The Auto Sensor Test as an AE Signal Source in Concrete Specimens

Abstract

1. Introduction

1.1. Theoretical Background of the Study

- Breaking the glass capillary

- Dropping a steel ball;

- Hsu–Nielsen test;

- Calibration pulse from an acoustic emission sensor.

1.2. Literature Review and Engineering Significance of the Study

1.3. Objectives and Scope of the Study

2. Materials and Methods

2.1. Materials

2.2. Methods

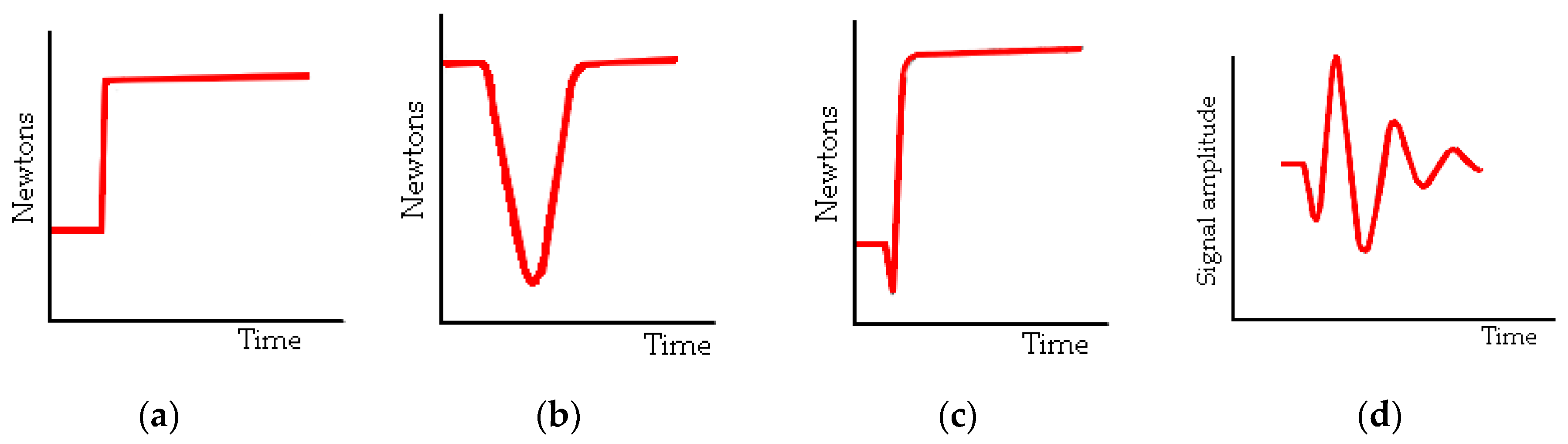

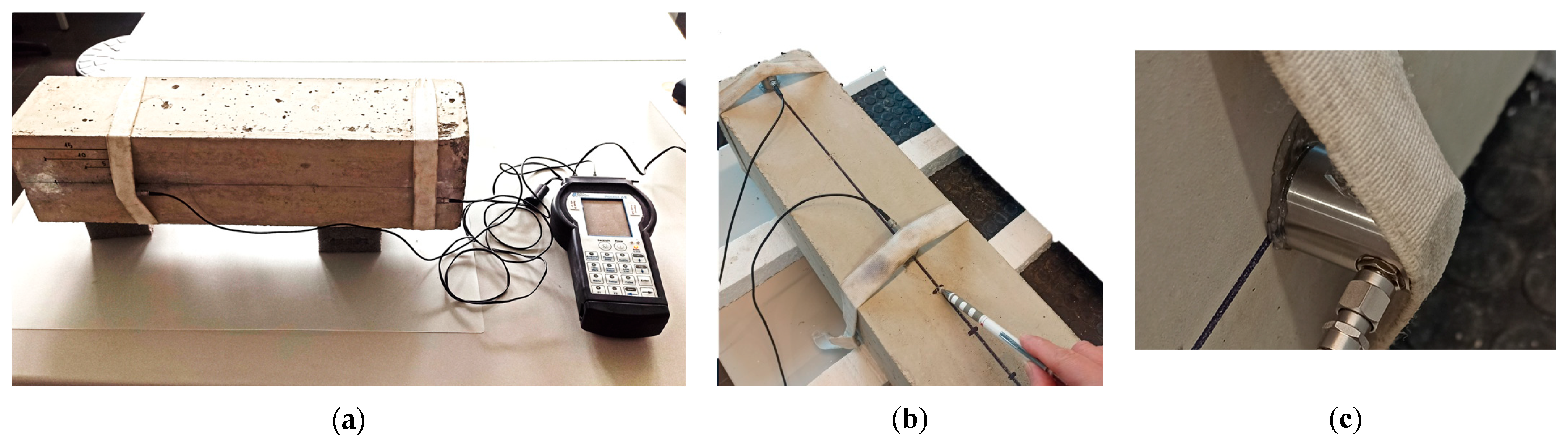

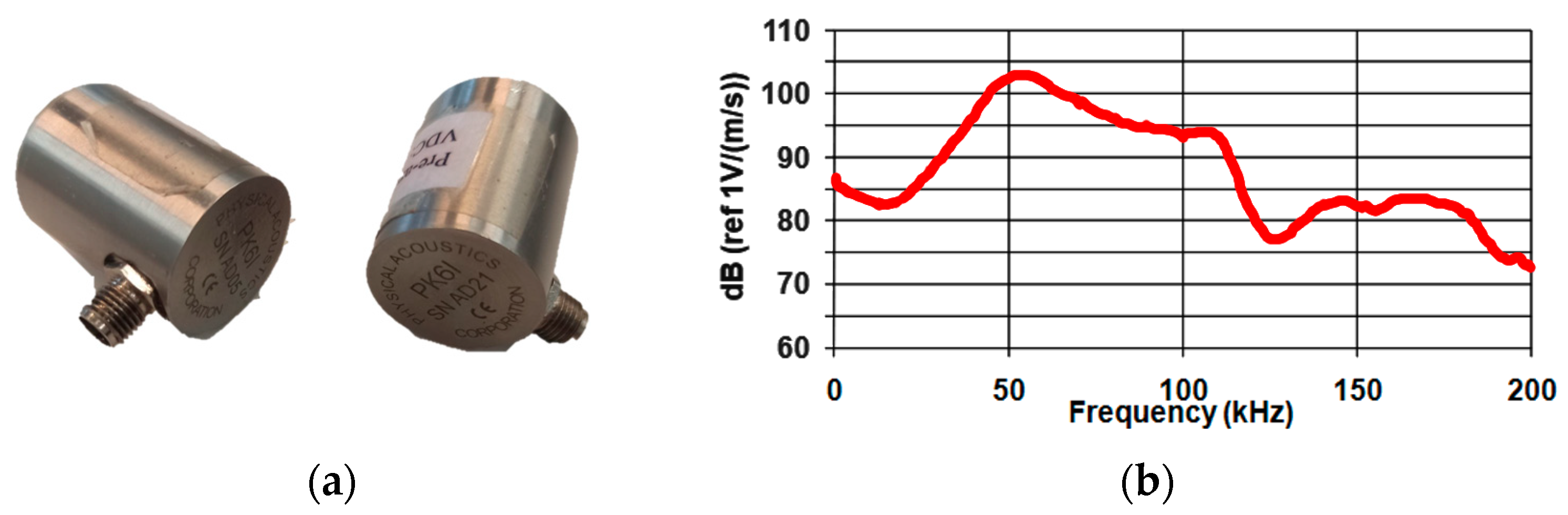

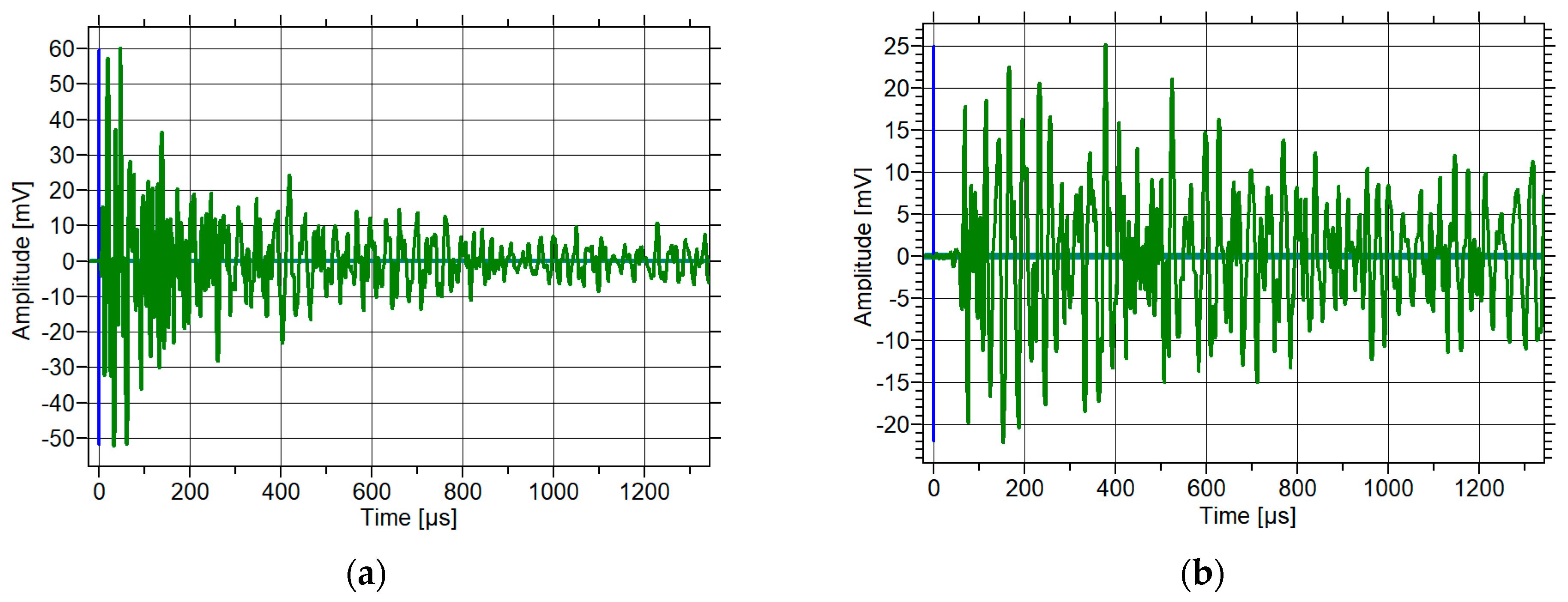

2.2.1. Elastic Wave Excitation Using a Sensor with an AST Function

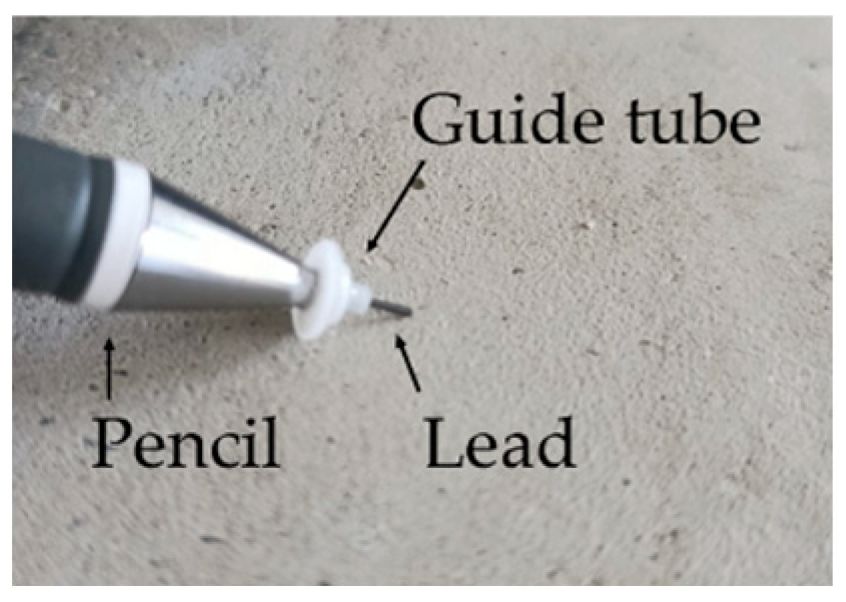

2.2.2. Elastic Wave Excitation Using the Hsu–Nielsen Test

