Combinatorial Enhancement of Aging Resistance in High-Content Crumb Rubber Asphalt via Warm-Mix Additives: Rheological and Microstructural Insights

Abstract

1. Introduction

2. Materials and Research Methodologies

2.1. Raw Materials

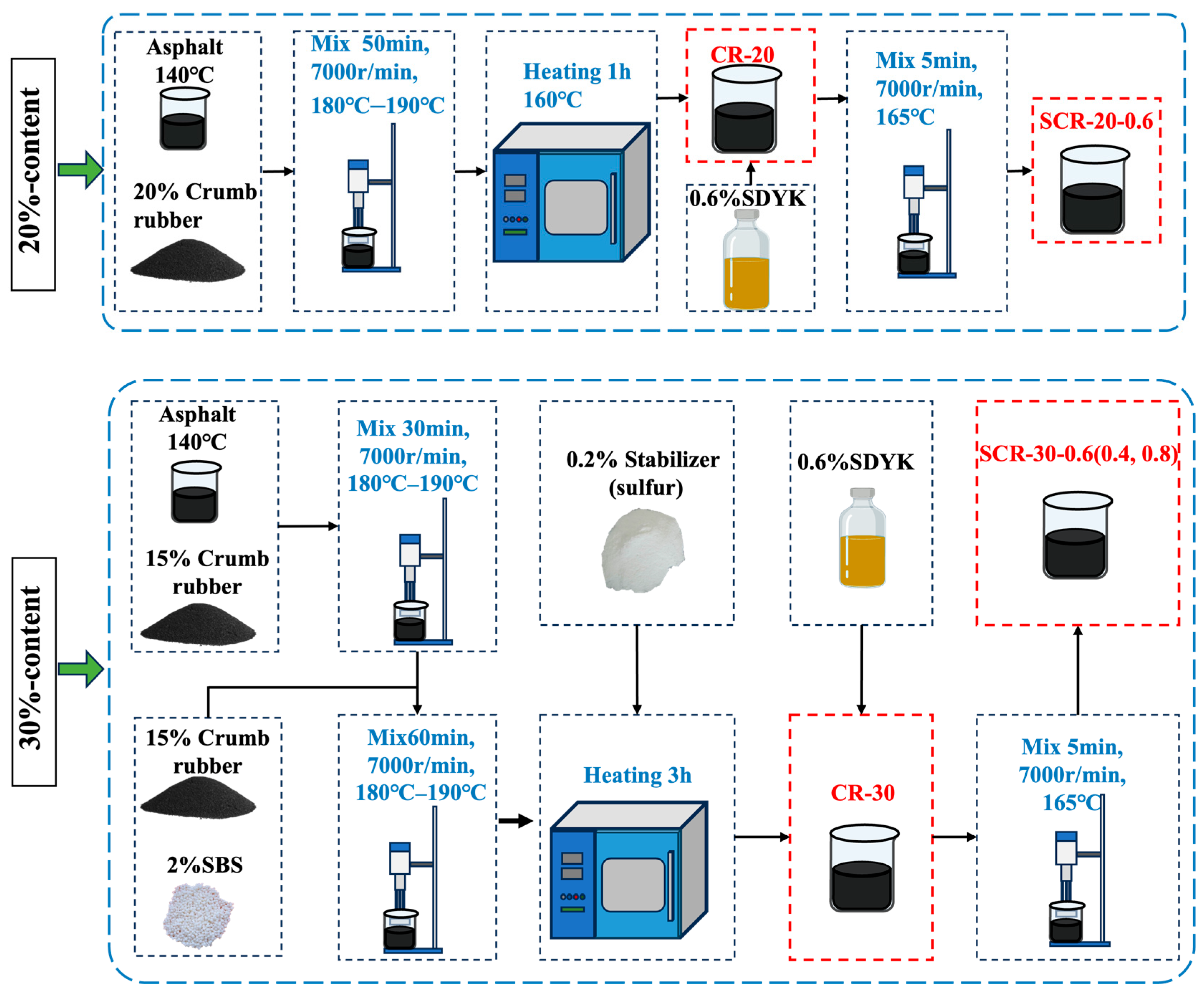

2.2. Experimental Design

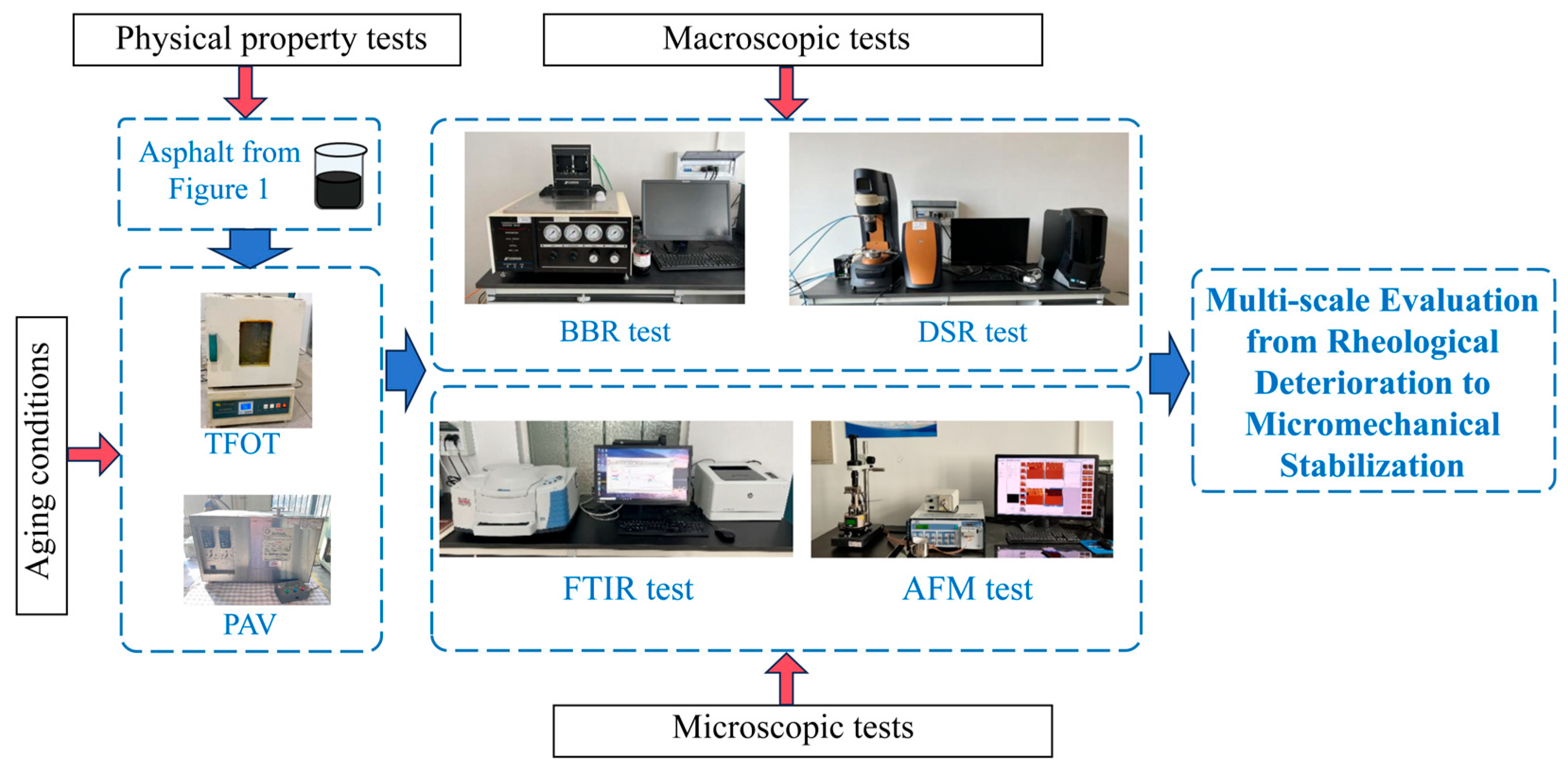

2.3. Research Methodologies

2.3.1. Physical Property of Asphalt

2.3.2. Accelerated Aging in Laboratory

2.3.3. Dynamic Shear Rheological Test

2.3.4. Bending Beam Rheological Test

2.3.5. Fourier Transform Infrared Spectroscopy Test

2.3.6. Atomic Force Microscope Test

3. Results and Discussion

