B2-NiAl Strengthened PH 13–8 Mo Steel Under Fe+ Ion Irradiation: Precipitate Stability and Interaction with Damage Defects

Highlights

- In our work, we find that NiAl precipitates larger than 5nm will survived after 8dpa irradiation at room temperature;

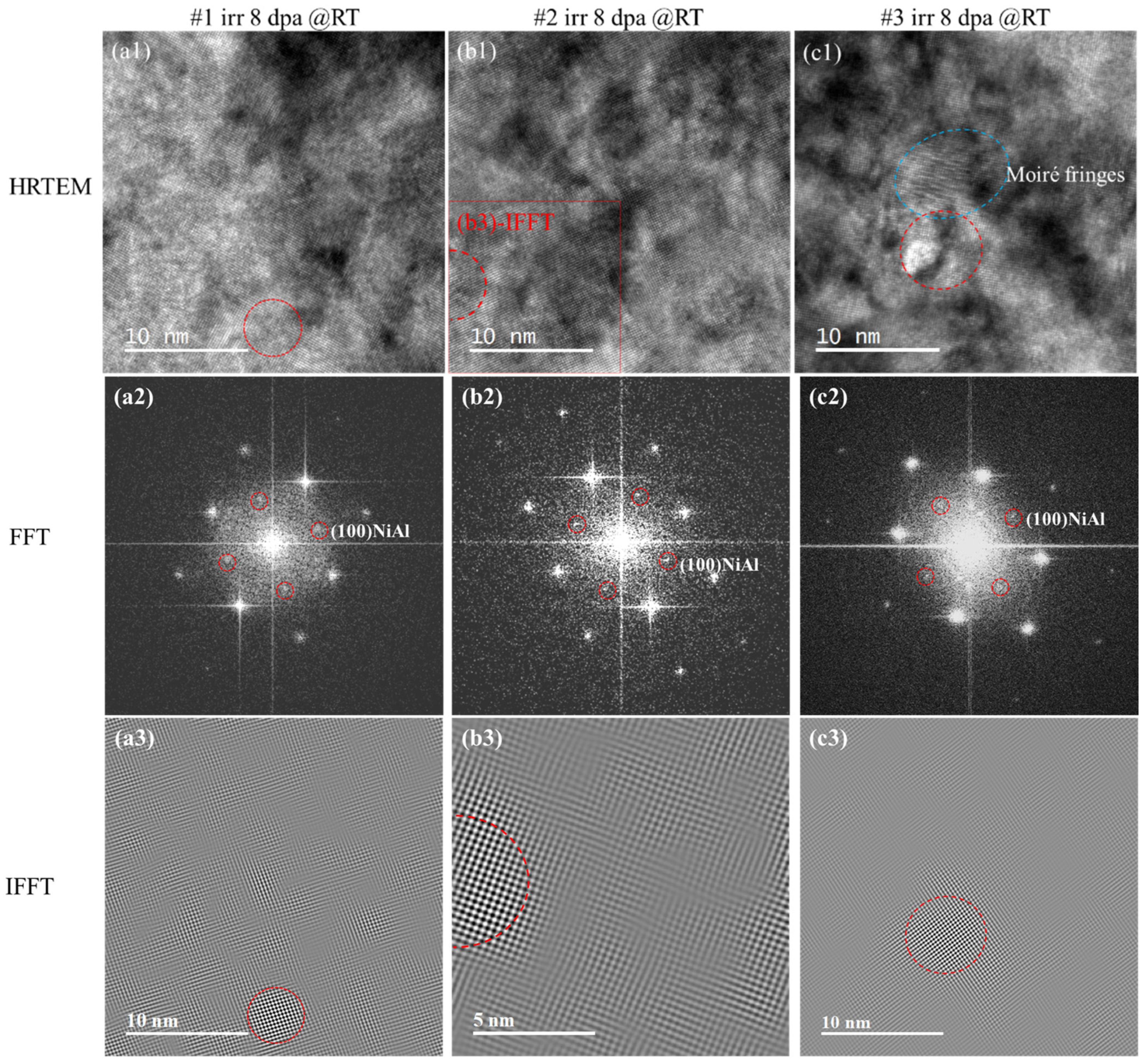

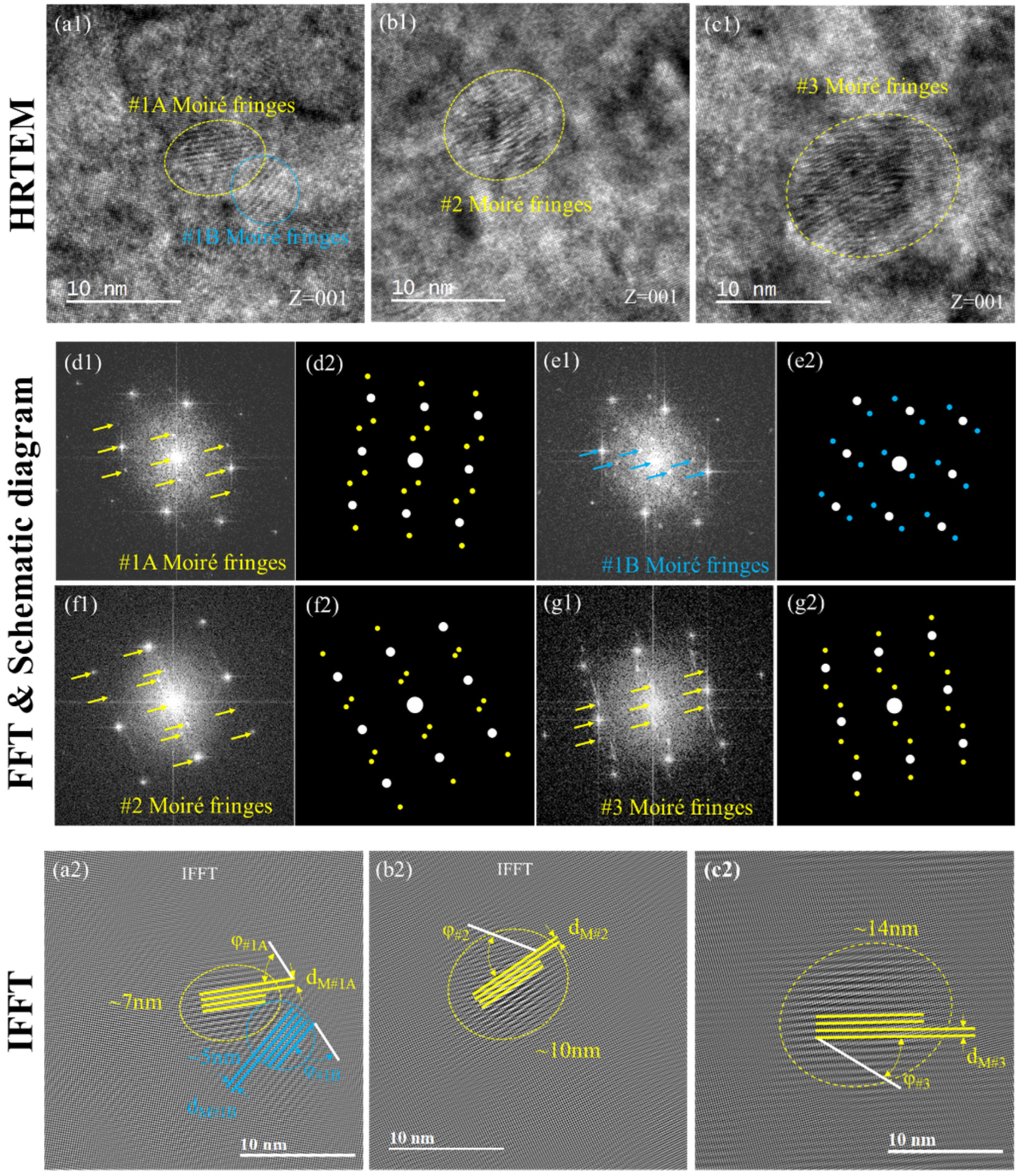

- We find that Moiré fringes are highly related with the precipitates which lose their superlattice crystal structure.

- Radiation-induced precipitate disordering is the main reason for the irradiation dissolution phenomenon.

- The Moiré fringes formation is attributed to the twisted effect between precipitates’ low index crystal planes overlapped with the BCC matrix at various angles.

