Material Behavior and Computational Validation of Deep CO2 Closed-Loop Geothermal Systems in Carbonate Reservoirs

Abstract

1. Introduction

2. Geologic Setting and Field Background

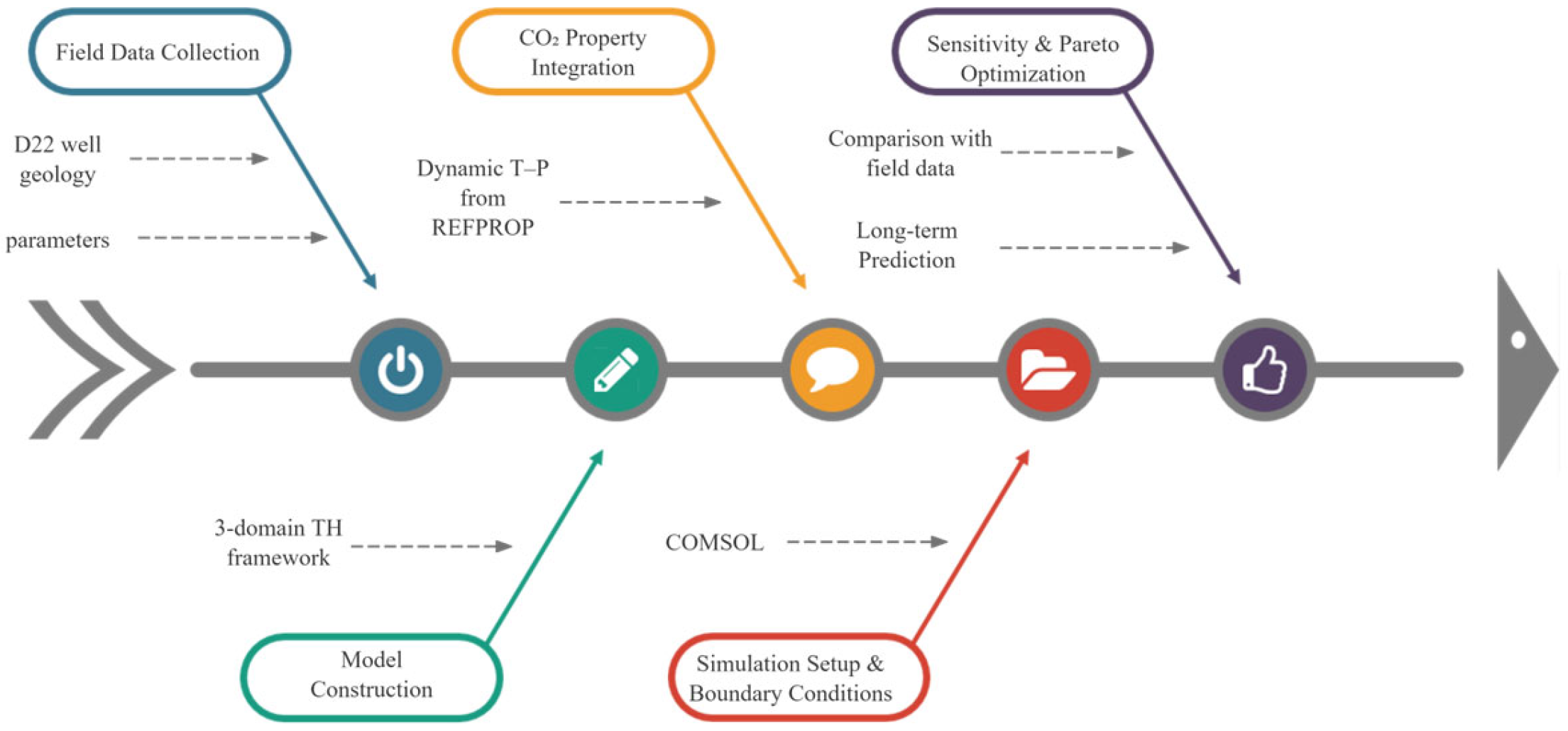

3. Methodology and Modeling

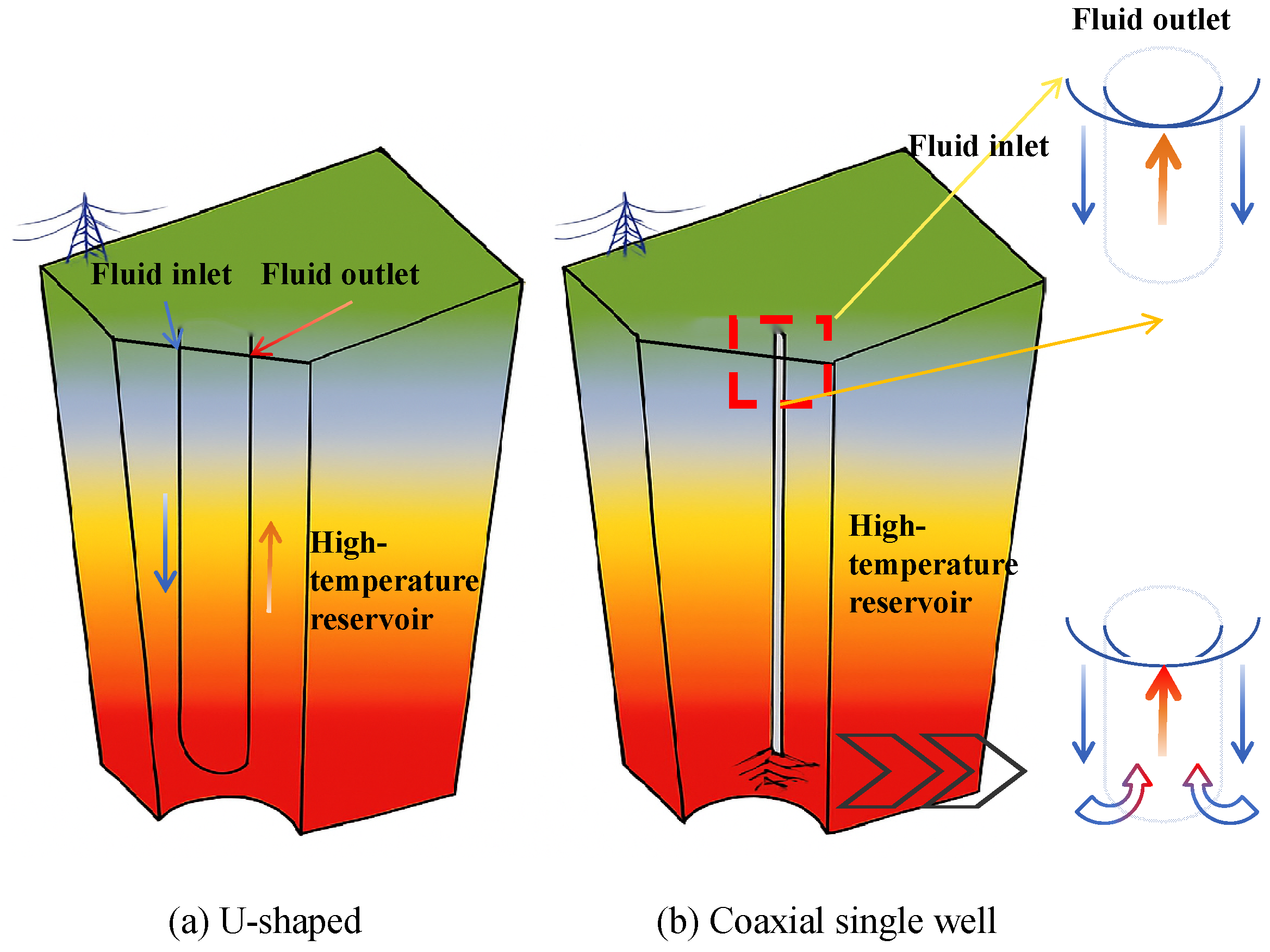

3.1. System Description

3.2. Governing Equations and Closure

