Investigating the Cracking Processes and Bearing Performance of Fissured Concrete SCB Specimens via DEM-Based Mesoscopic Modeling Considering Fissure Angle, Aggregate Content and Porosity

Abstract

1. Introduction

2. PFC Principles and Numerical Model

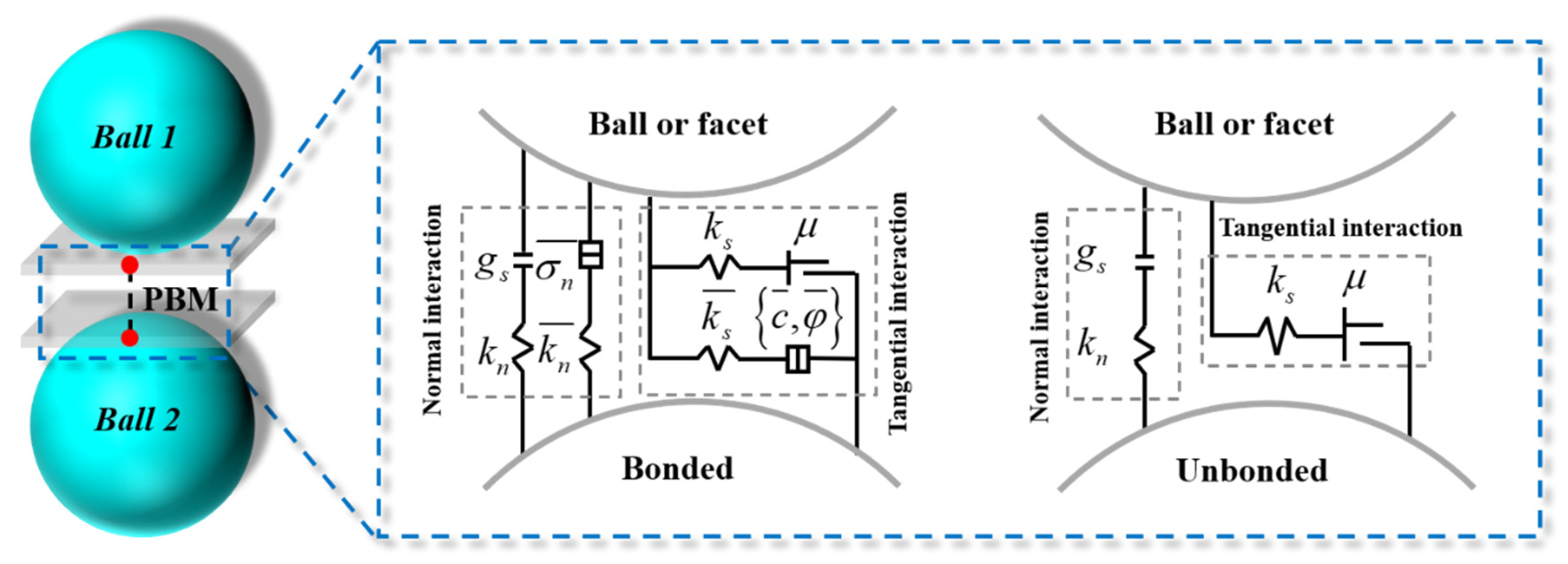

2.1. Parallel Bond Model (PBM)

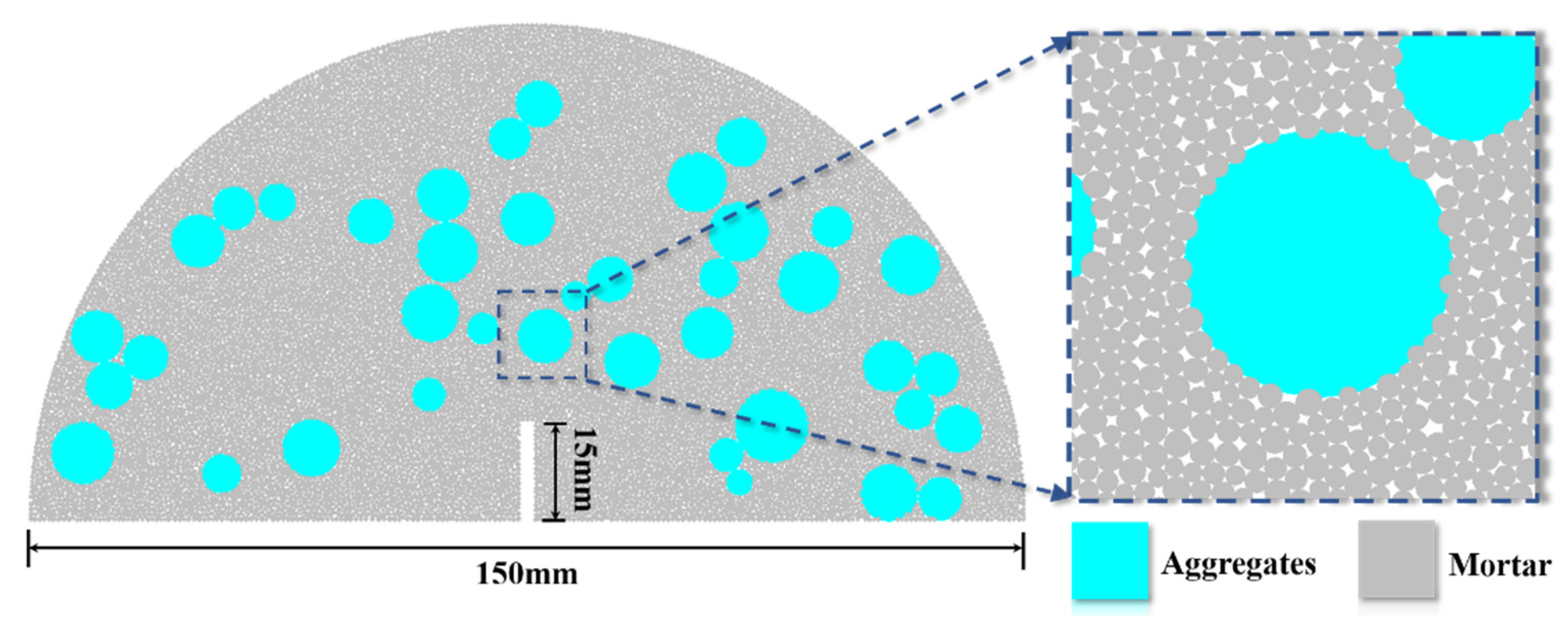

2.2. Model Generation Method

2.3. Calculation Schemes

3. Analysis of Numerical Simulation Results

