Application of an Improved Dual-Branch Model Based on Multi-Scale Feature Fusion in Fracture Surface Image Recognition

Abstract

1. Introduction

2. Materials and Methods

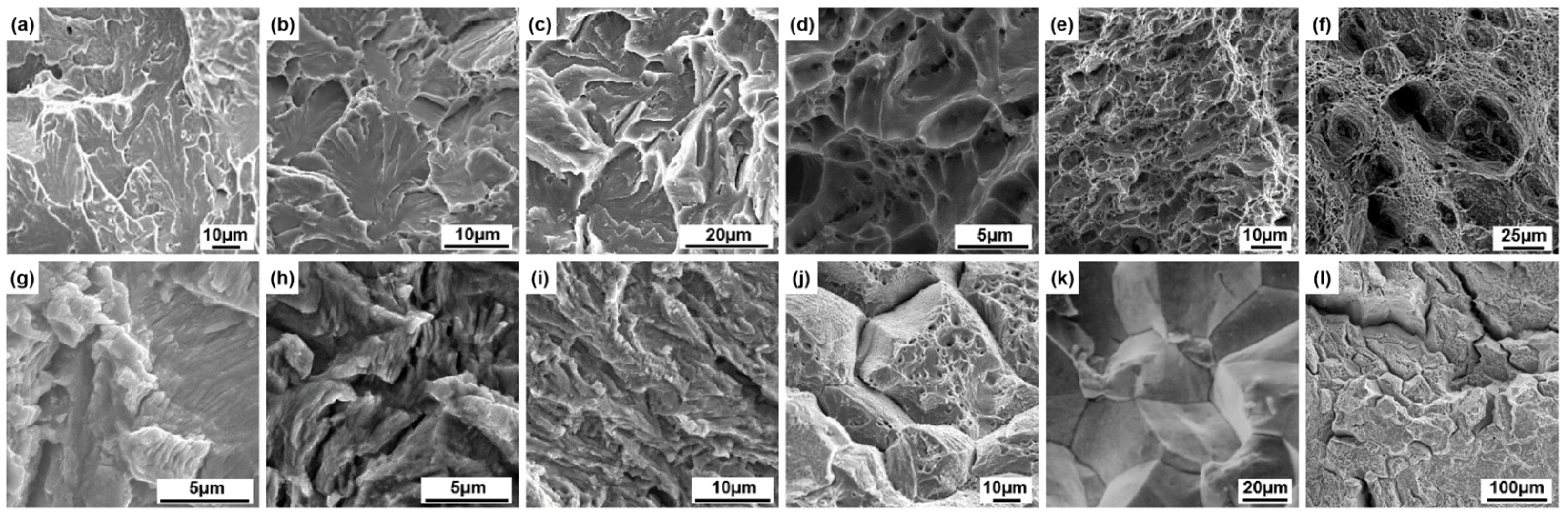

2.1. Dataset

2.2. Benchmark Model Selection

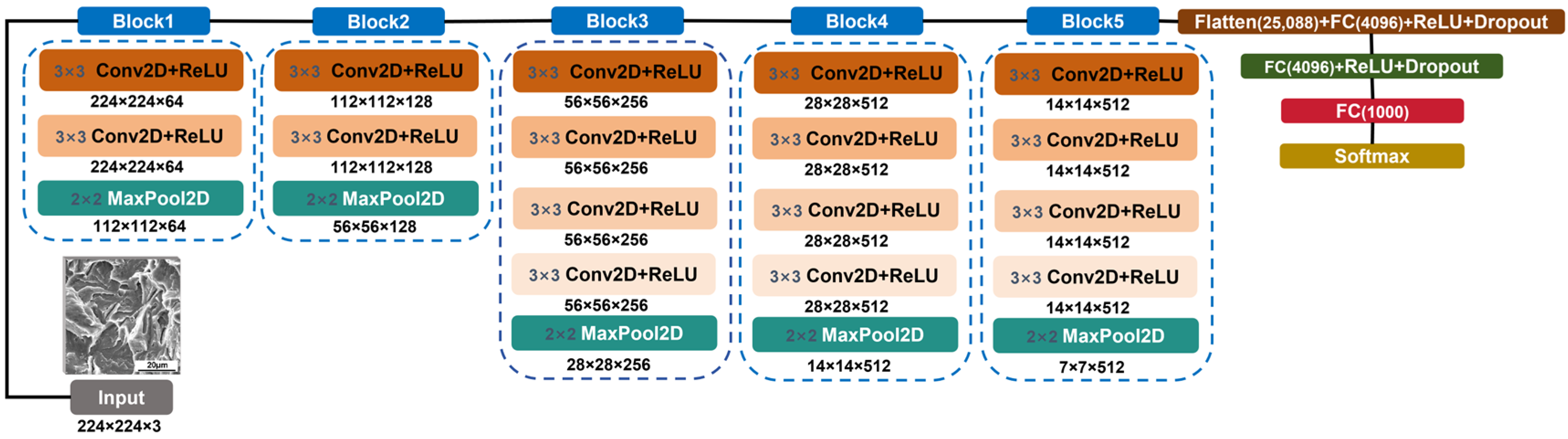

2.2.1. VGG19

2.2.2. Inception V3

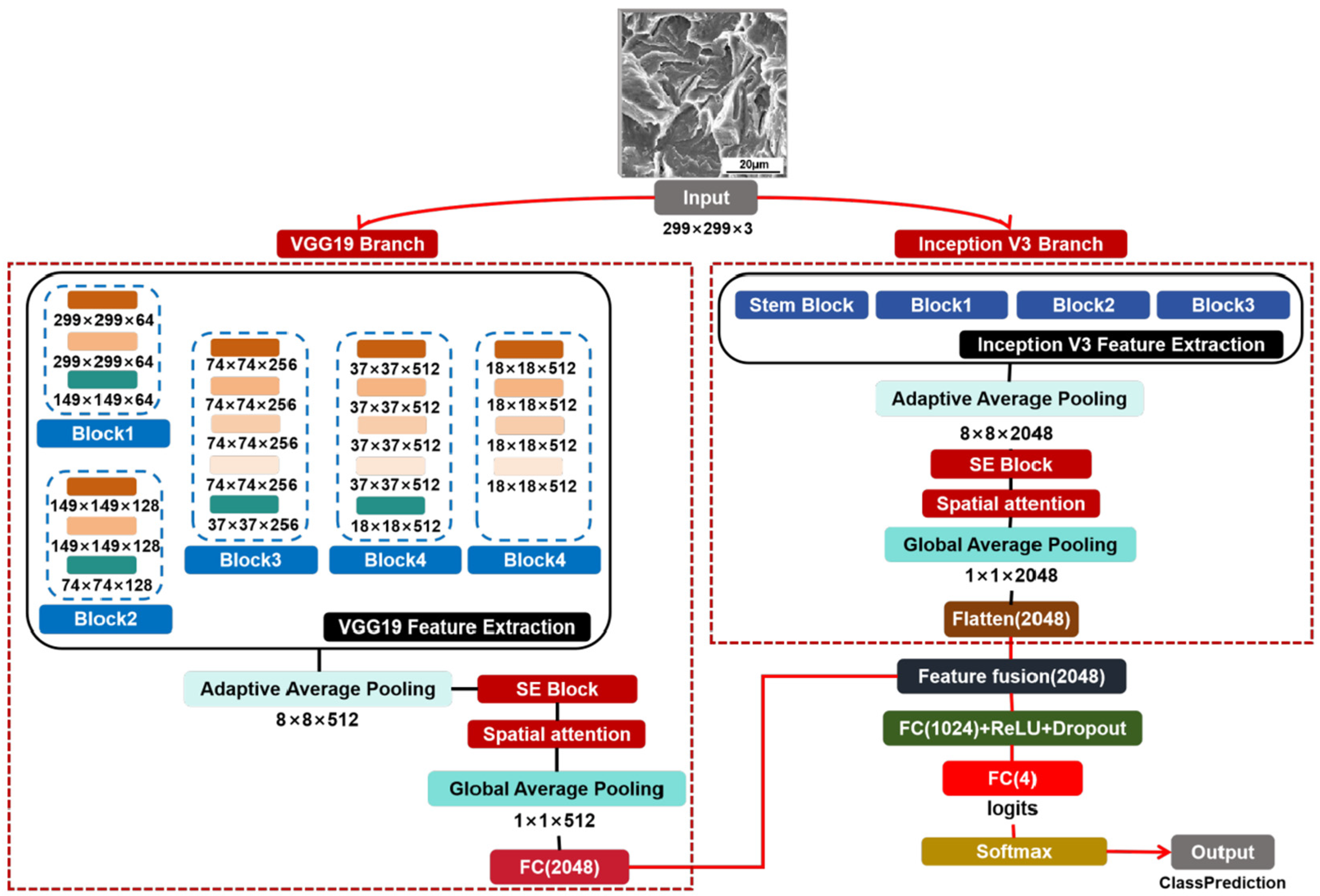

2.3. IDBM

2.4. Experimental Setup

3. Results

3.1. Key Requirements for Feature Extraction

3.1.1. Texture Extraction Results

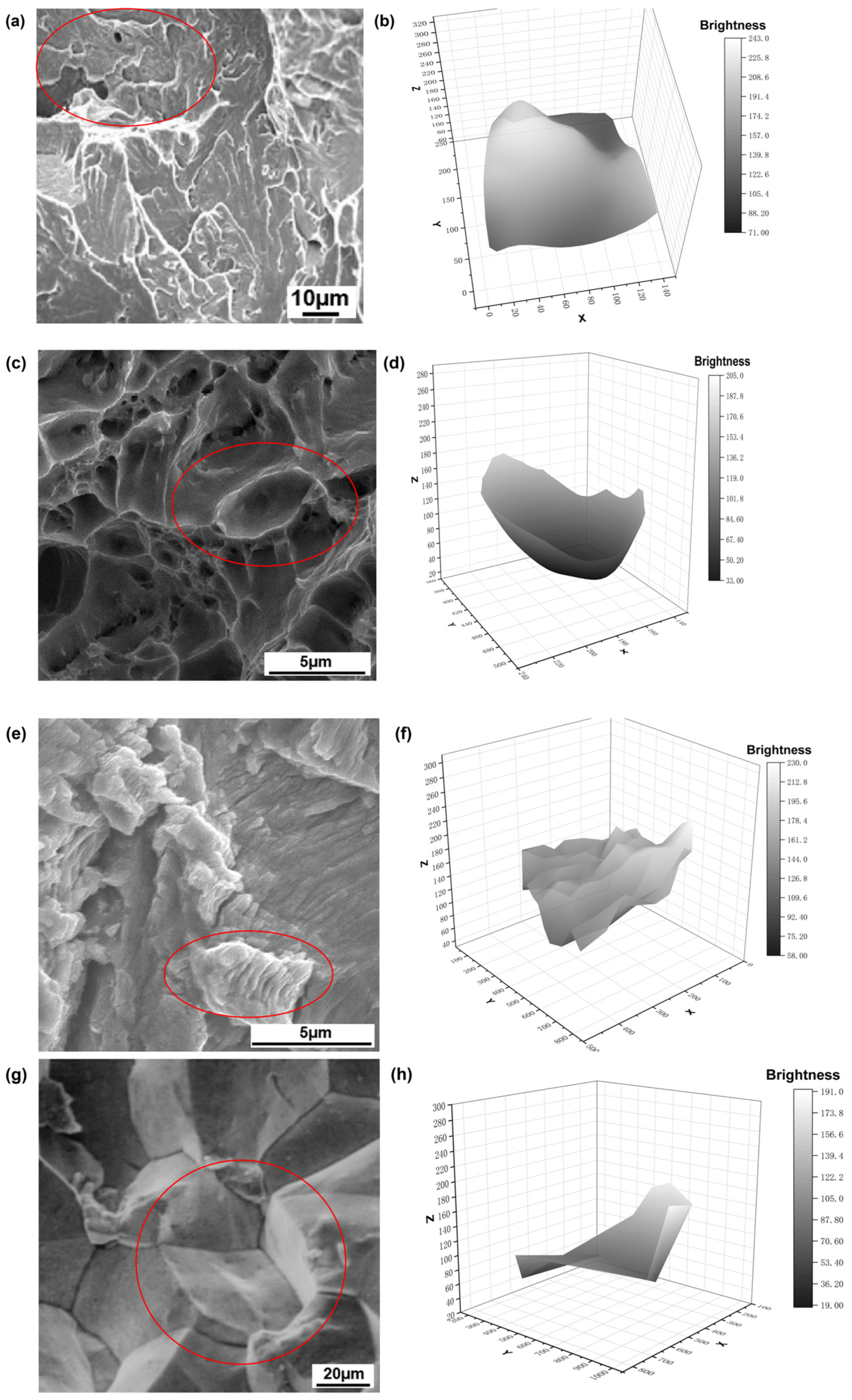

3.1.2. Three-Dimensional Transformation Results

3.2. Comparison of Feature Fusion Strategies

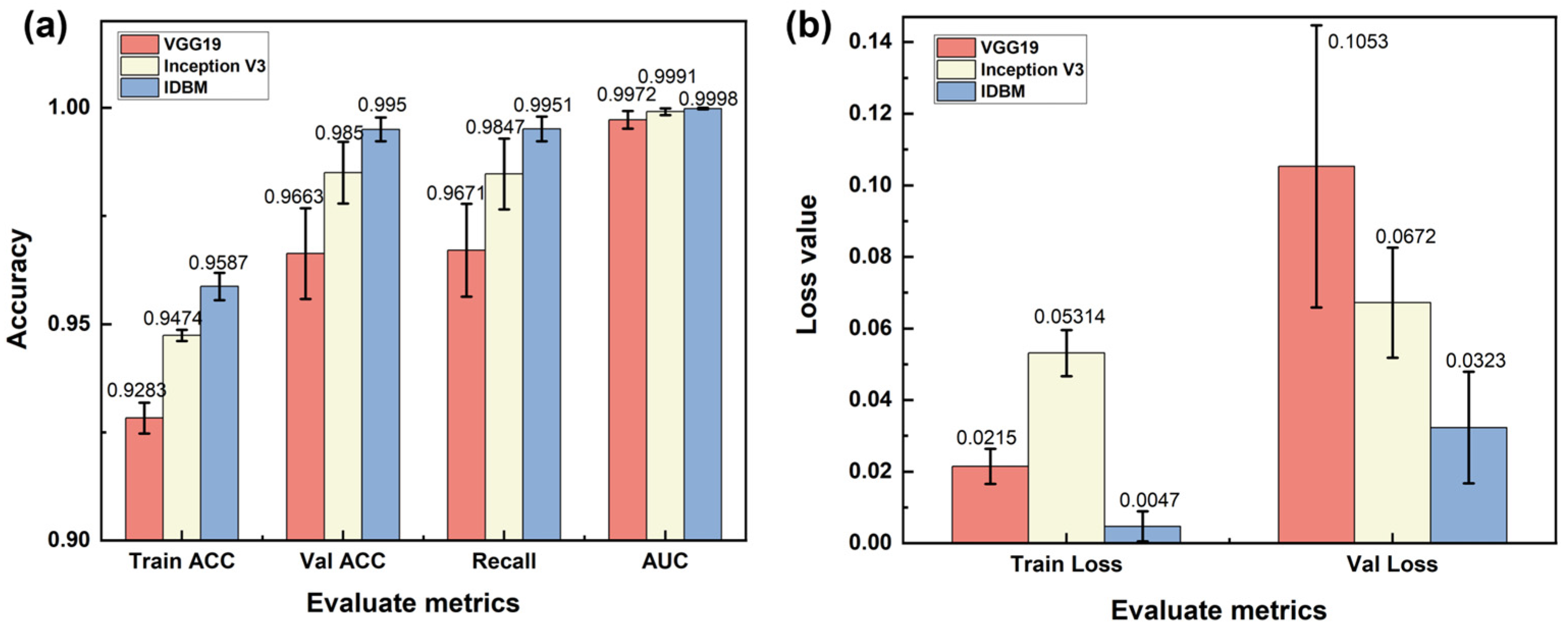

3.3. Model Evaluation

3.3.1. Evaluation Metrics

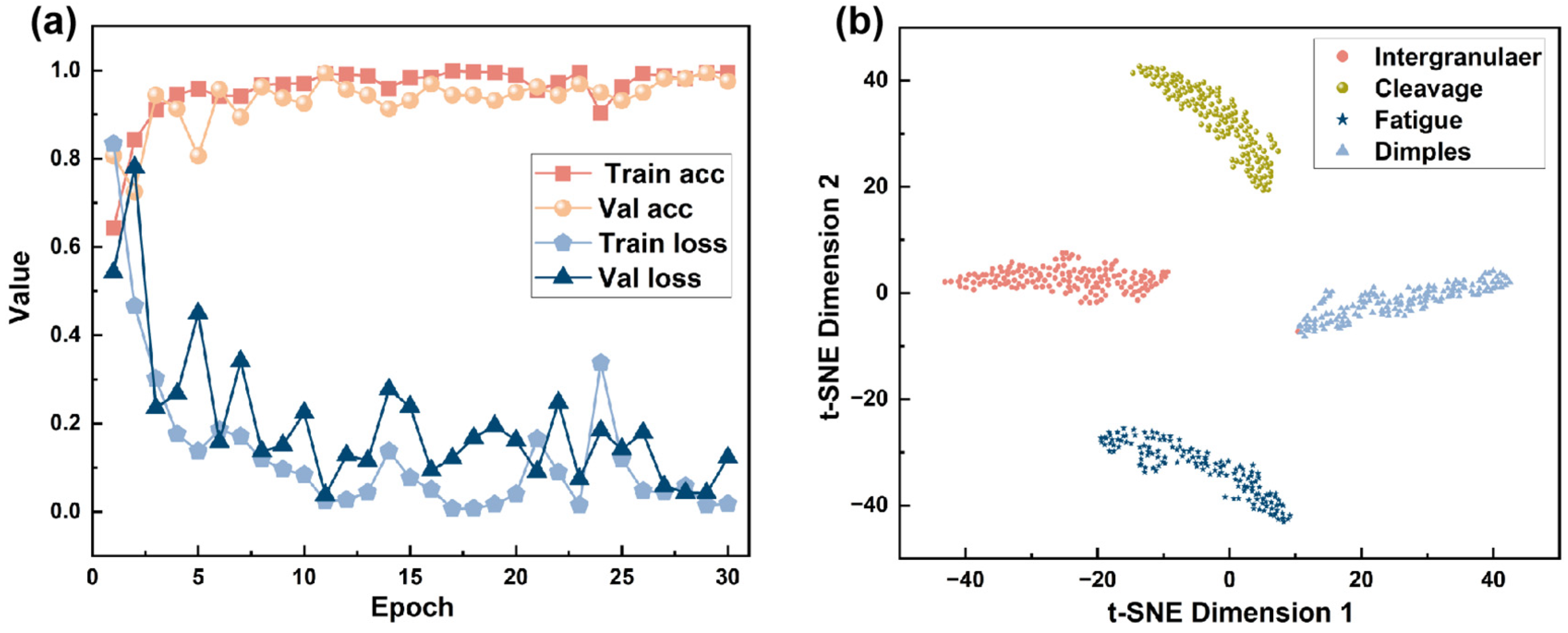

3.3.2. Training Monitoring and Dimensionality Reduction Visualization

3.4. Feature Extraction Visualization

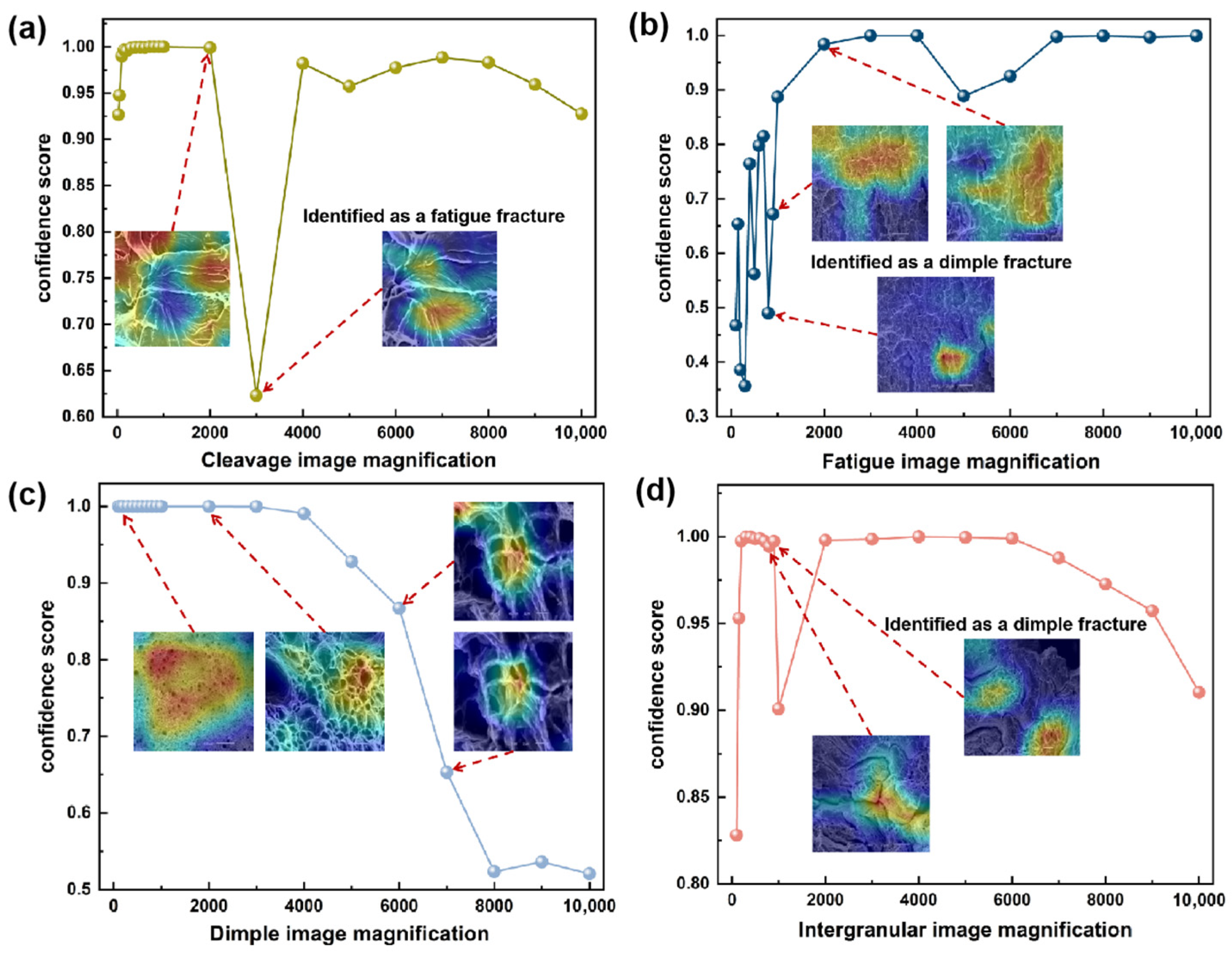

3.5. Model Adaptability to SEM Image Scale

4. Discussion

4.1. Analysis of Performance Advantages and Multi-Scale Feature Fusion Mechanism

4.2. Value of Interpretable Mechanisms and Scale Adaptation for Analyzing Material Failure