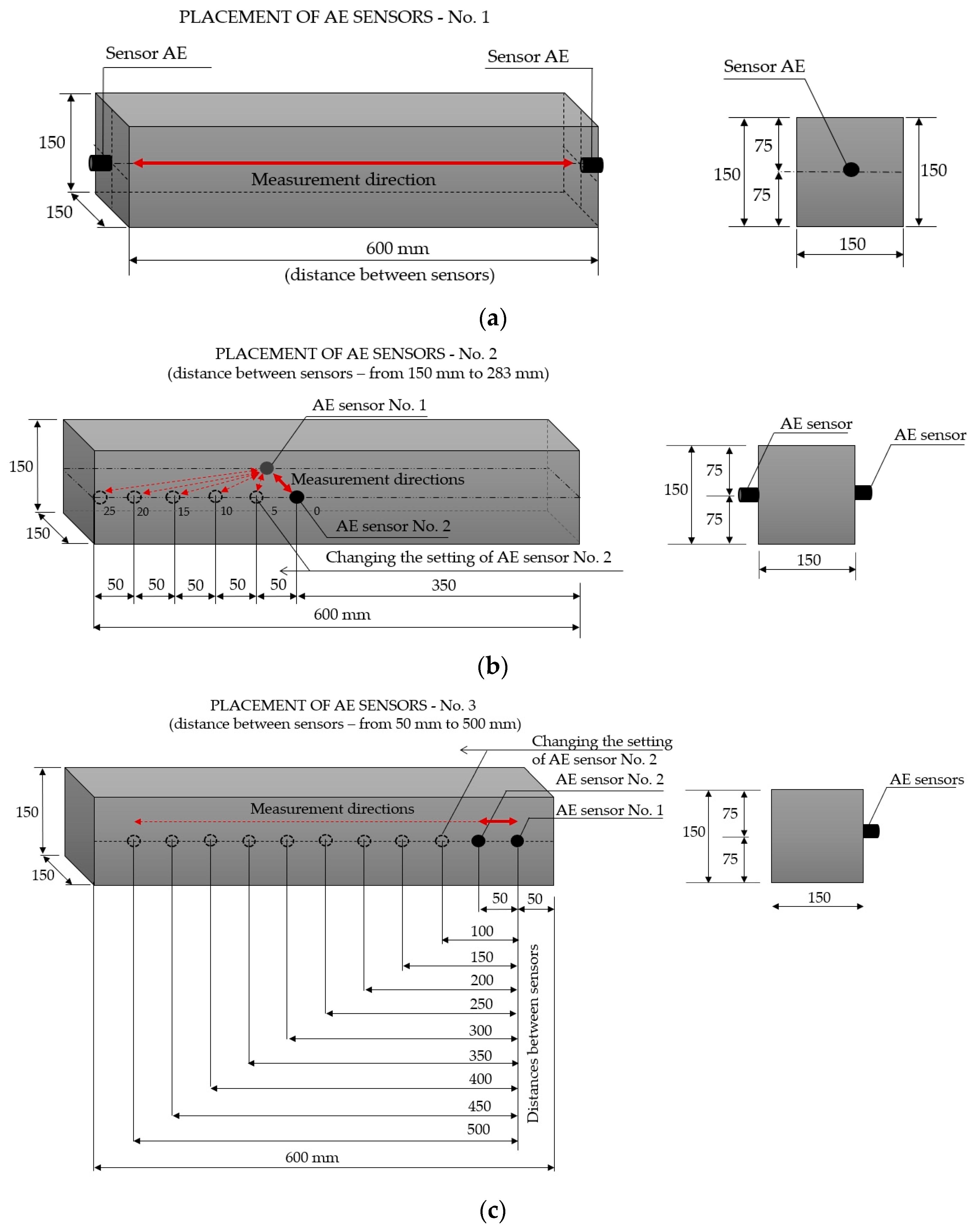

2.3. Placement of Measurement Sensors

2.3.1. Test Using a Sensor with an AST Function

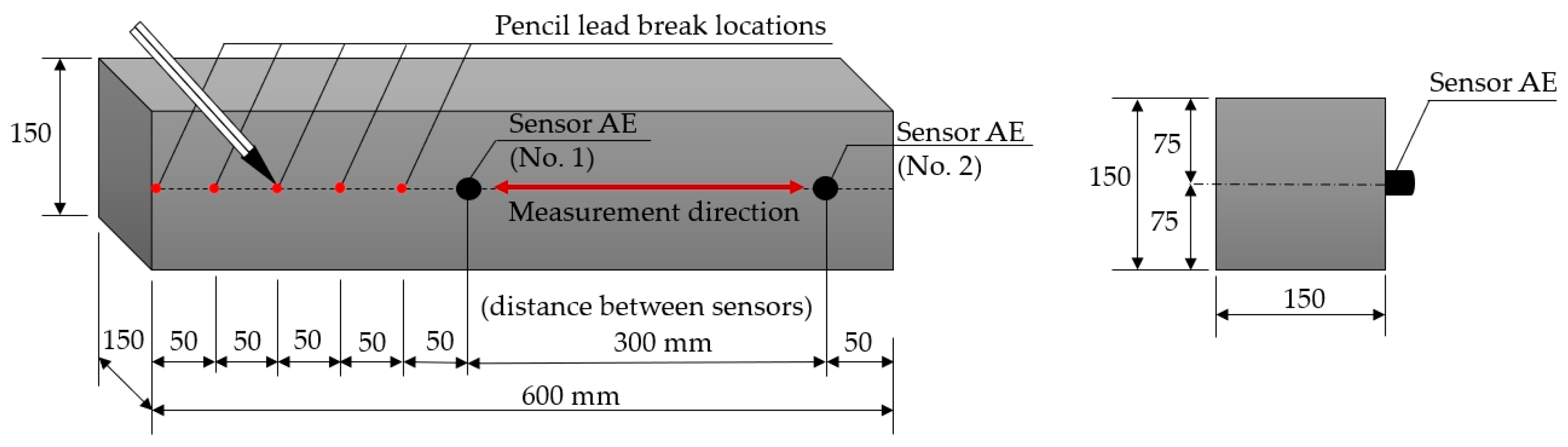

2.3.2. The Test Using Graphite (Pencil Lead) Fracture (Hsu–Nielsen Source)

3. Results

3.1. Results of AST Function Analysis

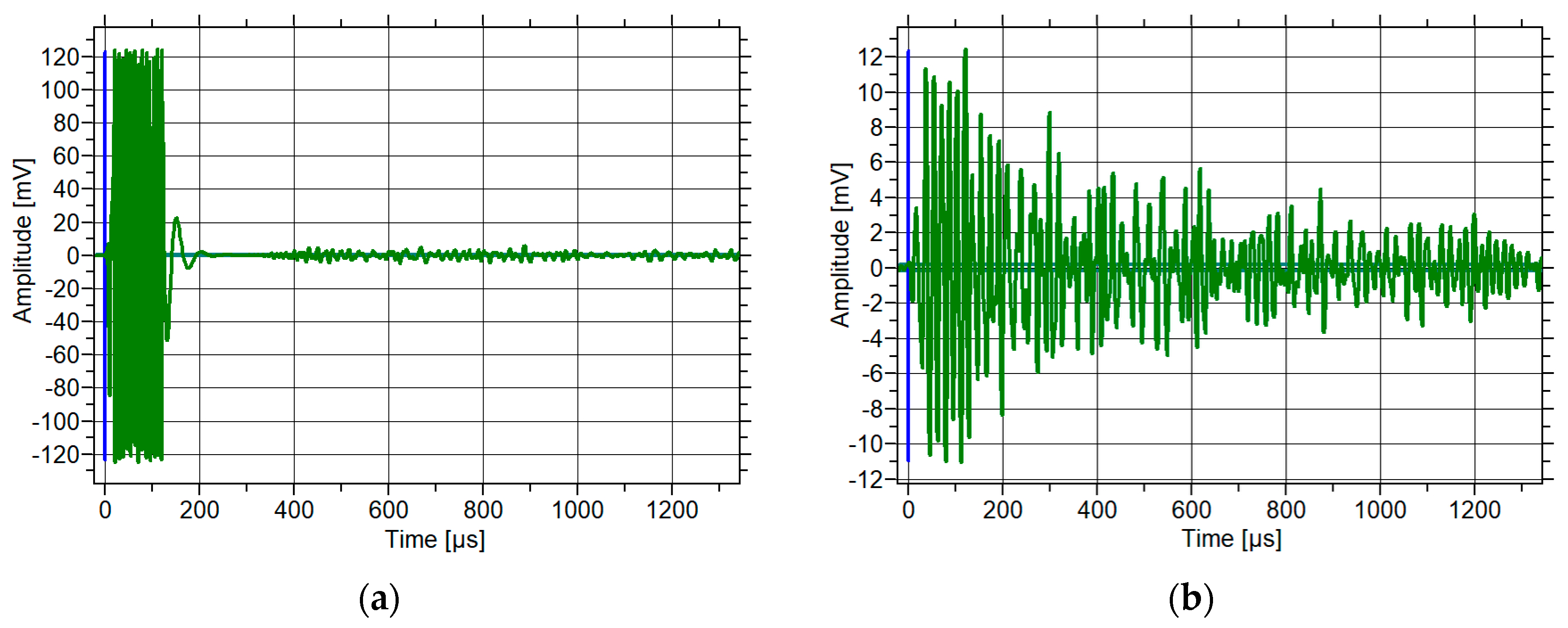

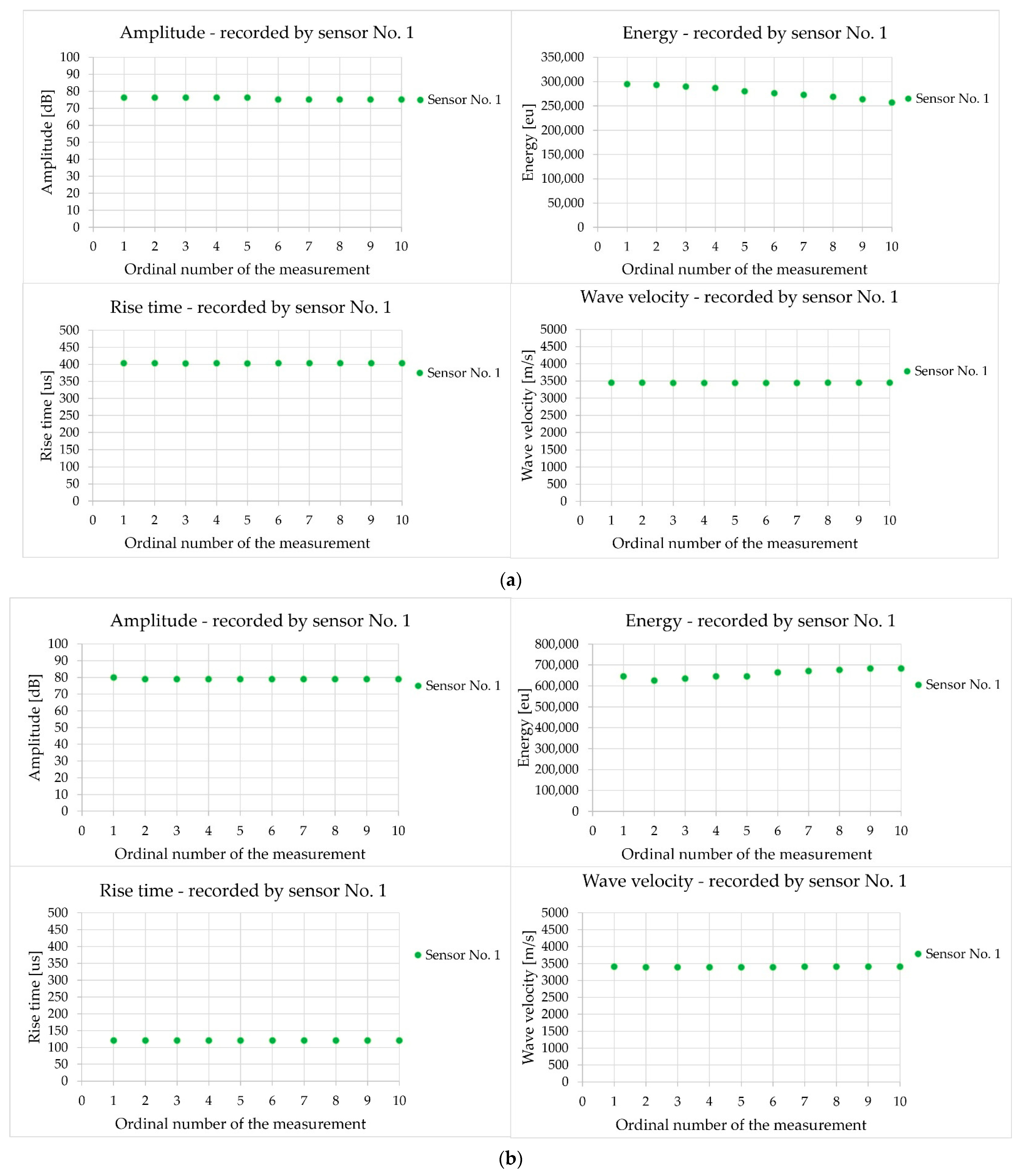

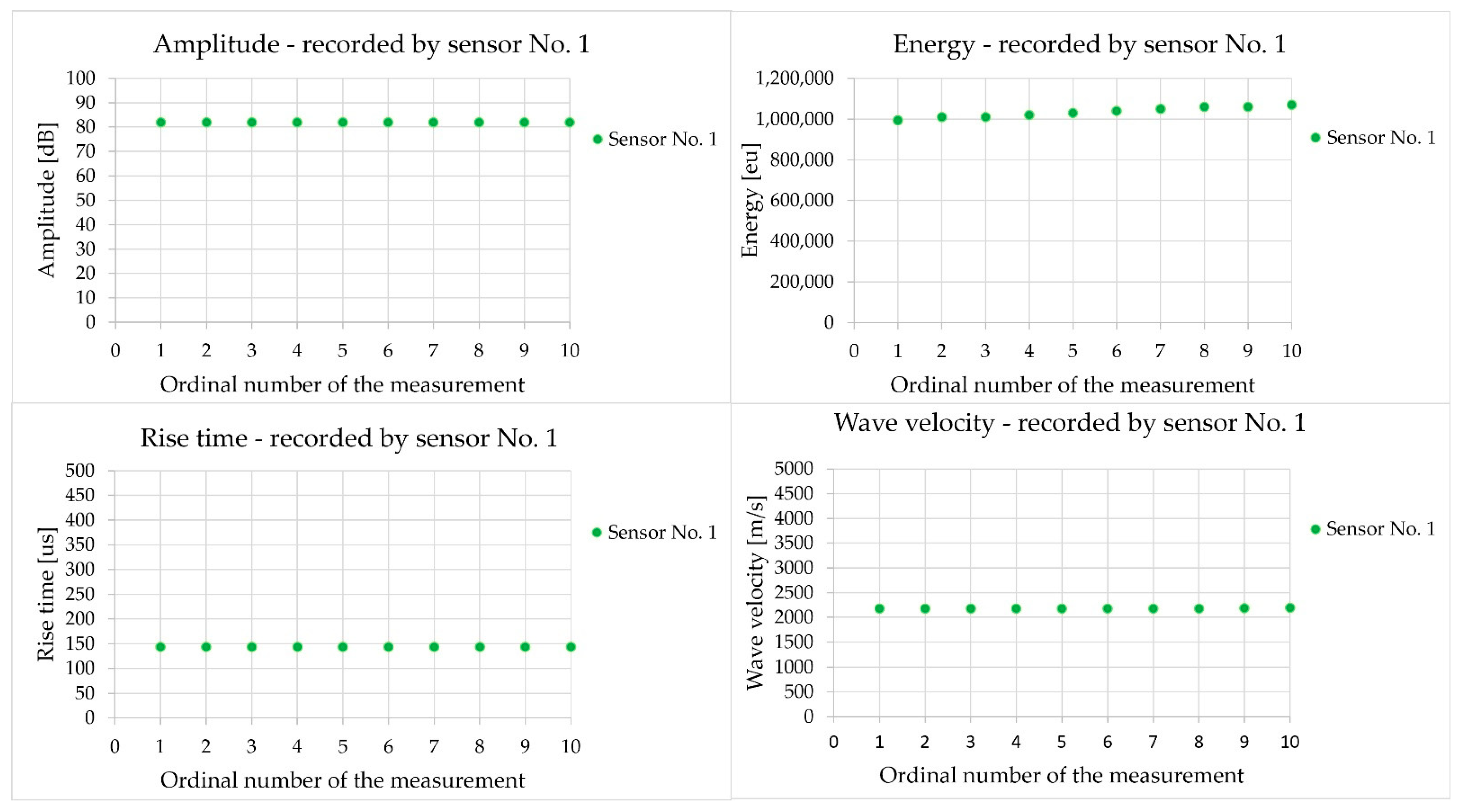