3.1. Optimization of Warm-Mixing Agent

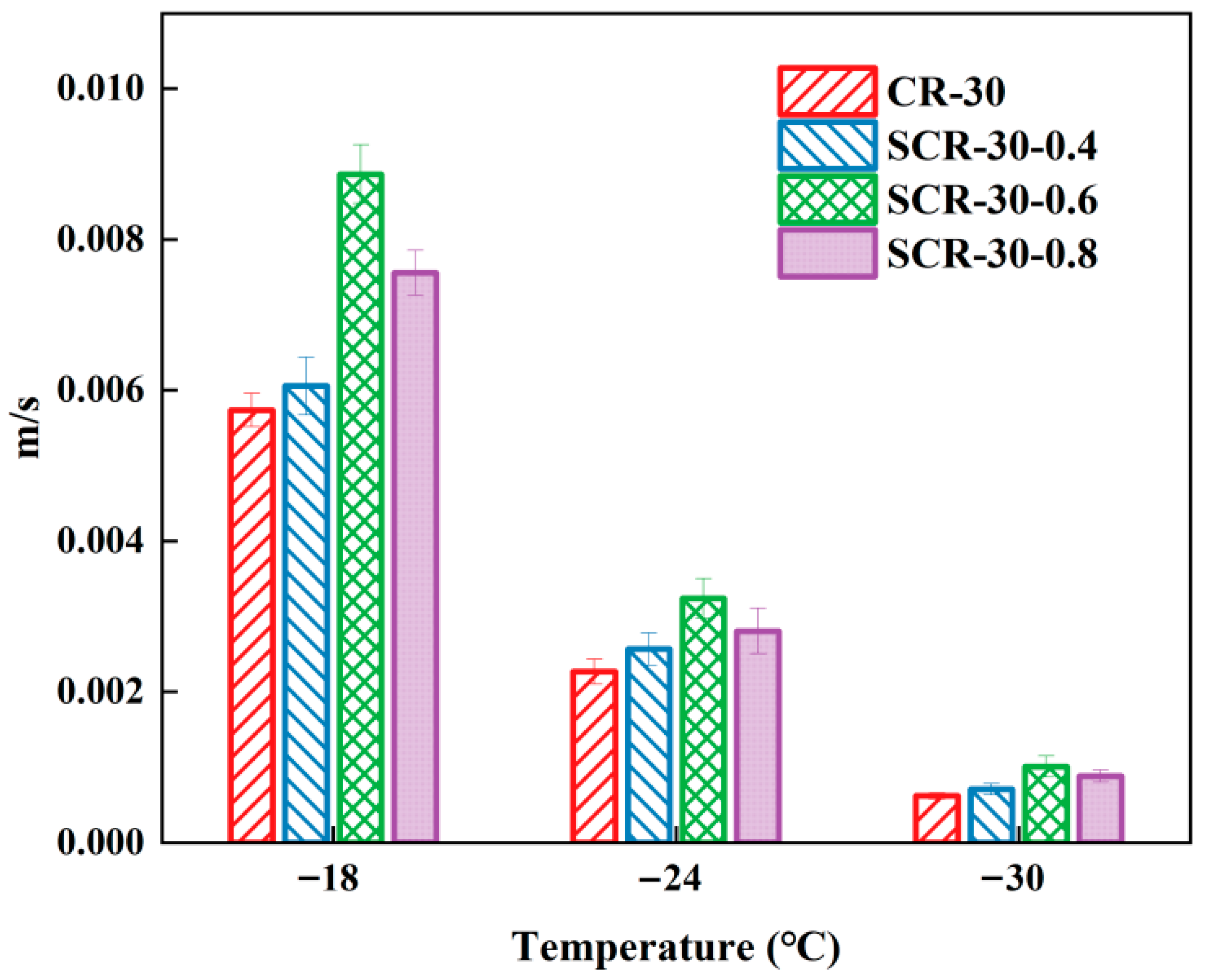

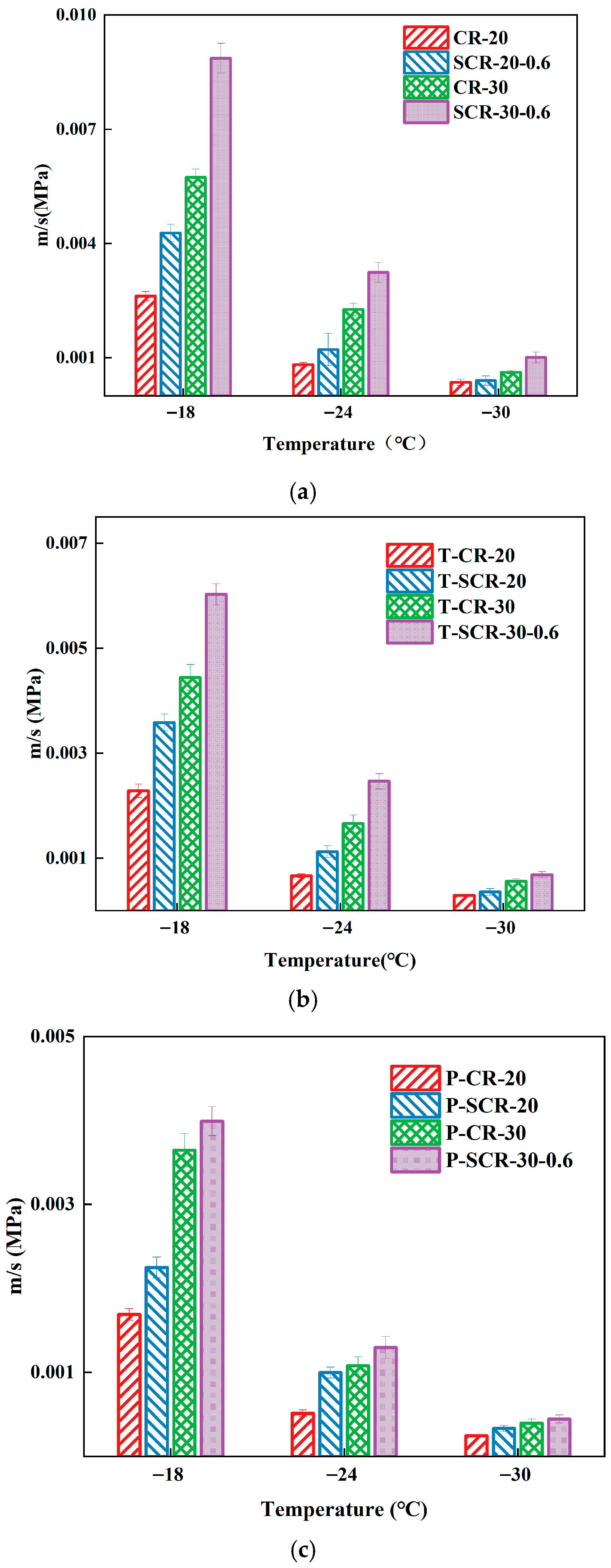

3.2. Improvement of Cracking Resistance

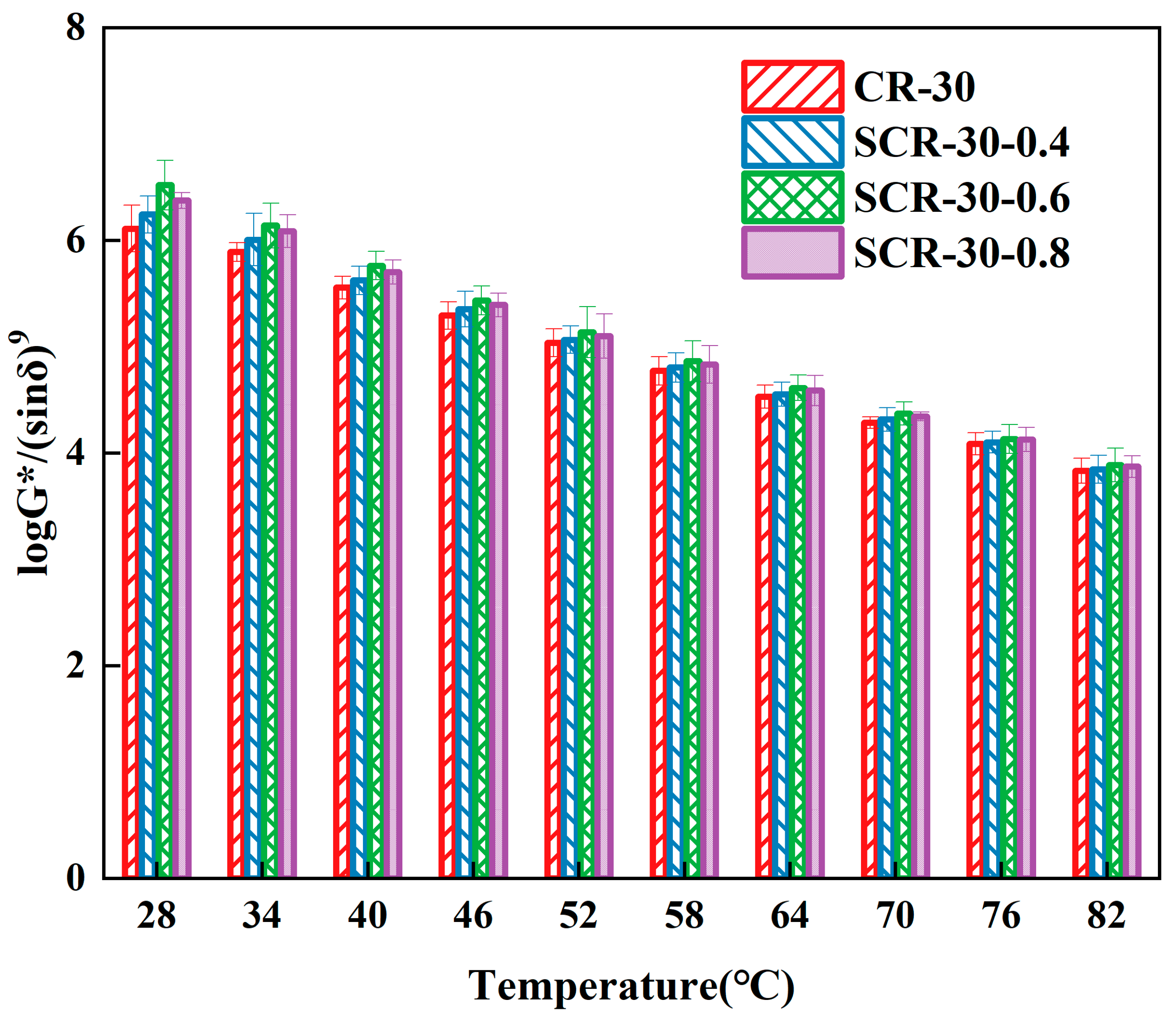

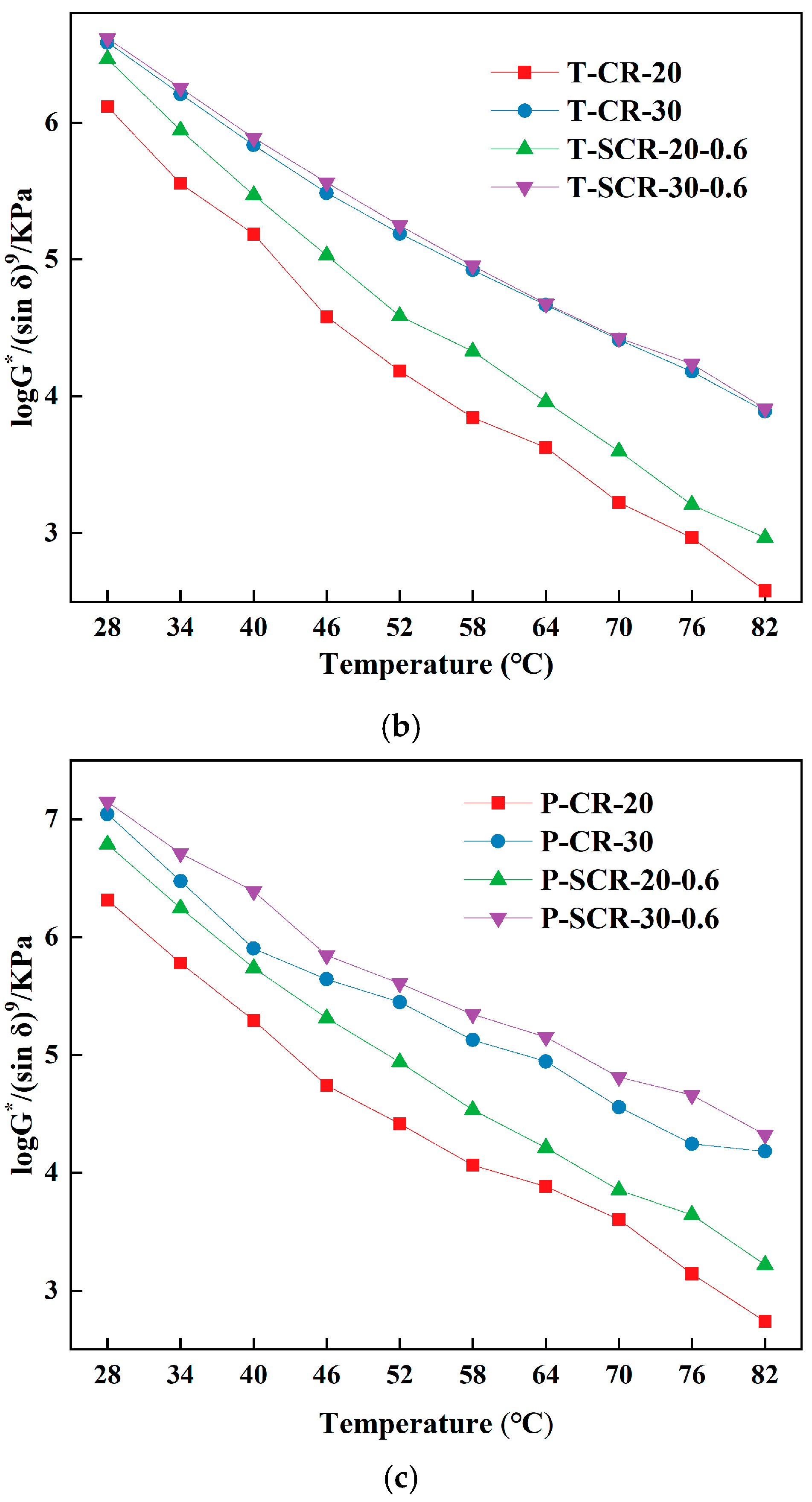

3.3. Improvement of Rutting Resistance

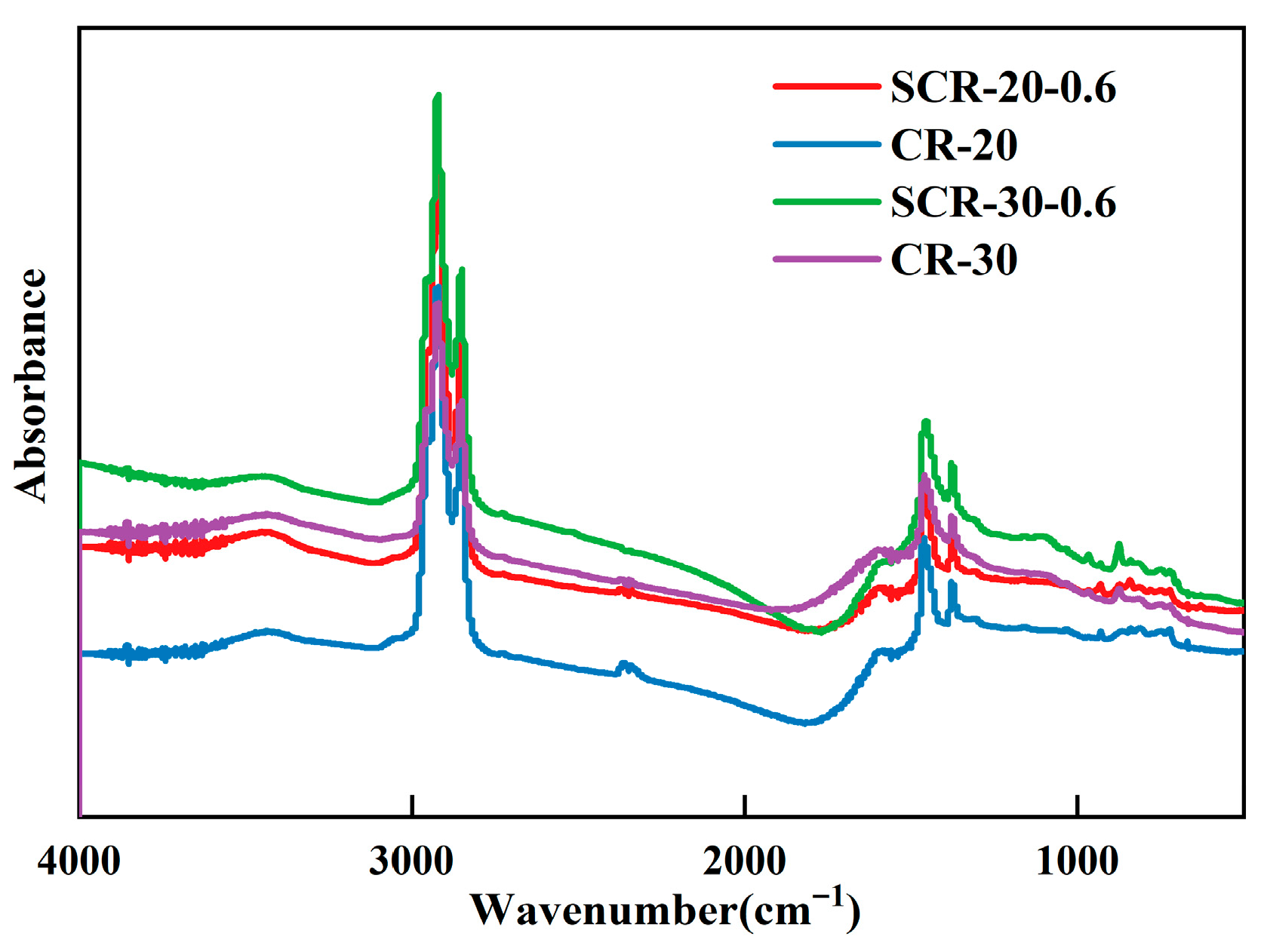

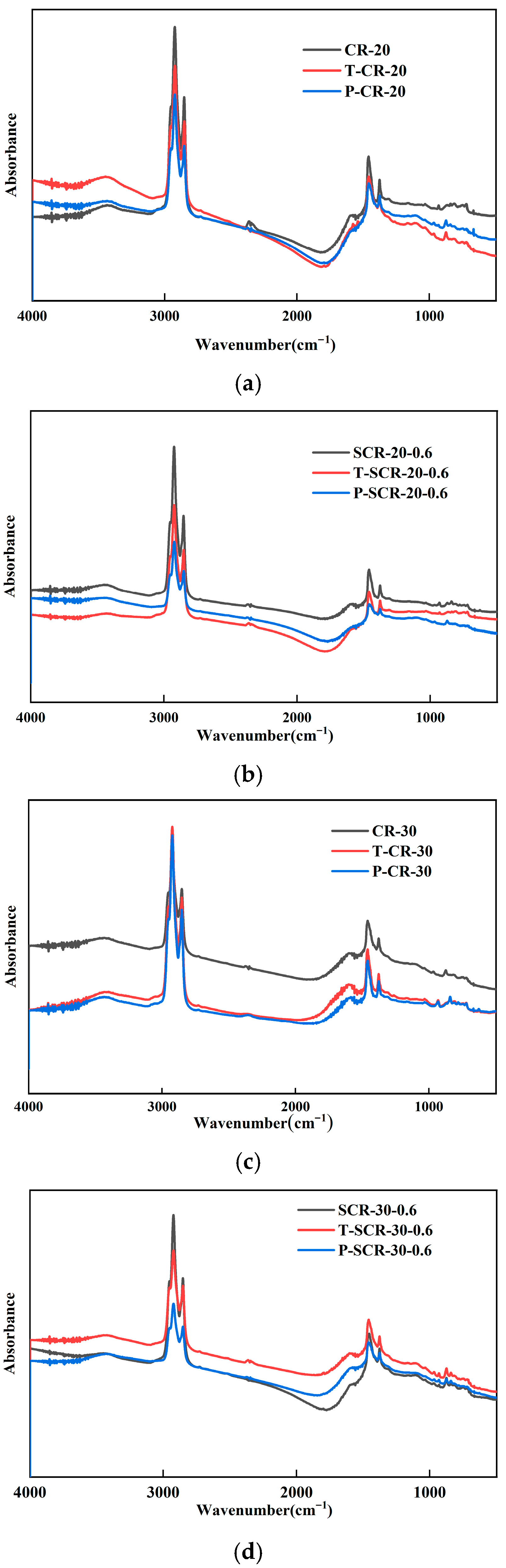

3.4. Quantitative Characterization of Chemical Functional Groups

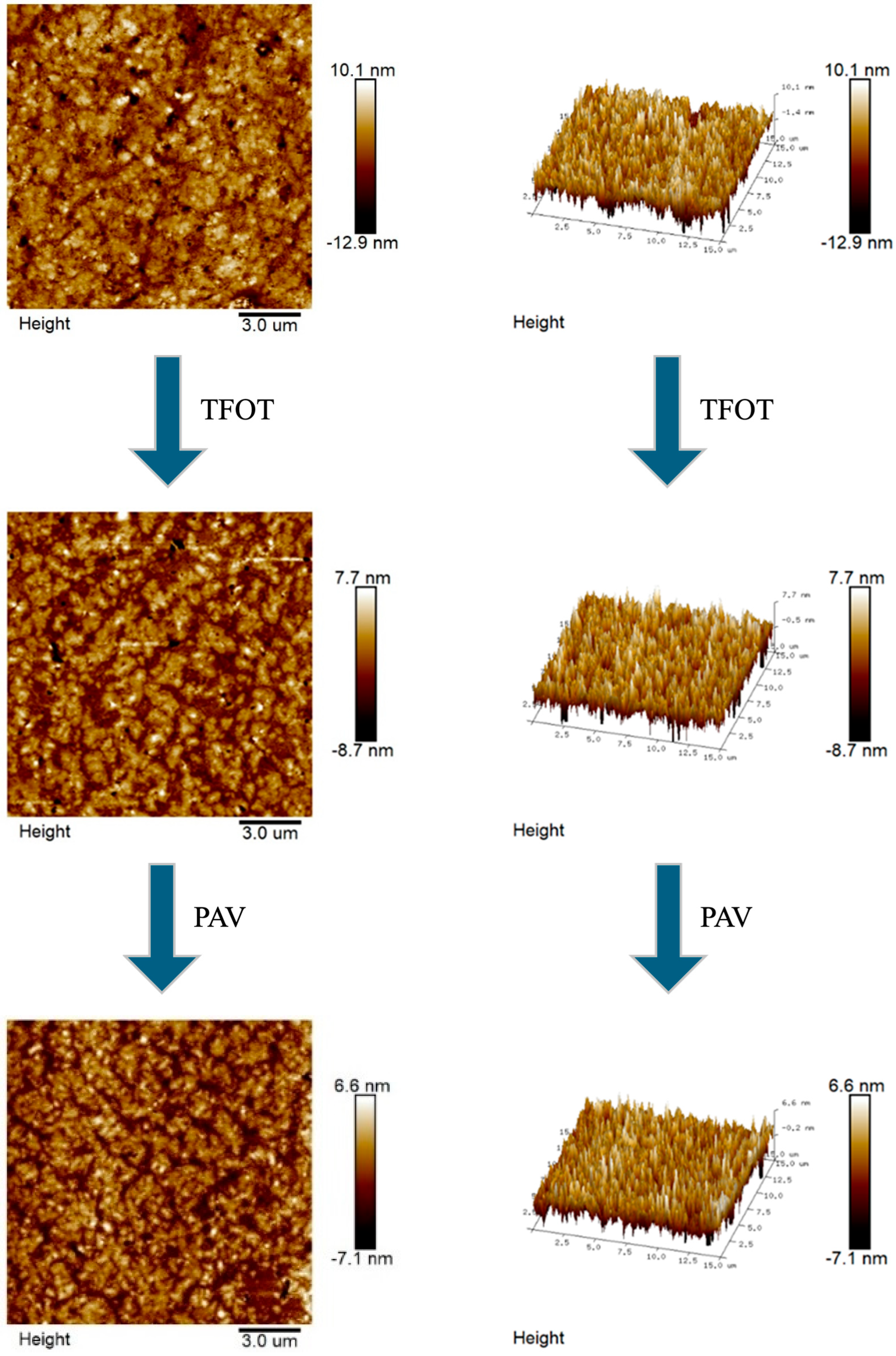

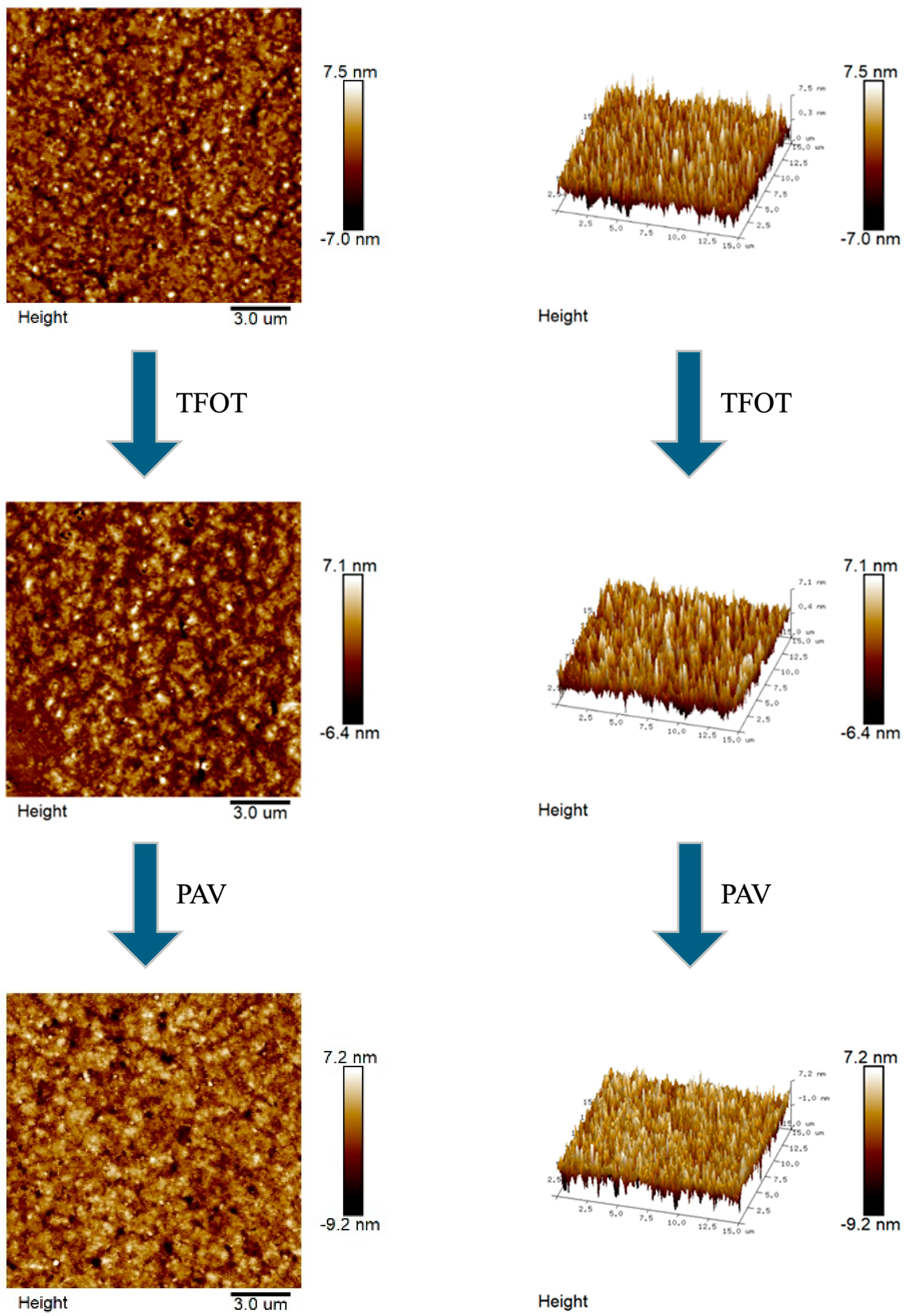

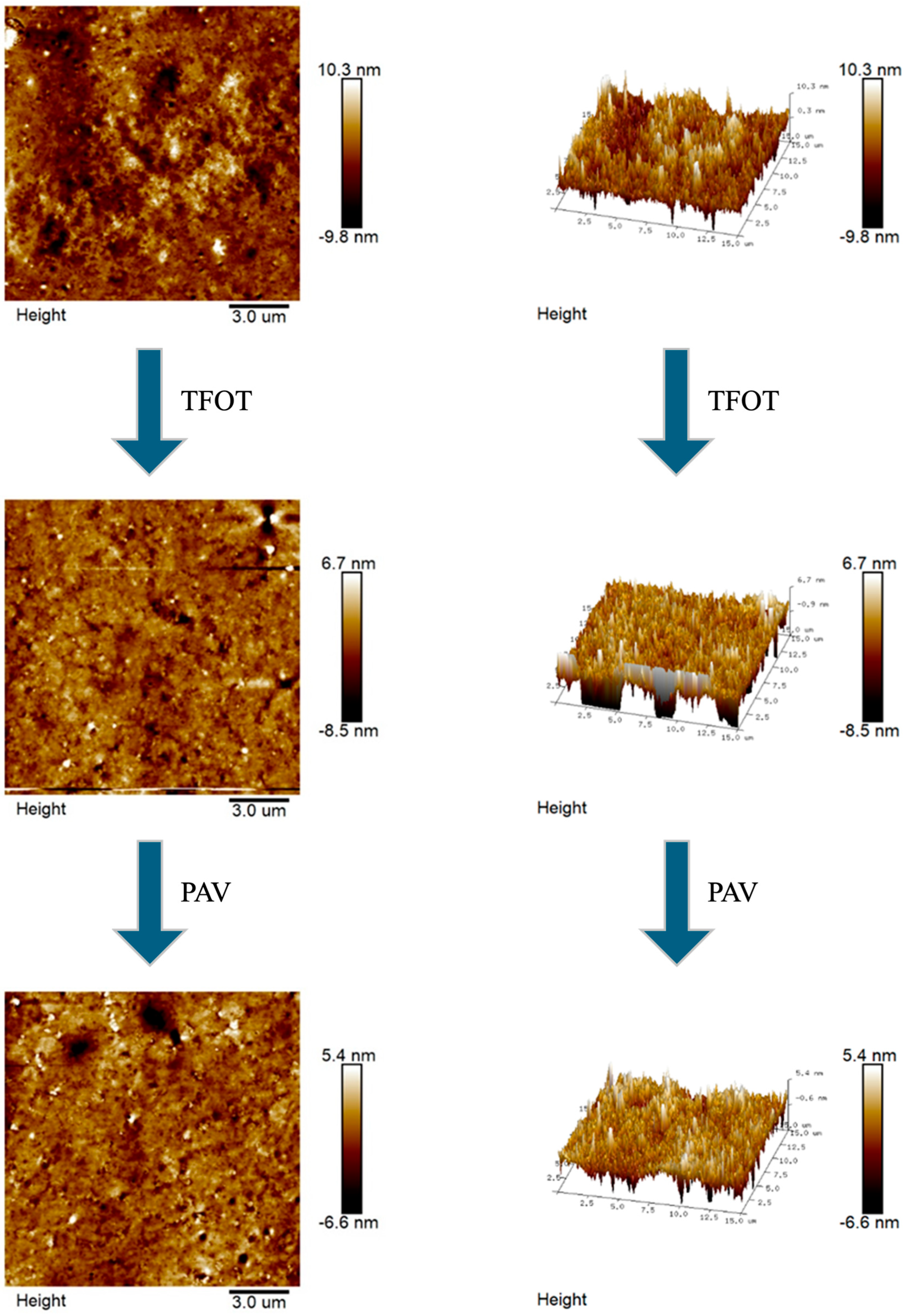

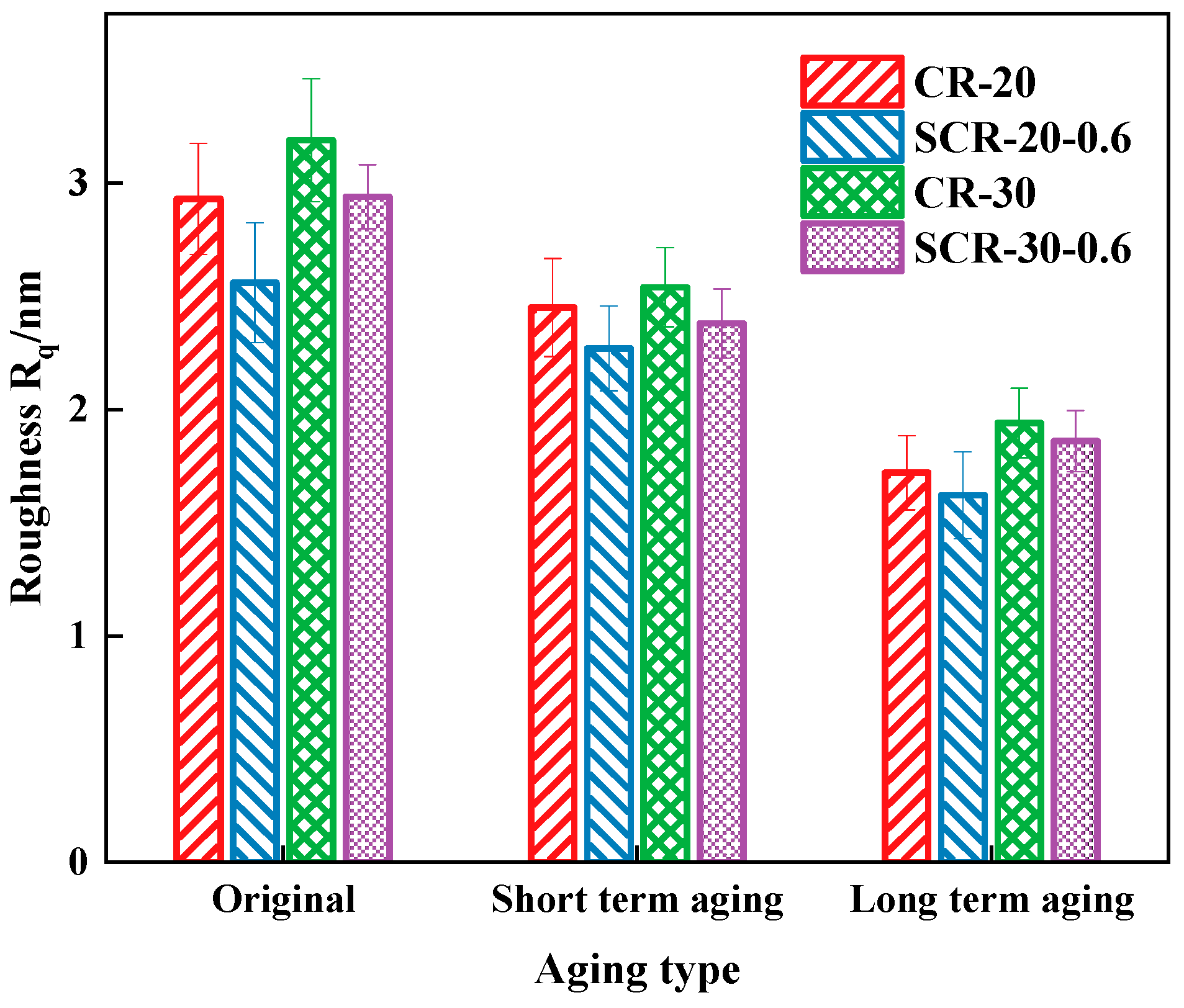

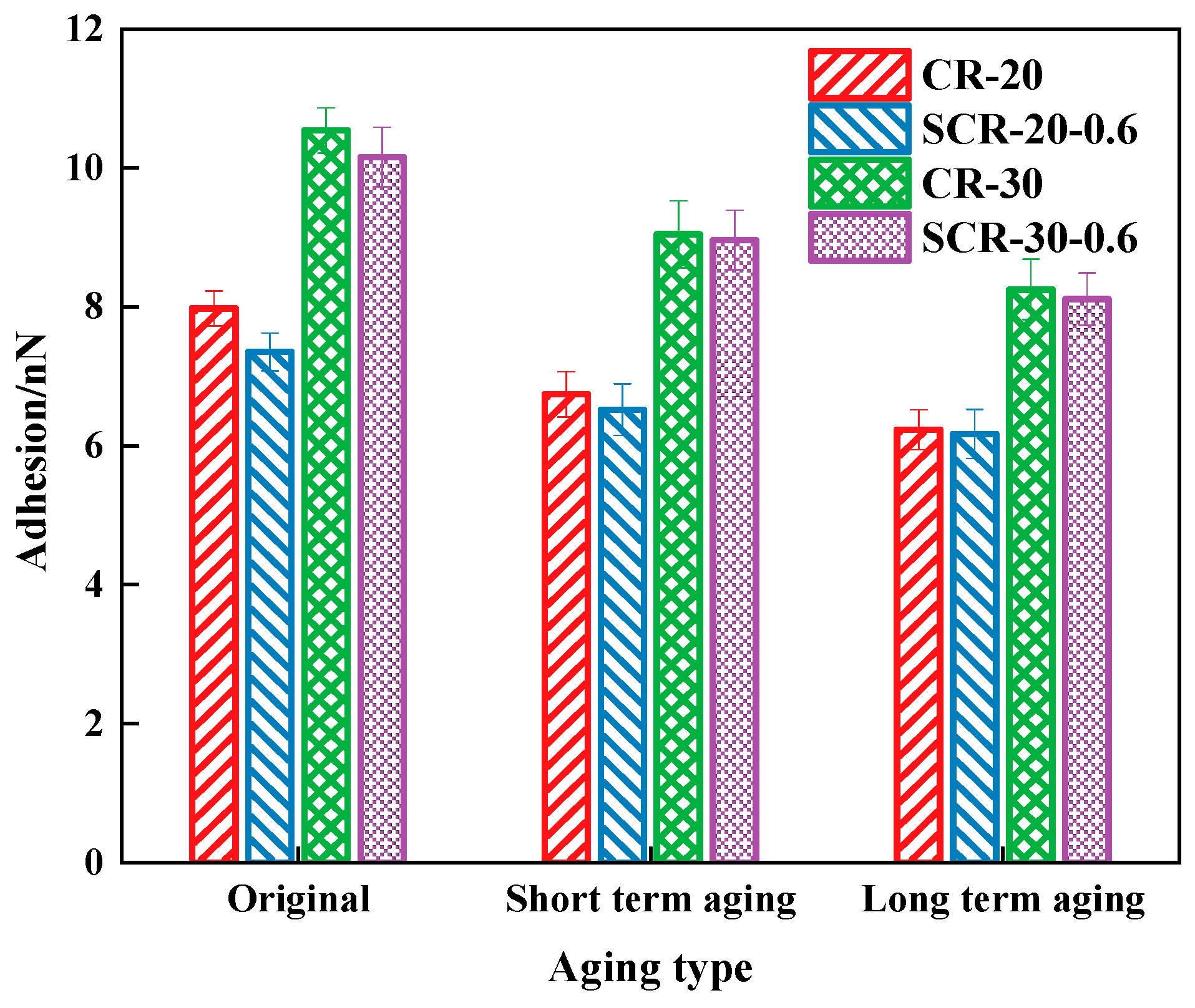