3.1. Crack Propagation Process

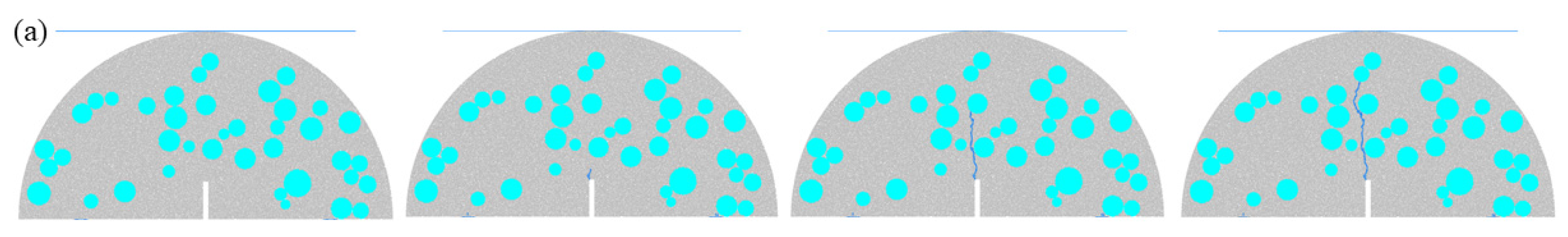

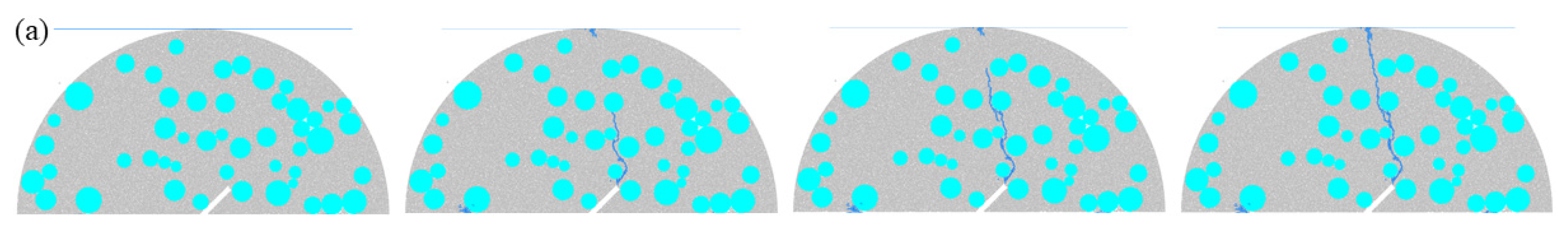

3.1.1. Effect of Different Prefabricated Fracture Angles on Fractured SCB Concrete Models

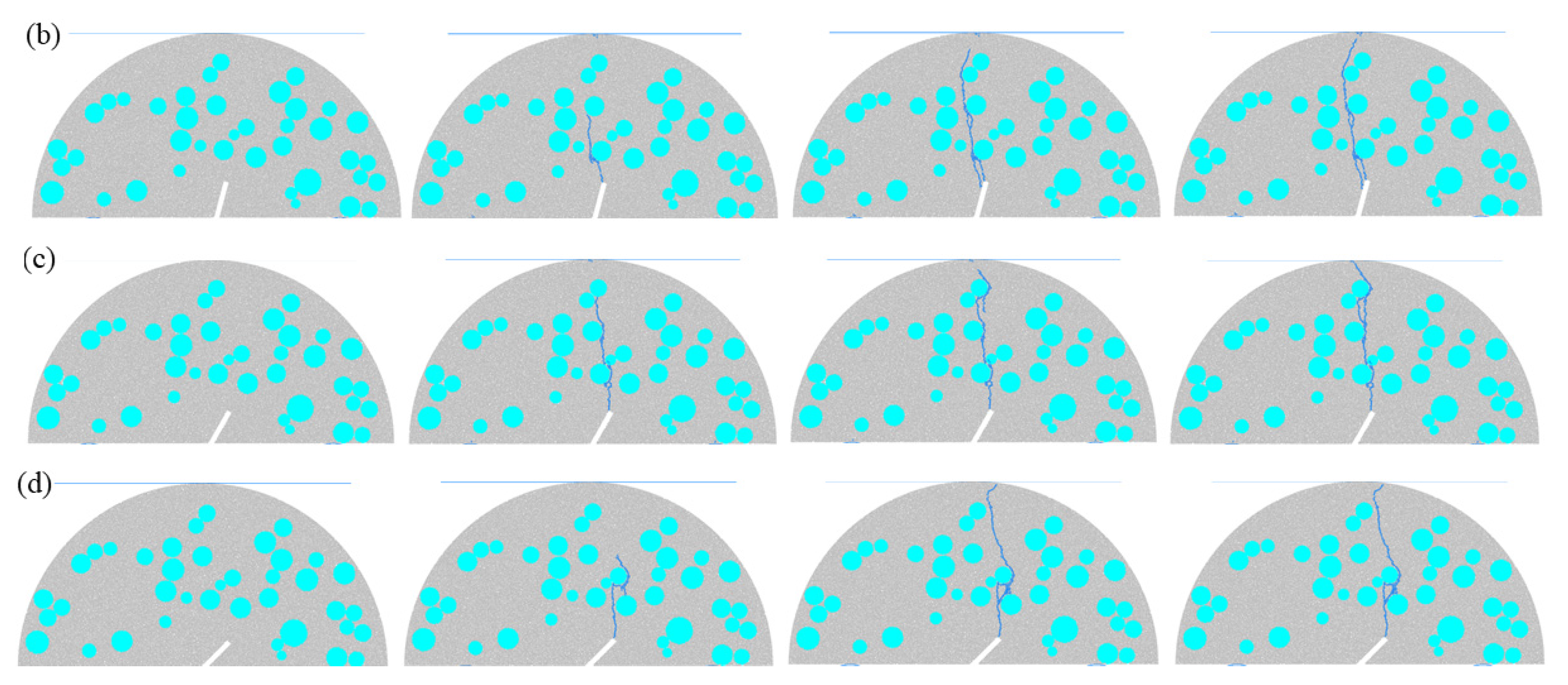

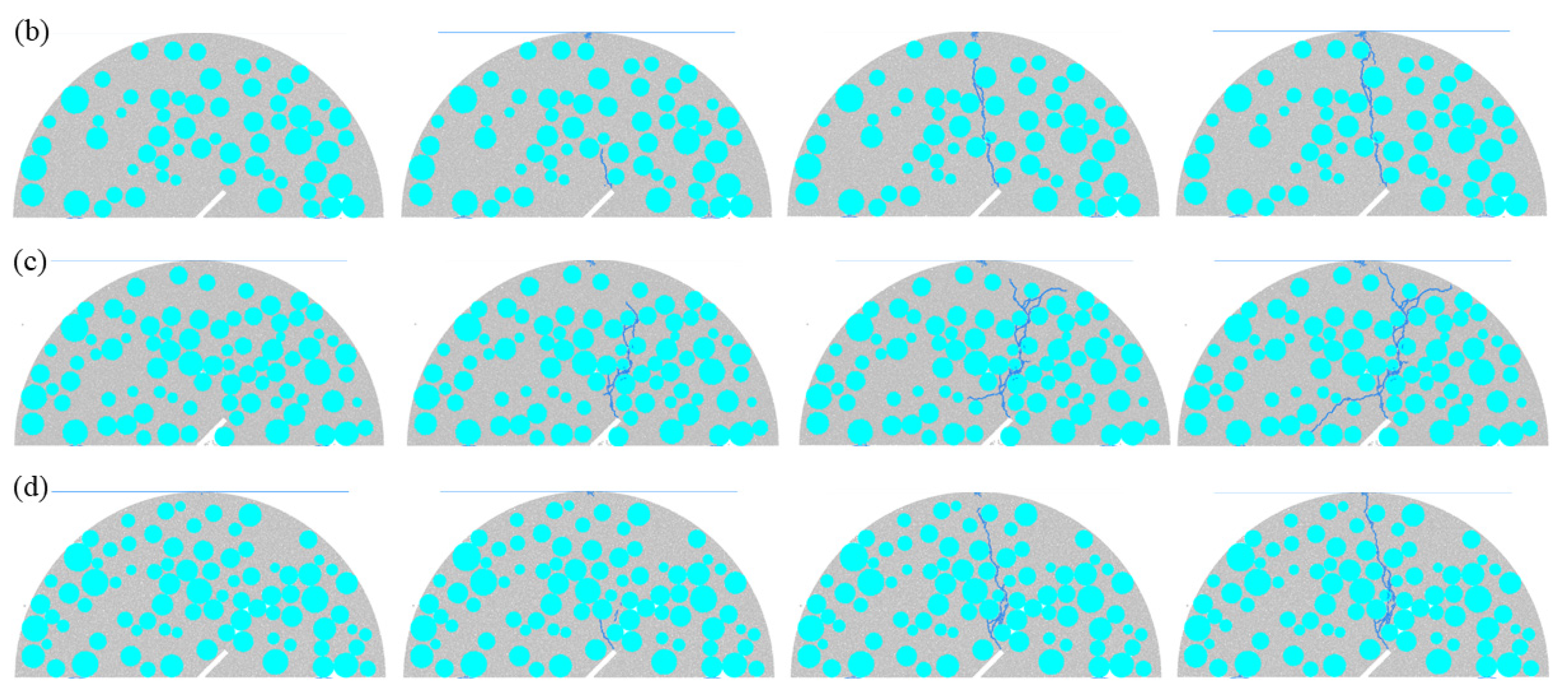

3.1.2. Effect of Different Aggregate Contents on Fractured SCB Concrete Models

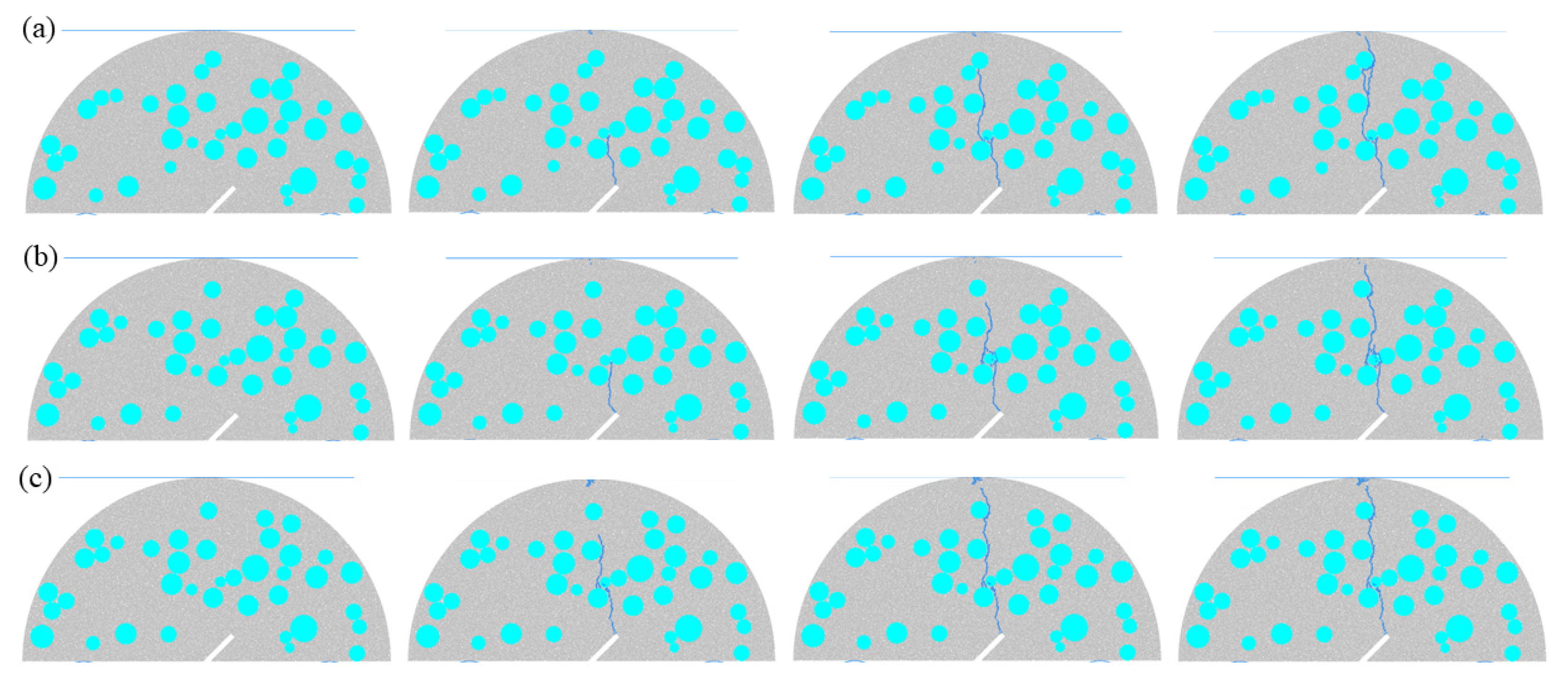

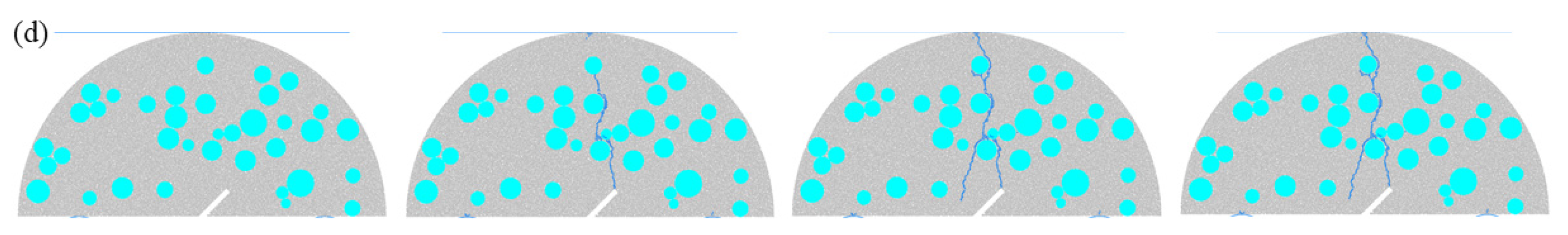

