make Cement-Free Hollow Blocks. Sustainability 2024, 16, 3494. [Google Scholar] [CrossRef]

- Liang, C.; Wang, S.; Cai, Z.; Yin, Y.; Gao, Y.; Guo, M.-Z.; Wang, X.; Ma, Z. Effects of CO2 curing methods on frost resistance and mechanical properties of recycled aggregate concrete. Case Stud. Constr. Mater. 2024, 20, e02973. [Google Scholar] [CrossRef]

- Gomes, R.I.; Bastos, D.; Farinha, C.B.; Pederneiras, C.M.; Veiga, R.; de Brito, J.; Faria, P.; Silva, A.S. Mortars with CDW Recycled Aggregates Submitted to High Levels of CO2. Infrastructures 2021, 6, 159. [Google Scholar] [CrossRef]

- Fernández, M.; Vega, D.F.; Suescum-Morales, D.; Jiménez, J.R.; Fernández-Rodríguez, J.M. Use of Carbonated Water as Kneading in Mortars Made with Recycled Aggregates. Materials 2022, 15, 4876. [Google Scholar] [CrossRef]

- Tang, P.; Xuan, D.; Cheng, H.W.; Poon, C.S.; Tsang, D.C.W. Use of CO2 curing to enhance the properties of cold bonded lightweight aggregates (CBLAs) produced with concrete slurry waste (CSW) and fine incineration bottom ash (IBA). J. Hazard. Mater. 2020, 381, 120951. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, K.; Yuan, Z.; Liu, S. Investigations into magnesium oxide carbon sequestration foamed concrete: Mechanical performance, microstructure and environmental benefits. Constr. Build. Mater. 2024, 421, 135679. [Google Scholar] [CrossRef]

- Gálvez-Martos, J.-L.; Chaliulina, R.; Medina-Martos, E.; Elhoweris, A.; Hakki, A.; Mwanda, J.; Al-Horr, Y. Eco-efficiency of a novel construction material produced by carbon capture and utilization. J. CO2 Util. 2021, 49, 101545. [Google Scholar] [CrossRef]

- Li, Q.; Su, A.; Gao, X. Preparation of durable magnesium oxysulfate cement with the incorporation of mineral admixtures and sequestration of carbon dioxide. Sci. Total Environ. 2022, 809, 152127. [Google Scholar] [CrossRef]

- Hwang, K.Y.; Ahn, J.Y.; Kim, C.; Seo, J.Y.; Hwang, I. Development of an MgO-based binder for stabilizing fine sediments and storing CO2. Environ. Geochem. Health 2015, 37, 1063–1072. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.Y.; Ahn, J.-Y.; Kim, C.; Choi, S.-J.; Ho, T.T.; Moon, D.H.; Hwang, I. Carbonation/granulation of mine tailings using a MgO/ground-granule blast-furnace-slag binder. J. Hazard. Mater. 2019, 378, 120760. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, T.; Silva, R.V.; De Brito, J.; Fernández, J.M.; Esquinas, A.R. Hydration of Reactive MgO as Partial Cement Replacement and Its Influence on the Macroperformance of Cementitious Mortars. Adv. Mater. Sci. Eng. 2019, 2019, 9271507. [Google Scholar] [CrossRef]

- Hay, R.; Otchere, C.; Kashwani, G.; Celik, K. Recycling carbonated reactive magnesium cement (RMC) as a building material. J. Clean. Prod. 2021, 320, 128838. [Google Scholar] [CrossRef]

- Feng, H.; Wen, J.; Shao, Q.; Yang, Y.Y.; Yao, X. Carbonation resistance of fly ash/slag based engineering geopolymer composites. Constr. Build. Mater. 2024, 449, 138471. [Google Scholar] [CrossRef]

- Wie, Y.M.; Lee, K.G.; Lee, K.H. Characteristics of Circulating Fluidized Bed Combustion (CFBC) Ash as Carbon Dioxide Storage Medium and Development of Construction Materials by Recycling Carbonated Ash. Materials 2024, 17, 4359. [Google Scholar] [CrossRef]

- Soto-Paz, J.; Arroyo, O.; Torres-Guevara, L.E.; Parra-Orobio, B.A.; Casallas-Ojeda, M. The circular economy in the construction and demolition waste management: A comparative analysis in emerging and developed countries. J. Build. Eng. 2023, 78, 107724. [Google Scholar] [CrossRef]