Abstract

1. Introduction

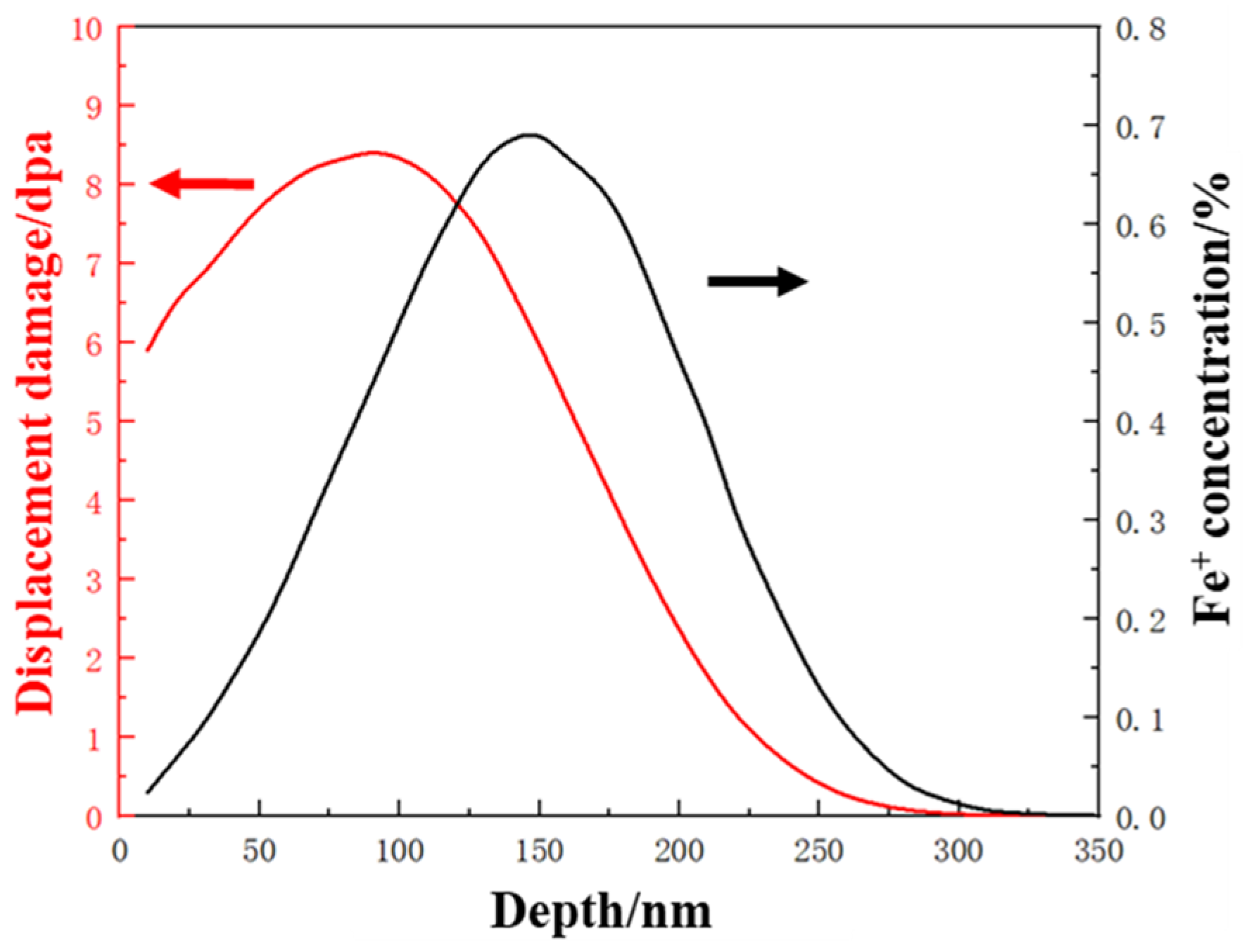

2. Materials and Methods

3. Results and Discussion

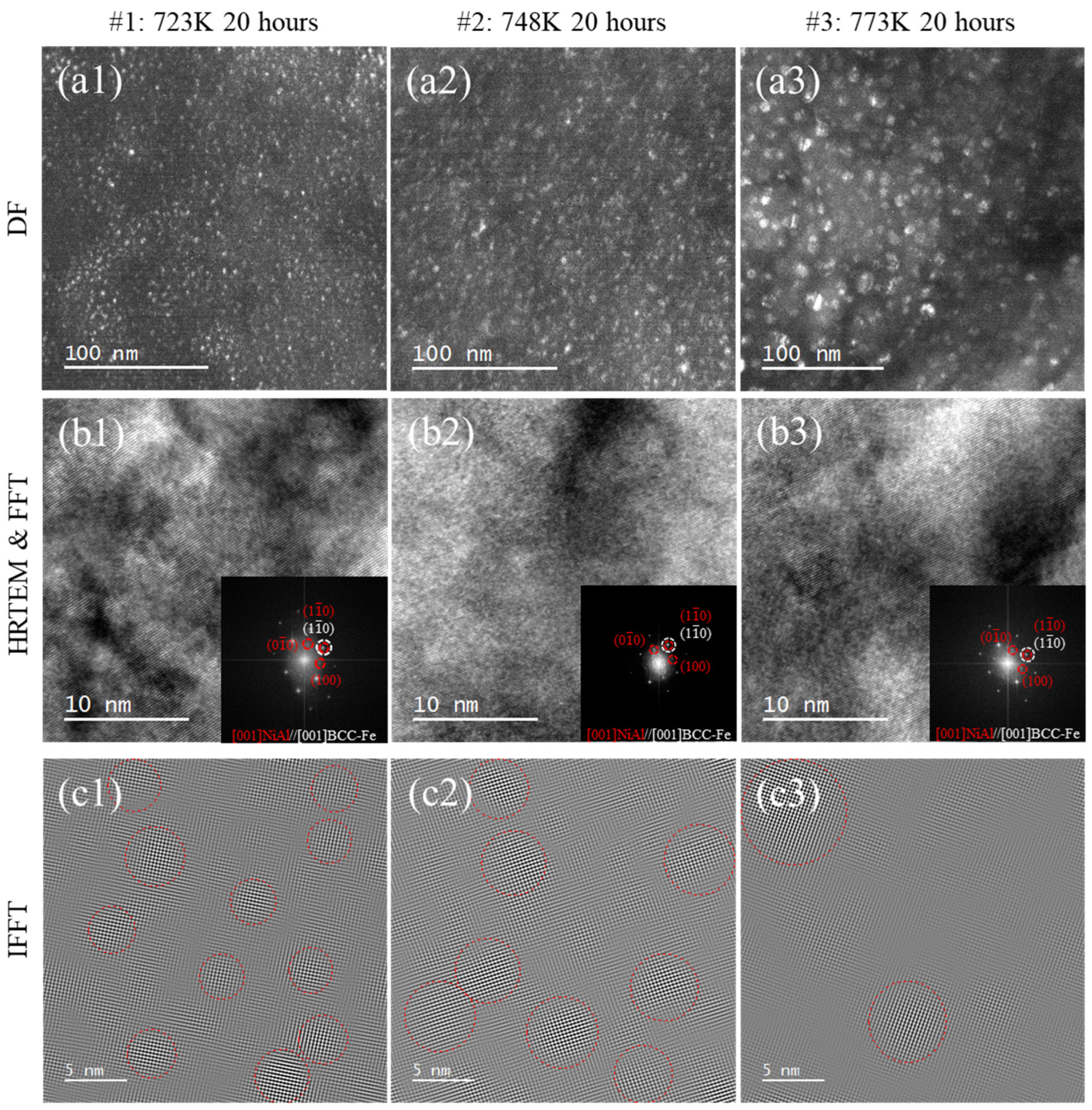

3.1. Characterization of the Precipitated Thermal Aging Samples