3.1.3. Effect of Different Porosities on Fractured SCB Concrete Models

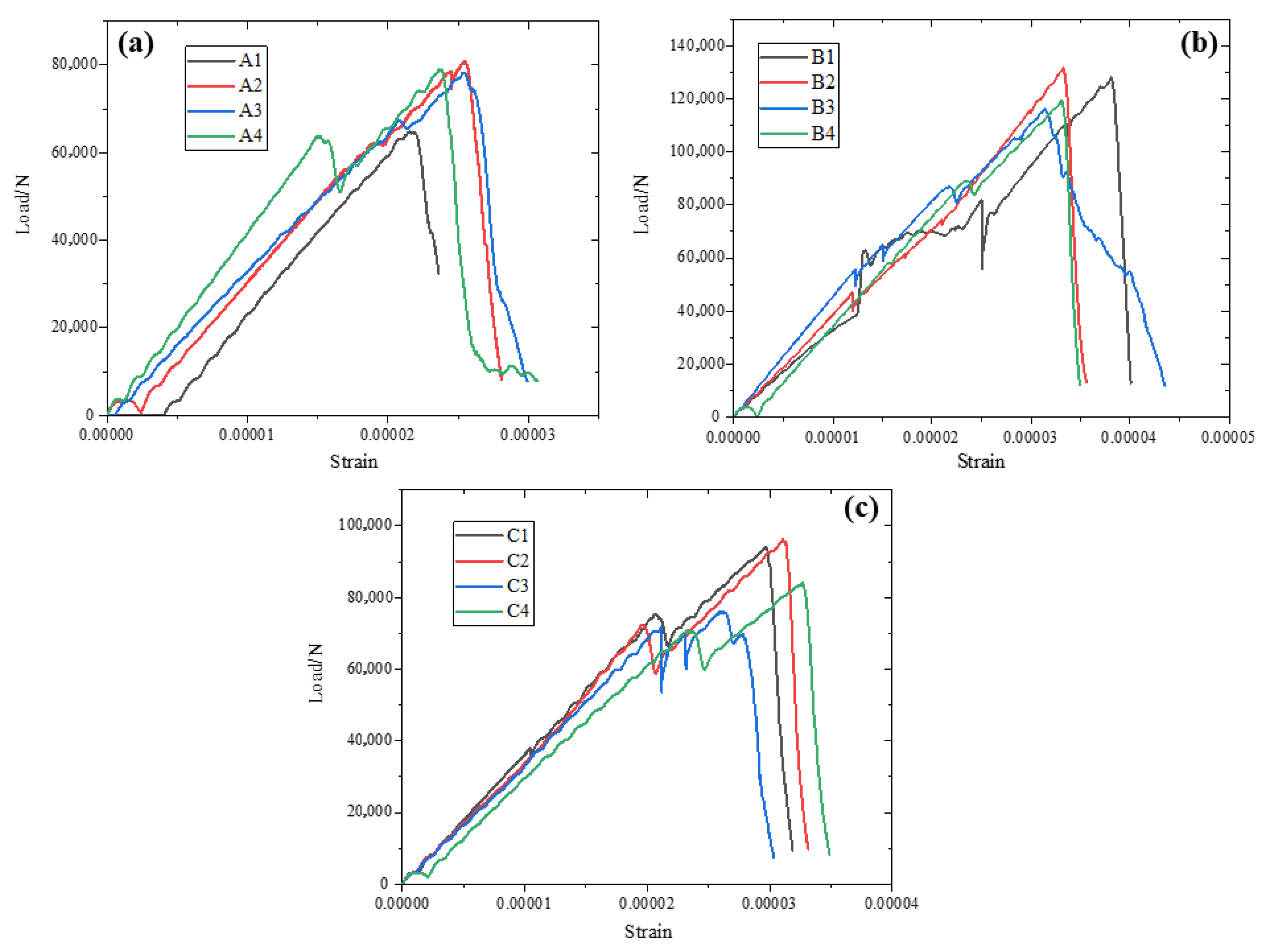

3.2. Load–Displacement Curves

4. Discussion

4.1. Influence Mechanism of Different Fracture Angles, Aggregate Contents, and Porosities on the Initiation Mechanism of SCB Specimens

4.2. Application Prospect of the Discrete Element Method in Simulating the Deterioration Process of Fractured Concrete

5. Conclusions

- (1)

- The prefabricated fracture angle exerts a significant regulatory effect on the crack propagation mode and bearing performance of fractured concrete SCB specimens, and the peak strength first increases and then decreases with the increase in the angle, reaching the optimal state when the angle is 15°. When the angle is 0°, the interior of the specimen is dominated by pure tensile stress, and the crack extends straight along the loading axis, eventually resulting in pure tensile fracture. At an angle of 15°, a tensile–shear composite stress field is formed, and the double cracks initiate and then merge for propagation. The number of bypassed aggregates is moderate, and the energy dissipation and bearing capacity reach a balance. When the angle ranges from 30° to 45°, the proportion of shear stress continues to increase, leading to more crack bifurcations and disordered paths, which fail to form an effective bearing path and thus result in the degradation of bearing performance.

