1. Introduction

This study focuses on sandwich panels, which consist of two thin, stiff facings and a thick but shear-deformable core. The facings, usually made of metal, serve as protective layers. From a mechanical point of view, their main task is to transfer the normal stresses resulting from the bending of the panel. The core of the panel provides thermal insulation and is made from materials with lower elastic moduli, such as polyisocyanurate foam, expanded polystyrene, or mineral wool. The core is susceptible to deformation, but transfers shear stresses and separates the facings, giving the panel flexural rigidity.

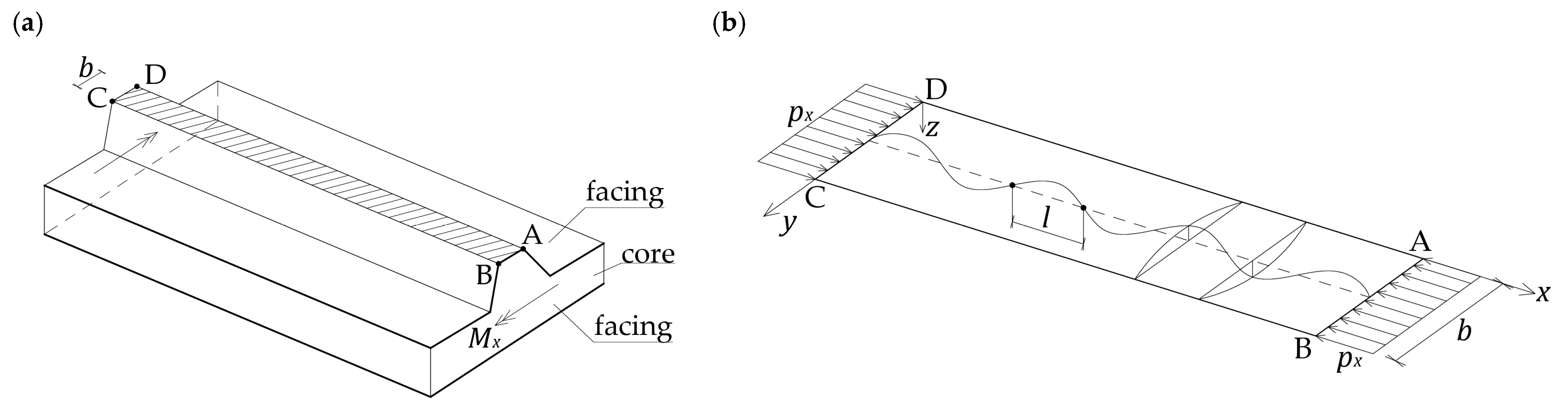

Sandwich panels are a universal solution that combines thermal insulation, lightness, durability, and quick installation. These types of elements are widely used in construction and many other industries, including aviation, space, and automotive. An example of a sandwich panel used for roofing is shown in

Figure 1.

The sandwich elements can fail in various ways, but their load-bearing capacity is most commonly limited by local instability, often in the form of wrinkling of the compressed facing. The compressive stress may result from axial compression, bending moments, or thermal effects. Accurately determining the panel’s load-bearing capacity requires identification of the critical stress level at which wrinkling occurs.

For decades, researchers have been studying how to predict wrinkling stress in sandwich structures. This is a crucial issue because it plays a critical role in ensuring structural stability. One of the earliest analytical solutions was proposed in [

1], where the energy method and a linear decay function were used to describe the core deformation. This approach was developed in [

2] by introducing an exponential decay function along the core thickness. The local buckling problem was solved here for both 2D and 3D problems, but the facing deformation function in each direction was sinusoidal. In [

3], a different approach was used, involving modeling the wrinkling problem using differential equations. The 2D problem was solved by applying the Airy stress function.

