Abstract

Load spectrum enhancement is a pivotal accelerated fatigue testing methodology employed to substantially reduce test duration and associated costs. This technique operates by strategically elevating load amplitudes while ensuring the preservation of the original failure mechanism. In this study, a novel fatigue life prediction model for variable amplitude loading is developed by integrating the theories of Equivalent Initial Flaw Size (EIFS) and the Equivalent Plastic Zone (EPZ). This integrated approach explicitly accounts for both the small crack effect and load interaction effects, which are critical yet often oversimplified aspects of fatigue damage accumulation. The model is subsequently applied to quantitatively establish the relationship between the Load Enhancement Factor (LEF) and the test time or compression ratio. Finally, fatigue tests on typical 2A14 aluminum alloy structures under variable amplitude loading are conducted to validate the proposed model. The results demonstrate a significant life reduction with increasing LEF, achieving a remarkable test time reduction of over 50% at an LEF of 1.2. All experimental data fall within a scatter band of three, relative to the model prediction. Additionally, the predicted mean compression ratio exhibits approximate agreement with the experimental data, with errors within an acceptable range. This work provides a physically grounded and practically validated framework for implementing efficient and reliable load spectrum enhancement.

1. Introduction

The increasing design lifetimes of aircraft have led to significantly longer ground fatigue tests [1]. To effectively reduce test durations and associated costs, meticulous processing of the load spectrum is essential. Commonly used accelerated techniques include small load truncation [2,3], load equivalence [4], and load enhancement [5]. Among these methods, load enhancement is widely adopted due to its operational convenience in load spectrum processing. This method is usually achieved by proportionally increasing the original load spectrum while ensuring that the failure mechanism remains unchanged. The scaling factor applied in this process is referred to as the load enhancement factor (LEF).

Establishing the relationship between the accelerated factor (or test time compression ratio) and the LEF is central to load enhancement. Extensive research has been devoted to this topic. For instance, fatigue tests on Airbus A320 and Boeing 777 empennage structures employed a LEF of 1.25 [6]. The LEF of fatigue tests on the composite aircraft structures of the Starship was taken as 1.15 by massive experiments [7]. Dong et al. [8] derived the relationship between fatigue life and LEF using the structural detail fatigue rating (DFR) and damage accumulation theory. Dang et al. [9] further refined Dong’s method by ensuring the invariance of Ground–Air–Ground load. Although these methods are convenient for engineering applications, they are largely phenomenological or empirically based, lacking support from interpretation of the fatigue mechanism. To address this limitation, some researchers have attempted to establish this relationship based on linear elastic fracture mechanics (LEFM). Zhang et al. [10] derived an exponential relationship between accelerated and original crack growth life using the Paris model. Zhang et al. [11] proposed a formula relating crack propagation life to the LEF considering the crack closure, which is particularly effective for constant amplitude (CA) loading spectra. For variable amplitude (VA) loading, where load interaction effects are significant, Zhang et al. [12] modified Walker’s model and derived the relationship between accelerated factor with the LEF. Generally, these models provide valuable insights but share a common limitation: they predominantly focus on long crack growth behavior, thereby neglecting the critical influence of the small crack growth phase on the total fatigue life. This oversight can lead to non-conservative predictions, as the small crack phase often constitutes a substantial portion of the life of many engineering components.

Successful implementation of load spectrum enhancement relies on accurately establishing the relationship between the accelerated factor/compression ratio and the LEF, which in turn requires precise prediction of fatigue life under VA loading. Accurate fatigue life prediction under VA loading must address two challenges: first, the small crack problem. The starting point for calculating structural fatigue life is often a small crack, and the traditional crack growth methodologies based on LEFM tend to yield non-conservative life estimations due to the small crack effect [13,14,15].

Though many scholars have investigated the small crack growth behavior of various materials and proposed several small crack growth models [16,17,18,19,20,21,22], the small crack problem has not been fully resolved. To avoid the complex small crack problem, some scholars [23,24,25,26,27] have introduced the concept of equivalent initial flaw size (EIFS). The core idea is to determine a crack length such that the fatigue life calculated using the long crack growth model aligns with the experimental life data. Liu and Mahadevan [24] proposed that the EIFS can be obtained from the Kitagawa–Takahashi diagram [28]. Zhang et al. [26,27] developed a fatigue life prediction model under CA loading based on EIFS and crack closure, demonstrating good agreement with experimental data for various materials and structures.

The second major challenge is the load interaction effect. Under VA loading, overloads/underloads can induce crack growth retardation/acceleration, significantly influencing the whole fatigue life [29,30,31,32]. The load interaction is usually explained by the crack closure mechanism [33,34,35]. Thus, tracing the variation in crack closure is an effective means to characterize the load interaction effect. In our previous work, Zhang and Liu [36] proposed a virtual crack annealing (VCA) model to compute the crack closure level under CA loading. The VCA model conceptualizes fatigue crack closure zones as annealed material, enabling analytical prediction of crack opening stress through residual stress reversal in an equivalent crack. Further, Jiang et al. [37,38] extended the VCA model to the VA loading conditions by incorporating load interaction effects through variations in crack closure, determined by tracking evolution in the crack tip forward and reverse plastic zones. This modified approach, termed the equivalent plastic zone (EPZ) model, has been validated against crack growth data from VA loading experiments, confirming its effectiveness in characterizing crack tip physical states.

