Comparative Study of Different Additive Manufacturing Methods for H13 Tool Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Parameters of AM Methods

2.2.1. FDMS—Desktop Metal Studio System

2.2.2. FDMS—Zetamix

2.2.3. Binder Jetting

2.2.4. LPBF

2.2.5. DED

2.3. Methods for Testing and Characterization in “As-Printed” State

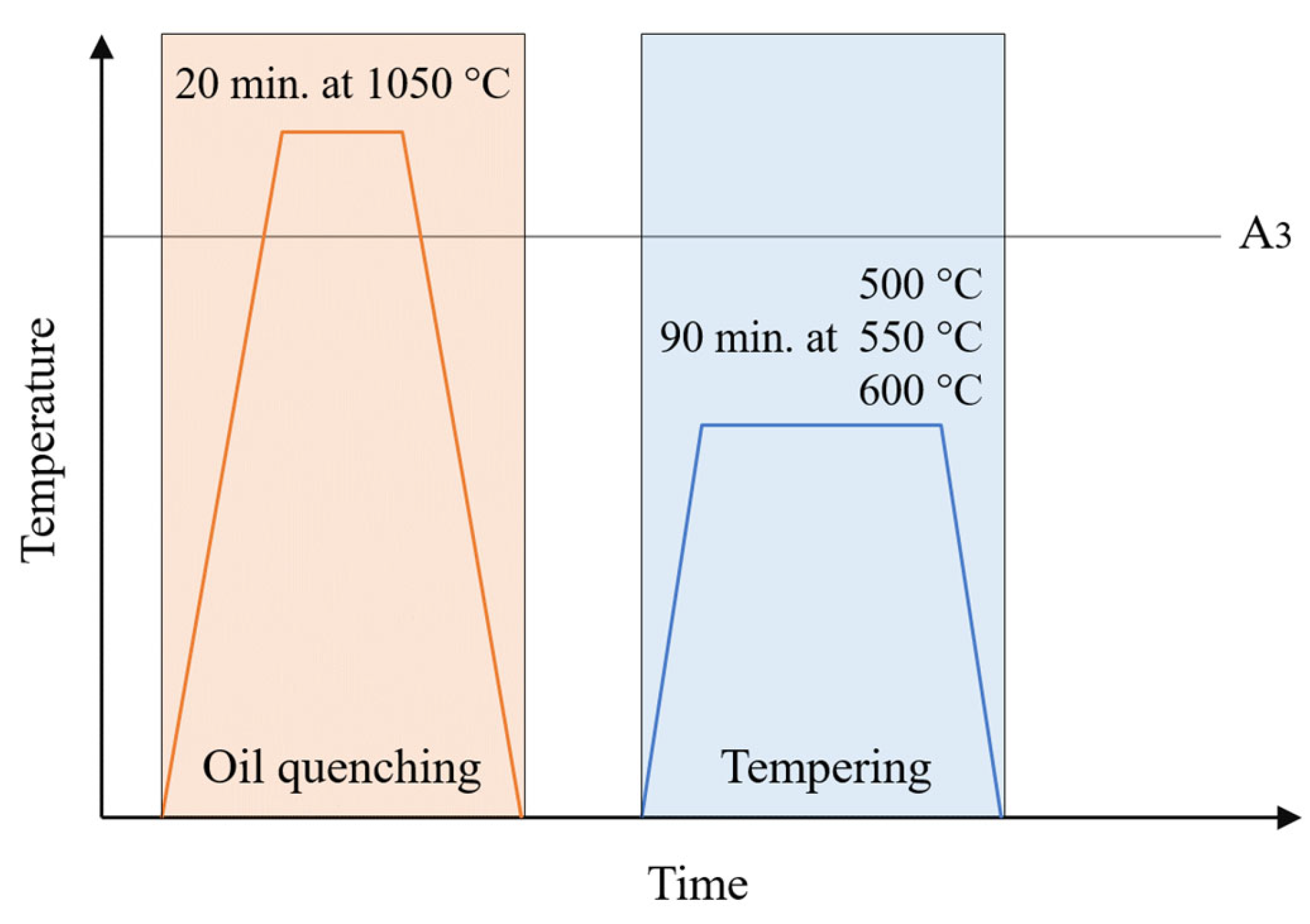

2.4. Methodology of Evaluation of Heat Treatment Influence on Microstructure and Properties of Printed H13 Steel

- Tempering at 500 °C

- Tempering at 550 °C

- Tempering at 600 °C

- Quenching

- Quenching + tempering at 500 °C

- Quenching + tempering at 550 °C

- Quenching + tempering at 600 °C

3. Results

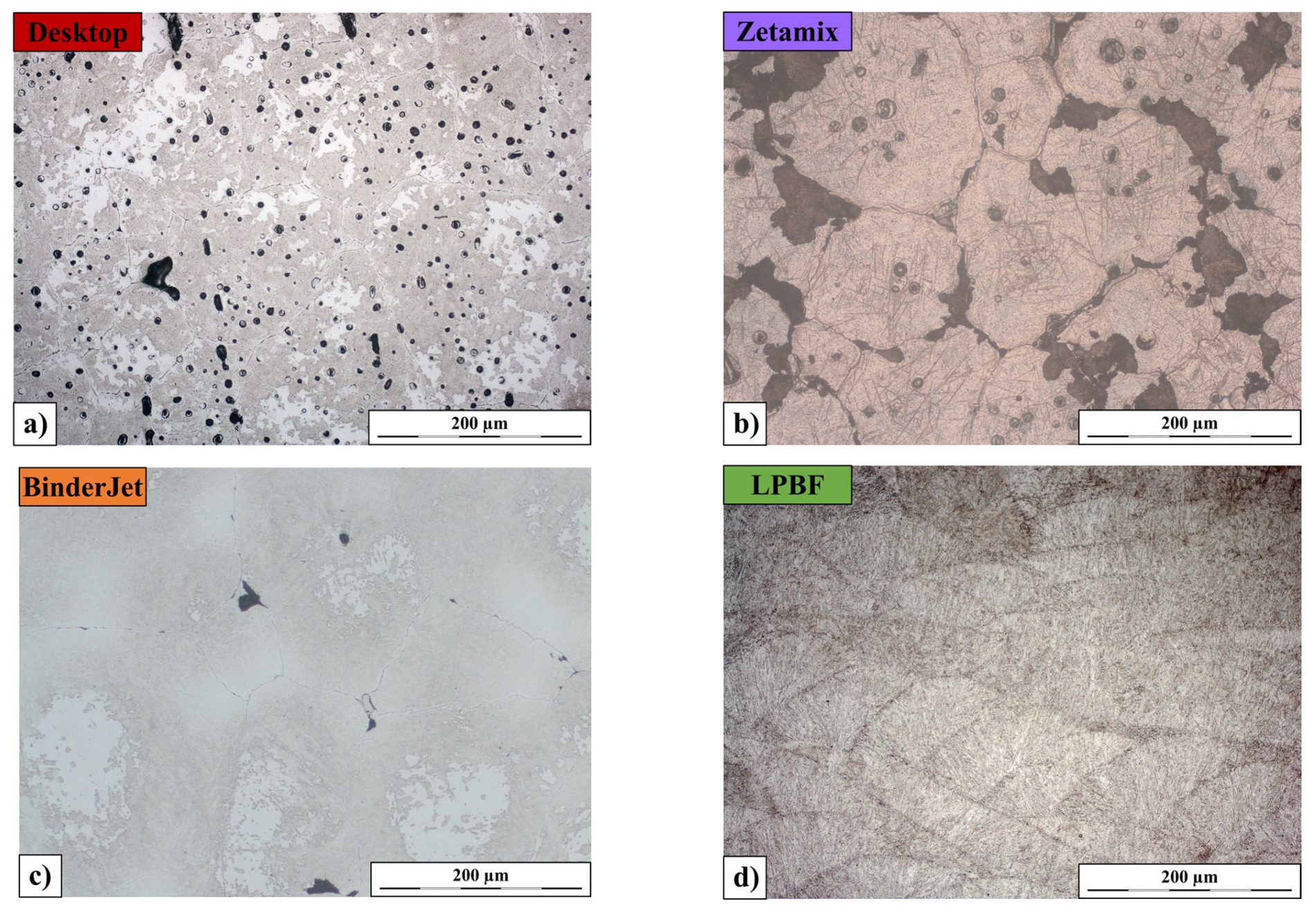

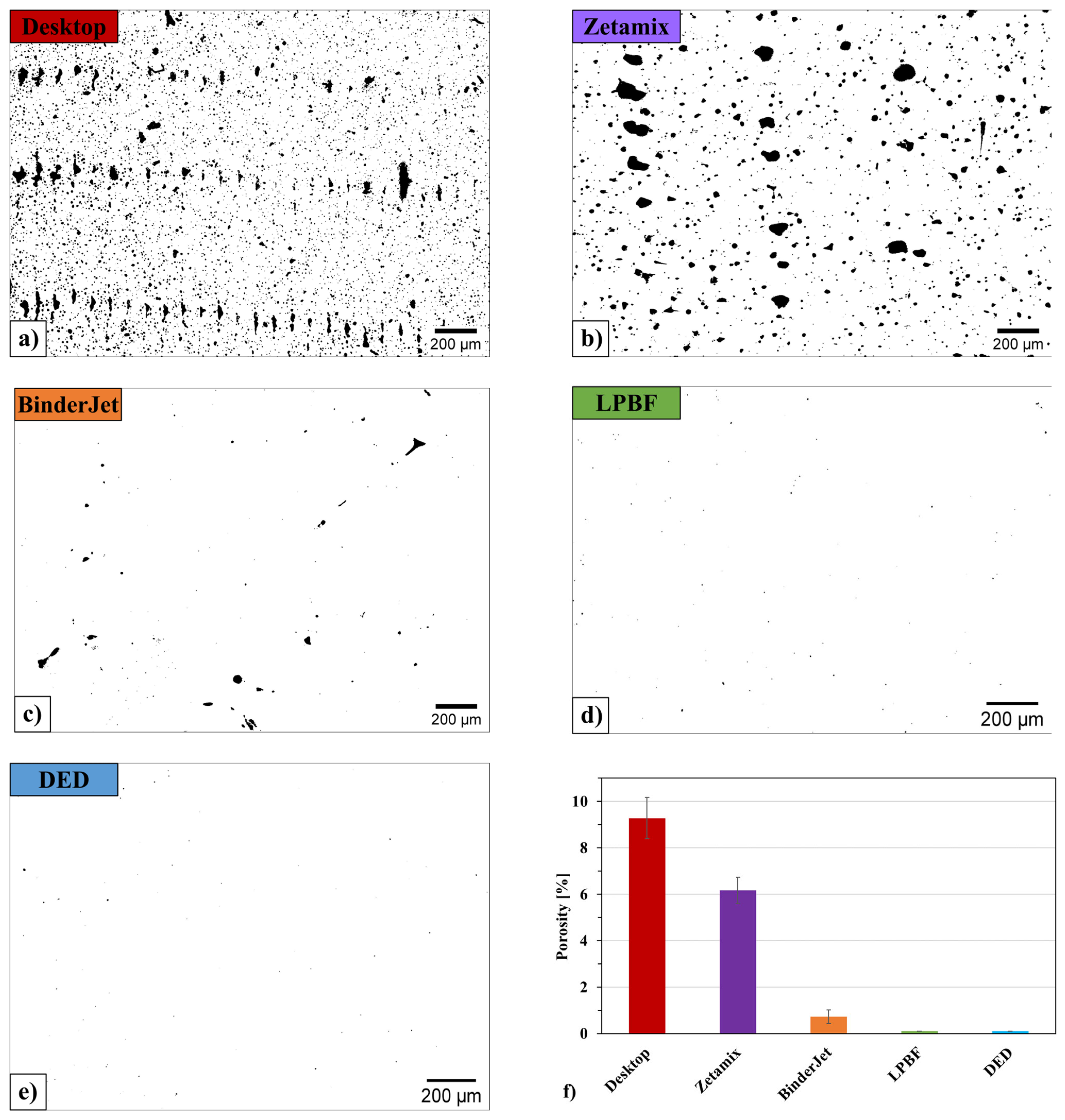

