Experimental Study on the Performance Evaluation of Hybrid Liner to Prevent the Migration of Oil Pollutant

Abstract

1. Introduction

2. Materials and Methods

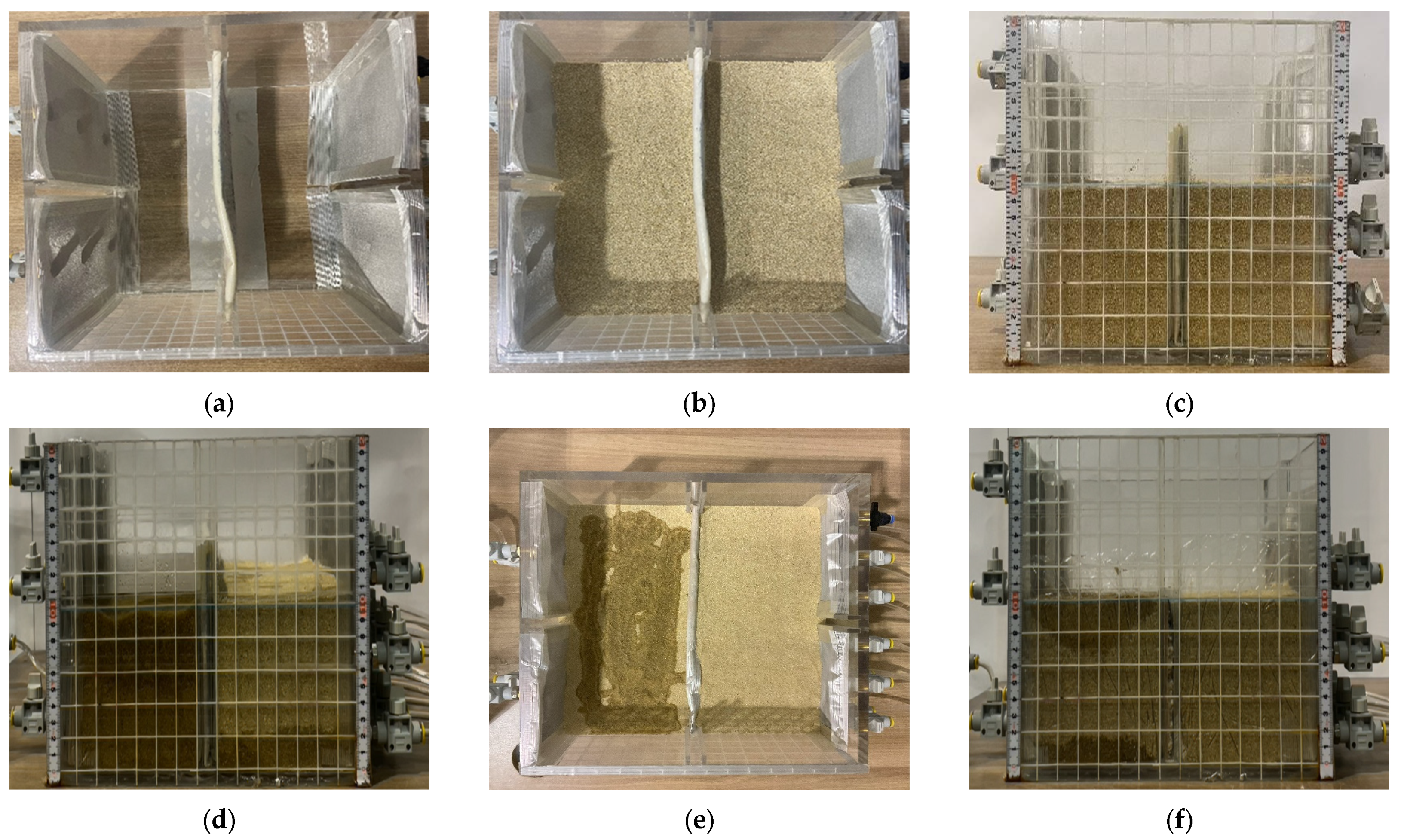

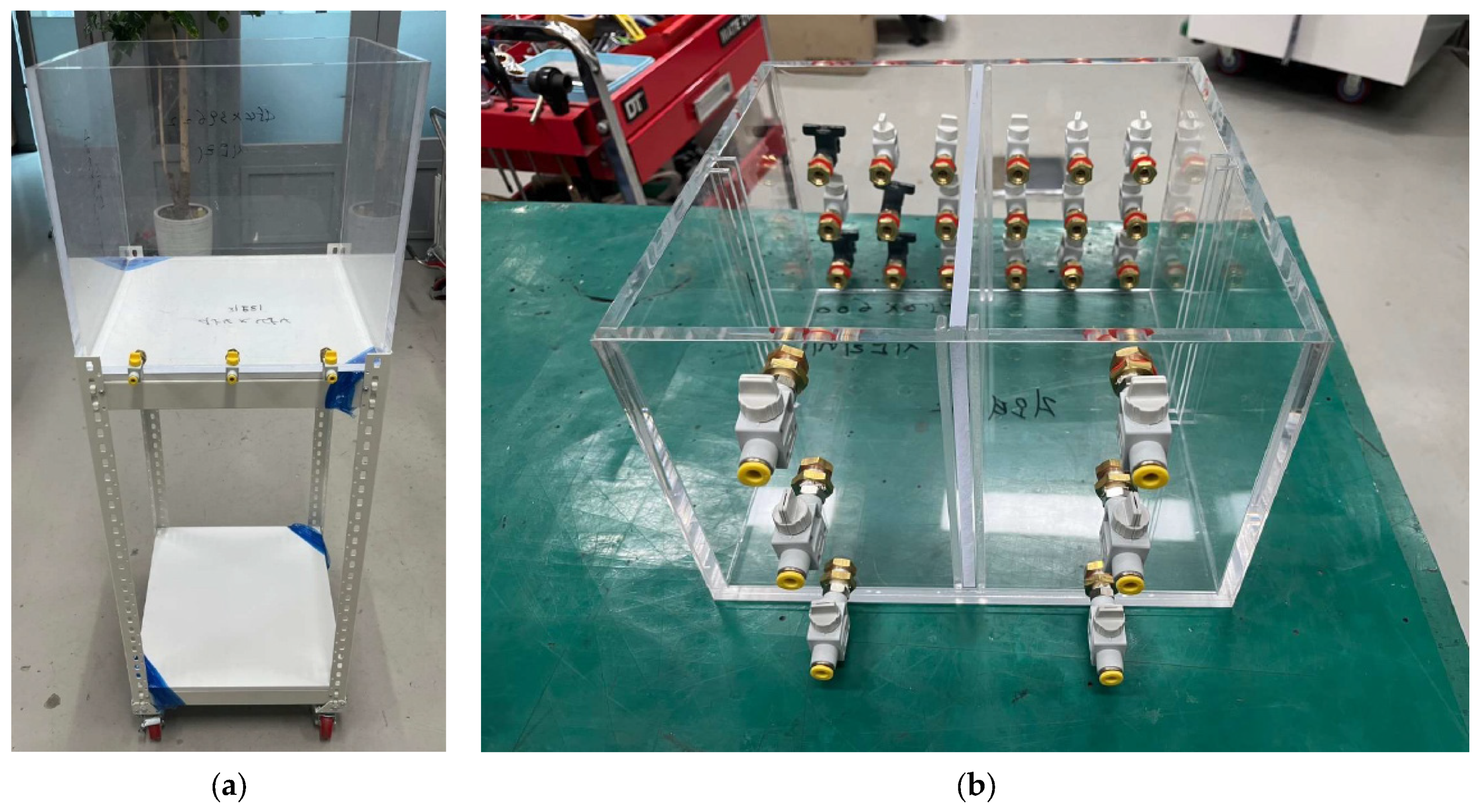

2.1. Experiment Equipment and Procedure

- Liner installation: hybrid liner was installed in alignment with the guide stick located at the center of the soil box. To ensure stable boundary conditions during the experiment, the perimeter of the liner was sealed to the acrylic wall of the soil box using a silicone gun. The sealant was applied uniformly along the edges to eliminate potential side-flow paths and to ensure that all flow passed through the soil and the reactive liner.

- Formation of model ground for each layer: soil was placed in five layers of equal relative density (35%). The model ground was composed of pure standard sand or silty sand containing 95% standard sand and 5% fine soil. The characteristics of the two soils according to USCS classification are shown in Table 1. The addition of 5% fine soil was intended to simulate the presence of fine particles commonly observed in natural ground, and to increase capillary and slight cohesive effects between sand particles, thereby reproducing realistic permeability behavior under groundwater flow.

- Flow occurrence and groundwater stabilization: after installing the hybrid liner and preparing the model ground, groundwater was introduced until stabilization of flow in the model ground was confirmed. The groundwater level was maintained at 30% of the model ground height to ensure a steady flow velocity.

- Spill out points and distance ratio: spill out points were selected on the ground surface at horizontal offsets from the liner of 0.85D, 0.50D, and 0.15D (D = 0.14 m is the distance between the liner and the inlet side wall of the soil box). Here, the distance ratio denotes the normalized horizontal offset of a spill point from the liner, 0.85D represents the farthest location (near the wall), 0.50D the intermediate, and 0.15D the nearest location relative to the liner.

- TPH spill out simulation: a fixed volume of 900 mL of pure diesel was applied after groundwater flow had stabilized. This amount corresponds to approximately 10% of the pore volume of the model ground (30 cm × 30 cm × 10 cm) and was selected to generate a rapid and observable interaction with the reactive material of the hybrid liner. Before application, the diesel was homogenized and then evenly spread over the designated spill location to simulate a sudden surface leakage event representative of underground storage tank (UST) failures. Using a constant spill volume ensured reproducibility and eliminated ambiguity associated with density-based descriptions.