- (2)

- The aggregate content has a significant impact on the mechanical properties of SCB specimens by changing the internal heterogeneous characteristics of concrete and the crack propagation resistance. The peak strength first increases and then decreases with the increase in aggregate content, achieving the best performance when the content is 40%. When the aggregate content is 30%, the mortar matrix is continuous, and the crack propagation resistance is low, mainly resulting in pure tensile fracture. At a content of 35%, the increase in the number of aggregates enhances the crack bypass resistance, thereby improving the bearing performance. When the content reaches 40%, the aggregates form a semi-continuous distribution, which significantly enhances the crack propagation resistance through the “blocking-diversion” effect without the problem of concentrated defects in the interface transition zone (ITZ). At a content of 45%, the excessive aggregation of aggregates leads to an increase in the total area of the ITZ, and cracks preferentially propagate along the ITZ, resulting in a decrease in bearing performance.

- (3)

- As a key internal defect parameter of concrete, porosity significantly affects the crack evolution and bearing capacity of SCB specimens. The peak strength first increases and then decreases with the increase in porosity, attaining the optimal value when the porosity is 4%. When the porosity is 3%, the pores are sparse and have little interference with the stress field at the crack tip, and the crack extends stably but with insufficient propagation resistance. At a porosity of 4%, a small number of pores promote the formation of a stable bearing path for cracks through slight stress concentration without damaging the material continuity. When the porosity ranges from 5% to 6%, the pores are connected to form “crack shortcuts”, and the multi-pore collaborative cracking leads to the rapid evolution of the crack network, which severely damages the material integrity and causes a significant decline in bearing capacity. This indicates that an appropriate level of porosity can optimize the bearing performance through stress adjustment, while an excessively high porosity will exacerbate deterioration.

- (4)

- The discrete element method (DEM) demonstrates significant advantages and reliability in simulating the cracking process of fractured concrete SCB specimens, providing an efficient tool for the study of the mesoscopic fracture mechanism of concrete. Compared with traditional experiments, DEM can accurately capture the entire process from microcrack initiation and propagation to macroscopic penetration, clearly presenting mesoscopic behaviors such as the damage of the aggregate–mortar interface and pore-induced crack bifurcation. In contrast to the continuous medium method, it does not rely on the continuity assumption and can more truly reflect the influence of the heterogeneous characteristics of concrete on fracture. Meanwhile, DEM enables efficient parametric research, facilitating the rapid analysis of the coupling effect of multiple variables on fracture. The research results not only enrich the mesoscopic fracture theory of concrete but also provide theoretical support for the mix ratio optimization of concrete materials in infrastructure and safety assessment.

- (5)

- This study has certain limitations that need to be addressed in subsequent work. Firstly, the current two-dimensional (2D) DEM model is used to construct the fissured concrete SCB specimens, which cannot fully reflect the three-dimensional (3D) spatial distribution characteristics of the concrete mesostructure. This may lead to deviations in the description of the 3D crack propagation path and the interaction of heterogeneous interfaces. Secondly, the interfacial transition zone (ITZ) in the model is characterized by an indirect assignment method (setting the interface bond strength to 70–80% of that of the mortar matrix), without independently subdividing the geometric parameters (e.g., thickness) and mechanical parameters (e.g., elastic modulus) of the ITZ. This makes it difficult to accurately quantify the regulatory mechanism of the ITZ on crack initiation and propagation. Finally, the numerical simulation does not introduce the coupling effect of environmental factors (such as temperature changes and freeze–thaw cycles) and loads, which cannot fully match the service scenarios of concrete structures in actual engineering. In subsequent studies, it is necessary to construct a 3D DEM model using real mesostructural data of concrete obtained by X-ray computed tomography (X-CT) scanning, and integrate multi-field coupling effects to further improve the engineering applicability of the simulation results.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, X.; Li, J.; Zhao, X.; Liang, Y. Propagation characteristics and prediction of blast-induced vibration on closely spaced rock tunnels. Tunn. Undergr. Space Technol. 2022, 123, 104416. [Google Scholar] [CrossRef]

- Wang, X.; Li, Z.; Li, W.; He, C.; Wang, Z. Analysis and prediction of dynamic stress concentration in jointed coal using boundary element method. Theor. Appl. Fract. Mech. 2025, 140, 105136. [Google Scholar] [CrossRef]

- Xiao, W. Analytical theory on instability sliding of surrounding rock blocks in tunnel roof under stress wave actions. Chin. J. Theor. Appl. Mech. 2024, 56, 183–197. [Google Scholar]

- Wang, X.; Zhang, X.; Li, W.; Jiang, Y.; Li, Z.; Wang, C. Analytical theoretical study on ultra-low friction characteristics of coal rock interfaces under stress wave action. J. China Coal Soc. 2024, 49, 4495–4507. [Google Scholar]

- Liu, P.; Li, S.; Jin, H. Shape parameterization method and hydrodynamic noise characteristics of low-noise toroidal propeller. Ocean Eng. 2025, 328, 121088. [Google Scholar] [CrossRef]

- Khan, J.; Yao, H.; Zhao, J.; Li, Q.; Xiang, W.; Jiang, J.; Tahir, A. Petrogenesis and tectonic implications of the tertiary choke shield basalt and continental flood basalt from the central Ethiopian plateau. J. Earth Sci. 2023, 34, 86–100. [Google Scholar] [CrossRef]

