Study on the Structure and Antioxidant Properties of Seamless Knitted Fabrics with Antioxidant Fibers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Selection of Yarn Program

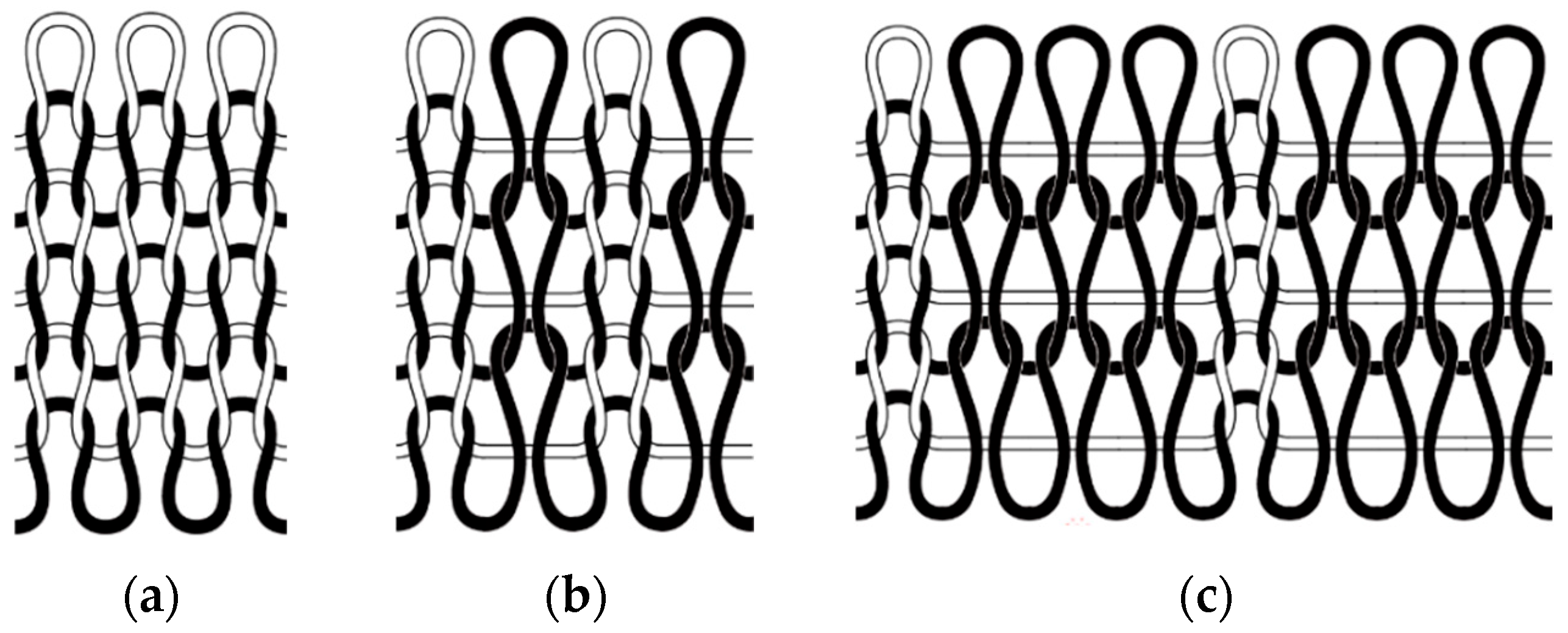

2.1.2. Fabric Structure Design

- (1)

- Weft flat knit

- (2)

- 1+1 false rib

- (3)

