1. Introduction

Machine components employed across various industrial sectors typically demand precise shaping [

1] and surface preparation [

2] to meet functional and quality requirements. Milling is a key process in modern manufacturing, widely used for precise and efficient material removal across various industries. Its capability to produce complex geometries, smooth surfaces, and tight dimensional tolerances makes it indispensable in the production of components for aerospace, automotive, medical, and tooling applications. Among the different milling methods, end milling is particularly valued for its flexibility in machining intricate profiles and its suitability for advanced materials such as polymer matrix composites and high-performance alloys [

3,

4].

The most commonly used materials for end mills are cemented carbide, high-speed steel, and tool steels with physical vapor deposition (PVD) or chemical vapor deposition (CVD) coatings. A critical feature of an end mill is its flutes, which are precisely formed through grinding operations, typically using specialized grinding wheels to achieve the desired geometry and surface finish. The chip flutes are designed to efficiently evacuate machining chips, reduce cutting forces, and enhance heat dissipation. The geometric configuration of the flutes is essential for ensuring optimal cutter performance and long tool life. The manufacturing of such cutters is a complex and demanding process, typically carried out through precision grinding. Nevertheless, recent research continues to advance the reliability, accuracy, and performance of CNC-based flute grinding technologies.

Li et al. [

5] proposed a two-pass grinding strategy for end mill flutes with segmented helix angles, achieving optimized cutting-edge geometry through precise control of grinding wheel positioning and the implementation of advanced posture control algorithms. Microcrack formation during end mill flute grinding was investigated in [

6], where the authors employed recurrence analysis to identify and characterize the defects. The problem of grinding milling cutters was investigated by Wang et al. [

7]. The authors developed a grinding force model and carried out the design and optimization of the cutter. The mathematical model of grinding forces demonstrated that the selected grinding parameters did not induce edge fracture. The grinding damage mechanism of the cutting edge was predominantly governed by brittle removal, whereas the helix flute experienced a combination of plastic and brittle removal mechanisms. Article [

8] presented a method for designing grooves in cutters with variable pitch and helix angle, taking into account the practical feasibility of the manufacturing process. Optimization of the groove structure was proposed to increase cutting efficiency and enhance the surface quality of the machined parts. Moreover, in [

9], authors developed a mathematical model of the grinding process for end mills with helical cutting edges, taking into account both the tool geometry and the trajectory of the grinding wheel. The proposed model was implemented in a CAD/CAM simulation environment, enabling precise reconstruction of the blade profile and prediction of machining errors. The results offer valuable guidance for optimizing the grinding process with respect to geometric accuracy and surface quality of cutting tools. Zheng et al. [

10] introduced a novel method for grinding the flutes of conical milling cutters. The authors developed an approach for accurately calculating the flute profiles of complex geometries by deriving the conical cutting edge line and determining the grinding wheel’s position throughout the process, based on the design requirements for the rake angle and core radius. Subsequently, a calculation method for modeling complex flute profiles was applied and validated. Ren et al. [

11] presented a precise method for grinding grooves in cylindrical cutters using standard 1V1/1A1 grinding wheels. The method utilizes a system of nonlinear equations to accurately determine the grinding wheel’s position throughout the groove grinding process, accounting for all three essential groove parameters. The influence of technological parameters on temperature, grinding forces, and surface roughness during the single-pass grinding of carbide end mill flutes was systematically investigated in [

12]. The study showed that cutting parameters significantly affect the thermal, mechanical, and surface properties in grinding.

This paper differs from previous studies in three main aspects. First, while earlier work applied recurrence analyis to cutting processes, it mainly characterized signal complexity rather than modeling a direct relationship between cutting parameters and recurrence measures [

13,

14,

15]. Our approach explicitly captures this dependency, offering deeper insight into process dynamics. Second, the proposed RQA-based model estimates recurrence metrics as functions of cutting parameters and supports predictive assessment of grinding process stability and periodicity. Third, we introduce the Dominant Index (DI) as a novel sensitivity metric that clearly identifies which parameter most strongly influences grinding forces. The integration of DI with recurrence analysis is new, while confirming known trends, such as feed rate effects validates the approach. By combining DI with established sensitivity measures, we provide a robust tool for analyzing and interpreting machining dynamics.

5. Discussion

The recurrence-based findings provide a foundation for developing predictive mathematical models of individual indicators, allowing for precise estimation without the need for extensive experimentation. This is especially important given the high time and resource demands associated with empirical studies in tool production.