5. Conclusions

- This study presents an IDBM built upon the VGG19 and Inception V3 architectures. The model incorporates channel and spatial attention mechanisms and utilizes a multi-scale feature fusion strategy with a fixed ratio of 0.8:0.2. Its core structure consists of dual-branch parallel feature extraction, adaptive attention weighting, and a fusion mechanism based on global average pooling. The architecture ultimately performs high-accuracy classification of four fracture types through a fully connected classification layer.

- The IDBM employs a fixed-ratio multi-scale fusion strategy, which exhibits superior performance in fracture surface image recognition compared to conventional approaches such as direct concatenation, adaptive fusion, and pyramid feature fusion. The model achieves a Val ACC of 99.50%, a Recall of 99.51%, and an AUC of 0.9998. This strategy effectively reduces overfitting risks while enhancing the generalization capacity of the model and discriminative stability.

- Through three-dimensional reconstruction of fracture surface SEM images, a quantitative mapping between pixel values and surface topography was established. The integration of this method with texture feature extraction significantly enhances the interpretability of the model. Furthermore, it provides a theoretical and empirical basis in materials science for designing convolutional kernels and selecting baseline models in novel algorithm development, thereby facilitating structural optimization and feature visualization in fracture surface recognition models.

- Based on the scale adaptability tests, the optimal magnification ranges for the four fracture surface types are summarized as follows: cleavage fracture (≤2000×), fatigue fracture (900–3000×), dimple fracture (100–7000×), and intergranular fracture (100–900×). The experimental results demonstrate that the IDBM exhibits strong robustness across varying magnification levels. Furthermore, it remains essential to select a suitable imaging scale depending on the specific fracture type and the preservation state of its microstructural characteristics.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lu, Y.; Wang, L.; Pan, D.; Chen, X. Summary of metal fracture image recognition method. J. Phys. Conf. Ser. 2021, 1982, 012070. [Google Scholar] [CrossRef]

