Wear Performance of a Physical Vapour Deposition-Coated, Spark Plasma Sintered TiB2/Ti Composite Lubricated with Externally Introduced hBN at Temperatures up to 900 °C

Abstract

1. Introduction

2. Materials and Methods

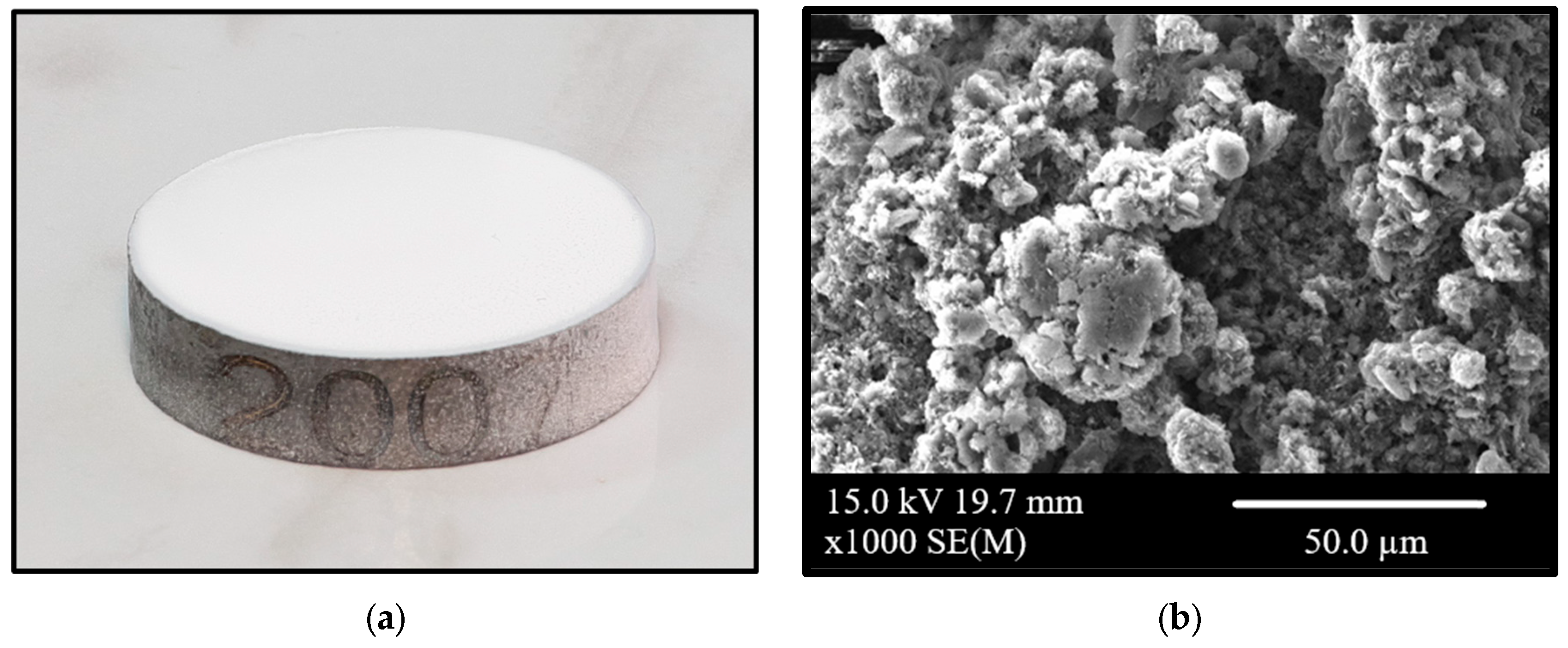

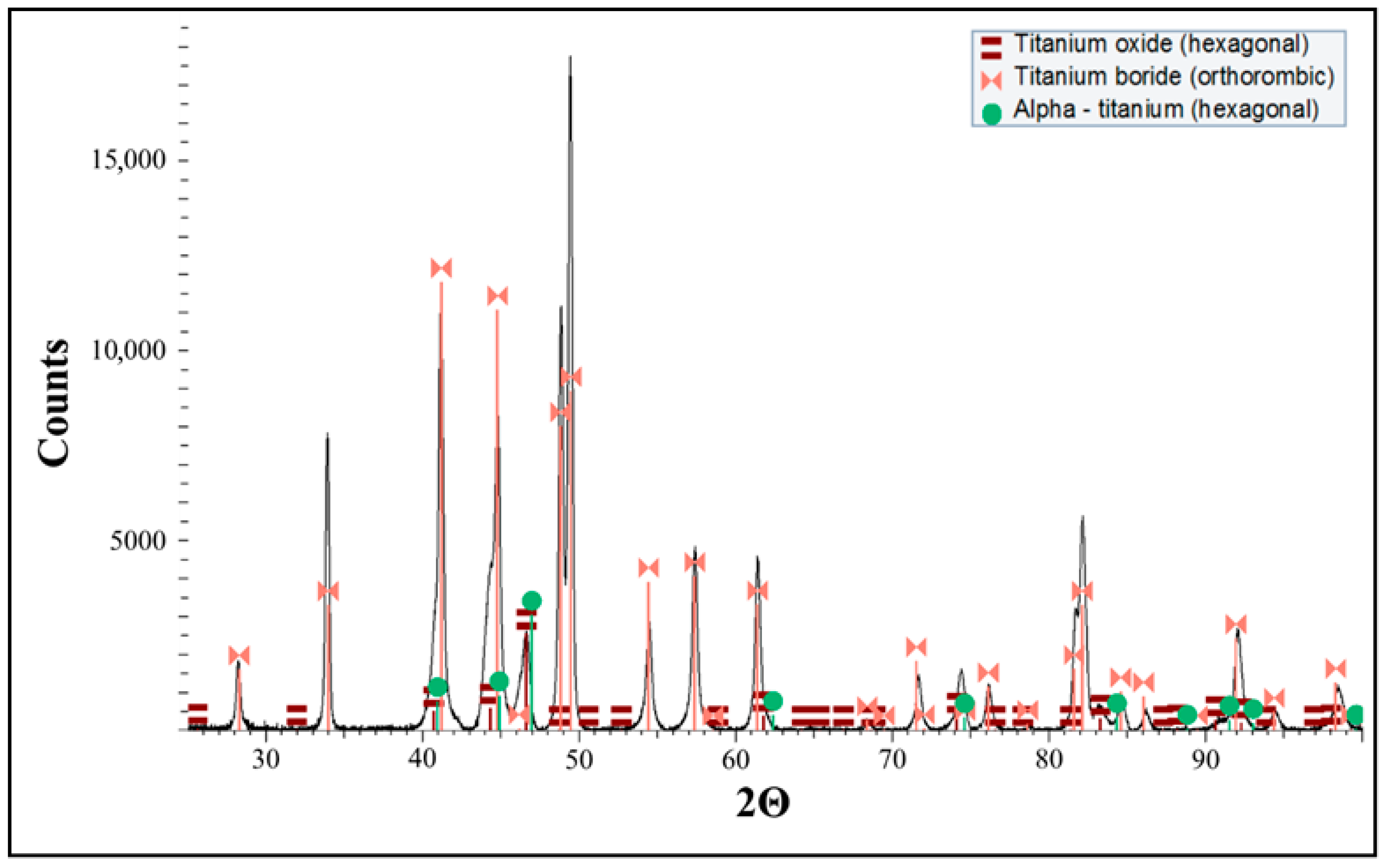

2.1. The TiB2/Ti Composite

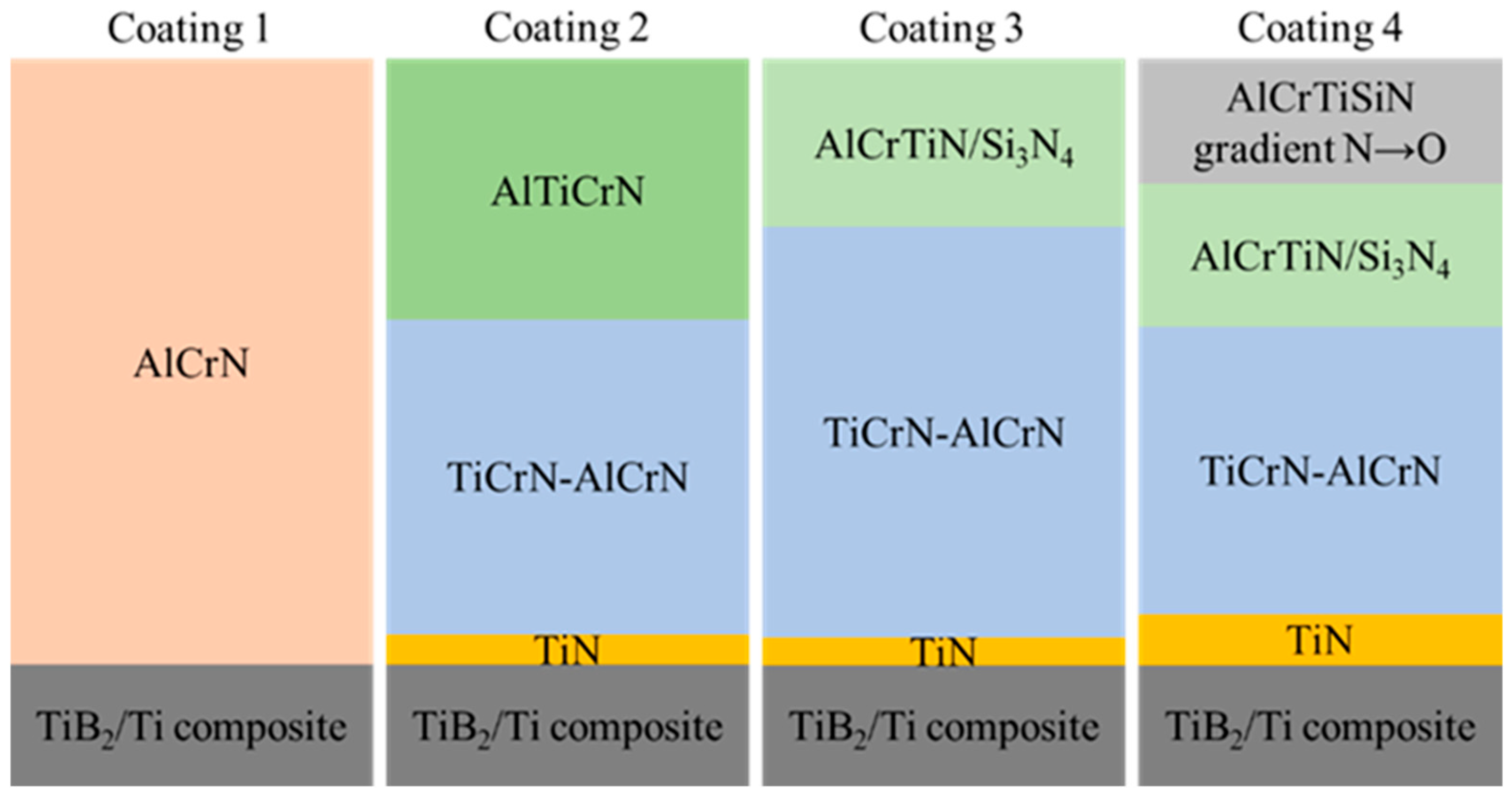

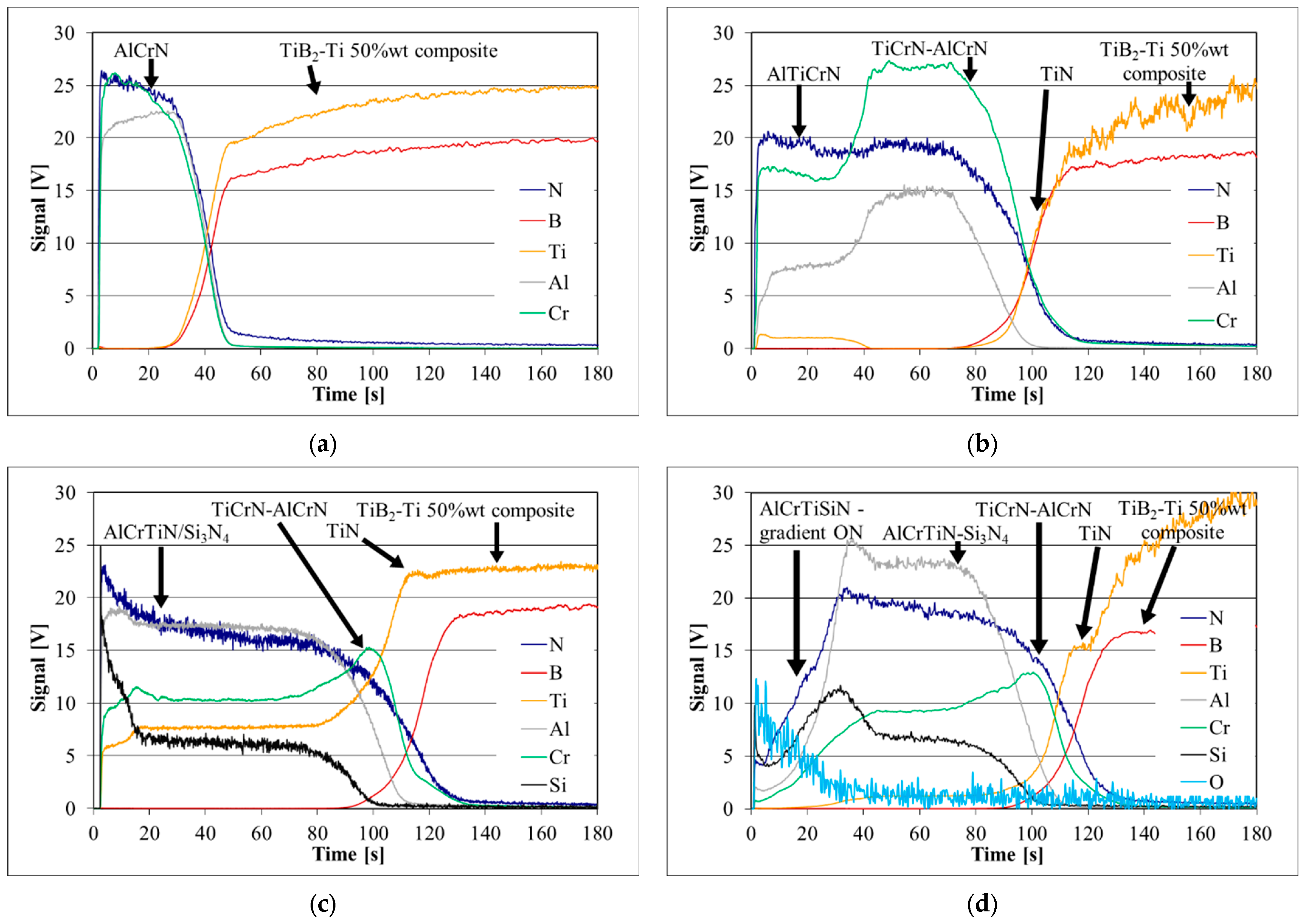

2.2. Coating Deposition

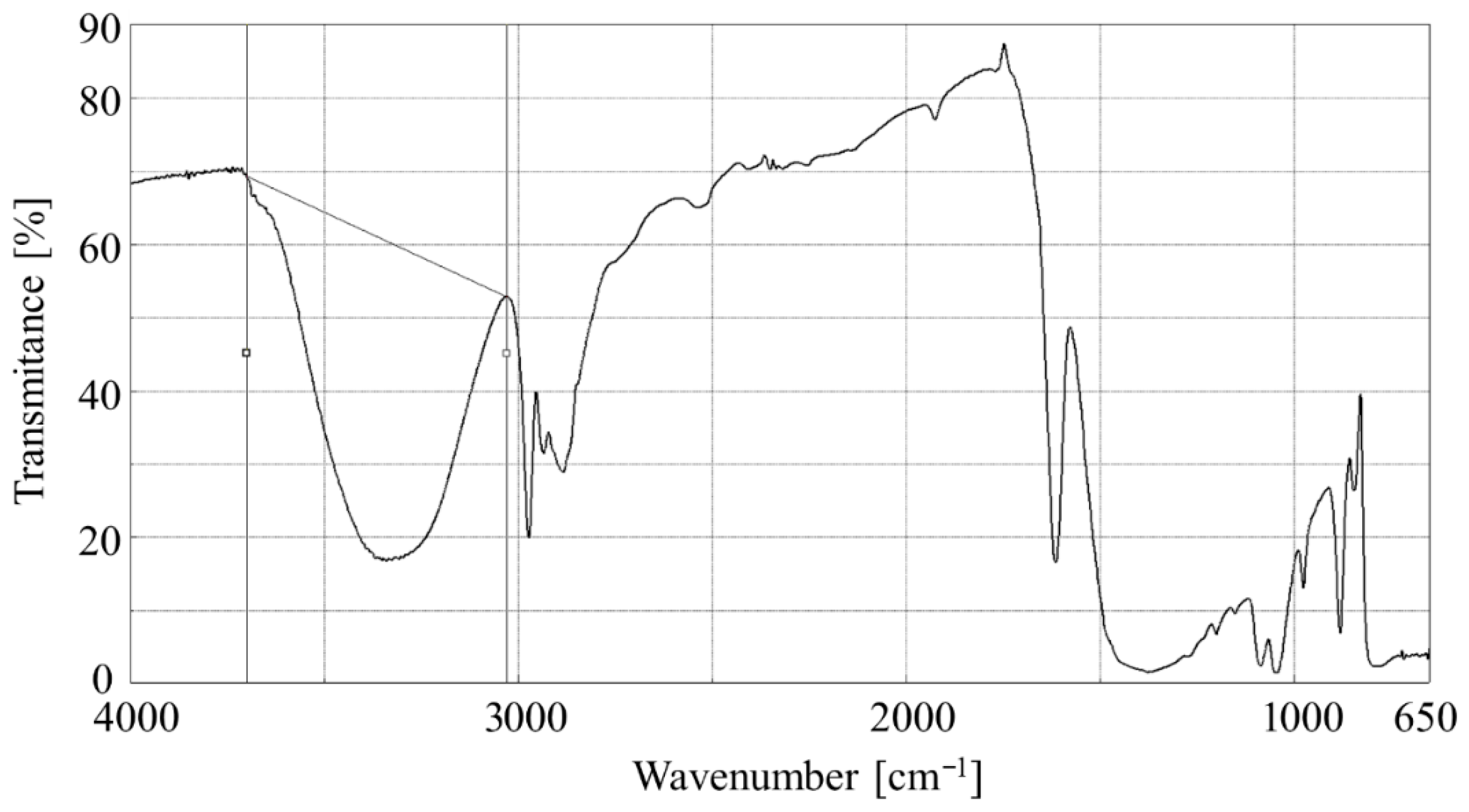