- 1+3 false rib

2.1.3. Establishment of Specimens

2.2. Experiments and Tests

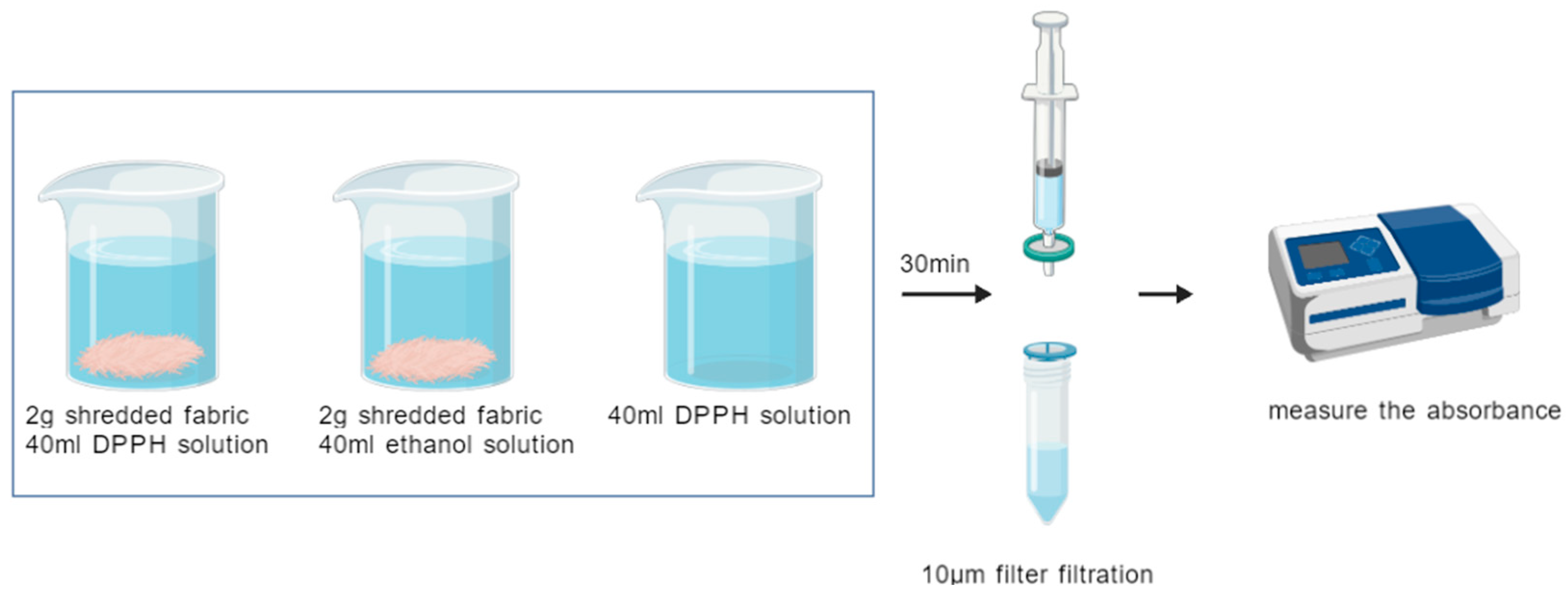

2.2.1. DPPH Radical Scavenging Rate Test Experiment

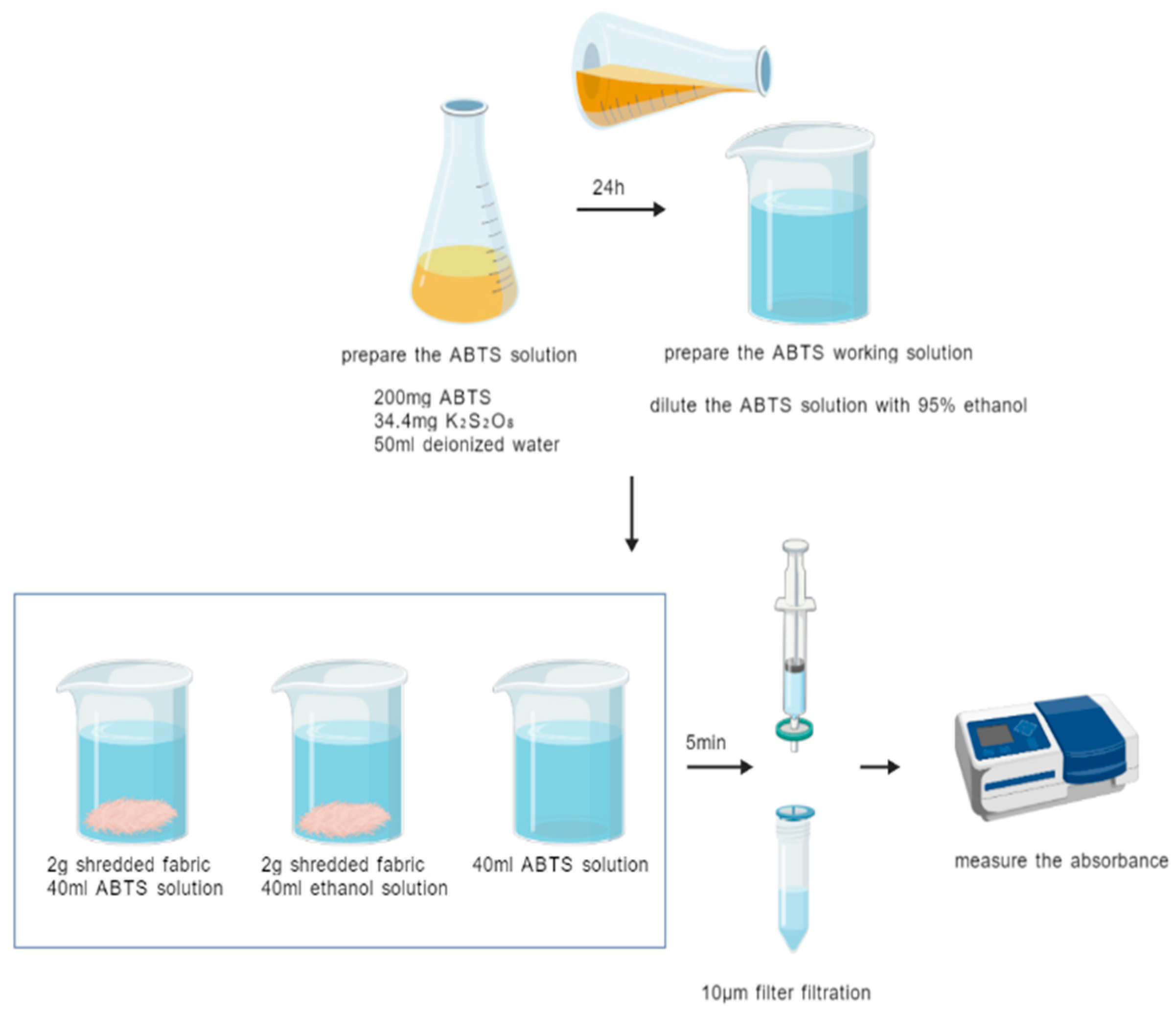

2.2.2. ABTS Radical Scavenging Rate Test Experiment

3. Results and Discussions

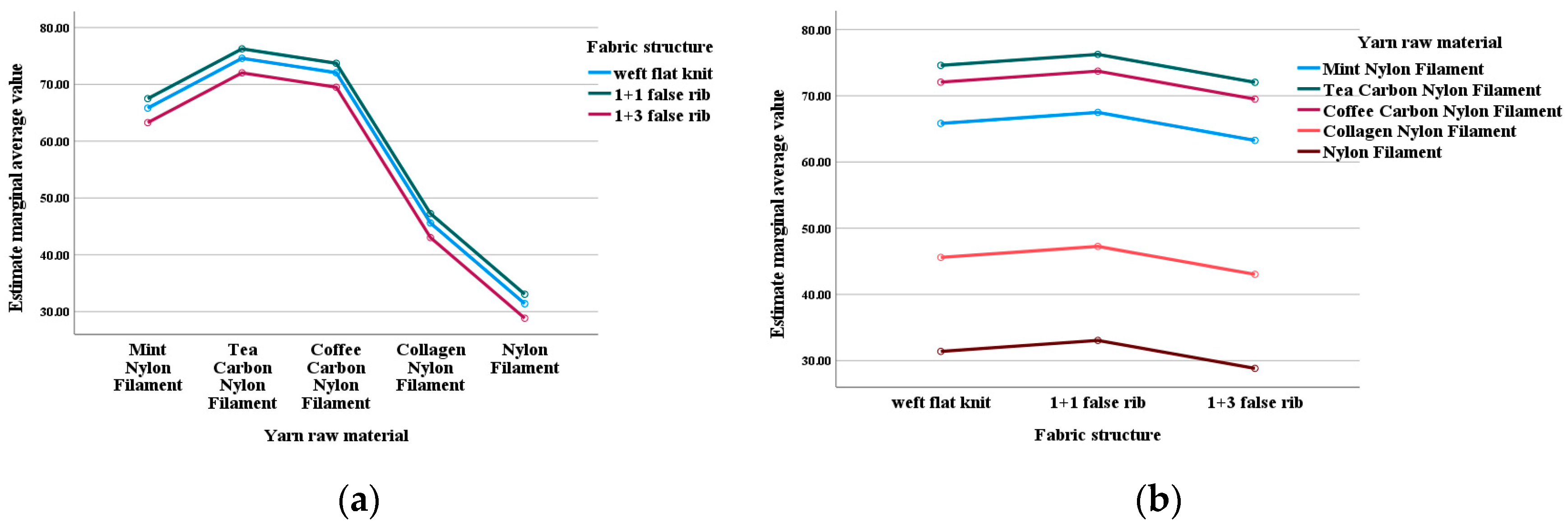

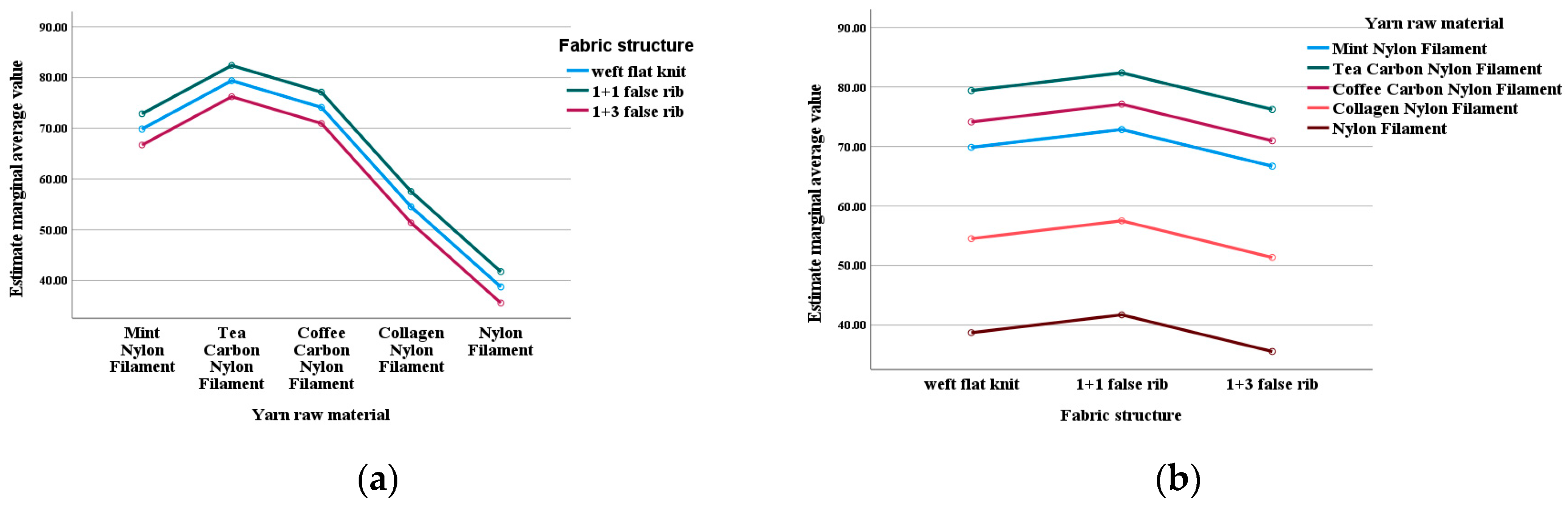

3.1. DPPH Radical Scavenging Rate Test Results

3.2. ABTS Radical Scavenging Rate Test Results

4. Conclusions

- (1)

- The DPPH and ABTS free radical scavenging rate results of 15 samples were analyzed. Both showed that, for yarn types, the free radical scavenging rates arranged from smallest to largest followed the order nylon filament < collagen nylon filament < mint nylon filament < coffee carbon nylon filament < tea carbon nylon filament, while for fabric structure, the free radical scavenging rates arranged from smallest to largest followed the order 1+3 false rib < weft flat knit < 1+1 false rib.

- (2)

- In the antioxidant performance tests of both DPPH radical scavenging experiments and ABTS radical scavenging, specimen #5 using tea carbon nylon filament as raw yarn material with a fabric structure of 1+1 false rib had the best antioxidant performance of all types. However, the antioxidant performance of specimen #15 with the 1+3 false rib structure using nylon filament as a coating was poor.