Building on directly upon the foundational concepts of EIFS [24,26,27] and the mechanistic crack closure prediction capabilities of the EPZ model [37,38], this study proposes a VA fatigue life prediction model that explicitly incorporates both the small crack effect and load interaction effect. And it is applied to fatigue load spectrum enhancement. The rest of this paper is organized as follows: First, the material properties, specimens, and experimental setup in this work are introduced. Next, the VA fatigue life prediction model is developed based on the EIFS and EPZ theory. Subsequently, the fatigue life tests of two typical structures under programmed load spectra at different LEFs are conducted to validate the proposed model. Finally, some discussion and conclusions are given.

2. Materials

2.1. Material Property

The material studied in this work was 2A14 aluminum alloy, with its chemical composition provided in Table 1. The Young’s modulus is 74.7 GPa, and the yield strength and ultimate strength are 377 and 458 MPa, respectively.

Table 1.

Chemical composition of 2A14-T6 aluminum alloy(wt.%).

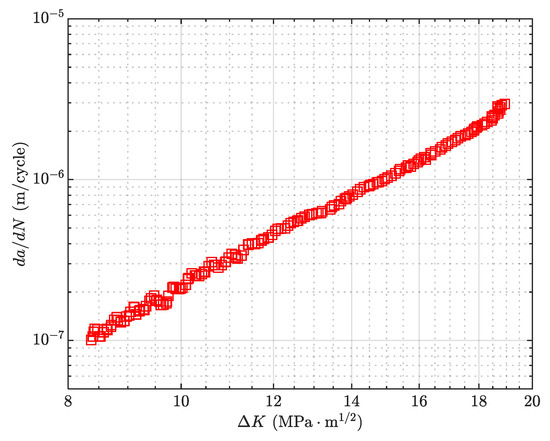

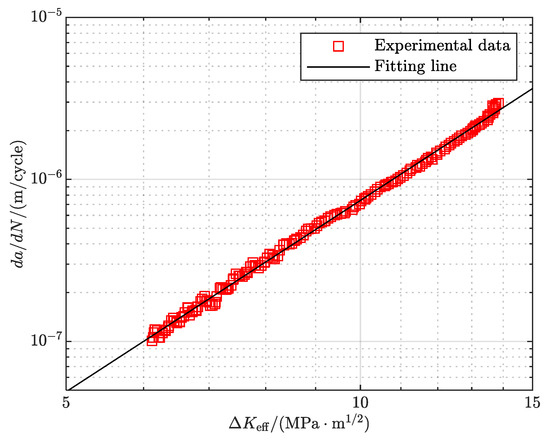

Referring to ASTM E647 [39], the compact tension (CT) specimen was designed to obtain the fatigue crack growth behavior, as illustrated in Figure 1.

Figure 1.

Crack propagation behavior of 2A14 aluminum alloy (R = 0.1).

2.2. Specimen

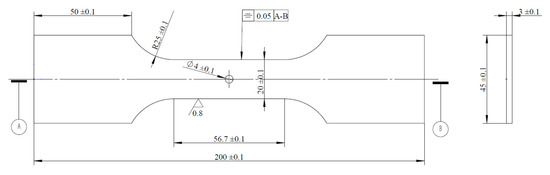

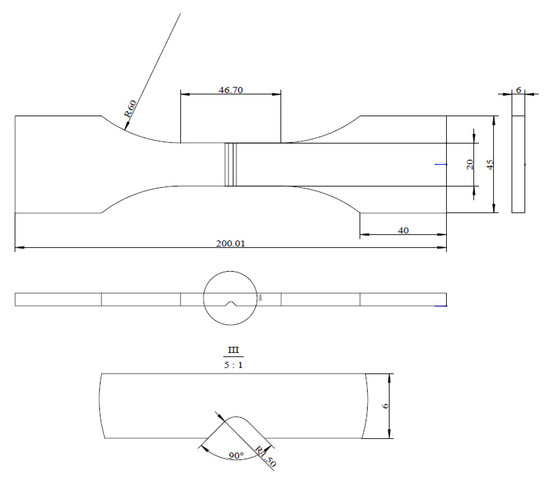

The specimens used in this study include a central-hole specimen and V-notched specimen, with their geometric dimensions shown in Figure 2 and Figure 3, respectively.

Figure 2.

Central-hole specimen (unit: mm).

Figure 3.

V-notched specimen (unit: mm).