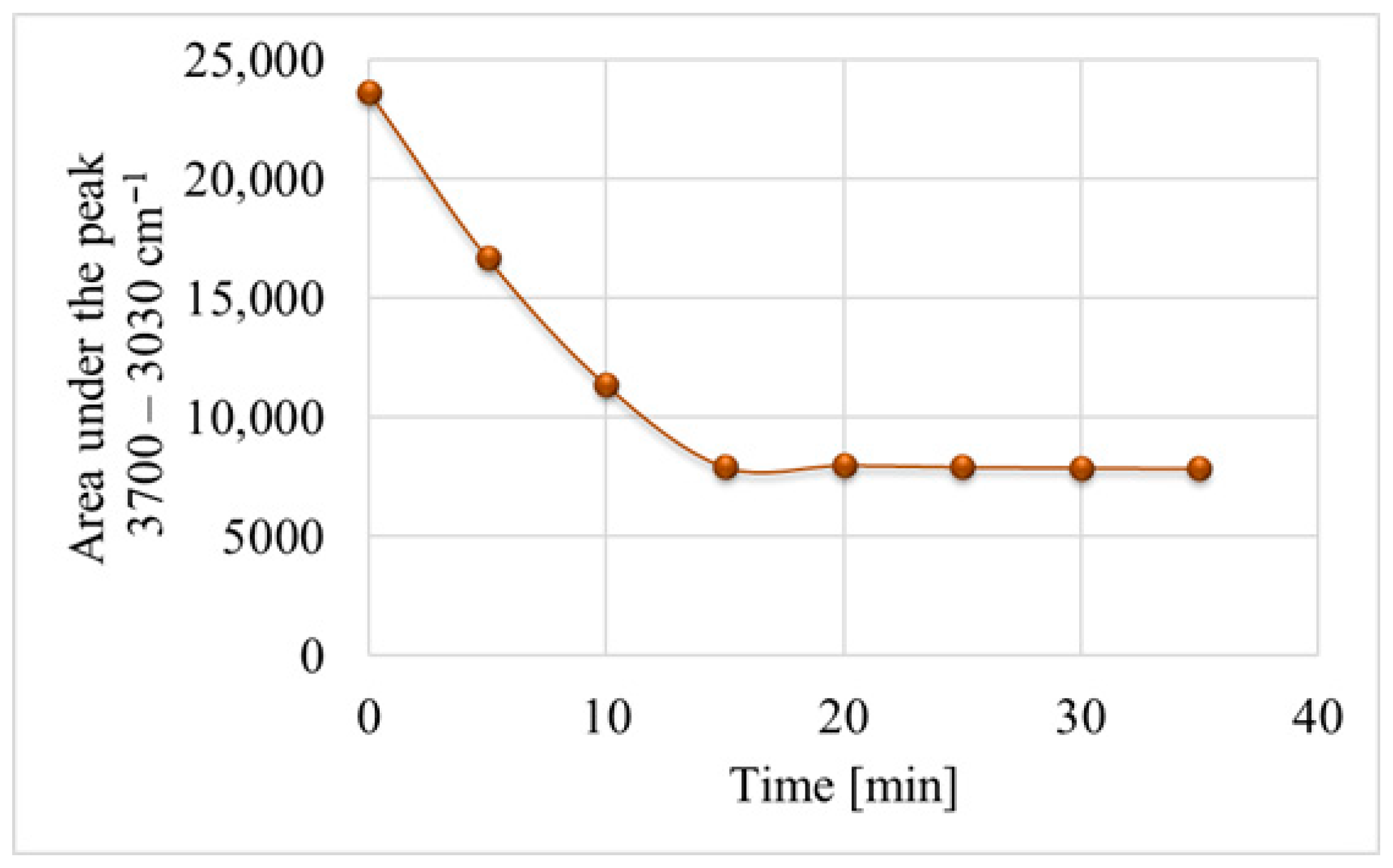

2.3. Solid Lubricant Deposition

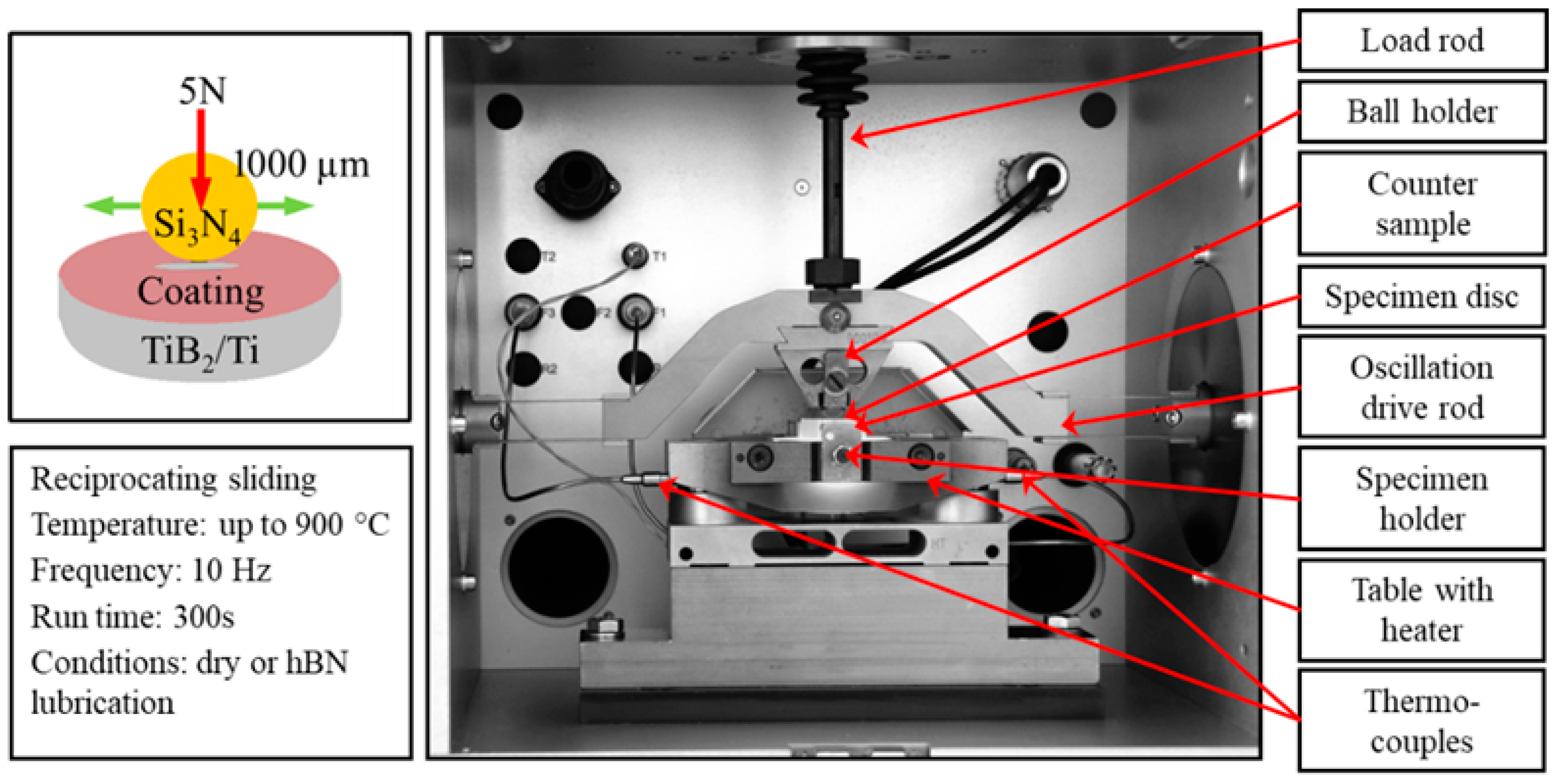

2.4. Wear Test Methodology

2.5. Surface Analysis Methods

3. Results

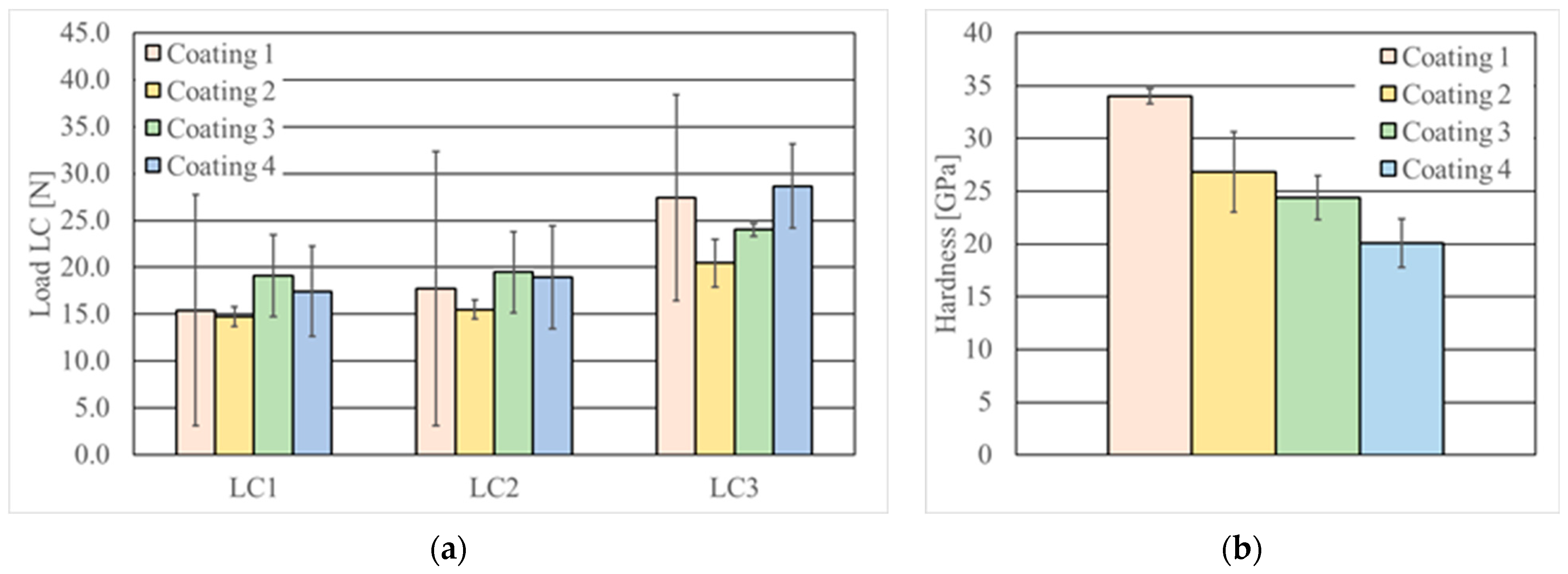

3.1. Material Characterisation

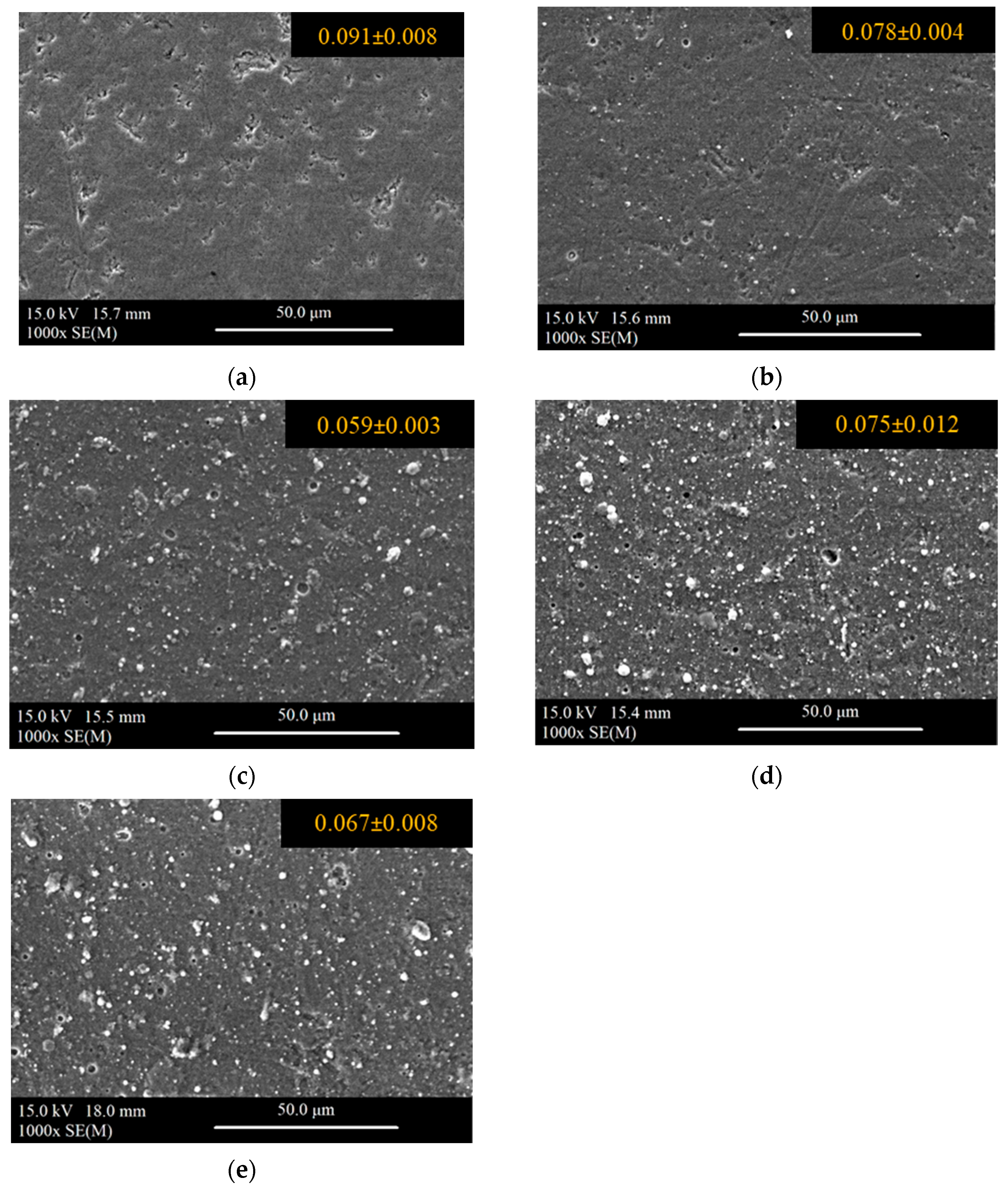

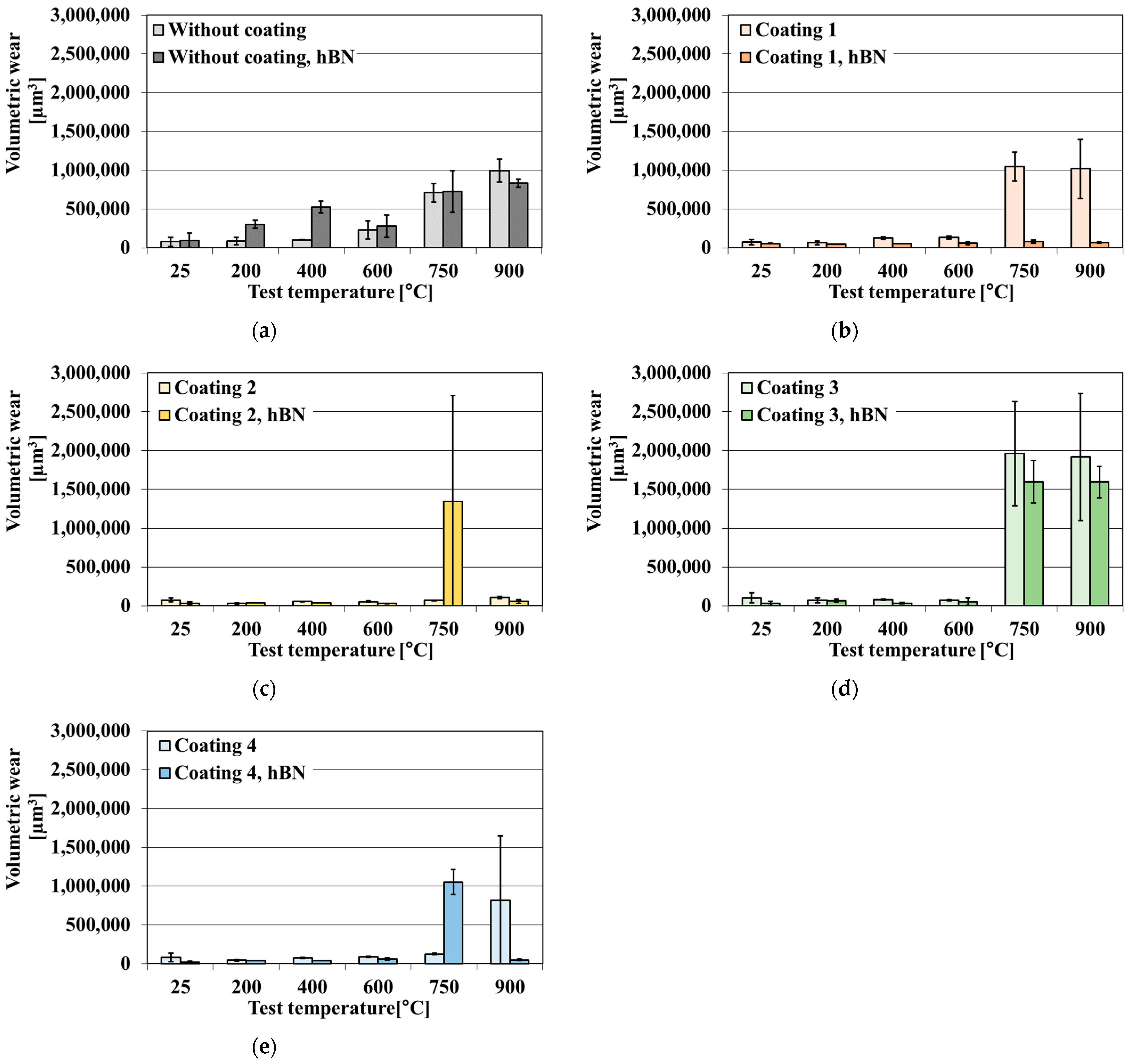

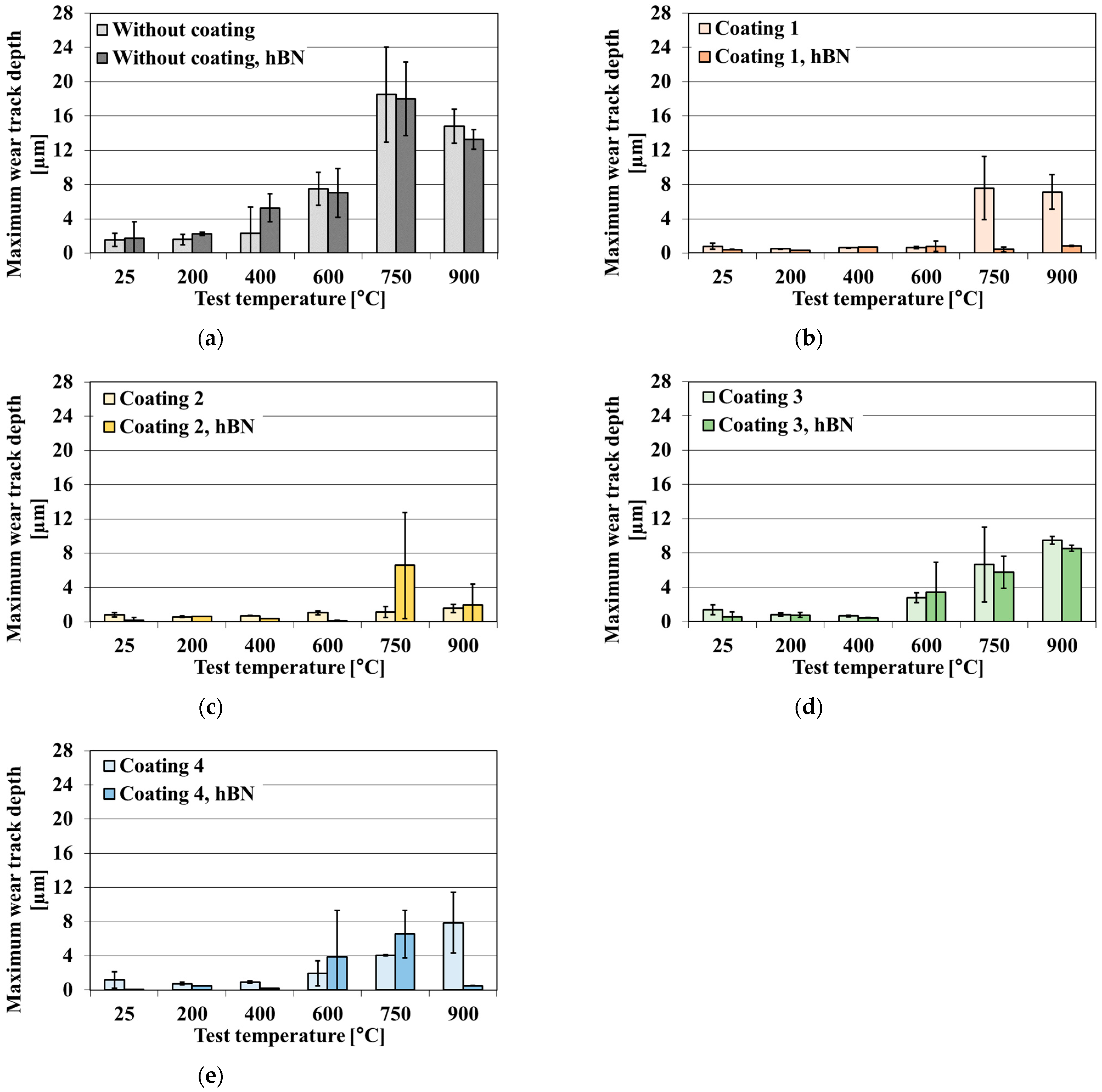

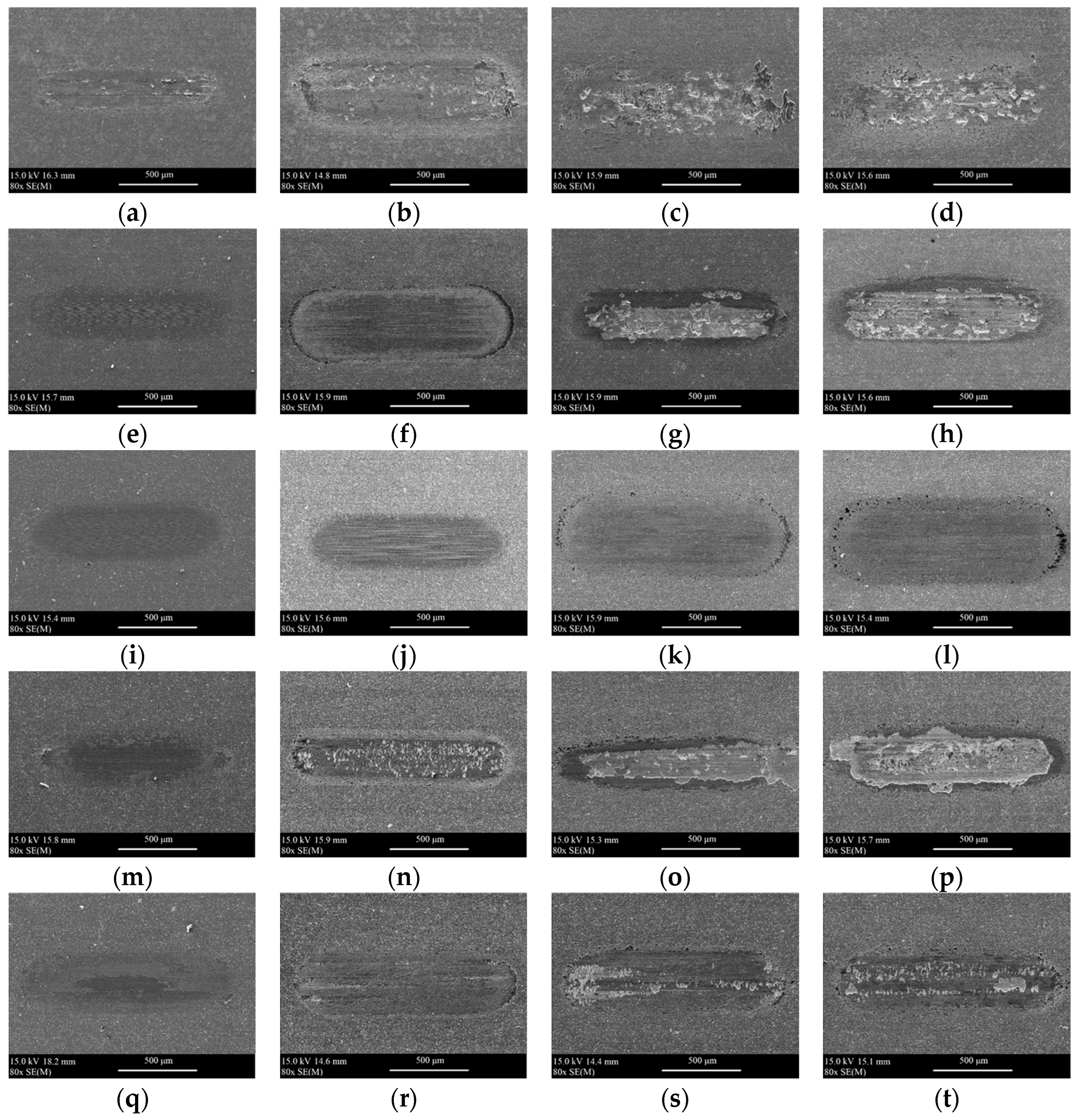

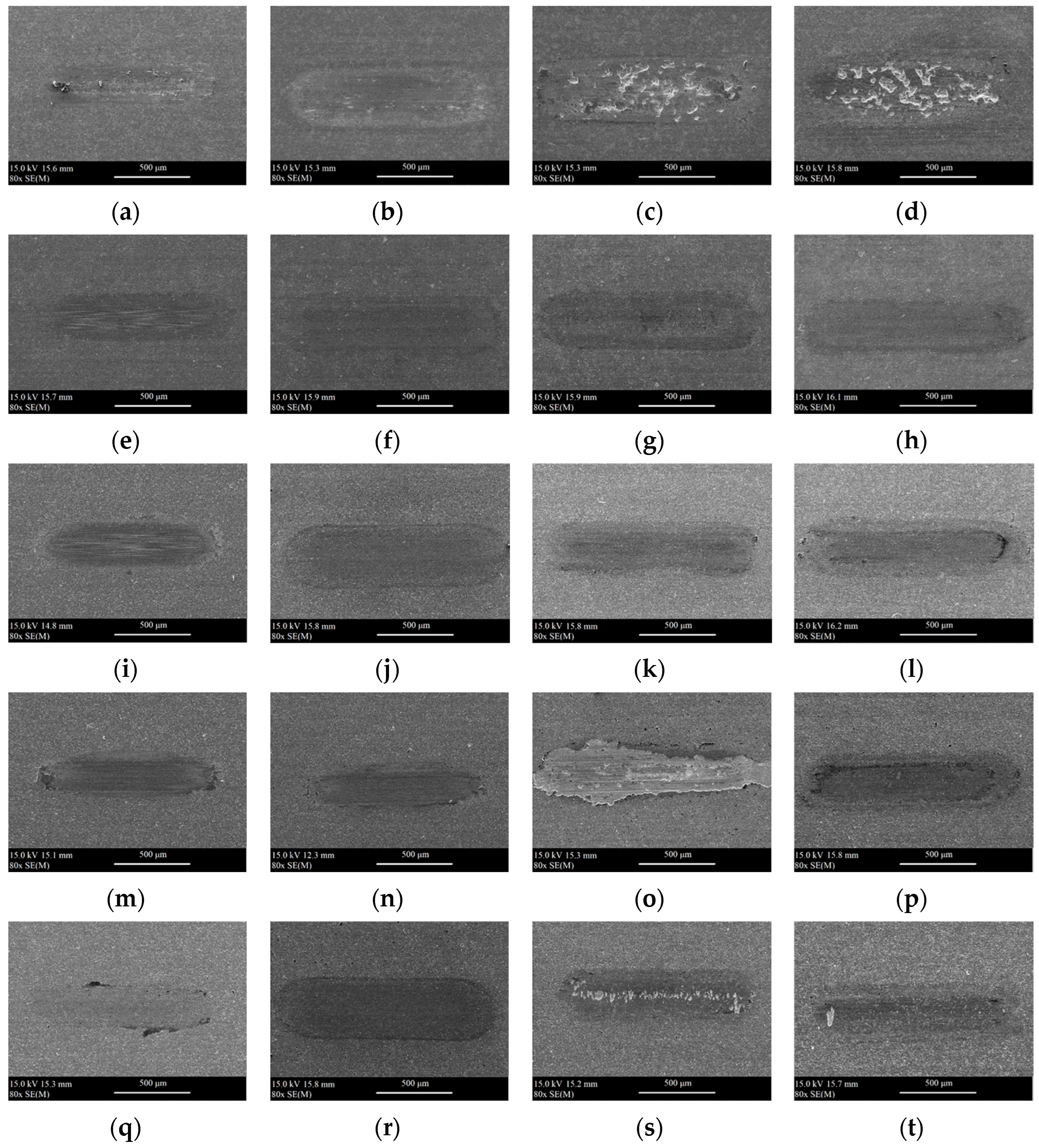

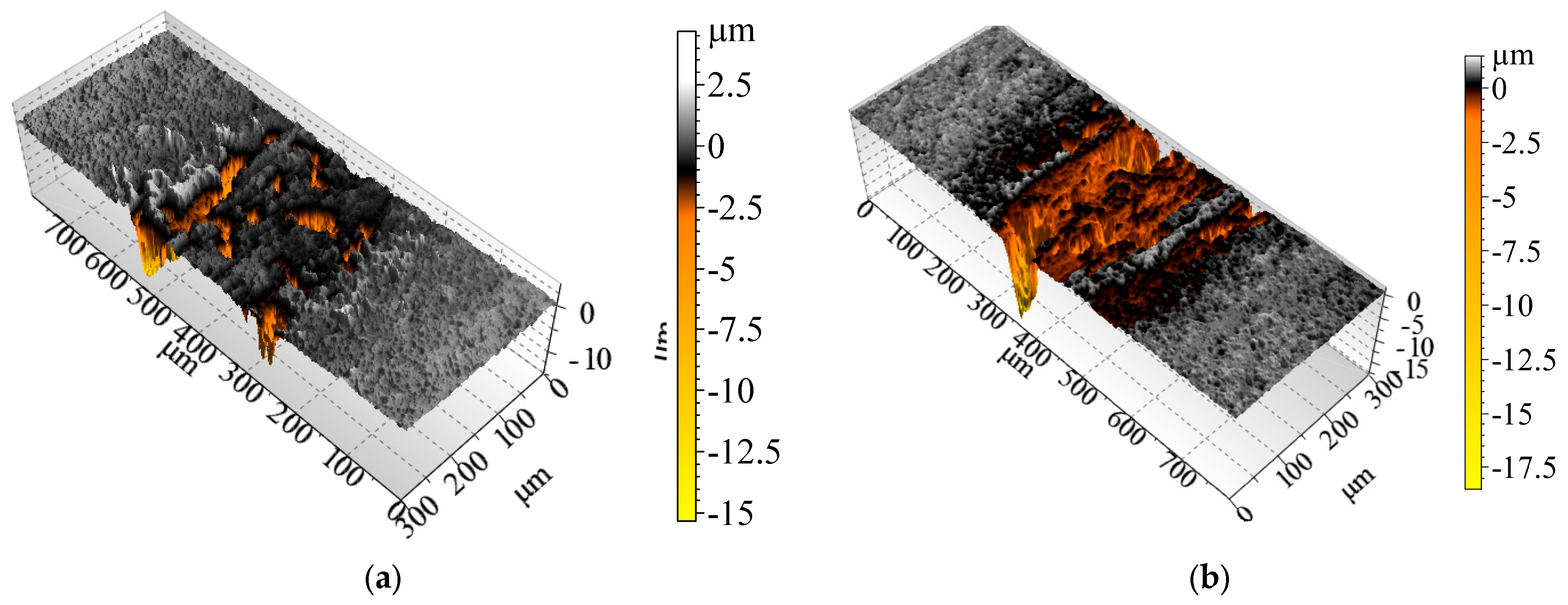

