Synergistic Gypsum–Carbonation Strategy and Non-Contact ITZ Quantification for CFBFA Artificial Aggregate Concrete

Abstract

1. Introduction

2. Materials and Methods

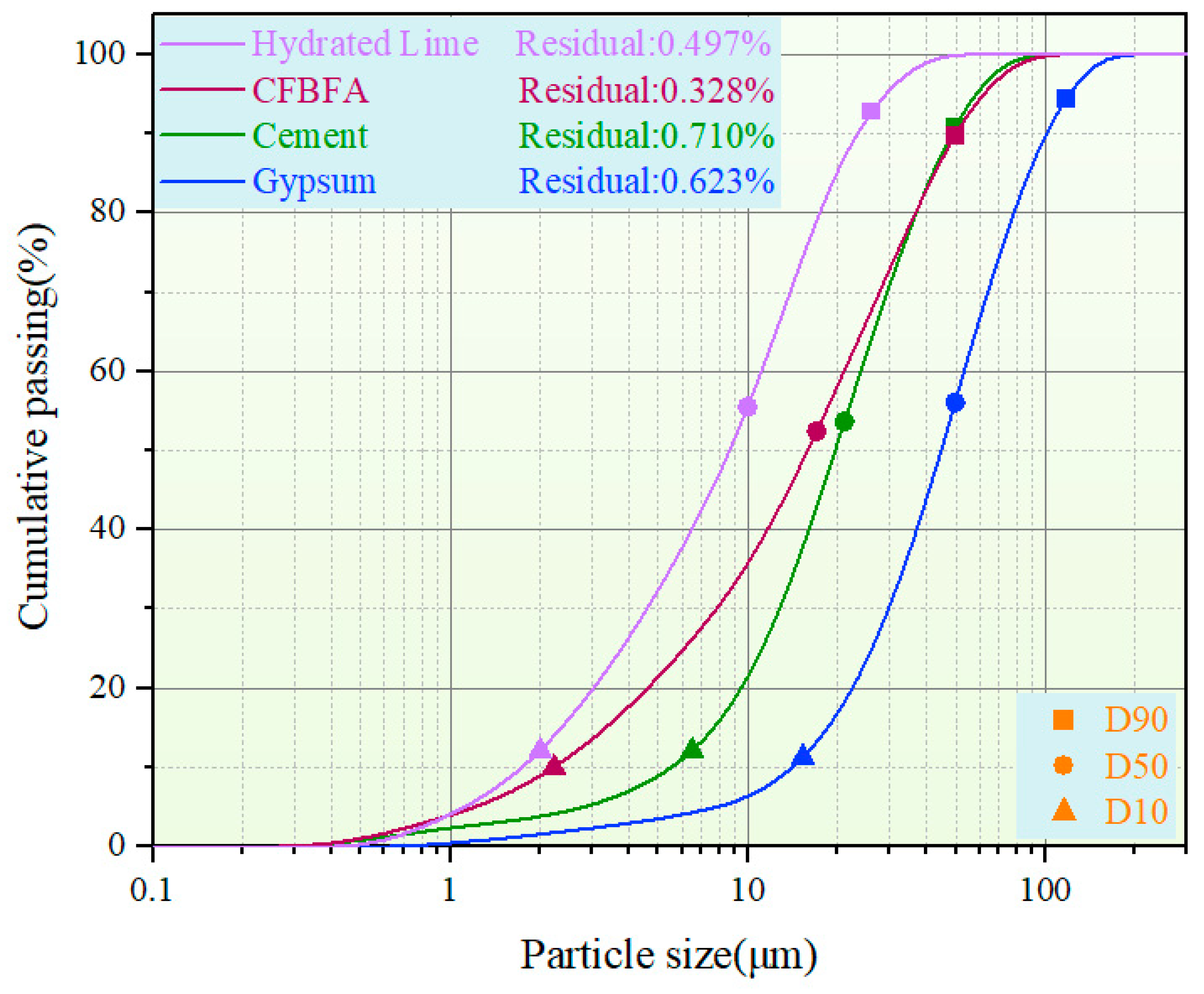

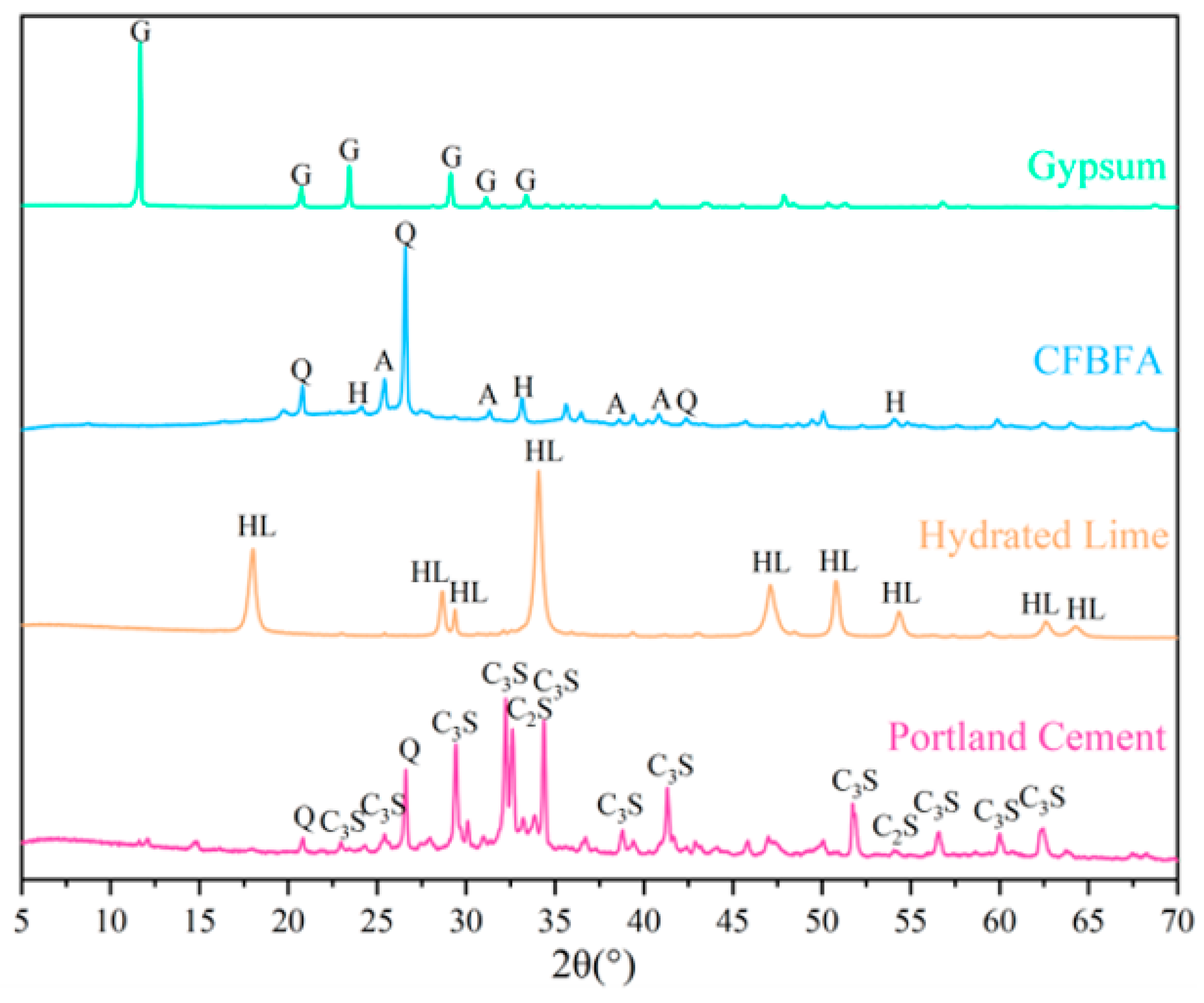

2.1. Materials and Mix Design

2.2. Preparation of Artificial Aggregates and Concrete Specimen

- 1.

- Preparation of CFBFA Artificial Aggregates (Composite Gravels)

- 2.