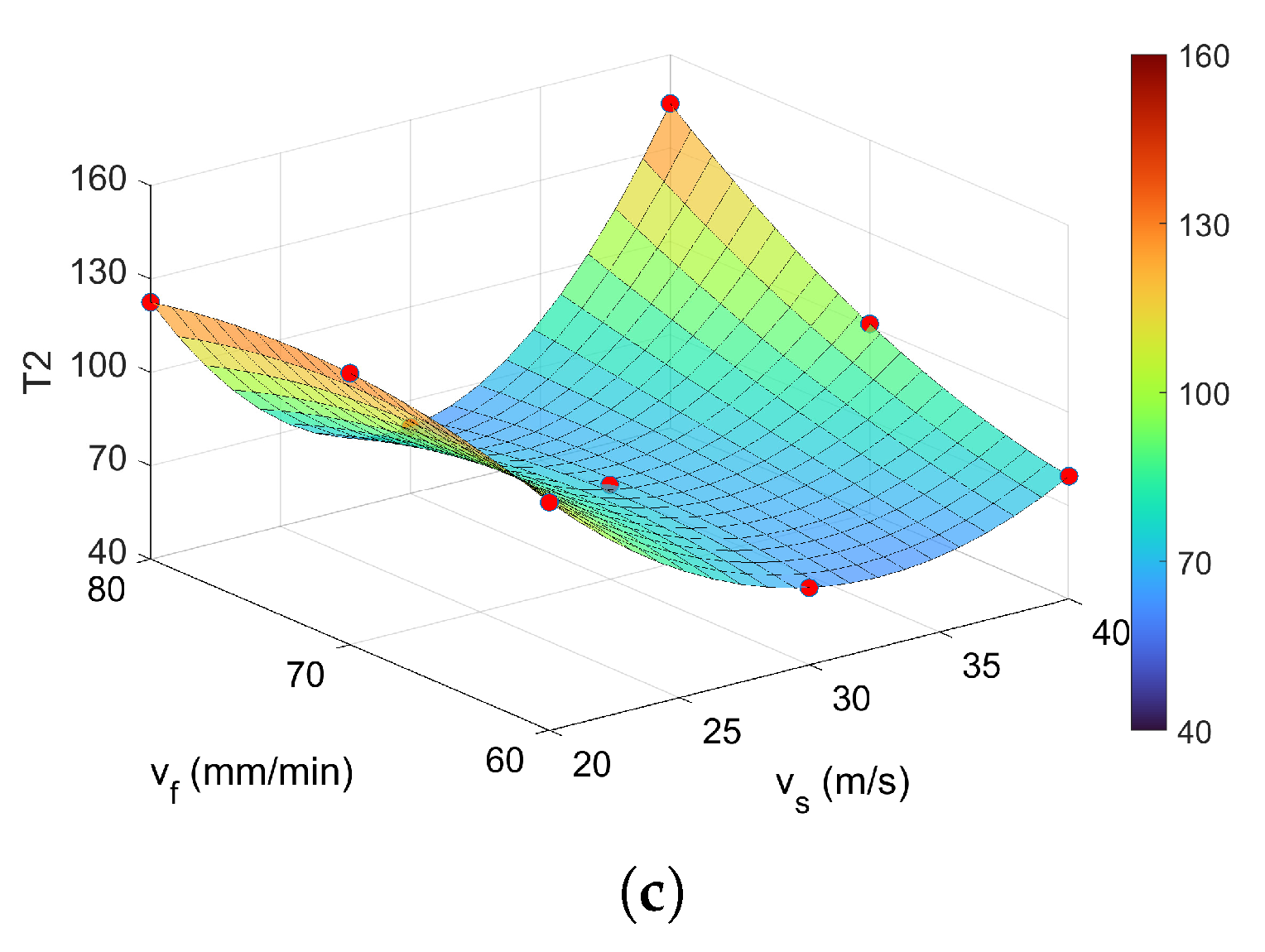

To construct a generalized model of recurrence measures, the poly22 fitting option in MATLAB version 24.2.0.2712019 (2024b) is applied. This method corresponds to a second-order polynomial surface approximation involving two independent variables-specifically, the cutting speed and feed rate in the present study. The proposed model enables surface fitting in three-dimensional space, where the response variable is expressed as a function of both inputs through a polynomial equation incorporating linear, interaction, and quadratic terms.

The recurrence indicator

was modeled as a second-order polynomial function of cutting speed

and feed rate

. This formulation captures both linear and nonlinear effects, as well as their interaction, allowing for a detailed surface analysis of the recurrence behavior across the process parameter space.

where

,

,

,

,

, and

denote the surface fitting coefficients listed in

Table 6. Surface fitting is performed via polynomial regression, which determines the optimal set of coefficients by minimizing the residual sum of squares between the empirical data and the polynomial surface function, with 95% confidence bounds.

Surface fitting is performed using polynomial regression, which determines the optimal set of coefficients by minimizing the residual sum of squares between the empirical data and the polynomial surface function. The resulting coefficients are accompanied by 95% confidence bounds, which indicate the statistical reliability of the fit.