3.2.1. Three-Domain Decomposition

3.2.2. Temperature- and Pressure-Dependent Fluid Properties

3.2.3. Boundary and Initial Conditions

3.2.4. CO2 Inventory in Closed-Loop Systems

3.3. Simulation Setup

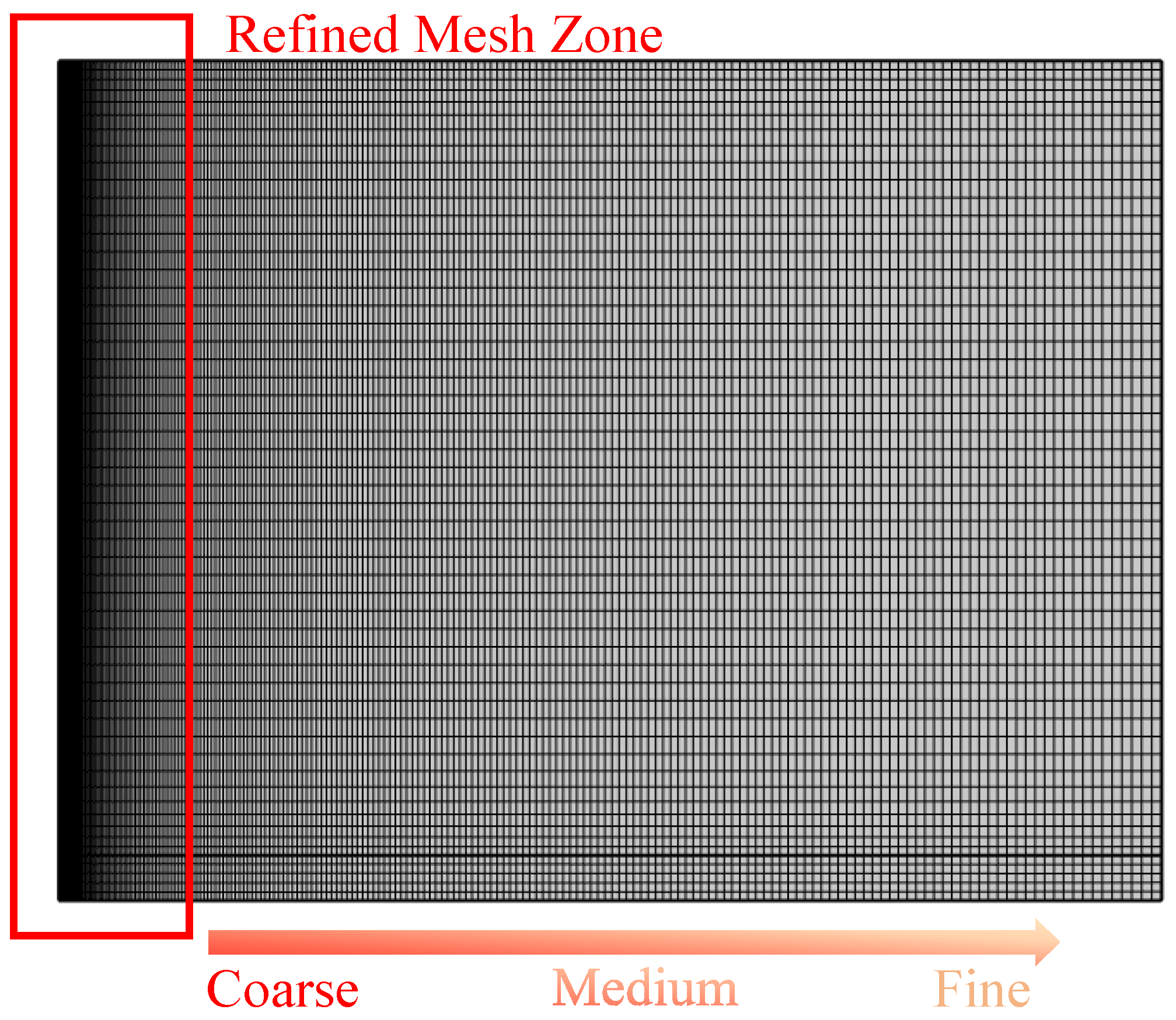

3.3.1. Mesh Discretization and Validation

3.3.2. Design of Operating Variables

- (1)