- Concrete Mixing and Curing

2.3. Testing and Characterization

2.4. Image Analysis for ITZ and Statistics

3. Result and Discussion

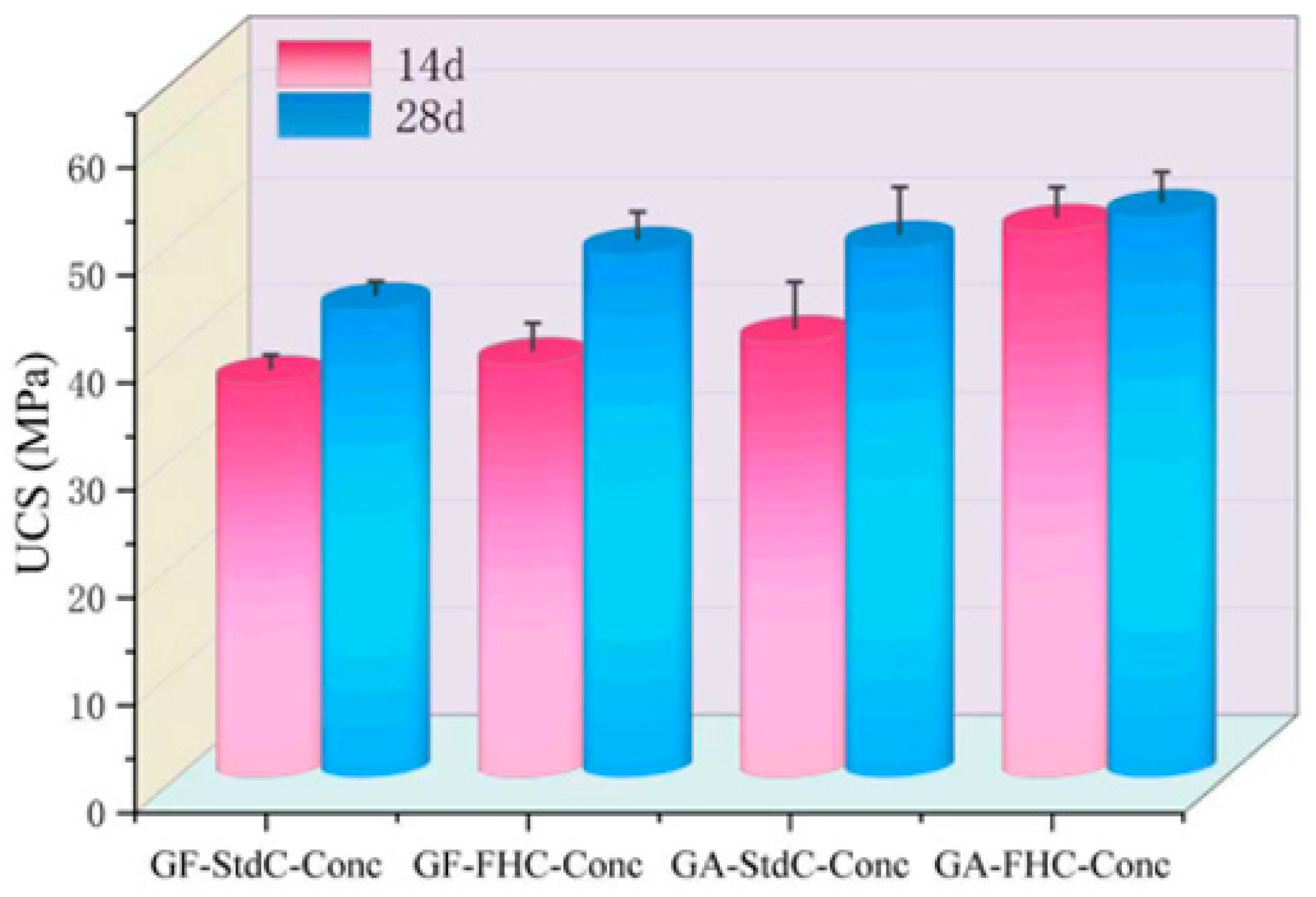

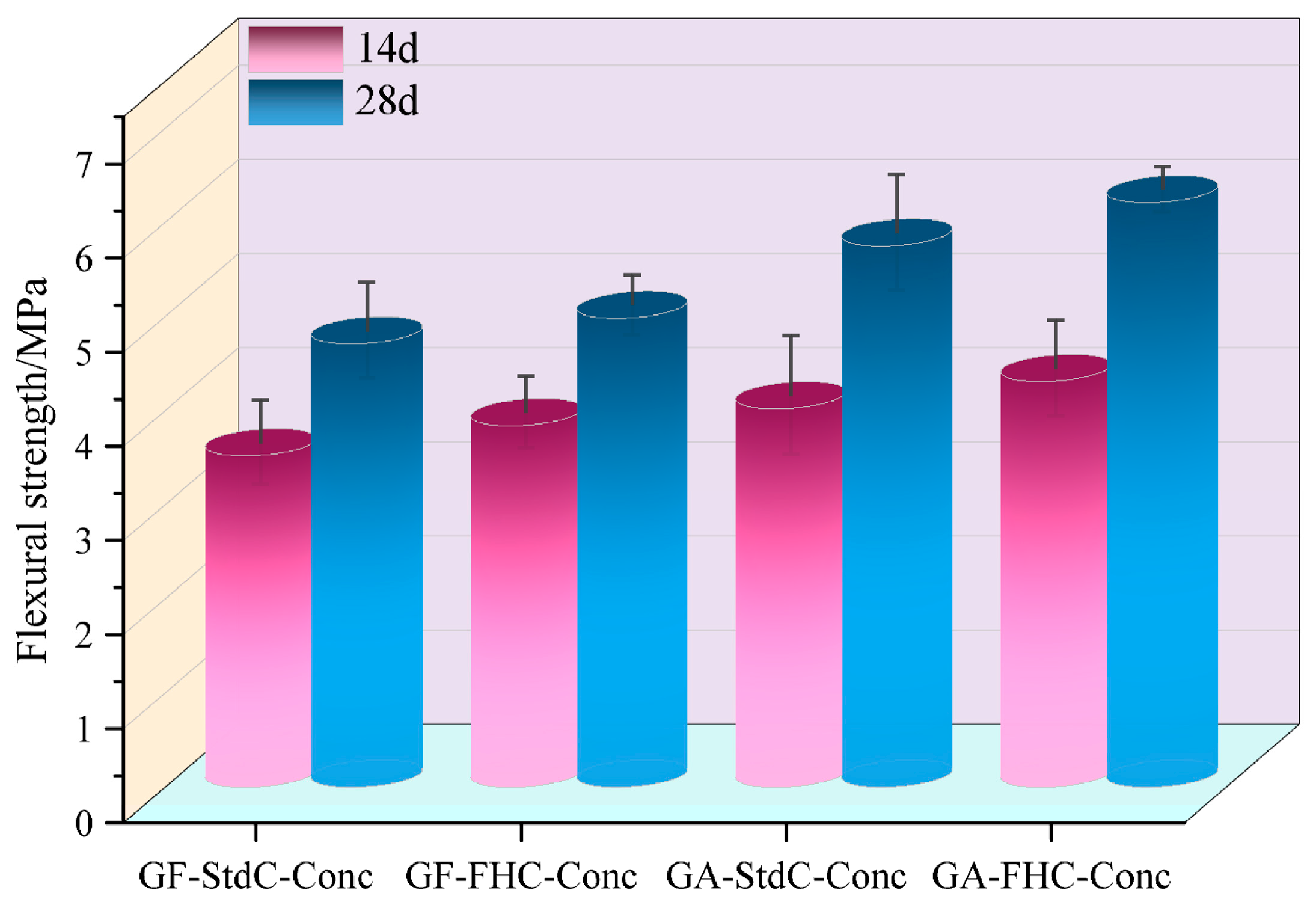

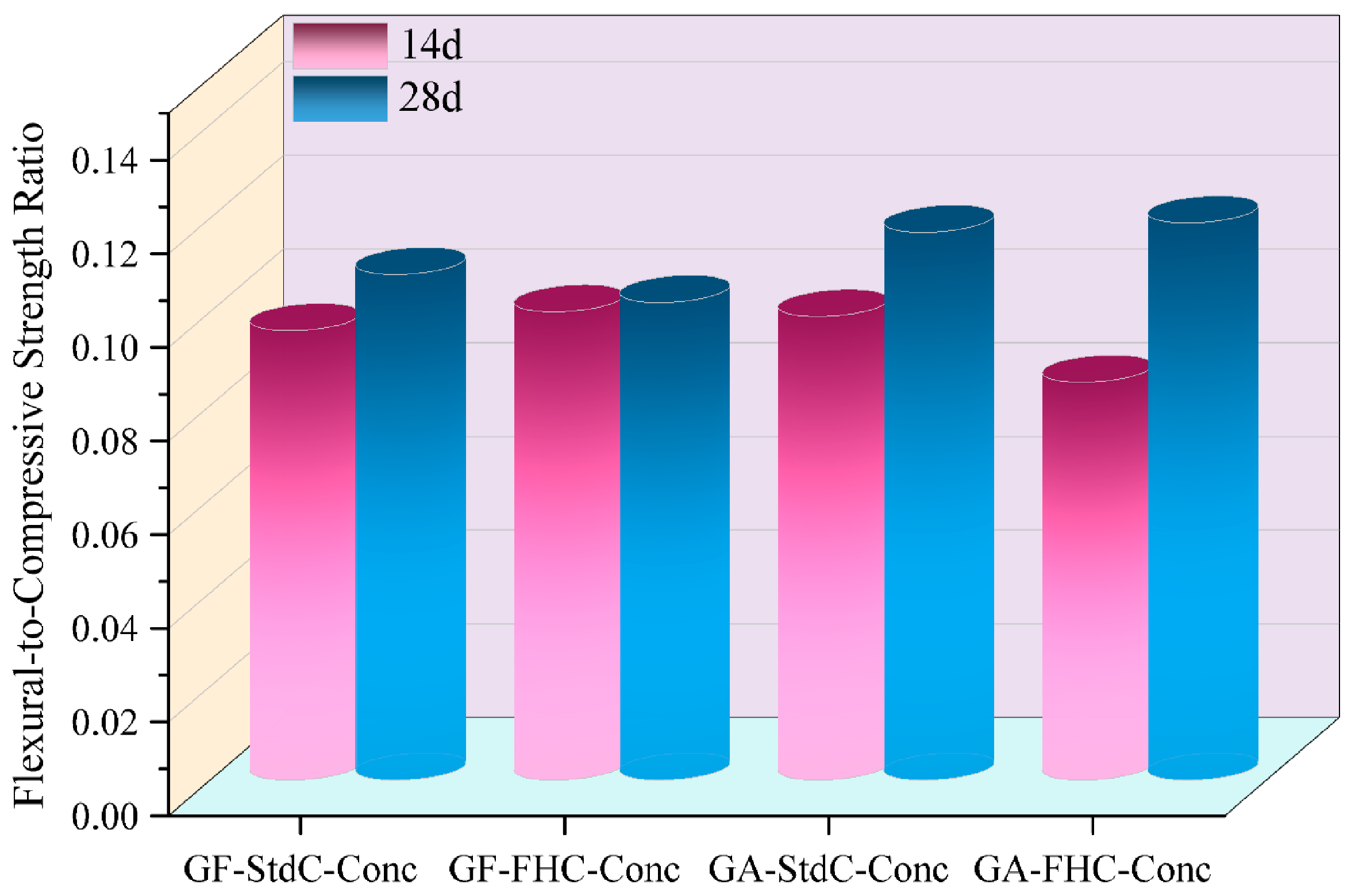