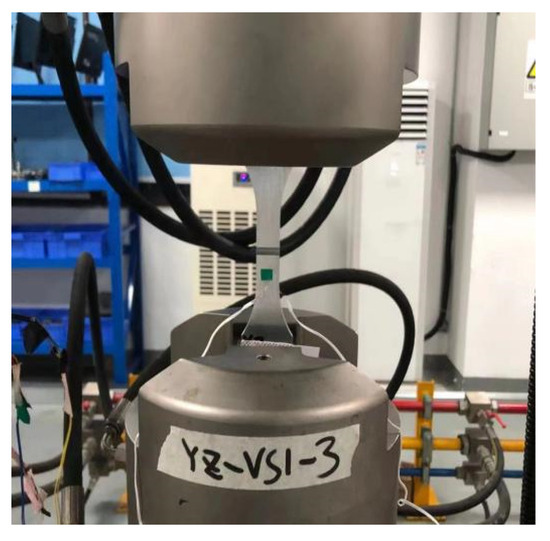

2.3. Experimental Setup

All fatigue tests were performed using an MTS Landmark 370.02 hydraulic servo fatigue testing system (MTS Systems Corporation, Eden Prairie, MN, USA, Figure 4) operating at a frequency of 10 Hz under load control.

Figure 4.

Experimental setup.

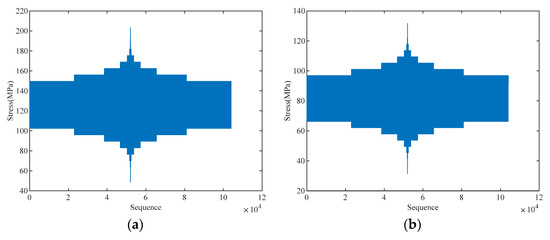

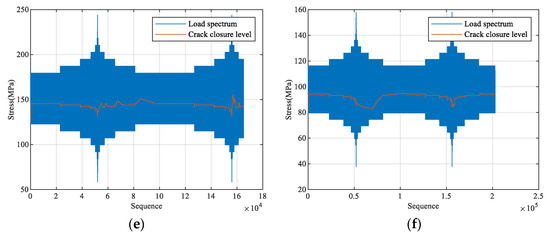

The original load spectra are 10-level programmed load spectra, denoted as CCTS0 and VS0, respectively, as shown in Figure 5.

Figure 5.

Original load spectra: (a) CCTS0; (b) VS0.

Based on the above original spectra, the load spectra were proportionally amplified with LEFs of 1.1 and 1.2. The corresponding enhanced spectra are denoted as CCTS1, CCTS2, VS1, and VS2.

2.4. Model Development

2.4.1. Equivalent Initial Flaw Size

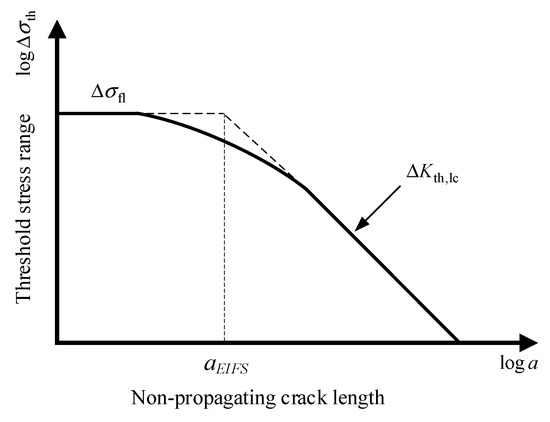

As mentioned earlier, some researchers [9,10,11] have introduced the concept of EIFS to avoid the complex small crack problem. Liu and Mahadevan [24] proposed that the EIFS can be calculated from the Kitagawa–Takahashi diagram [28], as illustrated in Figure 6.

Figure 6.

Kitagawa–Takahashi diagram.

The EIFS corresponds to the intersection point of the plain fatigue strength line and long crack threshold stress intensity factor (SIF) line, as expressed as follows:

where aEIFS is the EIFS, ΔKth,eff is the effective threshold SIF range for long cracks, Δσfl is the plain fatigue strength, Y is the geometry correction factor, and U is the crack closure ratio.

2.4.2. Equivalent Plastic Zone

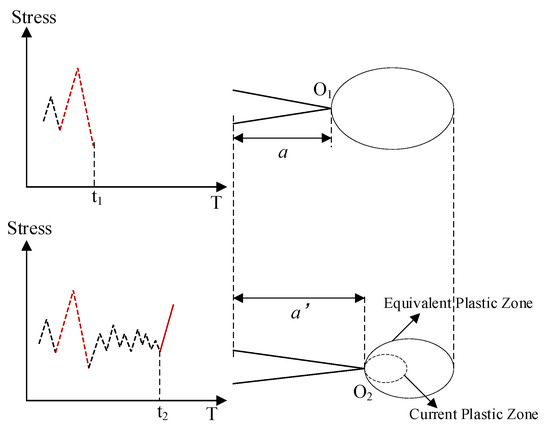

During cyclic loading and unloading, forward and reverse plastic zones develop periodically at the crack tip. The interaction between these zones reflects the load interaction effect. Therefore, tracing the plastic state at the crack tip provides a means to quantify the influence of load history on fatigue crack growth behavior. Jiang et al. [37] proposed the concept of EPZ to account for the impact of load sequence by tracking the cumulative plastic state resulting from historical loads, as depicted in Figure 7.

Figure 7.

Schematic diagram of equivalent plastic zone.