3.1. Microstructure in “As—Printed” State

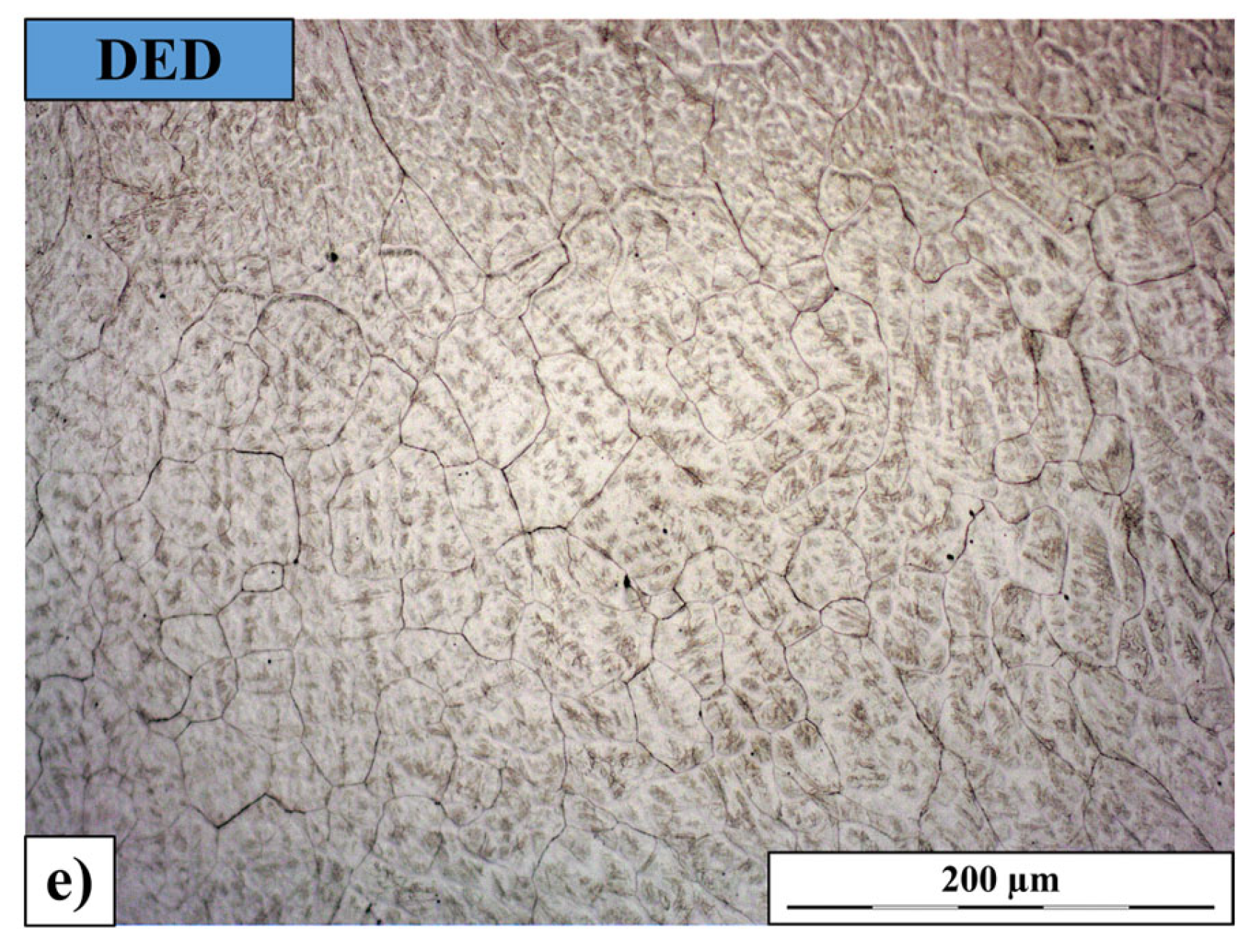

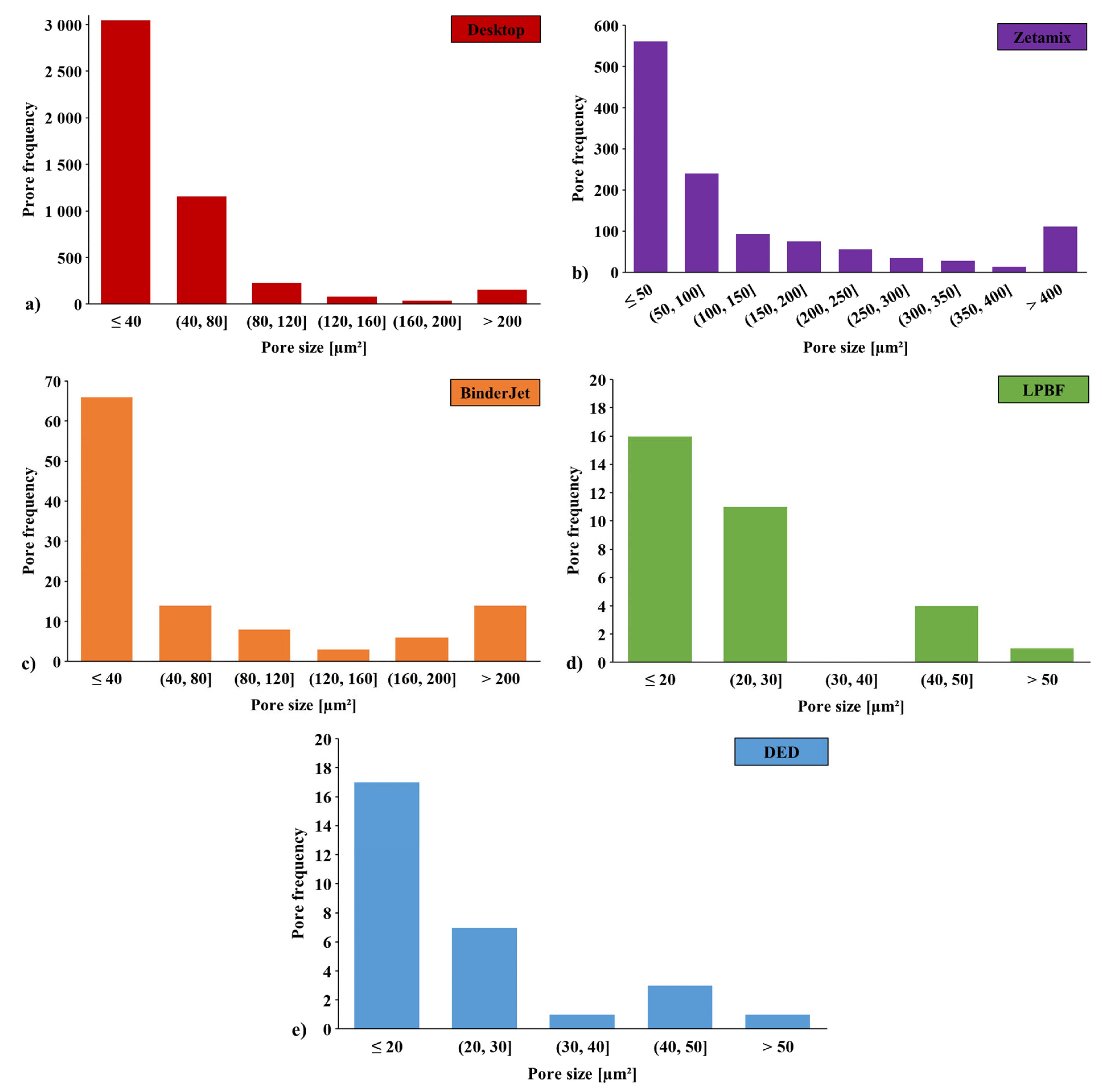

3.2. Porosity of Printed Parts

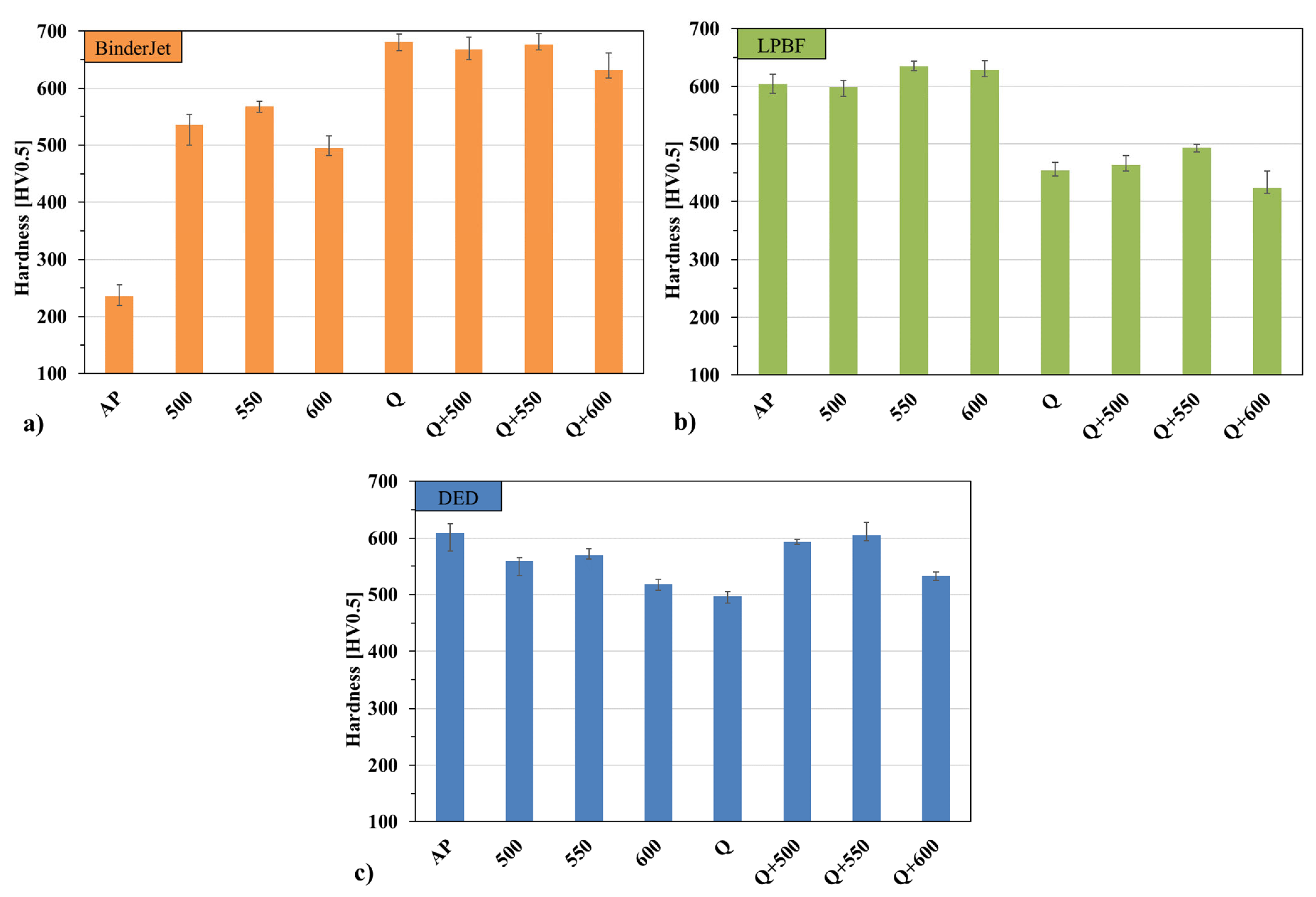

3.3. Evaluation of Heat Treatment Influence on Hardness of Printed H13 Steel

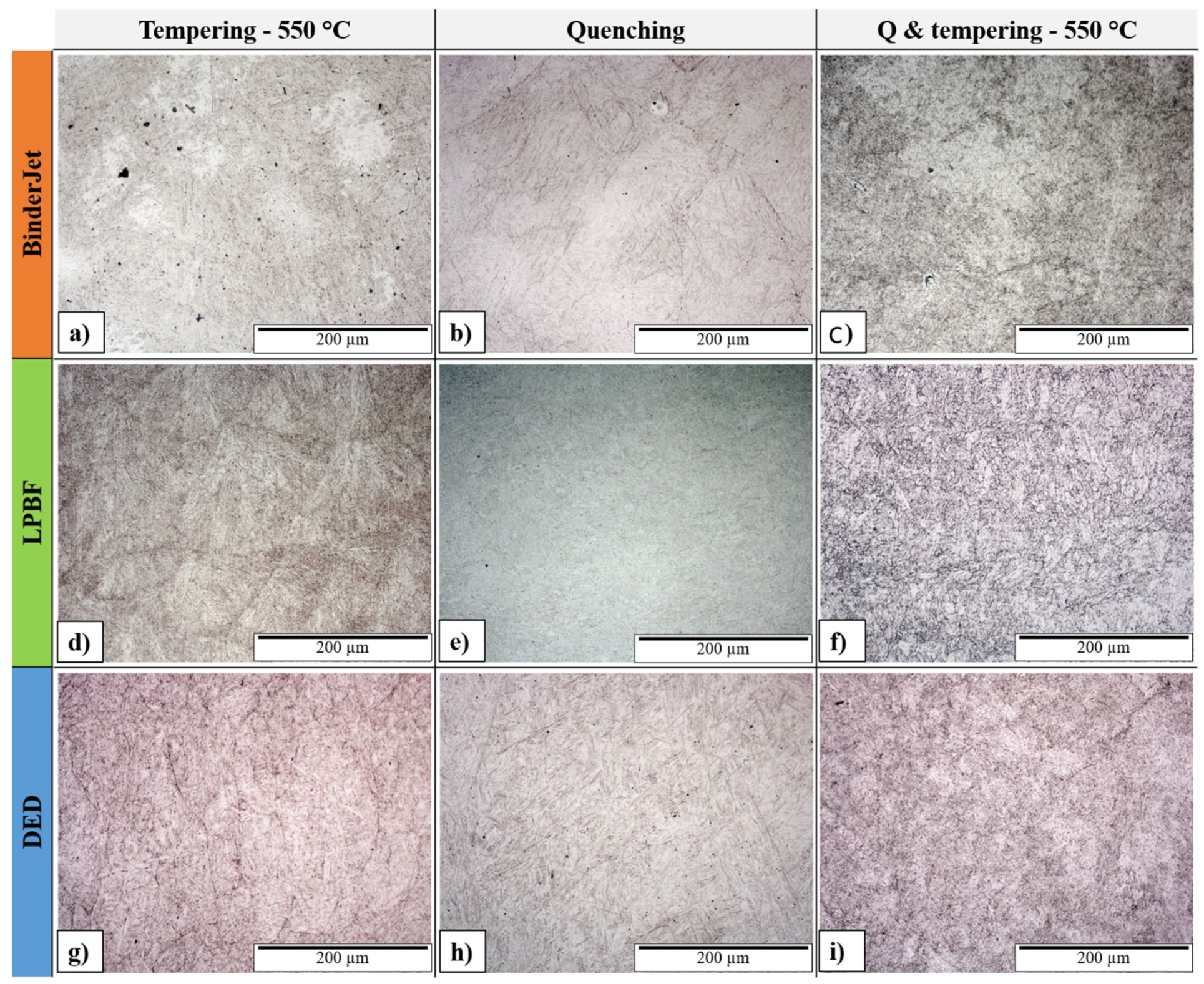

3.4. Results of Microstructure Analysis After Heat Treatment Processes

4. Discussion

5. Conclusions

- Hardness After Heat Treatment: Binder Jetting, LPBF, and DED all demonstrated hardness development after heat treatment (marked as “+”), indicating successful response to the applied thermal cycles. FDMS methods showed no hardness development after heat treatment (“−”) because of high porosity which causes limited possible applications compared to other technologies.