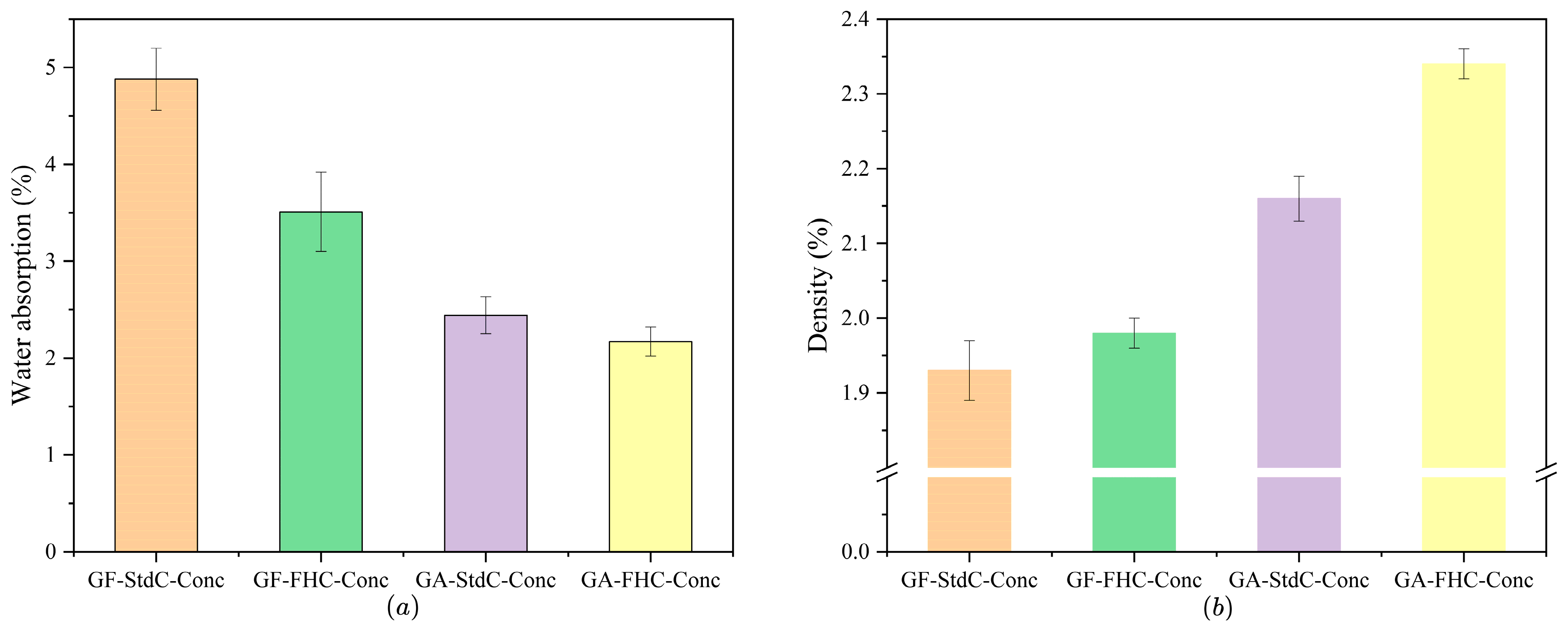

3.1. Physical Properties

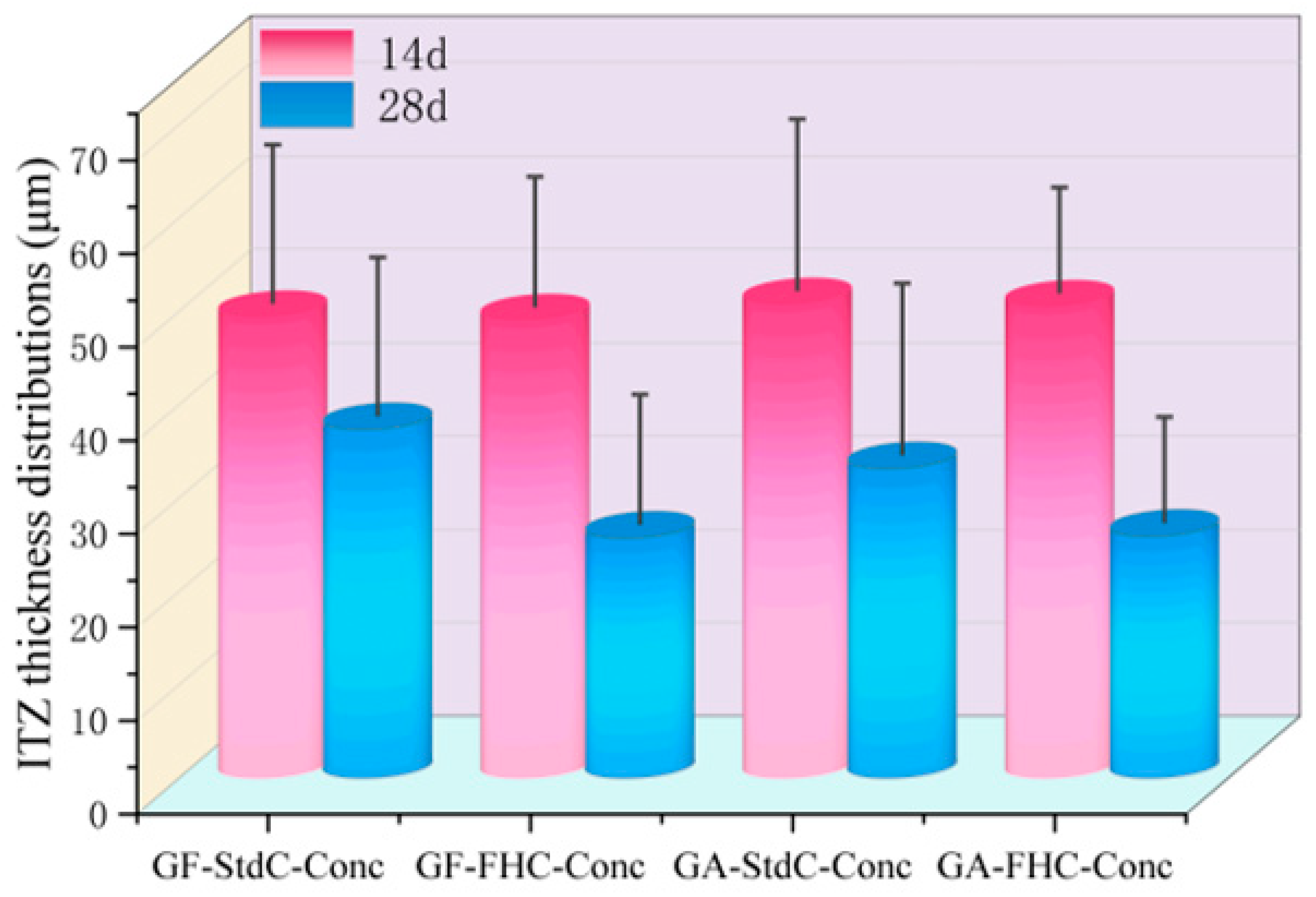

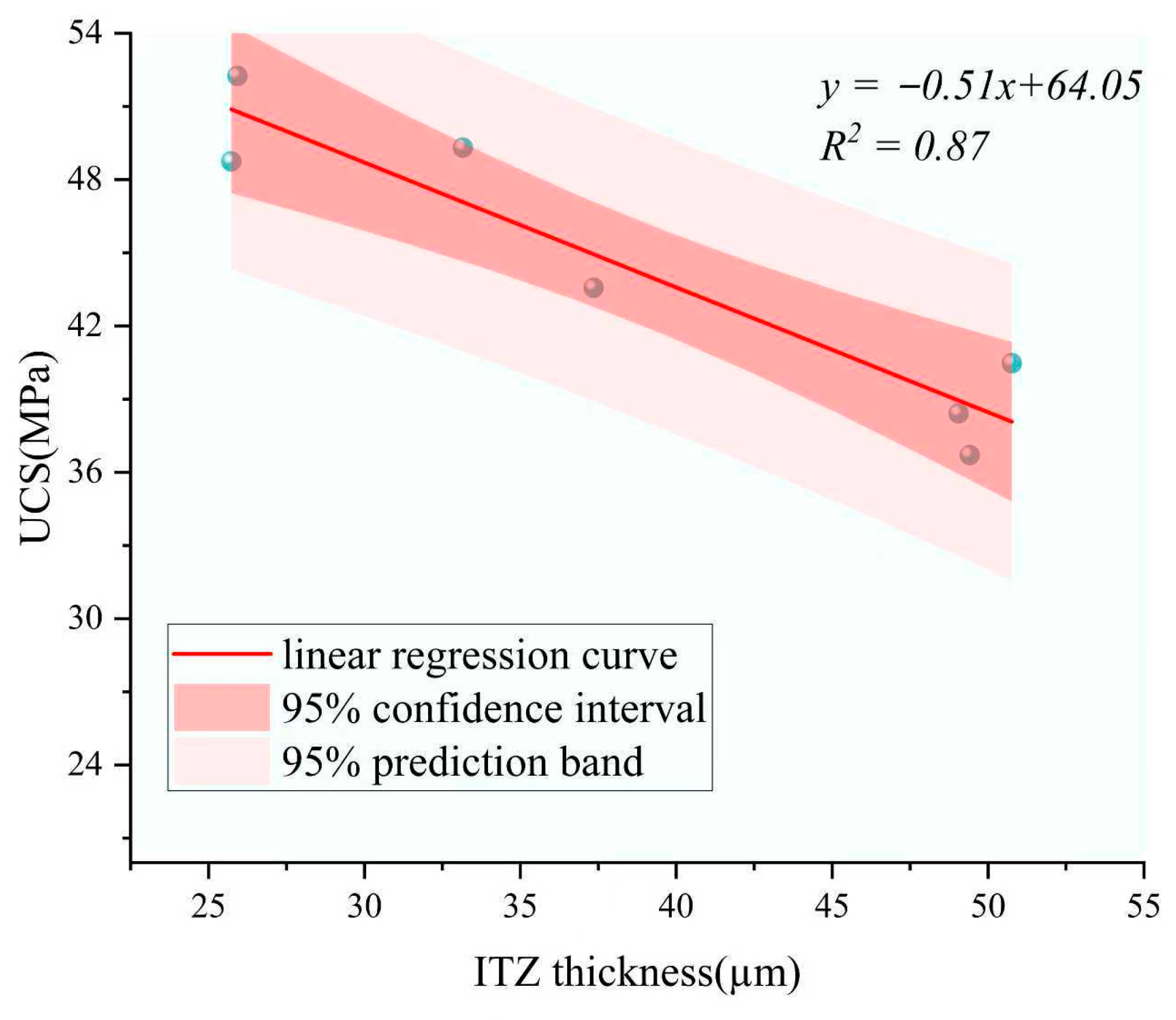

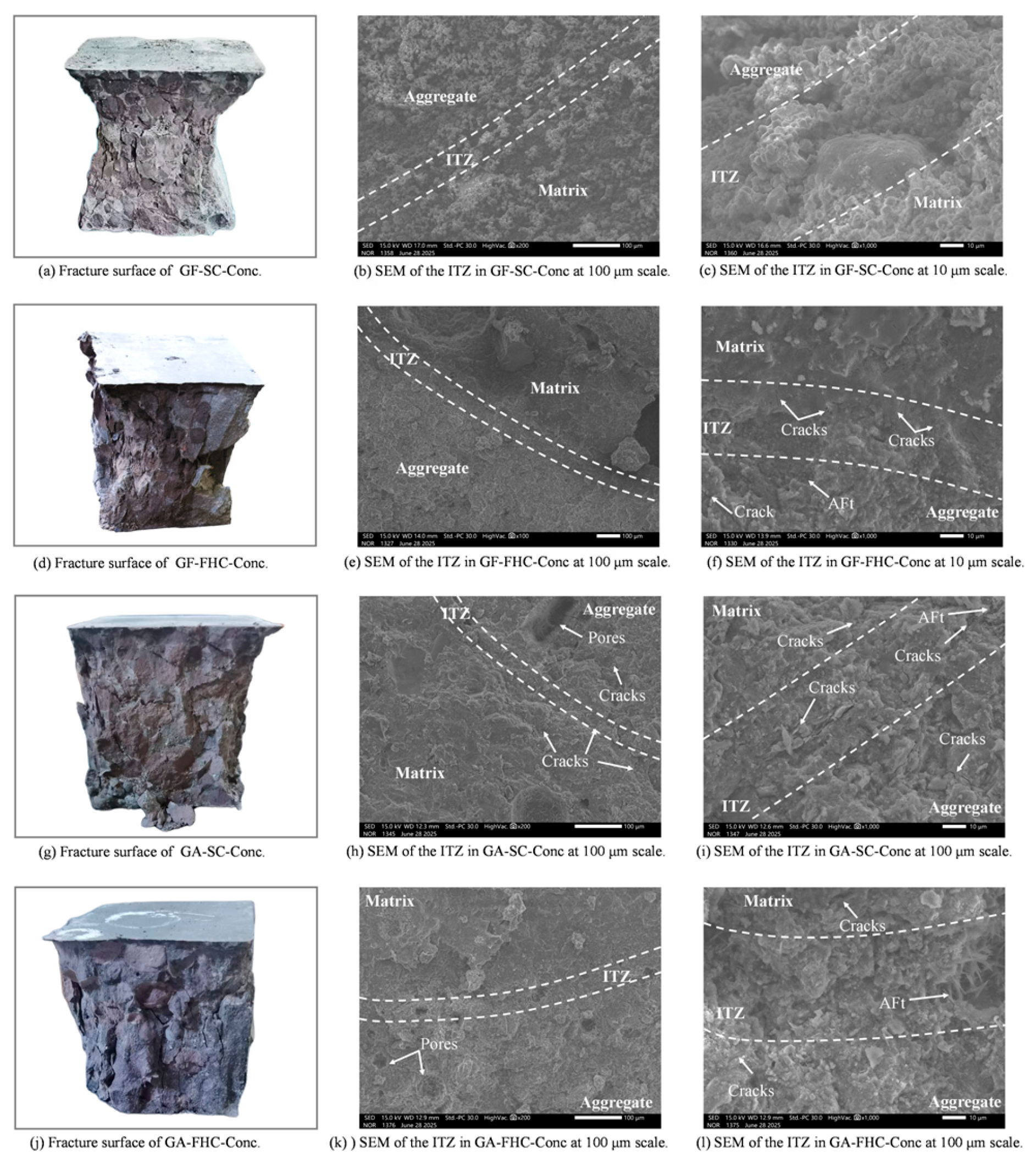

3.2. ITZ Thickness Analysis

