Facile Fabrication of Wood Fiber–Hydrogel Composites for Enhanced Water and Nutrient Efficiency in Soilless Cultivation

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. The Preparation of Wood Fiber–Hydrogel Composite (WF-Gel)

2.3. Plant Materials and Growth Conditions

2.4. Experimental Design and Treatments

2.5. Characterization of WF and WF-Gel

2.6. Physical and Chemical Properties of WF and WF-Gel Mixing with Peat as the Substrate

2.7. Water Retention Capacity

2.8. Growth Assessment of Plants

2.9. Plant Growth Measurement

2.10. Nutrient Characterization of Plants

2.11. Water-Use Efficiency

2.12. Statistical Analysis

3. Results and Discussion

3.1. Synthesis and Characterization of WF and WF-Gel

3.2. Characteristics of Peat Incorporated WF or WF-Gel as Growing Media

3.3. Water Retention Capacity of Peat Substrate Mixed with WF or WF-Gel

3.4. Chlorophyll Content and Relative Growth Rate

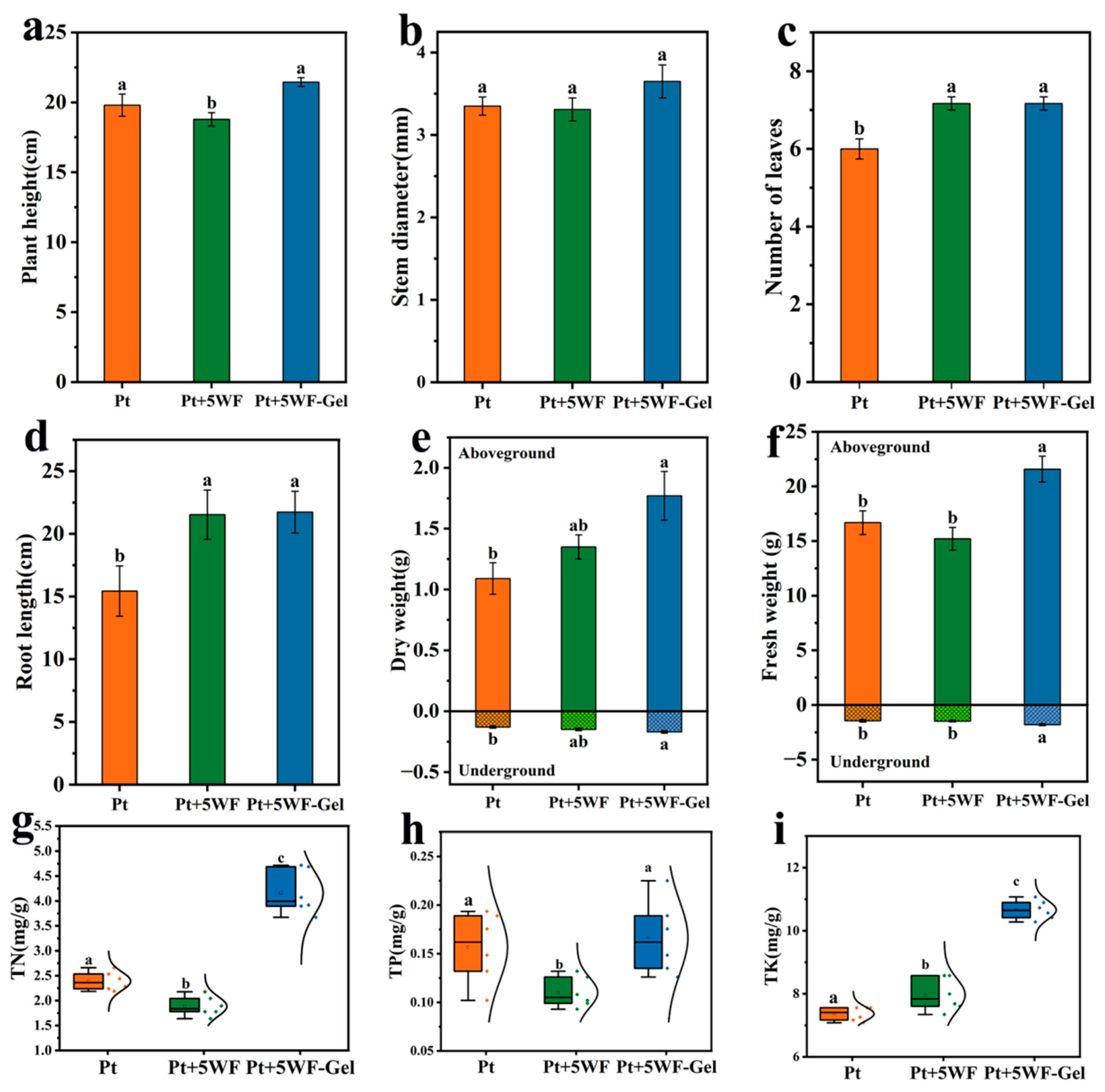

3.5. Plant Growth Index and Nutrient Content at Harvest

3.6. Irrigation Water-Use Efficiency

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gruda, N. Increasing Sustainability of Growing Media Constituents and Stand-Alone Substrates in Soilless Culture Systems. Agronomy 2019, 9, 298. [Google Scholar] [CrossRef]

- Savvas, D.; Gruda, N. Application of Soilless Culture Technologies in the Modern Greenhouse Industry–A Review. Eur. J. Hortic. Sci. 2018, 83, 280–293. [Google Scholar] [CrossRef]

- Dittrich, C.; Pecenka, R.; Løes, A.-K.; Cáceres, R.; Conroy, J.; Rayns, F.; Schmutz, U.; Kir, A.; Kruggel-Emden, H. Extrusion of Different Plants into Fibre for Peat Replacement in Growing Media: Adjustment of Parameters to Achieve Satisfactory Physical Fibre-Properties. Agronomy 2021, 11, 1185. [Google Scholar] [CrossRef]