- Liu, T.; Yin, Z.; Lei, J.; Wang, F. Multiresolution Feature Extraction of Surface Topography in Metal Fatigue Damage Process. Laser Optoelectron. Prog. 2022, 59, 0815012. [Google Scholar] [CrossRef]

- Shi, L.; Yang, Y.; Hou, B.; Gu, W.; Zhao, H.; Feng, Y.; Hang, Z. A New Method for Determining Necking of Sheet Metal Based on Main Strain Topography. Coatings 2024, 14, 765. [Google Scholar] [CrossRef]

- Gonzalez-Mancera, G.; Gonzalez-Gonzalez, D.E. Importance of SEM in the Study of Fractography, Camshaft Failure. Microsc. Microanal. 2018, 24, 2246–2247. [Google Scholar] [CrossRef]

- Aydin, C. Enhanced material classification via mobilesemnet: Leveraging mobilenetv2 for SEM image analysis. Trait. Du Signal 2023, 40, 2779. [Google Scholar] [CrossRef]

- Anbarlooie, B.; Toudeshky, H.H. Damage mechanisms analyses in DP steels using SEM images, FEM, and non-local peridynamics methods. Mech. Adv. Mater. Struct. 2025, 32, 1549–1563. [Google Scholar] [CrossRef]

- Ministry of Aerospace Industry; Failure Analysis Center for Aeronautical Equipment. Fractography of Metallic Materials and Atlas; Science Press: Beijing, China, 1991. [Google Scholar]