- Fan, L.; Wang, J.; Liu, X.; Luo, H.; Zhang, K.; Fu, X.; Li, M.; Li, X.; Jiang, B.; Chen, J.; et al. Whether the carbon emission from green roofs can be effectively mitigated by recycling waste building material as green roof substrate during five-year operation? Environ. Sci. Pollut. Res. 2020, 27, 40893–40906. [Google Scholar] [CrossRef]

- Ashraf, M.S.; Ghouleh, Z.; Shao, Y. Production of eco-cement exclusively from municipal solid waste incineration residues. Resour. Conserv. Recycl. 2019, 149, 332–342. [Google Scholar] [CrossRef]

- José, N.; Ahmed, H.; Miguel, B.; Luís, E.; Jorge, B. Magnesia (Mgo) production and characterization, and its influence on the performance of cementitious materials: A review. Materials 2020, 13, 4752. [Google Scholar] [CrossRef]

- Kastiukas, G.; Ruan, S.; Unluer, C.; Liang, S.; Zhou, X. Environmental Assessment of Magnesium Oxychloride Cement Samples: A Case Study in Europe. Sustainability 2019, 11, 6957. [Google Scholar] [CrossRef]

- Torréns-Martín, D.; Fernández-Carrasco, L.J.; Blanco-Varela, M.T. Up to 100% Replacement of Natural Materials from Residues: Recycling Blast Furnace Slag and Fly Ash as Self-Leveling Cementitious Building Materials. Materials 2023, 16, 3350. [Google Scholar] [CrossRef] [PubMed]

- Huseien, G.F.; Tang, W.; Yu, Y.; Wong, L.S.; Mirza, J.; Dong, K.; Gu, X. Evaluation of high-volume fly-ash cementitious binders incorporating nanosilica as eco-friendly sustainable concrete repair materials. Constr. Build. Mater. 2024, 447, 138022. [Google Scholar] [CrossRef]

- Coffetti, D.; Rapelli, S.; Coppola, L. Alkali-Activated Slag as Sustainable Binder for Pervious Concrete and Structural Plaster: A Feasibility Study. Materials 2024, 17, 4084. [Google Scholar] [CrossRef]

- Xu, B.; Li, H.; Zhang, X.; Chen, L.; Yang, Y.; Zhao, Y.; Huo, F.; Zhou, T.; Liu, Z.; Li, B. From waste to resource: Upcycling red mud as eco-friendly geopolymer for the circular economy. J. Environ. Chem. Eng. 2025, 13, 119847. [Google Scholar] [CrossRef]

- Xiao, R.; Dai, X.; Zhong, J.; Ma, Y.; Jiang, X.; He, J.; Wang, Y.; Huang, B. Toward waste glass upcycling: Preparation and characterization of high-volume waste glass geopolymer composites. Sustain. Mater. Technol. 2024, 40, e00890. [Google Scholar] [CrossRef]

- Tan, Q.; Shangguan, J.; Yang, Q.; Wang, D.; Xie, N.; Zhang, Y. Recycling red mud for low-carbon pavement: Performance evaluation and environment risk assessment. Transp. Res. D Transp. Environ. 2024, 136, 104428. [Google Scholar] [CrossRef]

- Grengg, C.; Rudic, O.; Saade, M.; Steindl, F.; Wilkening, M.; Jodlbauer, A.; Zoegl, I.; Wohlmuth, D.; Mittermayr, F. Alkali activated steel slag—Oil composites: Towards resource efficiency and CO2 neutrality. Cem. Concr. Res. 2024, 186, 107678. [Google Scholar] [CrossRef]

- Nepal, J.; Ahmad, W.; Munsif, F.; Khan, A.; Zou, Z. Advances and prospects of biochar in improving soil fertility, biochemical quality, and environmental applications. Front. Environ. Sci. 2023, 11, 1114752. [Google Scholar] [CrossRef]

- Xu, H.; Cai, A.; Wu, D.; Liang, G.; Xiao, J.; Xu, M.; Colinet, G.; Zhang, W. Effects of biochar application on crop productivity, soil carbon sequestration, and global warming potential controlled by biochar C:N ratio and soil pH: A global meta-analysis. Soil Tillage Res. 2021, 213, 105125. [Google Scholar] [CrossRef]