- (3)

- This study confirms that knitted fabrics made from tea carbon nylon yarn with a 1+1 false rib structure possess excellent antioxidant properties. These fabrics show great potential for subsequent applications. First, they could be used to develop high-end intimate apparel that combines comfort and antibacterial functions. Second, they are suitable for manufacturing healthy home textiles and baby–mother textiles. Third, they also have application prospects in industrial textiles such as medical protection. This work provides a new direction and material basis for the development of high-value functional textiles and the high-value utilization of tea resources.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.; Zhou, Q.; Rather, L.J.; Li, Q. Agricultural waste of Eriobotrya japonica L. (Loquat) seeds and flora leaves as source of natural dye and bio-mordant for colouration and bio-functional finishing of wool Textile. Ind. Crops Prod. 2021, 169, 113633. [Google Scholar] [CrossRef]

- Li, R.; Pan, X.; Wang, J.; Yang, J.; Zhang, J. Application and development of different kinds of antioxidants. Chem. Eng. Equip. 2020, 12, 251–252. [Google Scholar]

- Li, S.; Ma, Y.; Wang, Y.; Si, W.; Zhu, C.; Zhang, H. Research progress of antioxidant textiles. Dye. Finish. Technol. 2024, 46, 16–21. [Google Scholar]

- Wang, H.; Yin, X.; Xia, B.; Zheng, Q.; Cui, M. Protective Effect and Mechanism of Endogenous Antioxidant Metallothionein on Myocardial Damage Induced by Chronic Intermittent Hypoxia. Chin. J. Health Preserv. 2023, 41, 14–17. [Google Scholar]

- Zhu, H.Y.; He, Y.M.; Li, M.; Yang, L. Analysis of in vivo lipid peroxidation status on AUB in dysfunctional AUB and AUB in organic diseases. Heilongjiang Med. 2021, 34, 521–524. [Google Scholar]

- Zhang, J.; Gao, B.; Ye, B.; Sun, Z.; Qian, Z.; Yu, L.; Bi, Y.; Ma, L.; Ding, Y.; Du, Y.; et al. Mitochondrial—Targeted Delivery of Polyphenol—Mediated Antioxidases Complexes against Pyroptosis and Inflammatory Diseases. Adv. Mater. 2023, 35, e2208571. [Google Scholar] [CrossRef] [PubMed]

- Xian, K.; Luo, H.; Li, R.; Wang, H.; Zhang, J.; Wang, G.R. Extraction and Analysis of Antioxidant Activity of Menthol Essential Oil. Agric. Sci. Technol. Inf. 2023, 127–131. [Google Scholar]

- Lai, D.; Zhu, X.; Li, T.; Zhang, Q.; Peng, Q.H. Effect of Heating Methods on Nutritional Components and Antioxidant Activity of Purple Potato. Food Sci. 2023, 44, 245–251. [Google Scholar]

- Zhao, P.; Fang, J.; Zhao, Y.; Wang, Y.N.; Chen, X.; Cao, H.M. Dyeing and Functional Modification of Silk with Curcumin and Luteolin. Dye. Finish. 2024, 50, 24–28+54. [Google Scholar]

- Wang, Y. Study on Extraction of Tea Polyphenols from Green Tea by Pulsed Electric Field Combined with Ultrasonic Wave and Preparation of Instant Tea Powder. Master’s Thesis, South China University of Technology, Guangzhou, China, 2022. [Google Scholar]

- Lei, X.; Zhang, M.; Lin, H.; Wang, L.L.; Zheng, D.Y. Carbonylation Modification of Epigallocatechin, Its UV Absorption and Antioxidant Activity. J. Tea Sci. 2024, 44, 493–500. [Google Scholar]

- Ji, L. Production Practice of Coffee Carbon Odor-Removing Functional Weft-Knitted Fabrics. Knitt. Ind. 2022, 12, 20–22. [Google Scholar]

- Pan, C.; Shi, Y.; Luo, X.; Ye, T.S.; Huang, J.Y.; Jiang, T. Research Progress on the Role of Caffeic Acid and Its Derivatives in Diabetes and Its Complications. Cent. South Pharm. 2025, 23, 484–489. [Google Scholar]

- Hong, K.H. Effects of Tannin Mordanting on Coloring and Functionalities of Wool Fabrics Dyed with Spent Coffee Grounds. Fash. Text. 2018, 5, 33. [Google Scholar] [CrossRef]

