Quantitative Assessment of Concrete Surface Topography: Effects of Mechanical Treatment and Measurement Resolution

Highlights

- Surface preparation strongly alters concrete surface morphology.

- Aggressive treatments increase roughness; moderate treatments smooth surfaces.

- The measurement scale affects parameter values; coarser scales reduce detail.

- Some parameters are robust to scale, suitable for comparative studies.

- Accurate surface characterization requires considering both treatment and scale.

- The findings guide a reproducible evaluation of concrete surfaces in engineering research.

Abstract

1. Introduction

2. Materials and Methods

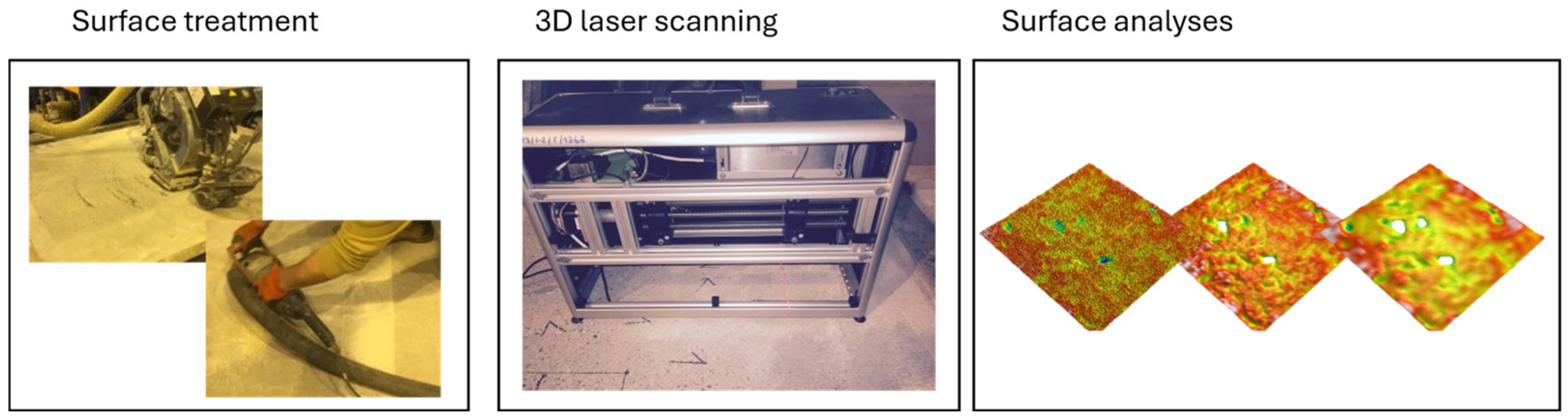

2.1. Three-Dimensional Laser Scanning

2.2. Materials

2.3. Mechanical Treatment of Samples

2.4. Data Acquisition and Analysis

2.5. Description of Selected Analyzed Morphological Parameters

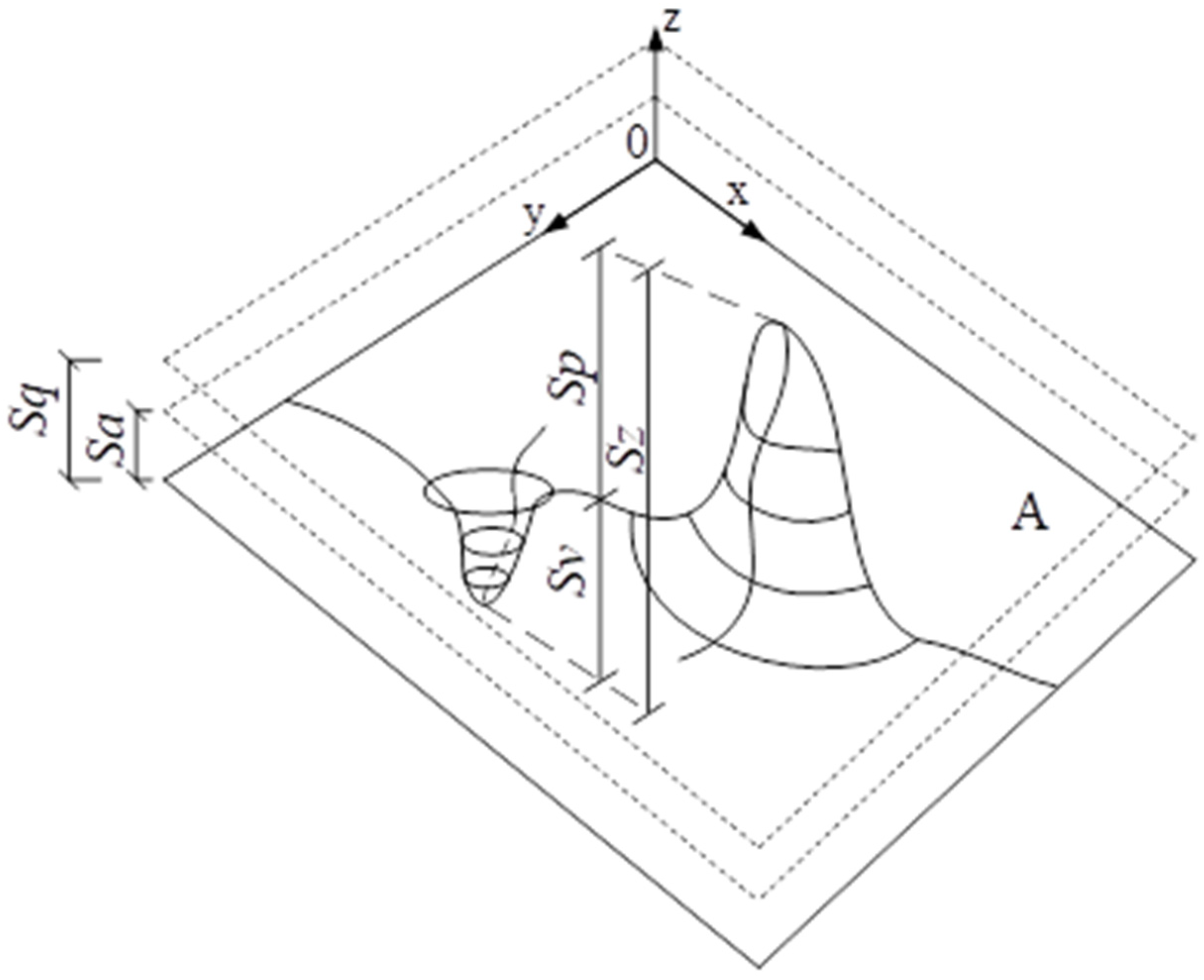

2.5.1. Height Parameters

2.5.2. Hybrid Parameters

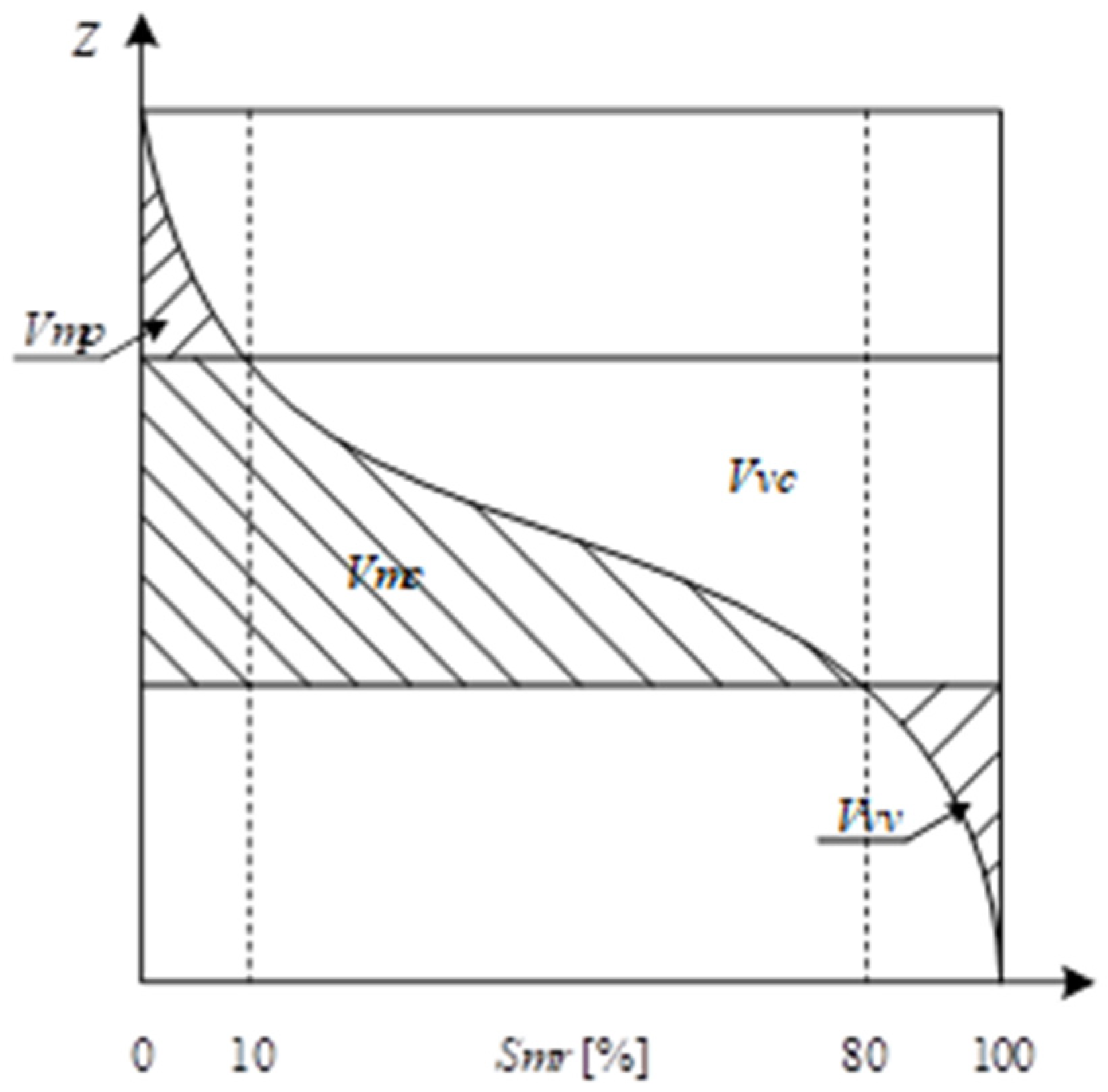

2.5.3. Volume Parameters

3. Results

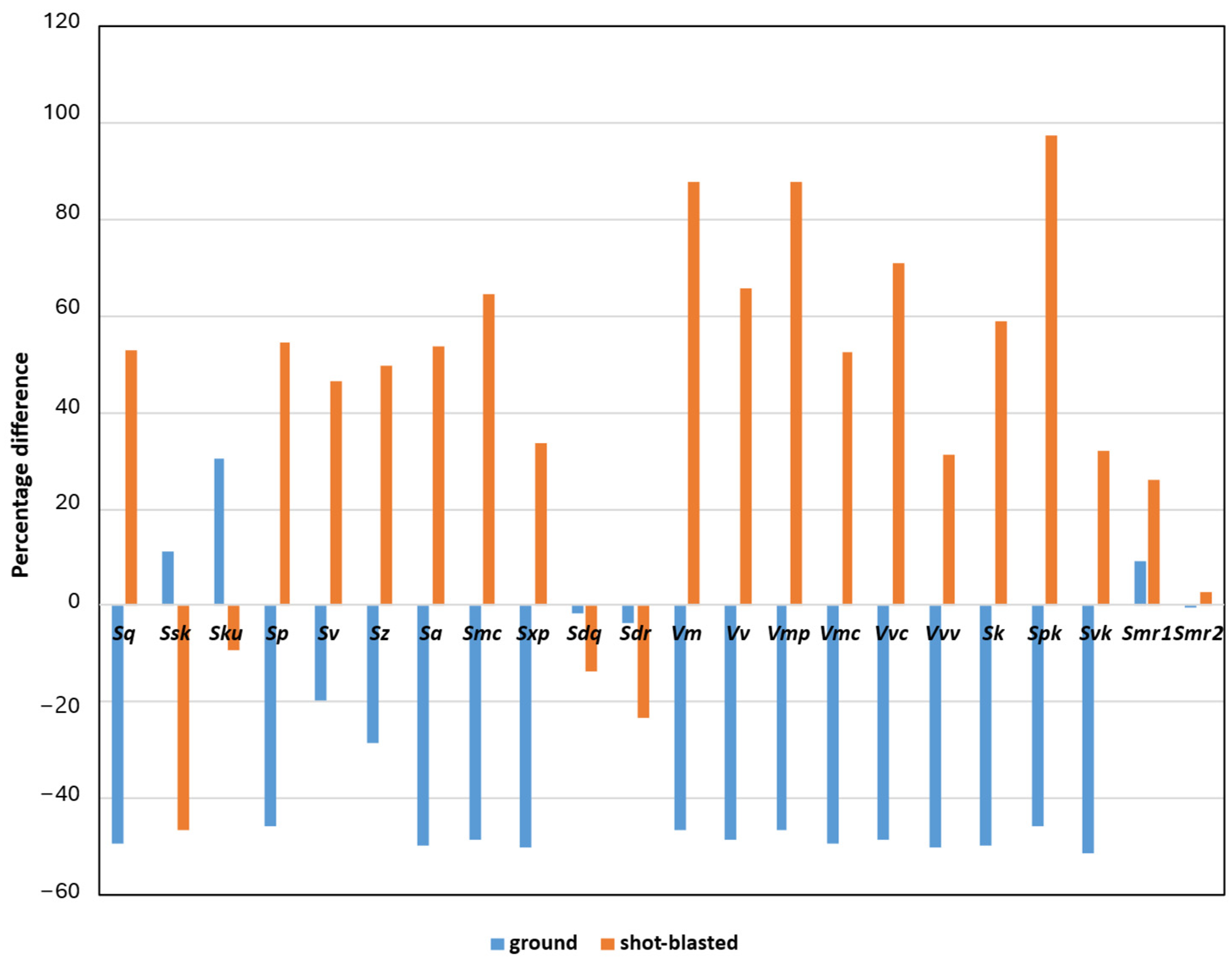

3.1. The Influence of the Surface Treatment Method on Morphological Parameters

3.2. The Scale Effect on Morphological Parameters

4. Discussion

5. Conclusions

- This study demonstrated that the method of surface preparation exerts a dominant effect on the morphological parameters of concrete surfaces. Grinding significantly reduces amplitude- and volume-related parameters, producing smoother and more leveled surfaces with lower roughness and peak-to-valley values, whereas shot blasting substantially increases these parameters, generating rougher surfaces with enhanced micro-geometric features. This confirms that mechanical treatment can effectively tailor surface characteristics for specific functional or adhesive requirements.