- Gaudig, G. Sphagnum Growth and Its Perspectives for Sphagnum Farming. Ph.D. Thesis, University of Greifswald, Greifswald, Germany, 2020. [Google Scholar]

- Venkataramani, S.; Kafle, A.; Singh, M.; Singh, S.; Simpson, C.; Siebecker, M.G. Greenhouse Cultivation of Cucumber (Cucumis sativus L.) in Standard Soilless Media Amended with Biochar and Compost. HortScience 2023, 58, 1035–1044. [Google Scholar] [CrossRef]

- Zabaleta, R.; Sánchez, E.; Fabani, P.; Mazza, G.; Rodriguez, R. Almond Shell Biochar: Characterization and Application in Soilless Cultivation of Eruca Sativa. Biomass Convers. Biorefin. 2024, 14, 18183–18200. [Google Scholar] [CrossRef]

- Jackson, B.E. Challenges and Considerations of Using Wood Substrates: Physical Properties. Greenh. Grow. 2018, 11, 54–56. [Google Scholar]

- Jackson, B.E.; Bartley, P. Wood Substrates: The Plant’s Perspective. Grow. Talks 2017, 2, 54–56. [Google Scholar]

- Poleatewich, A.; Michaud, I.; Jackson, B.; Krause, M.; DeGenring, L. The Effect of Peat Moss Amended with Three Engineered Wood Substrate Components on Suppression of Damping-Off Caused by Rhizoctonia Solani. Agriculture 2022, 12, 2092. [Google Scholar] [CrossRef]

- Lahti, S. The Effects of Added Wood Fibre in Peat-Based Growing Medium on Petunia x Hybrida. Master’s Thesis, Yrkeshögskolan Novia, Vaasa, Finland, 2022. [Google Scholar]

- Woznicki, T.; Kusnierek, K.; Roos, U.M.; Andersen, S.; Zimmer, K.; Sønsteby, A. Exploration of Alternative Growing Media in Strawberry Production with Focus on Wood Fiber from Norway Spruce. In Proceedings of the III International Symposium on Growing Media, Composting and Substrate Analysis, Milan, Italy, 24–28 June 2019; pp. 15–22. [Google Scholar] [CrossRef]

- Kusnierek, K.; Heltoft, P.; Møllerhagen, P.J.; Woznicki, T. Hydroponic Potato Production in Wood Fiber for Food Security. npj Sci. Food 2023, 7, 24. [Google Scholar] [CrossRef]