- Li, W. Preparation and Application Research of High-Strength Collagen Fiber. Master’s thesis, South China University of Technology, Guangzhou, China, 2024. [Google Scholar]

- Hu, H.; Zhang, H.; Wang, J.; Wang, L.W.; Liu, Q. Application of Recombinant Collagen in Biomedicine. Prog. Biochem. Biophys. 2025, 52, 395–416. [Google Scholar]

- Wang, Q. Study on the Relationship between Structure and Properties of Seamless Knitted Fabrics of Protein Fibers for Autumn and Winter. Master’s Thesis, Zhejiang Sci-Tech University, Hangzhou, China, 2023. [Google Scholar]

- Mikučionienė, D.; Čiukas, R.; Mickevičienė, A. The influence of knitting structure on mechanical properties of weft knitted fabrics. Mater. Sci. 2010, 16, 221–225. [Google Scholar]

- Chen, W.; Jin, Z.; Chen, S.; Fang, C.; Zheng, C. Study on the Permeability and Absorption Performance of the Crotch Layer in Seamless Knitted Period Underwear. Materials 2024, 17, 1119. [Google Scholar] [CrossRef] [PubMed]

- Kodžoman, D.; Hladnik, A.; Čuden, A.P.; Čok, V. Assessment and semantic categorization of fabric visual texture preferences. Autex Res. J. 2023, 23, 279–291. [Google Scholar] [CrossRef]

- Chen, W.; Jin, Z.; Mao, L. Structure and Wear Comfort Performance of Aloe Vera Fiber Seamless Knitted Fabrics. Fash. Des. Eng. 2025, 4, 1–3. [Google Scholar]

- T/CCTA 20102-2023; Determination and Evaluation of Oxidation Resistance of Textiles by DPPH and ABTS Methods. China Cotton Textile Association: Beijing, China, 2023.

- Min, F.; Hu, Y.; Hu, D. Knowledge Understanding of Two-Factor Variance Analysis with Interaction in Probability and Statistics. Math. Commun. 2024, 19, 1–5. [Google Scholar]

- Wang, Q.; Lu, J.; Jin, Z.; Chen, K.; Zhao, M.; Sun, Y. Study on the Structure and Skin Moisturizing Properties of Hyaluronic Acid Viscose Fiber Seamless Knitted Fabric for Autumn and Winter. Materials 2022, 15, 1806. [Google Scholar] [CrossRef] [PubMed]

| Raw Yarn Materials | Fineness | Yarn Name | Supplier |

|---|---|---|---|

| Yarn | 7.78 tex (70 D/48 F) | Mint Nylon Filament | Shandong Rare Technology Co. (Jinan, China) |

| Tea Carbon Nylon Filament | Chinachem New Material Technology Co. (Xiamen, China) | ||

| Coffee Carbon Nylon Filament | Chinachem New Material Technology Co. (Xiamen, China) | ||

| Collagen Nylon Filament | Taicang Fangke Textile Co. (Suzhou, China) | ||

| Nylon Filament | Yiwu Huading Nylon Co. (Jinhua, China) |

| No. | Factor | |

|---|---|---|

| A (Raw Yarn Materials) | B (Fabric Microstructures) | |

| 1 | Mint Nylon Yarn | weft flat knit |

| 2 | Tea Carbon Nylon Yarn | 1+1 false rib |

| 3 | Coffee Carbon Nylon Yarn | 1+3 false rib |

| 4 | Collagen Nylon Yarn | --- |

| 5 | Nylon yarn | --- |

| Specimen No. | A (Raw Yarn Materials) | B (Fabric Microstructures) |

|---|---|---|

| #1 | Mint Nylon Yarn | weft flat knit |

| #2 | Mint Nylon Yarn | 1+1 false rib |

| #3 | Mint Nylon Yarn | 1+3 false rib |

| #4 | Tea Carbon Nylon Yarn | weft flat knit |

| #5 | Tea Carbon Nylon Yarn | 1+1 false rib |

| #6 | Tea Carbon Nylon Yarn | 1+3 false rib |

| #7 | Coffee Carbon Nylon Yarn | weft flat knit |

| #8 | Coffee Carbon Nylon Yarn | 1+1 false rib |

| #9 | Coffee Carbon Nylon Yarn | 1+3 false rib |

| #10 | Collagen Nylon Yarn | weft flat knit |

| #11 | Collagen Nylon Yarn | 1+1 false rib |

| #12 | Collagen Nylon Yarn | 1+3 false rib |

| #13 | Nylon Yarn | weft flat knit |

| #14 | Nylon yarn | 1+1 false rib |

| #15 | Nylon Yarn | 1+3 false rib |

| Specimen No. | DPPH Radical Scavenging Rate/% | Specimen No. | DPPH Radical Scavenging Rate/% |