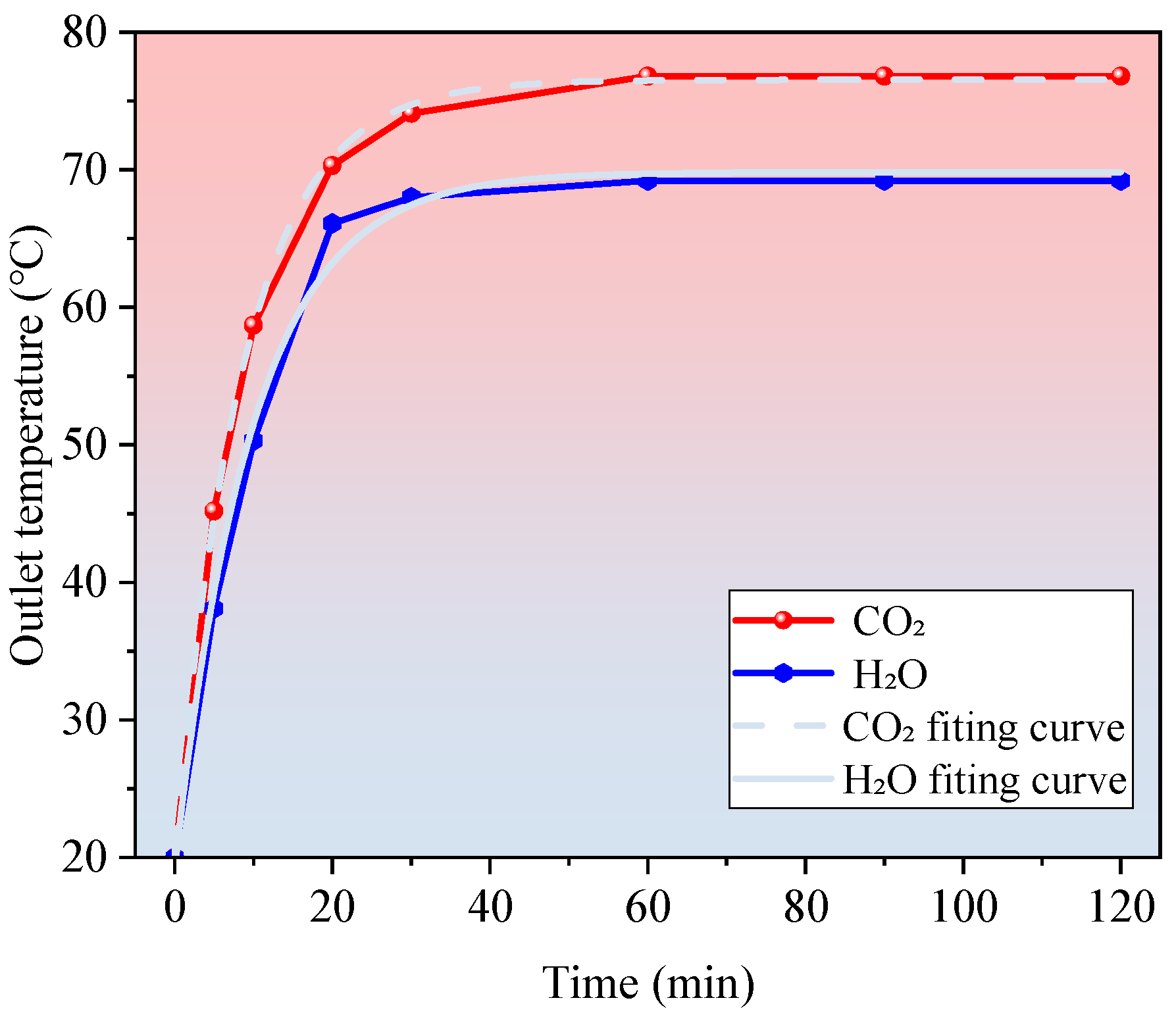

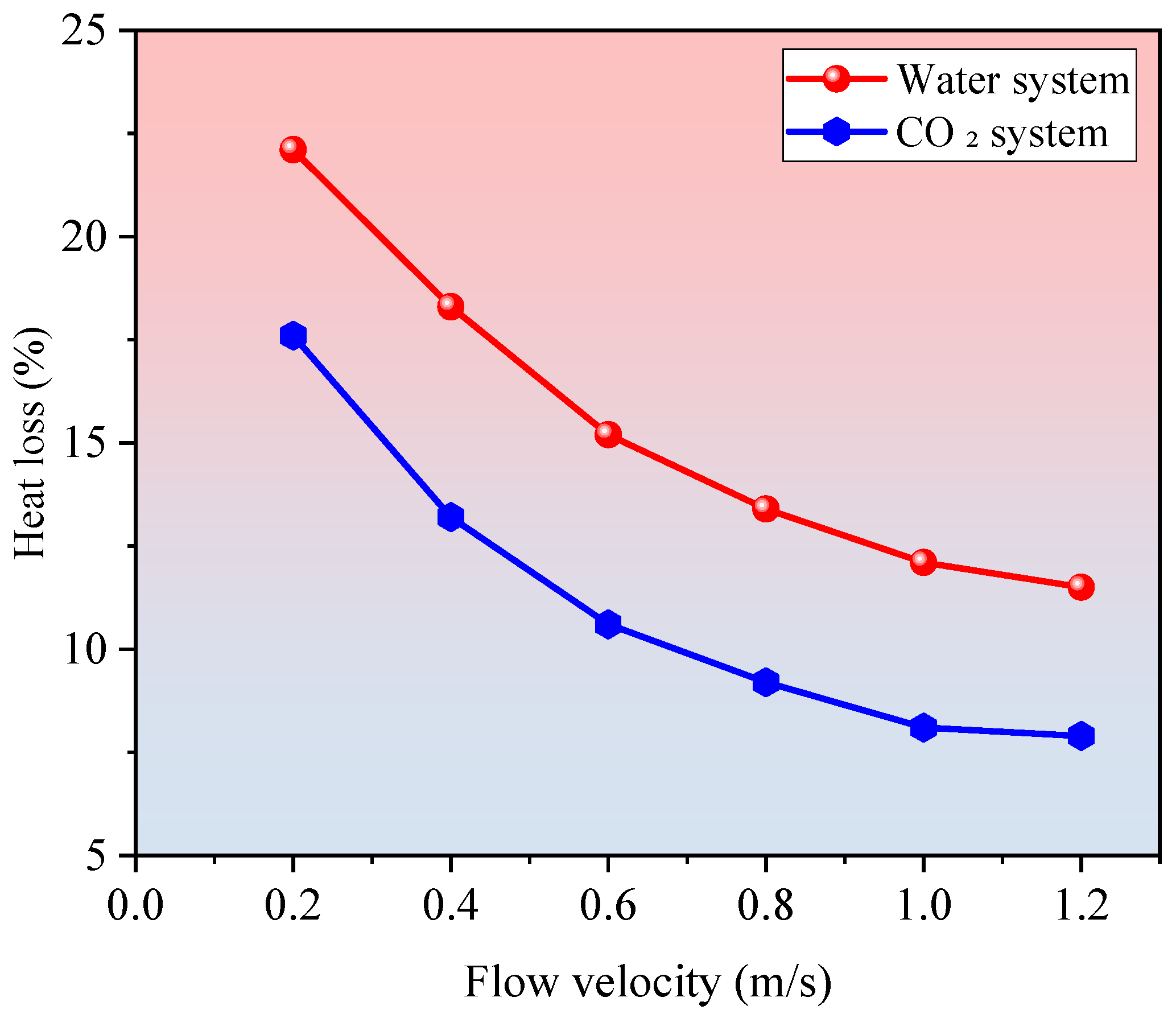

- A comparative analysis was performed to evaluate the heat transfer performance of water (H2O) and carbon dioxide (CO2) as working fluids. Given the significant sensitivity of CO2 thermophysical properties to changes in temperature and pressure, a combination of look-up tables and real-time updating models was employed to dynamically retrieve values for specific heat capacity, density, thermal conductivity, and viscosity. In contrast, water was modeled as a fluid with constant physical properties, serving as a benchmark under conventional heat transfer conditions.

- (2)

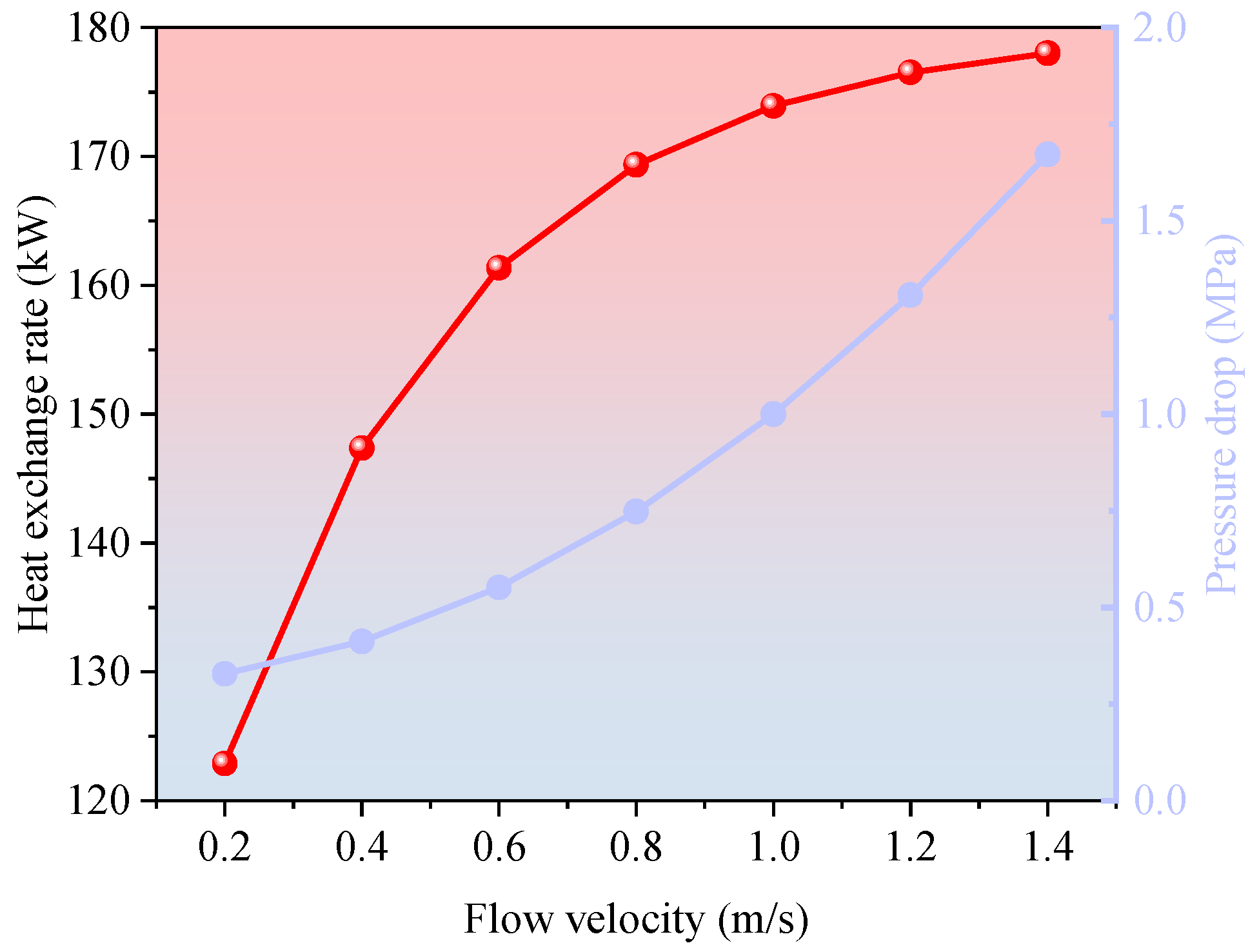

- To assess the impact of fluid velocity on system performance, the circulating flow rate was set to five discrete values: 0.2 m/s, 0.4 m/s, 0.8 m/s, 1.0 m/s, and 1.2 m/s. Corresponding changes in outlet temperature, heat recovery rate, and pressure drop were evaluated under each flow condition.

- (3)

- Based on the structural and lithological profile of the D22 well in the Xiongan New Area, simulated well depths were set at 1000 m, 1500 m, 2000 m, 2500 m, and 3000 m. The geothermal reservoir temperature at each depth was estimated using a regional geothermal gradient of 3.8 °C per 100 m. These values were used to analyze variations in heat exchange capacity and wellbore heat loss behavior under different burial depths.