- Microstructure: LPBF and DED produced relatively uniform microstructures with controlled grain morphology. Binder Jetting exhibited segregation of alloying elements (vanadium, chromium) in specific regions, requiring diffusion during tempering to achieve secondary hardening. FDMS methods demonstrated more extensive segregation patterns due to inter-powder boundaries and limited material homogenization during sintering.

- Production Cost and Equipment Accessibility: FDMS (particularly Zetamix) offers the lowest cost of printing devices and greatest accessibility, making it the most attractive for applications tolerating lower density. Binder Jetting requires one of the most expensive printing systems on the market, justified only by high precision requirements and substantial order volumes. LPBF and DED occupy intermediate equipment cost ranges, with competitive material costs of 60–80 EUR/kg and 25–40 EUR/kg, respectively, compared to 100–700 EUR/kg for Binder Jetting and FDMS methods.

- Production Time and Process Efficiency: Binder Jetting demonstrated the highest deposition rate (5.5 kg/h apparent throughput), followed by DED (1–2 kg/h), FDMS methods (1.5–3 kg/h), and LPBF (0.1–0.5 kg/h). For applications requiring lower density, FDMS printing using composite filaments filled with metal powders is the most attractive option due to its accessibility and reasonable deposition efficiency. For applications requiring densities close to 100% and very high dimensional accuracy, LPBF performs best. For large parts where high surface precision is not essential, DED based on wire melting is a suitable choice. Binder Jetting represents a viable option for high-precision, small-series production only if large-scale orders are available to offset the high equipment cost. Ultimately, technology selection must account for part geometry, size constraints, required density, dimensional accuracy, production volume, and total cost of ownership.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ahmed, I.A.A.L.-K.; Mohammed, A.I.; Allow, M.A. Improvement of Forging Die Life by Failure Mechanism Analysis. Available online: https://www.degruyterbrill.com/document/doi/10.1515/jmbm-2021-0034/html?utm_source=researchgate.net&medium=article (accessed on 1 November 2025).