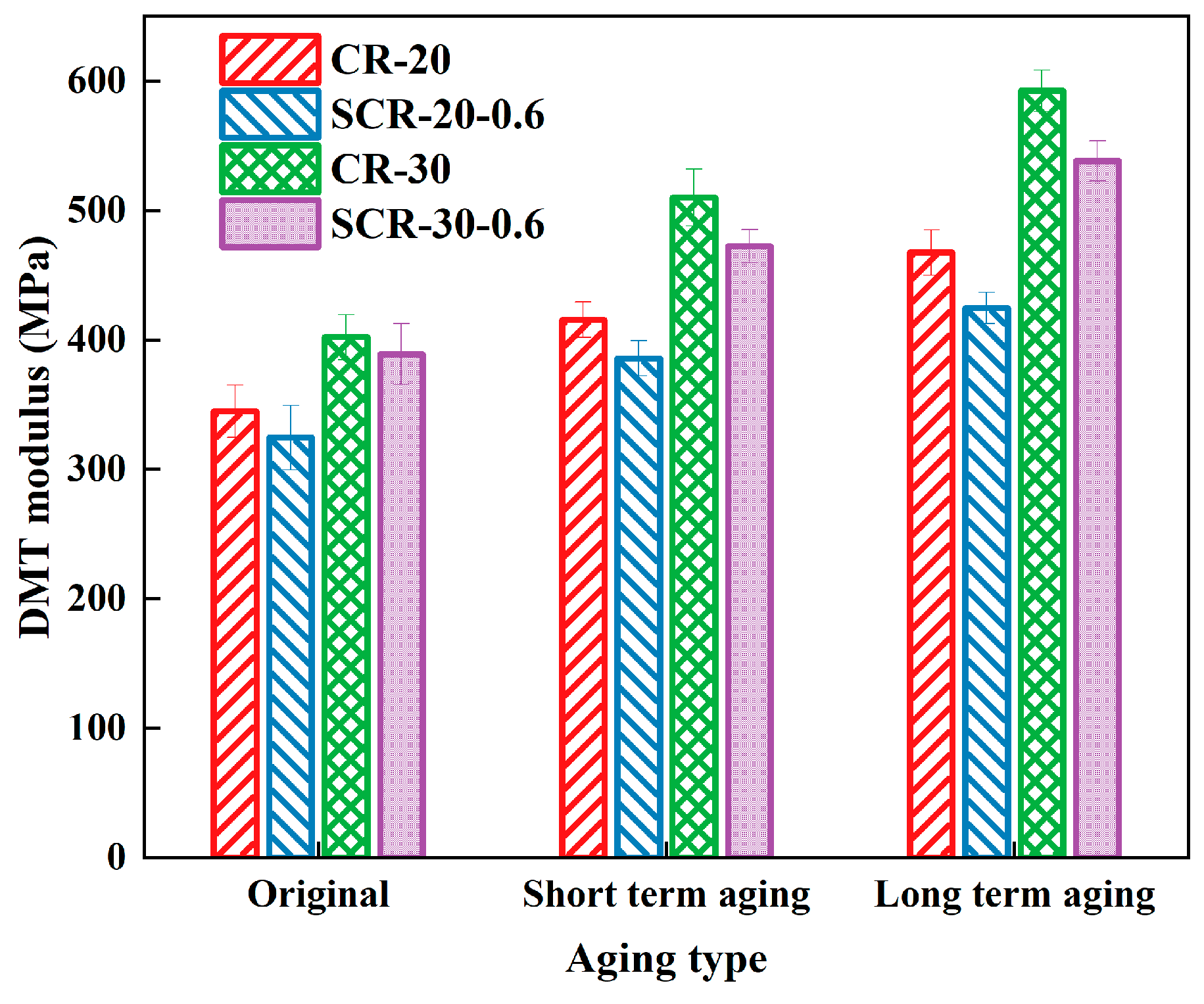

3.5. Nanoscale Morphology and Mechanical Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dong, F.; Jiang, Y.; Yu, X.; Jin, Y.; Lu, J.; Zhushen, Y.; Lu, H. Reconstruction of crosslinked network in terminal blend rubber powder modified asphalt with BR to enhance thermal storage stability and rheological properties. Constr. Build. Mater. 2025, 458, 139751. [Google Scholar] [CrossRef]

- Zhang, M.; Cao, D.; Huang, X.; Wang, G. Evaluation and characterization of rubber powder distribution on the ductility of rubber asphalt from the mesoscopic view. Mater. Lett. 2025, 379, 137627. [Google Scholar] [CrossRef]