- Measurement of permeability: In this study, the evaluation of the hybrid liner focused on the reduction in hydraulic conductivity as the primary indicator of barrier activation. Because continuous permeability monitoring required maintaining an undisturbed soil profile, destructive sampling for TPH extraction and instrumental quantification (such as Soxhlet extraction or GC-based analysis) was not performed. Previous studies using the same reactive material have already verified its absorption and gelation behavior through direct laboratory quantification of TPH. Building upon these findings, the present experiment prioritized permeability-based assessment to capture the time-dependent reaction of the liner under flowing groundwater conditions. The permeability coefficient of the model ground was obtained through a constant-head test [44]. A stable hydraulic gradient was maintained by controlling the water level in the upstream reservoir, and flow rates were recorded at designated intervals under steady-flow conditions. This allowed continuous monitoring of how hydraulic conductivity varied as the liner interacted with the introduced TPH. Although the permeability decreased over time due to interaction between TPH and the reactive liner, the hydraulic gradient itself was kept constant by maintaining a fixed upstream head. In a constant-head test, only the head difference must remain constant; variations in flow rate do not violate the test principle. Therefore, even as the permeability dropped, the constant-head condition remained valid throughout the experiment.

2.2. Experimental Cases

3. Experimental Results

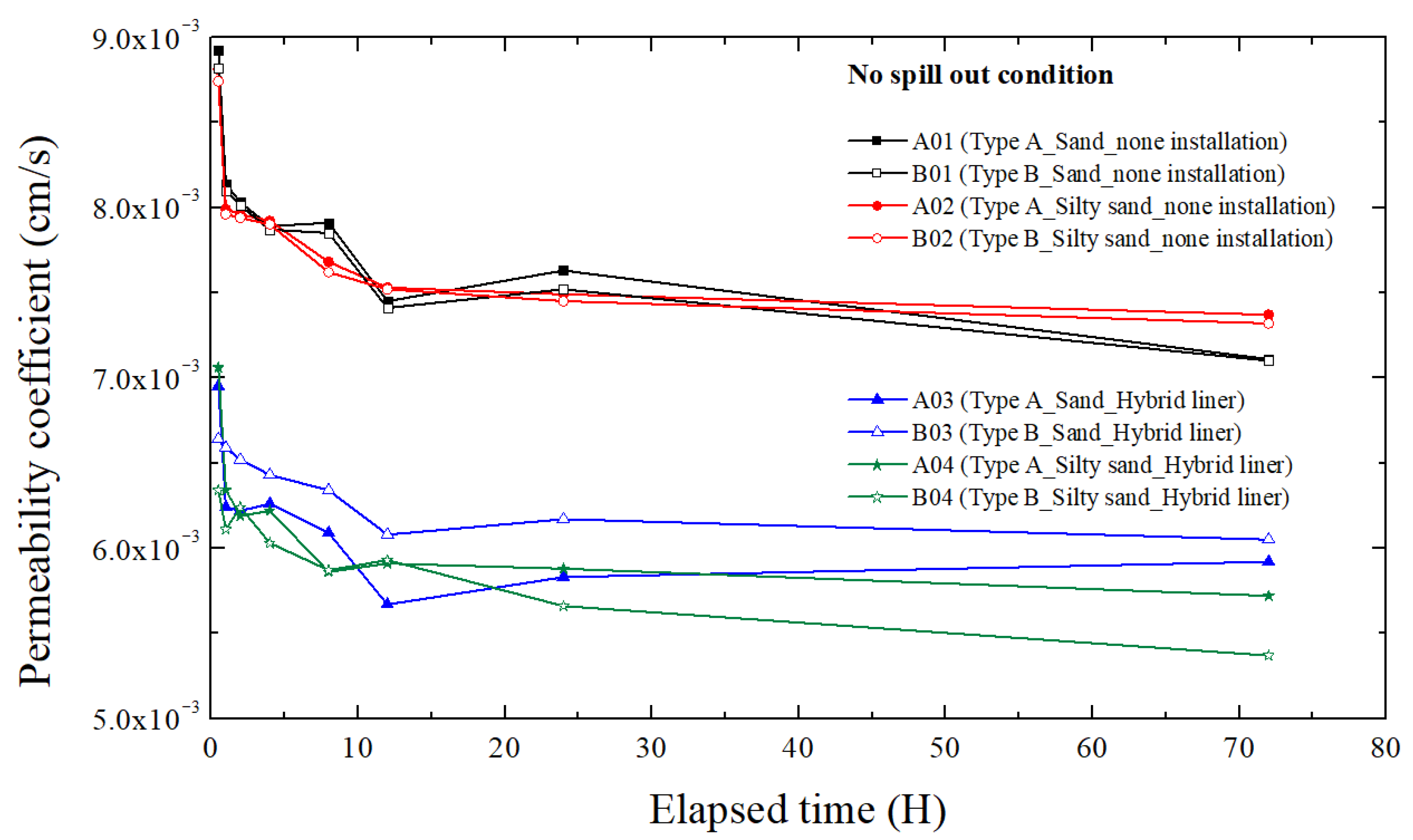

3.1. Verification Under No Spill Out Condition

3.2. Verification Under Spill Out Condition

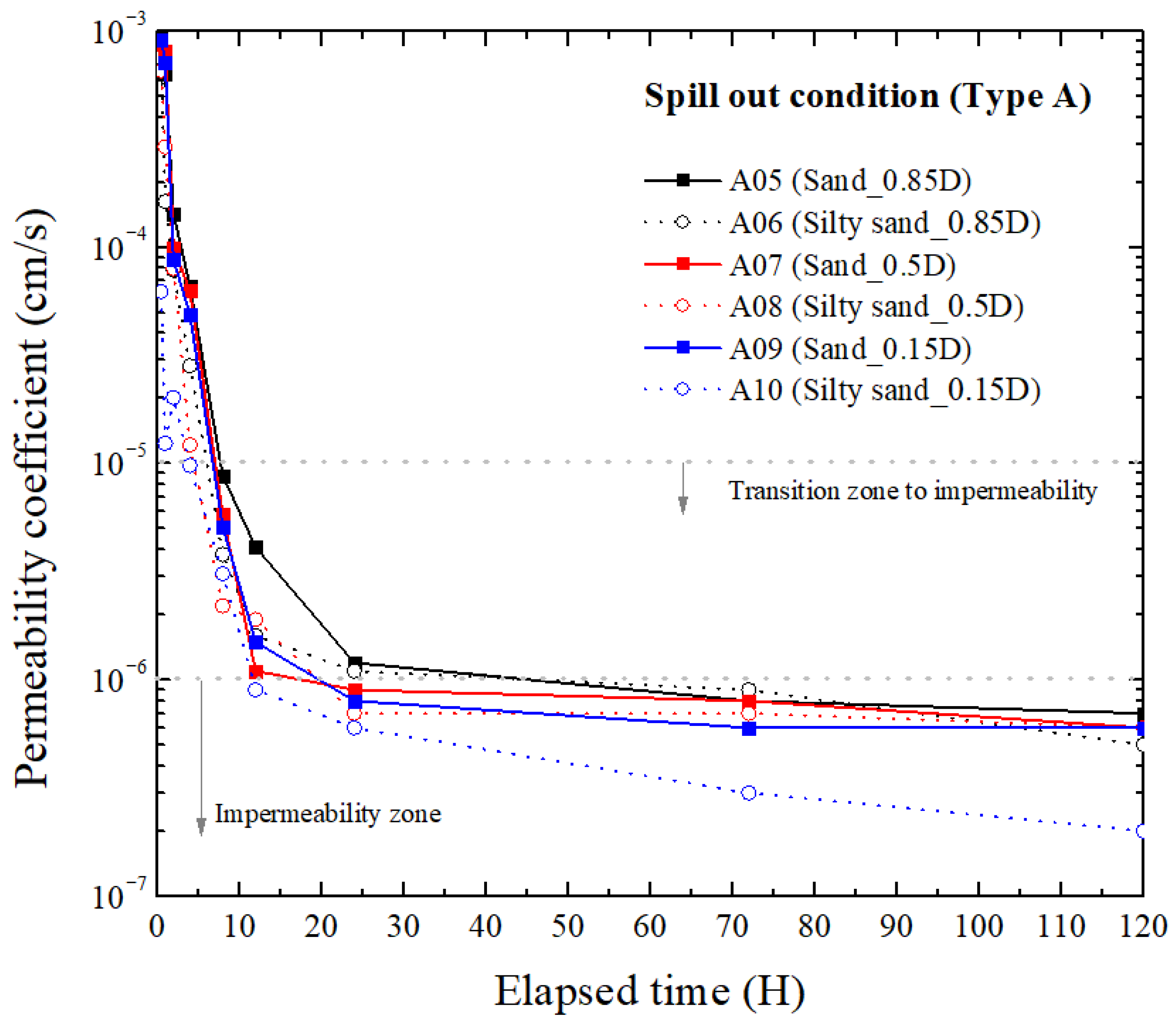

3.2.1. Type A

3.2.2. Type B

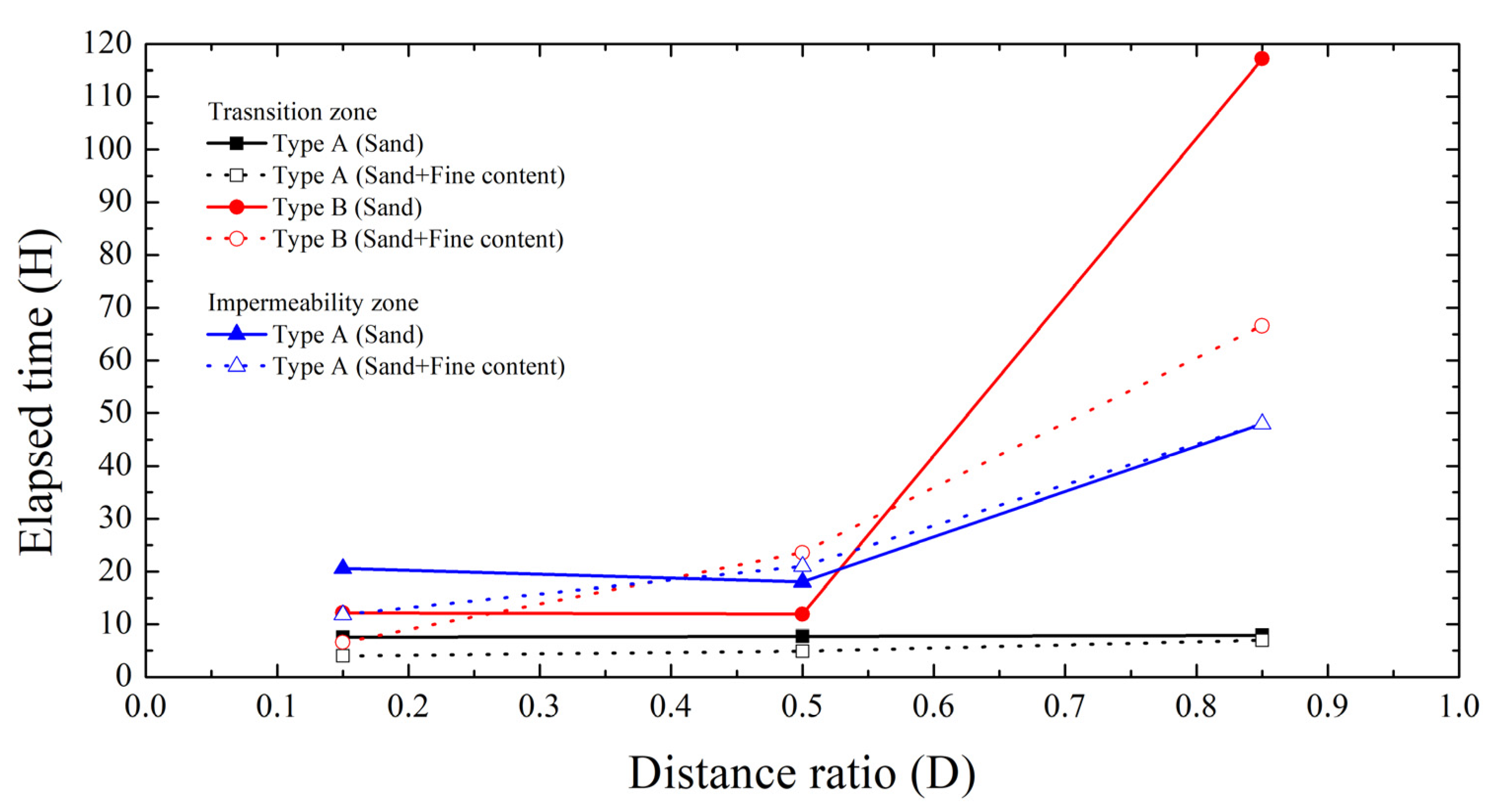

3.2.3. Elapsed Time to Reach Transition and Impermeability Zone

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Greekdrink, M.J.; Van Loosdrecht, M.C.M.; Luyben, K.C.A. Biodegradability of diesel oil. Biodegradation 1996, 7, 73–81. [Google Scholar] [CrossRef]

- Zhang, Z.; Hou, Z.; Yang, C.; Ma, C.; Tao, F.; Xu, P. Degradation of n-alkanes and polycyclic aromatic hydrocarbons in petroleum by a newly isolated Pseudomonas aeruginosa DQ8. Bioresour. Technol. 2011, 102, 4111–4116. [Google Scholar] [CrossRef]