The classical approaches presented above are still used and have been extended to more complex problems. The issue of wrinkling of sandwich panels with composite facings under biaxial load was investigated in [

4]. The local instability of a thin orthotropic layer was analyzed in [

5]. The effects of anisotropy and multiaxial loading on the wrinkling of sandwich panels were discussed in [

6]. Another interesting problem is local instability in the case of a bi-modular core [

7]. The stiffness of such a core differs in tension and compression, which obviously affects the structure’s behavior. The effect of transverse core compressibility was considered in [

8], where the static and dynamic responses of layered structures, including the wrinkling phenomenon, were examined. A similar problem concerning local dynamic instability, i.e., large-amplitude, small-wavelength lateral vibrations, was addressed in [

9], where the criterion for the onset of dynamic wrinkling and a critical value of the facing damping coefficient were presented for the elastic foundation model. The damping of sandwich composites, expressed as the logarithmic decrement, damping ratio, and loss factor, can be determined experimentally using the free vibration decay effect, evaluated using the logarithmic decrement and half-power bandwidth methods [

10].

The application of the extended high-order sandwich panel theory to the problem of sandwich panels wrinkling was presented in [

11]. The authors demonstrated good agreement between the theoretical and experimental results. The behavior of structures with a functionally graded core material in the context of local instability was analyzed in [

12]. A new method for predicting the wrinkling stress in sandwich panels was proposed in [

13]. This method can be easily applied to compute the wrinkling stress of panels with functionally graded material cores.

Scientific research on the wrinkling of thin facings is still of great interest because the problem of local instability is important in many applications. The issue of local buckling in the context of using sandwich panels in light aviation was discussed in [

14], where among other things, experimental methods and failure scenarios were examined. The analysis of sandwich structures, which have been widely applied in the wings and horizontal tails of aircraft, was presented in [

15]. The study proposed a reasonable strategy for resisting wrinkling deformation of sandwich structures. New applications of sandwich structures often necessitate the development of new materials or structural solutions. In [

16], structures made of unidirectional carbon/epoxy facings and aluminum honeycomb and closed-cell polyvinylchloride foam cores were studied. The experimental results confirmed that wrinkling failure is prevalent in cases of low through-thickness stiffness and long beam spans. According to [

17,

18], the influence of production parameters and operating conditions necessitates extensive experimental studies to accurately predict sandwich panel damage, enabling the reliable application of advanced models and failure criteria.

Slightly different structures, namely those made of printed polylactic acid, were studied in [

19]. Three honeycomb core topologies were subjected to bending: conventional, re-entrant auxetic, and chiral. Different failure mechanisms were identified for each of these structures, including local loss of stability. The problem of the compression behavior of sandwich elements was also discussed in [

20]. In this case, an aluminum honeycomb structure filled with ethylene vinyl acetate copolymer foam was investigated.

Both new applications of sandwich panels and the introduction of new material solutions require detailed strength analyses. This is particularly applicable to products manufactured on a large scale. This article addresses the problem of damage to the facings of deep-profiled panels. The inspiration for conducting this research was the expectations of sandwich panel manufacturers regarding the effectiveness of introducing deep-profiled facings. The solution presented in this paper considers the impact of all the most significant parameters of sandwich panels on the wrinkling of the metal facing when it rests on a 3D core. A novelty in relation to previous theoretical solutions is the use of a two-dimensional model of the facing (band) with the simultaneous possibility of introducing various boundary conditions (including elastic support) on the longitudinal edges of this band. Previous classical solutions [

1,

2,

3] were based exclusively on the sine deformation function. The introduction of different support conditions necessitates the use of different functions, and the corresponding critical loads (and stresses) differ significantly from those presented in previous solutions, as discussed in this paper.

2. Formulation of the Problem

The sandwich panel shown in

Figure 1 is typically used as a roof covering element placed on purlins. In such cases, the panel is subjected to loads including its own weight, wind and snow actions, and, importantly, various thermal impacts. As a result of these loads, a complex state of stress develops in each component of the sandwich panel (top face, core, and bottom face). In the case of tension or compression, it dominates along the direction of the panel, and this results from the bending of the sandwich panel. The purpose of the core is to transfer shear stresses and ensure cooperation between the facings.

This article focuses on the deep-profiled facing (top facing in

Figure 1). When the facing is stretched, its load-bearing capacity is relatively high. When the facing is compressed, the problem of local instability occurs. This is due to the high slenderness of the element. The typical thickness of the facing is 0.5 mm, whereas the span of the panel is approximately 3 m. It is also noteworthy that bending the panel shown in

Figure 1 produces the highest stresses in regions furthest from the center of the neutral plane. Specifically, in the case of a deep-profiled facing, this stress occurs in the narrow ridge bands. One such band is marked in

Figure 2a (band ABCD).