|---|---|---|---|

| #1 | 64.6 | #9 | 68.1 |

| #2 | 68.9 | #10 | 45.2 |

| #3 | 63.1 | #11 | 43.0 |

| #4 | 75.0 | #12 | 47.7 |

| #5 | 79.9 | #13 | 30.7 |

| #6 | 68.0 | #14 | 32.8 |

| #7 | 74.0 | #15 | 29.8 |

| #8 | 73.2 |

| Dependent Variable: DPPH Radical Scavenging Rate | |||||

|---|---|---|---|---|---|

| Source | Class III Sum of Squares | Degrees of Freedom | Mean Square | F | Significance |

| Modified model | 4233.383 a | 6 | 705.564 | 69.895 | <0.001 |

| Intercept | 49,766.400 | 1 | 49,766.400 | 4929.970 | <0.001 |

| A (raw yarn material) | 4188.187 | 4 | 1047.047 | 103.723 | <0.001 |

| B (fabric microstructure) | 45.196 | 2 | 22.598 | 2.239 | 0.169 |

| Error | 80.757 | 8 | 10.095 | ||

| Total | 54,080.540 | 15 | |||

| Revised total | 4314.140 | 14 | |||

| Specimen No. | ABTS Radical Scavenging Rate/% | Specimen No. | ABTS Radical Scavenging Rate/% |

|---|---|---|---|

| #1 | 71.4 | #9 | 70.0 |

| #2 | 72.3 | #10 | 48.3 |

| #3 | 65.7 | #11 | 58.2 |

| #4 | 80.4 | #12 | 56.9 |

| #5 | 85.1 | #13 | 39.7 |

| #6 | 72.5 | #14 | 40.6 |

| #7 | 76.8 | #15 | 35.7 |

| #8 | 75.4 |

| Dependent Variable: ABTS Radical Scavenging Rate | |||||

|---|---|---|---|---|---|

| Source | Class III Sum of Squares | Degrees of Freedom | Mean Square | F | Significance |

| Modified model | 3395.072 a | 6 | 565.845 | 41.491 | <0.001 |

| Intercept | 60,040.067 | 1 | 60,040.067 | 4402.518 | <0.001 |

| A (raw yarn material) | 3300.187 | 4 | 825.047 | 60.498 | <0.001 |

| B (fabric microstructure) | 94.885 | 2 | 47.443 | 3.479 | 0.082 |

| Error | 109.101 | 8 | 13.638 | ||

| Total | 63,544.240 | 15 | |||

| Revised total | 3504.173 | 14 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, L.; Chang, L.; Shen, S.; Jin, Z.; Zhao, M. Study on the Structure and Antioxidant Properties of Seamless Knitted Fabrics with Antioxidant Fibers. Materials 2025, 18, 5446. https://doi.org/10.3390/ma18235446

Yan L, Chang L, Shen S, Jin Z, Zhao M. Study on the Structure and Antioxidant Properties of Seamless Knitted Fabrics with Antioxidant Fibers. Materials. 2025; 18(23):5446. https://doi.org/10.3390/ma18235446

Chicago/Turabian StyleYan, Lei, Lu Chang, Shuhan Shen, Zimin Jin, and Mingtao Zhao. 2025. "Study on the Structure and Antioxidant Properties of Seamless Knitted Fabrics with Antioxidant Fibers" Materials 18, no. 23: 5446. https://doi.org/10.3390/ma18235446

APA StyleYan, L., Chang, L., Shen, S., Jin, Z., & Zhao, M. (2025). Study on the Structure and Antioxidant Properties of Seamless Knitted Fabrics with Antioxidant Fibers. Materials, 18(23), 5446. https://doi.org/10.3390/ma18235446