Quantitative Characterization of Tensile Strength for Carburized Materials Using a Novel Composite Strength Method

Abstract

1. Introduction

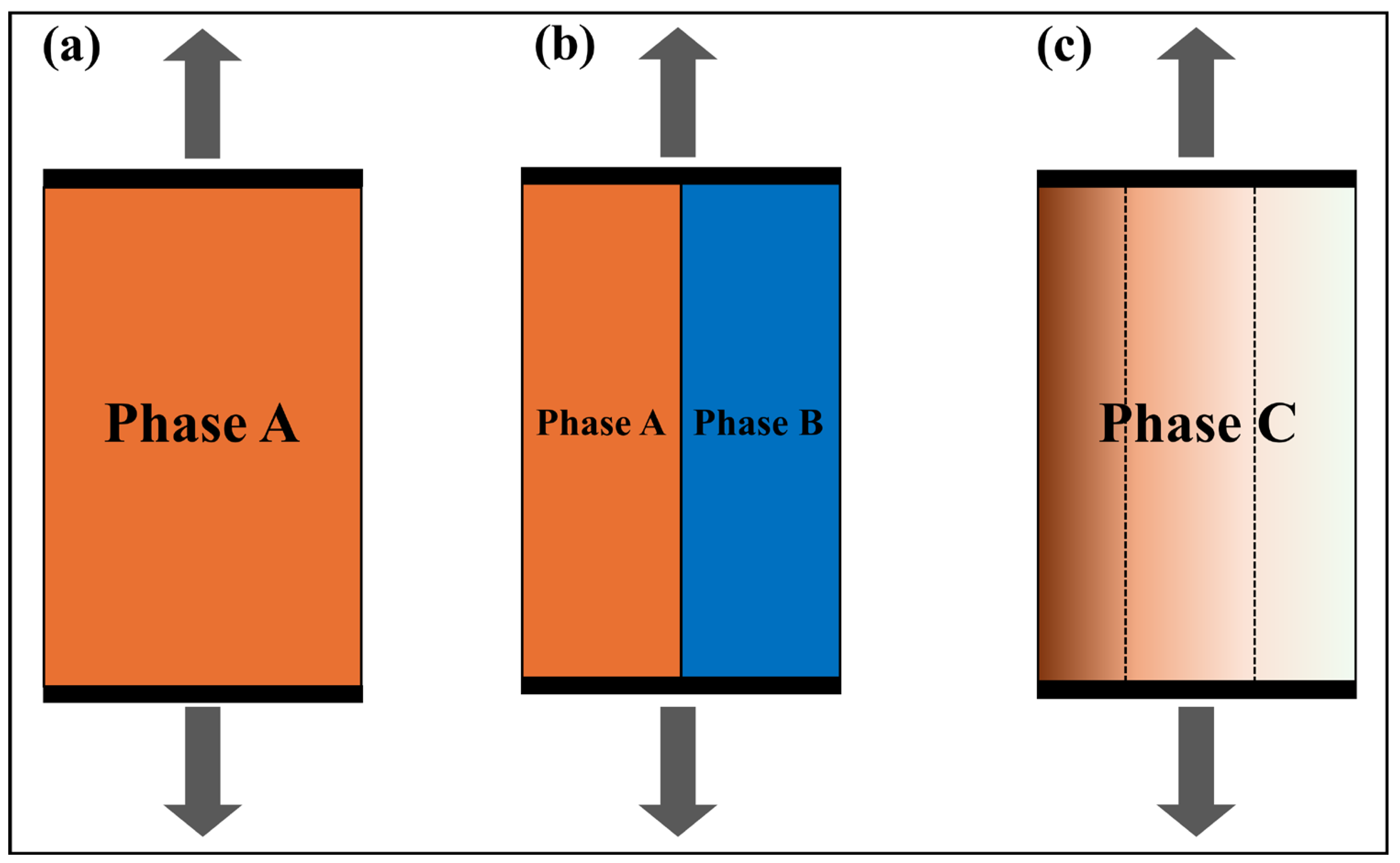

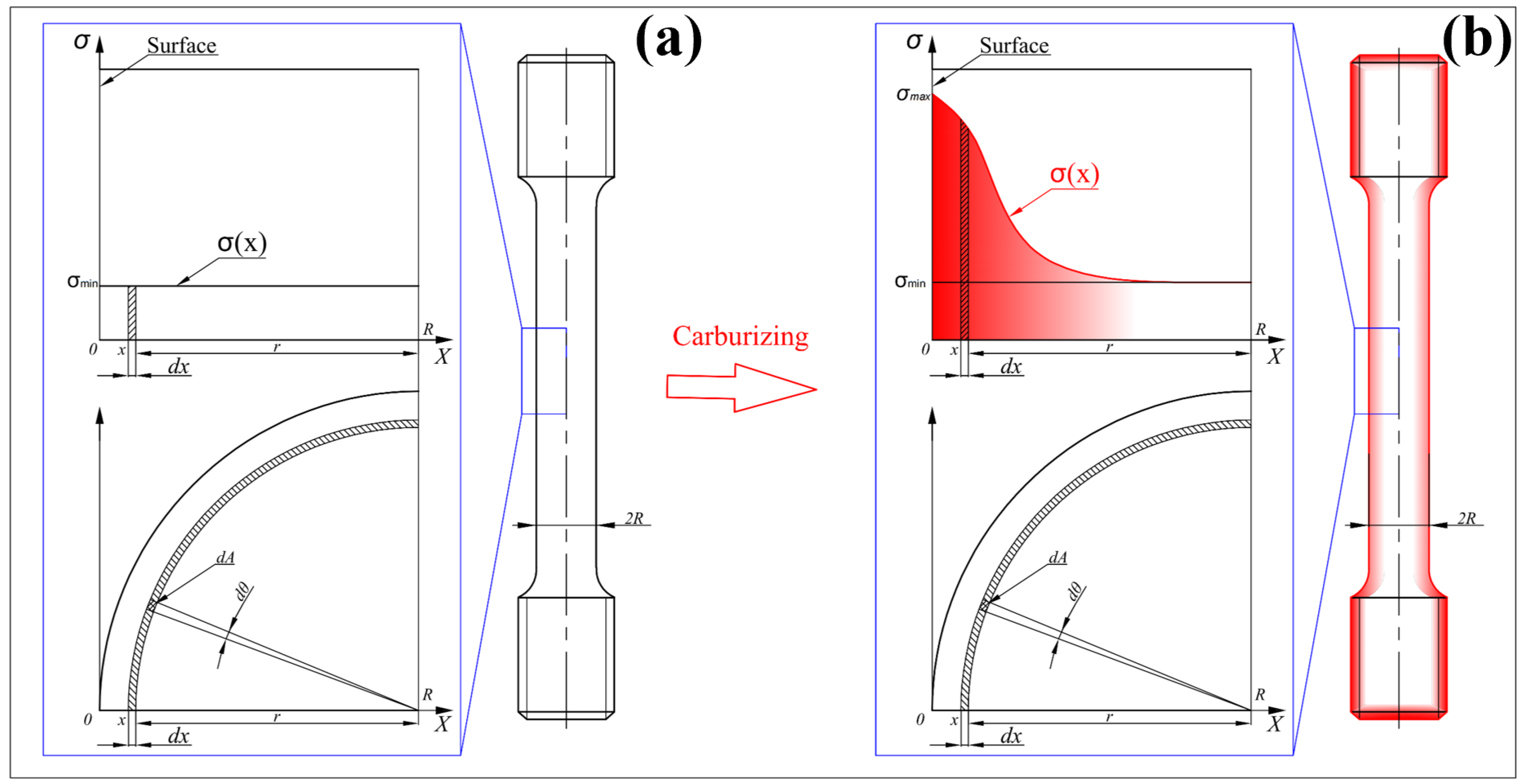

2. Quantitative Characterization of Carburized Specimens

3. Experiments

3.1. Material

3.2. Heat Treatment

3.3. Microhardness and Tensile Test

4. Results and Discussion

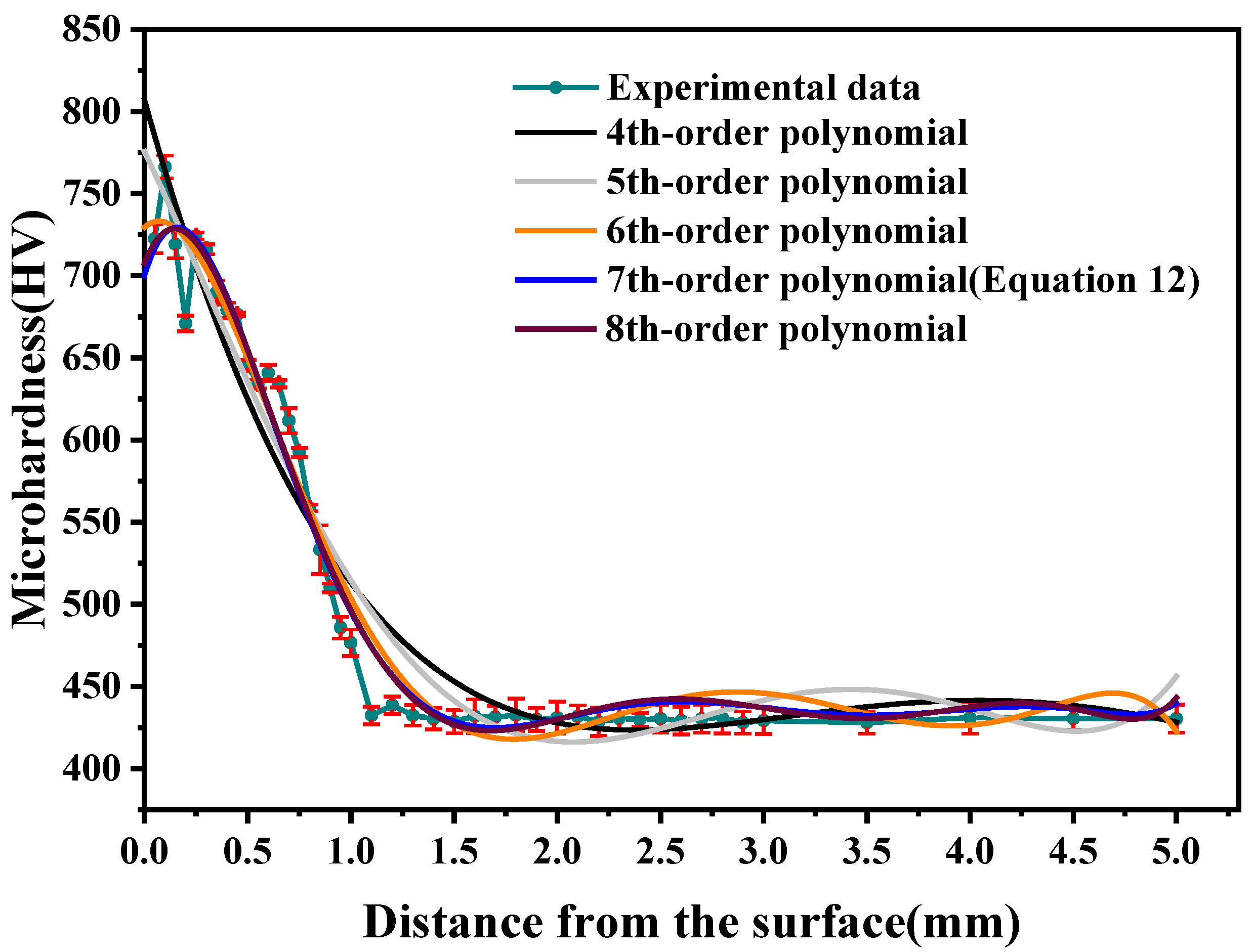

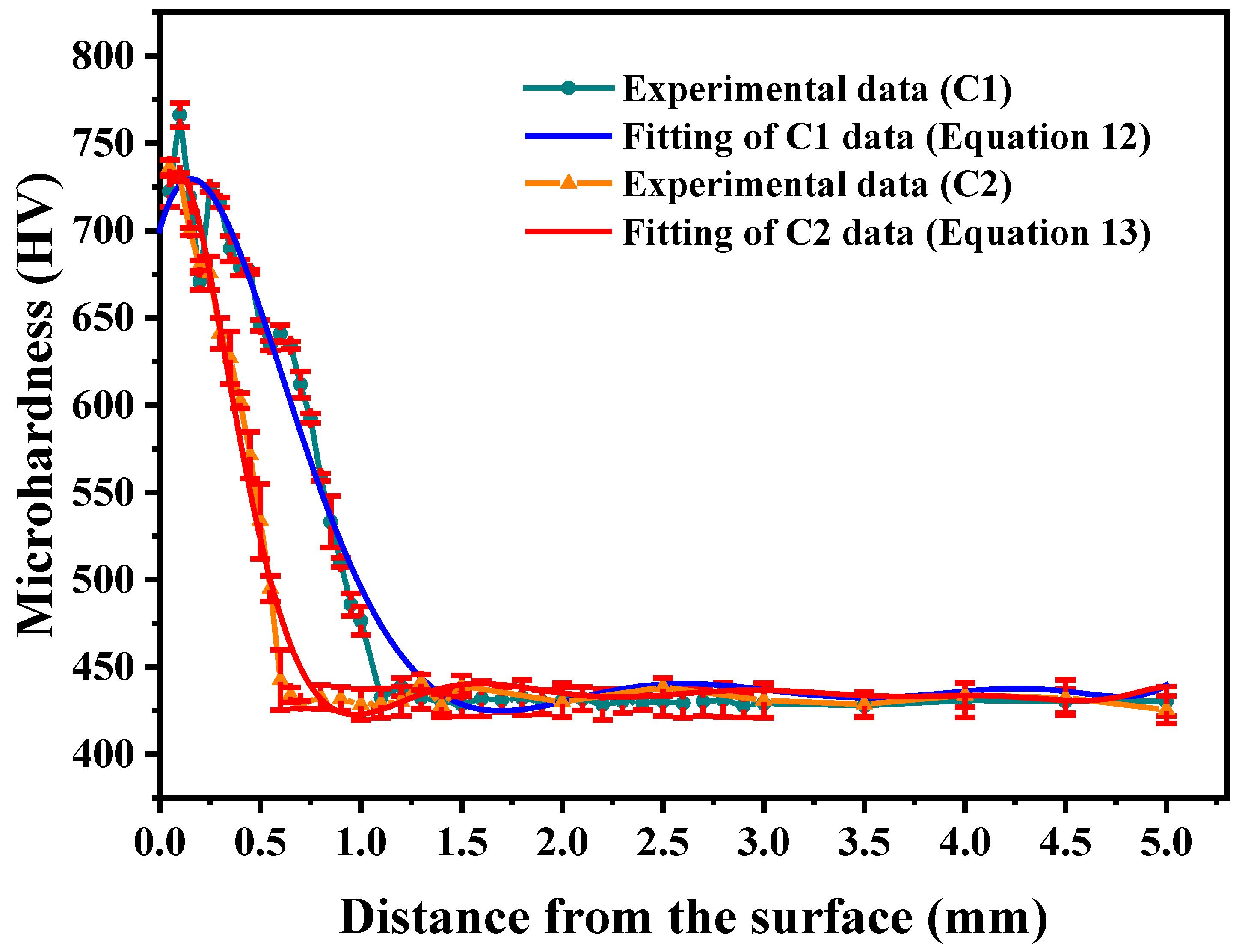

4.1. Results of Microhardness

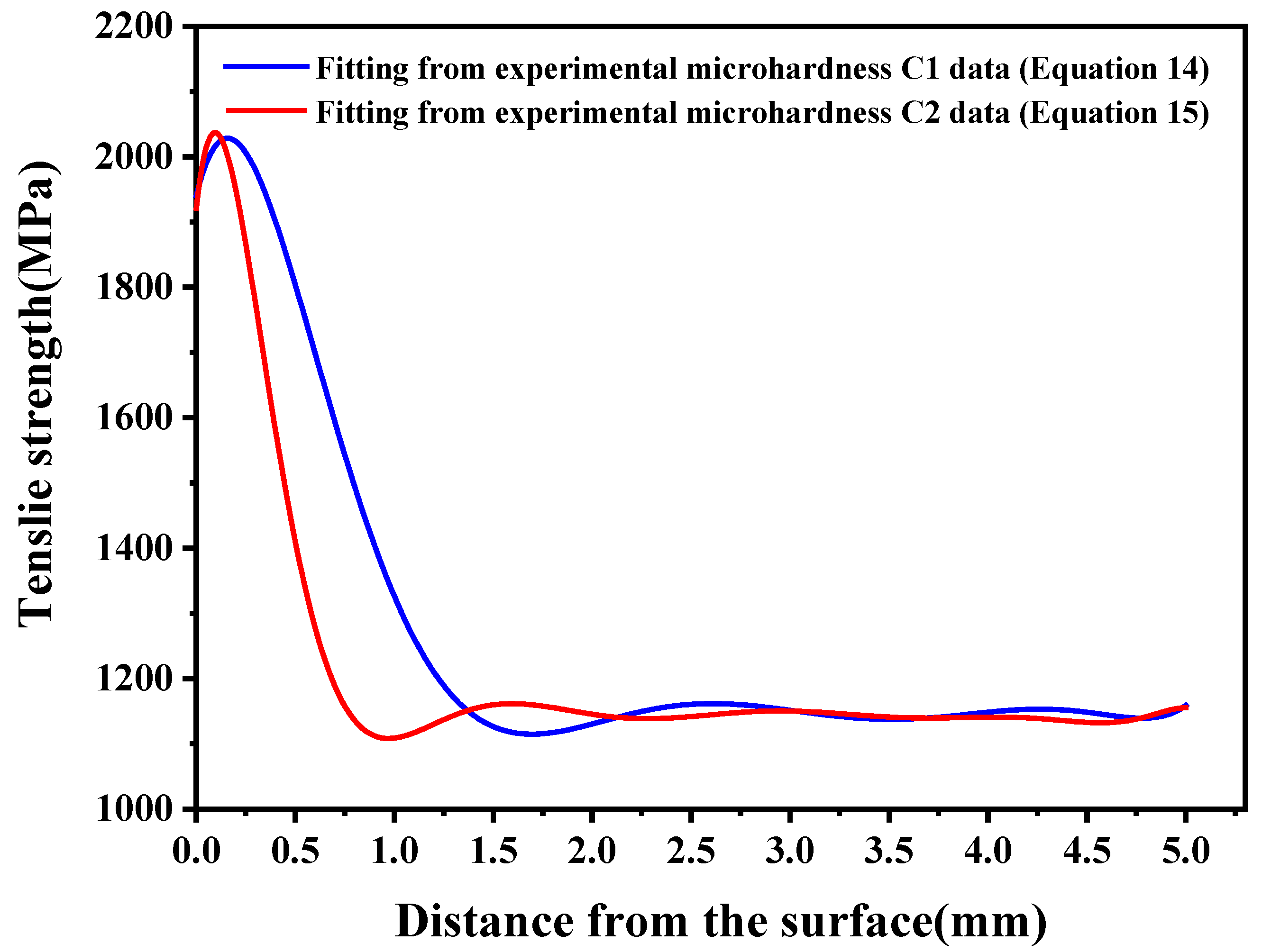

4.2. Results of Characterized Strength

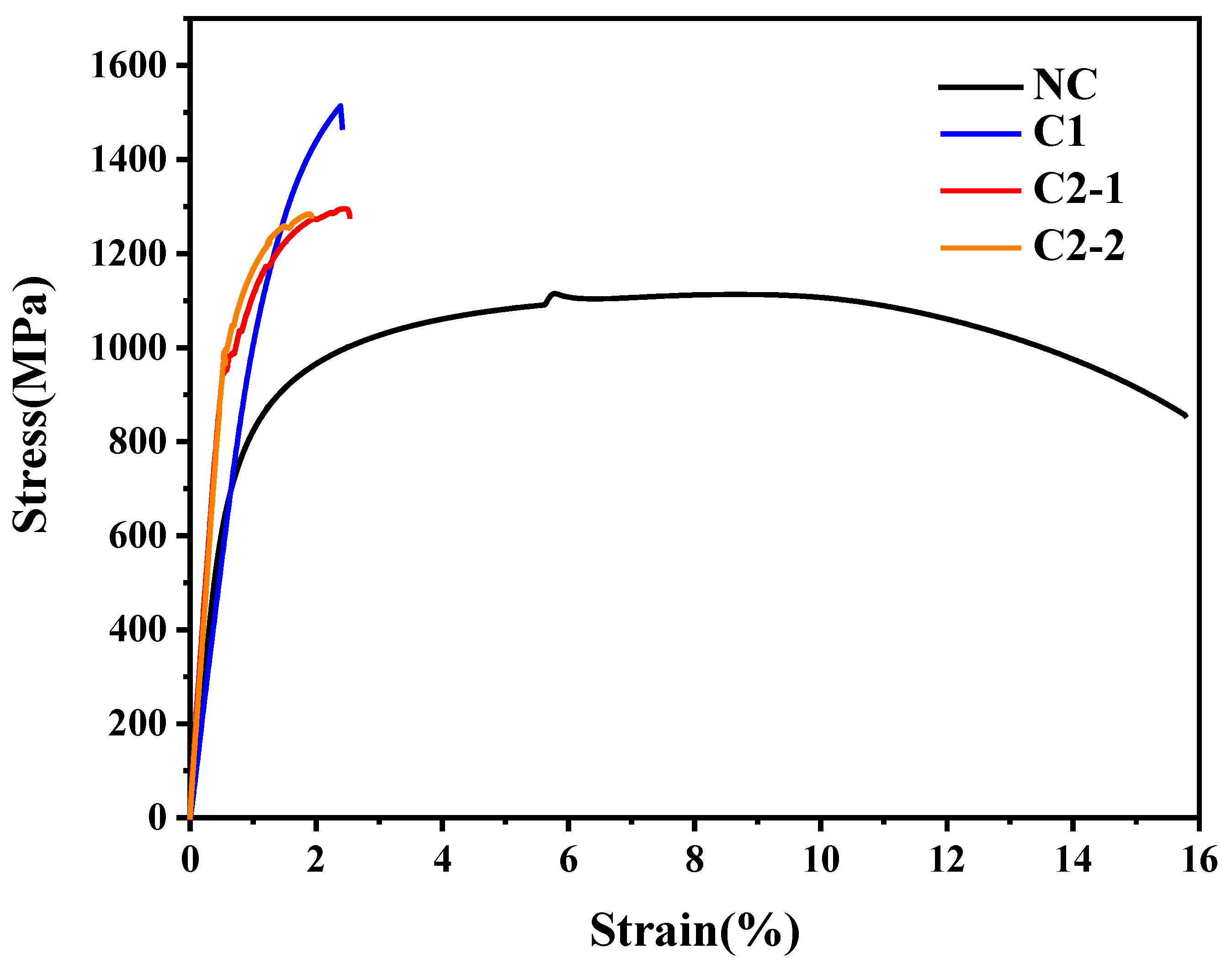

4.3. Results of Stress–Strain Curve

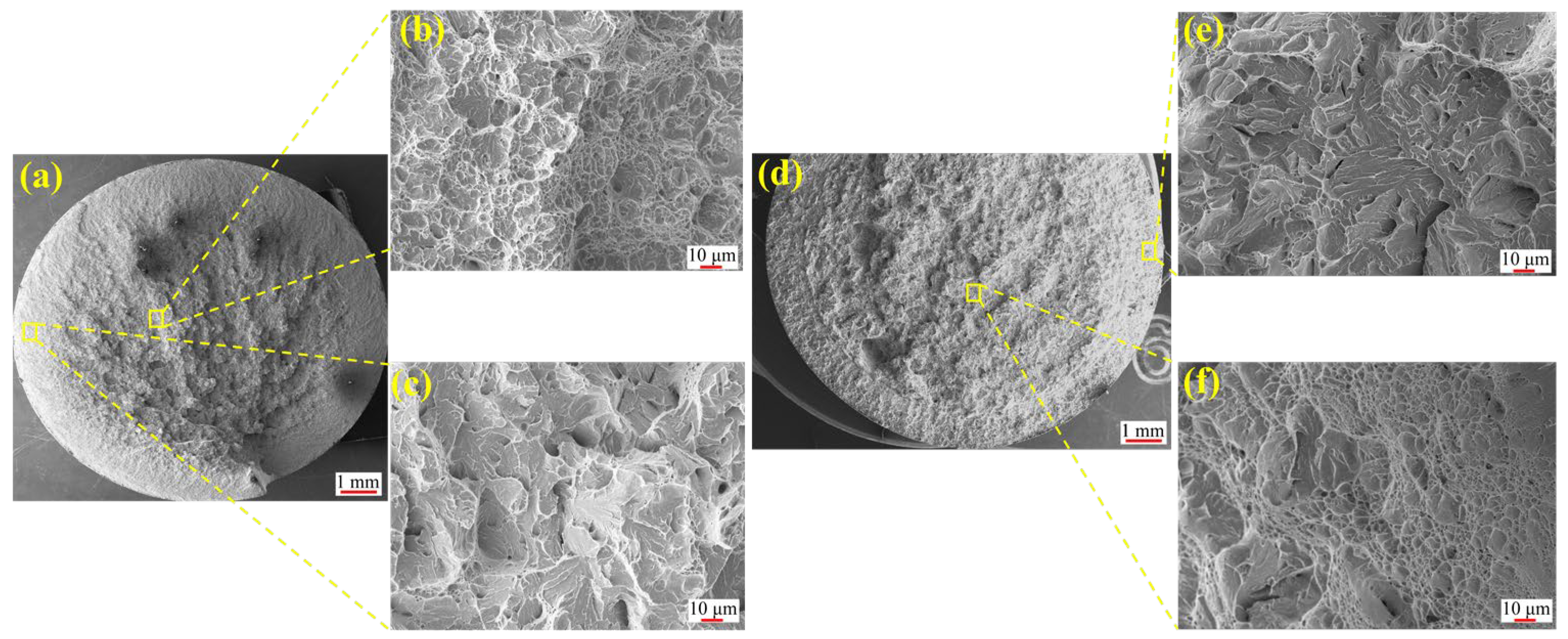

4.4. Results of Fracture Surface Morphology

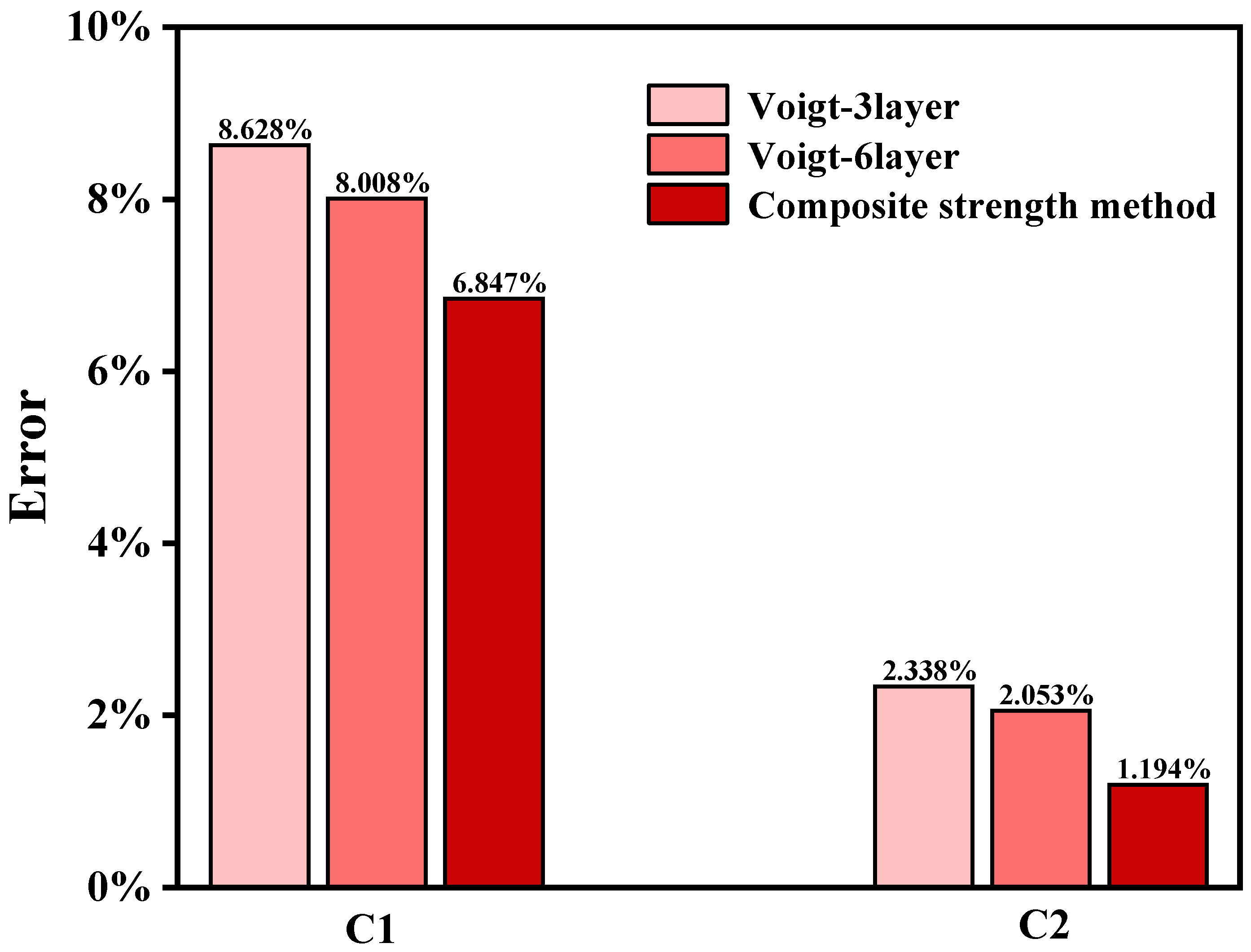

4.5. The Proposed Composite Strength Method vs. Conventional Multilayer Method