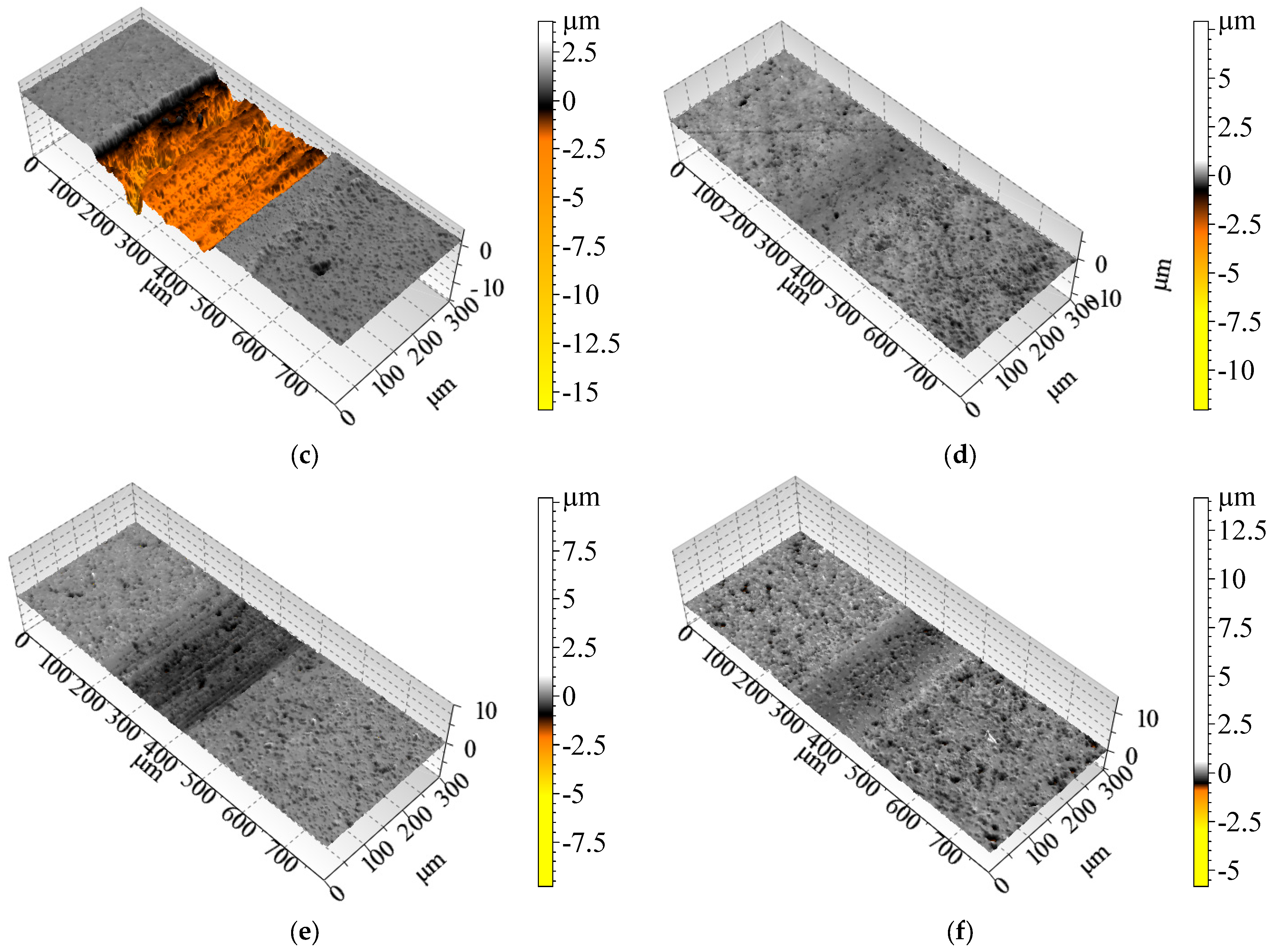

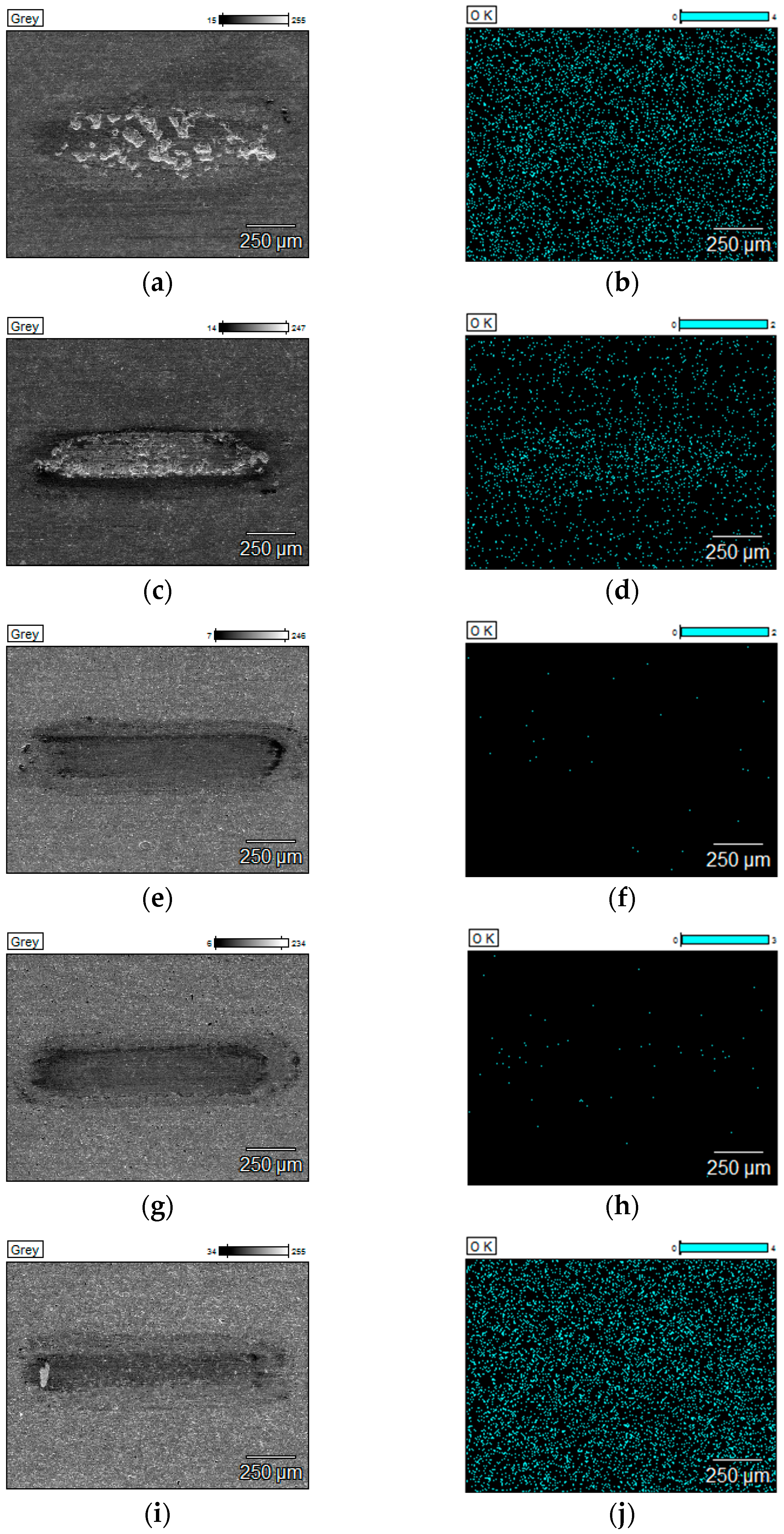

3.2. Wear Results

4. Discussion and Conclusions

- TiB2/Ti composites are not recommended for use in friction pairs operating under oscillating motion at high temperatures exceeding 400 °C due to their susceptibility to significant wear. The obtained results indicate the following key factors influencing wear intensity: surface oxidation, crack propagation, and grain tear-out.

- The application of commercial AlCrN coatings to the surface of TiB2/Ti composites provides protection against surface oxidation, grain tear-out, and crack propagation at temperatures up to 600 °C.

- The best protection against wear and oxidation at higher temperatures (even up to 900 °C) was achieved for coatings when coating with AlCrN and AlTiCrN external layers and hBN lubricant were used simultaneously.

- It was observed that the coating and solid lubricant can have a synergetic or antagonistic effect on wear behaviour, depending on the coating material and the temperature range. The synergetic effect is observed for the hBN and AlCrN coating in the entire temperature range up to 900 °C, and for all coatings at 900 °C. The antagonistic effect was obtained for, e.g., Coating 2 (TiN | TiCrN-AlCrN | AlTiCrN) at 750 °C, Coating 3 (TiN | TiCrN-AlCrN | AlCrTiN/Si3N4) at 600 °C, and Coating 4 (TiN | TiCrN-AlCrN | AlCrTiN/Si3N4 | AlCrTiSiN with an increasing oxygen gradient in the outer layer coating).