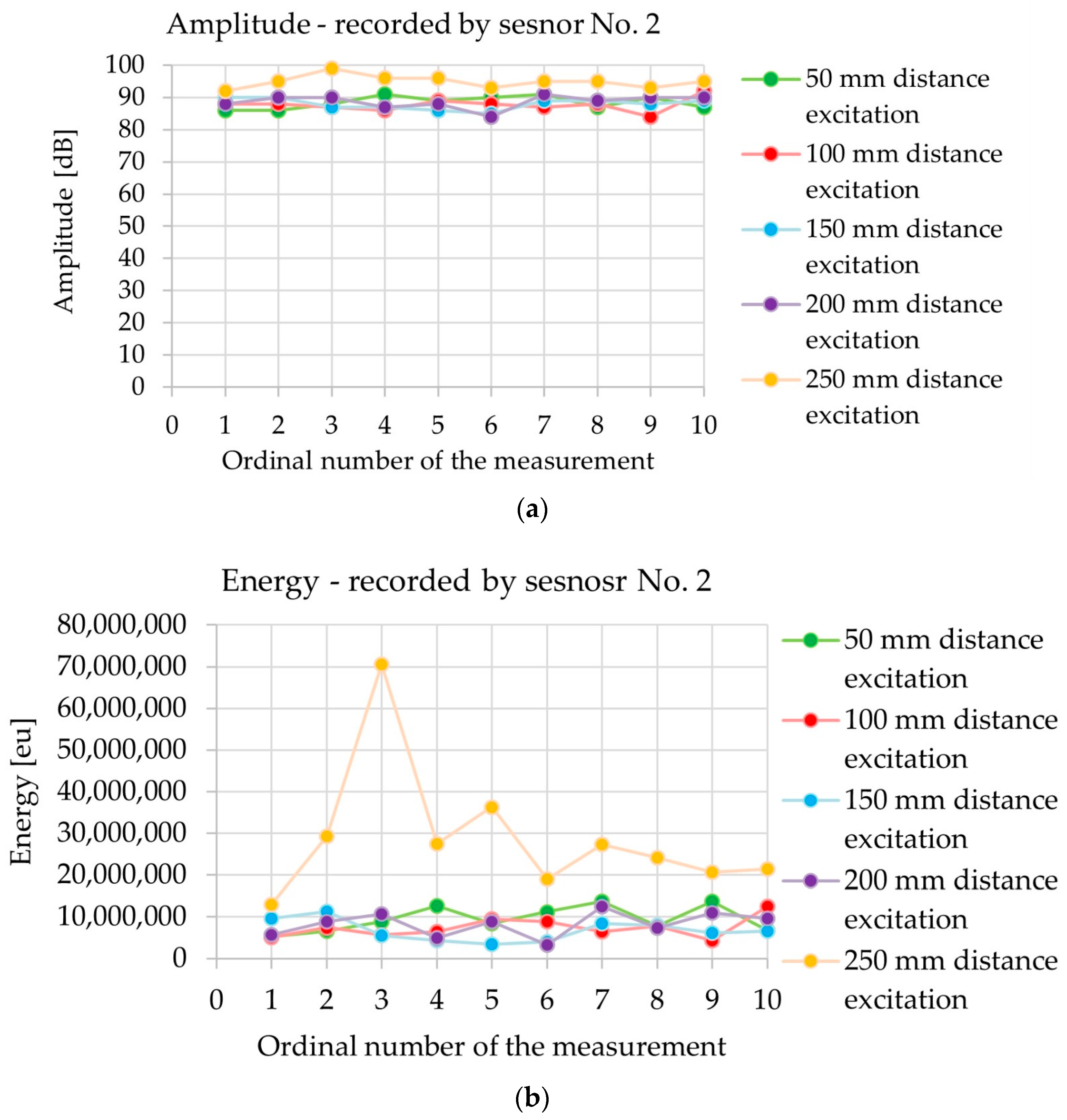

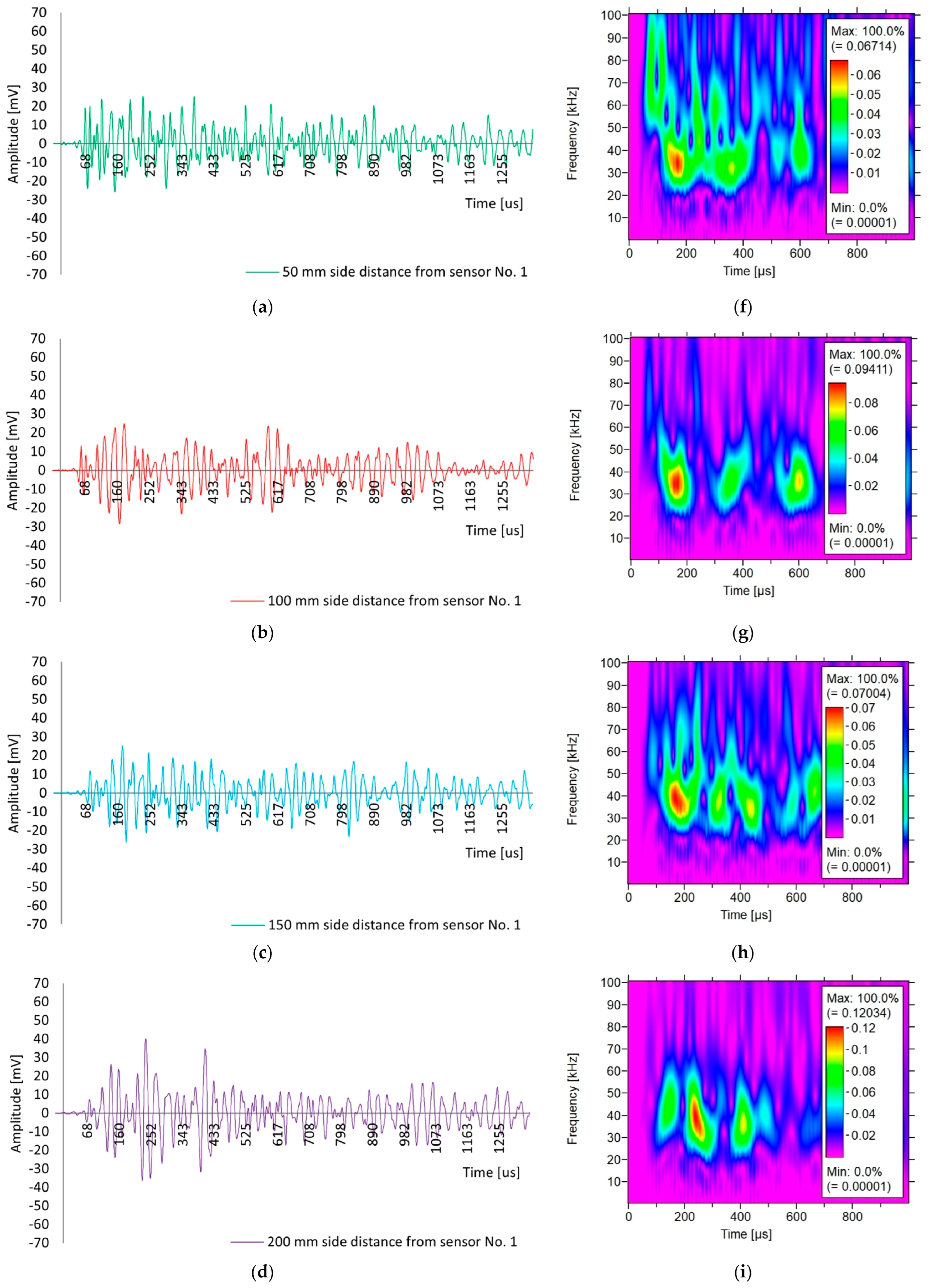

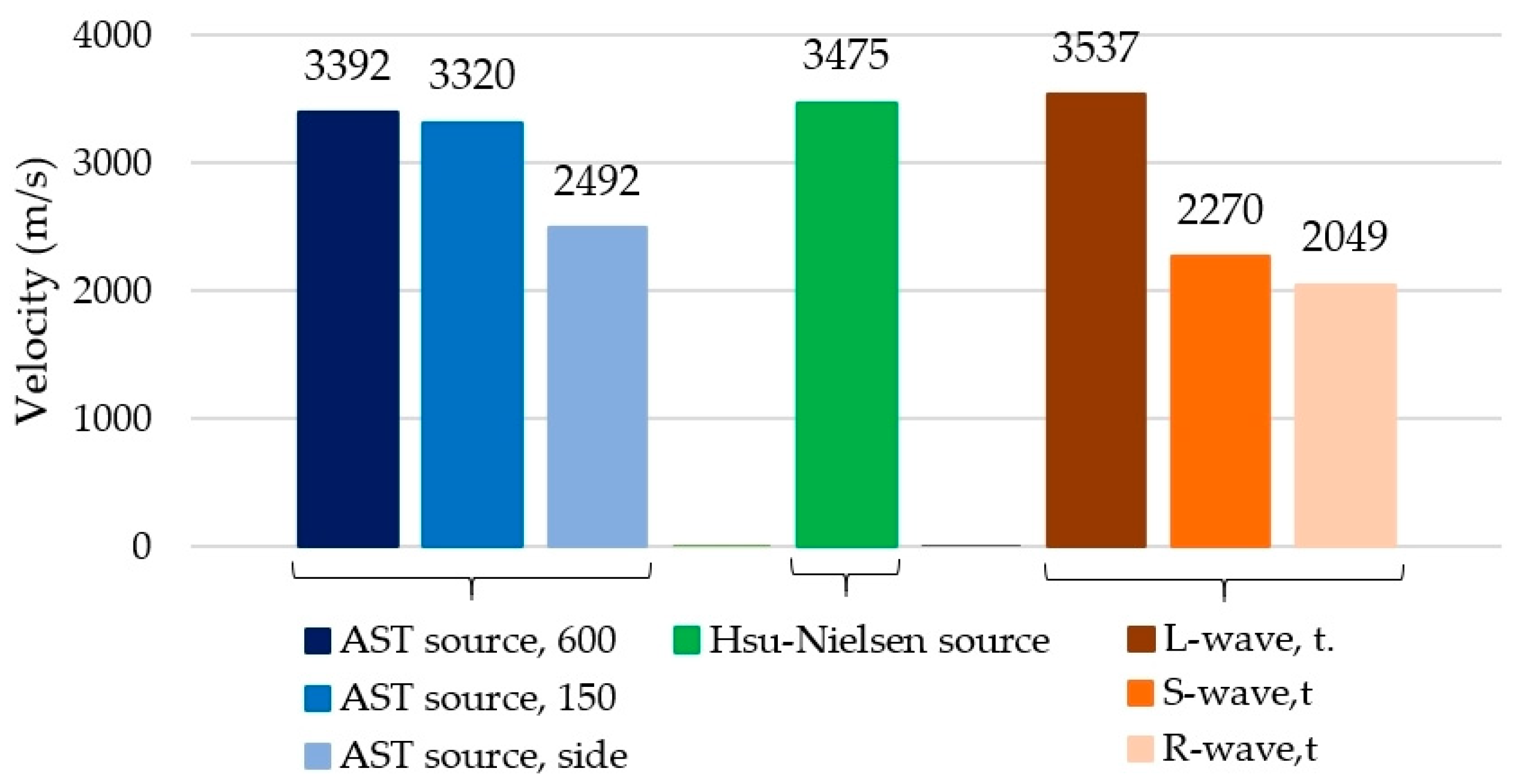

3.1.1. Analysis of Acoustic Wave Parameters—Direct Measurement

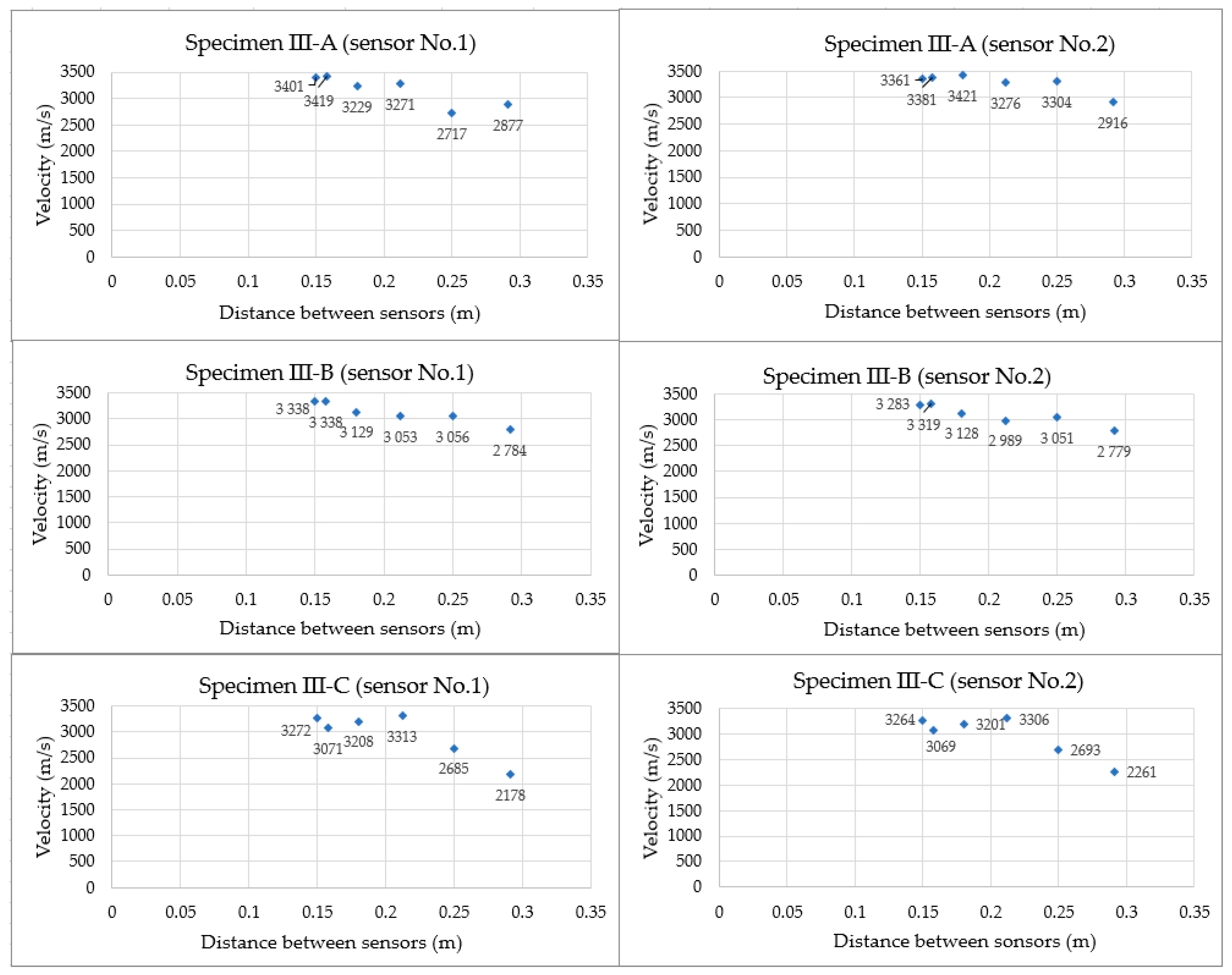

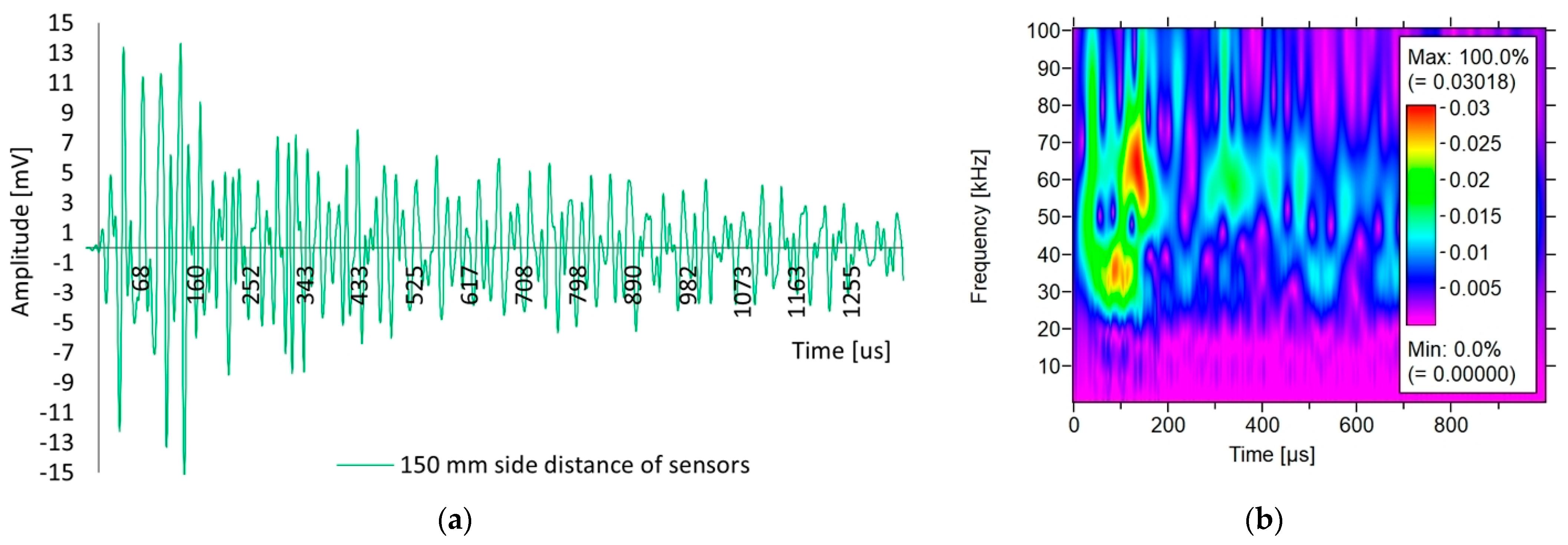

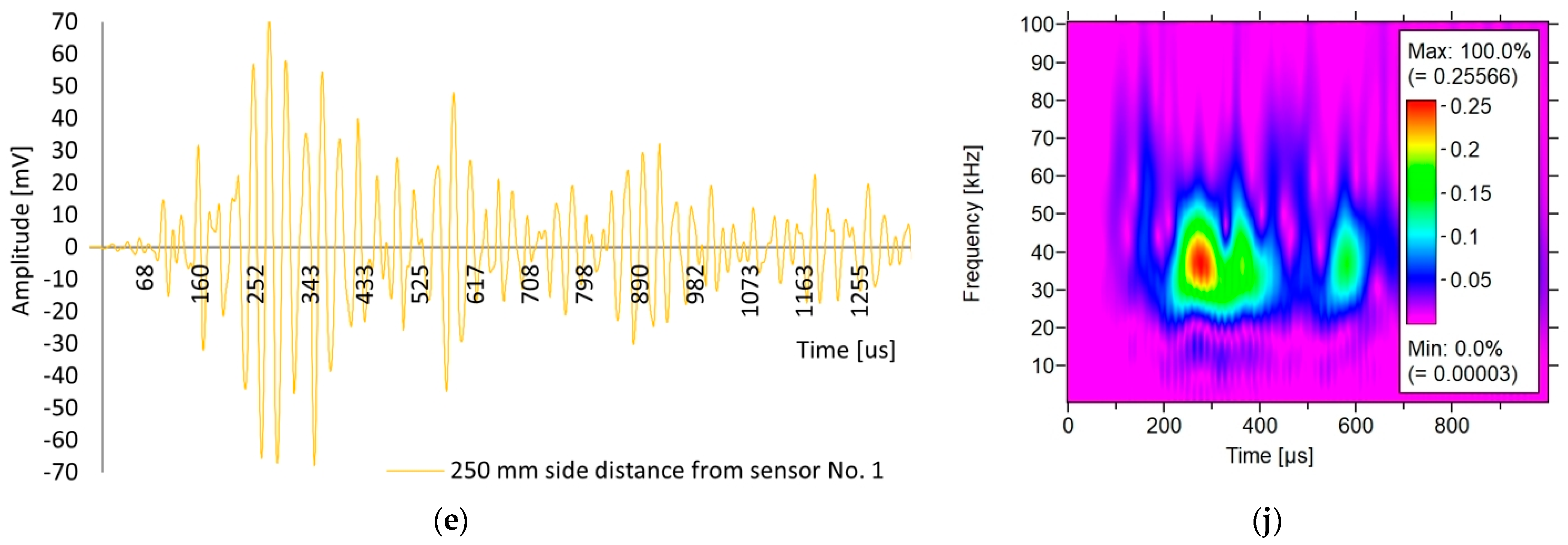

3.1.2. Analysis of Acoustic Wave Parameters—Indirect Measurement