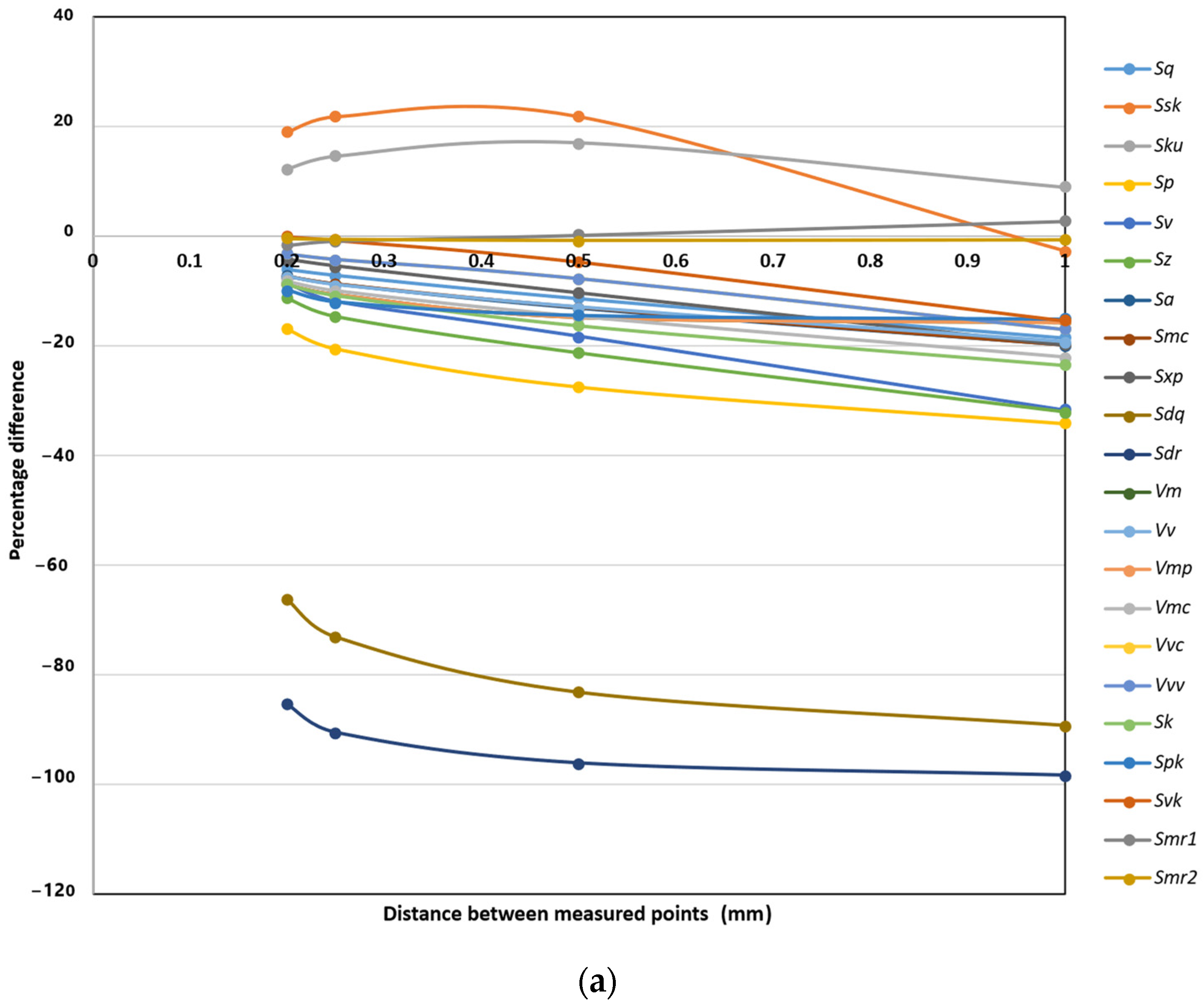

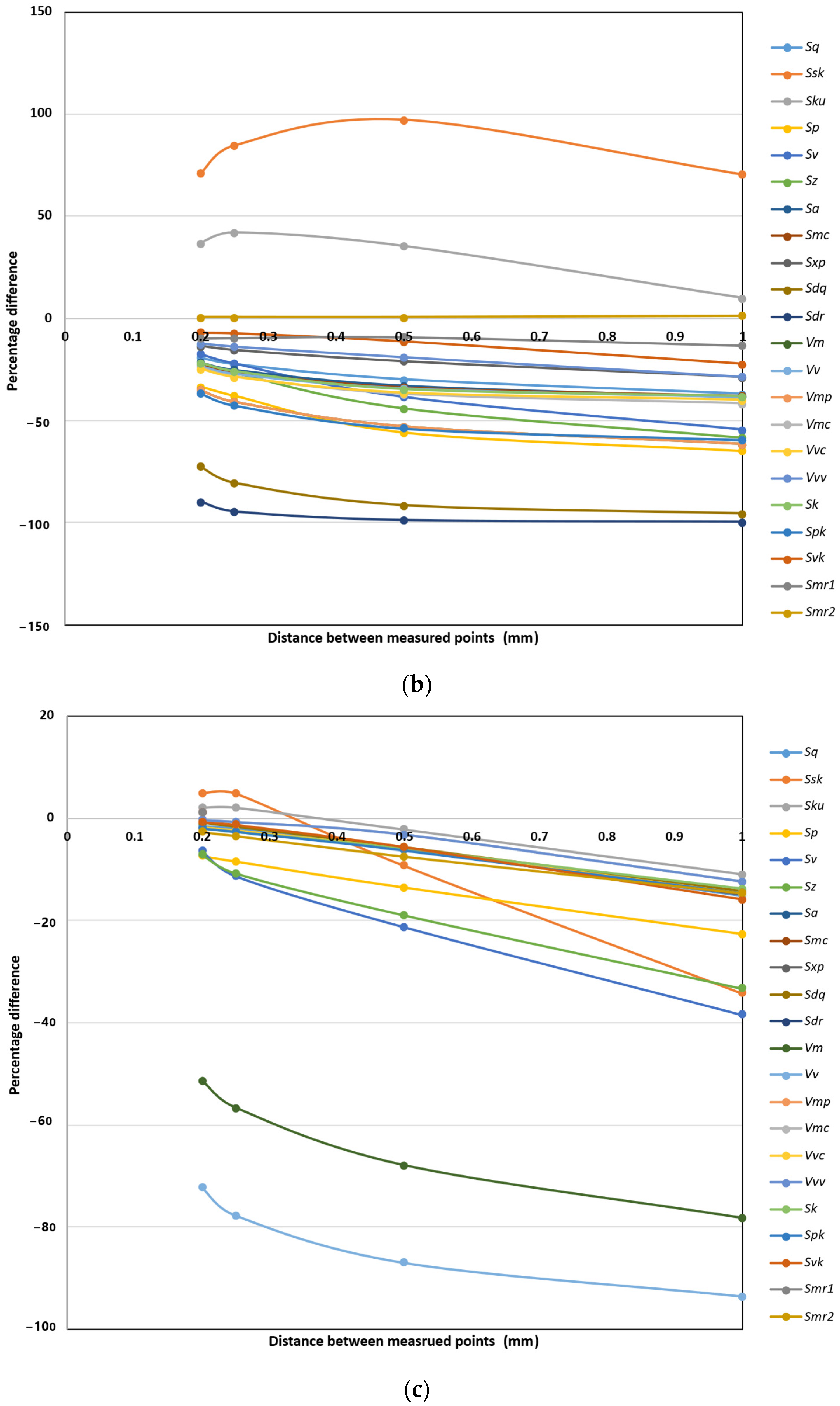

- Measurement resolution also significantly influences the calculated morphological parameters. As the measurement interval increases, most parameters systematically decrease due to the loss of fine surface details at coarser resolutions. Parameters related to surface slope and developed area (Sdq, Sdr) are highly scale-sensitive, showing reductions exceeding 80–90%, whereas Ssk, Sku, Smr1, and Smr2 remain relatively stable (<5% variation), indicating their reliability for comparative assessments. Ground surfaces are the most sensitive to scale changes, while patched and shot-blasted surfaces show more stable responses.

- The accurate characterization of concrete surface morphology requires consistent surface preparation combined with controlled measurement resolution. This highlights the importance of mechanically controlled surface treatments to achieve reproducible surfaces, which are critical for functional performance, including adhesion, friction, and bonding.

- From a practical engineering perspective, the findings suggest that mechanical treatment methods should be selected and standardized according to the desired surface properties, and measurement protocols should account for scale effects to ensure reliable quality control and performance evaluation. In layered systems it is important to also take into account the type of the material that is connected to the concrete substrate, either concrete or mortar overlays of epoxy coating.