Considering an overload occurring at time t1, a large plastic zone is formed at the crack tip (located at point O1). Then, the crack propagates within this previously formed large plastic zone. At a later time t2, the crack tip moves to point O2. If the plastic zone generated by the current load does not exceed the boundary of the historical plastic zone, the EPZ influences the current crack growth behavior rather than the current plastic zone. The size of the EPZ is calculated using Dugdale’s model, as follows:

where Deq,i is the diameter of EPZ at the i-th cycle, di is the actual plastic zone size at the i-th cycle, a0 is the initial crack length, and daj is the crack increment.

Specifically, the EPZ includes the equivalent monotonic and reverse plastic zone:

where Dm,eq,i and Dr,eq,i are the equivalent monotonic and cyclic plastic zones at the i-th cycle, respectively, and dm,i and dr,i are the monotonic and cyclic plastic zones at the i-th cycle, respectively.

The sizes of the monotonic and reversed plastic zones are computed using a modified Dugdale model [40]:

where Kmax is the peak SIF, Kop is the crack opening SIF, σy is the yield stress, σmax is the max stress, and a is the crack length.

The EPZ effectively captures the plastic effect caused by load history. Since plasticity is a primary mechanism of crack closure, the influence of the crack-tip plastic state can be described through variations in the crack closure level. Based on the EPZ theory, Jiang et al. [37] derived an analytical solution for the crack closure level under VA loading:

where σop is the crack closure level, σmin,eq is the equivalent minimum stress, σmin is the minimum stress, dm,eq is the equivalent monotonic crack tip plastic zone size, dr is the reversed crack tip plastic zone size.

2.4.3. Fatigue Life Prediction Model Under Variable Amplitude Loading

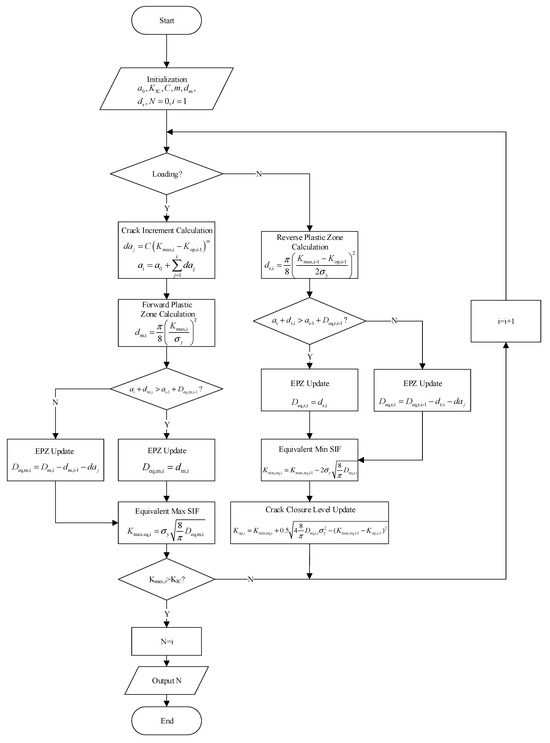

Integrating the EIFS and EPZ theory, the fatigue life prediction process under VA loading is schematically illustrated in Figure 8. It comprises the following steps:

Figure 8.

Flowchart of the fatigue life prediction algorithm.

1: Model initialization.

Before model prediction, model parameters are calibrated using fundamental material properties (yield strength, fracture toughness) and fatigue crack growth data (da/dN versus ΔK).

2: Cycle-by-cycle iteration.

The VA load spectrum is processed cycle by cycle.

Loading phase: For each cycle, the monotonic EPZ is updated. The corresponding equivalent maximum SIF (Kmax,eq) and crack increment (Δa) are calculated.

Unloading phase: The reverse EPZ is updated. The equivalent minimum SIF is determined to estimate the crack closure level for the next cycle.

3: Termination criterion

The above process is repeated until the peak SIF exceeds the fracture toughness. The number of cycles consumed in this period is taken as the fatigue life.

3. Results and Discussion

3.1. Model Prediction

3.1.1. Model Calibration

In this investigation, the Elber model [41] is used to depict the fatigue crack growth behavior, expressed as follows:

where da/dN is the crack growth rate, C, m are the model constants, ΔKeff is the effective SIF range, and ΔK is the SIF range.

U can be obtained by Newman’s empirical formula [42]:

where

The value of Smax/σ0 is set to 0.3, consistent with the value for aluminum alloys in NASGRO dataset. α is the constraint factor and related to the stress state. In this study, it is taken as 2. R is the stress ratio.

Thus, the relationship between crack growth rate and effective SIF range can be obtained as shown in Figure 9. The data exhibit a linear relationship in the log–log coordinate system, confirming the applicability of the Elber model. The material constants C and m are determined via least-squares fitting, as summarized in Table 2.

Figure 9.

da/dN versus ΔKeff.

Table 2.

Elber model fitting results.