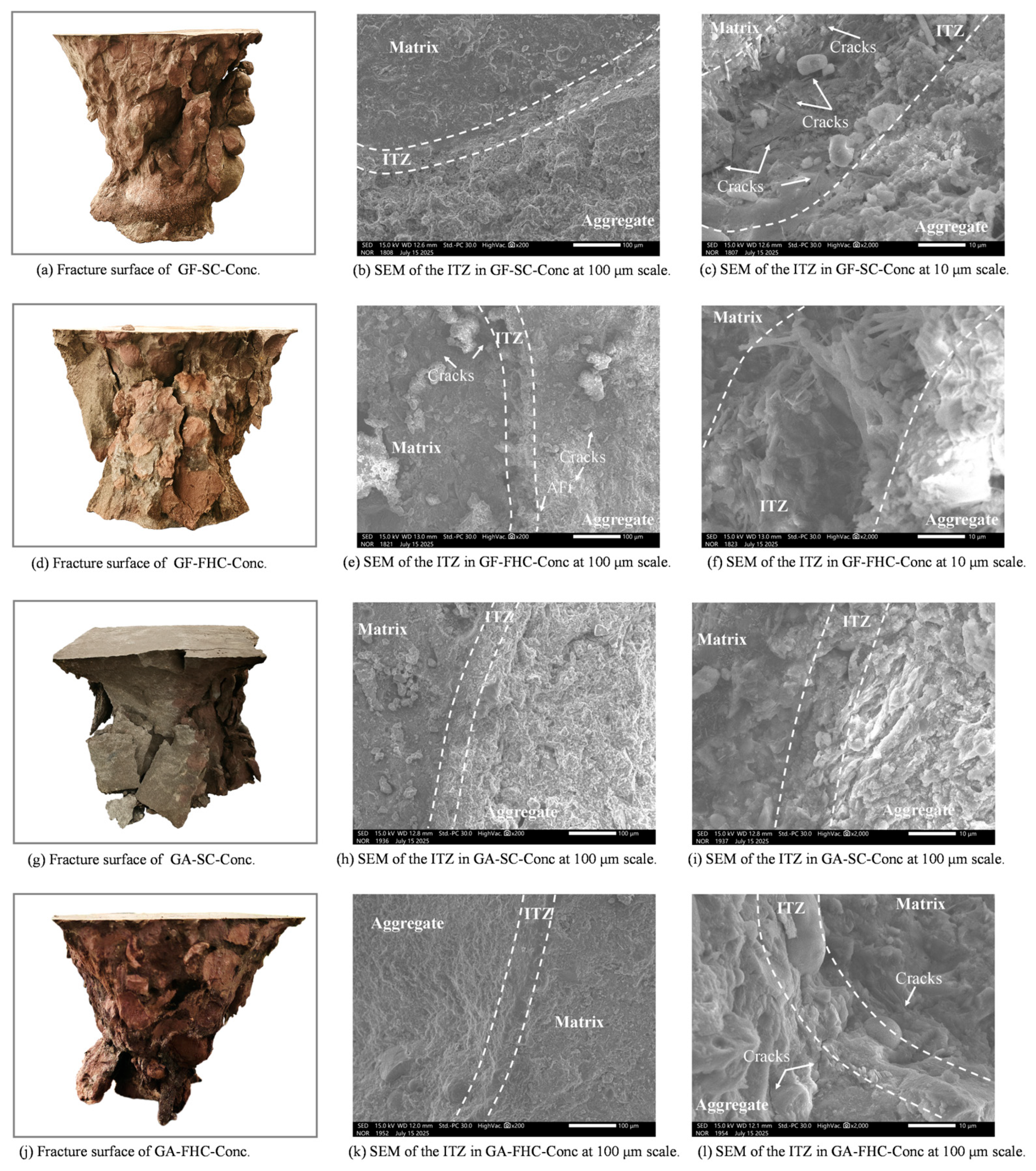

3.3. SEM Microstructure

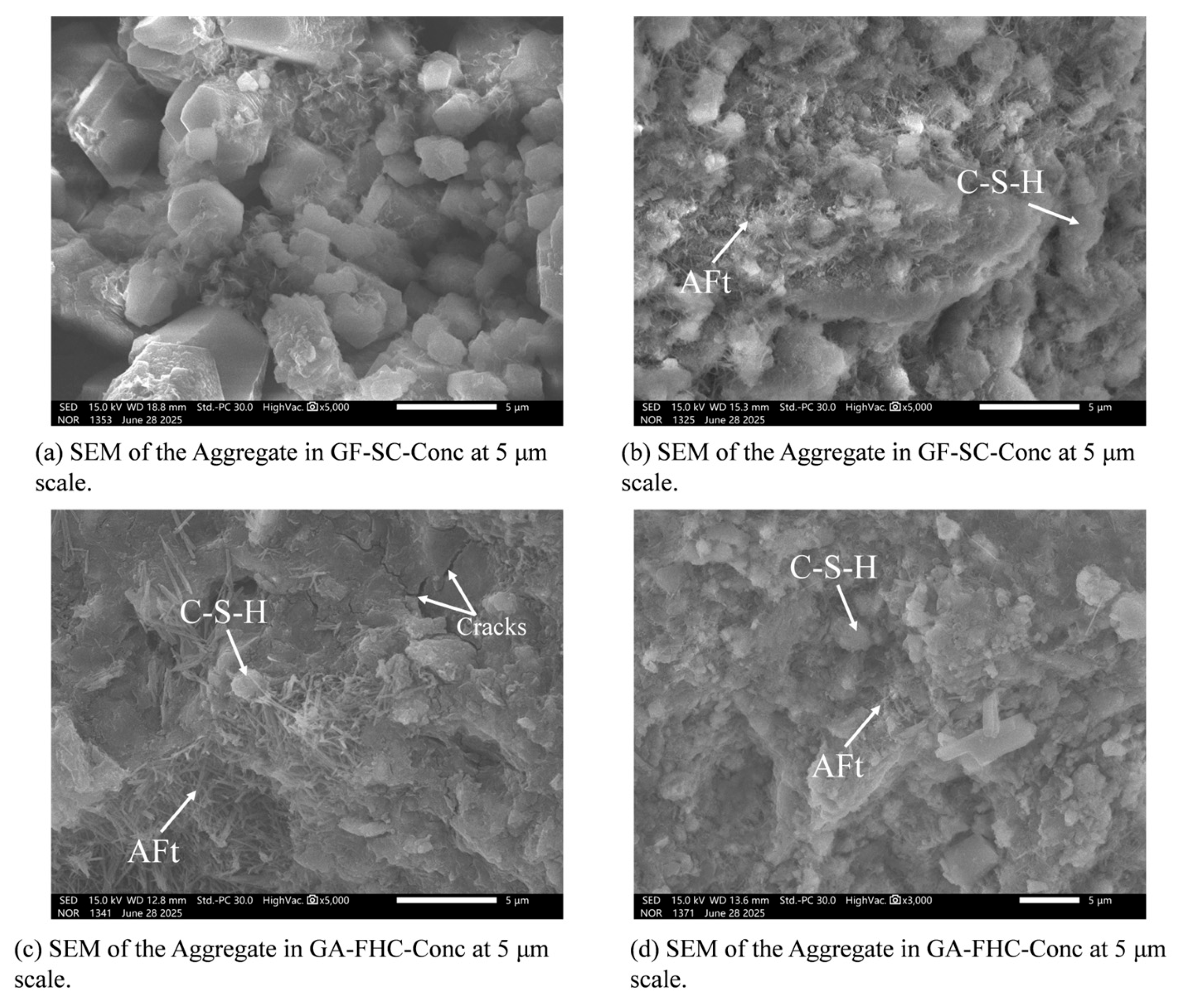

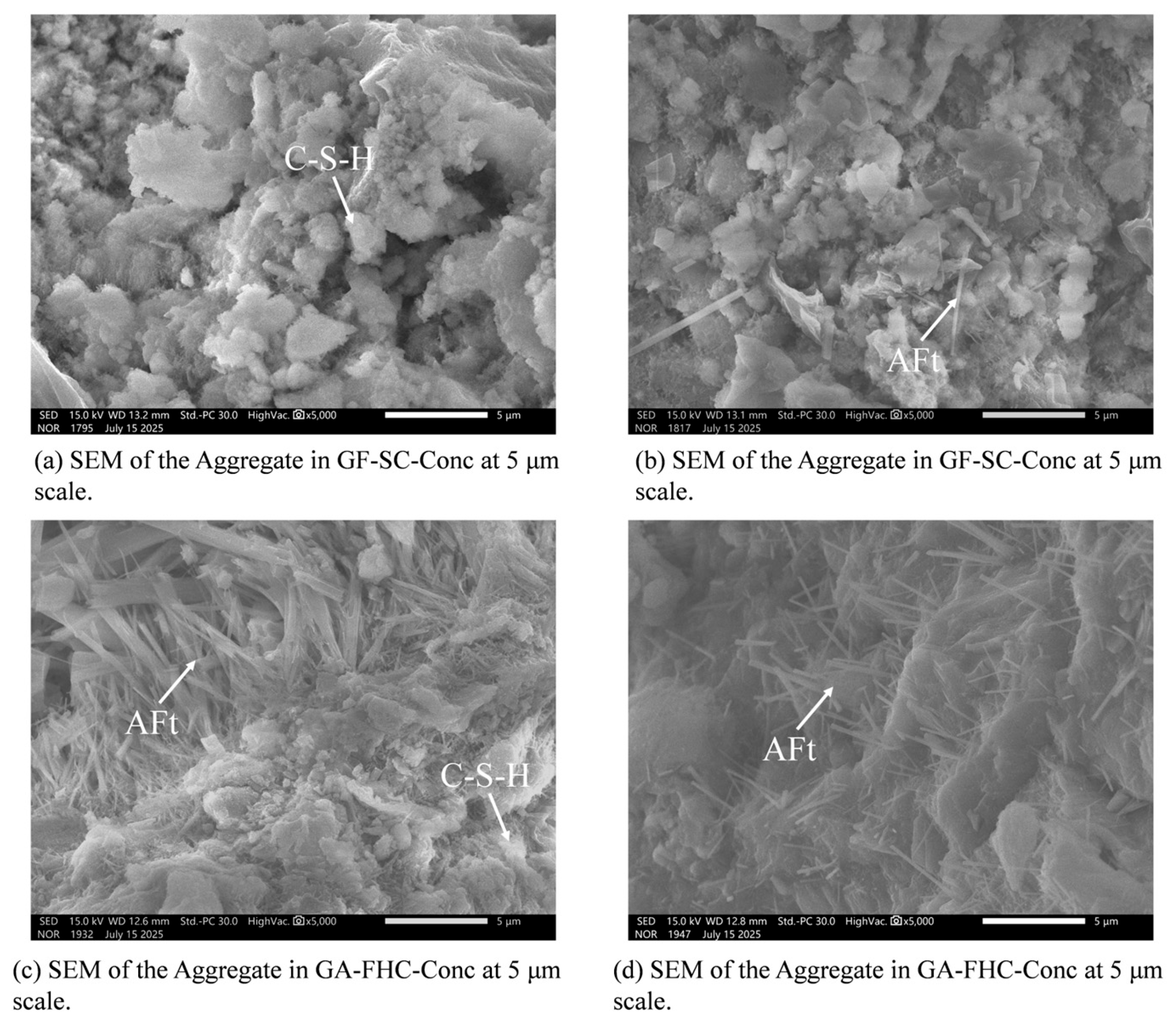

3.4. Microstructural Evolution Within the Aggregate Region

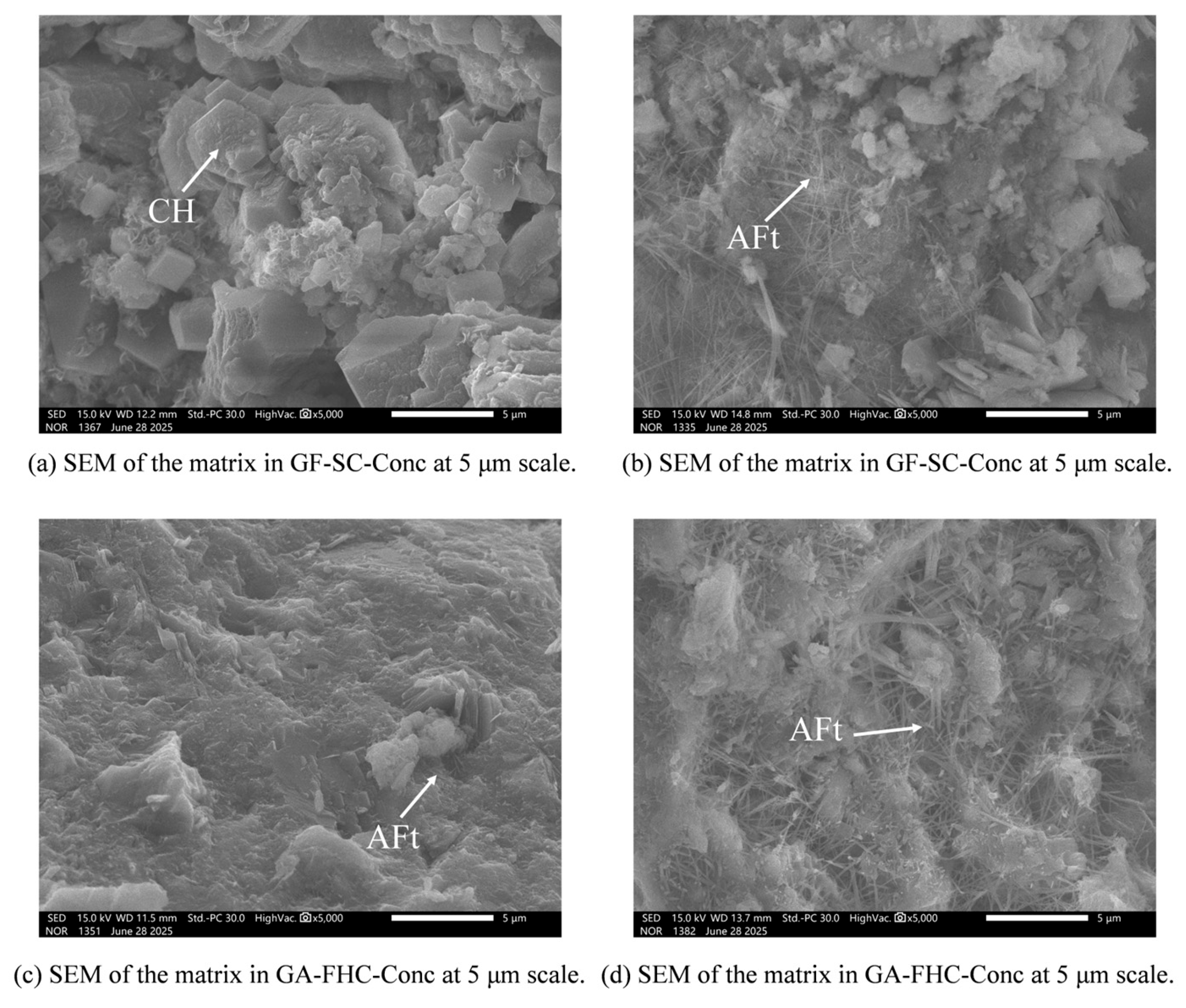