- Hanniet, Q.; Petit, E.; Calas-Etienne, S.; Etienne, P.; Aissou, K.; Gervais, C.; Miele, P.; Charlot, B.; Salameh, C. Rational design of SiBCN microstructures using direct photolithography of patternable preceramic photoresists. Mater. Des. 2022, 223, 111234. [Google Scholar] [CrossRef]

- Pawar, S.; Mukhopadhyay, G. Learning from Failure Investigation of Worm Wheel Gearbox in a Wire Rod Mill. J. Fail. Anal. Prev. 2020, 20, 1456–1461. [Google Scholar] [CrossRef]

- Zhang, Y.H.; Ma, E.; Sun, J.; Han, W.Z. Unveiling the intrinsic rhenium effect in Tungsten. Acta Mater. 2024, 264, 119586. [Google Scholar] [CrossRef]

- Wang, J.; Yang, Y.; Mao, J.; Huang, Z.; Huang, C.; Xu, W. Cnn-rnn: A unified framework for multi-label image classification. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; pp. 2285–2294. [Google Scholar]

- Maurício, J.; Domingues, I.; Bernardino, J. Comparing vision transformers and convolutional neural networks for image classification: A literature review. Appl. Sci. 2023, 13, 5521. [Google Scholar] [CrossRef]