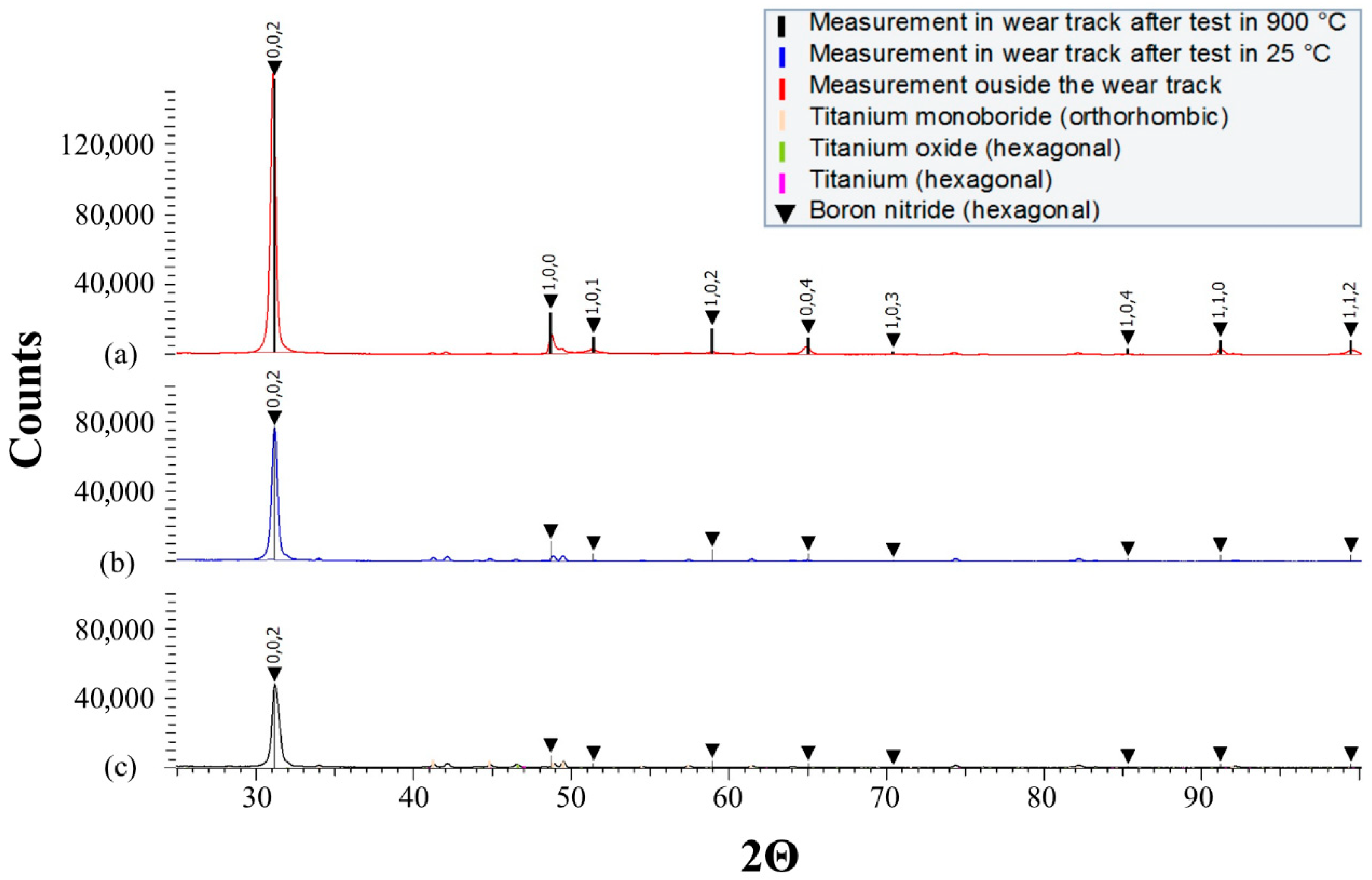

- XRD results showed that inside the wear track after the test at 900 °C, the hBN phase is arranged in a way that the hexagonal planes of the unit cells are parallel to the sample surface. These planes arrangement is optimal to reduce friction and wear. Easily sheared hexagonal layers are held by weak van der Waals forces, which leads to easy breaking of chemical bonds and, as a consequence, to low motion resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Namini, A.S.; Dilawary, S.A.A.; Motallebzadeh, A.; Asl, M.S. Effect of TiB2 Addition on the Elevated Temperature Tribological Behavior of Spark Plasma Sintered Ti Matrix Composite. Compos. Part B-Eng. 2019, 172, 271–280. [Google Scholar] [CrossRef]

- Kumar, R.; Antonov, M.; Liu, L.; Hussainova, I. Sliding Wear Performance of In-Situ Spark Plasma Sintered Ti-TiBw Composite at Temperatures up to 900 °C. Wear 2021, 476, 203663. [Google Scholar] [CrossRef]

- Kuncser, A.; Vasylkiv, O.; Borodianska, H.; Demirskyi, D.; Badica, P. High bending strength at 1800 °C exceeding 1 GPa in TiB2-B4C composite. Sci. Rep. 2023, 13, 6915. [Google Scholar] [CrossRef]

- Morsi, K.; Patel, V.V. Processing and Properties of Titanium–Titanium Boride (TiBw) Matrix Composites—A Review. J. Mater. Sci. 2007, 42, 2037–2047. [Google Scholar] [CrossRef]

- Kaczmar, J.W.; Pietrzak, K.; Włosiński, W. The Production and Application of Metal Matrix Composite Materials. J. Mater. Process. Technol. 2000, 106, 58–67. [Google Scholar] [CrossRef]

- Lindroos, V.K.; Talvitie, M.J. Recent Advances in Metal Matrix Composites. J. Mater. Process. Technol. 1995, 53, 273–284. [Google Scholar] [CrossRef]

- Qin, Y.; Geng, L.; Ni, D. Dry Sliding Wear Behavior of Extruded Titanium Matrix Composite Reinforced by in situ TiB Whisker and TiC Particle. J. Mater. Sci. 2011, 46, 4980–4985. [Google Scholar] [CrossRef]

- Qin, Y.; Lu, W.; Qin, J.; Zhang, D. Oxidation Behavior of in situ Synthesized TiB/Ti Composite in Air Environment. Mater. Trans. 2004, 45, 3241–3246. [Google Scholar] [CrossRef]

- Mao, Y.S.; Wang, L.; Chen, K.M.; Wang, S.Q.; Cui, X.H. Tribo-layer and its Role in Dry Sliding Wear of Ti–6Al–4V Alloy. Wear 2013, 297, 1032–1039. [Google Scholar] [CrossRef]

- Li, X.X.; Zhou, Y.; Ji, X.L.; Li, Y.X.; Wang, S.Q. Effects of Sliding Velocity on Tribooxides and Wear Behavior of Ti–6Al–4V Alloy. Tribol. Int. 2015, 91, 228–234. [Google Scholar] [CrossRef]

- Zhang, Q.Y.; Zhou, Y.; Wang, L.; Cui, X.H.; Wang, S.Q. Investigation on Tribo-layers and their Function of a Titanium Alloy During Dry Sliding. Tribol. Int. 2016, 94, 541–549. [Google Scholar] [CrossRef]

- Dalili, N.; Edrisy, A.; Farokhzadeh, K.; Li, J.; Lo, J.; Riahi, A.R. Improving the Wear Resistance of Ti–6Al–4V/TiC Composites through Thermal Oxidation (TO). Wear 2010, 269, 590–601. [Google Scholar] [CrossRef]

- Atar, E.; Kayali, E.S.; Cimenoglu, H. Characteristics and Wear Performance of Borided Ti6Al4V Alloy. Surf. Coat. Technol. 2008, 202, 4583–4590. [Google Scholar] [CrossRef]

- Pu, Y.; Guo, B.; Zhou, J.; Zhang, S.; Zhou, H.; Chen, J. Microstructure and Tribological Properties of in situ Synthesized TiC, TiN, and SiC Reinforced Ti3Al Intermetallic Matrix Composite Coatings on Pure Ti by Laser Cladding. Appl. Surf. Sci. 2008, 255, 2697–2703. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, W.T.; Wang, M.C.; Man, H.C. In-situ Synthesis and Wear Performance of TiC Particle Reinforced Composite Coating on Alloy Ti6Al4V. Surf. Coat. Technol. 2001, 138, 95–100. [Google Scholar] [CrossRef]

- Kumar, R.; Antonov, M. Self-lubricating Materials for Extreme Temperature Tribo-applications. Mater. Today-Proc. 2020, 44, 4583–4589. [Google Scholar] [CrossRef]

- Holovenko, Y.; Antonov, M.; Kollo, L.; Hussainova, I. Friction Studies of Metal Surfaces with Various 3D Printed Patterns Tested in Dry Sliding Conditions, P.I. Mech. Eng. J.-J. Eng. 2018, 232, 43–53. [Google Scholar] [CrossRef]

- Morsi, K.; Patel, V.V.; Naraghi, S.; Garay, J.E. Processing of Titanium–Titanium Boride Dual Matrix Composites. J. Mater. Process. Technol. 2008, 196, 236–242. [Google Scholar] [CrossRef]

- Liu, L.J.; Zhang, Z.H.; Jia, X.T.; Wang, Q.; Song, Q.; Li, X.Y.; Cheng, X.W. The effect of spark plasma sintering parameters on the densification and mechanical properties of TiB2-TiC-TiB composites. Int. J. Appl. Ceram. Technol. 2024, 21, 207–219. [Google Scholar] [CrossRef]

- Bloyce, A.; Morton, P.H.; Bell, T. Surface Engineering of Titanium and Titanium Alloys. ASM Handb. 1994, 5, 2232–2233. [Google Scholar] [CrossRef]

- Namini, A.S.; Azadbeh, M.; Asl, M.S. Effect of TiB2 Content on the Characteristics of Spark Plasma Sintered Ti–TiBw Composites. Adv. Powder Technol. 2017, 28, 1564–1572. [Google Scholar] [CrossRef]

- Liu, L.J.; Zhang, Z.H.; Jia, X.T.; Wang, Q.; Xu, T.H.; Hu, J.Z.; Cheng, X.W. TiB2 composites fabricated by spark plasma sintering at low temperature. J. Ceram. Soc. Jpn. 2024, 132, 121–127. [Google Scholar] [CrossRef]

- Liu, L.; Ivanov, R.; Kumar, R.; Minasyan, T.; Antonov, M.; Hussainova, I. Functionally Gradient Ti6Al4V-TiB Composite Produced by Spark Plasma Sintering. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1140, 012004. [Google Scholar] [CrossRef]

- Niu, B.; Zhang, F.; Zhang, J.; Ji, W.; Wang, W.; Fu, Z. Ultra-fast Densification of Boron Carbide by Flash Spark Plasma Sintering. Scripta Mater. 2016, 116, 127–130. [Google Scholar] [CrossRef]

- Bhat, B.V.R.; Subramanyam, J.; Prasad, V.V.B. Preparation of Ti-TiB-TiC & Ti-TiB Composites by in-situ Reaction Hot Pressing. Mat. Sci. Eng. A-Struct. 2002, 325, 126–130. [Google Scholar] [CrossRef]

- Singh, H.; Hayat, M.; Zhang, H.; Das, R.; Cao, P. Effect of TiB2 Content on Microstructure and Properties of in situ Ti-TiB Composites. Int. J. Min. Met. Mater. 2019, 26, 915–924. [Google Scholar] [CrossRef]

- Liu, K.; Xia, M.J.; Teng, J.Z.; Dai, D.H. Fretting wear behavior of in-situ (TiC+TiB) reinforced Ti-based composite by laser power bed fusion: Role of friction counterparts and operating frequency. Mater. Today Commun. 2023, 37, 107076. [Google Scholar] [CrossRef]

- Meng, X.; Sun, Z.G.; Chu, X.R.; Guo, Y.H.; Chang, H.; Wang, Y.Q. Microstructural evolution and wear properties of in-situ (TiB plus TiC)-reinforced Ti6Al4V matrix composite coating by laser melting deposition. Mater. Charact. 2023, 205, 113192. [Google Scholar] [CrossRef]