3.5. Matrix Microstructure and Ion Transport Dynamics

3.6. ITZ Morphology, Crack Behavior, and Failure Patterns

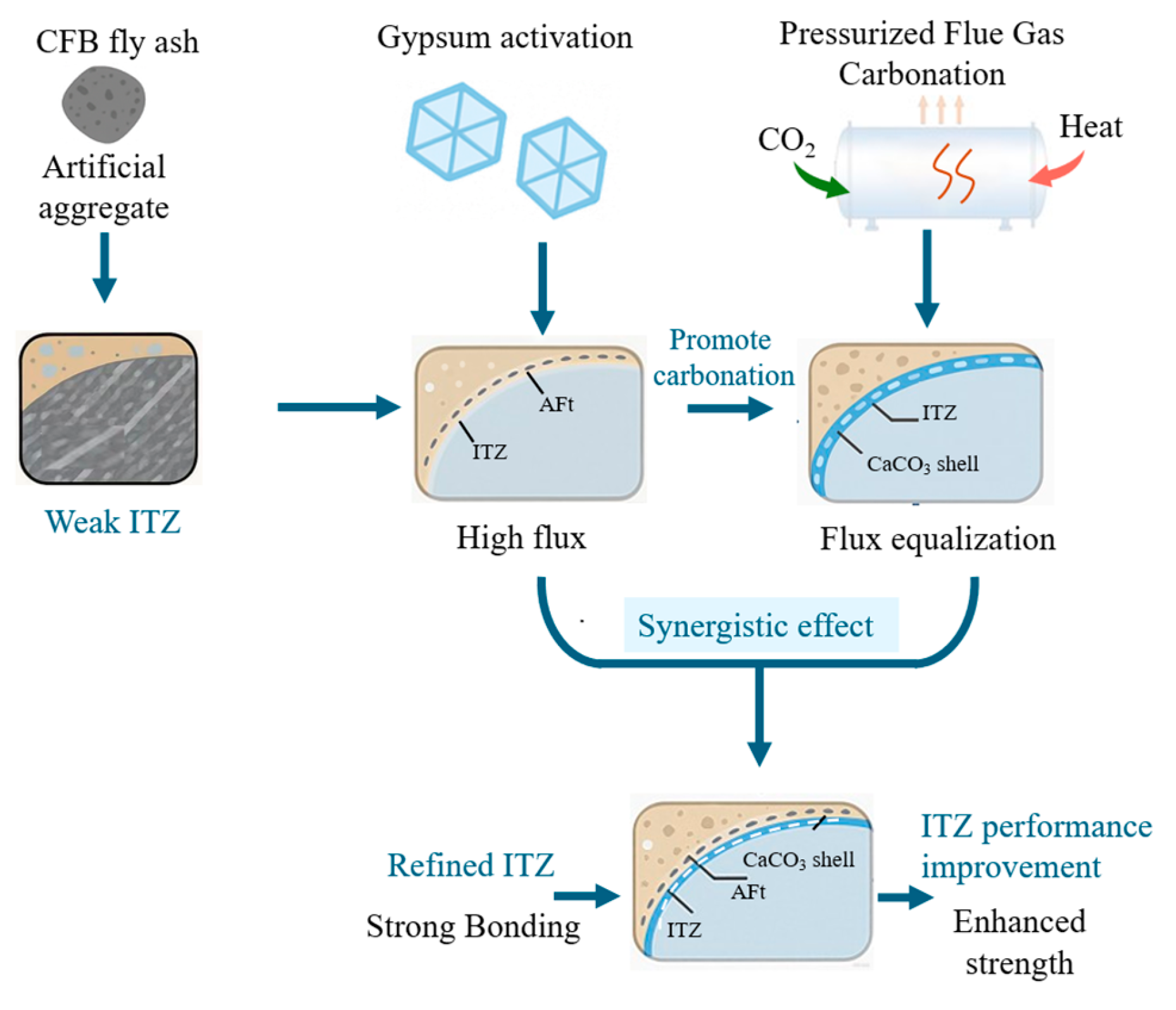

3.7. Synergistic Role of Carbonation and Gypsum on ITZ Optimization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Xiao, Y.; Li, W.; Yang, S. Gravel Excavation and Geomorphic Evolution of the Mining Affected River in the Upstream Reach of the Yangtze River, China. Int. J. Sediment Res. 2022, 37, 272–286. [Google Scholar] [CrossRef]