5. Conclusions and Outlook

- A novel composite strength method for the quantitative strength prediction of carburized materials is established. By utilizing only microhardness data from the carburized layer, this approach provides accurate tensile strength predictions without uniaxial tensile testing, demonstrating significant potential for engineering performance evaluation.

- Experimental validation using C1 and C2 specimens with different carburizing depths confirms that the tensile strength prediction error of this method remains below 7%, with a minimum error reaching 1.2%. Compared to the conventional Voigt-related multilayer method, the proposed method demonstrates a significant improvement in both evaluation efficiency and accuracy, achieving over 41.8% enhancement in prediction precision.

- By introducing the Taylor series expansion, a mapping relationship between discrete hardness values and continuous strength properties has been established. This approach breaks through the Voigt theory-based layered discretization approximation paradigm. Requiring only hardness as the core measurement metric, it transcends the traditional research path that relies on complex crystal structure-microstructure-mechanical property correlations, demonstrating significant potential for engineering applications.

- Due to experimental limitations, this study validates the proposed model only on 20CrNiMo steel. However, future research could extend the verification to different material types, specimen diameters, and complex testing conditions (irregularly shaped specimens) to further demonstrate the universality of the model. The authors will continue in-depth research in this field with the aim of achieving more valuable results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix A.1

References

- Cao, L.; Li, M.; Zhang, J.; Lin, G.; Gong, B.; Mao, X.; Zhang, L.; Li, Y. Study on Deterioration Characteristics of Low-Carbon Steel’s Mechanical Properties and Fracture Mechanism under Marine Engineering Environment. Adv. Civ. Eng. 2021, 2021, 6122943. [Google Scholar] [CrossRef]

- Chen, X.; Jiang, W.; Sun, J.; Li, Y.; Ma, W.; Xu, Z.; Jiang, Q.; Chen, J.; Li, Y. The effects of composite surface modification on the bending fatigue properties of 20CrNiMo steel. Opt. Laser Technol. 2025, 180, 111566. [Google Scholar] [CrossRef]

- Sun, K.; Xu, S.; Ma, X.; Liu, R.; Ju, X.; Li, J.; Pan, Y.; Wang, W. Effect of Ultrasonic Surface Rolling on the Microstructure and Corrosion Properties of Gear Steel 20CrNiMo After Carburizing. J. Mater. Eng. Perform. 