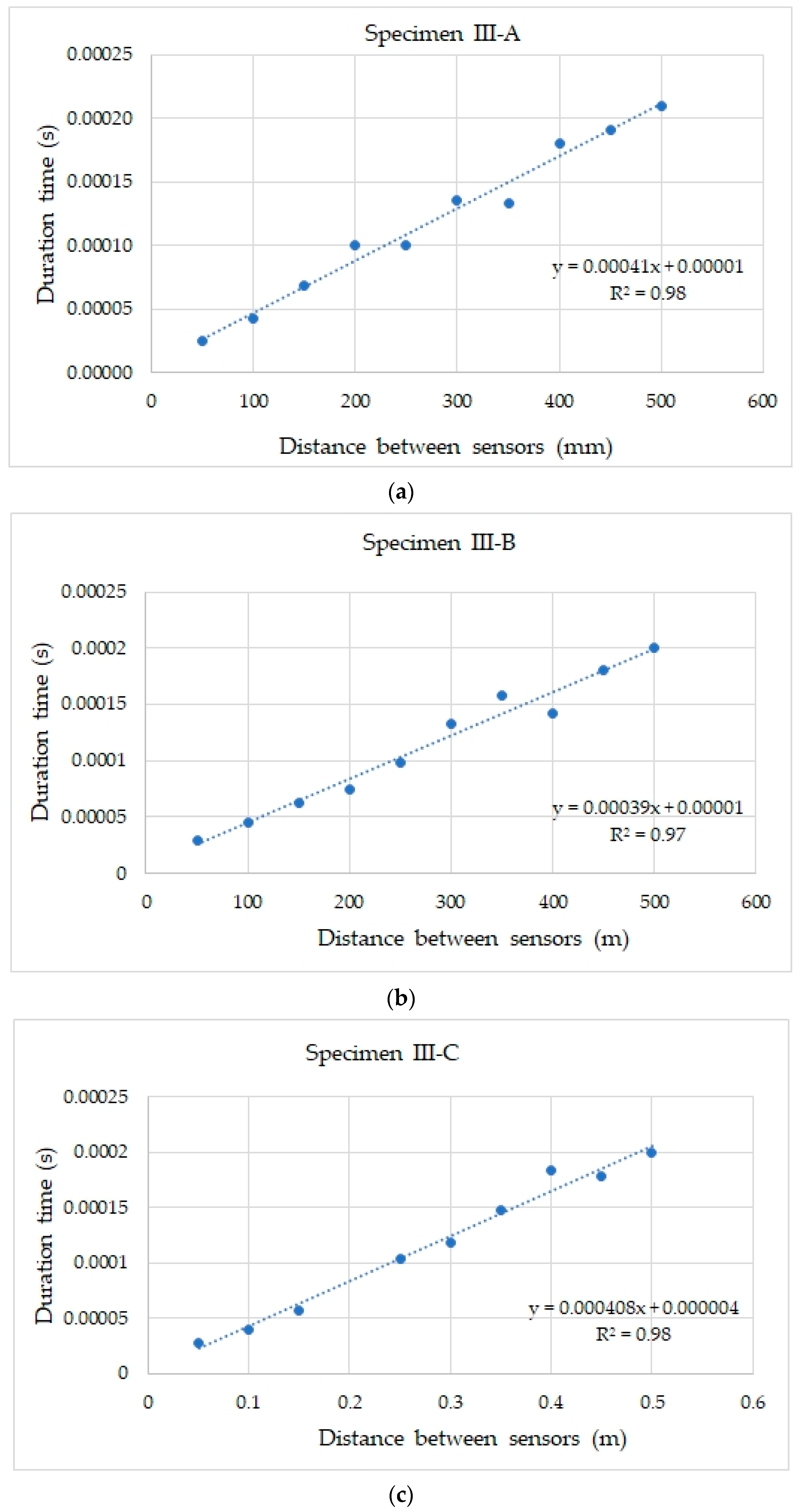

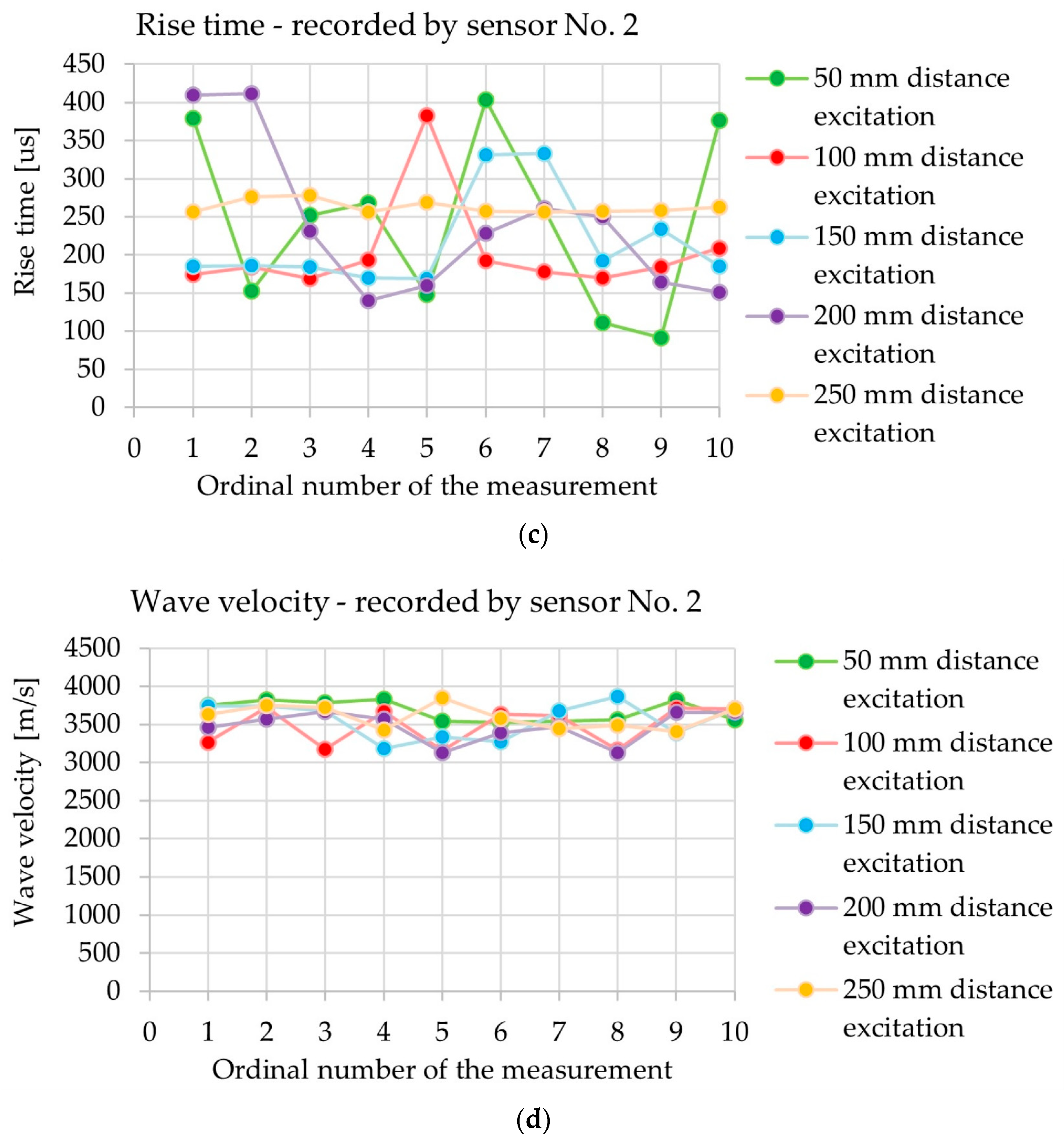

3.2. Results of Hsu–Nielsen Tests

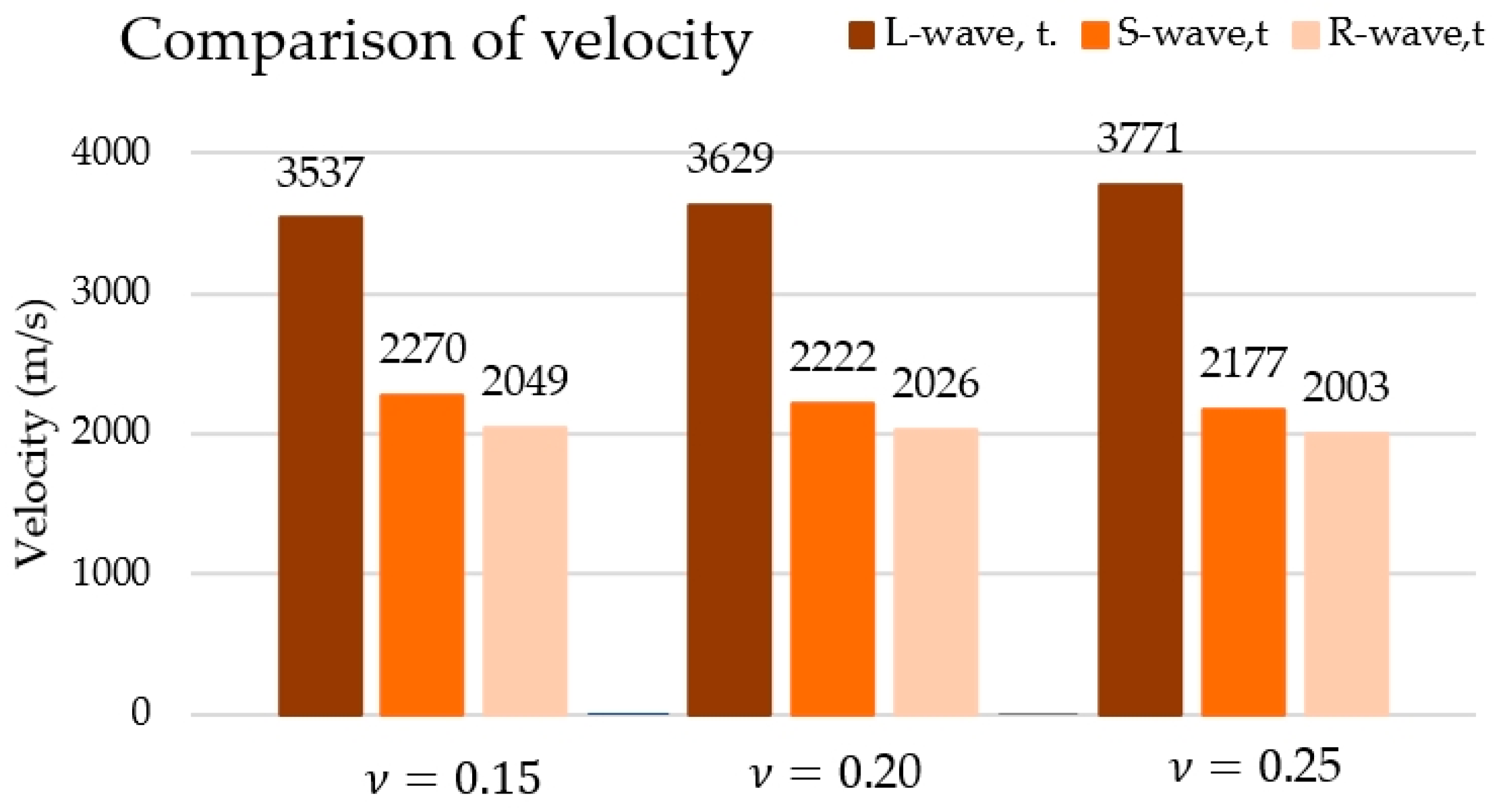

3.3. Results of the Theoretical Values of Velocity

4. Discussion

4.1. Discussion of the Research Findings

4.2. Advantages and Limitations of Testing Using AST

4.3. Proposal for Further Research

- Analysis of test results for elements with varying degrees of degradation and cracking;

- Analysis of the impact of temperature and humidity changes, concrete age, type of cement, aggregate and the presence of reinforcement on wave propagation;

- Analysis of the impact of maximum sensor spacing on the results obtained;

- Analysis of the impact of sensors with varying resonance frequencies on the results.