4. Results and Analysis

4.1. Thermal Response Analysis

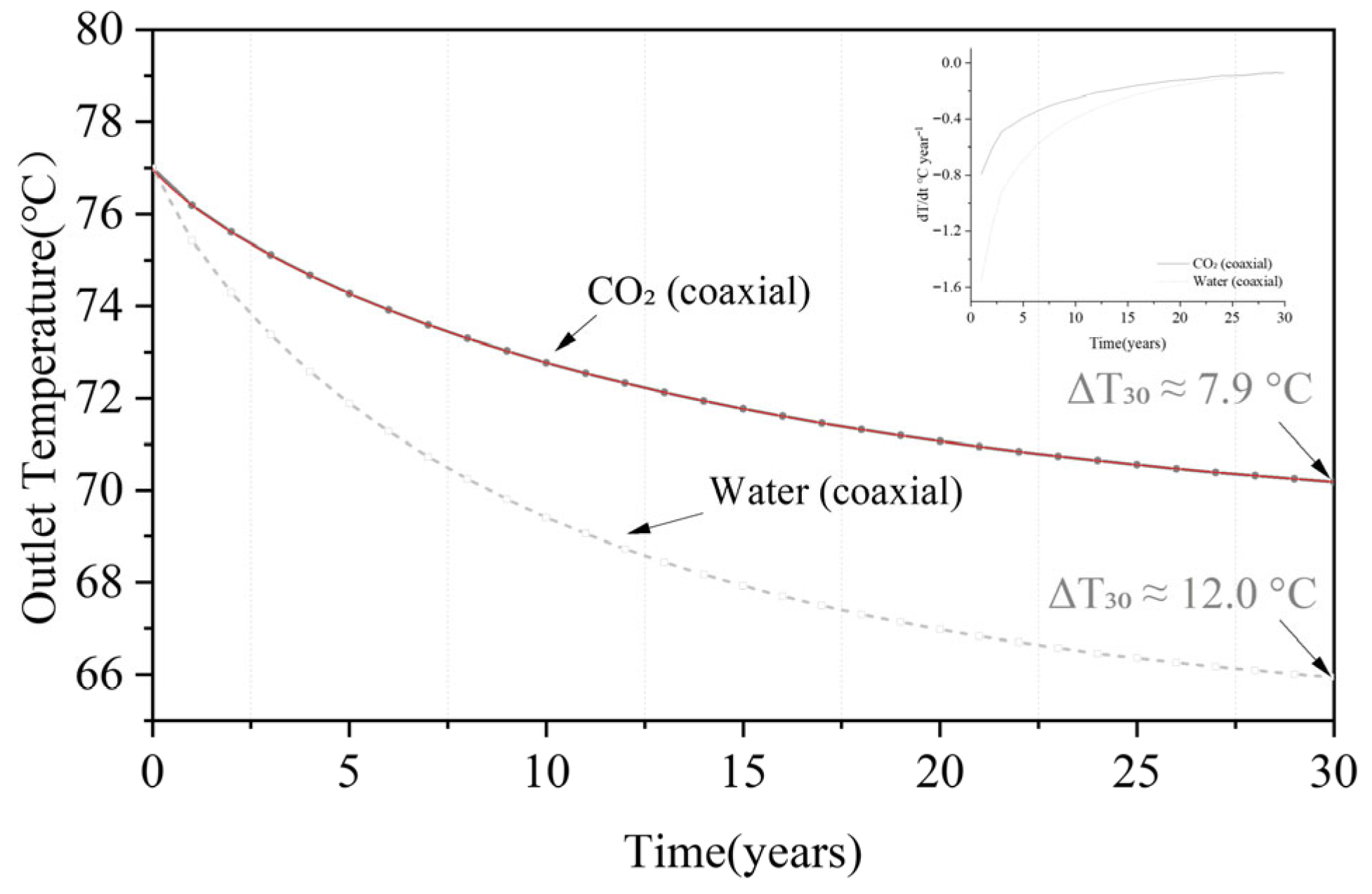

4.1.1. Temporal Variation in Outlet Temperature

4.1.2. Thermal Power Comparison Analysis

4.2. Wellbore Heat Loss and Efficiency

4.3. Sensitivity Analysis

4.4. Comparison with Field Data (D22 Well)

5. Discussion

5.1. Mechanism Illustration of CO2 Heat Transfer Enhancement

5.2. Long-Term Operational Performance

6. Conclusions

- (1)