- Cui, X.H.; Shan, J.; Yang, Z.R.; Wei, M.X.; Wang, S.Q.; Dong, C. Alloying Design for High Wear-Resistant Cast Hot-Forging Die Steels. J. Iron Steel Res. Int. 2008, 15, 67–72. [Google Scholar] [CrossRef]

- Čamek, L.; Jelen, L. Increasing Material Durability for Drop Hot Forging. In Proceedings of the METAL 2009—18th International Conference on Metallurgy and Materials, Conference Proceedings. Hradec Nad Moravici, Czech Republic, 19–21 May 2009. [Google Scholar]

- Bandyopadhyay, T.R.; Rao, P.K.; Prabhu, N. Behavior of Alloying Elements during Electro-Slag Remelting of Ultrahigh Strength Steel. Metall. Min. Ind. 2012, 4, 6–16. [Google Scholar]

- Walkenhorst, U. Hot Work Tool Steels For Forging Dies; Uddeholm Company: Hagfors, Sweden, 2013. [Google Scholar]

- Qi, Y.F.; Li, J.; Shi, C.B.; Zhang, Y.; Zhu, Q.T.; Wang, H. Effect of Directional Solidification of Electroslag Remelting on the Microstructure and Primary Carbides in an Austenitic Hot-Work Die Steel. J. Mater. Process Technol. 2017, 249, 32–38. [Google Scholar] [CrossRef]

- Hawryluk, M.; Widomski, P.; Ziemba, J. Analysis of the Causes of Rapid Damage of Forging Tools/Analiza Przyczyn Występowania Nagłych Uszkodzeń Narzędzi Kuźniczych. Met. Metal. Form. Obróbka Plast. Met. 2017, 28, 75–92. [Google Scholar]

- Jiang, B.; Gao, J.; Peng, Z. Effects of deep cryogenic treatment on the microstructure and properties of H13 steel. J. Phys. Conf. Ser. 2025, 2954, 012022. [Google Scholar] [CrossRef]

- Balaško, T.; Burja, J.; Medved, J. High-Temperature Oxidation of Four Hot-Work Tool Steels. Mater. Technol. 2018, 52, 775–780. [Google Scholar] [CrossRef]

- Łataś, Z.; Ciski, A.; Šuchmann, P. Cryogenic Treatment of Hot Forging Dies. In Proceedings of the 15th IFHTSE—International Federation for Heat Treatment and Surface Engineering Congress 2006, Vienna, Austria, 25–29 September 2006. [Google Scholar]

- Shinde, T.; Dhokey, N.B. Evolution of Tertiary Carbides and Its Influence on Wear Behavior, Surface Roughness and Fatigue Limit of Die Steels. In Proceedings of the Fatigue, Durability and Fracture Mechanics, Bengaluru, India, 28–30 September 2016; Springer: Singapore, 2018; pp. 237–252. [Google Scholar]

- Šuchmann, P.; Nižňanská, J. Effect of Deep Cryogenic Treatment on Carbides Precipitation Kinetics during Tempering of the X37CrMoV5-1 Hot Working Tool Steel. In Proceedings of the European Conference on Heat Treatment 2015 and 22nd IFHTSE Congress—Heat Treatment and Surface Engineering from Tradition to Innovation, Venice, Italy, 20–22 May 2015. [Google Scholar]

- Amini, K.; Negahbani, M.; Ghayour, H. The Effect of Deep Cryogenic Treatment on Hardness and Wear Behavior of the H13 Tool Steel. Metall. Ital. 2015, 107, 53–58. [Google Scholar]

- Escherová, J.; Krbata, M.; Kohutiar, M.; Barényi, I.; Chochlíková, H.; Eckert, M.; Jus, M.; Majerský, J.; Janík, R.; Dubcová, P. The Influence of Q & T Heat Treatment on the Change of Tribological Properties of Powder Tool Steels ASP2017, ASP2055 and Their Comparison with Steel X153CrMoV12. Materials 2024, 17, 974. [Google Scholar] [CrossRef]

- Krbata, M.; Kohutiar, M.; Escherova, J.; Klučiar, P.; Studeny, Z.; Trembach, B.; Beronská, N.; Breznická, A.; Timárová, Ľ. Continuous Cooling Transformation of Tool Steels X153CrMoV12 and 100MnCrW4: Analysis of Microstructure and Hardness Changes. Appl. Mech. 2025, 6, 16. [Google Scholar] [CrossRef]

- Krbata, M.; Ciger, R.; Kohutiar, M.; Eckert, M.; Barenyi, I.; Trembach, B.; Dubec, A.; Escherova, J.; Gavalec, M.; Beronská, N. Microstructural Changes and Determination of a Continuous Cooling Transformation (CCT) Diagram Using Dilatometric Analysis of M398 High-Alloy Tool Steel Produced by Microclean Powder Metallurgy. Materials 2023, 16, 4473. [Google Scholar] [CrossRef]

- Mazur, M.; Brincat, P.; Leary, M.; Brandt, M. Numerical and Experimental Evaluation of a Conformally Cooled H13 Steel Injection Mould Manufactured with Selective Laser Melting. Int. J. Adv. Manuf. Technol. 2017, 93, 881–900. [Google Scholar] [CrossRef]

- Mazur, M.; Leary, M.; McMillan, M.; Elambasseril, J.; Brandt, M. SLM Additive Manufacture of H13 Tool Steel with Conformal Cooling and Structural Lattices. Rapid Prototyp. J. 2016, 22, 504–518. [Google Scholar] [CrossRef]

- Fonseca, E.B.; Gabriel, A.H.G.; Araújo, L.C.; Santos, P.L.L.; Campo, K.N.; Lopes, E.S.N. Assessment of Laser Power and Scan Speed Influence on Microstructural Features and Consolidation of AISI H13 Tool Steel Processed by Additive Manufacturing. Addit. Manuf. 2020, 34, 101250. [Google Scholar] [CrossRef]

- Lei, F.; Wen, T.; Yang, F.; Wang, J.; Fu, J.; Yang, H.; Wang, J.; Ruan, J.; Ji, S. Microstructures and Mechanical Properties of H13 Tool Steel Fabricated by Selective Laser Melting. Materials 2022, 15, 2686. [Google Scholar] [CrossRef]

- Katancik, M.; Mirzababaei, S.; Ghayoor, M.; Pasebani, S. Selective Laser Melting and Tempering of H13 Tool Steel for Rapid Tooling Applications. J. Alloys Compd. 2020, 849, 156319. [Google Scholar] [CrossRef]

- Miyauchi, H.; Matsumoto, H.; Yokota, K. Selective Laser Melting with Changing Input Energy Periodically for Production of Partially Hardened Laminate Structure in H13 Steel. J. Manuf. Process 2022, 73, 839–848. [Google Scholar] [CrossRef]