- Zhao, W.; Niu, Y.; Geng, J.; Li, X.; He, Z. A review of sulfidation gases test methods, generation mechanism, and suppression deodorants of crumb rubber modified asphalt. Fuel 2025, 385, 134161. [Google Scholar] [CrossRef]

- Ni, N.; Tang, J.; Li, M.; Zhang, L.; Yuan, H. Study of the Rheological Properties of Rubberized Asphalt Mortar: Mechanisms of Action of Rubber Powder and Filler–Binder Ratio. Buildings 2024, 15, 107. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Y.; Yang, F.; Zhang, M.; Jing, H.; Li, Z.; Bature, A.I.; Ma, Q. Effect of spatial distribution of rubber powder on ductility of rubber asphalt from mesoscopic mechanical perspective: For bio-based materials recycling. Ind. Crops Prod. 2024, 222 Pt 5, 120103. [Google Scholar] [CrossRef]

- Yu, S.; Chen, F.; Hu, D.; Cao, D.; Liu, C.; Wang, Q.; Zhang, Y.; Yalikun, N. Effect of hydrogen peroxide oxidation waste rubber powder on asphalt compatibility. Constr. Build. Mater. 2024, 453, 139074. [Google Scholar] [CrossRef]

- Dalhat, M.A.; Al-Adham, K. Review on laboratory preparation processes of polymer modified asphalt binder. J. Traffic Transp. Eng. 2023, 10, 159–184. [Google Scholar] [CrossRef]

- You, L.; Li, X.; Zhu, X.; Si, C.; Long, Z.; Diab, A.; You, Z.; Awed, A.M. Stabilization mechanism and rheological properties of sustainable cold-mixed high rubber content emulsified asphalt. Constr. Build. Mater. 2024, 450, 138620. [Google Scholar] [CrossRef]

- Yang, C.; Wu, S.; Cui, P.; Amirkhanian, S.; Zhao, Z.; Wang, F.; Zhang, L.; Wei, M.; Zhou, X.; Xie, J. Performance characterization and enhancement mechanism of recycled asphalt mixtures involving high RAP content and steel slag. J. Clean. Prod. 2022, 336, 130484. [Google Scholar] [CrossRef]

- Nanjegowda, V.H.; Biligiri, K.P. Utilization of high contents of recycled tire crumb rubber in developing a modified-asphalt-rubber binder for road applications. Resour. Conserv. Recycl. 2023, 192, 26. [Google Scholar] [CrossRef]