- Liu, Y.; Kumar, D.; Lim, K.H.; Lai, Y.L.; Hu, Z.; Ambikakumari Sanalkumar, K.U.; Yang, E.-H. Efficient Utilization of Municipal Solid Waste Incinerator Bottom Ash for Autoclaved Aerated Concrete Formulation. J. Build. Eng. 2023, 71, 106463. [Google Scholar] [CrossRef]

- Ahmed, H.; Tiznobaik, M.; Huda, S.B.; Islam, M.S.; Alam, M.S. Recycled Aggregate Concrete from Large-Scale Production to Sustainable Field Application. Constr. Build. Mater. 2020, 262, 119979. [Google Scholar] [CrossRef]

- Mei, N.; Zhi, W.; Jue-Shi, Q.; Sheng-Xuan, T. Characteristics of Fluidized Bed Coal Combustion Fly Ash and Slag and Its Adaptability with Current Standards. Bull. Chin. Ceram. Soc. 2019, 38, 688–693+701. [Google Scholar]

- Ohenoja, K.; Pesonen, J.; Yliniemi, J.; Illikainen, M. Utilization of Fly Ashes from Fluidized Bed Combustion: A Review. Sustainability 2020, 12, 2988. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, X.; Zhang, Z.; Li, Y.; Gu, J. Synergic Effects of Circulating Fluidized Bed Fly Ash-Red Mud-Blast Furnace Slag in Green Cementitious Materials: Hydration Products and Environmental Performance. J. Build. Eng. 2022, 58, 105007. [Google Scholar] [CrossRef]

- Wu, C.-R.; Zhan, B.-J.; Hong, Z.-Q.; Cui, S.-C.; Cui, P.; Kou, S.-C. Hydration Behavior of Circulating Fluidized Bed Fly Ash (CFBFA) as a Cementitious Binder. Constr. Build. Mater. 2022, 314, 125625. [Google Scholar] [CrossRef]

- Li, X.; Chen, Q.; Huang, K.; Ma, B.; Wu, B. Cementitious Properties and Hydration Mechanism of Circulating Fluidized Bed Combustion (CFBC) Desulfurization Ashes. Constr. Build. Mater. 2012, 36, 182–187. [Google Scholar] [CrossRef]

- Nguyen, H.-A.; Chang, T.-P.; Shih, J.-Y.; Chen, C.-T.; Nguyen, T.-D. Influence of Circulating Fluidized Bed Combustion (CFBC) Fly Ash on Properties of Modified High Volume Low Calcium Fly Ash (HVFA) Cement Paste. Constr. Build. Mater. 2015, 91, 208–215. [Google Scholar] [CrossRef]

- Park, S.M.; Lee, N.K.; Lee, H.K. Circulating Fluidized Bed Combustion Ash as Controlled Low-Strength Material (CLSM) by Alkaline Activation. Constr. Build. Mater. 2017, 156, 728–738. [Google Scholar] [CrossRef]

- Liu, X.; Li, Y.; Zhang, L.; Cang, D. Utilization of CFB Fly Ash in Eco-Cement: Mechanical Properties and Microstructural Analysis. In Proceedings of the Advances in Composites, PTS 1 and 2; Bu, J.L., Jiang, Z.Y., Jiao, S., Eds.; Trans Tech Publications Ltd.: Zurich, Switzerland, 2011; Volume 150–151, pp. 885–889. [Google Scholar]

- Chen, G.-Y.; Huang, W.-H. Activation of Blast Furnace Slag with CFB Fly Ash as a Supplementary Binder Material: Hydration Products and Effects of Sulfate Attack. Crystals 2021, 12, 41. [Google Scholar] [CrossRef]

- Xu, N. Adding Hydrated Lime for Regulating Hydration and Carbonation Properties of Circulating Fluidized Bed Boiler Fly Ash. Mater. Today Commun. 2024, 41, 111008. [Google Scholar] [CrossRef]

- Bekkeri, G.B.; Shetty, K.K.; Nayak, G. Effects of Cold-Bonded Artificial Aggregate Properties on the Behaviour of Concrete. Mater. Res. Express 2024, 11, 085202. [Google Scholar] [CrossRef]

- Lee, K.H.; Lee, K.G.; Lee, Y.S.; Wie, Y.M. Manufacturing and Application of Artificial Lightweight Aggregate from Water Treatment Sludge. J. Clean. Prod. 2021, 307, 127260. [Google Scholar] [CrossRef]

- Yue, G.; Ma, Z.; Liu, M.; Liang, C.; Ba, G. Damage Behavior of the Multiple ITZs in Recycled Aggregate Concrete Subjected to Aggressive Ion Environment. Constr. Build. Mater. 2020, 245, 118419. [Google Scholar] [CrossRef]

- Kirthika, S.K.; Singh, S.K. Durability Studies on Recycled Fine Aggregate Concrete. Constr. Build. Mater. 2020, 250, 118850. [Google Scholar] [CrossRef]

- Barabanshchikov, Y.G.; Usanova, K.Y.; Sukhrob, U.; Mirsoxibjon, S. Properties of Concrete Containing High-Calcium Fly Ash Artificial Aggregate. E3S Web Conf. 2023, 401, 03016. [Google Scholar] [CrossRef]

- Xu, Z.; Bai, Z.; Wu, J.; Long, H.; Deng, H.; Chen, Z.; Yuan, Y.; Fan, X. Microstructural Characteristics and Nano-Modification of Interfacial Transition Zone in Concrete: A Review. Nanotechnol. Rev. 2022, 11, 2078–2100. [Google Scholar] [CrossRef]

- Jiang, Y.; Ling, T.-C. Production of Artificial Aggregates from Steel-Making Slag: Influences of Accelerated Carbonation during Granulation and/or Post-Curing. J. CO2 Util. 2020, 36, 135–144. [Google Scholar] [CrossRef]

- Xu, N.; He, Y.; Sa, R.; Wang, N.; Yang, Y.; Ma, S. Optimizing Mechanical Properties and Environmental Benefits of CFBFA Composite Gravels Through Gypsum, Hydrated Lime Addition, and CO2 Carbonation Curing. Solids 2025, 6, 9. [Google Scholar] [CrossRef]

- Mehmood, N.; Zhu, P.; Liu, H.; Li, H.; Zhu, X. Influence of Accelerated Carbonation Conditions on the Physical Properties Improvement of Recycled Coarse Aggregate. Materials 2025, 18, 901. [Google Scholar] [CrossRef]

- Liu, J.; Ma, K.; Shen, J.; Xie, Y.; Long, G. Influence of CO2 Enhancement of Recycled Aggregate on Microstructure of ITZs in Recycled Concrete. J. Build. Eng. 2023, 65, 105805. [Google Scholar] [CrossRef]

- Zhang, M.; Cai, S.; Huo, Y.; Chen, Z.; Wu, Z. Measurement of Oxide Layer Thickness on 7050 Aluminum Alloy Surface Based on Image Processing Technology. J. Phys. Conf. Ser. 2020, 1549, 5. [Google Scholar] [CrossRef]

- Hu, M.; He, J.; Alsabaan, M. Image Identification Method of Ice Thickness on Transmission Line Based on Visual Sensing. Mob. Netw. Appl 2023, 28, 1783–1792. [Google Scholar] [CrossRef]

- Wang, J.; Yao, S.; Chen, N. Synergistic Reinforcement of Foamed Cementitious Materials Using CO2 Foaming Agent. J. Mater. Civ. Eng. 2025, 37, 04025020. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Standard for Geotechnical Testing Method. China Planning Press: Beijing, China, 2019.

- Le Page, Y.; Donnay, G. Refinement of the Crystal Structure of Low-Quartz. Acta Cryst. B 1976, 32, 2456–2459. [Google Scholar] [CrossRef]

- Finger, L.W.; Hazen, R.M. Crystal Structure and Isothermal Compression of Fe2O3, Cr2O3, and V2O3 to 50 Kbars. J. Appl. Phys. 1980, 51, 5362–5367. [Google Scholar] [CrossRef]

- Li, X.H.; Xu, X.L.; Wang, D.X.; Yang, S.W.; Liu, G.S.; Shen, C.Z.; Li, Y.F.; Lü, Q.C.; Wang, J.W. Effect of polymeric ferric sulfate on crystallization characteristics of gypsum. Clean Coal Technol. 2025, 31, 698–706. [Google Scholar] [CrossRef]

- Chaix-Pluchery, O.; Pannetier, J.; Bouillot, J.; Niepce, J.C. Structural Prereactional Transformations in Ca(OH)2. J. Solid State Chem. 1987, 67, 225–234. [Google Scholar] [CrossRef]

- Mumme, W.; Hill, R.J.; Bushnell-wye, G.; Segnit, E. Rietveld Crystal Structure Refinements, Crystal Chemistry and Calculated Powder Diffraction Data for the Polymorphs of Dicalcium Silicate and Related Phases. N. Jb. Miner. Abr. 1995, 169, 35–68. [Google Scholar]

- ASTM C39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C642; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM E1876-22; Standard Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio by Impulse Excitation of Vibration. ASTM International: West Conshohocken, PA, USA, 2022.

