Press Hardening of High-Carbon Low-Density Steels

Abstract

1. Introduction

- -

- ferritic (Al ~ 5–9%, Mn < 5%, C < 0.05%),

- -

- ferrite-based duplex (Al ~ 3–7%, Mn ~ 2–12%, C ~ 0.05–0.5%),

- -

- austenite-based duplex (Al ~ 5–10%, Mn ~ 5–30%, C ~ 0.4–0.7%),

- -

- austenitic (Al ~ 5–12%, Mn ~ 12–30%, C ~ 0.6–2.0%) [2].

2. Experimental Programme

2.1. Materials

2.2. Small Omega Tool

- -

- The 7SiAl in the four modes achieved hardnesses ranging from 343 to 376 HV10, Rm ranging from 1086 to 1210 MPa, Rp0.2 ranging from 726 to 919 MPa, and ductility ranging from 3.9 to 7.5%.

- -

- For 7Al, the measured values ranged from 326 to 377 HV10, Rm 1031 to 1245 MPa, Rp0.2 539 to 898 MPa, and ductility 4.1 to 8.3%.

- -

- In the case of 5Al, 470 to 669 HV10, Rm 857 to 2023 MPa, Rp0.2 796 to 1545 MPa, and ductility from 0.7 to 6.6% were obtained.