- Tahami, S.A.; Mirhosseini, A.F.; Dessouky, S.; Mork, H.; Kavussi, A. The use of high content of fine crumb rubber in asphalt mixes using dry process. Constr. Build. Mater. 2019, 222, 643–653. [Google Scholar] [CrossRef]

- Al-Khateeb, G.G.; Ramadan, K.Z. Investigation of the effect of rubber on rheological properties of asphalt binders using superpave DSR. Ksce J. Civ. Eng. 2015, 19, 127–135. [Google Scholar] [CrossRef]

- Zhou, T.; Zhou, J.; Li, Q.; Li, B. Aging Properties and Mechanism of Microwave-Activated Crumb Rubber Modified Asphalt Binder. Front. Mater. 2020, 7, 603938. [Google Scholar] [CrossRef]

- Ibrahim, I.M.; Fathy, E.S.; El-Shafie, M.; Elnaggar, M.Y. Impact of incorporated gamma irradiated crumb rubber on the short-term aging resistance and rheological properties of asphalt binder. Constr. Build. Mater. 2015, 81, 42–46. [Google Scholar] [CrossRef]

- Cong, P.; Hao, H.; Luo, W. Investigation of Carbonyl of Asphalt Binders Containing Antiaging Agents and Waste Cooking Oil Using FTIR Spectroscopy. J. Test. Eval. 2019, 47, 20180146. [Google Scholar] [CrossRef]

- Ilyin, S.O.; Arinina, M.P.; Mamulat, Y.S.; Malkin, A.Y.; Kulichikhin, V.G. Rheological properties of road bitumens modified with polymer and solid nanosized additives. Colloid J. 2014, 76, 425–434. [Google Scholar] [CrossRef]

- Johnson, J.L.; German, R.M. Phase equilibria effects on the enhanced liquid phase sintering of tungsten-copper. Metall. Trans. A 1993, 24, 2369–2377. [Google Scholar] [CrossRef]

- Fan, Y.; Sun, L.; Duan, D.; Zhang, B.; Wang, G.; Zhang, S.; Yu, W. Enhancing the Storage Stability and Rutting Resistance of Modified Asphalt through Surface Functionalization of Waste Tire Rubber Powder. Appl. Sci. 2024, 14, 4195. [Google Scholar] [CrossRef]

- Wen, Y.; Liu, Q.; Chen, L.; Pei, J.; Zhang, J.; Li, R. Review and comparison of methods to assess the storage stability of terminal blend rubberized asphalt binders. Constr. Build. Mater. 2020, 258, 119586. [Google Scholar] [CrossRef]

- Ji, Z.; Wang, Z.; Feng, L.; He, P.; Li, S. Chemical and Rheological Evaluation of the Ageing Behaviour of High-Content Crumb Rubber Asphalt Binder. Polymers 2024, 16, 3088. [Google Scholar] [CrossRef]

- Ju, Z.; Ge, D.; Lv, S.; Jin, D.; Xue, Y.; Xian, J.; Zhang, W. Performance evaluation of bio-oil and high rubber content modified asphalt: More effective waste utilization. Case Stud. Constr. Mater. 2024, 21, e03828. [Google Scholar] [CrossRef]

- Nanjegowda, V.H.; Biligiri, K.P. Recyclability of rubber in asphalt roadway systems: A review of applied research and advancement in technology. Resour. Conserv. Recycl. 2020, 155, 104655. [Google Scholar] [CrossRef]

- Huang, Y.; Long, K.; Qu, C.; Yan, C.; Ai, C.; Zhou, S. Evaluation of terminal blend rubberized asphalt incorporating high crumb rubber content. Case Stud. Constr. Mater. 2025, 22, e04285. [Google Scholar] [CrossRef]

- Hossain, K.M.Z.; Suhana, K.; Binti, K.H.Y.; Rasdan, I.M.; Mohammed, B.A.; Obada, A. Performance of High Content Reclaimed Asphalt Pavement (RAP) in Asphaltic Mix with Crumb Rubber Modifier and Waste Engine Oil as Rejuvenator. Appl. Sci. 2021, 11, 5226. [Google Scholar] [CrossRef]

- Li, H.; Hao, G.; Feng, Z.; Yang, F.; Guo, P.; Ma, Q.; Yang, J. Investigation of the aggregation behavior of rubber asphalt components induced by short-term Aging: A perspective from molecular dynamic simulations and microscopic tests. J. Mol. Liq. 2024, 414 Pt B, 22. [Google Scholar] [CrossRef]

- Souliman, M.I.; Mamlouk, M.; Eifert, A. Cost-effectiveness of Rubber and Polymer Modified Asphalt Mixtures as Related to Sustainable Fatigue Performance. Procedia Eng. 2016, 145, 404–411. [Google Scholar] [CrossRef]

- Li, F.; Zhang, X.; Wang, L.; Zhai, R. The preparation process, service performances and interaction mechanisms of crumb rubber modified asphalt (CRMA) by wet process: A comprehensive review. Constr. Build. Mater. 2022, 354, 129168. [Google Scholar] [CrossRef]

- Tang, N.; Yang, K.K.; Alrefaei, Y.; Dai, J.G.; Wang, Q. Reduce VOCs and PM emissions of warm-mix asphalt using geopolymer additives. Constr. Build. Mater. 2020, 244, 118338. [Google Scholar] [CrossRef]

- Cui, Y.; Sun, G.; Han, J.; Zhao, L. Microstructure and high-and-low temperature performance of two kinds of asphalt under salt freezing cycle. Acta Mater. Compos. Sin. 2017, 34, 906–914. [Google Scholar]

- Yousefi, A.A.; Underwood, B.S.; Ghodrati, A.; Behnood, A.; Vahidi, E.; Nowrouzi, A.; Ayar, P.; Haghshenas, H.F. Towards a durable and sustainable warm mix asphalt: Techno-economic and environmental evaluation considering balanced mix design approach. J. Clean. Prod. 2025, 486, 144311. [Google Scholar] [CrossRef]

- Wang, G.; Wang, X.; Lv, S.; Qin, L.; Peng, X. Laboratory Investigation of Rubberized Asphalt Using High-Content Rubber Powder. Materials 2020, 13, 4437. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Weng, Y.; Cai, X.; Li, J.; Xiao, F.; Sun, G.; Zhang, F. Statistical modeling of low-temperature properties and FTIR spectra of crumb rubber modified asphalts considering SARA fractions. J. Clean. Prod. 2022, 374, 134016. [Google Scholar] [CrossRef]

- Zhang, Q. Research on the Rheological and Microstructural Properties of Warm-Mix Crumb Rubber Modified Asphalt Under Aging Conditions. Master’s Thesis, Inner Mongolia University of Technology, Hohhot, China, 2020. [Google Scholar]

- Wang, L.; Li, J.; Gui, W. The influence of surfactants on the high and low temperature performance of warm-mix rubber powder modified asphalt. Mater. Reports 2019, 33, 986–990. [Google Scholar]

- ASTM D5/D5M-2013; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D36/D36M-14(2020); Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D113/D113M-17(2023); Standard Test Method for Ductility of Asphalt Materials. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM D4402-87(2000); Standard Test Method for Viscosity Determinations of Unfilled Asphalts Using the Brookfield Thermosel Apparatus. ASTM International: West Conshohocken, PA, USA, 2000.

- ASTM D1754/D1754M-09; Standard Test Method for Effect of Heat and Air on Asphaltic Materials (Thin-Film Oven Test). ASTM International: West Conshohocken, PA, USA, 2009.

- ASTM D6521-13; Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV). ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM D7552-09; Standard Test Method for Determining the Complex Shear Modulus (G*) of Bituminous Mixtures Using Dynamic Shear Rheometer. ASTM International: West Conshohocken, PA, USA, 2009.

- ASTM D6648-08(2016); Standard Test Method for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR). ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM E1252-98(2021); Standard Practice for General Techniques for Obtaining Infrared Spectra for Qualitative Analysis. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM E2859-11(2017); Standard Guide for Size Measurement of Nanoparticles Using Atomic Force Microscopy. ASTM International: West Conshohocken, PA, USA, 2017.