- Balasundar, P.; Senthil, S.; Narayanasamy, P.; Ramkumar, T. Microstructure and tribological properties of microwave-sintered Ti0.8Ni-0.3Mo/TiB composites. Ceram. Int. 2023, 49, 6055–6062. [Google Scholar] [CrossRef]

- Bao, Y.; Huang, L.; An, Q.; Zhang, R.; Geng, L.; Ma, X.; Tang, G.; Zhang, H. Wear resistance of TiB/Ti composite coating fabricated by TIG cladding using Ti-TiB2 cored wire. Surf. Coat. Technol. 2023, 474, 130086. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Tjong, S.C.; Gen, L. In-situ Ti-TiB Metal–Matrix Composite Prepared by a Reactive Pressing Process. Scripta Mater. 2000, 42, 367–373. [Google Scholar] [CrossRef]

- Song, Y.; Qiu, F.; Savvakin, D.; Xu, X.; Stasiuk, O.; Ivasishin, O.; Cheng, T. In Situ Ti6Al4V/TiB Composites Prepared by Hydrogen-Assisted Sintering of Blends Containing TiH2 and Ball-Milled Ti+TiB2 Powders. Materials 2022, 15, 1049. [Google Scholar] [CrossRef] [PubMed]

- Wyżga, P.; Jaworska, L.; Bućko, M.M.; Szutkowska, M.; Klimczyk, P. Spiekanie Nanokrystalicznych Faz Azotkowo–Borkowych. Mater. Ceram./Ceram. Mater. 2014, 66, 98–102. [Google Scholar]

- Michalczewski, R.; Kalbarczyk, M.; Słomka, Z.; Osuch-Słomka, E.; Łuszcz, M.; Liu, L.; Antonov, M.; Hussainova, I. Sliding Wear Performance of AlCrN Coating on TiB2/Ti Composites at High Temperatures. Materials 2021, 14, 6771. [Google Scholar] [CrossRef]

- Kumar, R.; Torres, H.; Aydinyan, S.; Antonov, M.; Varga, M.; Ripoll, M.R.; Hussainova, I. Microstructure and high temperature tribological behaviour of self-lubricating Ti-TiBx composite doped with NiBi. Surf. Coat. Technol. 2022, 447, 128827. [Google Scholar] [CrossRef]

- Hejwowski, T. Nowoczesne Powłoki Nakładane Cieplnie Odporne Na Zużycie Ścierne i Erozyjne, Monografie; Politechnika Lubelska: Lublin, Poland, 2013. [Google Scholar]

- Shafyei, H.; Salehi, M.; Bahrami, A. Fabrication, Microstructural Characterization and Mechanical Properties Evaluation of Ti/TiB/TiB2 Composite Coatings Deposited on Ti6Al4V Alloy by Electro-Spark Deposition Method. Ceram. Int. 2020, 46, 15276–15284. [Google Scholar] [CrossRef]

- Liang, X.; Gao, Y.; Lin, Z.; Chen, S.; Liu, C.; Tian, K.; Zhang, H.; Tang, G. Effects of LaB6 on the High-Temperature Oxidation Behavior of TiC+TiBx Reinforced Titanium Matrix Composite Coatings Fabricated by Laser Cladding. Surf. Coat. Technol. 2021, 421, 127445. [Google Scholar] [CrossRef]

- Mościcki, T.; Psiuk, R.; Radziejewska, J.; Wiśniewska, M.; Garbiec, D. Properties of Spark Plasma Sintered Compacts and Magnetron Sputtered Coatings Made from Cr, Mo, Re and Zr Alloyed Tungsten Diboride. Coatings 2021, 11, 1378. [Google Scholar] [CrossRef]

- Ling, C.L.; Yajid, M.A.M.; Tamin, M.N.; Kamarudin, M.; Taib, M.A.A.; Nosbi, N.; Ali, W.F.F.W. Effect of Substrate Roughness and PVD Deposition Temperatures on Hardness and Wear Performance of AlCrN-coated WC-Co. Surf. Coat. Technol. 2022, 436, 128304. [Google Scholar] [CrossRef]

- Cadena, N.L.; Cue-Sampedro, R.; Siller, H.R.; Arizmendi-Morquecho, A.M.; Rivera-Solorio, C.I.; Di-Nardo, S. Study of PVD AlCrN Coating for Reducing Carbide Cutting Tool Deterioration in the Machining of Titanium Alloys. Materials 2013, 6, 2143–2154. [Google Scholar] [CrossRef] [PubMed]

- Warcholiński, B.; Gilewicz, A.; Myśliński, P.; Dobruchowska, E.; Murzyński, D. Structure and Properties of AlCrN Coatings Deposited Using Cathodic Arc Evaporation. Coatings 2020, 10, 793. [Google Scholar] [CrossRef]

- Hosokawa, A.; Saito, R.; Ueda, T. Milling Characteristics of VN/AlCrN-multilayer PVD Coated Tools with Lubricity and Heat Resistance. CIRP Ann.-Manuf. Technol. 2020, 69, 49–52. [Google Scholar] [CrossRef]

- Mo, J.L.; Zhu, M.H.; Leyland, A.; Matthews, A. Impact Wear and Abrasion Resistance of CrN, AlCrN and AlTiN PVD Coatings. Surf. Coat. Technol. 2013, 215, 170–177. [Google Scholar] [CrossRef]

- Alvi, S.A.; Akhtar, F. High temperature tribology of polymer derived ceramic composite coatings. Sci. Rep. 2018, 8, 15105. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Zhang, L.; Ke, R.; Wan, Q.; Wang, Z.; Lu, Z. Thermal Stability and Oxidation Behavior of AlTiN, AlCrN and AlCrSiWN Coatings. Int. J. Refract. Met. Hard Mater. 2014, 43, 241–249. [Google Scholar] [CrossRef]

- Wu, L.; Qiu, L.; Du, Y.; Zeng, F.; Lu, Q.; Tan, Z.; Yin, L.; Chen, L.; Zhu, J. Structure and Mechanical Properties of PVD and CVD TiAlSiN Coatings Deposited on Cemented Carbide. Crystals 2021, 11, 598. [Google Scholar] [CrossRef]

- Endrino, J.L.; Derflinger, V. The Influence of Alloying Elements on the Phase Stability and Mechanical Properties of AlCrN Coatings. Surf. Coat. Technol. 2005, 200, 988–992. [Google Scholar] [CrossRef]

- Ramadoss, R.; Kumar, N.; Pandian, R.; Dash, S.; Ravindran, T.R.; Arivuoli, D.; Tyagi, A.K. Tribological Properties and Deformation Mechanism of TiAlN Coating Sliding with Various Counterbodies. Tribol. Int. 2013, 66, 143–149. [Google Scholar] [CrossRef]

- Wang, X.; Kwon, Y.; Schrock, D.; Kim, D. Friction Coefficient and Sliding Wear of AlTiN Coating under Various Lubrication Conditions. Wear 2013, 304, 67–76. [Google Scholar] [CrossRef]

- Moghaddam, P.V.; Prakash, B.; Vuorinen, E.; Fallqvist, M.; Andersson, J.M.; Hardell, J. High Temperature Tribology of TiAlN PVD Coating Sliding Against 316L Stainless Steel and Carbide-Free Bainitic Steel. Tribol. Int. 2021, 159, 106847. [Google Scholar] [CrossRef]

- Hovsepian, P.E.; Lewis, D.B.; Luo, Q.; Münz, W.-D.; Mayrhofer, P.H.; Mitterer, C.; Zhou, Z.; Rainforth, W.M. TiAlN Based Nanoscale Multilayer Coatings Designed to Adapt Their Tribological Properties at Elevated Temperatures. Thin Solid Film 2005, 485, 160–168. [Google Scholar] [CrossRef]

- Bernardes, C.F.; Fukumasu, N.K.; Lima, A.O.; Souza, R.M.; Machado, I.F. Influence of Growth Defects on the Running-in Behavior of an a-C:H:W Coating under Pure Sliding Contact Conditions. Surf. Coat. Technol. 2020, 402, 126278. [Google Scholar] [CrossRef]

- Michalczewski, R.; Kalbarczyk, M.; Słomka, Z.; Hussainova, I.; Liu, L.; Antonov, M. Adhesion of AlCrN Coating Deposited on TiB2/Ti Composites Sintered by SPS Dedicated for High Temperature Tribological applications. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1140, 012010. [Google Scholar] [CrossRef]

- Geng, D.; Li, H.; Chen, Z.; Xu, Y.X.; Wang, Q. Microstructure, Oxidation Behavior and Tribological Properties of AlCrN/Cu Coatings Deposited by a Hybrid PVD Technique. J. Mater. Sci. Technol. 2022, 100, 150–160. [Google Scholar] [CrossRef]

- Ye, F.; Lou, Z.; Wang, Y.; Liu, W. Wear Mechanism of Ag as Solid Lubricant for Wide Range Temperature Application in Micro-Beam Plasma Cladded Ni60 Coatings. Tribol. Int. 2022, 167, 107402. [Google Scholar] [CrossRef]

- Michalczewski, R.; Kalbarczyk, M.; Maldonado-Cortés, D. The Method of Tribotesting of PVD Coated Elements in Oscillation Motion at High Temperature. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1140, 012024. [Google Scholar] [CrossRef]

- Antonov, M.; Afshari, H.; Baronins, J.; Adoberg, E.; Raadik, T.; Hussainova, I. The Effect of Temperature and Sliding Speed on Friction and Wear of Si3N4, Al2O3, and ZrO2 Balls Tested Against AlCrN PVD Coating. Tribol. Int. 2018, 118, 500–514. [Google Scholar] [CrossRef]

- Łuszcz, M.; Michalczewski, R.; Kalbarczyk, M.; Osuch-Słomka, E.; Molenda, J.; Liu, L.; Antonov, M.; Hussainova, I. Effect of hBN on wear of AlCrN coated spark plasma sintered TiB2/Ti composites at temperatures up to 900 °C. Tribologia 2022, 299, 43–55. [Google Scholar] [CrossRef]

- Łuszcz, M.; Michalczewski, R.; Kalbarczyk, M.; Osuch-Słomka, E.; Słomka, Z.; Liu, L.; Antonov, M.; Hussainova, I. Effect of solid lubricants on wear of PVD-coated spark plasma-sintered TiB2/Ti composites. AIP Conf. Proc. 2024, 2989, 040010. [Google Scholar] [CrossRef]

- Michalczewski, R.; Kalbarczyk, M.; Słomka, Z.; Sowa, S.; Łuszcz, M.; Osuch-Słomka, E.; Maldonado-Cortés, D.; Liu, L.; Antonov, M.; Hussainova, I. The Wear of PVD Coated Elements in Oscillation Motion at High Temperature. Proc. Estonian Acad. Sci. 2021, 70, 500–507. [Google Scholar] [CrossRef]

- Kumar, R.; Hussainova, I.; Rahmani, R.; Antonov, M. Solid Lubrication at High-Temperatures—A Review. Materials 2022, 15, 1695. [Google Scholar] [CrossRef]

- Kałdoński, T. Tribologiczne Zastosowania Azotku Boru; Wojskowa Akademia Techniczna: Warszawa, Poland, 2006. [Google Scholar]

- Yin, L.; Zhao, K.; Ding, Y.; Wang, Y.; He, Z.; Huang, S. Effect of hBN Addition on the Fabrication, Mechanical and Tribological Properties of Sialon Materials. Ceram. Int. 2022, 48, 7715–7722. [Google Scholar] [CrossRef]

- Thachnatharen, N.; Khalid, M.; Arulraj, A.; Sridewi, N. Tribological Performance of Hexagonal Boron Nitride (hBN) as Nano-Additives in Military Grade Diesel Engine Oil. Mater. Today–Proc. 2022, 50, 70–73. [Google Scholar] [CrossRef]

- Ünal, E.; Karahan, İ.H. Effects of Ultrasonic Agitation Prior to Deposition and Additives in the Bath on Electrodeposited Ni-B/hBN Composite Coatings. J. Alloy. Compd. 2018, 763, 329–341. [Google Scholar] [CrossRef]

