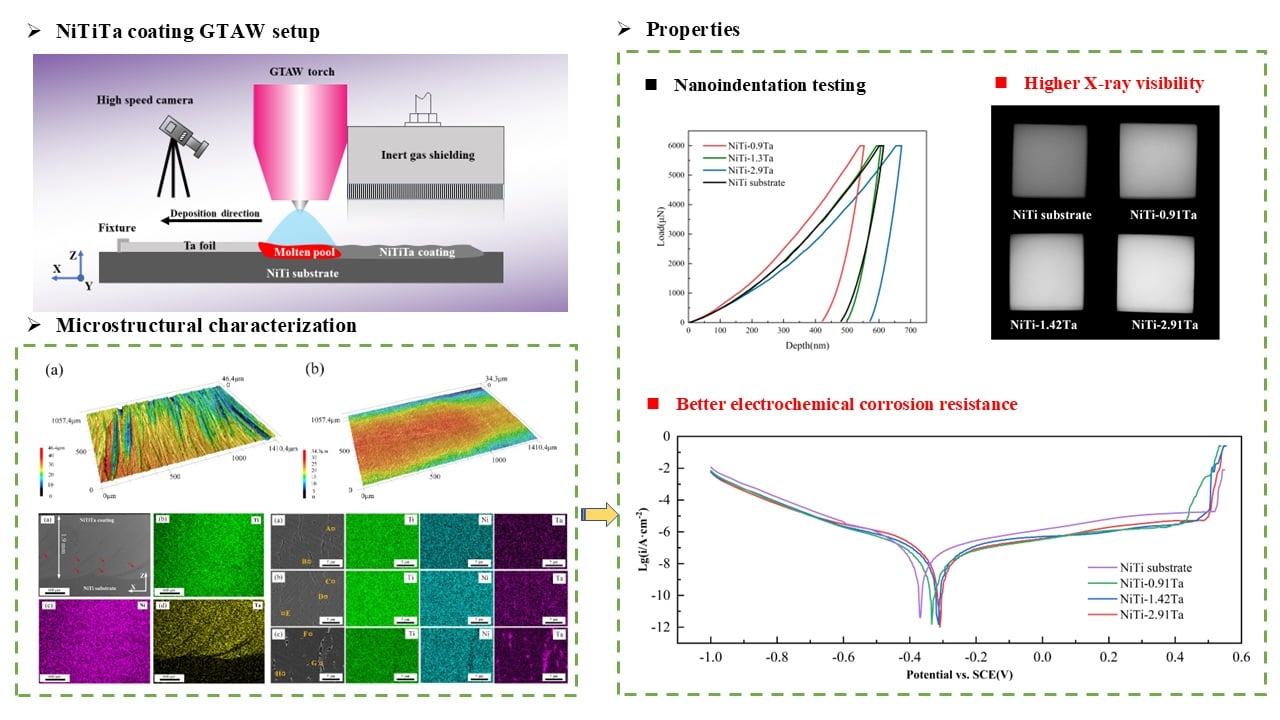

Effect of Ta Content on the Microstructure and Properties of NiTiTa Functional Coatings in Situ Synthesized by Directed Energy Deposition

Abstract

Share and Cite

Ao, S.; Xing, Y.; Liu, S.; Zuo, X.; Li, Y. Effect of Ta Content on the Microstructure and Properties of NiTiTa Functional Coatings in Situ Synthesized by Directed Energy Deposition. Materials 2025, 18, 5255. https://doi.org/10.3390/ma18225255

Ao S, Xing Y, Liu S, Zuo X, Li Y. Effect of Ta Content on the Microstructure and Properties of NiTiTa Functional Coatings in Situ Synthesized by Directed Energy Deposition. Materials. 2025; 18(22):5255. https://doi.org/10.3390/ma18225255

Chicago/Turabian StyleAo, Sansan, Yawei Xing, Shaozhu Liu, Xinde Zuo, and Yang Li. 2025. "Effect of Ta Content on the Microstructure and Properties of NiTiTa Functional Coatings in Situ Synthesized by Directed Energy Deposition" Materials 18, no. 22: 5255. https://doi.org/10.3390/ma18225255

APA StyleAo, S., Xing, Y., Liu, S., Zuo, X., & Li, Y. (2025). Effect of Ta Content on the Microstructure and Properties of NiTiTa Functional Coatings in Situ Synthesized by Directed Energy Deposition. Materials, 18(22), 5255. https://doi.org/10.3390/ma18225255