2.3. Combined Tool

2.4. Different Heat Treatment Parameters

2.5. Equipment Used for Evaluation

3. Results

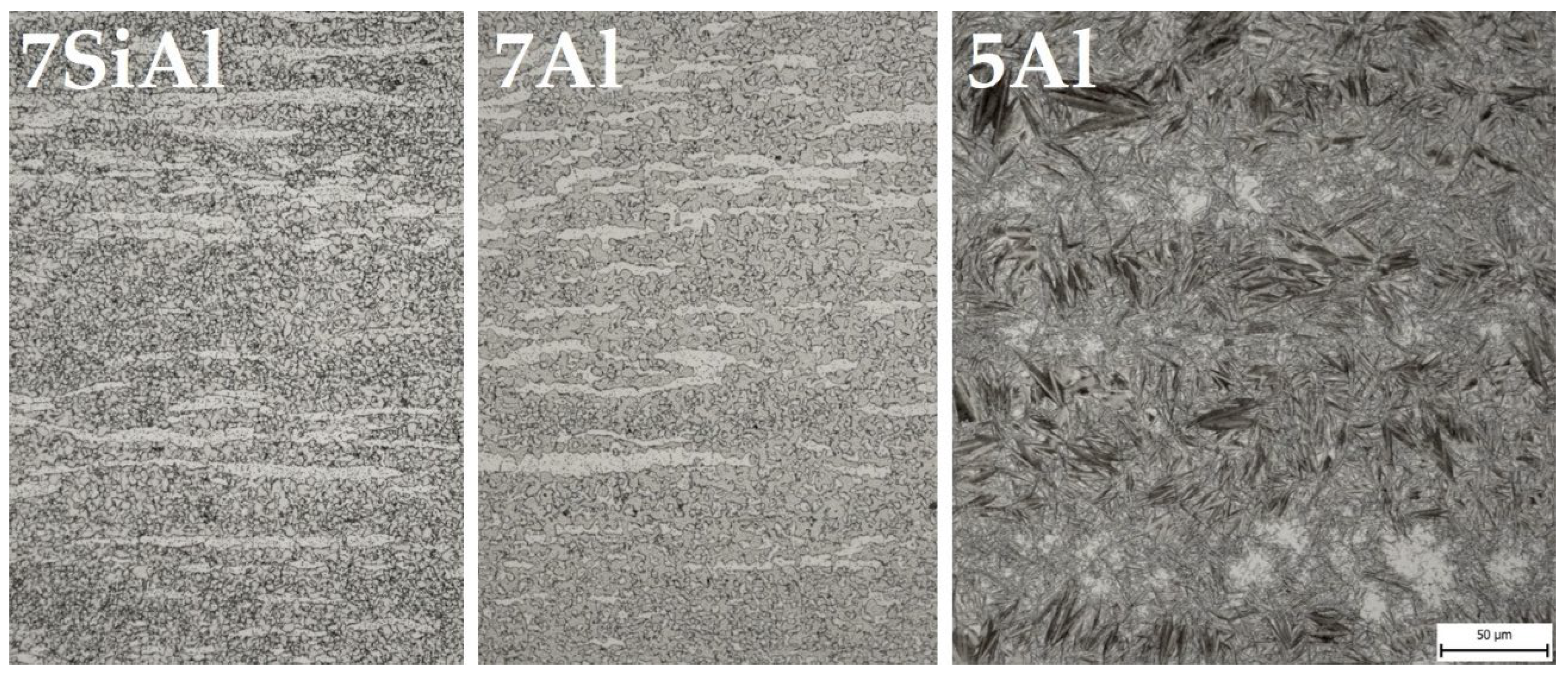

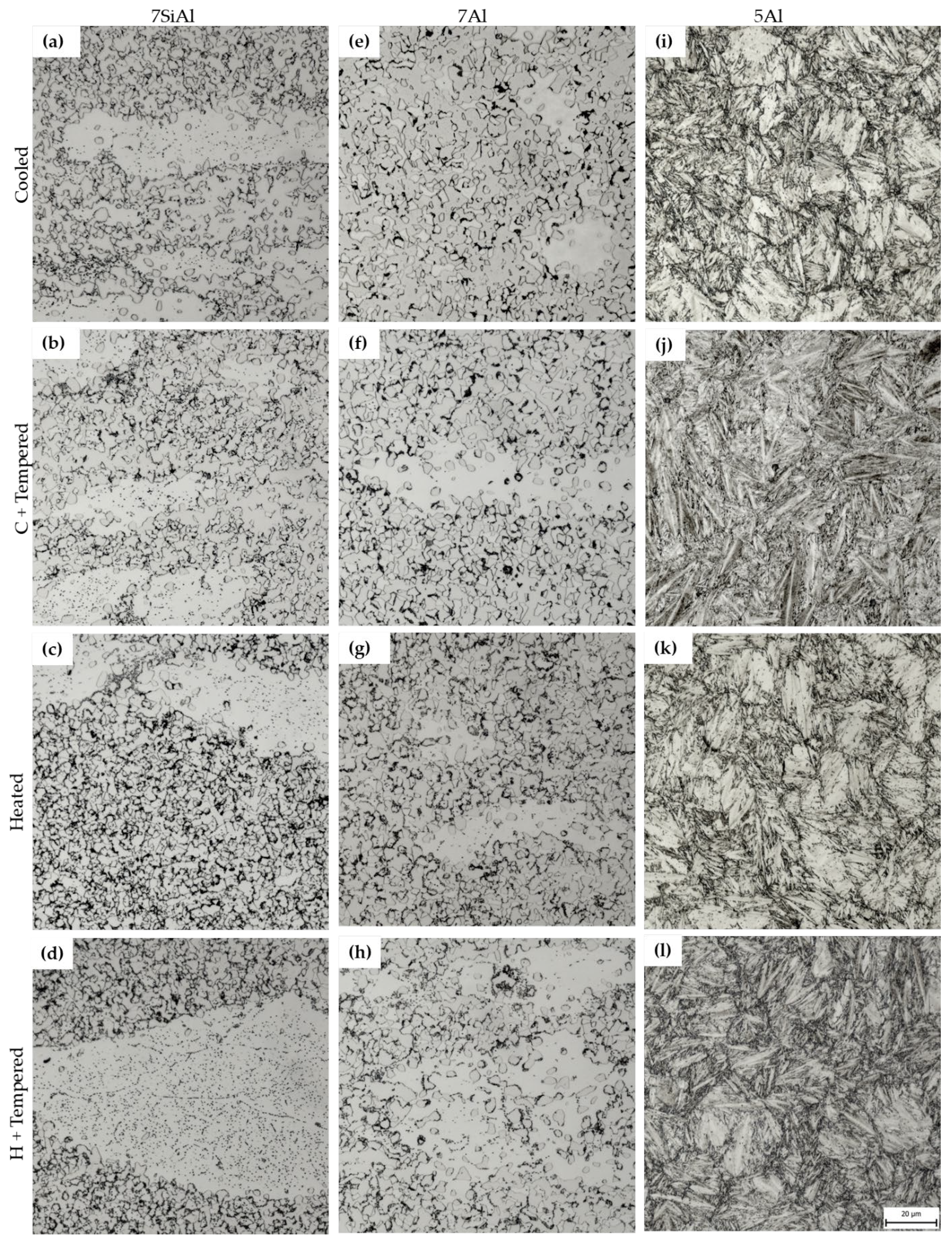

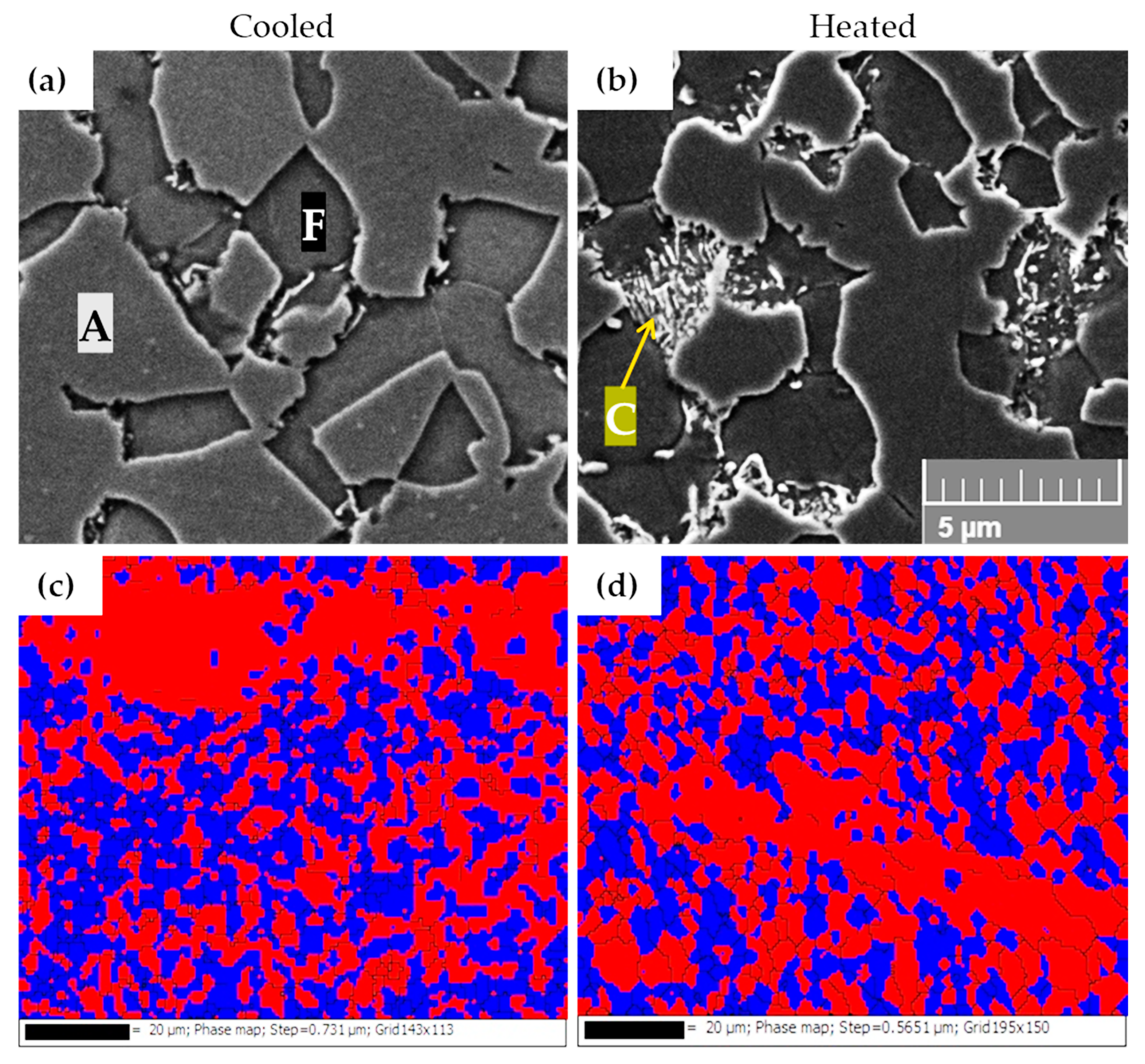