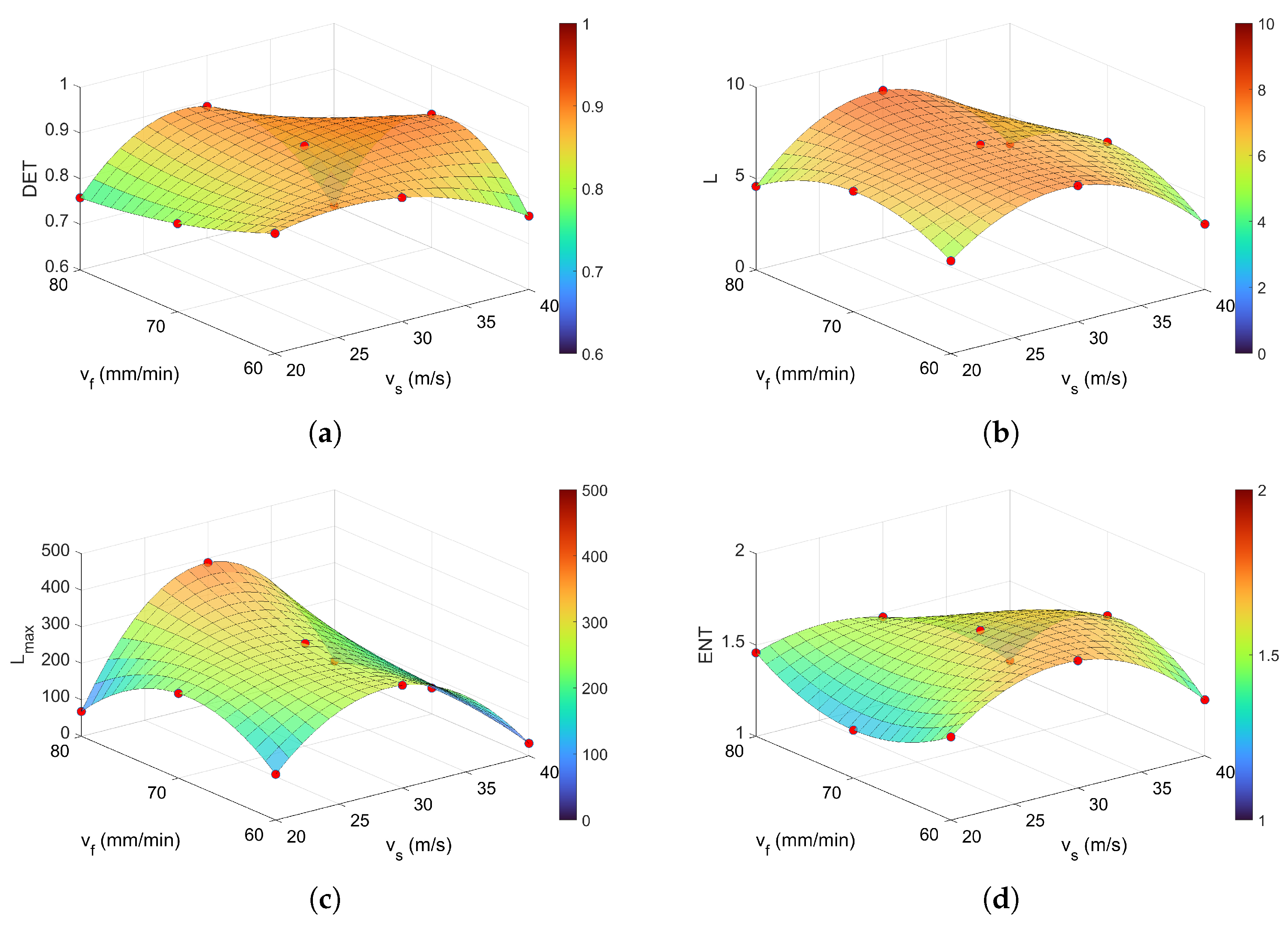

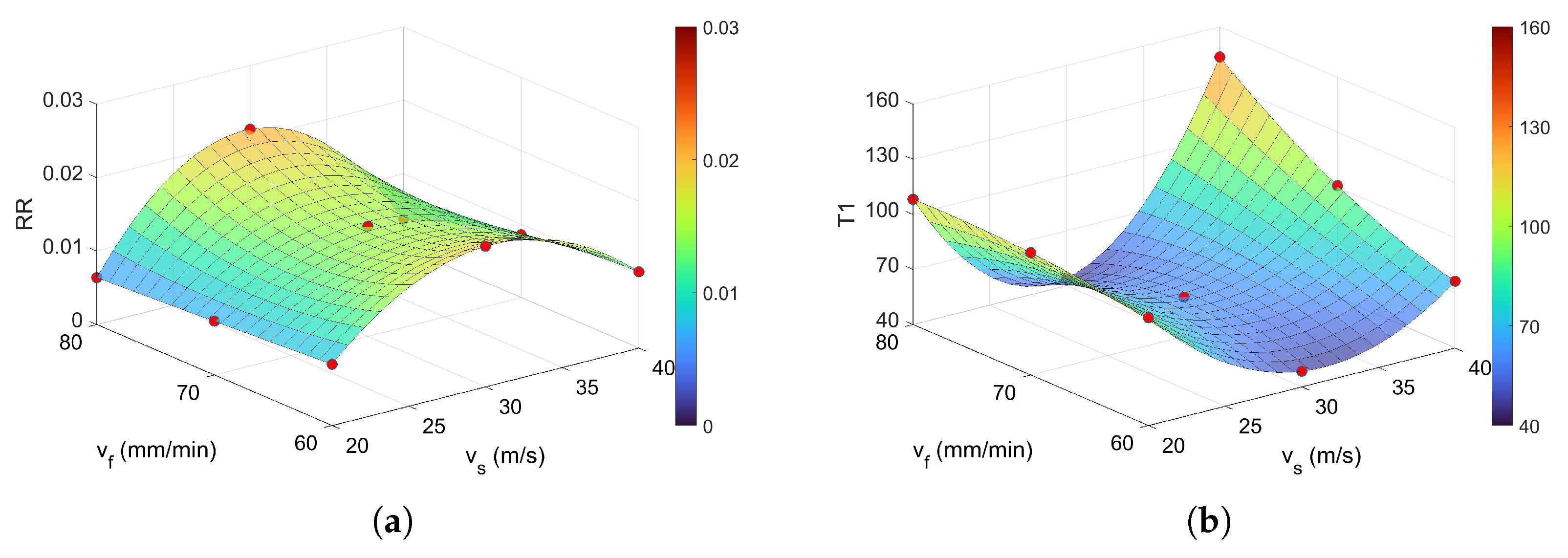

The results obtained from the recurrence model (Equation (

4)), developed within the proposed mathematical framework, were superimposed as red markers onto the surfaces presented in

Section 4.4. The close agreement between these markers and the numerically computed values of the RQA indicators confirms the model’s predictive accuracy.

To evaluate the quality of the fitted model or recurrence measures, several statistical metrics are calculated, including residuals, root mean square error (

), normalized root mean square error (

), mean absolute error (

), the coefficient of determination (

), and the adjusted coefficient of determination (

) of the model coefficients

Table 7. These measures provide a comprehensive assessment of the model’s accuracy and statistical significance, ensuring the reliability of the derived conclusions.