- Taye, M.M. Understanding of machine learning with deep learning: Architectures, workflow, applications and future directions. Computers 2023, 12, 91. [Google Scholar] [CrossRef]

- Papia, E.M.; Kondi, A.; Constantoudis, V. Machine learning applications in SEM-based pore analysis: A review. Microporous Mesoporous Mater. 2025, 394, 113675. [Google Scholar] [CrossRef]

- Sun, Z.; Shi, J.; Wang, J.; Jiang, M.; Wang, Z.; Bai, X.; Wang, X. A deep learning-based framework for automatic analysis of the nanoparticle morphology in SEM/TEM images. Nanoscale 2022, 14, 10761–10772. [Google Scholar] [CrossRef]

- Nigam, R.; Khavala, V.B.; Dash, K.; Mishra, N. Image-driven deep-learning-enabled automatic microstructural recognition. Emerg. Mater. Res. 2023, 12, 47–51. [Google Scholar] [CrossRef]

- Mishra, S.P.; Rahul, M.R. A detailed study of convolutional neural networks for the identification of microstructure. Mater. Chem. Phys. 2023, 308, 128275. [Google Scholar] [CrossRef]

- Chen, Q.; Wei, H.; Wang, B.; Ruan, L.; Han, Y. Material structure segmentation method based on graph attention. Mater. Today Commun. 2023, 35, 105941. [Google Scholar] [CrossRef]

- Wu, T.; Li, Z.N. Optimization Design of an Aviation Component Metal Fracture Identification System Based on TRIZ Theory. Henan Sci. Technol. 2023, 42, 39–43. [Google Scholar]

- Wang, C.H. Metal Fracture Image Recognition Based on N-Net and Its FPGA Hardware Implementation. Master’s Thesis, Dalian Jiaotong University, Dalian, China, 2023. [Google Scholar] [CrossRef]

- Tsopanidis, S.; Osovski, S. Unsupervised machine learning in fractography: Evaluation and interpretation. Mater. Charact. 2021, 182, 111551. [Google Scholar] [CrossRef]

- Yan, H.; Zhong, C.; Lu, W.; Wu, Y. Metal fracture recognition: A method for multi-perception region of interest feature fusion. Appl. Intell. 2023, 53, 23983–24007. [Google Scholar] [CrossRef]

- Zhong, Q.P.; Zhao, Z.H. Fractography (Deluxe Edition); Higher Education Press: Beijing, China, 2006. [Google Scholar]

- Guo, B. Research on Automatic Assessment Method of DWTT Fracture Images. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2015. [Google Scholar]

- Pan, B.; Liu, C.; Su, B.; Ju, Y.; Fan, X.; Zhang, Y.; Sun, L.; Fang, Y.; Jiang, J. Research on species identification of wild grape leaves based on deep learning. Sci. Hortic. 2024, 327, 112821. [Google Scholar] [CrossRef]

- Liao, J.; Guo, L.; Jiang, L.; Yu, C.; Liang, W.; Li, K.; Pop, F. A machine learning-based feature extraction method for image classification using ResNet architecture. Digit. Signal Process. 2025, 160, 105036. [Google Scholar] [CrossRef]

- Shang, Y.B.; Jia, D.S.; Qu, Y.T. Fine-grained vehicle recognition based on multi-scale fused attention mechanism. Automot. Appl. Technol. 2024, 49, 25–29. [Google Scholar]

- Feng, Z.; Ji, H.; Daković, M.; Cui, X.; Zhu, M.; Stanković, L. Cluster-CAM: Cluster-weighted visual interpretation of CNNs’decision in image classification. Neural Netw. 2024, 178, 106473. [Google Scholar] [CrossRef] [PubMed]

- Gu, B.L. Influence and Evaluation of Service Conditions on Microstructure and Properties of Typical Heat-Resistant Steels for Supercritical and Ultra-Supercritical Boilers. Ph.D. Thesis, School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing, China, 2023. [Google Scholar]

- Zhang, K.X. The Application of Deep Learning in the Identification of Metal Fracture Images and the Prediction of Their Lifespan. Master’s Thesis, School of Materials Science and Engineering, Beihang University, Beijing, China, 2022. [Google Scholar]

- Cui, Y.; Wang, C. Metal Fractography; Harbin Institute of Technology Press: Harbin, China, 1998. [Google Scholar]

- Stone, R.V.; Cox, T.B.; Low, J.R.; Psioda, J.A. Microstructural aspects of fracture by dimpled rupture. Int. Met. Rev. 1985, 30, 157–180. [Google Scholar] [CrossRef]

- Ma, R.; Chen, X.C.; Jin, L.K.; Yang, W.D.; Yang, H.; Li, Z.; Li, L. Failure analysis of early cracking of 8418 steel aluminum alloy die-casting die. Heat Treat. Met. 2020, 45, 235–239. [Google Scholar] [CrossRef]

- Zheng, X.; Battalgazy, B.; Molkeri, A.; Tsopanidis, S.; Osovski, S.; Srivastava, A. Role of length-scale in machine learning based image analysis of ductile fracture surfaces. Mech. Mater. 2023, 181, 104661. [Google Scholar] [CrossRef]

- Zhang, N.; Fu, H.; Liu, P.; Wang, C.; Zhang, Y.; Lookman, T.; Huang, H.; Su, Y. Machine learning-based quantitative analysis of metal ductile fracture surface. Materialia 2023, 32, 101904. [Google Scholar] [CrossRef]

- Simonyan, K.; Zisserman, A. Very deep convolutional networks for large-scale image recognition. arXiv 2014, arXiv:1409.1556. [Google Scholar]

- Szegedy, C.; Vanhoucke, V.; Ioffe, S.; Shlens, J.; Wojna, Z. Rethinking the inception architecture for computer vision. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; pp. 2818–2826. [Google Scholar]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 521, 436–444. [Google Scholar] [CrossRef]