- Morishita, T.; Soe, H.M.; Htay, H.; Lwin, T.H.; Guotana, J.M.; Tamura, A.; Mizukami, T.; Zaw, K. Origin and evolution of ultramafic rocks along the Sagaing fault, Myanmar. J. Earth Sci. 2023, 34, 122–132. [Google Scholar] [CrossRef]

- Yu, S.; Li, Y.; Gao, Y. Investigating the crack propagation processes of grouted/ungrouted fissured tunnel specimens using 3D printing technology and SPH simulation method. Constr. Build. Mater. 2025, 500, 144213. [Google Scholar] [CrossRef]

- Cai, B.; Chen, H.; Xu, Y.; Fan, C.; Tang, Y. Effect of notch-to-depth ratio on shear fracture properties of plain and fiber-reinforced manufactured sand concrete using double notched cube test. J. Build. Eng. 2025, 113, 114062. [Google Scholar] [CrossRef]

- Yao, J.X.; Geng, Y.; Yuan, W.Y.; Dong, W. Experimental and numerical investigations on rate-dependent fracture behavior of concrete-rock interface. Theor. Appl. Fract. Mech. 2024, 133, 104646. [Google Scholar] [CrossRef]

- Teng, G.; Zheng, C.; Chen, X.; Lan, X.; Zhu, Y.; Shan, C. Numerical fracture investigation of single-edge notched asphalt concrete beam based on random heterogeneous FEM model. Constr. Build. Mater. 2021, 304, 124581. [Google Scholar] [CrossRef]

- Zitouni, M.; Arruda, M.R.T. Fracture energy regularization for the numerical modelling of concrete structures with recycled aggregate: An application with an UMAT user subroutine for ABAQUS. Mech. Res. Commun. 2025, 148, 104463. [Google Scholar] [CrossRef]

- Liu, Q.; Wei, D.; Gan, Y. Mesoscale modelling of triaxial concrete fracture: The role of aggregate shapes. Int. J. Mech. Sci. 2025, 302, 110570. [Google Scholar] [CrossRef]

- Rashidi, M.; Kargar, S.H.; Roshani, S. Experimental and numerical investigation of steel fiber concrete fracture energy. Structures 2024, 59, 105792. [Google Scholar] [CrossRef]

- Yadav, D.; Prashanth, M.H.; Kumar, N. Numerical study on the effect of steel fibers on fracture and size effect in concrete beams. Mater. Today Proc. 2023, 211, 135176. [Google Scholar] [CrossRef]

- Zhou, X.; Xie, Y.; Long, G.; Zeng, X.; Li, J.; Li, N.; Wang, F.; Umar, H.A. Influence of end friction confinement on dynamic mechanical properties and damage evolution of concrete by coupled DEM-FDM method. Eng. Fract. Mech. 2023, 281, 109150. [Google Scholar] [CrossRef]

- Zhou, M.; Zhang, W.; He, F.; Wang, Y.; Dong, S.; Pan, X.; Huang, J. Numerical study on dynamic fracture of rock-concrete bi-material Brazilian disks with a central interface crack. Eng. Fract. Mech. 2025, 315, 110816. [Google Scholar] [CrossRef]

- Wu, Z.X.; Lei, J.J.; Ye, C.P.; Yu, C.; Zhao, J.L. Coupled. FDM-DEM simulations of axial compression tests on FRP-confined concrete specimens. Constr. Build. Mater. 2022, 351, 128885. [Google Scholar] [CrossRef]

- Hang, Z.Y.; Mi, Z.K.; Wu, Y.F.; Wang, J.H.; Yu, Y. Fracture performance of concrete-epoxy mortar interface subjected to bending and shear: Experimental and numerical study. J. Build. Eng. 2024, 97, 110887. [Google Scholar] [CrossRef]

- Mukhtar, F. 3D-printed concrete fracture: Effects of cohesive laws, mixes, and print parameters in 3D extended FEM. Comput. Struct. 2025, 315, 107822. [Google Scholar] [CrossRef]

- Zeng, M.H.; Wang, H.W.; Wang, Y.J.; Zheng, J.J.; Wu, Z.M. Meso-crack propagation process of concrete based on macro-fracture parameters: Numerical and experimental. Theor. Appl. Fract. Mech. 2024, 129, 104216. [Google Scholar] [CrossRef]

- Xiao, F.; Xiao, X.; Li, J. Low-temperature fracture behavior of railway asphalt concretes under semi-circular bending: Experimental and numerical investigation. Constr. Build. Mater. 2023, 402, 132990. [Google Scholar] [CrossRef]

- Golewski, G.L.; Golewski, P.; Sadowski, T. Numerical modelling crack propagation under Mode II fracture in plain concretes containing siliceous fly-ash additive using XFEM method. Comput. Mater. Sci. 2012, 62, 75–78. [Google Scholar] [CrossRef]

- Zhu, X.; Chen, X.; Tian, H.; Ning, Y. Experimental and numerical investigation on fracture characteristics of self-compacting concrete mixed with waste rubber particles. J. Clean. Prod. 2023, 412, 137386. [Google Scholar] [CrossRef]

- Zhao, H.; Zhou, A. Effects of recycled aggregates on mechanical and fractural properties of concrete: Insights from DEM modelling. Compos. Part A 2024, 186, 108395. [Google Scholar] [CrossRef]