- Choi, B.; Lee, S.; Jho, E.H. Removal of TPH, UCM, PAHs, and Alk-PAHs in oil-contaminated soil by thermal desorption. Appl. Biol. Chem. 2020, 63, 83. [Google Scholar] [CrossRef]

- Ng, C.W.W.; Zheng, M.; Liu, H.; Poudyal, S. Effects of bed hydrophobicity on post-fire debris flow entrainment and momentum growth. J. Geophys. Res. Earth Surf. 2022, 127, e2022JF006783. [Google Scholar] [CrossRef]

- Awad, Y.M.; Kim, S.C.; Abd EI-Azeem, S.A.M.; Kim, K.H.; Kim, K.R.; Kim, K.J.; Jeon, C.; Lee, S.S. Veterinary antibiotics contamination in water, sediment, and soil near a swine manure composting facility. Environ. Earth Sci. 2014, 71, 1433–1440. [Google Scholar] [CrossRef]

- Tang, Z.; Zhang, L.; Huang, Q.; Yang, Y.; Nie, Z.; Cheng, J.; Yang, J.; Wang, Y.; Chao, M. Contamination and risk of heavy metals in soils and sediments from a typical plastic waste recycling area in North China. Ecotoxicol. Environ. Saf. 2015, 112, 343–351. [Google Scholar] [CrossRef] [PubMed]

- Ławniczak, Ł.; Woźniak-Karczewska, M.; Loibner, A.P.; Heipieper, H.J.; Chrzanowski, Ł. Microbial Degradation of Hydrocarbons—Basic Principles for Bioremediation: A Review. Molecules 2020, 25, 856. [Google Scholar] [CrossRef] [PubMed]