- Tan, C.; Sun, F.; Kong, T.; Zhang, W.; Yang, C.; Liu, C. A survey on deep transfer learning. In Proceedings of the International Conference on Artificial Neural Networks, Island of Rhodes, Greece, 4–7 October 2018; Springer International Publishing: Cham, Switzerland, 2018; pp. 270–279. [Google Scholar]

- Durmaz, A.R.; Müller, M.; Lei, B.; Thomas, A.; Britz, D.; Holm, E.A.; Eberl, C.; Mücklich, F.; Gumbsch, P. A deep learning approach for complex microstructure inference. Nat. Commun. 2021, 12, 6272. [Google Scholar] [CrossRef]

- DeCost, L.B.; Holm, A.E. A computer vision approach for automated analysis and classification of microstructural image data. Comput. Mater. Sci. 2015, 110, 126–133. [Google Scholar] [CrossRef]

- Nagaraj, P. Squeeze-Inception V3 with Slime Mould algorithm-based CNN features for lung cancer detection. Biomed. Signal Process. Control 2025, 100, 106924. [Google Scholar]

- Kumar, S.; Gupta, S.K.; Kaur, M.; Gupta, U. VI-NET: A hybrid deep convolutional neural network using VGG and inception V3 model for copy-move forgery classification. J. Vis. Commun. Image Represent. 2022, 89, 103644. [Google Scholar] [CrossRef]

- Azimi, S.M.; Britz, D.; Engstler, M.; Fritz, M.; Mücklich, F. Advanced steel microstructural classification by deep learning methods. Sci. Rep. 2018, 8, 2128. [Google Scholar] [CrossRef] [PubMed]

- Guan, S.; Lei, M.; Lu, H. A Steel Surface Defect Recognition Algorithm Based on Improved Deep Learning Network Model Using Feature Visualization and Quality Evaluation. IEEE Access 2020, 8, 49885–49895. [Google Scholar] [CrossRef]

- Goodfellow, I.; Bengio, Y.; Courville, A. Deep Learning: Adaptive Computation and Machine Learning Series; The MIT Press: Cambridge, MA, USA, 2016. [Google Scholar]

- Wen, Z.; Dejun, K. Effects of laser thermal sprayed AlNiCr coating on fatigue performances of S355 structural steel. Int. J. Fatigue 2020, 131, 105359. [Google Scholar] [CrossRef]

- Maruschak, P.; Konovalenko, I.; Sorochak, A. Methods for evaluating fracture patterns of polycrystalline materials based on the parameter analysis of ductile separation dimples: A review. Eng. Fail. Anal. 2023, 153, 107587. [Google Scholar] [CrossRef]

- Meng, X.; Yang, S.; Huang, Y.; Fang, Y.; Gu, J.; Xiong, Q.; Duan, C. Microstructure characterization and mechanism of fatigue crack propagation of 6082 aluminum alloy joints. Mater. Chem. Phys. 2021, 257, 123734. [Google Scholar] [CrossRef]

- Wang, H.B.; Chen, F.; Gao, Z.Y.; Cai, W.; Zhao, L.C. Effect of Fe content on fracture behavior of Ni–Mn–Fe–Ga ferromagnetic shape memory alloys. Mater. Sci. Eng. A 2006, 438–440, 990–993. [Google Scholar] [CrossRef]

- Eldred, K.C.; Hadyniak, S.E.; Hussey, K.A.; Brenerman, B.; Zhang, P.-W.; Chamling, X.; Sluch, V.M.; Welsbie, D.S.; Hattar, S.; Taylor, J. Thyroid hormone signaling specifies cone subtypes in human retinal organoids. Science 2018, 362, eaau6348. [Google Scholar] [CrossRef]

- CIE 2019; Colour-Matching Functions of CIE 1931 Standard Colorimetric Observer. International Commission on Illumination (CIE): Vienna, Austria, 2019.

- Huang, Y.C. Research and Implementation of Digital Decoding for NTSC Television Signals. Master’s Thesis, Nanjing University, Jiangsu, China, 2008. [Google Scholar]

- Avilés-Cruz, C.; Aguilar-Sanchez, M.; Vargas-Arista, B.; Garfias-Garcia, E. A new machine learning-based evaluation of ductile fracture. Eng. Fract. Mech. 2024, 302, 110072. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar]

- Hou, Y.; Jiang, P.; Xia, H.; Song, S.; Luo, J. Image stitching method based on feature optimization and circular function weighted fusion. J. Phys. Conf. Ser. 2023, 2562, 012014. [Google Scholar] [CrossRef]

- Hu, J.; Shen, L.; Sun, G. Squeeze-and-excitation networks. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Salt Lake City, UT, USA, 18–23 June 2018; pp. 7132–7141. [Google Scholar]

- Lin, T.Y.; Dollár, P.; Girshick, R.; He, K.; Hariharan, B.; Belongie, S. Feature pyramid networks for object detection. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Honolulu, HI, USA, 21–26 July 2017; pp. 936–944. [Google Scholar] [CrossRef]

- Kang, B.; Garcia Garcia, D.; Lijffijt, J.; Santos-Rodríguez, R.; De Bie, T. Conditional t-SNE: More informative t-SNE embeddings. Mach. Learn. 2020, 110, 2905–2940. [Google Scholar] [CrossRef] [PubMed]