In this paper, the case of a perfectly flat band ABCD, which is uniformly unidirectionally compressed in its plane, is considered. It is assumed that this band rests on an infinite core. Although this assumption may seem controversial at first, numerous studies have confirmed that core deformations disappear very quickly across their thickness. From a practical point of view, it can be assumed that deformations at a depth greater than 2 cm measured from the surface of the compressed facing are negligible [

21,

22].

As a result of uniaxial compression of the ABCD band of width

, at a specific load

, local instability occurs, exhibiting the form of periodic wrinkling in the

x-direction (

Figure 2b). The edges of the band limit the form of deformation in the

y-direction. The critical load

is sought, which causes wrinkling of the facing. Determining this load is essential because the wrinkling phenomenon is the primary failure mechanism of a sandwich panel. The key issue of this study is assessment of the influence of the bandwidth

and support conditions on the longitudinal edges of the analyzed band (BC, AD) on the critical load.

In the analysis, it was assumed that the materials of the facings and the core are homogeneous and that linear constitutive laws are valid. For the sake of generality, it was assumed that the core modulus of elasticity (in the z-direction, which is perpendicular to the facing plane) is independent of the core shear moduli and (moduli in the x-z and y-z planes, respectively). The case of elastic local buckling is considered (small deformations are assumed, and the effect of shortening the compressed element is ignored).

3. Determination of Critical Stress

The energy approach was employed to determine the critical load

and the corresponding critical (wrinkling) stress. As in [

2,

12], core deformations in the longitudinal direction (along the

-direction) were not included in the energy equilibrium equation. The justification for this approach can be found, among other sources, in [

23].