- Mertens, R.; Vrancken, B.; Holmstock, N.; Kinds, Y.; Kruth, J.-P.; Van Humbeeck, J. Influence of Powder Bed Preheating on Microstructure and Mechanical Properties of H13 Tool Steel SLM Parts. Phys. Procedia 2016, 83, 882–890. [Google Scholar] [CrossRef]

- He, Y.; Zhong, M.; Beuth, J.; Webler, B. A Study of Microstructure and Cracking Behavior of H13 Tool Steel Produced by Laser Powder Bed Fusion Using Single-Tracks, Multi-Track Pads, and 3D Cubes. J. Mater. Process Technol. 2020, 286, 116802. [Google Scholar] [CrossRef]

- Yan, J.J.; Zheng, D.L.; Li, H.X.; Jia, X.; Sun, J.F.; Li, Y.L.; Qian, M.; Yan, M. Selective Laser Melting of H13: Microstructure and Residual Stress. J. Mater. Sci. 2017, 52, 12476–12485. [Google Scholar] [CrossRef]

- Li, S.; Yang, S.; Zhao, Y.; Dong, Y.; Wang, Z. 2 GPa H13 Steels Fabricated by Laser Powder Bed Fusion and Tempering: Microstructure, Tensile Property and Strengthening Mechanism. Mater. Sci. Eng. A 2023, 888, 145803. [Google Scholar] [CrossRef]

- Trojan, K.; Ocelík, V.; Čapek, J.; Čech, J.; Canelo-Yubero, D.; Ganev, N.; Kolařík, K.; De Hosson, J.T.M. Microstructure and Mechanical Properties of Laser Additive Manufactured H13 Tool Steel. Metals 2022, 12, 243. [Google Scholar] [CrossRef]

- Telasang, G.; Dutta Majumdar, J.; Wasekar, N.; Padmanabham, G.; Manna, I. Microstructure and Mechanical Properties of Laser Clad and Post-Cladding Tempered AISI H13 Tool Steel. Metall. Mater. Trans. A 2015, 46, 2309–2321. [Google Scholar] [CrossRef]

- Ali, Y.; Henckell, P.; Hildebrand, J.; Reimann, J.; Bergmann, J.P.; Barnikol-Oettler, S. Wire Arc Additive Manufacturing of Hot Work Tool Steel with CMT Process. J. Mater. Process Technol. 2019, 269, 109–116. [Google Scholar] [CrossRef]

- Du, X.; Liu, X.; Shen, Y.; Liu, R.; Wei, Y. H13 Tool Steel Fabricated by Wire Arc Additive Manufacturing: Solidification Mode, Microstructure Evolution Mechanism and Mechanical Properties. Mater. Sci. Eng. A 2023, 883, 145536. [Google Scholar] [CrossRef]

- Tanvir, A.N.M.; Ahsan, M.d.R.U.; Seo, G.; Bates, B.; Lee, C.; Liaw, P.K.; Noakes, M.; Nycz, A.; Ji, C.; Kim, D.B. Phase Stability and Mechanical Properties of Wire + Arc Additively Manufactured H13 Tool Steel at Elevated Temperatures. J. Mater. Sci. Technol. 2021, 67, 80–94. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, Y.; Wu, Z.; Shi, C. Microstructure and Properties of Die Steel Fabricated by WAAM Using H13 Wire. Vacuum 2018, 149, 185–189. [Google Scholar] [CrossRef]

- Liu, J.; Kannan, R.; Zhang, D.; Liu, T.; Nandwana, P.; Devaraj, A. Multi-Scale Characterization of Supersolidus Liquid Phase Sintered H13 Tool Steel Manufactured via Binder Jet Additive Manufacturing. Addit. Manuf. 2022, 56, 102834. [Google Scholar] [CrossRef]

- Nandwana, P.; Kannan, R.; Siddel, D. Microstructure Evolution during Binder Jet Additive Manufacturing of H13 Tool Steel. Addit. Manuf. 2020, 36, 101534. [Google Scholar] [CrossRef]

- Li, S.; Deng, H.; Lan, X.; He, B.; Li, X.; Wang, Z. Developing Cost-Effective Indirect Manufacturing of H13 Steel from Extrusion-Printing to Post-Processing. Addit. Manuf. 2023, 62, 103384. [Google Scholar] [CrossRef]

- Kolomy, S.; Maly, M.; Sedlak, J.; Zouhar, J.; Slany, M.; Hrabec, P.; Kouril, K. Machinability of Extruded H13 Tool Steel: Effect of Cutting Parameters on Cutting Forces, Surface Roughness, Microstructure, and Residual Stresses. Alex. Eng. J. 2024, 99, 394–407. [Google Scholar] [CrossRef]

- Maly, M.; Kolomy, S.; Kasan, R.; Bartl, L.; Sedlak, J.; Zouhar, J. Mechanical Properties, Structure and Machinability of the H13 Tool Steel Produced By Material Extrusion. Manuf. Technol. 2024, 24, 608–617. [Google Scholar] [CrossRef]

- D’Andrea, D. Additive Manufacturing of AISI 316L Stainless Steel: A Review. Metals 2023, 13, 1370. [Google Scholar] [CrossRef]

- Gao, Y.; Jiang, W.; Zeng, D.; Liang, X.; Ma, C.; Xiao, W. Additive Manufacturing of Titanium Alloys for Biomedical Applications: A Systematic Review. Rev. Mater. Res. 2025, 1, 100011. [Google Scholar] [CrossRef]

- Durai Murugan, P.; Vijayananth, S.; Natarajan, M.P.; Jayabalakrishnan, D.; Arul, K.; Jayaseelan, V.; Elanchezhian, J. A Current State of Metal Additive Manufacturing Methods: A Review. Mater. Today Proc. 2022, 59, 1277–1283. [Google Scholar] [CrossRef]

- Tebianian, M.; Aghaie, S.; Razavi Jafari, N.; Elmi Hosseini, S.; Pereira, A.; Fernandes, F.; Farbakhti, M.; Chen, C.; Huo, Y. A Review of the Metal Additive Manufacturing Processes. Materials 2023, 16, 7514. [Google Scholar] [CrossRef]

- Li, J.; Kong, D. Micro-Structures and High-Temperature Friction-Wear Performances of Laser Cladded Cr–Ni Coatings. Materials 2018, 11, 137. [Google Scholar]

- NADCA #207. Special Quality Die Steel & Heat Treatment Acceptance Criteria for Die Casting Dies; NADCA Die Materials Committee: Arlington Heights, IL, USA, 2022; Volume 202. [Google Scholar]

- ASTM A681-08; Standard Specification for Tool Steels Alloy. ASTM International: West Conshohocken, PA, USA, 2022.