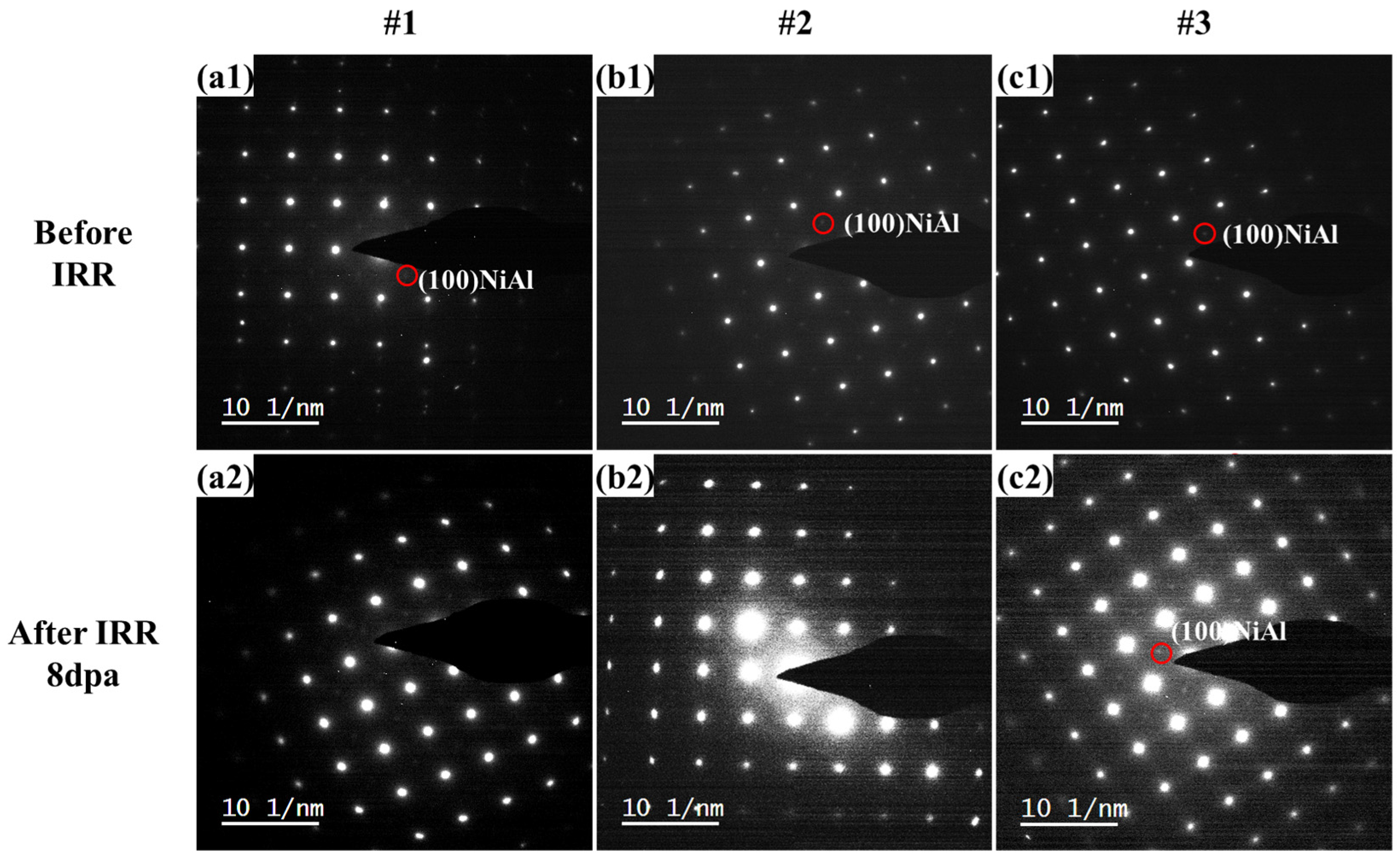

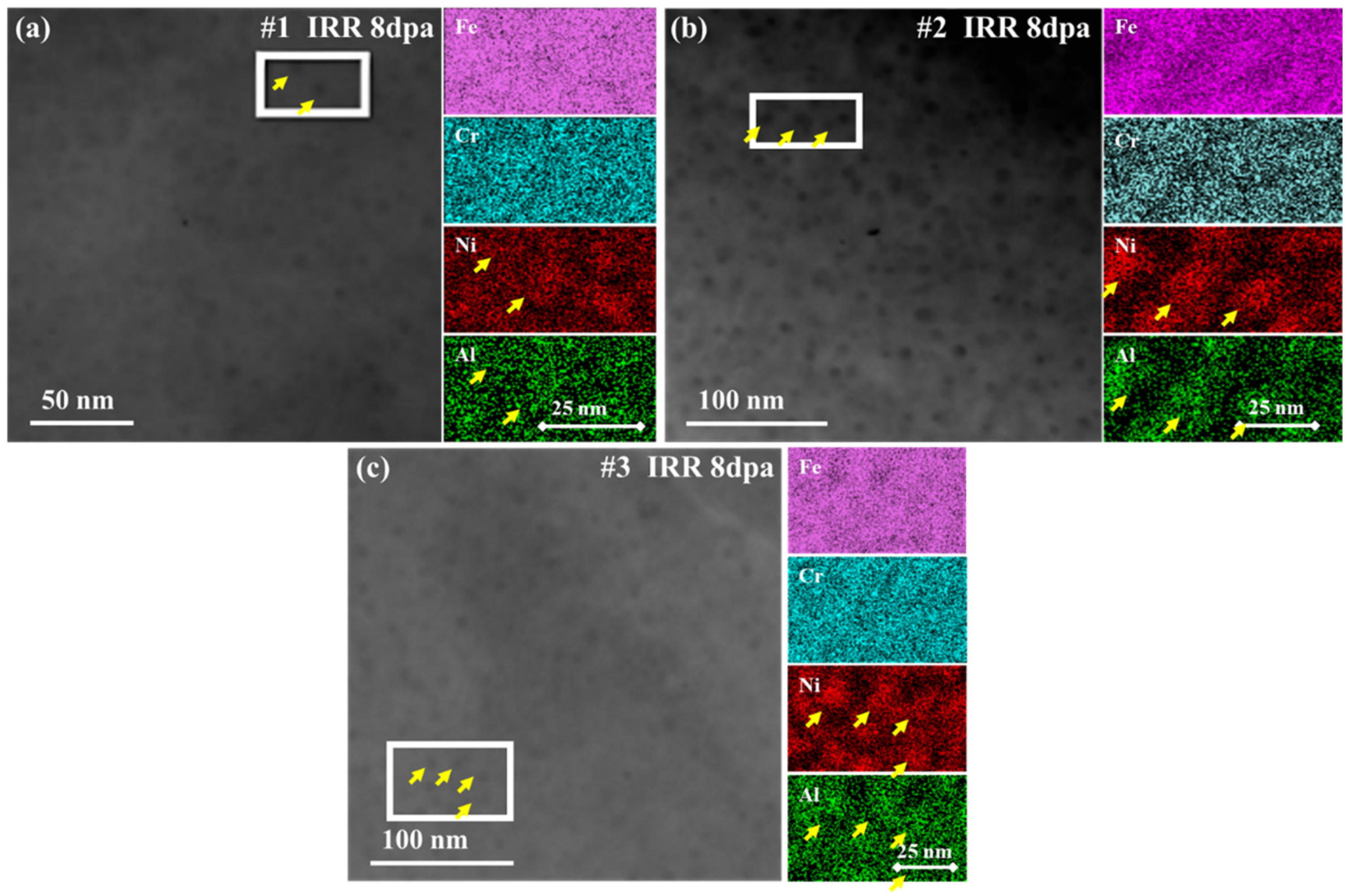

3.2. Phase Stability of NiAl Under Irradiation

3.3. Irradiation-Induced Moiré Fringes

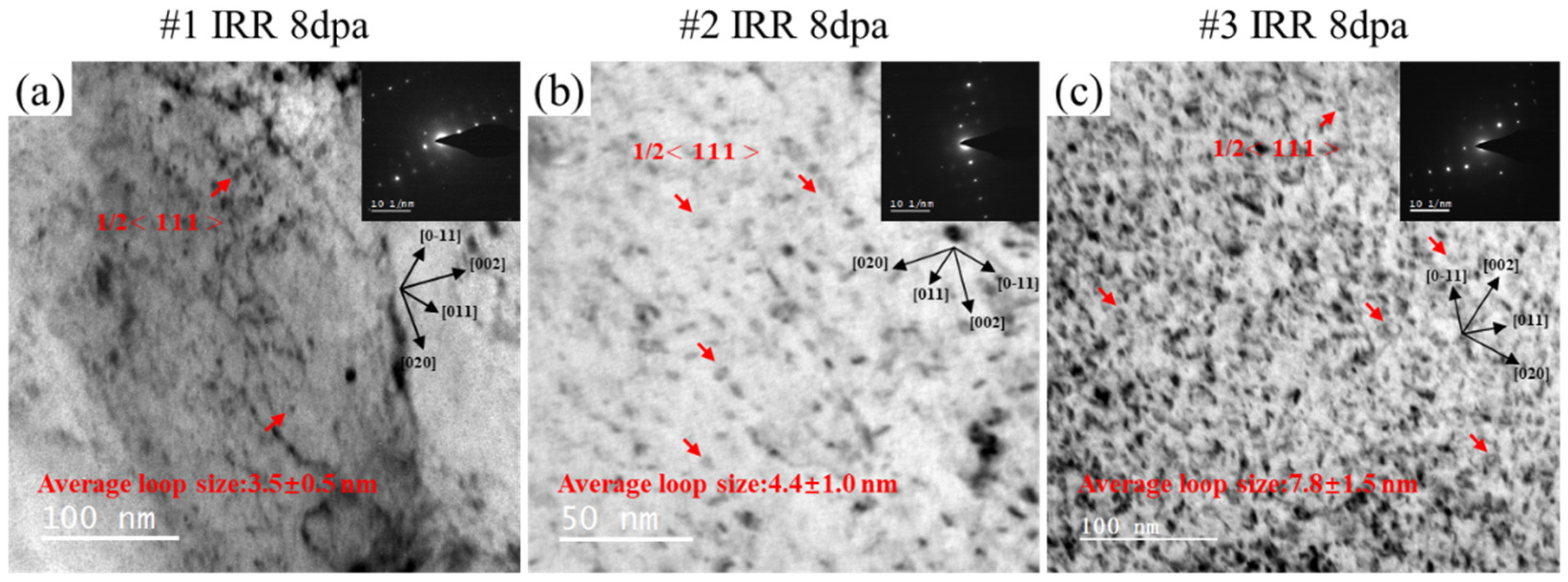

3.4. Irradiation-Induced Dislocation Loops

4. Conclusions

- Before irradiation, controlled state samples thermally aged at 723 K, 748 K and 773 K for 20 h presented uniformly distributed B2 NiAl precipitates in the matrix with sizes of 2.5, 4.9 and 8.1 nm, respectively.