- Xue, B.; Pei, J.; Zhou, B.; Zhang, J.; Li, R.; Guo, F. Using random heterogeneous DEM model to simulate the SCB fracture behavior of asphalt concrete. Constr. Build. Mater. 2020, 236, 117580. [Google Scholar] [CrossRef]

- Nitka, M.; Tejchman, J. Mesoscopic. simulations of a fracture process in reinforced concrete beam in bending using a 2D coupled DEM/micro-CT approach. Eng. Fract. Mech. 2024, 304, 110153. [Google Scholar] [CrossRef]

- Nitka, M.; Tejchman, J.A. three-dimensional meso-scale approach to concrete fracture based on combined DEM with X-ray μCT images. Cem. Concr. Res. 2018, 107, 11–29. [Google Scholar] [CrossRef]

- Skarżyński, Ł.; Nitka, M.; Tejchman, J. Modelling of concrete fracture at aggregate level using FEM and DEM based on X-ray μCT images of internal structure. Eng. Fract. Mech. 2015, 147, 13–35. [Google Scholar] [CrossRef]

- Zahoor, H.; Zhang, P.; Abasal, H. Effect of fiber dosage on water permeability using a newly designed apparatus and crack monitoring of steel fiber–reinforced concrete under direct tensile loading. Struct. Health Monit. 2022, 21, 2083–2096. [Google Scholar]

- Chang, J.; Gu, Y.; Ansari, W. Mechanism of blended steel slag mortar with CO2 curing exposed to sulfate attack. Constr. Build. Mater. 2020, 251, 118880. [Google Scholar] [CrossRef]

- Tong, Q.; Li, Z.; Fan, H.; Jahdali, N.; Al-Nahdi, M.M. Petrogenesis and tectonic implications of the Jabal Hadb ad Dayheen granitic complex, central Arabian shield. J. Earth Sci. 2023, 34, 20–36. [Google Scholar] [CrossRef]

- Zhu, Z.; Mediamartha, B.M.; Yu, S.; Li, Y.; Xu, J.; Gu, P. Simulation of the Mesoscale Cracking Processes in Concrete Under Tensile Stress by Discrete Element Method. Materials 2025, 18, 2981. [Google Scholar] [CrossRef]

| Parameters of Aggregates | Parameters of Mortar | ||

|---|---|---|---|

| Emod (Pa) | 5.55 × 1010 | Emod (Pa) | 1.3 × 1010 |

| Pb_emod (Pa) | 5.55 × 1010 | Pb_emod (Pa) | 1.3 × 1010 |

| Pb_ten (Pa) | 2 × 107 | Pb_ten (Pa) | 5 × 106 |

| Pb_coh (Pa) | 2.5 × 107 | Pb_coh (Pa) | 6 × 106 |

| Pb_fa (°) | 40 | Pb_fa (°) | 45 |

| Kratio | 1.5 | Kratio | 2 |

| Scheme | Details | Scheme | Details |

|---|---|---|---|

| A1 | α = 0° | B1 | Pagg = 30% |

| A2 | α = 15° | B2 | Pagg = 35% |

| A3 | α = 30° | B3 | Pagg = 40% |

| A4 | α = 45° | B4 | Pagg = 45% |

| C1 | Ppor = 3% | C2 | Ppor = 4% |

| C3 | Ppor = 5% | C4 | Ppor = 6% |

| Scheme | Peak Load (N) | Scheme | Peak Load (N) |

|---|---|---|---|

| A1 | 6311 | B1 | 128,311 |

| A2 | 7912 | B2 | 138,514 |

| A3 | 7739 | B3 | 117,662 |

| A4 | 7814 | B4 | 120,067 |

| C1 | 9112 | C2 | 9543 |

| C3 | 7388 | C4 | 8092 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Q.; Liu, S.; Li, Y.; Qiu, M.; Zhang, R.; Chen, C.; Yu, S. Investigating the Cracking Processes and Bearing Performance of Fissured Concrete SCB Specimens via DEM-Based Mesoscopic Modeling Considering Fissure Angle, Aggregate Content and Porosity. Materials 2025, 18, 5140. https://doi.org/10.3390/ma18225140

Li Q, Liu S, Li Y, Qiu M, Zhang R, Chen C, Yu S. Investigating the Cracking Processes and Bearing Performance of Fissured Concrete SCB Specimens via DEM-Based Mesoscopic Modeling Considering Fissure Angle, Aggregate Content and Porosity. Materials. 2025; 18(22):5140. https://doi.org/10.3390/ma18225140

Chicago/Turabian StyleLi, Qinrong, Suyi Liu, Yifei Li, Mingyue Qiu, Ruitong Zhang, Cheng Chen, and Shuyang Yu. 2025. "Investigating the Cracking Processes and Bearing Performance of Fissured Concrete SCB Specimens via DEM-Based Mesoscopic Modeling Considering Fissure Angle, Aggregate Content and Porosity" Materials 18, no. 22: 5140. https://doi.org/10.3390/ma18225140

APA StyleLi, Q., Liu, S., Li, Y., Qiu, M., Zhang, R., Chen, C., & Yu, S. (2025). Investigating the Cracking Processes and Bearing Performance of Fissured Concrete SCB Specimens via DEM-Based Mesoscopic Modeling Considering Fissure Angle, Aggregate Content and Porosity. Materials, 18(22), 5140. https://doi.org/10.3390/ma18225140