- Beckingham, L.E.; Peters, C.A.; Um, W.; Jones, K.W.; Lindquist, W.B. 2D and 3D Imaging Resolution Trade-Offs in Quantifying Pore Throats for Prediction of Permeability. Adv. Water Resour. 2013, 62, 1–12. [Google Scholar] [CrossRef]

- Zhao, F.; Hu, J.; Liu, T.; Zhou, T.; Ren, Q. Study of the Macro and Micro Characteristics of and Their Relationships in Cemented Backfill Based on SEM. Materials 2023, 16, 4772. [Google Scholar] [CrossRef]

- Catche, S.; Piquet, R.; Lachaud, F.; Castanié, B.; Benaben, A. Analysis of Hole Wall Defects of Drilled Carbon Fiber Reinforced Polymer Laminates. J. Compos. Mater. 2015, 49, 1223–1240. [Google Scholar] [CrossRef]

- Lyu, K.; She, W.; Miao, C.; Chang, H.; Gu, Y. Quantitative Characterization of Pore Morphology in Hardened Cement Paste via SEM-BSE Image Analysis. Constr. Build. Mater. 2019, 202, 589–602. [Google Scholar] [CrossRef]

- Xu, N.; Ma, S.; Wang, N.; Feng, Y.; Liu, Y.; Ren, K.; Bai, S. Optimization of Ternary Activator for Enhancing Mechanical Properties of Carbonized Cementitious Material Based on Circulating Fluidized Bed Fly Ash. Processes 2024, 12, 289. [Google Scholar] [CrossRef]

- Badgujar, S.; Kumar Dwivedi, A. Microstructural Analysis of Self-Compacting Concrete—A Review. Mater. Today Proc. 2022, 65, 1250–1259. [Google Scholar] [CrossRef]

- Joseph, S.; Mutti, M.; Ohkubo, T.; Maruyama, I.; Cizer, Ö. Microstructural Analysis of Cement Paste Blended with Blast Furnace Slag Using 1H NMR Relaxometry. Cem. Concr. Compos. 2024, 146, 105377. [Google Scholar] [CrossRef]

- Deng, X.; Shen, M.; Zhao, Y.; Bi, J.; Wang, C.; Zhang, Y.; Li, Y.; Ning, L. Fracture Behavior and Failure Mechanisms of Concrete-Rock Interfaces with Interfacial Grouting. Theor. Appl. Fract. Mech. 2025, 139, 105001. [Google Scholar] [CrossRef]

- Wu, X.; Tian, J.; Ma, H.; Zheng, Y.; Hu, S.; Wang, W.; Du, Y.; Huang, W.; Sun, C.; Zhu, Z. Investigation on Interface Fracture Properties and Nonlinear Fracture Model between ECC and Concrete Subjected to Salt Freeze-Thaw Cycles. Constr. Build. Mater. 2020, 259, 119785. [Google Scholar] [CrossRef]

- Akçaoğlu, T.; Tokyay, M.; Çelik, T. Effect of Coarse Aggregate Size and Matrix Quality on ITZ and Failure Behavior of Concrete under Uniaxial Compression. Cem. Concr. Compos. 2004, 26, 633–638. [Google Scholar] [CrossRef]

- Lu, C.; Yu, Q.; Wei, J.; Niu, Y.; Zhang, Y.; Lin, C.; Chen, P.; Shi, C.; Yang, P. Influence of Interface Transition Zones (ITZ) and Pore Structure on the Compressive Strength of Recycled Aggregate Concrete. Constr. Build. Mater. 2024, 456, 139299. [Google Scholar] [CrossRef]

- Jia, J.-Y.; Gu, X.-L. Effects of Coarse Aggregate Surface Morphology on Aggregate-Mortar Interface Strength and Mechanical Properties of Concrete. Constr. Build. Mater. 2021, 294, 123515. [Google Scholar] [CrossRef]

- Liu, Q.; Ma, J.; Qiao, P.; Wu, E.; Zhou, G. Mesoscale Modeling of New-to-Old Concrete Interface under Combined Shear and Compressive Loads. Eng. Fract. Mech. 2024, 307, 110331. [Google Scholar] [CrossRef]

- Khalilpour, S.; BaniAsad, E.; Dehestani, M. A Review on Concrete Fracture Energy and Effective Parameters. Cem. Concr. Res. 2019, 120, 294–321. [Google Scholar] [CrossRef]

- Xu, N.; Sa, R.; He, Y.; Guo, J.; Chen, Y.; Wang, N.; Feng, Y.; Ma, S. Stabilization of High-Volume Circulating Fluidized Bed Fly Ash Composite Gravels via Gypsum-Enhanced Pressurized Flue Gas Heat Curing. Materials 2025, 18, 3436. [Google Scholar] [CrossRef] [PubMed]

- Xia, W.; Cui, S.; Xu, L.; Shen, L.; Liu, P.; Woody Ju, J. Study on the Fracture Performance for Rock-Concrete Interface in the High Geothermal Tunnel Environment. Constr. Build. Mater. 2022, 347, 128568. [Google Scholar] [CrossRef]

- Lau, D.; Büyüköztürk, O. Fracture Characterization of Concrete/Epoxy Interface Affected by Moisture. Mech. Mater. 2010, 42, 1031–1042. [Google Scholar] [CrossRef]

| Material | CFBFA | Portland Cement | Gypsum | Hydrated Lime |

|---|---|---|---|---|

| SO3 | 3.075 ± 0.04 | 4.029 ± 0.02 | 51.549 | 0.647 |

| CaO | 5.067 ± 0.05 | 53.678 ± 0.21 | 43.205 | 93.886 |

| SiO2 | 46.237 ± 0.25 | 21.245 ± 0.04 | - | 0.928 |

| Al2O3 | 29.502 ± 0.20 | 7.298 ± 0.01 | 0.794 | 0.956 |

| Fe2O3 | 9.875 ± 0.08 | 4.591 ± 0.01 | - | - |

| MgO | - | 6.037 ± 0.02 | 3.925 | 2.511 |

| Mix | Dosage |

|---|---|

| Cement (kg/m3) | 806 |

| Fine aggregate (kg/m3) | 396 |

| Coarse aggregate (kg/m3) | See Note 1 |

| Water (kg/m3) | 242 |

| Liquid Superplasticizer (PCE) (L) | 19.5 |

| Sample | Curing Condition | Cement/wt% | Hydrated Lime/wt% | Gypsum/wt% | CFBFA/wt% |

|---|---|---|---|---|---|

| GF-StdC | Standard curing | 10 | 5 | 0 | 85 |

| GA-StdC | Standard curing | 10 | 5 | 5 | 80 |

| GF-FHC | FHC (1 h) + StdC (28 d) | 10 | 5 | 0 | 85 |

| GA-FHC | FHC (1 h) + StdC (28 d) | 10 | 5 | 5 | 80 |

| Sample | Bulk Density(g/cm3) | Crushing Strength (MPa) | Water Absorption for 24 h (%) |

|---|---|---|---|

| GF-StdC | 1.49 | 4.37 | 17.03 |

| GA-StdC | 1.74 | 7.39 | 6.65 |

| GF-FHC | 1.54 | 5.39 | 14.26 |

| GA-FHC | 1.75 | 9.13 | 3.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, N.; Guo, M.; Chen, Y.; Sa, R.; Huo, M.; Ma, S. Synergistic Gypsum–Carbonation Strategy and Non-Contact ITZ Quantification for CFBFA Artificial Aggregate Concrete. Materials 2025, 18, 5240. https://doi.org/10.3390/ma18225240

Xu N, Guo M, Chen Y, Sa R, Huo M, Ma S. Synergistic Gypsum–Carbonation Strategy and Non-Contact ITZ Quantification for CFBFA Artificial Aggregate Concrete. Materials. 2025; 18(22):5240. https://doi.org/10.3390/ma18225240

Chicago/Turabian StyleXu, Nuo, Mingyi Guo, Yiheng Chen, Rentuoya Sa, Mao Huo, and Suxia Ma. 2025. "Synergistic Gypsum–Carbonation Strategy and Non-Contact ITZ Quantification for CFBFA Artificial Aggregate Concrete" Materials 18, no. 22: 5240. https://doi.org/10.3390/ma18225240

APA StyleXu, N., Guo, M., Chen, Y., Sa, R., Huo, M., & Ma, S. (2025). Synergistic Gypsum–Carbonation Strategy and Non-Contact ITZ Quantification for CFBFA Artificial Aggregate Concrete. Materials, 18(22), 5240. https://doi.org/10.3390/ma18225240