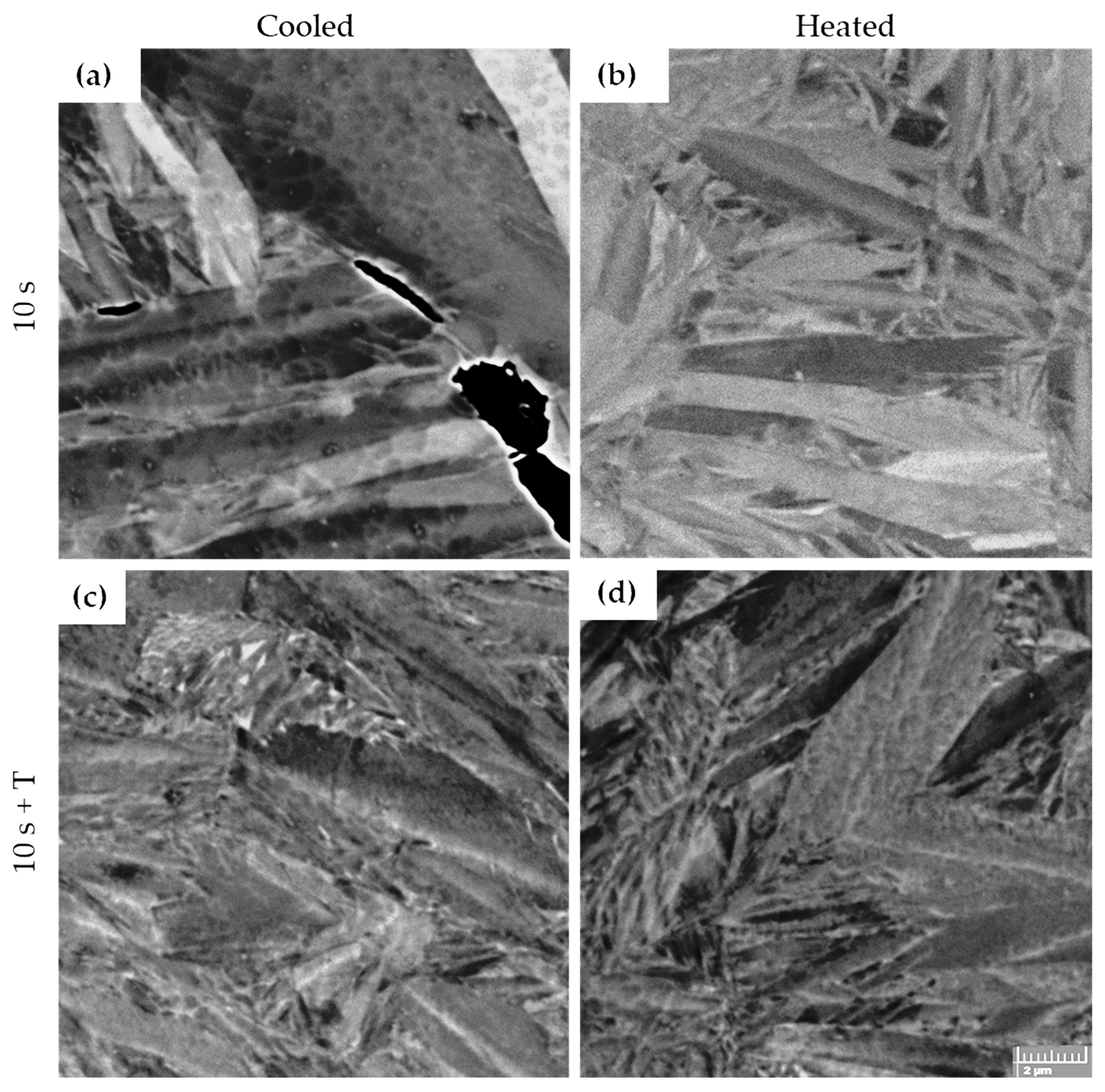

3.1. Microstructure Analysis

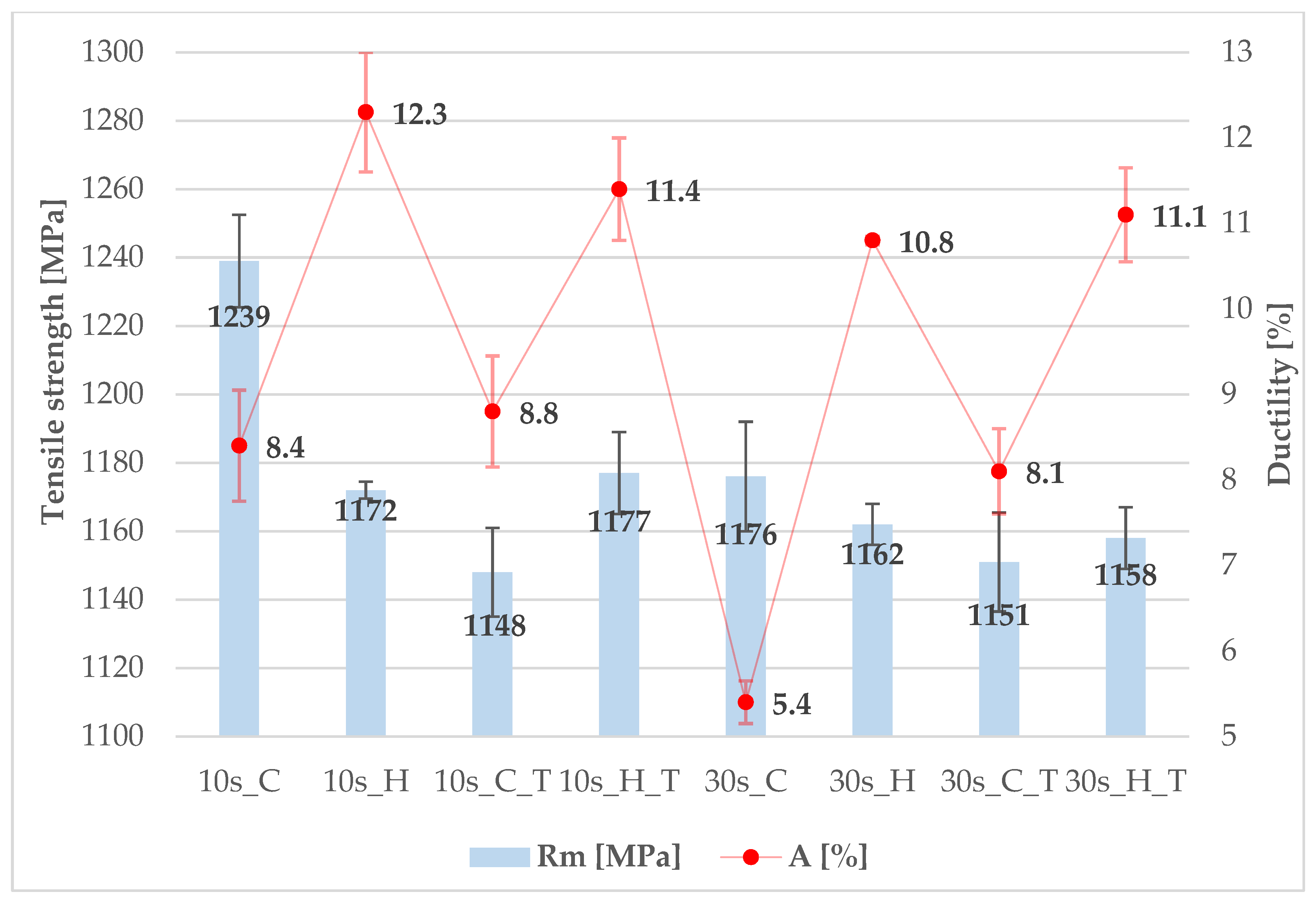

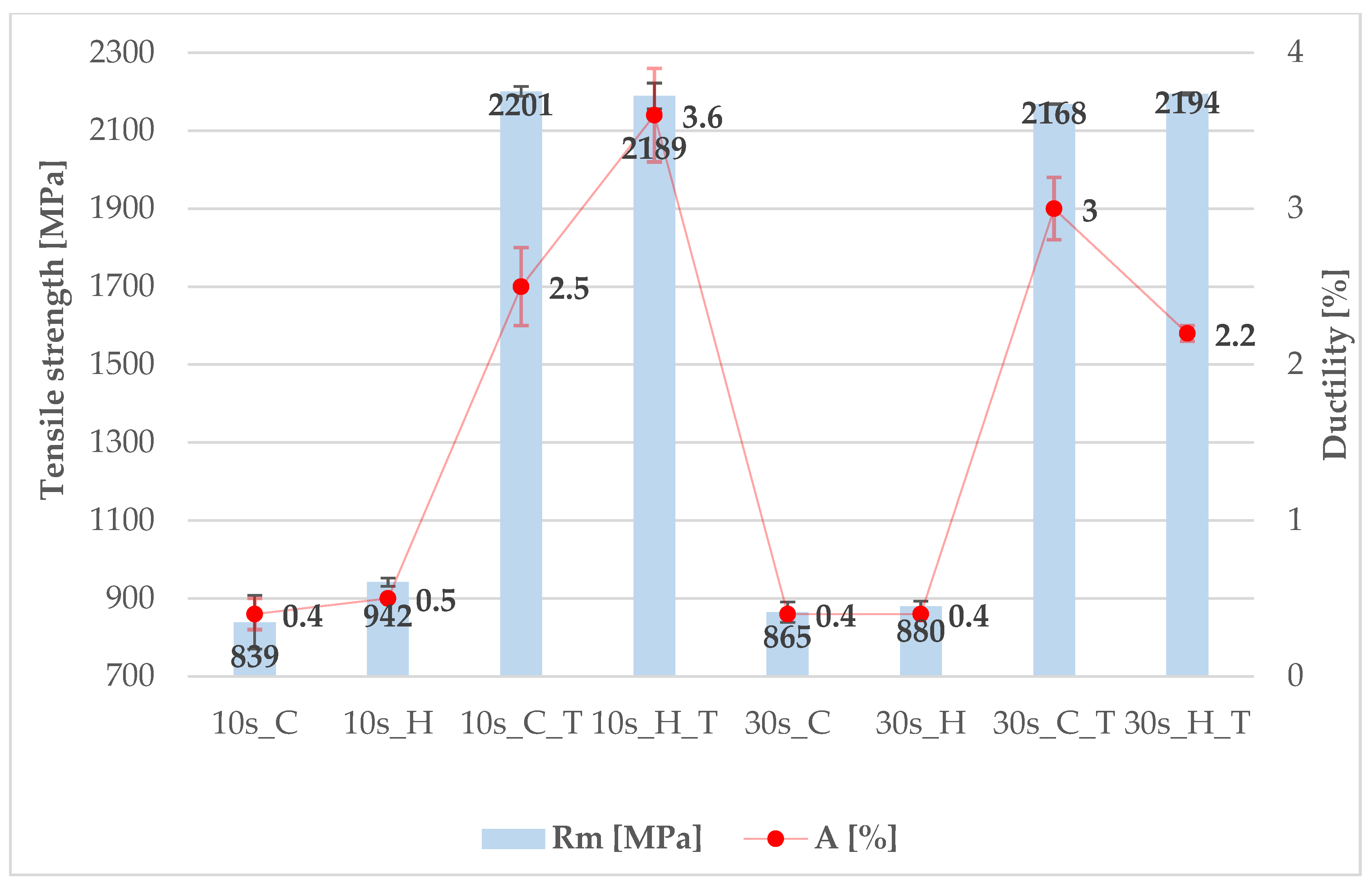

3.2. Mechanical Properties

4. Discussion

4.1. 7SiAl and 7Al

4.2. 5Al

5. Conclusions

- -

- All investigated high-carbon low-density steels (7SiAl, 7Al, 5Al) can be processed by press hardening without macroscopic defects.

- -

- All LDS variants exhibited a density reduction of ~9% compared to conventional press-hardening steel 22MnB5 (7.08–7.18 g/cm3 vs. ~7.8 g/cm3). This weight saving represents a significant advantage for automotive body structures and components aimed at reducing fuel consumption and CO2 emissions.