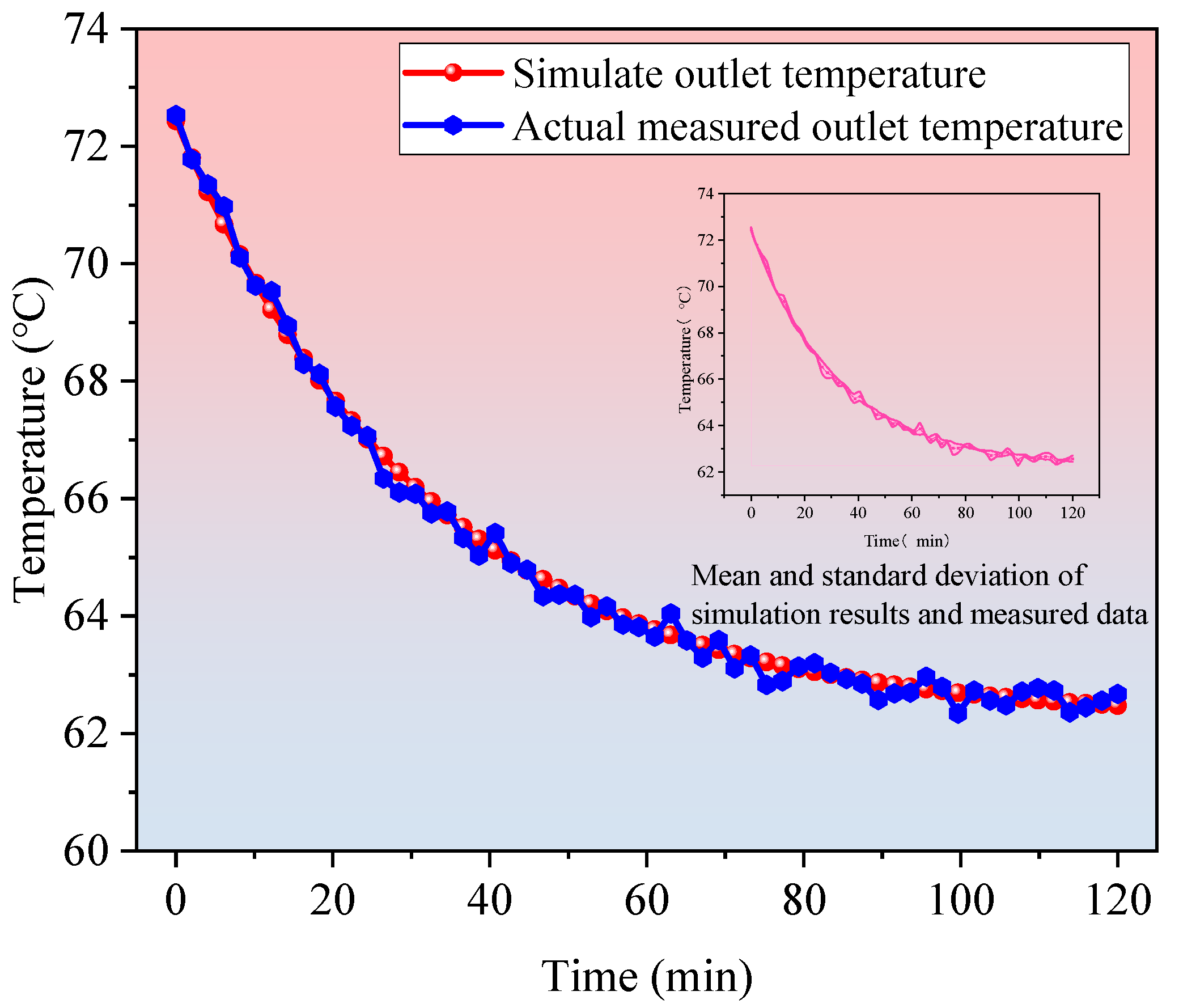

- The proposed rock–interface–fluid coupling model, integrated with pressure- and temperature-sensitive CO2 property functions, accurately predicts thermal responses in closed systems. Field validation against the D22 well demonstrates a deviation of less than 0.52% in outlet temperature and 0.5% in heating area, indicating strong predictive capacity.

- (2)

- Compared to water, CO2 exhibits superior heat transfer performance in deep geothermal environments due to enhanced thermal conductivity and low viscosity near its critical point. In single-well coaxial configurations, CO2 yields 44.9% higher thermal power output and 3–5% lower wellbore heat losses, making it a more efficient and sustainable choice for deep heat extraction.

- (3)

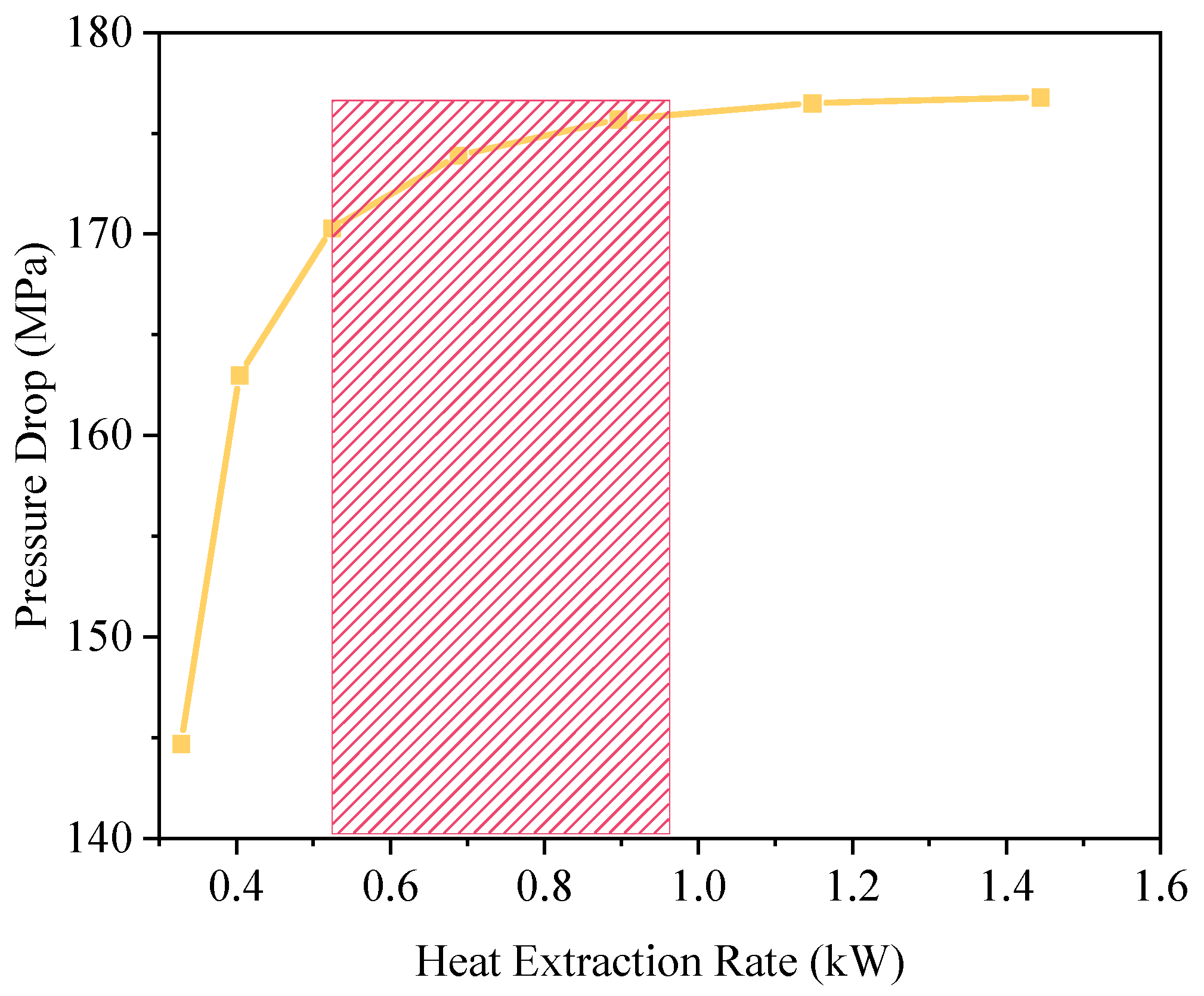

- Parametric sensitivity analysis and Pareto front optimization reveal that a flow rate of 0.9–1.1 m/s and a depth of 3000–3500 m offer the best trade-off between heat transfer efficiency and pressure drop. These results provide practical guidance for optimizing system design and reducing operating costs in similar geologic settings.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Tr | Rock temperature (°C) |