The regression models applied to the RQA indicators demonstrate varying levels of predictive accuracy and generalization. Indicators such as , , and exhibit very low , and values, indicating excellent local fit and minimal prediction error. These models are well-suited for precise estimation within their respective domains. The normalized root mean square error was used to assess model performance independently of the scale of the analyzed variables. It provides a dimensionless measure of error, allowing for direct comparison across different indicators. Lower values indicate better model fit, with values below 0.1 typically considered excellent. In this study, varied considerably across parameters, reflecting differences in data variability and model sensitivity. This suggests that the best-fitting are , and .

In contrast, , , and show significantly higher and values, which can be attributed to the larger scale of the analyzed variables. However, their normalized values remain within acceptable bounds, suggesting that the absolute error is proportional to the magnitude of the data. The determination coefficients are generally high across most indicators, with and exceeding 0.9, confirming strong explanatory power. Adjusted values also support this, although and show relatively low adjusted scores (0.0123 and 0.2256), indicating limited generalization despite low error metrics. Overall, the models provide reliable fits for most indicators, especially those with consistent scale and structure.

The analysis of the average derivative of

, as defined in Equation (

4), facilitates the identification of the dominant grinding parameter by evaluating the mean absolute values of the partial derivatives with respect to

and

across the examined range:

n represents the total number of data points considered in the analysis.

As shown in Equation (

7), the dominant index (

) is computed by assessing the difference between the partial derivatives given in Equations (

5) and (

6), thereby providing a quantitative measure of the relative impact of cutting speed and feed rate.

This indicator facilitates the evaluation of whether cutting speed () or feed rate () has a more significant impact on the selected recurrence metrics. A positive value of indicates that is the dominant factor, while a negative value suggests that exerts greater influence. Values of close to zero imply that both parameters contribute with comparable significance.

Figure 14a–j depict the dominant index values associated with individual recurrence indicators. The dimensionless nature of the DI index allows for relative comparison, indicating which parameter exerts a stronger influence on the selected

measure. To enhance the interpretability of the plot, a filled contour representation with DI isolines was used. Blue areas indicate negative DI values, while yellow and green correspond to positive ones. Yellow-highlighted regions mark areas where the feed rate exerts a stronger influence than grinding speed on the

metrics. A comprehensive analysis across all indicators reveals a consistent conclusion: cutting speed has the most pronounced effect on recurrence measures, as indicated by the predominance of blue-shaded regions. A localized dominance of feed rate is observed only around a grinding speed of 30 m/s, aligning with the previously presented RQA surface plots. This outcome is attributable to the presence of stability lobes and chatter phenomena, which define the boundaries between stable and unstable cutting regimes [

41].

It is noteworthy that

(

Figure 14a) demonstrates the greatest sensitivity among all indicators, as evidenced by the broad yellow-highlighted areas. Following closely are

(

Figure 14b) and

(

Figure 14g), which also show considerable responsiveness. Interestingly, some indicators exhibit greater sensitivity to the feed rate

than others. Indicators

(

Figure 14i),

(

Figure 14j), and

(

Figure 14f) show low responsiveness to feed rate but react more strongly to cutting speed. The recurrence time indicators display nearly identical dominance index maps, as seen in the

and

surfaces (see

Figure 13b,c), suggesting a consistent influence pattern. The dominance index

maps for

(

Figure 14b) and

(

Figure 14e) are notably symmetric with respect to feed rate and cutting speed. This symmetry implies that laminar states undergo similar changes with increasing feed rate across the entire range of cutting speeds. A comparable symmetry is also observed for

(

Figure 14f),

(

Figure 14g), and

(

Figure 14c). In contrast, the least symmetric

maps are associated with

(

Figure 14a),

(

Figure 14d),

(

Figure 14h), and the recurrence time indicators

(

Figure 14i) and

(

Figure 14j). This asymmetry suggests that near the critical grinding speed, the dominance of cutting speed (

) may increase significantly.

To summarize, the maps reveal that cutting speed tends to exert a greater impact on the RQA measures overall. Nevertheless, for specific parameters, the feed rate may also play a dominant role.