- -

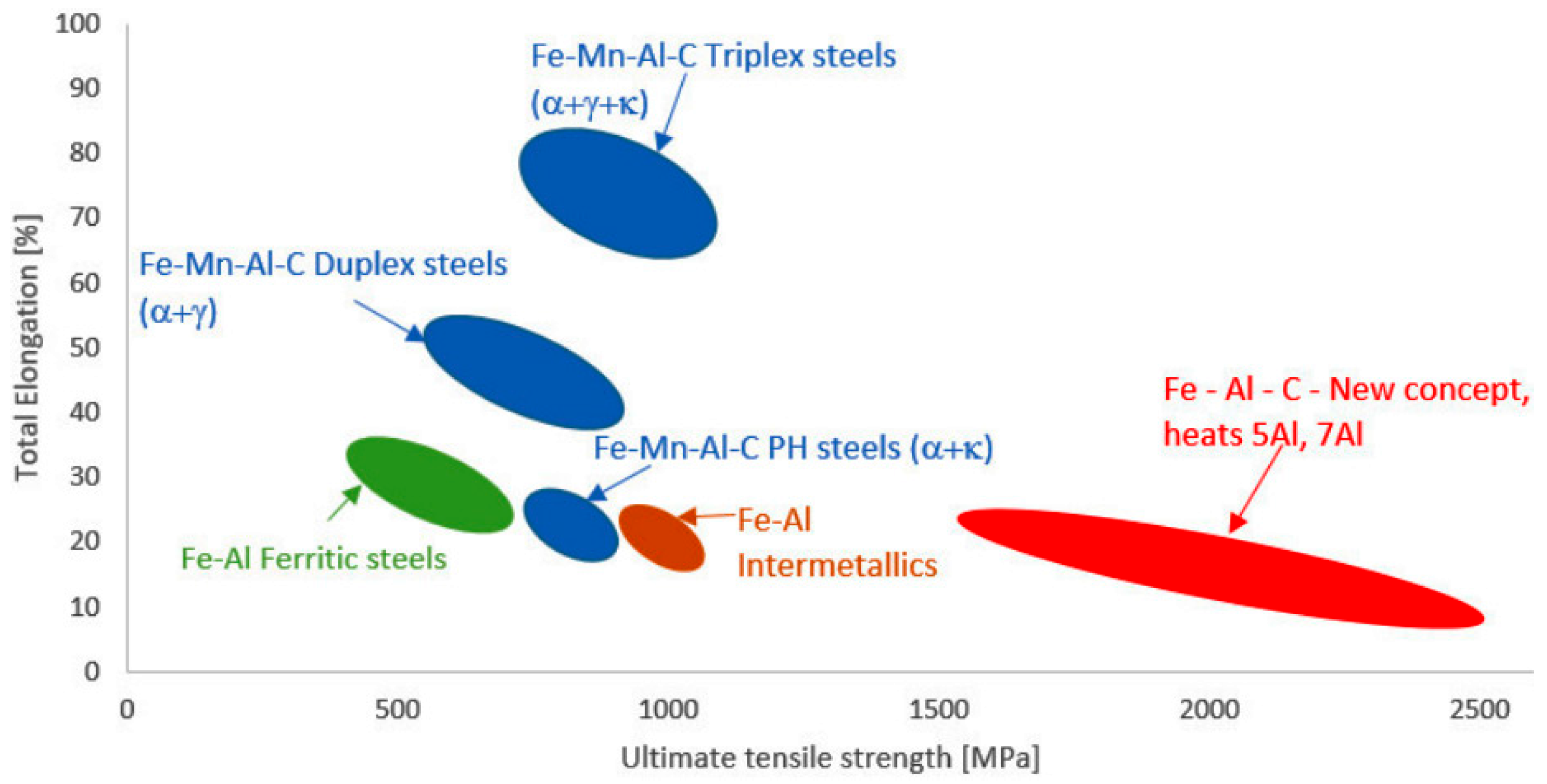

- Steels with 7% Al (7Al and 7SiAl) exhibit a rare duplex ferrite–austenite microstructure for steels of this chemical composition, achieving UTS ≈ 1100–1200 MPa and elongation up to 12%.

- -

- Steel 5Al forms a martensitic matrix with retained austenite; after tempering at 300 °C for 2 h, UTS exceeds 2200 MPa, but ductility remains low (≤3.6%).

- -

- Dwell time (10 vs. 30 s) has a negligible effect; 10 s is sufficient for practical processing.

- -

- Tempering improves properties only for 5Al; for 7Al and 7SiAl, it does not provide benefits.

- -

- This study provides the first systematic evaluation of press-hardening for Fe–Al–C steels with high carbon and reduced manganese, addressing a gap left by previous research and delivering comparative data for three compositions (7SiAl, 7Al, 5Al).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gutierrez-Urrutia, I. Low Density Fe-Mn-Al-C Steels: Phase Structures, Mechanisms and Properties. ISIJ Int. 2021, 61, 16–25. [Google Scholar] [CrossRef]

- Chen, S.; Rana, R.; Haldar, A.; Ray, R.K. Current State of Fe-Mn-Al-C Low Density Steels. Prog. Mater. Sci. 2017, 89, 345–391. [Google Scholar] [CrossRef]

- Hájek, J.; Nový, Z.; Kučerová, L.; Jirková, H.; Salvetr, P.; Motyčka, P.; Hajšman, J.; Bystřická, T. A New Alloying Concept for Low-Density Steels. Materials 2022, 15, 2539. [Google Scholar] [CrossRef] [PubMed]

- Springer, H.; Zhang, J.L.; Szczepaniak, A.; Belde, M.; Gault, B.; Raabe, D. Light, Strong and Cost Effective: Martensitic Steels Based on the Fe–Al–C System. Mater. Sci. Eng. A 2019, 762, 138088. [Google Scholar] [CrossRef]

- Stein, F.; Vogel, S.C.; Eumann, M.; Palm, M. Determination of the Crystal Structure of the ε Phase in the Fe-Al System by High-Temperature Neutron Diffraction. Intermetallics 2010, 18, 150–156. [Google Scholar] [CrossRef]

- Hájek, J.; Nový, Z.; Kučerová, L.; Jirková, H.; Donik, Č.; Jansa, Z. Mechanical Properties of High Carbon Low-Density Steels. Materials 2023, 16, 3852. [Google Scholar] [CrossRef]

- Zambrano, O.A. A general perspective of Fe–Mn–Al–C steels. J. Mater. Sci. 2018, 53, 14003–14062. [Google Scholar] [CrossRef]