- Čepulienė, R.; Butkevičienė, L.M.; Skinulienė, L.; Steponavičienė, V. Response of Cucumbers (Cucumis sativus L.) to Waste Wood Fiber Substrates and Additional Nitrogen Fertilization. Plants 2022, 11, 3464. [Google Scholar] [CrossRef]

- Harris, C. Evaluating Wood Fiber Soilless Substrates for Effects on Plant Performance and Nutrient Management in Container Crops. Master’s Thesis, University of New Hampshire, Durham, NH, USA, 2019. [Google Scholar]

- Komosa, A.; Piróg, J.; Kleiber, T. Changes of Macro and Micronutrients Contents in the Root Environment of Greenhouse Tomato Grown in Fiber Wood. J. Fruit Ornam. Plant Res. 2009, 70, 71–80. [Google Scholar] [CrossRef]

- Woznicki, T.; Jackson, B.E.; Sønsteby, A.; Kusnierek, K. Wood Fiber from Norway Spruce—A Stand-Alone Growing Medium for Hydroponic Strawberry Production. Horticulturae 2023, 9, 815. [Google Scholar] [CrossRef]

- Harris, C.N.; Dickson, R.W.; Fisher, P.R.; Jackson, B.E.; Poleatewich, A.M. Evaluating Peat Substrates Amended with Pine Wood Fiber for Nitrogen Immobilization and Effects on Plant Performance with Container-Grown Petunia. HortTechnology 2020, 30, 107–116. [Google Scholar] [CrossRef]

- Ma, L.; Chai, C.; Wu, W.; Qi, P.; Liu, X.; Hao, J. Hydrogels as the Plant Culture Substrates: A Review. Carbohydr. Polym. 2023, 305, 120544. [Google Scholar] [CrossRef]

- Ramli, R.A.; Lian, Y.M.; Nor, N.M.; Azman, N.I.Z. Synthesis, Characterization, and Morphology Study of Coco Peat-Grafted-Poly(Acrylic Acid)/NPK Slow Release Fertilizer Hydrogel. J. Polym. Res. 2019, 26, 266. [Google Scholar] [CrossRef]

- Wu, Y.; Brickler, C.; Li, S.; Chen, G. Synthesis of Microwave-Mediated Biochar-Hydrogel Composites for Enhanced Water Absorbency and Nitrogen Release. Polym. Test. 2021, 93, 106996. [Google Scholar] [CrossRef]

- Cao, L.; Li, N. Activated-Carbon-Filled Agarose Hydrogel as a Natural Medium for Seed Germination and Seedling Growth. Int. J. Biol. Macromol. 2021, 177, 383–391. [Google Scholar] [CrossRef]

- Tan, W.K.; Zhu, J.; Lim, J.Y.; Gao, Z.; Loh, C.S.; Li, J.; Ong, C.N. Use of Okara-Derived Hydrogel for Enhancing Growth of Plants by Minimizing Leaching and Locking Nutrients and Water in Growing Substrate. Ecol. Eng. 2021, 159, 106122. [Google Scholar] [CrossRef]

- Gessert, G. Measuring a Medium’s Air Space and Water Holding Capacity. Ornam. Northwest 1976, 1, 11–12. [Google Scholar]

- Zhang, D.; Peng, Q.; Yang, R.; Lin, W.; Wang, H.; Zhou, W.; Qi, Z.; Ouyang, L. Slight Carbonization as a New Approach to Obtain Peat Alternative. Ind. Crop. Prod. 2023, 202, 117041. [Google Scholar] [CrossRef]

- Shah, L.A.; Khan, M.; Javed, R.; Sayed, M.; Khan, M.S.; Khan, A.; Ullah, M. Superabsorbent Polymer Hydrogels with Good Thermal and Mechanical Properties for Removal of Selected Heavy Metal Ions. J. Clean. Prod. 2018, 201, 78–87. [Google Scholar] [CrossRef]

- Zhao, B.; Jiang, H.; Lin, Z.; Xu, S.; Xie, J.; Zhang, A. Preparation of Acrylamide/Acrylic Acid Cellulose Hydrogels for the Adsorption of Heavy Metal Ions. Carbohydr. Polym. 2019, 224, 115022. [Google Scholar] [CrossRef]