- Teefy, D.A. Remediation technologies screening matrix and reference guide: Version III. Remediat. J. 1997, 8, 115–121. [Google Scholar] [CrossRef]

- Sui, X.; Wang, X.; Li, Y.; Ji, H. Remediation of Petroleum-Contaminated Soils with Microbial and Microbial Combined Methods: Advances, Mechanisms, and Challenges. Sustainability 2021, 13, 9267. [Google Scholar] [CrossRef]

- Cho, K.; Myung, E.; Kim, H.; Purev, O.; Park, C.; Choi, N. Removal of Total Petroleum Hydrocarbons from Contaminated Soil through Microwave Irradiation. Int. J. Environ. Res. Public Health 2020, 17, 5952. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, J.H.; Jung, W.C.; Park, M.; Kim, M.S.; Lee, S.J.; Park, H. Changes in Soil Health with Remediation of Petroleum Hydrocarbon Contaminated Soils Using Two Different Remediation Technologies. Sustainability 2020, 12, 10078. [Google Scholar] [CrossRef]

- Feng, D.; Lorenzen, L.; Aldrich, C.; Mar, P.W. Exsitu diesel contaminated soil washing with mechanical methods. Miner. Eng. 2001, 14, 1093–1100. [Google Scholar] [CrossRef]

- Hernández-Espriú, A.; Sánchez-León, E.; Martnez-Santos, P.; Torres, L.G. Remediation of a diesel-contaminated soil from a pipeline accidental spill: Enhanced biodegradation and soil washing processes using natural gums and surfactants. J. Soils Sediments 2013, 13, 152–165. [Google Scholar] [CrossRef]

- Benyahia, F.; Embaby, A.S. Bioremediation of Crude Oil Contaminated Desert Soil: Effect of Biostimulation, Bioaugmentation and Bioavailability in Biopile Treatment Systems. Int. J. Environ. Res. Public Health 2016, 13, 219. [Google Scholar] [CrossRef]

- Kim, T.; Hong, J.K.; Jho, E.H.; Kang, G.; Yang, D.J.; Lee, S.J. Sequential biowashing-biopile processes for remediation of crude oil contaminated soil in Kuwait. J. Hazard. Mater. 2019, 378, 120710. [Google Scholar] [CrossRef]

- Diplock, E.E.; Mardlin, D.P.; Killham, K.S.; Paton, G.I. Predicting bioremediation of hydrocarbons: Laboratory to field scale. Environ. Pollut. 2009, 157, 1831–1840. [Google Scholar] [CrossRef] [PubMed]

- Varjani, S.J. Microbial degradation of petroleum hydrocarbons. Bioresour. Technol. 2017, 223, 277–286. [Google Scholar] [CrossRef] [PubMed]

- Mulligan, C.N. Sustainable remediation of contaminated soil using biosurfactants. Front. Bioeng. Biotechnol. 2021, 9, 635196. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Lee, Y.; Kim, J.; Kim, C. Field Application of Modified In Situ Soil Flushing in Combination with Air Sparging at a Military Site Polluted by Diesel and Gasoline in Korea. Int. J. Environ. Res. Public Health 2014, 11, 8806–8824. [Google Scholar] [CrossRef]

- Khalladi, R.; Benhabiles, O.; Bentahar, F.; Moulai-Mostefa, N. Surfactant remediation of diesel fuel polluted soil. J. Hazard. Mater. 2009, 164, 1179–1184. [Google Scholar] [CrossRef]

- Vreysen, S.; Maes, A. Remediation of Diesel Contaminated, Sandy-Loam Soil Using Low Concentrated Surfactant Solutions. J. Soils Sediments 2005, 5, 240–244. [Google Scholar] [CrossRef]

- Méndez, E.; Perez, M.; Romero, O.; Beltran, E.D.; Castro, S.; Corona, J.L.; Corona, A.; Cuevas, M.C.; Bustos, E. Effects of electrode material on the efficiency of hydrocarbon removal by an electrokinetic remediation process. Electrochim. Acta 2012, 86, 148–156. [Google Scholar] [CrossRef]

- Li, D.C.; Xu, W.F.; Mu, Y.; Yu, H.Q.; Jiang, H.; Crittenden, J. Remediation of Petroleum-Contaminated Soil and Simultaneous Recovery of Oil by Fast Pyrolysis. Environ. Sci. Technol. 2018, 52, 5330–5338. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, A.; Ng, W.J.; Liu, Y. Principle and applications of microbubble and nanobubble technology for water treatment. Chemosphere 2011, 84, 1175–1180. [Google Scholar] [CrossRef] [PubMed]

- Sayed, K.; Baloo, L.; Sharma, N.K. Bioremediation of Total Petroleum Hydrocarbons (TPH) by Bioaugmentation and Biostimulation in Water with Floating Oil Spill Containment Booms as Bioreactor Basin. Int. J. Environ. Res. Public Health 2021, 18, 2226. [Google Scholar] [CrossRef]