2024, 34, 12087–12097. [Google Scholar] [CrossRef]

- Rodenkirchen, C.; Ackerman, A.K.; Mignanelli, P.M.; Cliff, A.; Wise, G.J.; Breul, P.; Douglas, J.O.; Bagot, P.A.J.; Moody, M.P.; Appleton, M.; et al. Effect of Alloying on the Microstructure, Phase Stability, Hardness, and Partitioning Behavior of a New Dual-Superlattice Nickel-Based Superalloy. Metall. Mater. Trans. A 2023, 54, 1902–1923. [Google Scholar] [CrossRef]

- Luo, X.; Ren, X.; Jin, Q.; Qu, H.; Hou, H. Microstructural evolution and surface integrity of ultrasonic surface rolling in Ti6Al4V alloy. J. Mater. Res. Technol. 2021, 13, 1586–1598. [Google Scholar] [CrossRef]

- Maleki, E.; Unal, O.; Guagliano, M.; Bagherifard, S. The effects of shot peening, laser shock peening and ultrasonic nanocrystal surface modification on the fatigue strength of Inconel 718. Mater. Sci. Eng. A 2021, 810, 141029. [Google Scholar] [CrossRef]

- Mostafa, A.M.; Hameed, M.F.; Obayya, S.S. Effect of laser shock peening on the hardness of AL-7075 alloy. J. King. Saud. Univ. Sci. 2019, 31, 472–478. [Google Scholar] [CrossRef]

- Srivastava, M.; Hloch, S.; Krejci, L.; Chattopadhyaya, S.; Dixit, A.R.; Foldyna, J. Residual stress and surface properties of stainless steel welded joints induced by ultrasonic pulsed water jet peening. Measurement 2018, 127, 453–462. [Google Scholar] [CrossRef]

- Wu, L.J.; Luo, K.Y.; Liu, Y.; Cui, C.Y.; Xue, W.; Lu, J.Z. Effects of laser shock peening on the micro-hardness, tensile properties, and fracture morphologies of CP-Ti alloy at different temperatures. Appl. Surf. Sci. 2018, 431, 122–134. [Google Scholar] [CrossRef]