- Future research should focus on developing multi-scale assessment protocols integrating micro- and macro-scale surface features and correlating morphological parameters with performance metrics to optimize concrete surface treatments in both laboratory and field applications, thereby enhancing both scientific understanding and practical implementation.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sadowski, Ł.; Hoła, J.; Czarnecki, L.; Mathia, T.G. New paradigm in the metrology of concrete surface morphology: Methods, parameters and applications. Measurement 2020, 165, 108497. [Google Scholar] [CrossRef]

- Bissonnette, B.; Courard, L.; Garbacz, A. Concrete Surface Engineering; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Courard, L.; Piotrowski, T.; Garbacz, A. Near-to-surface properties affecting bond strength in concrete repair. Cem. Concr. Compos. 2014, 46, 73–80. [Google Scholar] [CrossRef]

- Garbacz, A.; Górka, M.; Courard, L. Effect of concrete surface treatment on adhesion in repair systems. Mag. Concr. Res. 2005, 57, 49–60. [Google Scholar] [CrossRef]

- Leach, R. (Ed.) Characterisation of Areal Surface Texture, 2nd ed.; Springer: Cham, Switzerland, 2024. [Google Scholar] [CrossRef]

- Sadowski, Ł.; Mathia, T.G. The metrology of ground concrete surfaces morphology with 3D laser scanner. Manag. Prod. Eng. Rev. 2015, 6, 42–50. [Google Scholar] [CrossRef]

- Sadowski, Ł.; Stefaniuk, D. The effect of surface treatment on the microstructure of the skin of concrete. Appl. Surf. Sci. 2018, 427, 934–941. [Google Scholar] [CrossRef]

- Sadowski, Ł.; Mathia, T.G. Multi-scale metrology of concrete surface morphology: Fundamentals and specificity. Constr. Build. Mater. 2016, 113, 613–621. [Google Scholar] [CrossRef]

- Majchrowski, R.; Grzelka, M.; Wieczorowski, M.; Sadowski, Ł.; Gapiński, B. Large area concrete surface topography measurements using optical 3D scanner. Metrol. Meas. Syst. 2015, 22, 565–576. [Google Scholar] [CrossRef]

- Raposo, J.M.; Cavaco, E.; Costa Neves, L.; Júlio, E. A novel roughness parameter for more precise estimation of the shear strength of concrete-to-concrete interfaces. Constr. Build. Mater. 2024, 410, 134146. [Google Scholar] [CrossRef]

- Nguyen, Q.T.; Sağıroğlu, S.; Livaoğlu, R. Effects of concrete-to-concrete surface treatment methods on the bending behavior of RC buildings: A numerical investigation. Structures 2025, 80, 110099. [Google Scholar] [CrossRef]

- Horszczaruk, E.; Brzozowski, P. Adhesion of underwater repair concrete to vertical surfaces. Case Stud. Constr. Mater. 2025, 22, e04238. [Google Scholar] [CrossRef]

- Jeyakaran, T.; Pornsiri, N.; Saengsoy, W.; Tangtermsirikul, S. Surface treatments to control concrete deterioration caused by iron sulfide-bearing aggregates. Constr. Build. Mater. 2024, 416, 135189. [Google Scholar] [CrossRef]

- Gharieb, M.; Nishikawa, T. Development of roughness prediction models for Laos national road network. CivilEng 2021, 2, 158–173. [Google Scholar] [CrossRef]

- Chen, S.-L.; Lin, C.-H.; Tang, C.-W.; Chu, L.-P.; Cheng, C.-K. Research on the international roughness index threshold of road rehabilitation in metropolitan areas: A case study in Taipei City. Sustainability 2020, 12, 10536. [Google Scholar] [CrossRef]

- Yin, Y.; Fan, Y. Influence of roughness on shear bonding performance of CFRP–concrete interface. Materials 2018, 11, 1875. [Google Scholar] [CrossRef] [PubMed]

- EN 1992-1-1:2004+A1:2014; Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings. European Committee for Standardization (CEN): Brussels, Belgium, 2014.

- International Federation for Structural Concrete. Model Code 2010—Final Draft; fib Bulletin 66; Fédération Internationale du Béton (fib): Lausanne, Switzerland, 2012; Volume 2. [Google Scholar]

- ISO 25178-2:2012; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2012.

- Javidmehr, S.; Empelmann, M. Shear bond between ultra-high-performance fibre reinforced concrete overlays and normal strength concrete substrates. Sustainability 2021, 13, 8229. [Google Scholar] [CrossRef]

- Zeng, W.; Wang, W.; Wang, Q.; Li, M.; Zhang, L.; Tong, Y. Effect of macro fibers on the permeability and crack surface topography of layered fiber reinforced concrete. Materials 2024, 17, 1733. [Google Scholar] [CrossRef]

- Podulka, P.; Kulisz, M.; Antosz, K. Evaluation of high-frequency measurement errors from turned surface topography data using machine learning methods. Materials 2024, 17, 1456. [Google Scholar] [CrossRef]

- Brown, C.A.; Johnsen, W.A.; Hult, K.M. Scale-sensitivity, fractal analysis and simulations. Int. J. Mach. Tools Manuf. 1998, 38, 633–637. [Google Scholar] [CrossRef]