- Adetutu, E.; Weber, J.; Aleer, S.; Dandie, C.E.; Aburto-Medina, A.; Ball, A.S.; Juhasz, A.L. Assessing impediments to hydrocarbon biodegradation in weathered contaminated soils. J. Hazard. Mater. 2013, 261, 847–853. [Google Scholar] [CrossRef]

- Jho, E.H.; Ryu, H.; Shin, D. Prediction of landfarming period using degradation kinetics of petroleum hydrocarbons: Test with artificially contaminated and field-aged soils and commercially available bacterial cultures. J. Soils Sediments 2014, 14, 138–145. [Google Scholar] [CrossRef]

- Goutam Mukherjee, A.; Ramesh Wanjari, U.; Eladl, M.A.; El-Sherbiny, M.; Elsherbini, D.M.A.; Sukumar, A.; Kannampuzha, S.; Ravichandran, M.; Renu, K.; Vellingiri, B. Mixed Contaminants: Occurrence, Interactions, Toxicity, Detection, and Remediation. Molecules 2022, 27, 2577. [Google Scholar] [CrossRef]

- Park, J.; Hong, G. Simulation on the Permeability Evaluation of a Hybrid Liner for the Prevention of Contaminant Diffusion in Soils Contaminated with Total Petroleum Hydrocarbon. Int. J. Environ. Res. Public Health 2022, 19, 13710. [Google Scholar] [CrossRef]

- Kong, D.J.; Wu, H.N.; Chai, J.C.; Arulrajah, A. State-of-the-Art Review of Geosynthetic Clay Liners. Sustainability 2017, 9, 2110. [Google Scholar] [CrossRef]

- Shackelford, C.D.; Meier, A.; Sample-Lord, K. Limiting membrane and diffusion behavior of a geosynthetic clay liner. Geotext. Geomembr. 2016, 44, 707–718. [Google Scholar] [CrossRef]

- Liu, Y.; Bouazza, A.; Gates, W.P.; Rowe, R.K. Hydraulic performance of geosynthetic clay liners to sulfuric acid solutions. Geotext. Geomembr. 2015, 43, 14–23. [Google Scholar] [CrossRef]

- Xue, Q.; Zhang, Q.; Liu, L. Impact of High Concentration Solutions on Hydraulic Properties of Geosynthetic Clay Liner Materials. Materials 2012, 5, 2326–2341. [Google Scholar] [CrossRef]

- Bohnhoff, G.L.; Shackelford, C.D. Improving membrane performance via bentonite polymer nanocomposite. Appl. Clay Sci. 2013, 86, 83–98. [Google Scholar] [CrossRef]

- Chung, S.L.; Lee, D.H. Remediation of PCE-contaminated Groundwater Using Permeable Reactive Barrier System with MOM Bentonite. J. Soil Groundw. Environ. 2012, 17, 73–80. [Google Scholar] [CrossRef]

- Guerin, T.F.; Hornerb, S.; McGovernb, T.; Davey, B. An application of permeable reactive barrier technology to petroleum hydrocarbon contaminated groundwater. Water Res. 2002, 36, 15–24. [Google Scholar] [CrossRef]

- Wang, J.; Zheng, Y.; Wang, A. Effect of Kapok Fiber Treated with Various Solvents on Oil Absorbency. Ind. Crop. Prod. 2012, 40, 178–184. [Google Scholar] [CrossRef]

- Shin, H.S.; Yoo, J.H.; Jin, L. A Study on Oil Absorption Rate and Oil Absorbency of Melt-blown Nonwoven. Text. Color. Finish. 2010, 22, 257–263. [Google Scholar] [CrossRef]

- Rengasamy, R.S.; Das, D.; Karan, C.P. Study of Oil Sorption Behavior of Filled and Structured Fiber Assemblies Made from Polypropylene, Kapok and Milkweed Fibers. J. Hazard. Mater. 2011, 186, 526–532. [Google Scholar] [CrossRef]

- Atta, A.; Arndt, K.F. Swelling and Network Parameters of High Oil Absorptive Network Based on 1-Octene and Isodecyl Acrylate Copolymers. J. Appl. Polym. Sci. 2005, 97, 80–91. [Google Scholar] [CrossRef]

- Nguyen, D.C.; Bui, T.T.; Cho, Y.B.; Kim, Y.S. Highly Hydrophobic Polydimethylsiloxane-Coated Expanded Vermiculite Sorbents for Selective Oil Removal from Water. Nanomaterials 2021, 11, 367. [Google Scholar] [CrossRef]

- Taylor, N.M.; Toth, C.R.A.; Collins, V.; Mussone, P.; Gieg, L.M. The Effect of an Adsorbent Matrix on Recovery of Microorganisms from Hydrocarbon-Contaminated Groundwater. Microorganisms 2021, 9, 90. [Google Scholar] [CrossRef]

- Park, J. Evaluation of Changes in the Permeability Characteristics of a Geotextile–Polynorbornene Liner for the Prevention of Pollutant Diffusion in Oil-Contaminated Soils. Sustainability 2021, 13, 4797. [Google Scholar] [CrossRef]

- ASTM D2434-22; Standard Test Methods for Measurement of Hydraulic Conductivity of Coarse-Grained Soils. ASTM International: West Conshohocken, PA, USA, 2022.