- After irradiation with given conditions, the superlattice diffraction spots of B2 NiAl of smaller size disappeared while the larger ones mostly survived. No elemental diffusion was found by EDS, indicating radiation-induced precipitate disordering is the main reason for radiation dissolution. The variation in superlattices was attributed to the sink strength of the precipitates, and the recoil dissolution was controlled by the critical size 8.1 nm.

- The Moiré fringes could be explained as {100}, {220} and {111} planes twisted with certain angles overlapped with the matrix in HRTEM images. The most observed defect planes were induced by the recoil dissolution of precipitates or interactions between precipitates and nearby mobile irradiation dislocations.

- This work not only improves the theoretical understanding, of the radiation tolerance of PH 13–8 Mo steel in irradiated environments but also provides solidate experimental data to gain insights into intermetallic strengthened material designs in the future.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| SAED | Selected Area Electron Diffraction |

| STEM | Scanning Transmission Electron Microscopy |

| EDS | Energy Dispersive Spectroscopy |

| ITER | International Thermonuclear Experimental Reactor |

| TEM | Transmission Electron Microscope |

| APT | Atom Probe Tomography |

| HRTEM | High Resolution Transmission electron microscope |

| DF | Dark Field |

| BF | Bright Field |

| CBED | Convergent Beam Electron Diffraction |

| FFT | Fast Fourier Transform |

| IFFT | Inverse Fast Fourier Transform |

| DM | Digital Micrograph |

| MD | Molecular Dynamic |

| PKA | Primary Knock Atom |

| BCC | Body-Centered Cubic |

References

- Haghdadi, N.; Laleh, M.; Moyle, M.; Primig, S. Additive manufacturing of steels: A review of achievements and challenges. J. Mater. Sci. 2021, 56, 64–107. [Google Scholar] [CrossRef]

- Lorenzetto, P.; Boireau, B.; Boudot, C.; Bucci, P.; Furmanek, A.; Ioki, K.; Liimatainen, J.; Peacock, A.; Sherlock, P.; Tähtinen, S. Manufacture of blanket shield modules for ITER. Fusion Eng. Des. 2005, 75–79, 291–296. [Google Scholar] [CrossRef]

- Wu, S.; Li, J.; Li, W.; Liu, S. Characterization of oxide dispersoids and mechanical properties of 14Cr-ODS FeCrAl alloys. J. Alloys Compd. 2020, 814, 152282. [Google Scholar] [CrossRef]

- Shen, J.; Li, Y.; Li, F.; Yang, H.; Zhao, Z.; Kano, S.; Matsukawa, Y.; Satoh, Y.; Abe, H. Microstructural characterization and strengthening mechanisms of a 12Cr-ODS steel. Mater. Sci. Eng. A 2016, 673, 624–632. [Google Scholar] [CrossRef]

- Van Renterghem, W.; Al Mazouzi, A.; Van den Berghe, S. Defect structure of irradiated PH 13-8 Mo steel. J. Nucl. Mater. 2007, 360, 128–135. [Google Scholar] [CrossRef]

- Li, X.; Zhang, J.; Akiyama, E.; Li, Q.; Wang, Y. Effect of heat treatment on hydrogen-assisted fracture behavior of PH 13-8 Mo steel. Corros. Sci. 2017, 128, 198–212. [Google Scholar] [CrossRef]

- Seetharaman, V.; Sundararaman, M.; Krishnan, R. Precipitation hardening in a PH 13-8 Mo stainless steel. Mater. Sci. Eng. 1981, 47, 1–11. [Google Scholar] [CrossRef]

- Xu, H.; Sun, C.; Guo, Q.; Song, K.; Liu, H.; Du, Y.; Wang, L.; Ru, X.; Yan, Z.; Cao, Y.; et al. The element enrichment behavior during the aging treatment of PH 13–8 Mo steel and its influence on the evolution of microstructures and mechanical properties. J. Mater. Res. Technol. 2025, 36, 2925–2937. [Google Scholar] [CrossRef]

- Cui, P.; Xia, T.; Wang, Y.; Jia, C.; Wang, H.; Bai, Q.; Zhang, Z.; Zheng, H.; Lai, Z.; Liu, Y.; et al. Uncovering the isothermal transformation dynamics and elemental diffusion behavior of reversed austenite in PH 13-8 Mo steel. Mater. Chem. Phys. 2024, 312, 128666. [Google Scholar] [CrossRef]

- Zheng, C.; Schoell, R.; Hosemann, P.; Kaoumi, D. Ion irradiation effects on commercial PH 13-8 Mo maraging steel Corrax. J. Nucl. Mater. 2019, 514, 255–265. [Google Scholar] [CrossRef]

- Jong, M.; Schmalz, F.; Rensman, J.W.; Luzginova, N.V.; Wouters, O.; Hegeman, J.B.J.; van der Laan, J.G. Post-irradiation characterization of PH 13-8 Mo martensitic stainless steel. J. Nucl. Mater. 2011, 417, 145–148. [Google Scholar] [CrossRef]