- Santos, P.M.D.; Júlio, E.N.B.S. A state-of-the-art review on roughness quantification methods for concrete surfaces. Constr. Build. Mater. 2013, 38, 912–923. [Google Scholar] [CrossRef]

- Salehi, M.; Noordermeer, J.W.M.; Reuvekamp, L.A.E.M.; Blume, A. Characterization of counter-surface substrates for a laboratory abrasion tester (LAT100) compared with asphalt and concrete to predict car tire performance. Lubricants 2022, 10, 8. [Google Scholar] [CrossRef]

- Tian, J.; Li, R.; Wu, T.; Zhang, M.; Xia, Y.; Huang, J. Design of a concrete shear device and investigation of the shear performance of new-to-old concrete interfaces. Materials 2025, 18, 4164. [Google Scholar] [CrossRef]

- Guo, F.; Zhang, J.; Pei, J.; He, H.; Yao, T.; Wang, D. Impact of macrotexture and microtexture on the skid resistance of asphalt pavement using three-dimensional (3D) reconstruction and printing technology. Materials 2025, 18, 2597. [Google Scholar] [CrossRef]

- Kozubal, J.; Wróblewski, R.; Muszyński, Z.; Wyjadłowski, M.; Stróżyk, J. Non-deterministic assessment of surface roughness as bond strength parameters between concrete layers cast at different ages. Materials 2020, 13, 2542. [Google Scholar] [CrossRef] [PubMed]

- Hoła, J.; Sadowski, Ł.; Reiner, J.; Stach, S. Usefulness of 3D surface roughness parameters for nondestructive evaluation of pull-off adhesion of concrete layers. Constr. Build. Mater. 2015, 84, 111–120. [Google Scholar] [CrossRef]

- Reiner, J.; Stankiewicz, M. Evaluation of the predictive segmentation algorithm for the laser triangulation method. Metrol. Meas. Syst. 2011, 18, 667–678. [Google Scholar] [CrossRef]

- Niemczewska-Wójcik, M.; Mańkowska-Snopczyńska, A.; Piekoszewski, W. The investigation of wear tracks with the use of noncontact measurement methods. Arch. Civ. Mech. Eng. 2013, 13, 158–167. [Google Scholar] [CrossRef]

- Stout, K.J. Development of Methods for the Characterisation of Roughness in Three Dimensions; Penton Press: London, UK, 2000. [Google Scholar]

- Farbák, M.; Vavruš, M.; Koteš, P.; Adamczak-Bugno, A. Shear analysis of “concrete-to-concrete” contact as an important parameter for strengthening concrete structures. Buildings 2025, 15, 3889. [Google Scholar] [CrossRef]

- Alhallaq, A.F.; Tayeh, B.A.; Shihada, S. Investigation of the bond strength between existing concrete substrate and UHPC as a repair material. Int. J. Eng. Adv. Technol. 2017, 6, 210–217. [Google Scholar]

- Zhang, B.; Yu, J.; Chen, W.; Liu, H.; Li, H.; Guo, H. Experimental study on bond performance of NC–UHPC interfaces with different roughness and substrate strength. Materials 2023, 16, 2708. [Google Scholar] [CrossRef]

- Czarnecki, S.; Sadowski, Ł.; Hoła, J. Artificial neural networks for non-destructive identification of the interlayer bonding between repair overlay and concrete substrate. Adv. Eng. Softw. 2020, 141, 102769. [Google Scholar] [CrossRef]

- Wyjadłowski, M.; Muszyński, Z.; Kujawa, P. Application of laser scanning to assess the roughness of the diaphragm wall for the estimation of earth pressure. Sensors 2021, 21, 7275. [Google Scholar] [CrossRef]