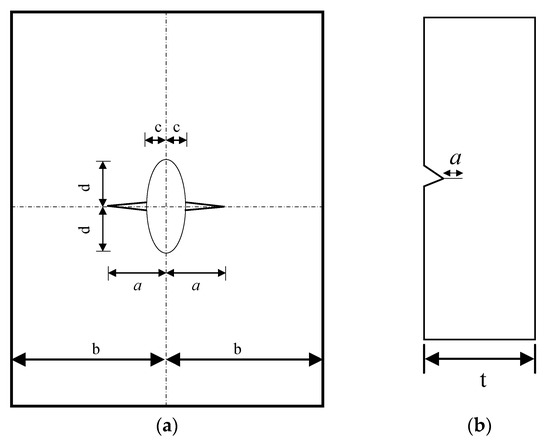

3.1.2. Calculation of EIFS

In this study, it is assumed that the crack in the central-hole specimen is an edge-through crack emanating from the central hole, while the crack in the V-notched specimen is treated as a single edge-through crack, as depicted in Figure 10.

Figure 10.

Schematic diagram of crack geometries for typical structures: (a) central hole specimen; (b) V-notched specimen.

The geometry correction factor for an edge-through crack at the central hole is from reference [43]:

where

For a V-notched specimen, the geometry correction factor is derived from reference [44]:

where Kt is the theoretical stress concentration factor and T is the specimen thickness.

Using Equation (1), the corresponding EIFSs are calculated and presented in Table 3.

Table 3.

Estimated EIFS.

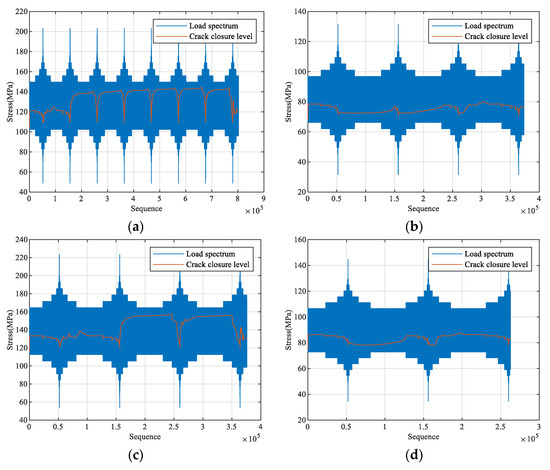

3.1.3. Estimation of Crack Closure

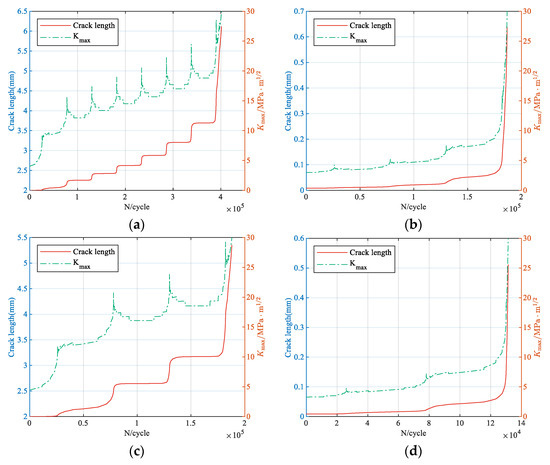

Based on the EPZ theory, the evolution of crack closure level under each enhanced load spectrum is predicted, as shown in Figure 11.

Figure 11.

Predicted crack closure level for each enhanced spectrum: (a) CCTS0; (b) VS0; (c) CCTS1; (d) VS1; (e) CCTS2; (f) VS2.

3.1.4. Fatigue Life Prediction

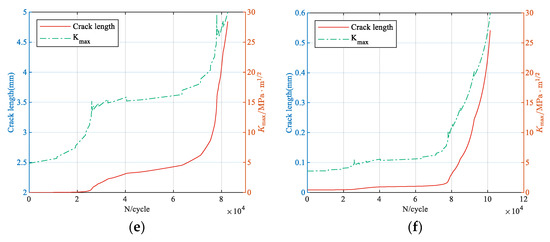

Subsequently, the crack increment is calculated cycle by cycle and accumulated to obtain the a–N curve. The variations in crack length and peak SIF with the number of cycles for each enhanced spectrum are shown in Figure 12. It can be seen that the peak SIF gradually increases as the crack length increases. Failure is considered to occur when the peak SIF exceeds the fracture toughness. The corresponding cycle count is the fatigue life, as listed in Table 4.

Figure 12.

Predicted crack length and Kmax for each enhanced spectrum: (a) CCTS0; (b) VS0; (c) CCTS1; (d) VS1; (e) CCTS2; (f) VS2.

Table 4.

Predicted fatigue life for each load spectrum.

3.2. Model Validation

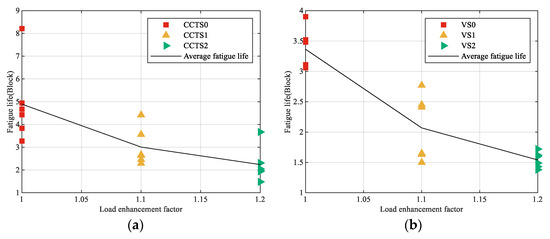

Fatigue life tests were conducted on both central-hole and V-notched specimens under the enhanced spectra, with six parallel specimens tested for each condition. The experimental results, summarized in Table 5 along with their corresponding statistical values in Table 6, reveal a clear trend: fatigue life exhibits a significant decrease with increasing load enhancement factor (LEF).