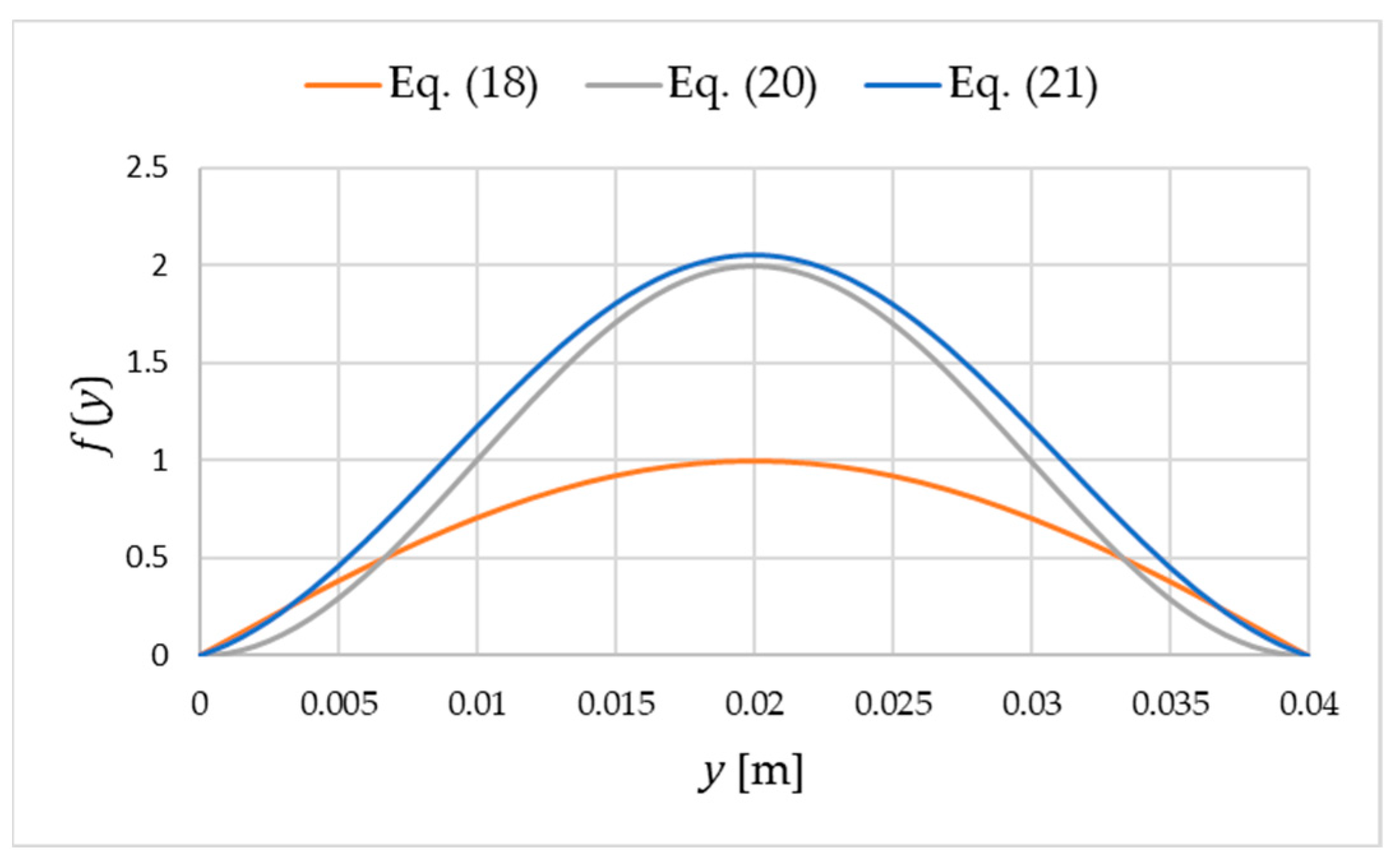

Assume that the facing deformation

has a sinusoidal form in the

x-direction as follows:

where

denotes the amplitude of deformation, and

is the length of the half-wave of the sine function in the

x-direction. The facing band is very long (

Figure 1 and

Figure 2), and the length

is not initially known and will be determined during the assessment of the critical load

. The function

, which represents the variation in deformation in the

y-direction, is given here in an arbitrary form to obtain a potential general solution. The form of the function

should reflect the boundary conditions established for the longitudinal edges of the facing band. In the simplest form, corresponding to a simply supported band,

.

The core deformation

disappears exponentially (

). This justifies the rapid disappearance of these deformations at the core depth:

The following energy balance equation should be satisfied for the system shown in

Figure 2b:

Here, the symbols denote the following:

—the strain energy of the facing due to bending,

—the strain energy of the core,

—the work performed by applied load .

Equation (3) can be written by taking into account the bandwidth

and the half-wavelength

of the sinusoid (increasing the integration length to

does not change the final solution). The strain energy of the facing, which should be treated as a plate, is expressed as follows:

For the facing thickness

, the modulus of elasticity of the facing material

, and the Poisson ratio

, the bending stiffness (per unit width) is expressed as follows:

The work performed by the external load

is expressed as follows:

The strain energy of the core consists of three terms corresponding to the

z-direction deformation and two shear deformations is expressed as follows:

The normal stress

and the shear stresses

and

in the core can be expressed using partial derivatives of Equation (2) as follows:

After substituting Equations (4)–(10) into Equation (3) and several transformations, an expression for the load

is obtained:

in which,

The condition for such a simplified solution is as follows:

To satisfy condition (15), it is sufficient for the function or its first derivative to be zero at the edges of the facing band, which aligns with expected boundary behavior. Of note, the terms , , and have different units: [m], [m−1], and [m−3].

In Equation (11), aside from the material constants and the expressions that depend on the assumed function

, there are only two unknowns, namely

and

. The critical load is obtained by simultaneously satisfying two equations representing the optimal conditions:

If the parameters

and

are determined from Equation (16), the critical stress is obtained from (11), and the corresponding wrinkling stress is expressed as follows:

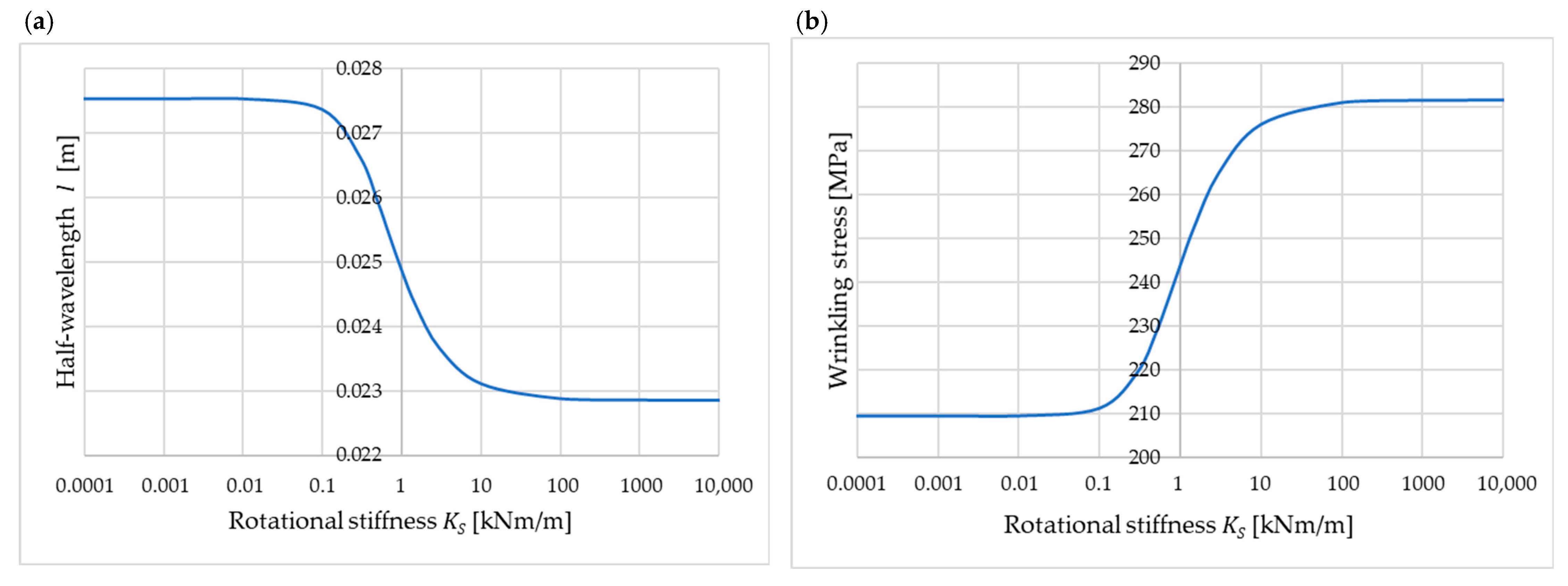

The presented solution to the problem is easy to apply. The general form of allows for the analysis of the influence of different stiffnesses of the support for the facing band on the value of the wrinkling stress. Thus, one can obtain, among other things, the upper limit of critical stress, which is of great importance when making decisions regarding changes in the sandwich panel production program.

The presented approach is limited by the assumptions presented in

Section 2. In the case of continuous core inhomogeneities located near the facing, this approach can be further developed as presented for the 2D problems in [

22] or [

23]. In the case of local delamination, the presented approach is inefficient; in such situations, 3D numerical models with definitions of damage initiation and stiffness degradation can be used.