- Gray, R.A.; Hawthorne, J.R. Mechanical properties behavior of neutron irradiated 12Ni-5Cr-3Mo maraging steel plate and companion weld metal. Nucl. Eng. Des. 1970, 11, 381–392. [Google Scholar] [CrossRef]

- Cupp, C.R.; Sadowski, E.P.; Trudeau, L.P. Some effects of neutron irradiation on maraging steel. Trans. Metall. Soc. AIME 1967, 239, 1468–1472. [Google Scholar]

- Van Renterghem, W.; Al Mazouzi, A.; Van den Berghe, S. Defect structure of J.W. Morris Jr., Making steel strong and cheap. Nat. Mater. 2017, 16, 787–789. [Google Scholar]

- Nemani, A.V.; Ghaffari, M.; Salahi, S.; Nasiri, A. On the microstructural characteristics and corrosion performance of as-printed and heat-treated PH 13–8 Mo martensitic stainless steel fabricated by wire arc additive manufacturing. Mater. Today Commun. 2023, 34, 105477. [Google Scholar] [CrossRef]

- Clement, C.; Lu, Y.; Wharry, J.P. Decoupling irradiation effects on deformation-induced martensitic transformations in commercial Ni-Cr-Fe alloys. Mater. Sci. Eng. A 2025, 920, 147563. [Google Scholar] [CrossRef]

- Ribis, J. 1.09—Phase Stability in Irradiated Alloys. In Comprehensive Nuclear Materials, 2nd ed.; Konings, R.J.M., Stoller, R.E., Eds.; Elsevier: Oxford, UK, 2020; pp. 265–309. [Google Scholar]

- Onimus, F.; Jourdan, T.; Xu, C.; Campbell, A.A.; Griffiths, M. 1.10—Irradiation Creep in Materials. In Comprehensive Nuclear Materials, 2nd ed.; Konings, R.J.M., Stoller, R.E., Eds.; Elsevier: Oxford, UK, 2020; pp. 310–366. [Google Scholar]

- Capdevila, C.; Miller, M.K.; Russell, K.F.; Chao, J.; González-Carrasco, J.L. Phase separation in PM 2000™ Fe-base ODS alloy: Experimental study at the atomic level. Mater. Sci. Eng. A 2008, 490, 277–288. [Google Scholar] [CrossRef]

- Bestautte, J.; Oudriss, A.; Lenci, M.; Bechet, D.; Obadia, Z.; Feaugas, X.; Christien, F. A multi-method approach to the study of hydrogen trapping in a maraging stainless steel: The impact of B2-NiAl precipitates and austenite. Corros. Sci. 2023, 224, 111509. [Google Scholar] [CrossRef]

- Hofer, C.; Stergar, E.; Maloy, S.A.; Wang, Y.Q.; Hosemann, P. An intermetallic forming steel under radiation for nuclear applications. J. Nucl. Mater. 2015, 458, 361–368. [Google Scholar] [CrossRef]

- Stoller, R.E.; Toloczko, M.B.; Was, G.S.; Certain, A.G.; Dwaraknath, S.; Garner, F.A. On the use of SRIM for computing radiation damage exposure. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2013, 310, 75–80. [Google Scholar] [CrossRef]

- Klinger, M.; Němec, M.; Polívka, L.; Gärtnerová, V.; Jäger, A. Automated CBED processing: Sample thickness estimation based on analysis of zone-axis CBED pattern. Ultramicroscopy 2015, 150, 88–95. [Google Scholar] [CrossRef] [PubMed]

- Nie, J.F.; Muddle, B.C. Strengthening of an Al–Cu–Sn alloy by deformation-resistant precipitate plates. Acta Mater. 2008, 56, 3490–3501. [Google Scholar] [CrossRef]

- Kong, B.S.; Shin, J.H.; Jang, C.; Na, Y.-E.; Jang, D.; Lee, H.J.; Yang, J.-S. Effect of proton irradiation on δ-ferrite in the thermally aged austenitic stainless steel weld: Precipitation of G-phase and additional hardening. J. Nucl. Mater. 2021, 544, 152656. [Google Scholar] [CrossRef]

- Nelson, R.S.; Hudson, J.A.; Mazey, D.J. The stability of precipitates in an irradiation environment. J. Nucl. Mater. 1972, 44, 318–330. [Google Scholar] [CrossRef]

- Was, G.S. Fundamentals of Radiation Materials Science: Metals and Alloys. Mater. Today 2007, 10, 52. [Google Scholar] [CrossRef]

- Was, G.S. (Ed.) Phase Stability Under Irradiation. In Fundamentals of Radiation Materials Science: Metals and Alloys; Springer: Berlin/Heidelberg, Germany, 2007; pp. 433–490. [Google Scholar]

- Malerba, L.; Bonny, G.; Terentyev, D.; Zhurkin, E.E.; Hou, M.; Vörtler, K.; Nordlund, K. Microchemical effects in irradiated Fe–Cr alloys as revealed by atomistic simulation. J. Nucl. Mater. 2013, 442, 486–498. [Google Scholar] [CrossRef]