- Ding, H.; Liu, D.; Cai, M.; Zhang, Y. Austenite-Based Fe-Mn-Al-C Lightweight Steels: Research and Prospective. Metals 2022, 12, 1572. [Google Scholar] [CrossRef]

- Kang, L.; Yuan, H.; Li, H.; Ji, Y.; Liu, H.; Liu, G.-M. Enhanced Mechanical Properties of Fe–Mn–Al–C Low Density Steel via Aging Treatment. Front. Mater. 2021, 8, 680776. [Google Scholar] [CrossRef]

- Sohrabizadeh, M.A.; Mazaheri, Y.; Sheikhi, M. The Effects of Age Hardening on Tribological Behavior of Lightweight Fe-Mn-Al-C Steel. J. Mater. Eng. Perform. 2021, 30, 4629–4640. [Google Scholar] [CrossRef]

- García-Domínguez, M.; Mejía, I.; Ramos-Fabián, N.I. Microstructural and mechanical evolution of duplex Fe–Mn–Al–C steels during microstructural conditioning: Influence of vanadium microalloying. MRS Adv. 2024, 9, 1816–1821. [Google Scholar] [CrossRef]

- Kim, H.; Suh, D.-W.; Kim, N.J. Fe–Al–Mn–C lightweight structural alloys: A review on the microstructures and mechanical properties. Sci. Technol. Adv. Mater. 2013, 14, 014205. [Google Scholar] [CrossRef] [PubMed]

- Karbasian, H.; Tekkaya, A.E. A review on hot stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Danielczyk, P.; Wróbel, I. Analysis of hot stamping tool cooling system—A case study. Materials 2021, 14, 2759. [Google Scholar] [CrossRef]

- Kaltzakorta, I.; Gutierrez, T.; Elvira, R.; Jimbert, P.; Guraya, T. Evolution of Microstructure during Isothermal Treatments of a Duplex-Austenitic 0.66C11.4Mn.9.9Al Low-Density Forging Steel and Effect on the Mechanical Properties. Metals 2021, 11, 214. [Google Scholar] [CrossRef]

- Robinson, A.L. Fuel efficiency drives the auto industry to reduce vehicle weight. MRS Bull. 2019, 44, 920–923. [Google Scholar] [CrossRef]

- Kim, H.C.; Wallington, T.J. Life Cycle Assessment of Vehicle Lightweighting: A Physics-Based Model To Estimate Use-Phase Fuel Consumption of Electrified Vehicles. Environ. Sci. Technol. 2016, 50, 11226–11233. [Google Scholar] [CrossRef]

- Venturato, G.; Novella, M.; Bruschi, S.; Ghiotti, A.; Shivpuri, R. Effects of phase transformation in hot stamping of 22MnB5 high strength steel. Procedia Eng. 2017, 183, 316–321. [Google Scholar] [CrossRef]

- Billur, E. Hot Stamping of Ultra High-Strength Steels from a Technological and Business Perspective, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Chen, J. Hot stamping. In Comprehensive Materials Processing; Elsevier: Amsterdam, The Netherlands, 2014; Volume 5, pp. 351–370. [Google Scholar]

- Pramanik, S.; Koppoju, S.; Anupama, A.V.; Sahoo, B.; Suwas, S. Strengthening Mechanisms in Fe-Al Based Ferritic Low-Density Steels. Mater. Sci. Eng. A 2018, 712, 574–584. [Google Scholar] [CrossRef]

- Pramanik, S.; Suwas, S. Low-Density Steels: The Effect of Al Addition on Microstructure and Properties. JOM 2014, 66, 1868–1876. [Google Scholar] [CrossRef]

- Jirková, H.; Vrtáček, J.; Peković, M.; Janda, T.; Kučerová, L. Influence of chromium and nobium on the press-hardening process of multiphase low-alloy TRIP steels. Mater. Sci. Forum 2021, 1016, 636–641. [Google Scholar] [CrossRef]

- JMatPro, version 12.1. Materials Property Simulation Package Public Release. Sente Software Ltd.: Guildford, UK, 2019.

- ČSN EN ISO 6892-1; Kovové Materiály—Zkoušení Tahem—Část 1: Zkušební Metoda za Pokojové Teploty. Úřad pro Technickou Normalizaci, Metrologii Astátní Zkušebnictví: Praha, Czech Republic, 2021; pp. 1–76.

- Votava, F.; Vrtáček, J.; Sýkora, J.; Weinar, M.; Jirková, H. Design of a Combined Tool for Sheet Tailoring during Press Hardening. Eng. Proc. 2022, 26, 1. [Google Scholar] [CrossRef]

- Votava, F.; Jirková, H.; Kučerová, L.; Jeníček, Š. Study of Transition Areas in Press-Hardened Steels in a Combined Tool for Hot and Cold Forming. Materials 2023, 16, 442. [Google Scholar] [CrossRef]

- Skowronek, A.; Grajcar, A.; Kozłowska, A.; Janik, A.; Morawiec, M.; Petrov, R.H. Temperature-Dependent Microstructural Evolution of Al-Rich Medium-Mn Steel During Intercritical Annealing. Metall. Mater. Trans. A 2022, 53, 3012–3021. [Google Scholar] [CrossRef]