- Huang, C.; Chen, Y.; Jin, L.; Yang, B. Properties of biochars derived from different straw at 500 °C pyrolytic temperature: Implications for their use to improving acidic soil water retention. Agric. Water Manag. 2024, 301, 108953. [Google Scholar] [CrossRef]

- Isopescu, D.N.; Adam, L.; Nistorac, A.; Bodoga, A. Carbon Footprint Assessment: Case Studies for Hemp-Based Eco-Concrete Masonry Blocks. Buildings 2024, 14, 3150. [Google Scholar] [CrossRef]

- Scrucca, F.; Ingrao, C.; Maalouf, C.; Moussa, T.; Polidori, G.; Messineo, A.; Arcidiacono, C.; Asdrubali, F. Energy and carbon footprint assessment of production of hemp hurds for application in buildings. Environ. Impact Assess. Rev. 2020, 84, 106417. [Google Scholar] [CrossRef]

- Mungkung, R.; Intrachooto, S.; Srisuwanpip, N.; Lamai, A.; Sorakon, K.; Kittipakornkarn, K. Life Cycle Assessment of Hempstone for Green Buildings. Chem. Eng. Trans. 2018, 63, 247–252. [Google Scholar] [CrossRef]

- Gao, Y.; Huang, C.; Chen, Y.; Chen, X.; Shen, Y.; Yu, H.Y. Sustainable production of in-situ CO2 capture and mineralization of multifunctional nanowood with excellent anisotropic, flame retardant, and durability for building construction. Ind. Crops Prod. 2024, 221, 119353. [Google Scholar] [CrossRef]

- Nabipour, H.; Hu, Y. Introduction to flame retardants for polymeric materials. In Bio-Based Flame-Retardant Technology for Polymeric Materials; Elsevier: Amsterdam, The Netherlands, 2022; pp. 1–27. [Google Scholar] [CrossRef]

- Tribot, A.; Amer, G.; Alio, M.A.; de Baynast, H.; Delattre, C.; Pons, A.; Mathias, J.-D.; Callois, J.-M.; Vial, C.; Michaud, P.; et al. Wood-lignin: Supply, extraction processes and use as bio-based material. Eur. Polym. J. 2019, 112, 228–240. [Google Scholar] [CrossRef]

- Kuoribo, E.; Shokry, H.; Hassanein, A.; Asawa, T.; Mahmoud, H. Fabrication of energy-efficient cement panels from construction waste for sustainable building application. Archit. Eng. Des. Manag. 2023, 1–23. [Google Scholar] [CrossRef]

- Chen, J.; Ter-Mikaelian, M.T.; Yang, H.; Colombo, S.J. Assessing the greenhouse gas effects of harvested wood products manufactured from managed forests in Canada. For. Int. J. For. Res. 2018, 91, 193–205. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J.; Xu, J.; Wang, Y.; Li, B.; Zhang, S. Carbon emission-based life cycle assessment of rural residential buildings constructed with engineering bamboo: A case study in China. J. Build. Eng. 2023, 76, 107182. [Google Scholar] [CrossRef]

- Zhao, B.; Yu, Y.; Xu, Y.; Guo, H. Bamboo as a sustainable construction material for residential buildings in the cold and severe cold regions of China. Archit. Eng. Des. Manag. 2023, 20, 1511–1528. [Google Scholar] [CrossRef]

- Walker, P.; Thomson, A.; Maskell, D. Straw bale construction. In Nonconventional and Vernacular Construction Materials: Characterisation, Properties and Applications; Woodhead Publishing: Cambridge, UK, 2019; pp. 189–216. [Google Scholar] [CrossRef]

- Abiola, O.S.; Kupolati, W.K.; Sadiku, E.R.; Ndambuki, J.M. Utilisation of natural fibre as modifier in bituminous mixes: A review. Constr. Build. Mater. 2014, 54, 305–312. [Google Scholar] [CrossRef]

- Hu, W.H.; Zhang, D.; Ftwi, E.; Ellis, B.R.; Li, V.C. Development of sustainable low carbon Engineered Cementitious Composites with waste polyethylene fiber, sisal fiber and carbonation curing. Resour. Conserv. Recycl. 2023, 197, 107096. [Google Scholar] [CrossRef]