6. Conclusions

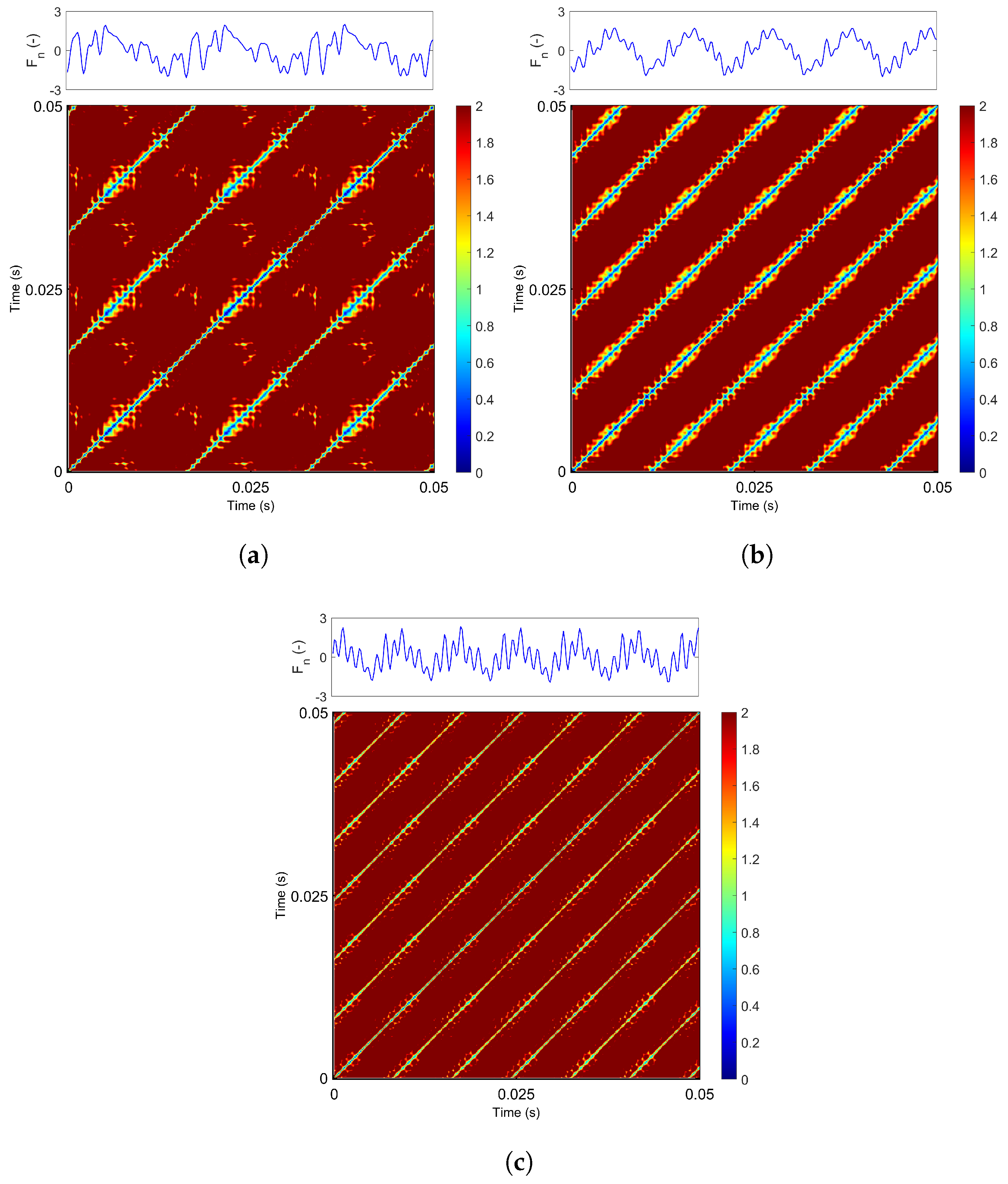

This study presents a comprehensive analysis of grinding forces dynamics during end mill machining. Due to the inherent complexity of the grinding process, this area remains relatively underexplored in the existing literature. In the experimental phase, grinding tests were conducted under varying cutting speeds and feed rates. Based on the collected data, a mathematical model describing the grinding force was developed. Additionally, recurrence diagrams were generated and analyzed using recurrence quantification analysis.