5. Conclusions

- PK6I sensors with the AST function are capable of emitting and receiving an acoustic wave propagating in concrete, while the AST function can be used not only to calibrate the sensors and check their connection with concrete, but can also be employed in the analysis of the material under study.

- The positioning of the sensors (on the side wall or opposite to each other) on the sample affects the type of acoustic wave recorded.

- The direct positioning of the sensors (opposite to each other) during the test using a sensor with the AST function allows for recording a longitudinal wave in concrete, with velocity values similar to those obtained in the Hsu–Nielsen test and those estimated theoretically.

- The indirect positioning of the sensors (on one wall) during the test using a sensor with the AST function allows for the recording of a wave travelling in concrete with velocities similar to those of transverse and surface waves estimated theoretically.

- The wave velocity when positioning sensors with the AST function on one wall (indirect measurement) can be estimated according to the approach for the ultrasonic method proposed in [50].

- The coefficient of variation of the wave velocity results obtained during 10-fold induction with a sensor equipped with the AST function was up to 1%, which was lower than the coefficient of variation obtained in the Hsu–Nielsen test at the same point (5.5%).

- When performing direct measurements using the AST function (sensors positioned facing one another), a slight displacement of the sensors in relation to their axes does not significantly affect the obtained wave velocity results within a radius of 100–150 mm, that is, a shift between the mass centres of the sensors within a radius of up to 100 mm caused differences in velocity values of 4.3% and within 150 mm by approximately 6%.

- The possibility of using changes in the selected parameters of the elastic wave emitted from a sensor with the AST function as an indicator of the damage and homogeneity of the concrete. The grounds for this conclusion stem from the fact that the energy, rise time, peak amplitude, and WT wavelet coefficient react to changes in path length and the type of wave propagation.

- The test results confirmed that PK6I sensors with the AST function can serve as an alternative signal source for estimating the velocity of a propagating wave in concrete and analysing other parameters of the wave received, that is, the peak amplitude, rise time, and energy, as well as waveform analysis and wavelet analysis.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hoła, J.; Bień, J.; Sadowski, Ł.; Schabowicz, K. Non-Destructive and Semi-Destructive Diagnostics of Concrete Structures in Assessment of Their Durability. Bull. Pol. Acad. Sci. Tech. Sci. 2015, 63, 87–96. [Google Scholar] [CrossRef]

- Schabowicz, K. Modern Acoustic Techniques for Testing Concrete Structures Accessible from One Side Only. Arch. Civ. Mech. Eng. 2015, 15, 1149–1159. [Google Scholar] [CrossRef]

- Tefera, B.B.; Tarekegn, A.G. Non-Destructive Testing Techniques for Condition Assessment of Concrete Structures: A Review. Am. J. Civ. Eng. 2025, 13, 10–31. [Google Scholar] [CrossRef]

- Helal, J.; Sofi, M.; Mendis, P.A. Non-Destructive Testing of Concrete: A Review of Methods. Electron. J. Struct. Eng. 2015, 14, 97–105. [Google Scholar] [CrossRef]

- Goszczyńska, B.; Świt, G.; Trąmpczyński, W.; Krampikowska, A.; Tworzewska, J.; Tworzewski, P. Experimental validation of concrete crack identification and location with the acoustic emission method. Arch. Civ. Mech. Eng. 2012, 12, 23–28. [Google Scholar] [CrossRef]

- Grosse, C.U.; Ohtsu, M.; Aggelis, D.G.; Shiotani, T. (Eds.) Acoustic Emission Testing: Basics for Research—Applications in Engineering, 2nd ed.; Springer Nature: Cham, Switzerland, 2021; pp. 1–763. [Google Scholar]

- Ohno, K. Application of acoustic emission for structure diagnosis. Diagnosis 2011, 2, 3–18. [Google Scholar]

- Tworzewski, P.; Teodorczyk, M.; Tworzewska, J. Tracking of Crack Formation in Concrete Using Acoustic Method and Digital Image Correlation. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 052032. [Google Scholar] [CrossRef]

- Adamczak-Bugno, A.; Lipiec, S.; Adamczak, J.; Vičan, J.; Bahleda, F. Identification of Destruction Processes and Assessment of Deformations in Compressed Concrete Modified with Polypropylene Fibers Exposed to Fire Temperatures Using Acoustic Emission Signal Analysis, Numerical Analysis, and Digital Image Correlation. Materials 2023, 16, 6786. [Google Scholar] [CrossRef]

- Bacharz, M.; Bacharz, K.; Trąmpczyński, W. The Correlation between Shrinkage and Acoustic Emission Signals in Early Age Concrete. Materials 2022, 15, 5389. [Google Scholar] [CrossRef]

- Bacharz, M.; Bacharz, K.; Trąmpczyński, W. Impact of Early-Age Curing and Environmental Conditions on Shrinkage and Microcracking in Concrete. Materials 2025, 18, 3185. [Google Scholar] [CrossRef]

- Li, W.; Zhu, J.; Mu, K.; Yang, W.; Zhang, X.; Zhao, X. Experimental Investigation of Concrete Crack Depth Detection Using a Novel Piezoelectric Transducer and Improved AIC Algorithm. Buildings 2024, 14, 3939. [Google Scholar] [CrossRef]

- Teodorczyk, M. The Effect of Longitudinal-Wave Attenuation in the Acoustic Emission Method on the Localisation and Identification of Destructive Processes. Ph.D. Thesis, Kielce University of Technology, Kielce, Poland, 2017. (In Polish). [Google Scholar]

- Raczkiewicz, W.; Bacharz, M.; Bacharz, K.; Teodorczyk, M. Reinforcement Corrosion Testing in Concrete and Fiber Reinforced Concrete Specimens Exposed to Aggressive External Factors. Materials 2023, 16, 1174. [Google Scholar] [CrossRef]

- Carino, N.J. Training: Often the Missing Link in Using NDT Methods. Constr. Build. Mater. 2013, 38, 1316–1320. [Google Scholar] [CrossRef]

- Graff, K. Wave Motion in Elastic Solids; Dover Publications: New York, NY, USA, 1991. [Google Scholar]

- Breckenridge, F.R.; Proctor, T.M.; Hsu, N.N.; Fick, S.E.; Eitzen, D.G. Transient Sources for Acoustic Emission Work. In Progress in Acoustic Emission V; Yamagushi, K., Takahashi, H., Niitsuma, H., Eds.; The Japanese Society of NDT: Tokyo, Japan, 1990; pp. 75–84. [Google Scholar]

- Sansalone, M.; Streett, W. Impact-Echo: Nondestructive Evaluation of Concrete and Masonry; Cayuga Press: New York, NY, USA, 1997. [Google Scholar]

- Lewińska-Romicka, A. Badania Nieniszczące. Podstawy Defektoskopii; WNT: Warszawa, Poland, 2001. [Google Scholar]

- Dzaye, E.D.; Schutter, G.D.; Aggelis, D.G. Study on mechanical acoustic emission sources in fresh concrete. Arch. Civ. Mech. Eng. 2018, 18, 742–754. [Google Scholar] [CrossRef]

- Królikowski, J.; Witczak, Z. Wzorcowe Źródła Emisji Akustycznej. In Emisja Akustyczna, Źródła, Metody, Zastosowania; Malecki, I., Ranachowski, J., Eds.; Polska Akademia Nauk, Instytut Podstawowych Problemów Techniki: Warszawa, Poland, 1994; pp. 467–485. [Google Scholar]

- Schumacher, T. Acoustic Emission Techniques Applied to Conventionally Reinforced Concrete Bridge Girders; Final Report SPR 633; Oregon State University: Corvallis, OR, USA, 2008. [Google Scholar]

- Ranachowski, Z. Metody Pomiaru i Analizy Sygnału Emisji Akustycznej; Instytut Podstawowych Problemów Techniki PAN: Warszawa, Poland, 1997. [Google Scholar]

- Oh, T.-M.; Kim, M.-K.; Lee, J.-W.; Kim, H.; Kim, M.-J. Experimental Investigation on Effective Distances of Acoustic Emission in Concrete Structures. Appl. Sci. 2020, 10, 6051. [Google Scholar] [CrossRef]

- Hsu, N.; Breckenridge, F. Characterization and Calibration of Acoustic Emission Sensors. Mater. Eval. 1981, 39, 60–68. [Google Scholar]

- Skubis, J.; Ranachowski, Z.; Boczar, T.; Lorenc, M. Analiza Możliwości Wykorzystania Metody Wzorcowania Hsu-Nielsena w układach do Pomiaru EA od Wyładowań Niezupełnych; Instytut Podstawowych Problemów Techniki PAN: Warszawa, Poland, 1994. [Google Scholar]

- Brunner, A.J.; Terrasi, G. Acousto-Ultrasonic Signal Analysis for Damage Detection in GFRP Adhesive Joints. J. Acoustic Emission 2008, 26, 152–159. [Google Scholar]

- Papasalouros, D.; Anastasopoulos, A.; Kourousis, D. Acoustic Emission Monitoring of Jacketed Concrete Beams & Columns. International Symposium on Non-Destructive Testing in Civil Engineering (NDT-CE 2025), 24–26 September 2025, Izmir, Turkey. e-J. Nondestruct. Test. 2025, 30, 31759. [Google Scholar] [CrossRef]

- Świt, G.; Teodorczyk, M. Application of the SiGMA analysis to the stress evaluation of the cracking structures. Eduk.-Tech.-Inform. 2014, 5, 676–681. [Google Scholar]

- Zhao, Y.; Zhao, Q.; Yang, T.; Chen, Y.; Zhang, P.; Liu, H. Investigation of crack propagation and acoustic emission characteristics in jointed rock under freeze–thaw cycles based on DEM. Int. J. Min. Sci. Technol. 2025, 35, 1171–1195. [Google Scholar] [CrossRef]

- Suzuki, H.; Kinjo, T.; Hayashi, Y.; Takemoto, M.; Ono, K. Wavelet Transform of Acoustic Emission Signals. J. Acoust. Emiss. 1996, 14, 69–84. [Google Scholar]

- Machorro-Lopez, J.M.; Hernandez-Figueroa, J.A.; Carrion-Viramontes, F.J.; Amezquita-Sanchez, J.P.; Valtierra-Rodriguez, M.; Crespo-Sanchez, S.E.; Yanez-Borjas, J.J.; Quintana-Rodriguez, J.A.; Martinez-Trujano, L.A. Analysis of Acoustic Emission Signals Processed with Wavelet Transform for Structural Damage Detection in Concrete Beams. Mathematics 2023, 11, 719. [Google Scholar] [CrossRef]