- Zeman, F. Energy and Material Balance of CO2 Capture from Ambient Air. Environ. Sci. Technol. 2007, 41, 7558–7563. [Google Scholar] [CrossRef]

- Keith, D.W.; Holmes, G.; Angelo, D.S.; Heidel, K. A Process for Capturing CO2 from the Atmosphere. Joule 2018, 2, 1573–1594. [Google Scholar] [CrossRef]

- Baciocchi, R.; Storti, G.; Mazzotti, M. Process design and energy requirements for the capture of carbon dioxide from air. Chem. Eng. Process. Process Intensif. 2006, 45, 1047–1058. [Google Scholar] [CrossRef]

- Mahmoudkhani, M.; Keith, D.W. Low-energy sodium hydroxide recovery for CO2 capture from atmospheric air—Thermodynamic analysis. Int. J. Greenh. Gas Control 2009, 3, 376–384. [Google Scholar] [CrossRef]

- Lackner, K.; Ziock, H.-J.; Grimes, P. Carbon Dioxide Extraction from Air: Is It An Option? Los Alamos National Lab.: Los Alamos, NM, USA, 1999. [Google Scholar]

- Socolow, R.; Desmond, M.; Aines, R.; Blackstock, J. Direct Air Capture of CO2 with Chemicals: A Technology Assessment for the APS Panel on Public Affairs. 2011. Available online: https://infoscience.epfl.ch/record/200555/files/dac2011.pdf (accessed on 15 February 2025).

- Lepaumier, H.; Picq, D.; Carrette, P.L. New Amines for CO2 Capture. II. Oxidative Degradation Mechanisms. Ind. Eng. Chem. Res. 2009, 48, 9068–9075. [Google Scholar] [CrossRef]

- Veltman, K.; Singh, B.; Hertwich, E.G. Human and environmental impact assessment of postcombustion CO2 capture focusing on emissions from amine-based scrubbing solvents to air. Environ. Sci. Technol. 2010, 44, 1496–1502. [Google Scholar] [CrossRef] [PubMed]

- Barzagli, F.; Giorgi, C.; Mani, F.; Peruzzini, M. Screening Study of Different Amine-Based Solutions as Sorbents for Direct CO2 Capture from Air. ACS Sustain. Chem. Eng. 2020, 8, 14013–14021. [Google Scholar] [CrossRef]

- Hanusch, J.M.; Kerschgens, I.P.; Huber, F.; Neuburger, M.; Gademann, K. Pyrrolizidines for direct air capture and CO2 conversion. Chem. Commun. 2019, 55, 949–952. [Google Scholar] [CrossRef]

- Inagaki, F.; Matsumoto, C.; Iwata, T.; Mukai, C. CO2-Selective Absorbents in Air: Reverse Lipid Bilayer Structure Forming Neutral Carbamic Acid in Water without Hydration. J. Am. Chem. Soc. 2017, 139, 4639–4642. [Google Scholar] [CrossRef]

- Hasib-ur-Rahman, M.; Siaj, M.; Larachi, F. Ionic liquids for CO2 capture—Development and progress. Chem. Eng. Process. Process Intensif. 2010, 49, 313–322. [Google Scholar] [CrossRef]

- Gurkan, B.; Goodrich, B.F.; Mindrup, E.M.; Ficke, L.E.; Massel, M.; Seo, S.; Senftle, T.P.; Wu, H.; Glaser, M.F.; Shah, J.K.; et al. Molecular design of high capacity, low viscosity, chemically tunable ionic liquids for CO2 capture. J. Phys. Chem. Lett. 2010, 1, 3494–3499. [Google Scholar] [CrossRef]

- Ramdin, M.; De Loos, T.W.; Vlugt, T.J.H. State-of-the-art of CO2 capture with ionic liquids. Ind. Eng. Chem. Res. 2012, 51, 8149–8177. [Google Scholar] [CrossRef]

- Chen, Y.; Ji, G.; Guo, S.; Yu, B.; Zhao, Y.; Wu, Y.; Zhang, H.; Liu, Z.; Han, B.; Liu, Z. Visible-light-driven conversion of CO2 from air to CO using an ionic liquid and a conjugated polymer. Green Chem. 2017, 19, 5777–5781. [Google Scholar] [CrossRef]