- Lee, J.Y.; Oh, S.J.; Kim, S.H.; Lee, K.; Park, J.J.; Hong, G. Evaluation on Strength Characteristics of Reactive Materials to Prevent the Diffusion of Organic Pollutants. J. Korean Geosynth. Soc. 2023, 22, 35–42. [Google Scholar]

| Soil Type | D10 (mm) | D30 (mm) | D60 (mm) | Cu | Cc | Ratio of Percent Finer Below 0.075 mm (%) | USCS Classification |

|---|---|---|---|---|---|---|---|

| Sand | 0.236 | 0.314 | 0.458 | 1.94 | 0.91 | 1.18 | Poorly graded sand (SP) |

| Silty sand | 0.154 | 0.301 | 0.435 | 2.82 | 1.35 | 6.12 | Poorly graded sand with silt (SP-SM) |

| Classification | TPH Spill Distance from Reactive Liner | TPH Spill Simulation | Hybrid Liner Installation | Soil Type | |

|---|---|---|---|---|---|

| Reactive Material | Cases | ||||

| Type A (polynorbonene 100%) | A01 | - | - | - | Sand |

| A02 | - | - | - | Silty sand | |

| A03 | - | - | O | Sand | |

| A04 | - | - | O | Silty sand | |

| A05 | 0.85D | O | O | Sand | |

| A06 | O | O | Silty sand | ||

| A07 | 0.50D | O | O | Sand | |

| A08 | O | O | Silty sand | ||

| A09 | 0.15D | O | O | Sand | |

| A10 | O | O | Silty sand | ||

| Type B (55% sand + 15% bentonite + 15% polynorbonene + 15% polyolefin) | B01 | - | - | - | Sand |

| B02 | - | - | - | Silty sand | |

| B03 | - | - | O | Sand | |

| B04 | - | - | O | Silty sand | |

| B05 | 0.85D | O | O | Sand | |

| B06 | O | O | Silty sand | ||

| B07 | 0.50D | O | O | Sand | |

| B08 | O | O | Silty sand | ||

| B09 | 0.15D | O | O | Sand | |

| B10 | O | O | Silty sand | ||

| Elapsed Time (H) | Permeability Coefficient (cm/s) | |||||||

|---|---|---|---|---|---|---|---|---|

| A01 | A02 | A03 | A04 | B01 | B02 | B03 | B04 | |

| 0.5 | 0.00892 | 0.00881 | 0.00695 | 0.00706 | 0.00882 | 0.00874 | 0.00664 | 0.00634 |

| 1 | 0.00814 | 0.00799 | 0.00624 | 0.00634 | 0.0081 | 0.00796 | 0.00659 | 0.00611 |

| 2 | 0.00803 | 0.00796 | 0.00622 | 0.00619 | 0.00801 | 0.00794 | 0.00652 | 0.00624 |

| 4 | 0.00789 | 0.00792 | 0.00626 | 0.00622 | 0.00787 | 0.0079 | 0.00643 | 0.00603 |

| 8 | 0.00791 | 0.00768 | 0.00609 | 0.00586 | 0.00785 | 0.00762 | 0.00634 | 0.00587 |

| 12 | 0.00745 | 0.00753 | 0.00567 | 0.00591 | 0.00741 | 0.00752 | 0.00608 | 0.00593 |

| 24 | 0.00763 | 0.00749 | 0.00583 | 0.00588 | 0.00752 | 0.00745 | 0.00617 | 0.00566 |

| 72 | 0.00711 | 0.00737 | 0.00592 | 0.00572 | 0.0071 | 0.00732 | 0.00605 | 0.00537 |

| 120 | - | - | - | - | - | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.-Y.; Han, J.-G.; Park, J.; Jo, Y.; Hong, G.; Lee, K. Experimental Study on the Performance Evaluation of Hybrid Liner to Prevent the Migration of Oil Pollutant. Materials 2025, 18, 5311. https://doi.org/10.3390/ma18235311

Lee J-Y, Han J-G, Park J, Jo Y, Hong G, Lee K. Experimental Study on the Performance Evaluation of Hybrid Liner to Prevent the Migration of Oil Pollutant. Materials. 2025; 18(23):5311. https://doi.org/10.3390/ma18235311

Chicago/Turabian StyleLee, Jong-Yoon, Jung-Geun Han, Jeongjun Park, Yongnam Jo, Gigwon Hong, and Kicheol Lee. 2025. "Experimental Study on the Performance Evaluation of Hybrid Liner to Prevent the Migration of Oil Pollutant" Materials 18, no. 23: 5311. https://doi.org/10.3390/ma18235311

APA StyleLee, J.-Y., Han, J.-G., Park, J., Jo, Y., Hong, G., & Lee, K. (2025). Experimental Study on the Performance Evaluation of Hybrid Liner to Prevent the Migration of Oil Pollutant. Materials, 18(23), 5311. https://doi.org/10.3390/ma18235311