- Darmon, M.; Khalid, N.; Ramaniraka, M.; Dorval, V.; Henault, J.-M.; Chaix, J.F. Modeling of ultrasonic velocity and attenuation for concrete inspection: A review. Ultrasonics 2025, 154, 107690. [Google Scholar] [CrossRef]

- Li, Y.; Guo, S.; Su, Z.; Ding, K.; Loh, X.J. Lightweight and conformal acousto-ultrasonic sensing network for multi-scale structural health monitoring: A review. FlexMat 2024, 2, 4–29. [Google Scholar] [CrossRef]

- Hinrichs, R.; Jiang, N.; Beltran, R.; Krause, T.; Kading, M.; Lange, A.; Schmidt, B.; Ostermann, J.; Marx, S. Analysis of the Repeatability of the Pencil Lead Break in Comparison to the Ball Impact and Electromagnetic Body-Noise Actuator. In Proceedings of the 20th World Conference on Non-Destructive Testing, Songdo Convensia, Incheon, Republic of Korea, 27–31 May 2024. [Google Scholar]

- Li, D.; Yang, K.; He, Z.; Zhou, H.; Li, J. Acoustic Emission Wave Velocity Attenuation of Concrete and Its Application in Crack Localization. Sustainability 2020, 12, 7405. [Google Scholar] [CrossRef]

- Li, J.; Qin, L. Study on Acoustic Emission Localization of Concrete Using Modified Velocity. Adv. Civ. Eng. 2019, 2019, 1–11. [Google Scholar] [CrossRef]

- Tsimogiannis, A.; Georgali, B.; Anastassopoulos, A. Acoustic Emission/Acousto-Ultrasonic Data Fusion for Damage Evaluation in Concrete. J. Acoustic Emission 2000, 18, 21–28. [Google Scholar]

- Linek, M. Airport Cement Concrete with Ceramic Dust of Increased Thermal Resistance. Materials 2022, 15, 3673. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Hu, X.; Liu, Y.; Zhou, D.; Yuan, B.; Liu, S.; Luo, Z.; Li, X.; Jin, D.; Xu, F. Multiscale characterization of geopolymers modified with alkali-catalyzed nano-silica: Effects on dispersion and mechanical properties. Cem. Concr. Compos. 2025, 165, 106324. [Google Scholar] [CrossRef]

- Kumar, T.U.; Kumar, M.V.; Salnkhe, S.; Cep, R. Evaluation of non-destructive testing and long-term durability of geopolymer aggregate concreto. Front. Built Environ. 2024, 10, 1454687. [Google Scholar] [CrossRef]

- Teodorczyk, M. Influence of Aggregate Gradation on the Longitudinal Wave Velocity Changes in Unloaded Concrete. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 032084. [Google Scholar] [CrossRef]

- National Declaration of Basalt Aggregate “Bazalt-Gracze” Sp. z o.o. Gracze Performance. Available online: https://bazalt-gracze.pl/images/ce_12620_2_8.pdf (accessed on 7 April 2025).

- National Declaration of Basalt Aggregate “Bazalt-Gracze” Sp. z o.o. Gracze Performance. Available online: https://bazalt-gracze.pl/images/ce_12620_8_16.pdf (accessed on 7 April 2025).

- National Declaration of Cement CEMIII/A 42,5N—LH/HSR/NA Górażdże Performance. Available online: https://www.heidelbergmaterials.pl/pl/cement-hutniczy-pn-b-19808-cem-iii-a-425n-hsr-na (accessed on 7 April 2025).

- PN-EN 1330-9:2017; Non-Destructive Testing. Terminology. Part 9: Terms Used in Acoustic Emission Testing. PKN: Warszawa, Poland, 2017.

- MISTRAS Group Inc. PK6I Sensor. Medium Frequency Integral Preamplifier Resonant Sensor. Product Data Sheet; MISTRAS: Princeton Junction, NJ, USA, 2011. [Google Scholar]

- ASTM E976-10; Standard Guide for Determining the Reproducibility of Acoustic Emission Sensor Response. ASTM International: West Conshohocken, PA, USA, 2010.

- Ranachowski, Z. Emisja Akustyczna w Diagnostyce Obiektów Technicznych. Drog. Mosty 2012, 2, 45–56. [Google Scholar]

- PN-EN 12504-4:2021-12; Testing Concrete in Structures—Part 4: Determination of Ultrasonic Pulse Velocity. PKN: Warszawa, Poland, 2021.

- Abolle-Okoyeagu, C.J.; Fatukasi, S.; Reuben, B. Measurement and Simulation of the Propagation of Impulsive Acoustic Emission Sources in Pipes. Acoustics 2024, 6, 620–637. [Google Scholar] [CrossRef]

- Ghadarah, N.; Ayre, D. A review on Acoustic Emission Testing for Structural Health Monitoring of Polymer-Based Composites. Sensors 2023, 23, 6945. [Google Scholar] [CrossRef]

- Oh, S.C. Comparison of Ultrasonic Velocities between Direct and Indirect Methods on 30 mm × 30 mm Spruce Lumber. J. Korean Wood Sci. Technol. 2020, 48, 562–568. [Google Scholar] [CrossRef]

- Yaman, I.O.; Inci, G.; Yesiller, N.; Aktan, H.M. Ultrasonic Pulse Velocity in Concrete Using Direct and Indirect Transmission. ACI Mater. J. 2001, 98, 6. Available online: https://www.researchgate.net/publication/48909415_ (accessed on 11 October 2025). [CrossRef] [PubMed]

- Hearer, P.M. Introduction to Seismology, 2nd ed.; Cambridge University Press: New York, NY, USA, 2009. [Google Scholar]

- Anderson, F.L. Huygens’ Principle geometric derivation and elimination of the wake and backward wave. Sci. Rep. 2021, 11, 20257. [Google Scholar] [CrossRef]

- Khan, Z.; Majid, A.; Cascante, G. Measurement of Ultrasonic Wave Velocities. In Proceedings of the 57th Canadian Geotechnical Conference Geo Quebec 2004, Quebec City, QC, Canada, 24–27 October 2004; Available online: https://members.cgs.ca/documents/conference2004/articles/G11.290.pdf (accessed on 11 October 2025).

- Baggens, O.; Ryden, N. Systematic errors in Impact-Echo thickness estimation due to near field effects. NDTE Int. 2015, 69, 16–27. [Google Scholar] [CrossRef]

- Piyush; Dhiman, N.; Kumar, B.; Yadav, S.; Dubey, P.K. Measurement of ultrasonic pulse velocity with improved accuracy using automatic threshold error correction. Rev. Sci. Instrum. 2023, 94, 045101. [Google Scholar] [CrossRef]

| Parameter | Basalt Aggregate 2/8 [43] | Basalt Aggregate 8/16 [44] |

|---|---|---|

| Specific gravity (Mg/m3) | 3.18 | 3.17 |

| Water absorption (%) | 0.9 | 0.7 |

| Dust content (%) | 1.5 | 1.5 |

| Resistance to crushing | LA15 | LA15 |

| Resistance to abrasion | MDE10 | MDE20 |

| Resistance to polishing | PSV50 | PSV50 |

| Resistance to surface abrasion | AAV10 | AAV10 |

| Frost resistance | F1 | F1 |

| Reactivity of alkaline | Non-reactive | Non-reactive |

| Components and Properties | Values [45] |

| Portland cement clinker (K) | 35–50% |

| Granulated blast furnace slag (S) | 50–65% |

| Secondary components | 0–5% |

| Compressive strength class | 42.5 N |

| Compressive strength after 2 days | Above or equal to 10 MPa |

| Compressive strength after 28 days | Between 42.5 MPa and 62.5 MPa |

| Number of Specimens | Mean Velocity (m/s) Measured from a Distance of 600 mm | Mean Velocity (m/s) Measured from a Distance of 150 mm | Difference in Velocity Values (%) |

|---|---|---|---|

| III-A | 3425 | 3381 | 0.86 |

| III-B | 3361 | 3310 | 1.02 |

| III-C | 3383 | 3268 | 2.28 |

| Mean value | 3390 | 3320 | 1.38 |

| Standard deviation | 32 | 51 | |

| Variation (%) | 0.95 | 1.52 |

| Statistical Parameters | Specimen III-A | Specimen III-B | Specimen III-C | |||

|---|---|---|---|---|---|---|

| Sensor No.1 | Sensor No.2 | Sensor No.1 | Sensor No.2 | Sensor No.1 | Sensor No.2 | |

| Mean value (m/s) | 3350 | 3388 | 3268 | 3243 | 3184 | 3178 |

| Standard deviation (m/s) | 86 | 25 | 99 | 83 | 84 | 81 |

| Coefficient of variation (%) | 2.6 | 0.7 | 3.0 | 2.6 | 2.6 | 2.6 |

| Velocity (m/s) | Specimen III-A | Specimen III-B | Specimen III-C |

|---|---|---|---|

| Velocity calculated according to PN-EN 12504-4:2021-12 [50] | 2433 | 2591 | 2451 |

| Statistical Parameters | Specimen III-A | Specimen III-B | Specimen III-C |

|---|---|---|---|

| Mean value of velocity (m/s) | 3558 | 3231 | 3637 |

| Standard deviation (m/s) | 76 | 215 | 149 |

| Coefficient of variation (%) | 1.97% | 6.67% | 2.39% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bacharz, M.; Teodorczyk, M.; Szulc, J. The Auto Sensor Test as an AE Signal Source in Concrete Specimens. Materials 2025, 18, 5084. https://doi.org/10.3390/ma18225084

Bacharz M, Teodorczyk M, Szulc J. The Auto Sensor Test as an AE Signal Source in Concrete Specimens. Materials. 2025; 18(22):5084. https://doi.org/10.3390/ma18225084

Chicago/Turabian StyleBacharz, Magdalena, Michał Teodorczyk, and Jarosław Szulc. 2025. "The Auto Sensor Test as an AE Signal Source in Concrete Specimens" Materials 18, no. 22: 5084. https://doi.org/10.3390/ma18225084

APA StyleBacharz, M., Teodorczyk, M., & Szulc, J. (2025). The Auto Sensor Test as an AE Signal Source in Concrete Specimens. Materials, 18(22), 5084. https://doi.org/10.3390/ma18225084