- Niedermaier, I.; Bahlmann, M.; Papp, C.; Kolbeck, C.; Wei, W.; Calderón, S.K.; Grabau, M.; Schulz, P.S.; Wasserscheid, P.; Steinrück, H.-P.; et al. Carbon dioxide capture by an amine functionalized ionic liquid: Fundamental differences of surface and bulk behavior. J. Am. Chem. Soc. 2014, 136, 436–441. [Google Scholar] [CrossRef]

- Chen, Y.; Zhou, X.Q.; Cao, Y.; Xue, Z.; Mu, T. Quantitative investigation on the physical and chemical interactions between CO2 and amine-functionalized ionic liquid [aEMMIM][BF4] by NMR. Chem. Phys. Lett. 2013, 574, 124–128. [Google Scholar] [CrossRef]

- Custelcean, R.; Williams, N.J.; Garrabrant, K.A.; Agullo, P.; Brethomé, F.M.; Martin, H.J.; Kidder, M.K. Direct Air Capture of CO2 with Aqueous Amino Acids and Solid Bis-iminoguanidines (BIGs). Ind. Eng. Chem. Res. 2019, 58, 23338–23346. [Google Scholar] [CrossRef]

- Seipp, C.A.; Williams, N.J.; Kidder, M.K.; Custelcean, R. CO2 Capture from Ambient Air by Crystallization with a Guanidine Sorbent. Angew. Chem. 2017, 129, 1062–1065. [Google Scholar] [CrossRef]

- Nikulshina, V.; Ayesa, N.; Gálvez, M.E.; Steinfeld, A. Feasibility of Na-based thermochemical cycles for the capture of CO2 from air—Thermodynamic and thermogravimetric analyses. Chem. Eng. J. 2008, 140, 62–70. [Google Scholar] [CrossRef]

- Stolaroff, J.K.; Lowry, G.V.; Keith, D.W. Using CaO- and MgO-rich industrial waste streams for carbon sequestration. Energy Convers. Manag. 2005, 46, 687–699. [Google Scholar] [CrossRef]

- Colombo, G.V. Study of CO2 Sorbents for Extravehicular Activity; NTRS: Washington, DC, USA, 1973. [Google Scholar]

- Campbell, J.S. Decomposition of Carbonates in Capture of Carbon Dioxide from Ambient Air. 2019. Available online: https://open.library.ubc.ca/soa/cIRcle/collections/ubctheses/24/items/1.0387012 (accessed on 15 February 2025).

- Ranjan, M.; Herzog, H.J. Feasibility of air capture. Energy Procedia 2011, 4, 2869–2876. [Google Scholar] [CrossRef]

- Kumar, A.; Madden, D.G.; Lusi, M.; Chen, K.; Daniels, E.A.; Curtin, T.; Perry, J.J.; Zaworotko, M.J. Direct Air Capture of CO2 by Physisorbent Materials. Angew. Chem. Int. Ed. 2015, 54, 14372–14377. [Google Scholar] [CrossRef]

- Wilson, S.M.W.; Tezel, F.H. Direct Dry Air Capture of CO2 Using VTSA with Faujasite Zeolites. Ind. Eng. Chem. Res. 2020, 59, 8783–8794. [Google Scholar] [CrossRef]

- Mukherjee, S.; Sikdar, N.; O’nolan, D.; Franz, D.M.; Gascón, V.; Kumar, A.; Kumar, N.; Scott, H.S.; Madden, D.G.; Kruger, P.E.; et al. Trace CO2 capture by an ultramicroporous physisorbent with low water affinity. Sci. Adv. 2019, 5, 9171–9200. [Google Scholar] [CrossRef]

- Kwon, H.T.; Sakwa-Novak, M.A.; Pang, S.H.; Sujan, A.R.; Ping, E.W.; Jones, C.W. Aminopolymer-Impregnated Hierarchical Silica Structures: Unexpected Equivalent CO2 Uptake under Simulated Air Capture and Flue Gas Capture Conditions. Chem. Mater. 2019, 31, 5229–5237. [Google Scholar] [CrossRef]

- Anyanwu, J.; Wang, Y.; Yang, R.T. Amine-Grafted Silica Gels for CO2 Capture Including Direct Air Capture. Ind. Eng. Chem. Res. 2020, 59, 7072–7079. [Google Scholar] [CrossRef]