- Sumanariu, C.A.; Amza, C.G.; Baciu, F.; Vasile, M.I.; Nicoara, A.I. Comparative Analysis of Mechanical Properties: Conventional vs. Additive Manufacturing for Stainless Steel 316L. Materials 2024, 17, 4808. [Google Scholar] [CrossRef]

- Piemontese, L. Manufacturing through Electron Beam Melting of Hot-Work Tool Steels. Ph.D. Thesis, Politecnico di Torino, Turin, Italy, 2024. [Google Scholar]

- Wang, H.; Li, J.; Shi, C.-B.; Li, J.; He, B. Evolution of Carbides in H13 Steel in Heat Treatment Process. Mater. Trans. 2017, 58, 152–156. [Google Scholar] [CrossRef]

- Kenevisi, M.S.; Gobber, F.S.; Fino, P.; Lombardi, M.; Bondioli, F.; Biamino, S.; Ugues, D. Tool Steels and Their Additive Manufacturing for Fabrication and Repair via PBF and DED Processes: Techniques, Challenges, and Applications. Mater. Des. 2025, 258, 114639. [Google Scholar] [CrossRef]

- Kannan, R.; Nandwana, P. Texture Evolution during Processing and Post-Processing of Maraging Steel Fabricated by Laser Powder Bed Fusion. Sci. Rep. 2022, 12, 6396. [Google Scholar] [CrossRef]

- Pellizzari, M.; Massignani, D.; Amirabdollahian, S.; Deirmina, F. Thermal Fatigue Behavior of AISI H13 Hot Work Tool Steel Produced by Direct Laser Metal Deposition. Steel Res. Int. 2023, 94, 2200449. [Google Scholar] [CrossRef]

- Kahlert, M.; Brenne, F.; Vollmer, M.; Niendorf, T. Influence of Microstructure and Defects on Mechanical Properties of AISI H13 Manufactured by Electron Beam Powder Bed Fusion. J. Mater. Eng. Perform. 2021, 30, 6895–6904. [Google Scholar] [CrossRef]

- Nandwana, P.; Kannan, R.; Unocic, K.A.; Fancher, C.M.; Goldsby, D.; Epps, K.; Pierce, D.T. High Temperature Tensile Properties of H13 Tool Steel Fabricated via Binder Jet Additive Manufacturing. J. Mater. Res. Technol. 2025, 37, 2577–2585. [Google Scholar] [CrossRef]

| C | Si | Mn | Cr | Mo | V | P | S | Fe |

|---|---|---|---|---|---|---|---|---|

| 0.32–0.45 | 0.80–1.20 | 0.20–0.60 | 4.75–5.50 | 1.10–1.75 | 0.80–1.20 | ≤0.030 | ≤0.030 | Balance |

| AM Method | Feedstock Type | Morphology | Particle Size/Distribution | Source/Notes |

|---|---|---|---|---|

| LPBF | Gas-atomized powder | Spherical | Dv10 = 26.4 μm, Dv50 = 45.0 μm, Dv90 = 62.4 μm; | Commercial supplier |

| FDMS Desktop Metal | Powder in thermoplastic binder | Irregular (powder composite) | Dv10 = 11.5 μm, Dv50 = 34.3 ± 3.2 μm, Dv90 = 63 μm | Extracted from H13 filament |

| FDMS Zetamix | Loose powder from filament | Irregular | Dv10 = 9.5 μm, Dv50 = 18.4 ± 1.6 μm, Dv90 = 44 μm | Extracted from H13 filament |

| Binder Jetting | Gas-atomized powder | Spherical | Dv10 ≈ 10–15 μm, Dv50 ≈ 25 μm, Dv90 ≈ 45 μm [34] | Commercial supplier; optimized for binder infiltration |

| DED | Wire feedstock (solid) | Wire (1.0 mm diameter) | Diameter: 1.0 mm | H13 composition (AISI H13 equivalent) |

| Method | FDMS (Desktop Metal) | FDMS (Zetamix) | Binder Jetting | LPBF | DED |

|---|---|---|---|---|---|

| density [%] | 90.7 | 94 | 99.3 | 99.9 | >99.9 |

| hardness as-printed | − | − | + | + | |

| hardness after HT | − | + | + | + | |

| deposition rate [kg/h] | 2–3 | 1.5–2.5 | 5.5 | 0.1–0.5 | 1–2 |

| accuracy of printed part | low | low | high | high | medium |

| cost of material [EUR/kg] | 500–700 | 500–700 | 100–500 | 60–80 | 25–40 |

| cost of printing device | medium | low | high | medium | medium |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Widomski, P.; Kaszuba, M.; Dobras, D.; Terefinko, D.; Kołodziński, M. Comparative Study of Different Additive Manufacturing Methods for H13 Tool Steel. Materials 2025, 18, 5299. https://doi.org/10.3390/ma18235299

Widomski P, Kaszuba M, Dobras D, Terefinko D, Kołodziński M. Comparative Study of Different Additive Manufacturing Methods for H13 Tool Steel. Materials. 2025; 18(23):5299. https://doi.org/10.3390/ma18235299

Chicago/Turabian StyleWidomski, Paweł, Marcin Kaszuba, Daniel Dobras, Dominik Terefinko, and Michał Kołodziński. 2025. "Comparative Study of Different Additive Manufacturing Methods for H13 Tool Steel" Materials 18, no. 23: 5299. https://doi.org/10.3390/ma18235299

APA StyleWidomski, P., Kaszuba, M., Dobras, D., Terefinko, D., & Kołodziński, M. (2025). Comparative Study of Different Additive Manufacturing Methods for H13 Tool Steel. Materials, 18(23), 5299. https://doi.org/10.3390/ma18235299