- Englebert, A.; Cornu, O.; Vleeschouwer, C.D. Poly-cam: High resolution class activation map for convolutional neural networks. Mach. Vis. Appl. 2024, 35, 89. [Google Scholar] [CrossRef]

| Methods | Fixed Proportion | Train Loss ± SD | Train ACC ± SD | Val Loss ± SD | Val ACC ± SD | Recall ± SD | AUC ± SD | Overfitting Risk ± SD | |

|---|---|---|---|---|---|---|---|---|---|

| Direct Concatenation | - | - | 0.0150 ± 0.0081 | 0.9580 ± 0.0118 | 0.1000 ± 0.0300 | 0.9700 ± 0.0103 | 0.9741 ± 0.0091 | 0.9984 ± 0.0011 | 0.1121 ± 0.0599 |

| Adaptive Concatenation | - | - | 0.0100 ± 0.0070 | 0.9506 ± 0.0027 | 0.1115 ± 0.0300 | 0.9676 ± 0.0053 | 0.9679 ± 0.0046 | 0.9979 ± 0.0008 | 0.1106 ± 0.0417 |

| FPN | - | - | 0.0180 ± 0.0076 | 0.9154 ± 0.0218 | 0.0983 ± 0.0541 | 0.9775 ± 0.0105 | 0.9826 ± 0.0124 | 0.9983 ± 0.0013 | 0.0691 ± 0.0390 |

| Fixed-Ratio Concatenation | 0.9 Fvgg | 0.1 Finc | 0.0040 ± 0.0049 | 0.9476 ± 0.0058 | 0.0627 ± 0.0190 | 0.9850 ± 0.0035 | 0.9853 ± 0.0037 | 0.9993 ± 0.0005 | 0.0832 ± 0.0283 |

| 0.8 Fvgg | 0.2 Finc | 0.0047 ± 0.0042 | 0.9587 ± 0.0031 | 0.0323 ± 0.0156 | 0.9950 ± 0.0028 | 0.9951 ± 0.0028 | 0.9998 ± 0.0002 | 0.0364 ± 0.0259 | |

| 0.7 Fvgg | 0.3 Finc | 0.0054 ± 0.0025 | 0.9588 ± 0.0020 | 0.0560 ± 0.0275 | 0.9812 ± 0.0076 | 0.9823 ± 0.0071 | 0.9994 ± 0.0006 | 0.0778 ± 0.0450 | |

| 0.6 Fvgg | 0.4 Finc | 0.0080 ± 0.0053 | 0.9600 ± 0.0024 | 0.0729 ± 0.0510 | 0.9838 ± 0.0095 | 0.9835 ± 0.0097 | 0.9989 ± 0.0014 | 0.0646 ± 0.0392 | |

| 0.5 Fvgg | 0.5 Finc | 0.0056 ± 0.0036 | 0.9577 ± 0.0043 | 0.0799 ± 0.1580 | 0.9800 ± 0.0052 | 0.9807 ± 0.0054 | 0.9989 ± 0.0005 | 0.0674 ± 0.0206 | |

| 0.4 Fvgg | 0.6 Finc | 0.0102 ± 0.0051 | 0.9573 ± 0.0032 | 0.1056 ± 0.0378 | 0.9700 ± 0.0081 | 0.9705 ± 0.0085 | 0.9976 ± 0.0014 | 0.1088 ± 0.0338 | |

| 0.3 Fvgg | 0.7 Finc | 0.0090 ± 0.0084 | 0.9608 ± 0.0045 | 0.1019 ± 0.0285 | 0.9700 ± 0.0081 | 0.9695 ± 0.0103 | 0.9982 ± 0.0010 | 0.1031 ± 0.0323 | |

| 0.2 Fvgg | 0.8 Finc | 0.0116 ± 0.0051 | 0.9598 ± 0.0030 | 0.1055 ± 0.0230 | 0.9700 ± 0.0068 | 0.9700 ± 0.0059 | 0.9980 ± 0.0009 | 0.1199 ± 0.0456 | |

| 0.1 Fvgg | 0.9 Finc | 0.0064 ± 0.0058 | 0.9609 ± 0.0019 | 0.0976 ± 0.0306 | 0.9675 ± 0.0051 | 0.9681 ± 0.0045 | 0.9983 ± 0.0014 | 0.1230 ± 0.0579 | |

| Models | PC1 Explained Variance Proportion (%) | PC2 Explained Variance Proportion (%) | PC1 and PC2 Explained Variance Proportion (%) |

|---|---|---|---|

| VGG19 | 56.97 | 3.82 | 60.79 |

| Inception V3 | 30.03 | 21.10 | 51.13 |

| IDBM | 76.59 | 11.58 | 88.18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, F.; Wang, D.; Yang, F.; Zhou, M.; Li, Y.; Zheng, Z.; Shi, J.; Zhang, Z. Application of an Improved Dual-Branch Model Based on Multi-Scale Feature Fusion in Fracture Surface Image Recognition. Materials 2025, 18, 5233. https://doi.org/10.3390/ma18225233

Gao F, Wang D, Yang F, Zhou M, Li Y, Zheng Z, Shi J, Zhang Z. Application of an Improved Dual-Branch Model Based on Multi-Scale Feature Fusion in Fracture Surface Image Recognition. Materials. 2025; 18(22):5233. https://doi.org/10.3390/ma18225233

Chicago/Turabian StyleGao, Fei, Denghui Wang, Fulai Yang, Mingping Zhou, Yuan Li, Zhen Zheng, Jianpeng Shi, and Zheng Zhang. 2025. "Application of an Improved Dual-Branch Model Based on Multi-Scale Feature Fusion in Fracture Surface Image Recognition" Materials 18, no. 22: 5233. https://doi.org/10.3390/ma18225233

APA StyleGao, F., Wang, D., Yang, F., Zhou, M., Li, Y., Zheng, Z., Shi, J., & Zhang, Z. (2025). Application of an Improved Dual-Branch Model Based on Multi-Scale Feature Fusion in Fracture Surface Image Recognition. Materials, 18(22), 5233. https://doi.org/10.3390/ma18225233