- Vörtler, K.; Mamivand, M.; Barnard, L.; Szlufarska, I.; Garner, F.A.; Morgan, D. Simulated spatial and temporal dependence of chromium concentration in pure Fe and Fe14%Cr under high dpa ion irradiation. J. Nucl. Mater. 2016, 479, 23–35. [Google Scholar] [CrossRef]

- Tikhonchev, M. Parameters of cascade mixing for FeCr alloy: Results of atomistic simulation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2022, 533, 40–49. [Google Scholar] [CrossRef]

- Svetukhin, V.; L’vov, P.; Gaganidze, E.; Tikhonchev, M.; Dethloff, C. Kinetics and thermodynamics of Cr nanocluster formation in Fe–Cr system. J. Nucl. Mater. 2011, 415, 205–209. [Google Scholar] [CrossRef]

- Harrison, R.W.; Carruthers, A.W.; Hinks, J.A.; Burke, M.G.; Donnelly, S.E. Cascade size and dose rate effects on α′ precipitation in ion-irradiated Fe14Cr alloy. Scr. Mater. 2019, 172, 33–37. [Google Scholar] [CrossRef]

- Simonen, E.P.; Charlot, L.A.; Bruemmer, S.M. Quantification of defect-solute coupling from inverse-Kirkendall segregation. J. Nucl. Mater. 1995, 225, 117–122. [Google Scholar] [CrossRef]

- Yao, T.; Wagner, A.R.; Liu, X.; EI-Azab, A.; Harp, J.M.; Gan, J.; Hurley, D.H.; Benson, M.T.; He, L. On spinodal-like phase decomposition in U–50Zr alloy. Materialia 2020, 9, 100592. [Google Scholar] [CrossRef]

- Tu, J.F. TEM Nano-Moiré Pattern Analysis of a Copper/Single Walled Carbon Nanotube Nanocomposite Synthesized by Laser Surface Implanting. C 2018, 4, 19. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Cr | Ni | Mo | Al | Fe |

|---|---|---|---|---|---|---|---|---|

| wt.% | 0.03 | 0.24 | 0.29 | 11.9 | 9.11 | 1.36 | 1.78 | Bal. |

| at.% | 0.13 | 0.47 | 0.29 | 12.52 | 8.49 | 0.78 | 3.61 | Bal. |

| Number | Heat Treatment | Average Size (nm) | Number Density 1022/m3 |

|---|---|---|---|

| #1 | 723 K, 20 h | 2.5 ± 0.3 | 2.01 ± 0.161 |

| #2 | 748 K, 20 h | 4.9 ± 0.3 | 0.94 ± 0.015 |

| #3 | 773 K, 20 h | 8.1 ± 0.3 | 0.35 ± 0.004 |

| dF/M(110) (nm) | dm (nm) | Φ (°) | Solution#1 | Solution#2 | |||||

|---|---|---|---|---|---|---|---|---|---|

| dNiAl(hkl) | α (°) | dNiAl(hkl) | α (°) | ||||||

| #1A | 0.294295 | 0.507257 | 65.61 | 0.317820 | 34.389127 | 0.85744 | 0.218401 | 21.486198 | 1.815751 |

| #1B | 0.294295 | 0.578619 | 73.92 | 0.324969 | 30.000012 | 0.82013 | 0.197647 | 10.447733 | 2.217108 |

| #2 | 0.292533 | 0.475533 | 53.92 | 0.400547 | 32.114138 | 0.533389 | 0.245788 | Invalid | 1.416547 |

| #3 | 0.297648 | 0.632557 | 58.34 | 0.348979 | 28.125003 | 0.727454 | 0.22726 | 17.188734 | 1.715375 |

| Equivalent Results | Plane Family of d1 | Twisted Angle (°) | Plane | Twisted Angle (°) |

|---|---|---|---|---|

| #1A | 100 | 34 | 220 | 21 |

| #1B | 100 | 30 | 111 | 10 |

| #2 | 100 | 30 | - | - |

| #3 | 100 | 28 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Z.; Yang, R.; Chen, M.; Ding, Y.; Liu, C.; Zhang, J.; Li, B.; Zheng, C. B2-NiAl Strengthened PH 13–8 Mo Steel Under Fe+ Ion Irradiation: Precipitate Stability and Interaction with Damage Defects. Materials 2025, 18, 5524. https://doi.org/10.3390/ma18245524

Huang Z, Yang R, Chen M, Ding Y, Liu C, Zhang J, Li B, Zheng C. B2-NiAl Strengthened PH 13–8 Mo Steel Under Fe+ Ion Irradiation: Precipitate Stability and Interaction with Damage Defects. Materials. 2025; 18(24):5524. https://doi.org/10.3390/ma18245524

Chicago/Turabian StyleHuang, Zijing, Roudi Yang, Ming Chen, Yiting Ding, Chenglu Liu, Jiahan Zhang, Binghang Li, and Ce Zheng. 2025. "B2-NiAl Strengthened PH 13–8 Mo Steel Under Fe+ Ion Irradiation: Precipitate Stability and Interaction with Damage Defects" Materials 18, no. 24: 5524. https://doi.org/10.3390/ma18245524

APA StyleHuang, Z., Yang, R., Chen, M., Ding, Y., Liu, C., Zhang, J., Li, B., & Zheng, C. (2025). B2-NiAl Strengthened PH 13–8 Mo Steel Under Fe+ Ion Irradiation: Precipitate Stability and Interaction with Damage Defects. Materials, 18(24), 5524. https://doi.org/10.3390/ma18245524