- Mohammadreza, K.G.S.; Gholamreza, K.; Hesam, P.; Mohamma, D.J.; Hamid, B.; Masoud, S. Effects of heat treatment on the intermetallic compounds and mechanical properties of the stainless steel 321-aluminum 1230 explosive-welding interface. Int. J. Min. Met. Mater. 2017, 24, 1267–1277. [Google Scholar] [CrossRef]

- Palanisamy, A.; Jeyaprakash, N.; Sivabharathi, V.; Sivasankaran, S. Influence of heat treatment on the mechanical and tribological properties of Incoloy 800H Superalloy. Arch. Civ. Mech. Eng. 2021, 21, 10. [Google Scholar] [CrossRef]

- Pang, Z.; Yu, S.; Xu, J. Study of Effect of Quenching Deformation Influenced by 17CrNiMo6 Gear Shaft of Carburization. Phys. Procedia 2013, 50, 103–112. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, Z.; Shan, Q.; Li, Z.; Jiang, Y.; Ge, R. Influence of Heat-Treatment on Enhancement of Yield Strength and Hardness by Ti-V-Nb Alloying in High-Manganese Austenitic Steel. Metals 2019, 9, 299. [Google Scholar] [CrossRef]

- Xue, N.; Wu, Q.; Zhang, Y.; Li, B.; Zhang, Y.; Yang, S.; Zhu, Y.; Guo, J.; Gao, H. Review on research progress and comparison of different residual stress strengthening methods for titanium alloys. Eng. Fail. Anal. 2023, 144, 106937. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, J.; Wu, L.; Wang, Z.; Liu, L.; Ji, V.; Qu, S. Surface integrity and bending fatigue behavior of aeronautic gear steel under combined carburized treatment and shot peening. Int. J. Fatigue 2023, 169, 107488. [Google Scholar] [CrossRef]

- Cao, Z.; Liu, T.; Yu, F.; Cao, W.; Zhang, X.; Weng, Y. Carburization induced extra-long rolling contact fatigue life of high carbon bearing steel. Int. J. Fatigue 2020, 131, 105351. [Google Scholar] [CrossRef]

- Yin, L.; Ma, X.; Tang, G.; Fu, Z.; Yang, S.; Wang, T.; Wang, L.; Li, L. Characterization of carburized 14Cr14Co13Mo4 stainless steel by low pressure carburizing. Surf. Coat. Technol. 2019, 358, 654–660. [Google Scholar] [CrossRef]

- Chen, W.; He, X.; Yu, W.; Wang, M.; Yao, K. Microstructure, Hardness, and Tensile Properties of Vacuum Carburizing Gear Steel. Metals 2021, 11, 300. [Google Scholar] [CrossRef]

- Shi, L.; Cui, X.; Li, J.; Jin, G.; Liu, J.; Tian, H. Improving the wear resistance of heavy-duty gear steels by cyclic carburizing. Tribol. Int. 2022, 171, 107576. [Google Scholar] [CrossRef]

- Touati, S.; Ghelani, L.; Zemmouri, A.; Boumediri, H. Optimization of gas carburizing treatment parameters of low carbon steel using Taguchi and grey relational analysis (TA-GRA). Int. J. Adv. Manuf. Technol. 2022, 120, 7937–7949. [Google Scholar] [CrossRef]

- Mathews, J.A.; Farahani, H.; Sietsma, J.; Petrov, R.H.; Mecozzi, M.G.; Santofimia, M.J. Microstructures in a carburized steel after isothermal pearlitic treatment. J. Mater. Sci. Technol. 2023, 160, 66–75. [Google Scholar] [CrossRef]

- Mo, J.; Yuan, Q.; Liang, W.; Zhang, Z.; Hu, H.; Xu, G. Effect of the Normalizing Temperature on the Size and Homogeneity of Austenite Grain in 20CrMnTi Carburized Gear Steel. Arab. J. Sci. Eng. 2024, 50, 13593–13604. [Google Scholar] [CrossRef]

- Wang, G.; Sang, X.; Zhang, Y.; Zhao, M.; Xu, G.; Peng, Z. Carburization-induced microstructure evolution and hardening mechanism of 18CrNiMo7-6 steel. J. Mater. Res. Technol. 2023, 25, 1649–1661. [Google Scholar] [CrossRef]

- Farivar, H.; Deepu, M.J.; Hans, M.; Phanikumar, G.; Bleck, W.; Prahl, U. Influence of post-carburizing heat treatment on the core microstructural evolution and the resulting mechanical properties in case-hardened steel components. Mater. Sci. Eng. A 2019, 744, 778–789. [Google Scholar] [CrossRef]

- Fan, X.; Qu, R.; Zhang, Z. Relation Between Strength and Hardness of High-Entropy Alloys. Acta. Metall. Sin. (Engl. Lett.) 2021, 34, 1461–1482. [Google Scholar] [CrossRef]

- Zhang, P.; Li, S.X.; Zhang, Z.F. General relationship between strength and hardness. Mater. Sci. Eng. A 2011, 529, 62–73. [Google Scholar] [CrossRef]

- Wang, L.; Huang, Z. On strength prediction of laminated composites. Compos. Sci. Technol. 2022, 219, 109206. [Google Scholar] [CrossRef]

- Voigt, W. Ueber die Beziehung zwischen den beiden Elasticitätsconstanten isotroper Körper. Ann. Phys. Berl. 1889, 274, 573–587. [Google Scholar] [CrossRef]

- Reuss, A. Berechnung der Fließgrenze von Mischkristallen auf Grund der Plastizitätsbedingung für Einkristalle. ZAMM-J. Appl. Math. Mech. Z. Angew. Math. Und Mech. 1929, 9, 49–58. [Google Scholar] [CrossRef]

- Liu, B.; Feng, X.; Zhang, S. The effective Young’s modulus of composites beyond the Voigt estimation due to the Poisson effect. Compos. Sci. Technol. 2009, 69, 2198–2204. [Google Scholar] [CrossRef]