5. Conclusions

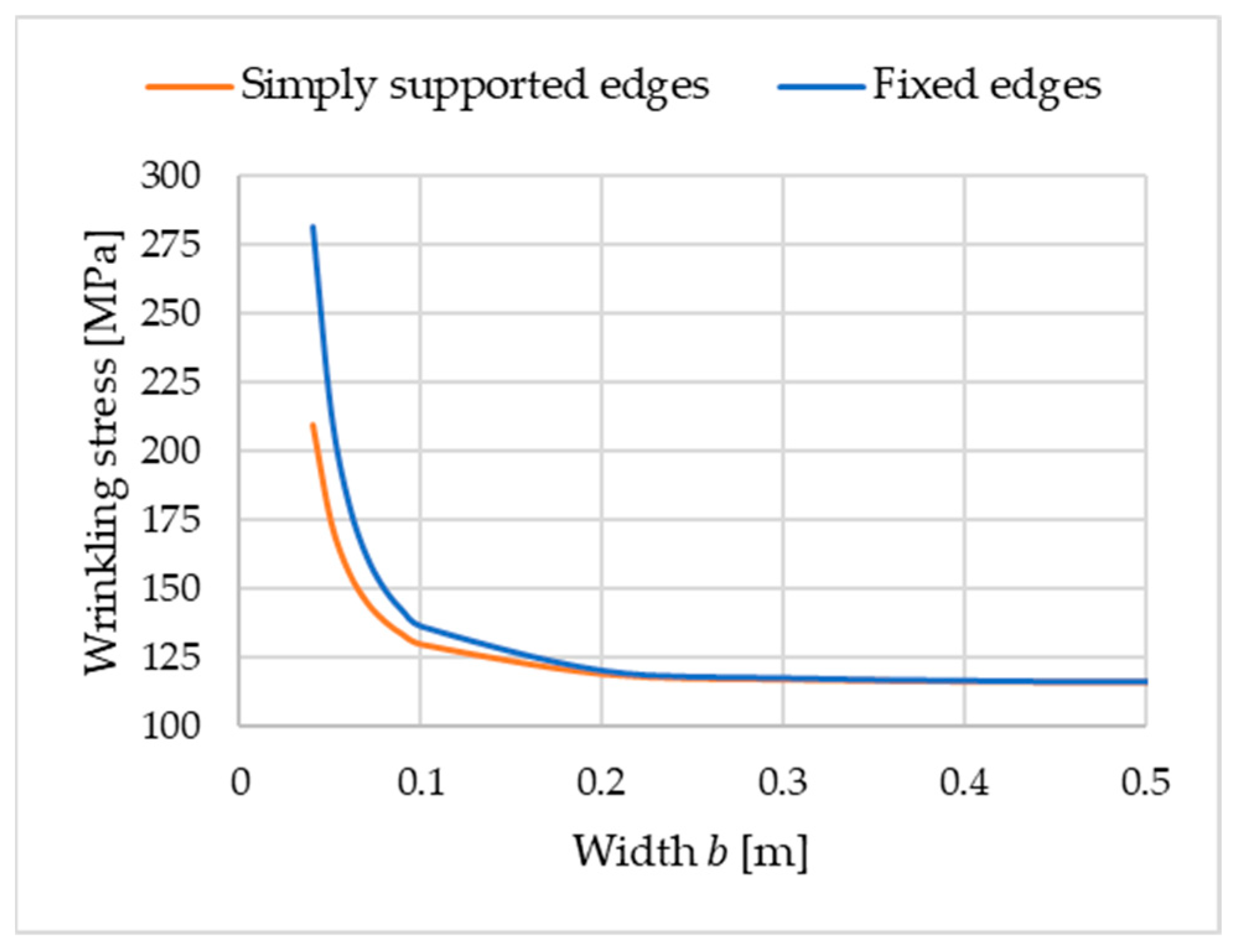

The problem of local instability (wrinkling) of the facing band of a sandwich panel was analyzed in this study. The facing band rests on a shear-deformable core and can be considered supported at its edges due to the deep profiling of the facing. Both the support of the band on the core and the support of the band edges stabilize the band deformations. In this study, the case of uniaxial compression of the facing band, which is caused by typical mechanical actions, was considered.

In the first part of this paper, an energy approach was applied to the problem. This enabled the determination of the compressive load function of the facing band and the evaluation of optimal conditions for evaluating the wrinkling stress. The solution was presented in a general form for an arbitrary function describing the deformation of the facing band. The solution was obtained by assuming elastic local buckling. In cases of complex postcritical behavior or the occurrence of plastic flow effects, a more advanced model should be employed.

In the next stage of considerations, the derived equations were used, and exemplary solutions for the basic forms of the deformation function were presented. The presented theoretical approach enabled us to demonstrate that a significant increase in wrinkling stresses occurs for a bandwidth of less than 0.10 m. In addition, values corresponding to different support conditions of the band were obtained because the range of wrinkling stresses obtained in practice was known. To the authors’ knowledge, the results presented have not been previously obtained based on theoretical considerations.

Based on the derived equations, an analysis of the wrinkling stress variation as a function of the change in the facing thickness and parameters describing the core stiffness was performed. One observation is that wrinkling stress increases strongly with increasing thickness of the facing. This relationship, although logical, is inconsistent with the current normative provisions concerning sandwich panels.

The considerations presented in the article explain the issue of the influence of bandwidth on wrinkling stress. The derived equations can be directly used when planning a change in the production program of sandwich panels. The analyses presented indicate both the real possibilities of improving the load-bearing capacity of sandwich panels and the limitations related to increasing this capacity.