- Darunte, L.A.; Oetomo, A.D.; Walton, K.S.; Sholl, D.S.; Jones, C.W. Direct Air Capture of CO2 Using Amine Functionalized MIL-101(Cr). ACS. Sustain. Chem. Eng. 2016, 4, 5761–5768. [Google Scholar] [CrossRef]

- Luo, W.; Li, B.; Xu, M.; Pang, C.; Lester, E.; Xu, L.; Kow, K.-W. In-situ release and sequestration of CO2 in cement composites using LTA zeolites. Sci. Total Environ. 2023, 872, 162133. [Google Scholar] [CrossRef]

| Material Mix | Biomass Source | Production Process | Application in the Built Environment | Ref. |

|---|---|---|---|---|

|

|

| Bricks | [23] |

|

|

| Cementitious paste | [25] |

|

|

| Hemp-based boards | [21] |

| Byproducts from:

|

|

| [26] |

|

|

| Aggregates | [20] |

|

|

| Filler | [19] |

|

|

| Biopave | [27] |

|

|

| Tiles | [28] |

|

| Alkaline Treatment (NaOH-Based) | Insulation panels | [29] |

|

| Pyrolysis at 500 °C | Filler | [30] |

|

|

| Hemp-lime concrete wall | [31] |

|

|

| Pavement repair mortars | [32] |

Steel–GluBam hybrid truss consisting of:

|

| Steel-GluBam hybrid truss | [33] | |

|

|

| Aggregates in cement-bonded biochar particleboards | [34] |

|

| Straw bale rural house | [35] | |

|

|

| Lightweight concrete | [36] |

|

|

| Filler | [37] |

|

|

| Filler | [38] |

|

|

| Tiles | [39] |

|

|

| Hempcrete wall | [40] |

| Bacteria Used | Metabolization Mechanism | Carbonation Condition | CO2 Uptake/Reduction | Application | Ref. |

|---|---|---|---|---|---|

| Carbonic anhydrase |

|

| Cementitious materials | [51] |

| CA and urease |

|

| Cementitious materials and concrete cracking repair | [50] |

| CA |

| Dust Control in sand | [49] | |

| Oxygenic photosynthesis (by Cyanobacteria) |

| Concrete cracking repair | [52] |

| Liquid Sorbent Type | Examples | CO2 Capture Mechanism | Regeneration Temperature | Advantages | Limitations | Ref. |

|---|---|---|---|---|---|---|

| Alkaline Hydroxides | NaOH, KOH, and Ca(OH)2 | Forms stable carbonates (Na2CO3, K2CO3, CaCO3) | >900 °C |

|

| [119,120,123] |

| Amines | MEA, Alkanolamines, and Pyrrolizidine-based Amines | Binds CO2 via acid-base reactions |

|

| [124,127,128,129] | |

| Ionic Liquids | [P4444][p-2-O] IL and Functionalized ILs | Physical and chemical interactions |

|

| [133,134] | |

| Low-Regeneration Energy Sorbents | Potassium Sarcosinate, Potassium Glycinate, and Guanidine | Crystallization of carbonate salts (m-BBIG, guanidine) | 60–120 °C |

|

| [136,137] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hamed, E.A.E.; Khan, S.A.; Yousaf, A.; Koç, M. A Comprehensive Review of Carbon Capture, Storage, and Reduction Strategies Within the Built Environment. Materials 2025, 18, 5646. https://doi.org/10.3390/ma18245646

Hamed EAE, Khan SA, Yousaf A, Koç M. A Comprehensive Review of Carbon Capture, Storage, and Reduction Strategies Within the Built Environment. Materials. 2025; 18(24):5646. https://doi.org/10.3390/ma18245646

Chicago/Turabian StyleHamed, Eyad Abdelsalam Elsayed, Shoukat Alim Khan, Arslan Yousaf, and Muammer Koç. 2025. "A Comprehensive Review of Carbon Capture, Storage, and Reduction Strategies Within the Built Environment" Materials 18, no. 24: 5646. https://doi.org/10.3390/ma18245646

APA StyleHamed, E. A. E., Khan, S. A., Yousaf, A., & Koç, M. (2025). A Comprehensive Review of Carbon Capture, Storage, and Reduction Strategies Within the Built Environment. Materials, 18(24), 5646. https://doi.org/10.3390/ma18245646