Table 5.

Fatigue life for each load spectrum.

Table 6.

Mean fatigue life and compression ratio for each load spectrum.

The relationship between fatigue life and LEF for each enhanced spectrum is shown in Figure 13. It is clear that the fatigue life decreases significantly with increasing LEF, which aligns with the fundamental principle that elevated stress amplitudes accelerate damage accumulation [45]. Notably, the application of an LEF of 1.2 resulted in a reduction in the total test time to approximately 50% of that required under the original spectrum, underscoring the practical efficiency of the load enhancement methodology.

Figure 13.

Relationship between fatigue life and LEF: (a) central-hole specimen; (b) V-notched specimen.

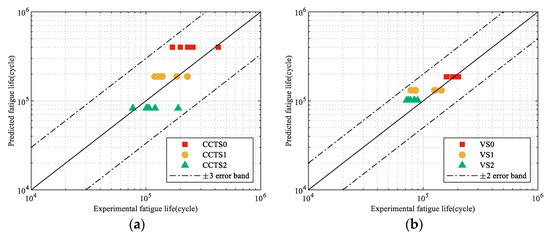

A comparison of the model prediction and experimental data for both specimens is presented in Figure 14. For the central-hole specimen, all experimental data fall within a scatter band of three relative to the model prediction. The prediction accuracy is notably higher for the V-notched specimen, with all results confined within a scatter factor of two. This discrepancy in accuracy can be attributed to the differences in crack initiation and early growth behavior between the two specimen geometries. The stress field at the V-notch is more constrained, leading to a more predictable crack initiation site and a reduced small-crack growth phase, which is inherently more stochastic. Generally, the proposed model accurately predicts the fatigue life of the two structures under spectrum loading.

Figure 14.

Comparison of model prediction and experimental data under each enhanced spectrum: (a) CH specimen; (b) V-notched specimen.

The relative errors of compression ratio for both structures are quantified in Table 7. The central-hole specimen exhibits larger errors than the V-notched specimen, which is consistent with the above observations. The maximum error is about 50%, which remains within an acceptable limit for engineering application [8].

Table 7.

Comparison of predicted and experimental compression ratio.

4. Conclusions

This study establishes a novel accelerated fatigue testing methodology based on fracture mechanics to investigate fatigue load spectrum enhancement. A new fatigue life prediction model for variable amplitude loading is developed to accurately forecast both the fatigue life and the test time compression ratio. Based on the comprehensive experimental and modeling framework, the key conclusions are as follows:

(1) A fatigue life prediction model for variable amplitude loading is proposed by integrating the theories of Equivalent Initial Flaw Size (EIFS) and the Equivalent Plastic Zone (EPZ). This model provides a physically grounded methodology for load enhancement.

(2) The model prediction is in good agreement with the experimental data. All experimental data fall within a factor of three compared to the model prediction. The maximum error between mean fatigue life and the model prediction is about 50%.

(3) A significant reduction in fatigue testing time is achieved with increasing LEF. Specifically, employing a load enhancement factor (LEF) of 1.2 achieves savings of over 50% in total fatigue testing time.

In the future, the current work will be extended to more loading scenarios.

Author Contributions

Conceptualization, P.W. and W.Z.; methodology, L.C.; software, L.C.; validation, L.C. and P.W.; investigation, L.C.; writing—original draft preparation, L.C. and Y.W.; writing—review and editing, Y.H.; visualization, L.C. and Y.W.; supervision, P.W.; project administration, W.Z.; funding acquisition, W.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China (No.52375139, No.51875019).

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author due to privacy.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CA | Constant amplitude |

| EIFS | Equivalent initial flaw size |

| EPZ | Equivalent plastic zone |

| LEF | Load enhancement factor |

| LEFM | Linear elastic fracture mechanics |

| SIF | Stress intensity factor |

| VCA | Virtual crack annealing |

| VA | Variable amplitude |

Nomenclature

| Symbol | Illustration |

| a | Crack length |

| a0 | Initial crack length |

| aEIFS | Equivalent initial flaw size |

| Ai(i = 1,2,3) | Crack closure coefficients |

| C,m | Material constants |

| da | Crack increment |

| da/dN | Crack growth rate |

| dm | Monotonic crack tip plasticity zone size |

| dr | Reverse crack tip plasticity zone size |

| Deq | Equivalent crack tip plasticity zone size |

| Dm,eq | Monotonic equivalent crack tip plasticity zone size |

| Dr,eq | Reverse equivalent crack tip plasticity zone size |

| f | Crack closure parameter |

| Kt | Theoretical stress concentration factor |

| Kmax | Maximum stress intensity factor |

| Kop | Crack opening stress intensity factor |

| ΔK | Stress intensity factor |

| ΔKeff | Effective stress intensity factor |

| ΔKth | Threshold stress intensity factor |

| ΔKth,eff | Effective threshold stress intensity factor |

| R | Stress ratio |

| T | Specimen thickness |

| U | Crack closure ratio |

| Y | Geometric correction factor |

| σmax | Maximum stress |

| σmin | Minimum stress |

| σmin,eq | Equivalent minimum stress |

| σop | Crack closure stress |

| σy | Yield strength |

| Δσfl | Fatigue limit |

References

- He, X.; Li, T.; Li, Y.; Dong, Y.; Wang, T. Developing an accelerated flight load spectrum based on the nz-N curves of a fleet. Int. J. Fatigue 2018, 117, 246–256. [Google Scholar] [CrossRef]