| αr | Thermal diffusivity (m2·s−1) |

| Rinterface | Interfacial thermal resistance (K·m2·W−1) |

| ρf | Fluid density (kg·m−3) |

| cp,f | Specific heat capacity (J·kg−1·K−1) |

| CLGS | Closed-loop geothermal system |

| TH | Thermo-hydraulic |

| EGS | Enhanced geothermal system |

References

- Huo, C.; Lin, Y.; Li, G.; Zhang, J.; Pan, H.; Zhao, Y.; Wang, D. Research progress on geothermal resource exploration technologies in China under carbon neutrality background. Sci. Technol. Eng. 2023, 23, 4917–4927. [Google Scholar]

- Xia, Q.; Guo, S.; Ma, J.; Meng, B.; Cai, W.; Kong, Y. Review of geothermal energy utilization technologies. Taiyangneng 2024, 7, 109–117. [Google Scholar]

- Zhao, C.; Shang, H.; Jin, D.; Wang, H.; Xu, S.; Wang, X.; Zhang, W. Numerical simulation analysis of coaxial heat exchange capacity in deep vertical wells. Meitan Dizhi Yu Kantan 2020, 48, 174–181. [Google Scholar]

- Feng, B.; Liu, X.; Zhang, G.; Shangguan, S.; Hu, Z.; Yuan, Y.; Feng, G. Numerical simulation of sustainable development potential for single-well closed-loop geothermal systems. Nat. Gas Ind. 2020, 40, 146–155. [Google Scholar]

- Wang, Z.; Hu, B.; Zhang, J.; Li, Z. Simulation of pump head for circulating power equipment in large-volume single-well heat exchange systems in layered thermal reservoirs. Zhongguo Kuangye 2022, 31, 164–171. [Google Scholar]

- Liu, W.; Dong, Y.; Zhang, X.; Wang, T. Development potential and environmental benefits analysis of medium-deep borehole heat exchanger heating systems in northwestern provincial capitals. Xibei Dizhi 2023, 56, 186–195. [Google Scholar]

- Chen, C.; Li, J.; Wang, Z.; Gu, S.; Li, S. Distribution characteristics and development strategies of geothermal resources in northern Songliao Basin. Petrol. Geol. Oilfield Dev. Daqing 2024, 43, 215–222. [Google Scholar]

- Bi, S.; Wan, Z.; Zhang, H.; Wang, M.; Wang, J.; Liu, Z.; Wang, C. Development and utilization of geothermal resources in Tangkou Coal Mine. Meitan Kexue Jishu 2018, 46, 208–214. [Google Scholar]

- Pruess, K. Enhanced geothermal systems (EGS) using CO2 as working fluid—A novel approach for generating renewable energy with simultaneous sequestration of carbon. Geothermics 2006, 35, 351–367. [Google Scholar] [CrossRef]

- Randolph, J.B.; Saar, M.O. Combining geothermal energy capture with geologic carbon dioxide sequestration. Geophys. Res. Lett. 2011, 38. [Google Scholar] [CrossRef]

- Cai, X.; Liu, Z.; Xu, K.; Li, B.; Yang, M. Numerical simulation on converting abandoned wells into double-well open-loop geothermal system. Appl. Therm. Eng. 2024, 248, 123324. [Google Scholar] [CrossRef]

- Aryanfar, Y.; Wu, W. Performance assessment of a transcritical CO2 cycle integrated with a double flash geothermal system and reverse osmosis desalination. Desalination 2025, 613, 119107. [Google Scholar] [CrossRef]

- Aydın, H.; Camcı, U.; Akın, S. An experimental investigation of hydraulic fracturing mechanisms in menderes metamorphic rocks: Prospects for enhanced geothermal systems. Geothermics 2025, 130, 103328. [Google Scholar] [CrossRef]

- Chen, H.; Shi, Y.; Liu, C.; Zhao, Z.; Yue, Y.; Li, M. Performance comparison of different well configurations for medium-deep coaxial closed-loop geothermal systems. Appl. Therm. Eng. 2025, 271, 126393. [Google Scholar] [CrossRef]

- Wu, X.; Cai, M.; Wu, X.; Li, P.; Zhang, S.; Sun, J. Experimental study on nonlinear failure criterion of HDR under cyclic water-induced thermal shock. Bull. Eng. Geol. Environ. 2025, 84, 255. [Google Scholar] [CrossRef]

- Liu, Z.; Xu, K.; Zhang, Q.; Yang, M. Numerical simulation on the heat recovery law of exploiting geothermal energy from a closed-loop geothermal system converted from an abandoned five-spot well pattern. ACS Omega 2022, 7, 41723–41731. [Google Scholar] [CrossRef]

- Wang, G.; Zhou, F.; Jia, H.; Wang, L.; Klitzsch, N.; Feng, G.; Yan, C.; Ma, H.; Liu, S.; Yin, Q.; et al. Heat extraction performance of multi-level, multi-branch, closed loop coaxial horizontal borehole heat exchanger geothermal system. Appl. Therm. Eng. 2025, 269, 126045. [Google Scholar] [CrossRef]

- Wu, X.; Li, P.; Miao, S.; Cai, M.; Liu, Y.; Wang, M.; Xiong, W. Multi-field Coupling Mechanism and Optimization of Heat Transfer in Deep Carbonate Geothermal Reservoirs Based on Acid Fracturing Modification. Case Stud. Therm. Eng. 2025, 73, 106591. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Y.; Jiang, G.; Hu, J.; Shi, Y.; Wang, S.; Hu, S. A Method for Determining Target Areas of Hot Dry Rock Resources: A Case Study in Continental China. Energies 2024, 17, 2435. [Google Scholar] [CrossRef]