- Kumar, R.; Aydinyan, S.; Ivanov, R.; Liu, L.; Antonov, M.; Hussainova, I. High-Temperature Wear Performance of hBN-Added Ni-W Composites Produced from Combustion-Synthesized Powders. Materials 2022, 15, 1252. [Google Scholar] [CrossRef]

- Wu, J.; Wang, H.; Wang, C.; Zhang, Z.; Tang, Y.; Hou, Z.; Wan, S.; Wu, D.; Tan, Z.; Ouyang, X. High-Pressure Synthesis of Al2O3-cBN-hBN Self-Lubricating Ceramic. Mater. Design 2022, 217, 110638. [Google Scholar] [CrossRef]

- Yilmaz, Z.; Savaci, U.; Turan, S.; Ay, N. The effect of in-situ formed layered hBN on the machinability and mechanical properties of SPS sintered SiC. Ceram. Int. 2022, 48, 1047–1056. [Google Scholar] [CrossRef]

- Dorkar, N.V.; Kim, Y.W.; Kumar, B.V.M. Role of hBN content, humidity, and temperature on the sliding wear behaviour of SiC ceramics. J. Eur. Ceram. Soc. 2023, 43, 7282–7295. [Google Scholar] [CrossRef]

- Tian, S.; Guo, W.; He, Q.; Wang, A.; Tian, T.; Liu, C.; Hu, L.; Zhang, Z.; Wang, H.; Wang, W.; et al. Synthesis of TiN–TiB2–hBN Composite Powders with a Core-Shell Structure and Preparation of Bulk Samples. Mater. Today Commun. 2021, 29, 102783. [Google Scholar] [CrossRef]

- Pompei, E.; Magagnin, L.; Lecis, N.; Cavallotti, P. Electrodeposition of nickel–BN composite coatings. Electrochim. Acta 2009, 54, 2571–2574. [Google Scholar] [CrossRef]

- Demir, M.; Kanca, E.; Karahan, İ.H. Characterization of Electrodeposited Ni–Cr/hBN Composite Coatings. J. Alloy. Compd. 2020, 844, 155511. [Google Scholar] [CrossRef]

- Huang, Z.; Zhao, W. Coupling Hybrid of hBN Nanosheets and TiO2 to Enhance the Mechanical and Tribological Properties of Composite Coatings. Prog. Org. Coat. 2020, 148, 105881. [Google Scholar] [CrossRef]

| Sintering Temperature [°C] | Heating Rate [°C/min] | Uniaxial Pressure [MPa] | Sintering Time [s] |

|---|---|---|---|

| 1250 | 100 | 50 | 900 |

| Parameter | Value |

|---|---|

| Test temperature [°C] | 25, 200, 400, 600, 750, 900 |

| Heating rate [°C/s] | 1 |

| Temperature stabilisation time [s] | 1200 |

| Load [N] | 5 |

| Stroke length [µm] | 1000 |

| Frequency [Hz] | 10 |

| Test duration [s] | 300 |

| Counter-sample ball diameter [mm] | 10 |

| Ball material [−] | Si3N4 |

| Minimum number of repetitions | 3 |

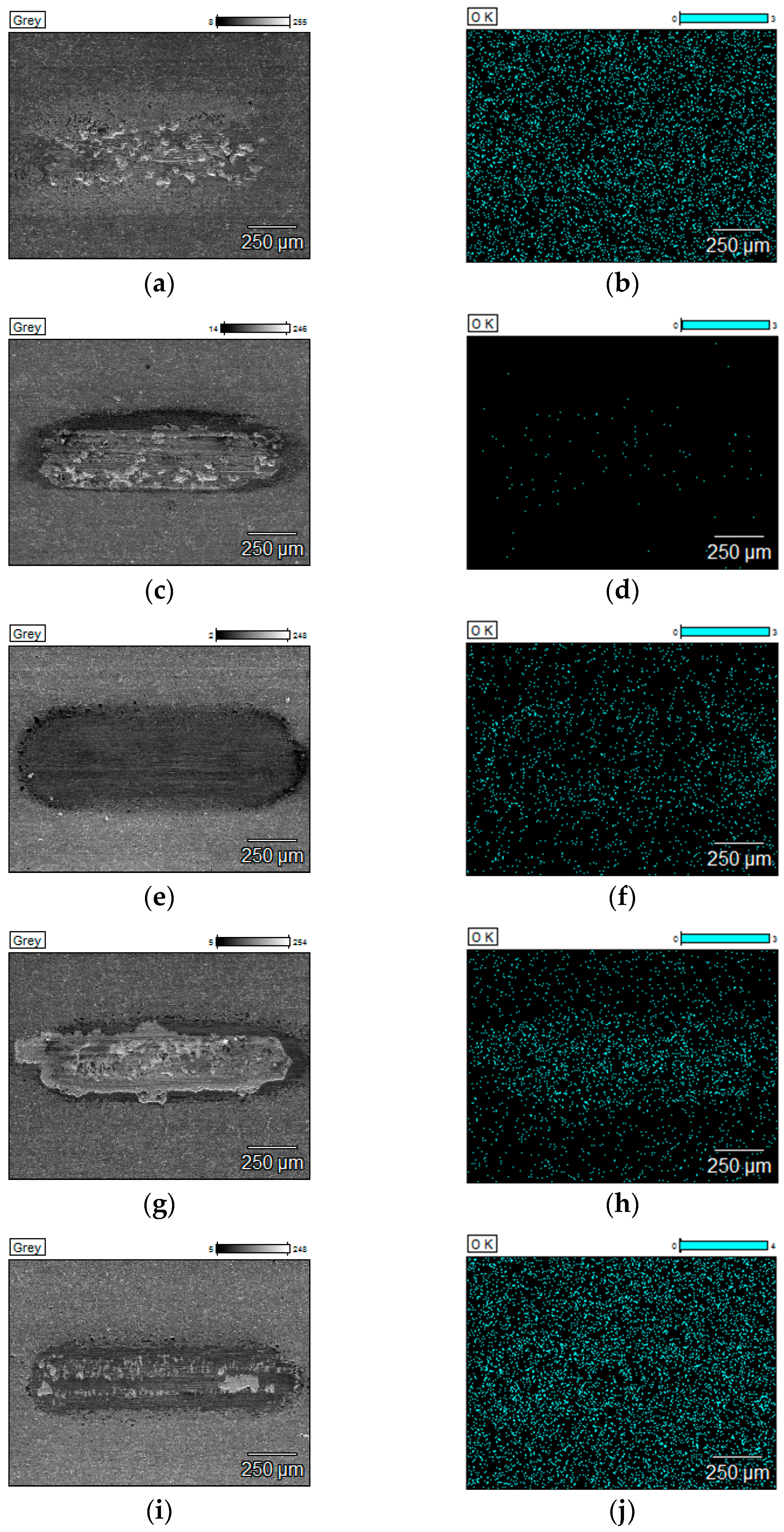

| Test Temperature [°C] | Out of the Wear Track | In the Wear Track | Out of the Wear Track | In the Wear Track | ||||

|---|---|---|---|---|---|---|---|---|

| Average [at%] | Confidence [at%] | Average [at%] | Confidence [at%] | Average [at%] | Confidence [at%] | Average [at%] | Confidence [at%] | |

| TiB2/Ti composite | TiB2/Ti composite, hBN | |||||||

| 25 | 0.0 | 0.1 | 47.4 | 15.9 | 0.0 | 0.1 | 50.9 | 5.6 |

| 600 | 44.9 | 3.0 | 59.7 | 1.6 | 45.5 | 1.8 | 39.3 | 7.2 |

| 750 | 58.5 | 0.9 | 57.2 | 5.7 | 57.1 | 2.2 | 56.8 | 3.5 |

| 900 | 63.8 | 0.5 | 65.3 | 1.4 | 61.0 | 1.6 | 63.4 | 2.3 |

| Coating 1 | Coating 1, hBN | |||||||

| 25 | 0.6 | 1.3 | 0.4 | 0.9 | 0.4 | 0.9 | 0.0 | 0.1 |

| 600 | 0.3 | 0.7 | 4.7 | 2.7 | 1.9 | 2.0 | 4.3 | 4.5 |

| 750 | 2.8 | 1.5 | 53.7 | 3.5 | 0.5 | 0.6 | 13.9 | 3.3 |

| 900 | 1.1 | 1.4 | 60.1 | 1.8 | 1.7 | 0.8 | 7.5 | 2.9 |

| Coating 2 | Coating 2, hBN | |||||||

| 25 | 0.6 | 0.4 | 0.5 | 1.0 | 1.4 | 1.7 | 1.5 | 1.5 |

| 600 | 4.1 | 1.1 | 0.5 | 0.7 | 4.7 | 2.4 | 0.7 | 0.9 |

| 750 | 5.6 | 2.4 | 7.2 | 0.7 | 5.8 | 2.6 | 6.2 | 2.0 |

| 900 | 4.9 | 2.7 | 15.5 | 2.5 | 3.7 | 1.8 | 13.6 | 7.1 |

| Coating 3 | Coating 3, hBN | |||||||

| 25 | 0.2 | 0.5 | 0.9 | 1.6 | 3.8 | 1.4 | 9.8 | 17.1 |

| 600 | 3.8 | 1.5 | 45.2 | 2.3 | 11.8 | 1.2 | 5.1 | 3.0 |

| 750 | 10.8 | 1.6 | 58.9 | 3.5 | 10.0 | 3.1 | 59.7 | 0.6 |

| 900 | 10.9 | 6.0 | 61.4 | 3.8 | 12.4 | 2.7 | 15.4 | 4.0 |

| Coating 4 | Coating 4, hBN | |||||||

| 25 | 44.3 | 0.5 | 34.6 | 16.8 | 45.8 | 1.0 | 44.9 | 0.7 |

| 600 | 43.4 | 2.0 | 37.6 | 3.2 | 44.6 | 1.0 | 17.6 | 4.8 |

| 750 | 45.5 | 0.9 | 46.4 | 3.7 | 45.8 | 0.5 | 50.9 | 0.4 |

| 900 | 45.8 | 0.5 | 50.4 | 6.6 | 44.6 | 0.7 | 47.0 | 1.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Michalczewski, R.; Łuszcz, M.; Kalbarczyk, M.; Słomka, Z.; Osuch-Słomka, E.; Molenda, J.; Liu, L.; Antonov, M.; Hussainova, I.; Rodríguez Ripoll, M. Wear Performance of a Physical Vapour Deposition-Coated, Spark Plasma Sintered TiB2/Ti Composite Lubricated with Externally Introduced hBN at Temperatures up to 900 °C. Materials 2025, 18, 5274. https://doi.org/10.3390/ma18235274

Michalczewski R, Łuszcz M, Kalbarczyk M, Słomka Z, Osuch-Słomka E, Molenda J, Liu L, Antonov M, Hussainova I, Rodríguez Ripoll M. Wear Performance of a Physical Vapour Deposition-Coated, Spark Plasma Sintered TiB2/Ti Composite Lubricated with Externally Introduced hBN at Temperatures up to 900 °C. Materials. 2025; 18(23):5274. https://doi.org/10.3390/ma18235274

Chicago/Turabian StyleMichalczewski, Remigiusz, Maciej Łuszcz, Marek Kalbarczyk, Zbigniew Słomka, Edyta Osuch-Słomka, Jarosław Molenda, Le Liu, Maksim Antonov, Irina Hussainova, and Manel Rodríguez Ripoll. 2025. "Wear Performance of a Physical Vapour Deposition-Coated, Spark Plasma Sintered TiB2/Ti Composite Lubricated with Externally Introduced hBN at Temperatures up to 900 °C" Materials 18, no. 23: 5274. https://doi.org/10.3390/ma18235274

APA StyleMichalczewski, R., Łuszcz, M., Kalbarczyk, M., Słomka, Z., Osuch-Słomka, E., Molenda, J., Liu, L., Antonov, M., Hussainova, I., & Rodríguez Ripoll, M. (2025). Wear Performance of a Physical Vapour Deposition-Coated, Spark Plasma Sintered TiB2/Ti Composite Lubricated with Externally Introduced hBN at Temperatures up to 900 °C. Materials, 18(23), 5274. https://doi.org/10.3390/ma18235274