- Heuler, P.; Seeger, T. A criterion for omission of variable amplitude loading histories. Int. J. Fatigue 1986, 8, 225–230. [Google Scholar] [CrossRef]

- Hailing, T.; Rui, B.; Jianyu, Z.; Xiaoling, Z.; Binjun, F. Influence of Low Load Truncation Level on Crack Growth for Al 2324-T39 and Al 7050-T7451. Chin. J. Aeronaut. 2009, 22, 401–406. [Google Scholar] [CrossRef][Green Version]

- Xiong, J.J.; Shenoi, R.A. A load history generation approach for full-scale accelerated fatigue tests. Eng. Fract. Mech. 2008, 75, 3226–3243. [Google Scholar] [CrossRef]

- Lameris, J. The Use of Load Enhancement Factors in the Certification of Composite Aircraft Structures; National Aerospace Laboratory NLR: Delft, The Netherlands, 1990; p. 58. [Google Scholar]

- Brandecker, B.; Hilgert, R. A320 full scale structural testing for fatigue and damage tolerance certification of metallic and composite structure. In Proceedings of the Congress of the International Council of the Aeronautical Sciences, Jerusalem, Israel, 28 August–2 September 1988; Volume 16, pp. 1244–1256. [Google Scholar]

- Tomblin, J.; Seneviratne, W. Determining the Fatigue Life of Composite Aircraft Structures Using Life and Load-Enhancement Factors; Air Traffic Organization: Washington DC, USA, 2011. [Google Scholar]

- Dong, D.; Li, Y.; Chen, X. Research on the relationship between load enhancement factor and fatigue life. J. Mech. Strength 2013, 35, 488–492. [Google Scholar] [CrossRef]

- Dang, K.; Chen, L.; Zhang, W. Load spectrum enhancement method with ground-air-ground invariance of aircraft metal structure. Eng. Test 2022, 62, 27–30. [Google Scholar] [CrossRef]

- Zhang, W.; Dong, D.; Chen, L.; Li, S. Effect on single crack growth lifetime with random fatigue load spectra enhancement. Sci. Technol. Eng. 2018, 18, 326–331. [Google Scholar] [CrossRef]

- Zhang, K.; Yan, W.; Chen, L.; Dong, D. Effect of structural load enhancement factor on fatigue crack growth life. J. Mech. Strength 2014, 36, 280–284. [Google Scholar] [CrossRef]

- Zhang, H.; Niu, Z.; Dong, D.; Chen, L. Research on load enhancement method for fatigue crack growth test. Eng. Mech. 2015, 32, 236–242. [Google Scholar] [CrossRef]

- Suresh, S.; Ritchie, R.O. Propagation of short fatigue cracks. Int. Met. Rev. 1984, 29, 445–475. [Google Scholar] [CrossRef]

- Miller, K.J. The behaviour of short fatigue cracks and their initiation part ii-a general summary. Fatigue Fract. Eng. M 1987, 10, 93–113. [Google Scholar] [CrossRef]

- Sangid, M.D. The physics of fatigue crack propagation. Int. J. Fatigue 2025, 197, 108928. [Google Scholar] [CrossRef]

- Newman, J.C.; Phillips, E.P.; Swain, M.H. Fatigue-life prediction methodology using small-crack theory. Int. J. Fatigue 1999, 21, 109–119. [Google Scholar] [CrossRef]

- McEvily, A.J. An analysis of the growth of small fatigue cracks. Mater. Sci. Eng. A 1991, 143, 127–133. [Google Scholar] [CrossRef]

- Ye, S.; Zhang, C.; Zhang, P.; Zhang, X.; Tu, S.; Wang, R. Fatigue life prediction of nickel-based GH4169 alloy on the basis of a multi-scale crack propagation approach. Eng. Fract. Mech. 2018, 199, 29–40. [Google Scholar] [CrossRef]

- Santus, C.; Taylor, D. Physically short crack propagation in metals during high cycle fatigue. Int. J. Fatigue 2009, 31, 1356–1365. [Google Scholar] [CrossRef]

- Hobson, P.D.; Brown, M.; Rios, E.R. Two Phases of Short Crack Growth in a Medium Carbon Steel. In The Behaviour of Short Fatigue Cracks; EGF Pub.1; Miller, K.J., Rios, E.R., Eds.; Mechanical Engineering Publications: London, UK, 1986. [Google Scholar]

- Hutař, P.; Poduška, J.; Šmíd, M.; Kuběna, I.; Chlupová, A.; Náhlík, L.; Polák, J.; Kruml, T. Short fatigue crack behaviour under low cycle fatigue regime. Int. J. Fatigue 2017, 103, 207–215. [Google Scholar] [CrossRef]