- Liu, Z.; Wu, M.; Zhou, H.; Chen, L.; Wang, X. Performance evaluation of enhanced geothermal systems with intermittent thermal extraction for sustainable energy production. J. Clean. Prod. 2024, 434, 139954. [Google Scholar] [CrossRef]

- Xu, Z.; Zhao, H.; Fan, L.; Jia, Q.; Zhang, T.; Zhang, X.; Han, D.; Tan, Y.; Liu, J. A literature review of using supercritical CO2 for geothermal energy extraction: Potential, methods, challenges, and perspectives. Renew. Energy Focus 2024, 51, 100637. [Google Scholar] [CrossRef]

- Cui, Y.; Zhu, C.; Qiu, N.; Tang, B.; Guo, S.; Lu, Z. The heat source origin of geothermal resources in Xiong’an new area, north China, in view of the influence of igneous rocks. Front. Earth Sci. 2022, 10, 818129. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, G.; Zhang, W.; Ma, F.; Zhu, X.; Yue, G.; Yu, M. Characteristics of the Rongcheng Bulge geothermal field and the evolution of geothermal fluids, Xiong’an New Area, China. Water 2022, 14, 2468. [Google Scholar] [CrossRef]

- Wang, G.; Ma, H.; Liu, S.; Yang, D.; Xu, X.; Fu, M.; Jia, H. Thermal power extraction from a deep, closed-loop, multi-level, multi-branch, U-shaped borehole heat exchanger geothermal system. Renew. Energy 2022, 198, 894–906. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, W.; Xu, K.; Zhang, Q.; Yan, L.; Li, B.; Cai, X.; Yang, M. Research progress of technologies and numerical simulations in exploiting geothermal energy from abandoned wells: A review. Geoenergy Sci. Eng. 2023, 224, 211624. [Google Scholar] [CrossRef]

- Zhong, C.; Xu, T.; Yuan, Y.; Feng, B.; Yu, H. The feasibility of clean power generation from a novel dual-vertical-well enhanced geothermal system (EGS): A case study in the Gonghe Basin, China. J. Clean. Prod. 2022, 344, 131109. [Google Scholar] [CrossRef]

- Zheng, Z.; Ma, Z.; Qi, J.; Su, G.; Lu, G.; Pei, S.; Jiang, Q. Multi-directional disturbance effect of shear mechanical behaviors and fracturing mechanisms of rockmass intermittent structural plane under true triaxial shear test. Int. J. Min. Sci. Technol. 2025, 35, 933–960. [Google Scholar] [CrossRef]

- Zheng, Z.; Li, R.; Pan, P.; Wang, W. Excavation disturbance response of deep-buried tunnel with novel dynamic anisotropic mechanical model and failure degree index. Tunn. Undergr. Space Technol. 2025, 158, 106429. [Google Scholar] [CrossRef]

- Davoodi, S.; Al-Shargabi, M.; Wood, D.A.; Slivkin, S.; Shishaev, G.; Rukavishnikov, V.S. Geothermal energy recovery from abandoned petroleum wells: A review of the challenges and opportunities. Sustain. Energy Technol. Assess. 2024, 68, 103870. [Google Scholar] [CrossRef]

- Song, X.; Xu, F.; Ji, J.; Shi, Y. Evaluation of the heat extraction performance of an abandoned well pattern in multilayer commingled production oil reservoirs. Nat. Gas Ind. B 2022, 9, 578–587. [Google Scholar] [CrossRef]

- Chen, C.; Xu, P. Cellular functions of cGAS-STING signaling. Trends Cell Biol. 2023, 33, 630–648. [Google Scholar] [CrossRef]

| Modeling Aspect | Conventional Models | This Study | Improvement |

|---|---|---|---|

| CO2 Properties | Ideal gas or constant properties | Dynamic T-P functions from NIST REFPROP | Captures near-critical enhancement |

| Thermal Coupling | Mainly rock–fluid (2-domain) | Rock–interface–fluid (3-domain) | Reduces wellbore heat loss error by ~8% |

| Validation | Limited to laboratory scale | Field data (D22 well) with multi-parameter match | Temperature error < 0.52%, pressure error < 4.9% |

| Optimization | Single-parameter sensitivity | Pareto multi-objective optimization | Identifies optimal operating window |

| Long-term Prediction | Typically <10 years | 30-year projection with uncertainty bounds | Provides reliable sustainability assessment |

| System Structure | Working Fluid | Average Thermal Power (kW) |

|---|---|---|

| U-shaped | H2O | 132.0 |

| U-shaped | CO2 | 152.8 |

| coaxial single-well | H2O | 128.5 |

| coaxial single-well | CO2 | 186.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, X.; Li, P.; Cai, M.; Jiang, T.; Mu, B.; Su, W.; Wang, M.; Li, C. Material Behavior and Computational Validation of Deep CO2 Closed-Loop Geothermal Systems in Carbonate Reservoirs. Materials 2025, 18, 5144. https://doi.org/10.3390/ma18225144

Wu X, Li P, Cai M, Jiang T, Mu B, Su W, Wang M, Li C. Material Behavior and Computational Validation of Deep CO2 Closed-Loop Geothermal Systems in Carbonate Reservoirs. Materials. 2025; 18(22):5144. https://doi.org/10.3390/ma18225144

Chicago/Turabian StyleWu, Xinghui, Peng Li, Meifeng Cai, Tingting Jiang, Bolin Mu, Wanlei Su, Min Wang, and Chunxiao Li. 2025. "Material Behavior and Computational Validation of Deep CO2 Closed-Loop Geothermal Systems in Carbonate Reservoirs" Materials 18, no. 22: 5144. https://doi.org/10.3390/ma18225144

APA StyleWu, X., Li, P., Cai, M., Jiang, T., Mu, B., Su, W., Wang, M., & Li, C. (2025). Material Behavior and Computational Validation of Deep CO2 Closed-Loop Geothermal Systems in Carbonate Reservoirs. Materials, 18(22), 5144. https://doi.org/10.3390/ma18225144