| Symbol of the Parameter | Patched | Ground | Shot-Blasted |

|---|---|---|---|

| Sq [mm] | 0.242 ± 0.053 | 0.122 ± 0.012 | 0.370 ± 0.056 |

| Ssk [-] | −0.790 ± 0.233 | −0.878 ± 0.387 | −0.423 ± 0.159 |

| Sku [-] | 5.373 ± 0.303 | 7.013 ± 3.398 | 4.867 ± 0.692 |

| Sp [mm] | 0.839 ± 0.174 | 0.455 ± 0.042 | 1.297 ± 0.131 |

| Sv [mm] | 1.617 ± 0.209 | 1.296 ± 0.690 | 2.367 ± 0.069 |

| Sz [mm] | 2.453 ± 0.293 | 1.750 ± 0.729 | 3.670 ± 0.135 |

| Sa [mm] | 0.182 ± 0.040 | 0.092 ± 0.007 | 0.280 ± 0.040 |

| Smc [mm] | 0.273 ± 0.050 | 0.140 ± 0.011 | 0.450 ± 0.060 |

| Sxp [mm] | 0.573 ± 0.162 | 0.285 ± 0.042 | 0.766 ± 0.175 |

| Sdq [-] | 1.093 ± 0.009 | 1.073 ± 0.606 | 0.943 ± 0.003 |

| Sdr [%] | 42.700 ± 0.497 | 41.067 ± 0.694 | 32.767 ± 0.125 |

| Vm [mm3/mm2] | 0.010 ± 0.003 | 0.005 ± 0.000 | 0.019 ± 0.002 |

| Vv [mm3/mm2] | 0.283 ± 0.052 | 0.145 ± 0.011 | 0.469 ± 0.063 |

| Vmp [mm3/mm2] | 0.010 ± 0.003 | 0.005 ± 0.000 | 0.019 ± 0.002 |

| Vmc [mm3/mm2] | 0.197 ± 0.044 | 0.100 ± 0.006 | 0.301 ± 0.038 |

| Vvc [mm3/mm2] | 0.246 ± 0.042 | 0.127 ± 0.008 | 0.420 ± 0.051 |

| Vvv [mm3/mm2] | 0.037 ± 0.011 | 0.018 ± 0.003 | 0.049 ± 0.011 |

| Sk [mm] | 0.524 ± 0.104 | 0.262 ± 0.011 | 0.834 ± 0.101 |

| Spk [mm] | 0.193 ± 0.065 | 0.105 ± 0.003 | 0.381 ± 0.047 |

| Svk [mm] | 0.377 ± 0.106 | 0.183 ± 0.035 | 0.497 ± 0.134 |

| Smr1 [%] | 9.000 ± 2.054 | 9.810 ± 0.417 | 11.333 ± 0.378 |

| Smr2 [%] | 86.900 ± 1.738 | 86.367 ± 0.939 | 89.167 ± 0.918 |

| Authors | Purposes | Used parameters and treatment methods | Advantages and disadvantages |

|---|---|---|---|

| Javidmehr and Empelmann [20] | Increase the bonding between the concrete substrate and UHPC | Sz, Sp, Sv, Sdr; treatment methods: brushing, sand blasting, water jetting, grooving | The usage of a few parameters to describe the surface is simple and more advanced than using just 2D parameters, but it is not well corelated with bonding strength |

| Farbak et al. [33] | Increase the bonding between various concretes | Coefficient of cohesion obtained by evaluation based on EN 1992-1-1 procedure and experimental tests; treatment methods: texturing with different curing conditions | The study proved that the obtained experimental values of the coefficients of cohesion are much higher (even 10 times) than assessed according to standards |

| AlHallaq et al. [34] | Investigating the bonding strength between the concrete substrate and the UHPC repair overlay | Ra, Rz; treatment methods: as-cast, wire brush, scarifying, scabbling | A very simple method of testing; however the correlations between parameters are not sufficient and are fully dependent on the selection of the profile tested |

| Zhang et al. [35] | Investigation of the bonding strength between the concrete substrate and UHPC | Ra, Rq; treatment method: texturing | Profile-based parameters are simple to evaluate and present some trends, but they are not well correlated with pull-off strength |

| Czarnecki et al. [36] | Investigating the bonding in repair concrete elements | Spk, Sk, S10z, Sda, S5v, Sha, Spd, Shv, S5p, Sdv, Sz, Vm, Sq, Sv, Sa, Vmp, Vv, Smc, Vmc, Vvc, Sxp, Vvv, Sp, Svk, Spc, Smr1, Str, and others obtained using acoustic testing combined with neural network algorithms; treatment methods: shot blasting, patching, and grinding | A very precise method of evaluating bonding; however it requires a lot of effort during the process (3 methods of testing and a prepared algorithm) |

| Wyjadłowski et al. [37] | Assessing the roughness of the diaphragm wall for the estimation of earth pressure | Sq, Ssk, Sku, Sz, Sa, Sdr, Vmp, Vmc, Vvc, Vvv | A very precise description of the roughness of the wall but requires special equipment |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Czarnecki, S. Quantitative Assessment of Concrete Surface Topography: Effects of Mechanical Treatment and Measurement Resolution. Materials 2025, 18, 5320. https://doi.org/10.3390/ma18235320

Czarnecki S. Quantitative Assessment of Concrete Surface Topography: Effects of Mechanical Treatment and Measurement Resolution. Materials. 2025; 18(23):5320. https://doi.org/10.3390/ma18235320

Chicago/Turabian StyleCzarnecki, Slawomir. 2025. "Quantitative Assessment of Concrete Surface Topography: Effects of Mechanical Treatment and Measurement Resolution" Materials 18, no. 23: 5320. https://doi.org/10.3390/ma18235320

APA StyleCzarnecki, S. (2025). Quantitative Assessment of Concrete Surface Topography: Effects of Mechanical Treatment and Measurement Resolution. Materials, 18(23), 5320. https://doi.org/10.3390/ma18235320