- Zheng, M.; Lian, F.; Zhu, Y.; Zhang, Y.; Liu, B.; Zhang, L.; Zheng, B. pH-Responsive Poly (Xanthan Gum-g-Acrylamide-g-Acrylic Acid) Hydrogel: Preparation, Characterization, and Application. Carbohydr. Polym. 2019, 210, 38–46. [Google Scholar] [CrossRef]

- Yi, C.; Niu, H.-Y.; Sui, L.; Zhu, J.-J.; Tian, Y.; Niu, C.-G.; Chen, Z.-L.; Wei, H.; Huang, D.-W. A Low-Cost Bio-Based Cellulose Composite Hydrogel with Cross-Linked Structures for Efficient Capture of Heavy Metal Ions. Sep. Purif. Technol. 2025, 358, 130213. [Google Scholar] [CrossRef]

- Mohd Amin, M.C.I.; Ahmad, N.; Pandey, M.; Jue Xin, C. Stimuli-Responsive Bacterial Cellulose-g-Poly(Acrylic Acid-Co-Acrylamide) Hydrogels for Oral Controlled Release Drug Delivery. Drug Dev. Ind. Pharm. 2014, 40, 1340–1349. [Google Scholar] [CrossRef]

- Carrillo, I.; Mendonça, R.T.; Ago, M.; Rojas, O.J. Comparative Study of Cellulosic Components Isolated from Different Eucalyptus Species. Cellulose 2018, 25, 1011–1029. [Google Scholar] [CrossRef]

- Zaharia, A.; Radu, A.-L.; Iancu, S.; Florea, A.-M.; Sandu, T.; Minca, I.; Fruth-Oprisan, V.; Teodorescu, M.; Sarbu, A.; Iordache, T.-V. Bacterial Cellulose-Poly(Acrylic Acid- Co-N, N ′-Methylene-Bis-Acrylamide) Interpenetrated Networks for the Controlled Release of Fertilizers. RSC Adv. 2018, 8, 17635–17644. [Google Scholar] [CrossRef]

- Mizell, A. Evaluation of Wood Fibers Derived from Different Tree Species and Processing Methods on Crop Growth and Microbial Activity in Soilless Substrates. Master’s Thesis, Louisiana State University, Baton Rouge, LA, USA, 2024. [Google Scholar]

- Das, D.; Bhattacharjee, S.; Bhaladhare, S. Preparation of Cellulose Hydrogels and Hydrogel Nanocomposites Reinforced by Crystalline Cellulose Nanofibers (CNFs) as a Water Reservoir for Agriculture Use. ACS Appl. Polym. Mater. 2023, 5, 2895–2904. [Google Scholar] [CrossRef]

- Qin, C.; Kan, X.; Xu, D.; Zhao, Y.; Qi, Y.; Wu, N.; Xu, W. Adjustable P(AM-Co-NIPAM)/Gelatin Hydrogel Soilless Cultivation Substrates for Soybean Seedling and Root Growth. Ind. Crop. Prod. 2025, 231, 121189. [Google Scholar] [CrossRef]

- Katiane, S.S.B.; Cleiton, G.S.B.; Guilherme, G.D.S.; Edilson, C. Effects of Hydrogel and Nitrogen Fertilization on the Production of Arugula in Successive Crops. Afr. J. Agric. Res. 2015, 10, 2601–2607. [Google Scholar] [CrossRef]

- Vandecasteele, B.; Muylle, H.; De Windt, I.; Van Acker, J.; Ameloot, N.; Moreaux, K.; Coucke, P.; Debode, J. Plant Fibers for Renewable Growing Media: Potential of Defibration, Acidification or Inoculation with Biocontrol Fungi to Reduce the N Drawdown and Plant Pathogens. J. Clean. Prod. 2018, 203, 1143–1154. [Google Scholar] [CrossRef]

- Greenwood, D.J.; Lemaire, G.; Gosse, G.; Cruz, P.; Draycott, A.; Neeteson, J.J. Decline in Percentage N of C3 and C4 Crops with Increasing Plant Mass. Ann. Bot. 1990, 66, 425–436. [Google Scholar] [CrossRef]