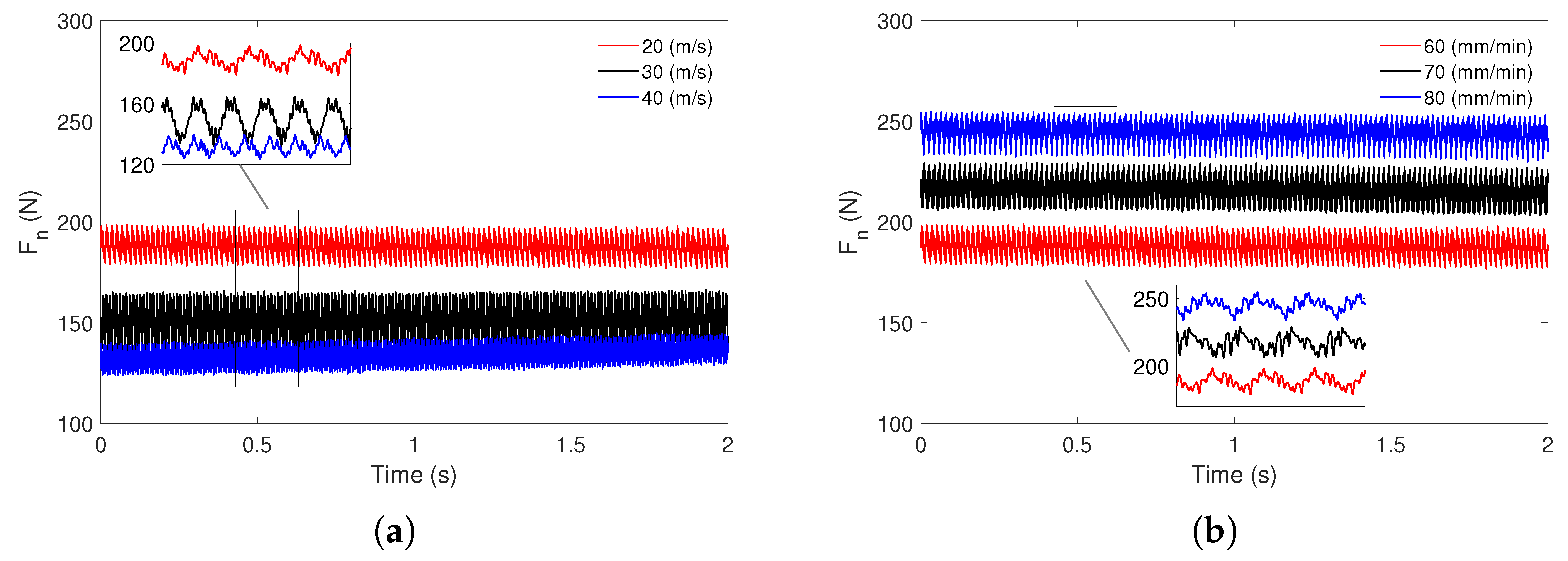

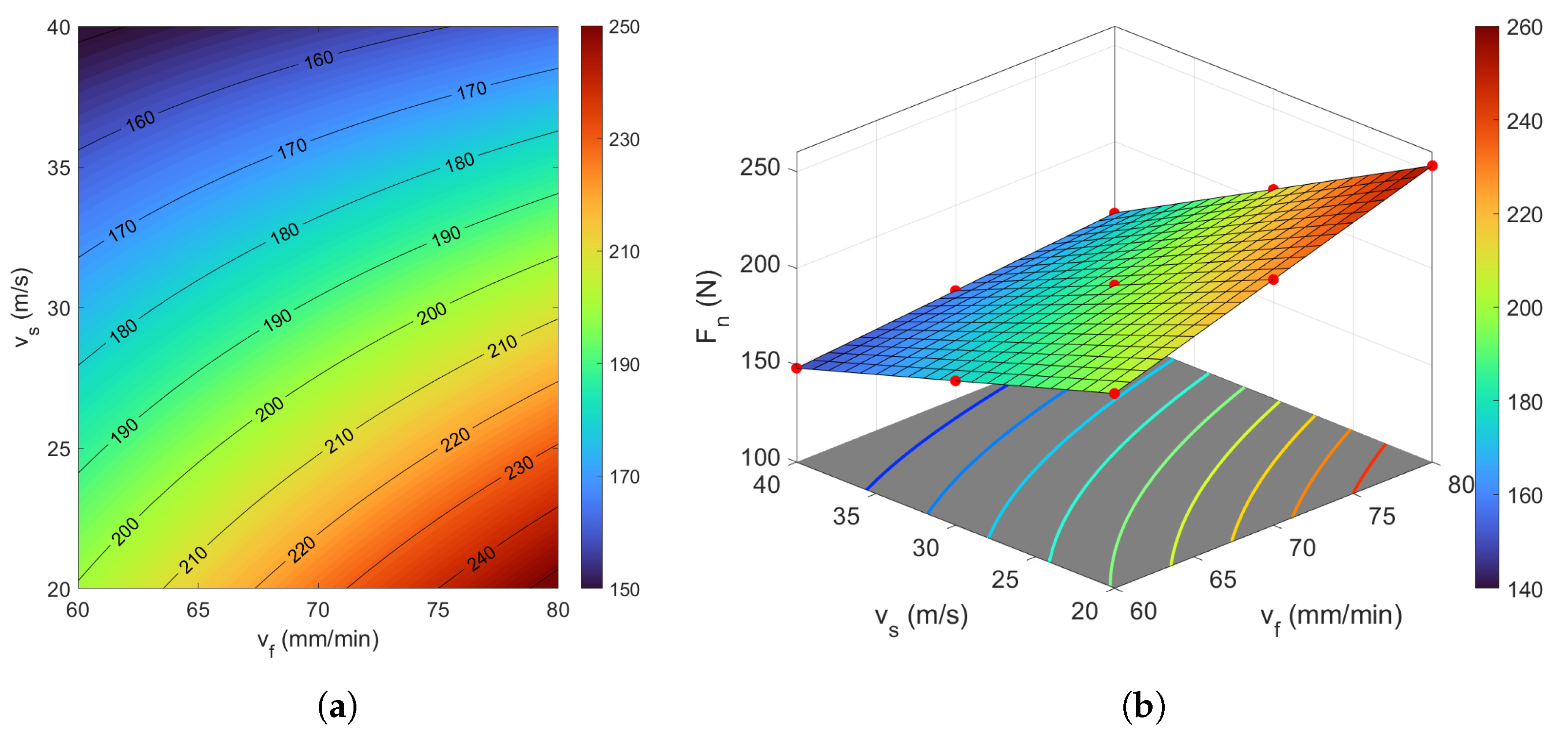

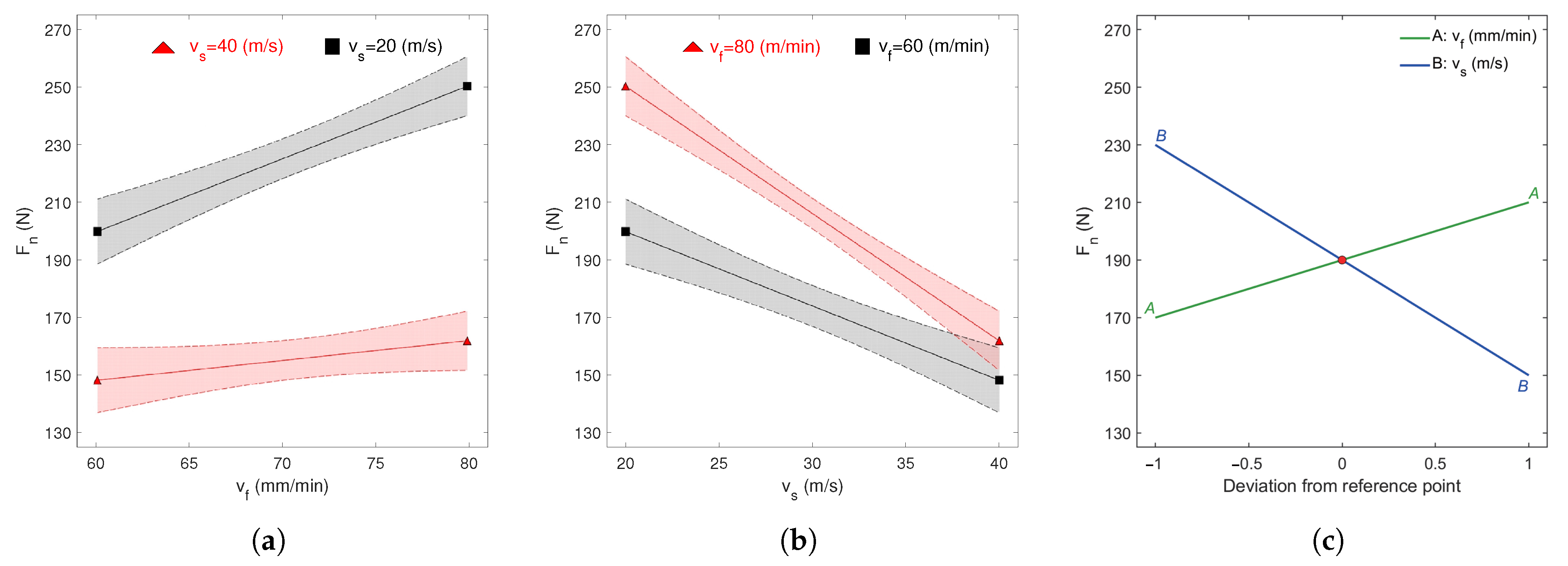

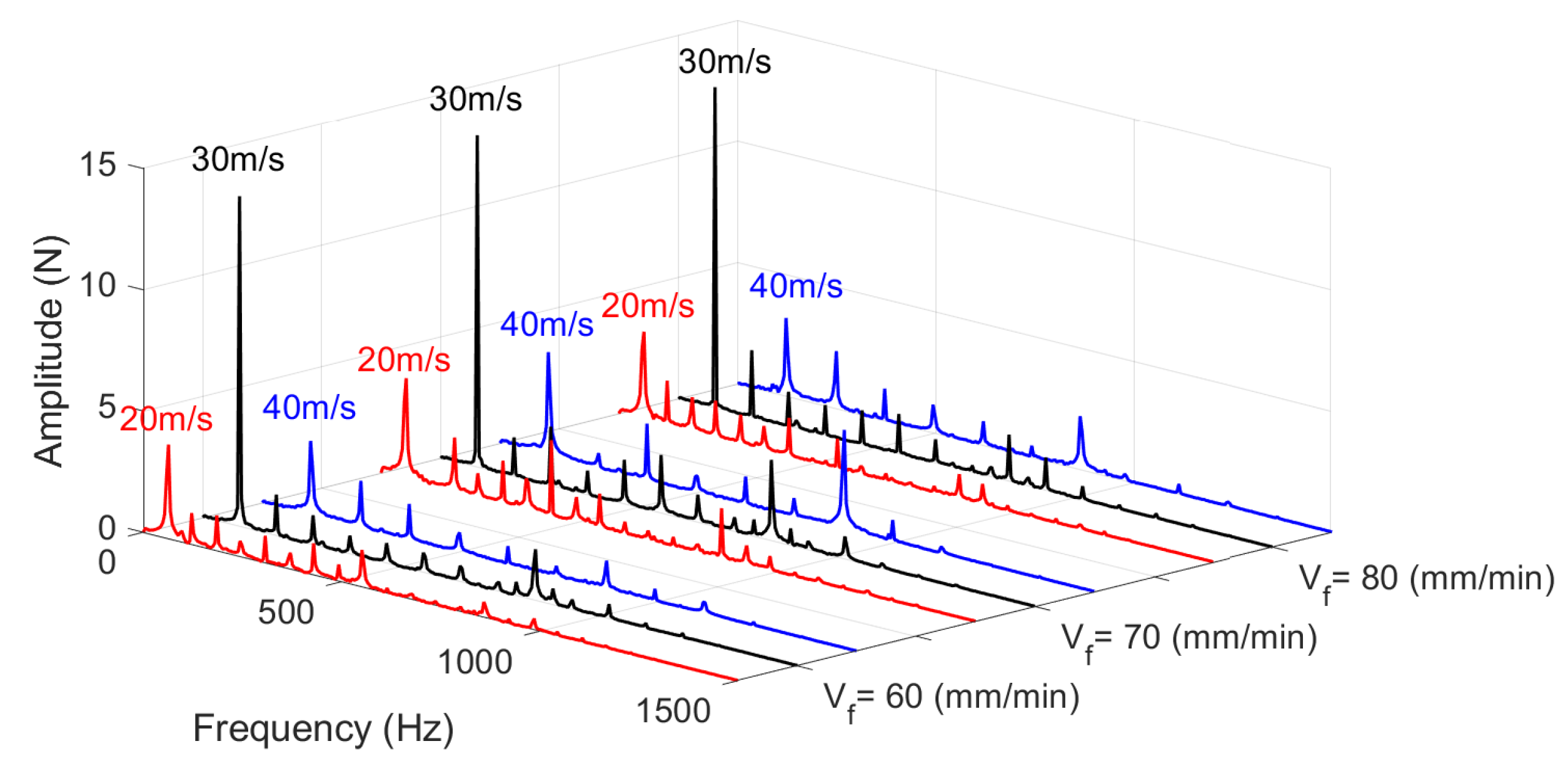

The results showed that during grinding with a 1A1-type diamond wheel, the single-pass straight flute of the TSF22 ultrafine grained cemented carbide end mill experienced an average cutting force of approximately 200 N, with peak values reaching up to 250 N. These values were observed at cutting speeds ranging from 20 to 40 m/s and feed rates between 60 and 80 mm/min.