- Walubita, L.F.; Fuentes, L.; Tanvir, H.; Chunduri, H.R.; Dessouky, S. Correlating the Asphalt-Binder BBR Test Data to the HMA (ML-OT) Fracture Properties. J. Mater. Civ. Eng. 2021, 33, 04021230. [Google Scholar] [CrossRef]

- Min, Z.; Chen, F.; Lu, J.; Li, M.; Shi, Z.; Huang, W. Correlation analysis of evaluation methods and indicators for low-temperature performance of epoxy asphalt. Constr. Build. Mater. 2024, 438, 137287. [Google Scholar] [CrossRef]

- Maccarrone, S.; Holleran, G.; Gnanaseelan, G.P. Properties of Polymer Modified Binders and Relationship to Mix and Pavement Performance (with Discussion and Closure). Asph. Paving Technol. Assoc. Asph. Paving Technol.-Proc. Tech. Sess. 1995, 64, 209–240. [Google Scholar]

- Lan, W.; Qi, Z.; Lei, F. valuation of Rheological and Microscopic Properties of Warm-Mixed Rubber Powder Modified Asphalt. J. Build. Mater. 2020, 23, 1458–1463+1495. [Google Scholar]

- Gui, W.; Liang, L.; Wang, L.; Gao, X.; Zhang, F. Performance evaluation of warm-mixed crumb rubber modified asphalt based on rheological characteristics. Constr. Build. Mater. 2021, 285, 122881. [Google Scholar] [CrossRef]

- Yao, A.; Feng, X.; Li, Y. The high-temperature and low-temperature rheological properties and microscopic mechanisms of high-concentration rubber powder-SBS composite modified asphalt. Chin. Sci. Technol. Pap. 2023, 18, 1340–1345. [Google Scholar]

- Yao, H.; Dai, Q.; You, Z. Fourier Transform Infrared Spectroscopy characterization of aging-related properties of original and nano-modified asphalt binders. Constr. Build. Mater. 2015, 101, 1078–1087. [Google Scholar] [CrossRef]

- Werkovits, S.; Primerano, K.; Schberl, T.R.; Hofko, B.; Grothe, H. How infrared and fluorescence spectroscopy can shed new light on the characterization of bitumen and its ageing processes. Road Mater. Pavement Des. Int. J. 2024, 25 (Suppl. 1), 72–83. [Google Scholar] [CrossRef]

- Yuan, J.; Ran, M.; Zhou, X.; Jiang, R.; Liu, L.; Zhou, X. In-situ detection on near-infrared spectra fingerprints of asphalt mixture after laboratory short- and long-term aging. Constr. Build. Mater. 2024, 421, 135722. [Google Scholar] [CrossRef]

- Hosahally, N.V.; Prapoorna, B.K.; Jagadeesh, M.; Debasish, M. Development of Organoclay Suitable for Applications in Recycled Rubber–Based Asphalt Binders: Montmorillonite Tailored with Quaternary Ammonium Salt. J. Mater. Civ. Eng. 2023, 35, 04022390. [Google Scholar] [CrossRef]

- Hofko, B.; Porot, L.; Cannone, A.F.; Poulikakos, L.; Huber, L.; Lu, X.; Mollenhauer, K.; Grothe, H. FTIR spectral analysis of bituminous binders: Reproducibility and impact of ageing temperature. Mater. Struct. 2018, 51, 45. [Google Scholar] [CrossRef]

- Wang, L.; Luo, X.D.; Zhang, Q.; Zhou, X.D.; Li, C. Analysis of Adhesion and Water Stability for Warm Mix Crumb Rubber Modified Asphalt-Aggregate System. Mater. Rev. 2022, 36, 123–130. [Google Scholar]

- Li, P.; Jiang, X.; Ding, Z.; Zhao, J.; Shen, M. Analysis of viscosity and composition properties for crumb rubber modified asphalt. Constr. Build. Mater. 2018, 169, 638–647. [Google Scholar] [CrossRef]

- Ragab, M.; Abdelrahman, M. Enhancing the crumb rubber modified asphalt’s storage stability through the control of its internal network structure—ScienceDirect. Int. J. Pavement Res. Technol. 2018, 11, 13–27. [Google Scholar] [CrossRef]

- Ramasamy, N.B. Effect of Polyphosphoric Acid on Aging Characteristics of PG 64-22 Asphalt Binder. Master’s Thesis, University of North Texas, Denton, TX, USA, 2010. [Google Scholar]

- Sun, E.; Zhao, Y.; Wang, G. Nano surface evolution properties of crumb rubber modified asphalt due to aging and adhesion failure mechanism. Constr. Build. Mater. 2024, 420, 13. [Google Scholar] [CrossRef]

- Qi, Z.; Chunqing, C.; Lan, W. Study on the High and Low Temperature Performance of SDYK Type Warm-Mix Asphalt Modified with Rubber Powder under Aging Effects. Funct. Mater. 2019, 50, 3201–3206+3214. [Google Scholar]

- He, L.; Ling, T.Q.; Ma, Y.; Ma, T.; Huang, X.M. Wide road application temperature-domain rheological properties of warm-mixed rubber asphalt. J. Transp. Eng. 2015, 15, 1–9. [Google Scholar]

- Derjaguin, B.V.; Muller, V.M.; Toporov, Y.P. Effect of contact deformations on the adhesion of particles. J. Colloid Interface Sci. 1975, 53, 314–326. [Google Scholar] [CrossRef]

- Butt, H.-J.; Cappella, B.; Kappl, M. Force measurements with the atomic force microscope: Technique, interpretation and applications. Surf. Sci. Rep. 2005, 59, 1–152. [Google Scholar] [CrossRef]

- Emiliano, P.; Edoardo, B. A Review on Bitumen Aging and Rejuvenation Chemistry: Processes, Materials and Analyses. Sustainability 2021, 13, 6523. [Google Scholar] [CrossRef]

| Technical Index | Technical Requirement | Test Result |

|---|---|---|

| Volume density g/cm3 | 1.15 ± 0.05 | 0.89 |

| Ash content% | ≤8 | 6 |

| Iron content% | ≤0.03 | 0.021 |

| Heating decrement% | ≤1 | 0.6 |

| Fiber content% | <1 | 0.4 |

| Asphalt Types | Symbols |

|---|---|

| Asphalt with 20% crumb rubber content | CR-20 |

| Asphalt made by adding SDYK with 20% crumb rubber content | SCR-20-0.6 |

| Asphalt with 30% crumb rubber content | CR-30 |

| Asphalt made by adding 0.4% SDYK with 30% crumb rubber content | SCR-30-0.4 |

| Asphalt made by adding 0.6% SDYK with 30% crumb rubber content | SCR-30-0.6 |

| Asphalt made by adding 0.8% SDYK with 30% crumb rubber content | SCR-30-0.8 |

| Short-term aging (TFOT) | T |

| Long-term aging (PAV) | P |

| Technical Index | Penetration at 25 °C, 100 g, 5 s, 0.1 mm (mm) | Softening Point (°C) | Ductility at 5 °C (mm) | Viscosity at 175 °C (Pa·s) |

|---|---|---|---|---|

| Specification | ASTM D5 | ASTM D36 | ASTM D113 | ASTM D4402 |

| Pen 90 base asphalt | 91.5 | 51.5 | 94 | 0.3 |

| CR-30 | 50.8 | 78.3 | 209 | 3.1 |

| SCR-30-0.4 | 49.5 | 90.9 | 217 | 3.0 |

| SCR-30-0.6 | 49.1 | 92.7 | 221 | 2.8 |

| SCR-30-0.8 | 49.3 | 91.2 | 219 | 2.9 |

| Asphalt Types | Carbonyl Index | Sulfoxide Index | Aromatic Ring Index | Aliphatic Index | Branched Chain Alkane Index |

|---|---|---|---|---|---|

| CR-20 | 0.00193 | 0.00305 | 0.00072 | 0.723 | 0.106 |

| T-CR-20 | 0.00216 | 0.00324 | 0.00089 | 0.637 | 0.090 |

| P-CR-20 | 0.00233 | 0.00347 | 0.00097 | 0.623 | 0.086 |

| SCR-20-0.6 | 0.00228 | 0.00365 | 0.00166 | 0.895 | 0.147 |

| T-SCR-20-0.6 | 0.00250 | 0.00387 | 0.00199 | 0.814 | 0.141 |

| P-SCR-20-0.6 | 0.00264 | 0.00404 | 0.00222 | 0.793 | 0.139 |

| CR-30 | 0.00217 | 0.00320 | 0.00079 | 0.655 | 0.104 |

| T-CR-30 | 0.00239 | 0.00334 | 0.00096 | 0.586 | 0.089 |

| P-CR-30 | 0.00251 | 0.00355 | 0.00103 | 0.567 | 0.085 |

| SCR-30-0.6 | 0.00322 | 0.00395 | 0.00167 | 0.820 | 0.127 |

| T-SCR-30-0.6 | 0.00325 | 0.00411 | 0.00195 | 0.788 | 0.122 |

| P-SCR-30-0.6 | 0.00342 | 0.00433 | 0.00209 | 0.779 | 0.121 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, J.; Han, X.; Shi, Y.; Xiao, Y.; Wang, L.; Liu, Z. Combinatorial Enhancement of Aging Resistance in High-Content Crumb Rubber Asphalt via Warm-Mix Additives: Rheological and Microstructural Insights. Materials 2025, 18, 5161. https://doi.org/10.3390/ma18225161

Guo J, Han X, Shi Y, Xiao Y, Wang L, Liu Z. Combinatorial Enhancement of Aging Resistance in High-Content Crumb Rubber Asphalt via Warm-Mix Additives: Rheological and Microstructural Insights. Materials. 2025; 18(22):5161. https://doi.org/10.3390/ma18225161

Chicago/Turabian StyleGuo, Jia, Xiang Han, Yuhan Shi, Yue Xiao, Lan Wang, and Zhendong Liu. 2025. "Combinatorial Enhancement of Aging Resistance in High-Content Crumb Rubber Asphalt via Warm-Mix Additives: Rheological and Microstructural Insights" Materials 18, no. 22: 5161. https://doi.org/10.3390/ma18225161

APA StyleGuo, J., Han, X., Shi, Y., Xiao, Y., Wang, L., & Liu, Z. (2025). Combinatorial Enhancement of Aging Resistance in High-Content Crumb Rubber Asphalt via Warm-Mix Additives: Rheological and Microstructural Insights. Materials, 18(22), 5161. https://doi.org/10.3390/ma18225161