- Valenzuela, H. Optimizing the Nitrogen Use Efficiency in Vegetable Crops. Nitrogen 2024, 5, 106–143. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhu, J.; Song, X.; Wen, Y.; Zhu, C.; Li, J. Biomass-Based Single- and Double-Network Hydrogels Derived from Cellulose Microfiber and Chitosan for Potential Application as Plant Growing Substrate. Carbohydr. Polym. 2023, 319, 121170. [Google Scholar] [CrossRef]

- Schulker, B.A.; Jackson, B.E. Impact of Wood Fiber Substrate Additions on Water Capture through Surface and Subsurface Irrigation. In Proceedings of the XXXI International Horticultural Congress (IHC2022): International Symposium on Innovative Technologies and Production, Angers, France, 14–20 August 2022; pp. 597–604. [Google Scholar] [CrossRef]

- Michel, J.-C.; Durand, S.; Jackson, B.E.; Fonteno, W.C. Analyzing Rehydration Efficiency of Hydrophilic (Wood Fiber) vs. Potentially Hydrophobic (Peat) Substrates Using Different Irrigation Methods. In Proceedings of the II International Symposium on Growing Media, Soilless Cultivation, and Compost Utilization in Horticulture, Ghent, Belgium, 22–27 August 2021; pp. 343–350. [Google Scholar] [CrossRef]

- Durand, S.; Jackson, B.E.; Fonteno, W.C.; Michel, J.-C. The Use of Wood Fiber for Reducing Risks of Hydrophobicity in Peat-Based Substrates. Agronomy 2021, 11, 907. [Google Scholar] [CrossRef]

- Mori, Y. New Agro-Technology (Imec) by Hydrogel Membrane. React. Funct. Polym. 2013, 73, 936–938. [Google Scholar] [CrossRef]

| Growing Substrate Type | pH | EC µs/cm | BD g/cm3 | TP % | AFP % | WFP % | WHC % |

|---|---|---|---|---|---|---|---|

| Pt | 5.25 ±0.049 a | 493 ±4 b | 0.16 ±0.00 a | 98.64 ±1.65 a | 57.28 ±7.63 a | 41.36 ±8.91 b | 358.51 ±55.66 b |

| Pt+5WF | 5.11 ±0.025 b | 462 ±5 b | 0.16 ±0.00 a | 97.02 ±4.98 a | 52.36 ±3.04 a | 44.66 ±3.16 b | 379.15 ±19.73 b |

| Pt+5WF-Gel | 5.08 ±0.053 b | 928 ±11 a | 0.16 ±0.00 a | 99.15 ±10.73 a | 32.01 ±11.52 b | 67.14 ±0.83 a | 519.60 ±5.20 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Qu, Y.; Chen, L.; Mo, H.; Ji, C.; Brosse, N.; Mubarok, M.; Zhou, X.; Di, Y.; Liao, J. Facile Fabrication of Wood Fiber–Hydrogel Composites for Enhanced Water and Nutrient Efficiency in Soilless Cultivation. Materials 2025, 18, 5461. https://doi.org/10.3390/ma18235461

Yang Z, Qu Y, Chen L, Mo H, Ji C, Brosse N, Mubarok M, Zhou X, Di Y, Liao J. Facile Fabrication of Wood Fiber–Hydrogel Composites for Enhanced Water and Nutrient Efficiency in Soilless Cultivation. Materials. 2025; 18(23):5461. https://doi.org/10.3390/ma18235461

Chicago/Turabian StyleYang, Zhengyong, Yao Qu, Longqing Chen, Huishu Mo, Chunyu Ji, Nicolas Brosse, Mahdi Mubarok, Xiaojian Zhou, Yining Di, and Jingjing Liao. 2025. "Facile Fabrication of Wood Fiber–Hydrogel Composites for Enhanced Water and Nutrient Efficiency in Soilless Cultivation" Materials 18, no. 23: 5461. https://doi.org/10.3390/ma18235461

APA StyleYang, Z., Qu, Y., Chen, L., Mo, H., Ji, C., Brosse, N., Mubarok, M., Zhou, X., Di, Y., & Liao, J. (2025). Facile Fabrication of Wood Fiber–Hydrogel Composites for Enhanced Water and Nutrient Efficiency in Soilless Cultivation. Materials, 18(23), 5461. https://doi.org/10.3390/ma18235461