- Luo, Y. Improved Voigt and Reuss Formulas with the Poisson Effect. Materials 2022, 15, 5656. [Google Scholar] [CrossRef]

- Amirpour, M.; Bickerton, S.; Calius, E.; Das, R.; Mace, B. Numerical and experimental study on deformation of 3D-printed polymeric functionally graded plates: 3D-Digital Image Correlation approach. Compos. Struct. 2019, 211, 481–489. [Google Scholar] [CrossRef]

- Chen, M.; Jin, G.; Ma, X.; Zhang, Y.; Ye, T.; Liu, Z. Vibration analysis for sector cylindrical shells with bi-directional functionally graded materials and elastically restrained edges. Compos. Part B Eng. 2018, 153, 346–363. [Google Scholar] [CrossRef]

- Genin, G.M.; Birman, V. Micromechanics and structural response of functionally graded, particulate-matrix, fiber-reinforced composites. Int. J. Solids Struct. 2009, 46, 2136–2150. [Google Scholar] [CrossRef]

- Nemat-Alla, M.; Ahmed, K.I.E.; Hassab-Allah, I. Elastic–plastic analysis of two-dimensional functionally graded materials under thermal loading. Int. J. Solids Struct. 2009, 46, 2774–2786. [Google Scholar] [CrossRef]

- Zhao, M.; Han, X.; Wang, G.; Xu, G. Determination of the mechanical properties of surface-modified layer of 18CrNiMo7-6 steel alloys after carburizing heat treatment. Int. J. Mech. Sci. 2018, 148, 84–93. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, L.; Xu, G.; Wang, G.; Zhao, M. Fatigue fracture of surface-modified layers in 18CrNiMo7-6 carburized steel. Eng. Fail. Anal. 2022, 131, 105839. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, Y.; Gao, C.; Xu, G.; Zhao, M. Effect of residual stress and microstructure on corrosion resistance of carburised 18CrNiMo7-6 steel. Anti-Corros. Methods Mater. 2020, 67, 357–366. [Google Scholar] [CrossRef]

- Čular, I.; Vučković, K.; Glodež, S.; Tonković, Z. Computational model for bending fatigue prediction of surface hardened spur gears based on the multilayer method. Int. J. Fatigue 2022, 161, 106892. [Google Scholar] [CrossRef]

- Čular, I.; Vučković, K.; Žeželj, D.; Glodež, S. Analytical approach for low and high cycle bending fatigue life prediction of carburized gear steel specimens. Eng. Fail. Anal. 2020, 108, 104328. [Google Scholar] [CrossRef]

- Hoseana, J. Extending the substitution method for integration. Math. Gaz. 2017, 101, 538–541. [Google Scholar] [CrossRef]

- Volčič, A. A Riemann-type theorem for a Riemann-type integral. Ric. Mat. 2019, 68, 333–339. [Google Scholar] [CrossRef]

- Liu, J.; Chen, C.; Feng, Q.; Fang, X.; Wang, H.; Liu, F.; Lu, J.; Raabe, D. Dislocation activities at the martensite phase transformation interface in metastable austenitic stainless steel: An in-situ TEM study. Mater. Sci. Eng. A 2017, 703, 236–243. [Google Scholar] [CrossRef]

- Shamsujjoha, M. Evolution of microstructures, dislocation density and arrangement during deformation of low carbon lath martensitic steels. Mater. Sci. Eng. A 2020, 776, 139039. [Google Scholar] [CrossRef]

- Pavlina, E.J.; Van Tyne, C.J. Correlation of Yield Strength and Tensile Strength with Hardness for Steels. J. Mater. Eng. Perform. 2008, 17, 888–893. [Google Scholar] [CrossRef]

- Wei, P.; Zhou, H.; Liu, H.; Zhu, C.; Wang, W.; Deng, G. Modeling of contact fatigue damage behavior of a wind turbine carburized gear considering its mechanical properties and microstructure gradients. Int. J. Mech. Sci. 2019, 156, 283–296. [Google Scholar] [CrossRef]

- Sun, K.; Lu, L.; Jiang, Y.; Wang, Y.; Zhou, K.; He, Z. Integrated effects of PM2.5 deposition, module surface conditions and nanocoatings on solar PV surface glass transmittance. Renew. Sust. Energ. Rev. 2018, 82, 4107–4120. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, S.; Liao, L. Near-optimal control of nonlinear dynamical systems: A brief survey. Annu. Rev. Control 2019, 47, 71–80. [Google Scholar] [CrossRef]

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. National Standards of the People’s Republic of China: Beijing, China, 2021.

| Element wt% | ||||||

|---|---|---|---|---|---|---|

| C | Si | Mn | Cr | Ni | Mo | Fe |

| 0.219 | 0.27 | 0.60 | 0.58 | 0.53 | 0.24 | Balance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Guo, Y.; Chen, S.; Zha, X.; Li, Z.; Xu, Z. Quantitative Characterization of Tensile Strength for Carburized Materials Using a Novel Composite Strength Method. Materials 2025, 18, 5205. https://doi.org/10.3390/ma18225205

Wang H, Guo Y, Chen S, Zha X, Li Z, Xu Z. Quantitative Characterization of Tensile Strength for Carburized Materials Using a Novel Composite Strength Method. Materials. 2025; 18(22):5205. https://doi.org/10.3390/ma18225205

Chicago/Turabian StyleWang, Hongjun, Yanding Guo, Shiqi Chen, Xuming Zha, Zejie Li, and Zhilong Xu. 2025. "Quantitative Characterization of Tensile Strength for Carburized Materials Using a Novel Composite Strength Method" Materials 18, no. 22: 5205. https://doi.org/10.3390/ma18225205

APA StyleWang, H., Guo, Y., Chen, S., Zha, X., Li, Z., & Xu, Z. (2025). Quantitative Characterization of Tensile Strength for Carburized Materials Using a Novel Composite Strength Method. Materials, 18(22), 5205. https://doi.org/10.3390/ma18225205