- Shyam, A.; Allison, J.E.; Jones, J.W. A small fatigue crack growth relationship and its application to cast aluminum. Acta Mater. 2005, 53, 1499–1509. [Google Scholar] [CrossRef]

- Molent, L.; Sun, Q.; Green, A.J. Characterisation of equivalent initial flaw sizes in 7050 aluminium alloy. Fatigue Fract. Eng. Mater. 2006, 29, 916–937. [Google Scholar] [CrossRef]

- Liu, Y.; Mahadevan, S. Probabilistic fatigue life prediction using an equivalent initial flaw size distribution. Int. J. Fatigue 2009, 31, 476–487. [Google Scholar] [CrossRef]

- Xiang, Y.; Lu, Z.; Liu, Y. Crack growth-based fatigue life prediction using an equivalent initial flaw model. Part I: Uniaxial loading. Int. J. Fatigue 2010, 32, 341–349. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, W.; Jiang, S. Fatigue life prediction based on crack closure and equivalent initial flaw size. Materials 2015, 8, 7145–7160. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, Q.; Li, X.; He, J. A simple fatigue life prediction algorithm using the modified NASGRO equation. Math. Probl. Eng. 2016, 2016, 4298507. [Google Scholar] [CrossRef]

- Kitagawa, H.; Takahashi, S. Fracture mechanical approach to very small fatigue crack growth and to the threshold condition. Trans. Jpn. Soc. Mech. Eng. A 1979, 45, 1289–1303. [Google Scholar] [CrossRef]

- Schijve, J. The application of small overloads for fractography of small fatigue cracks initiated under constant-amplitude loading. Int. J. Fatigue 2015, 70, 63–72. [Google Scholar] [CrossRef]

- Schijve, J. The significance of fractography for investigations of fatigue crack growth under variable-amplitude loading. Fatigue Fract. Eng. Mater. Struct. 1999, 22, 87–99. [Google Scholar] [CrossRef]

- Wheeler, O.E. Spectrum loading and crack growth. J. Basic Eng. 1972, 94, 181–186. [Google Scholar] [CrossRef]

- Willenborg, J.; Engle, R.; Wood, H. A Crack Growth Retardation Model Using an Effective Stress Concept; Wright-Patterson Air Force Base: Dayton, OH, USA, 1971. [Google Scholar]

- Neto, D.M.; Borges, M.F.; Antunes, F.V.; Jesus, J. Mechanisms of fatigue crack growth in Ti-6Al-4V alloy subjected to single overloads. Theor. Appl. Fract. Mech. 2021, 114, 103024. [Google Scholar] [CrossRef]

- Ward-Close, C.M.; Blom, A.F.; Ritchie, R.O. Mechanisms associated with transient fatigue crack growth under variable-amplitude loading: An experimental and numerical study. Eng. Fract. Mech. 1989, 32, 613–638. [Google Scholar] [CrossRef]

- Li, Y.; Ke, L.; Li, C.; Feng, P.; Feng, Z.; Qiu, M. Retardation mechanisms and modeling of fatigue crack growth of a high-strength steel after single overload. Int. J. Fatigue 2024, 183, 108267. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, Y. In Situ SEM testing for crack closure investigation and virtual crack annealing model development. Int. J. Fatigue 2012, 43, 188–196. [Google Scholar] [CrossRef]

- Jiang, S.; Zhang, W.; He, J.; Wang, Z. Comparative study between crack closure model and willenborg model for fatigue prediction under overload effects. Chin. J. Aeronaut. 2016, 29, 1618–1625. [Google Scholar] [CrossRef]

- Zhang, W.; Jiang, S.; Li, X.; Wang, Z. An approach to structural reliability evaluation under fatigue degradation and shocks. Mech. Syst. Signal Process. 2018, 113, 65–76. [Google Scholar] [CrossRef]

- ASTM E647-08; Standard Test Method for Measurement of Fatigue Crack Growth Rates. ASTM International: West Conshohocken, PA, USA, 2008.

- Yamada, Y.; Ziegler, B.; Newman, J.C. Application of a strip-yield model to predict crack growth under variable-amplitude and spectrum loading—Part 1: Compact specimens. Eng. Fract. Mech. 2011, 78, 2597–2608. [Google Scholar] [CrossRef]

- Elber, W. The significance of fatigue crack closure. In Damage Tolerance in Aircraft Structures; Rosenfeld, M., Ed.; ASTM International: West Conshohocken, PA, USA, 1971; Volume STP486-EB, pp. 230–242. ISBN 978-0-8031-0031-2. [Google Scholar]

- Newman, J.C. A crack opening stress equation for fatigue crack growth. Int. J. Fract. 1984, 24, R131–R135. [Google Scholar] [CrossRef]

- Führing, H. Approximation functions for K-factors of cracks in notches. Int. J. Fract. 1973, 9, 328–331. [Google Scholar] [CrossRef]

- Yao, W. Fatigue Life Estimation of Structures, 1st ed.; Science Press: Beijing, China, 2019; ISBN 978-7-03-058465-6. [Google Scholar]

- Schijve, J. Fatigue of Structures and Materials, 2nd ed.; Springer: Dordrecht, The Netherlands, 2009; ISBN 978-1-4020-6807-2. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).