- Li, T.; Wang, K.; Lei, Y. A Review of Welding Process for UNS S32750 Super Duplex Stainless Steel. Materials 2024, 17, 5215. [Google Scholar] [CrossRef]

- Haghdadi, N.; Ledermueller, C.; Chen, H.; Chen, Z.; Liu, Q.; Li, X.; Rohrer, G.; Liao, X.; Ringer, S.; Primig, S. Evolution of Microstructure and Mechanical Properties in 2205 Duplex Stainless Steels during Additive Manufacturing and Heat Treatment. Mater. Sci. Eng. A 2022, 835, 142695. [Google Scholar] [CrossRef]

| Material | C | Si | Mn | Cr | Ni | Al | S | P |

|---|---|---|---|---|---|---|---|---|

| 7SiAl (7%Al) | 0.69 | 0.58 | 0.53 | 2.06 | 1.004 | 7.06 | 0.007 | 0.01 |

| 7Al (7%Al) | 0.73 | 0.12 | 0.55 | 2.02 | 1.05 | 7.06 | 0.008 | 0.01 |

| 5Al (5%Al) | 1.07 | 0.16 | 0.53 | 2.03 | 1.56 | 4.97 | 0.006 | 0.008 |

| Materials | Furnace Temp. [°C] | Soaking Time [min] | Tool Temp. [°C] | Time in the Tool [s] | Heat Treatment |

|---|---|---|---|---|---|

| 7SiAl; 7Al; 5Al | 950 | 10 | 20 | 30 | 300 °C; 2 h |

| 20 | 30 | 600 °C, 2 h | |||

| 300 | 1800 | cooled in water | |||

| 20 | 30 | 600 °C, 1 h |

| Material | Rm [MPa] | Rp0.2 [MPa] | A [%] | HV10 |

|---|---|---|---|---|

| 7SiAl | 1109 ± 17 | 830 ± 7 | 7.5 | 358 ± 6 |

| 7Al | 1122 ± 7 | 729 ± 4 | 8.3 | 332 ± 2 |

| 5Al | 2023 ± 4 | 1545 ± 2 | 6.6 | 589 ± 14 |

| Material | Furnace Temp. [°C] | Soaking Time [min] | Tool Parts [°C] | Time in the Tool [s] | |

|---|---|---|---|---|---|

| Heated | Cooled | ||||

| 7SiAl | 950 | 10 | 250 | 20 | 10; 30 |

| 7Al | 950 | 10 | 285 | 20 | 10; 30 |

| 5Al | 950 | 10 | 50 | 20 | 10; 30 |

| Material | Sample | HV10 | Sample | HV10 | Sample | HV10 | Sample | HV10 |

|---|---|---|---|---|---|---|---|---|

| 7SiAl | 10s_C | 355 ± 2 | 10s_C_T | 353 ± 2 | 30s_C | 354 ± 2 | 30s_C_T | 349 ± 1 |

| 10s_H | 375 ± 2 | 10s_H_T | 372 ± 1 | 30s_H | 363 ± 7 | 30s_H_T | 360 ± 3 | |

| 7Al | 10s_C | 345 ± 3 | 10s_C_T | 332 ± 1 | 30s_C | 342 ± 6 | 30s_C_T | 334 ± 4 |

| 10s_H | 348 ± 2 | 10s_H_T | 342 ± 5 | 30s_H | 347 ± 2 | 30s_H_T | 340 ± 4 | |

| 5Al | 10s_C | 660 ± 6 | 10s_C_T | 692 ± 1 | 30s_C | 670 ± 3 | 30s_C_T | 659 ± 2 |

| 10s_H | 666 ± 3 | 10s_H_T | 700 ± 6 | 30s_H | 658 ± 3 | 30s_H_T | 658 ± 4 |

| Material | Part | Rm [MPa] | A [%] | HV10 | Regime |

|---|---|---|---|---|---|

| 7SiAl | C | 1144 | 8.4 | 355 | 10 s |

| H | 1201 | 10.2 | 375 | ||

| 7Al | C | 1239 | 8.4 | 345 | 10 s |

| H | 1172 | 12.3 | 348 | ||

| 5Al | C | 2201 | 2.5 | 692 | 10 s + T |

| H | 2189 | 3.6 | 700 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Votava, F.; Kučerová, L.; Jeníček, Š.; Leták, R.; Hájek, J.; Nový, Z. Press Hardening of High-Carbon Low-Density Steels. Materials 2025, 18, 5163. https://doi.org/10.3390/ma18225163

Votava F, Kučerová L, Jeníček Š, Leták R, Hájek J, Nový Z. Press Hardening of High-Carbon Low-Density Steels. Materials. 2025; 18(22):5163. https://doi.org/10.3390/ma18225163

Chicago/Turabian StyleVotava, Filip, Ludmila Kučerová, Štěpán Jeníček, Radek Leták, Jiří Hájek, and Zbyšek Nový. 2025. "Press Hardening of High-Carbon Low-Density Steels" Materials 18, no. 22: 5163. https://doi.org/10.3390/ma18225163

APA StyleVotava, F., Kučerová, L., Jeníček, Š., Leták, R., Hájek, J., & Nový, Z. (2025). Press Hardening of High-Carbon Low-Density Steels. Materials, 18(22), 5163. https://doi.org/10.3390/ma18225163