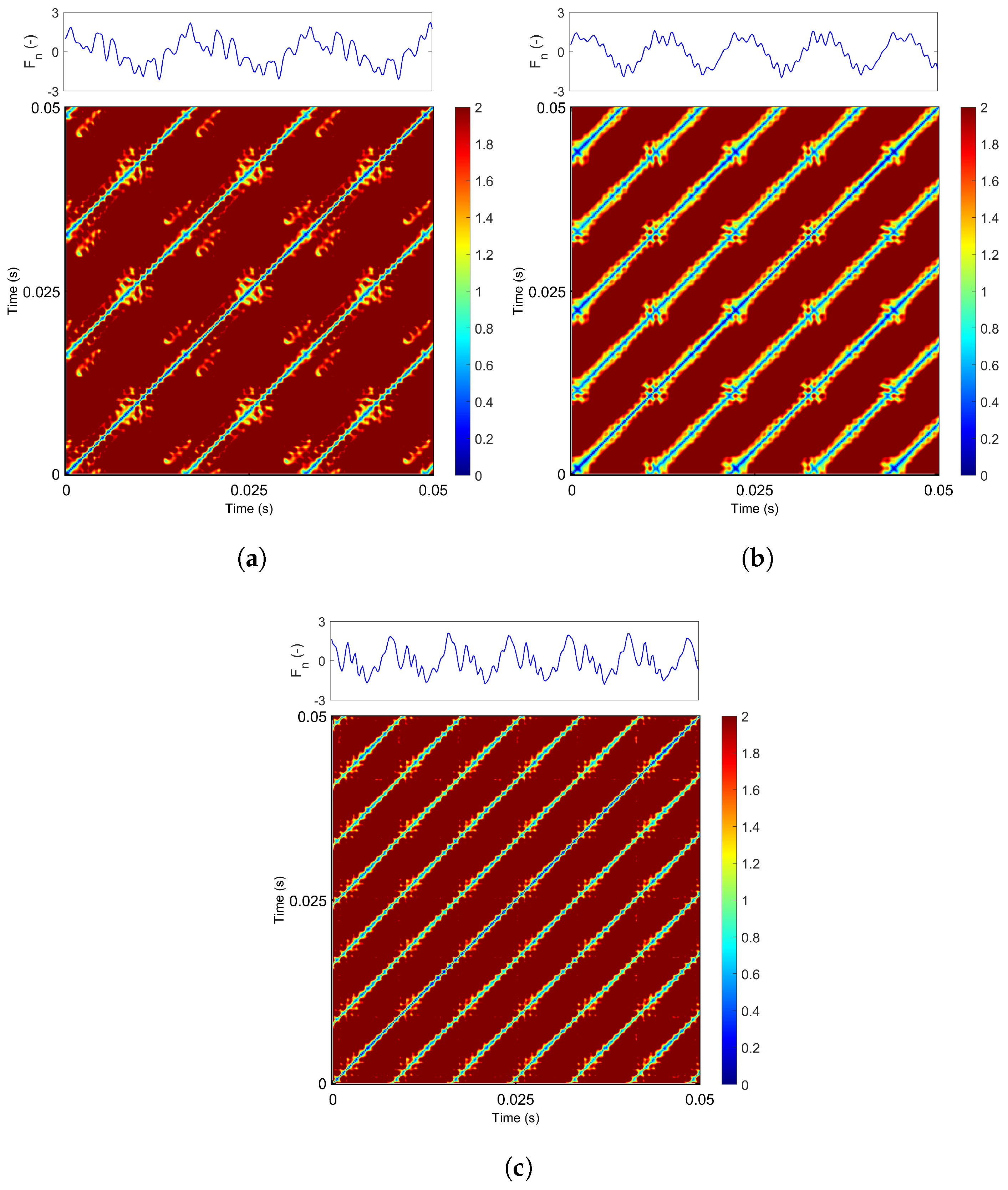

A similar conclusion was drawn from the recurrence plots: higher cutting speeds resulted in more periodic system dynamics, characterized by clearer diagonal structures and more dominant frequency components. The influence of feed rate on the RP structure was relatively minor; the main diagonal remained largely unchanged, with only additional recurrence points appearing. Interestingly, at a feed rate of 70 mm/min, the recurrence plots exhibited the most periodic structure. The RQA results confirmed that the analyzed signals generally exhibit predominantly deterministic behavior, as indicated by high values of the DET metric. Most recurrence indicators based on diagonal line structures reached their maximum values at a cutting speed of 30 m/s and a feed rate of 70 mm/min, suggesting that the system demonstrates the most stable and periodic behavior under these conditions (i.e., for the TSF22 tool, 1A1 grinding wheel, and within the analyzed parameter range). These findings support the recommendation of 30 m/s as the optimal cutting speed for end mill grinding.

Notably, the parameter did not fully corroborate this conclusion. Recurrence measures based on vertical line structures, such as and , also attained their highest values at a cutting speed of 30 m/s. Similar trends were observed for and the recurrence time metrics and . Among all indicators, , , and appeared to be the most sensitive to variations in cutting parameters, as evidenced by their highly complex surface profiles. In contrast, exhibited definitely lower sensitivity.

Based on the obtained RQA surface maps, nonlinear mathematical models of recurrence quantification were proposed. This modeling approach enables accurate prediction of system behavior without the need for extensive experimental procedures, which is particularly advantageous given the time and cost constraints associated with grinding process studies.

To evaluate which cutting parameter exerts a greater influence on recurrence measures, a new metric, referred to as the dominant index () was introduced. This index enables a comparative assessment of the relative impact of cutting speed and feed rate on the selected recurrence-based indicators. The maps revealed that, overall, cutting speed is the more dominant factor within the analyzed parameter space. However, near a cutting speed of 30 m/s, feed rate emerged as the more sensitive parameter. Symmetry observed in the maps for indicators such as , , , and suggests that feed rate sensitivity peaks around mm/min (notably, the RP diagrams for this setting were also more periodic). In contrast, asymmetry in the maps for , , , , and indicates that this value is slightly shifted.

The results obtained can be used to assess the stability of the chip groove grinding process and to avoid operating within hazardous parameter ranges. Additionally, the proposed mathematical models allow for the estimation of force values and recurrence indices, thereby improving grinding efficiency. These findings may also contribute to the detection of grinding wheel breakage, which remains one of the most critical challenges in this type of machining.