Effect of Gd Content on the Microstructure and Mechanical Properties of Hot Extruded Mg-xGd-4Y-1Sm-0.5Zr Alloys

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussions

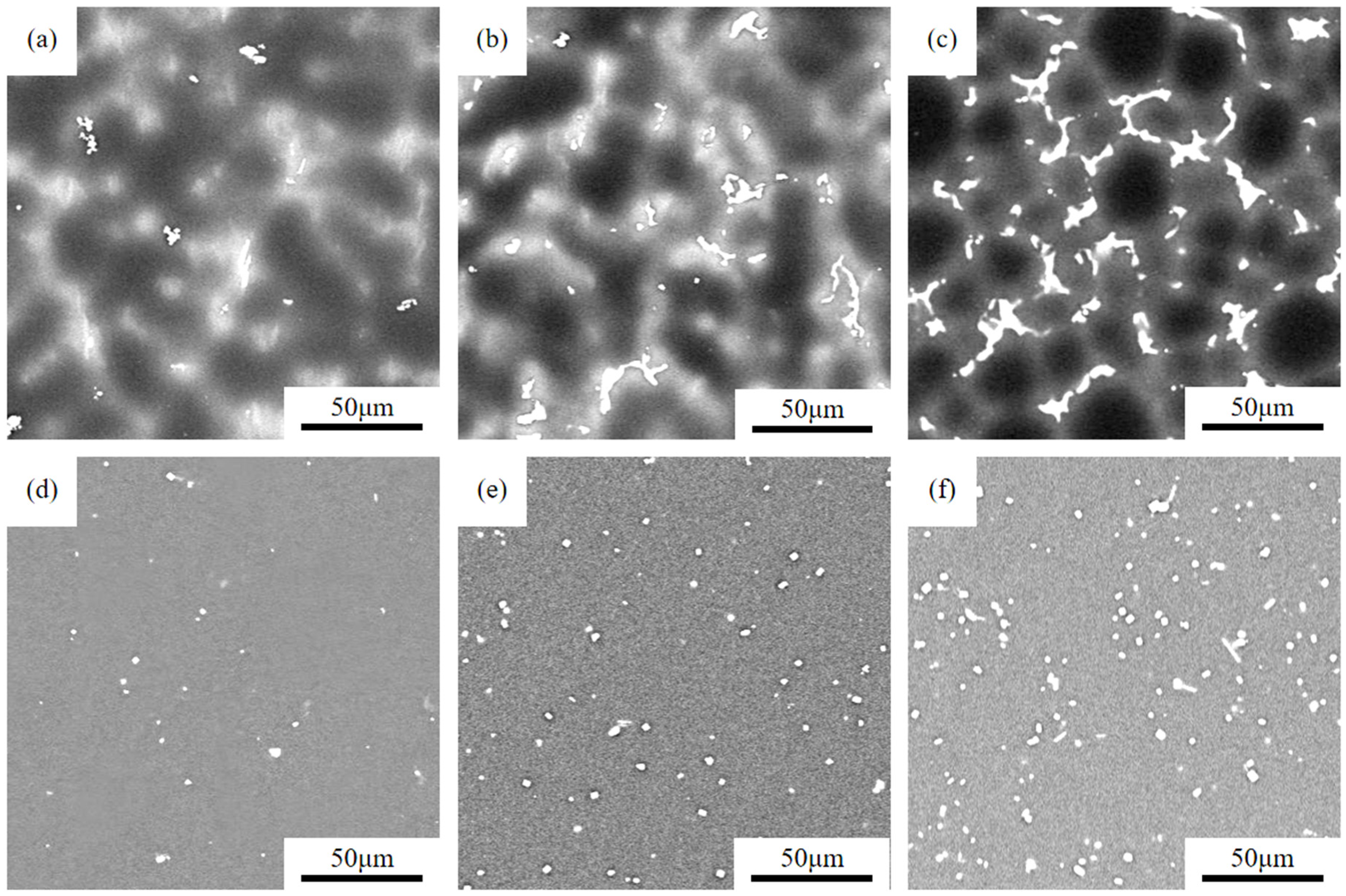

3.1. As-Cast and Solid Solution Microstructures

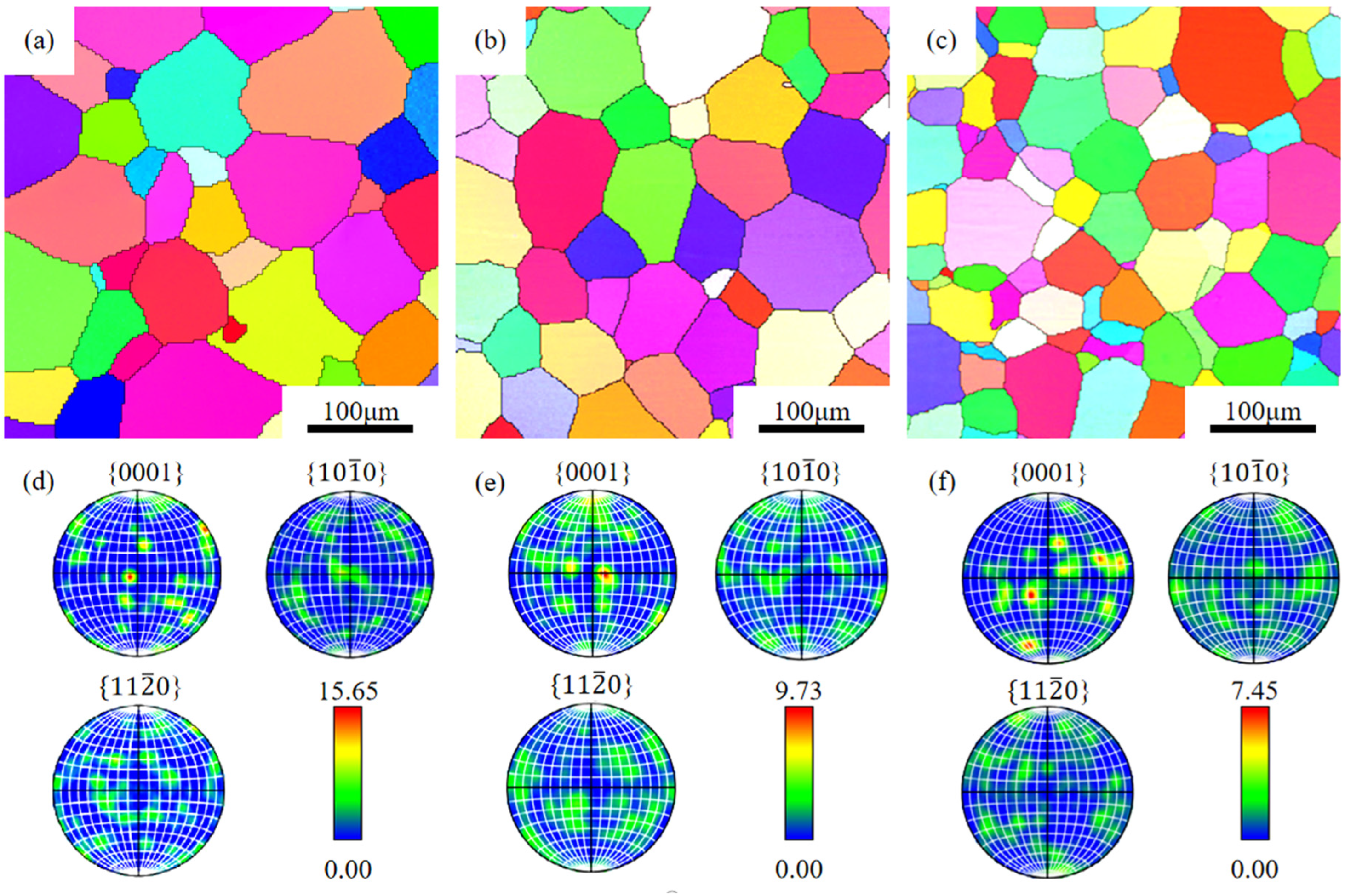

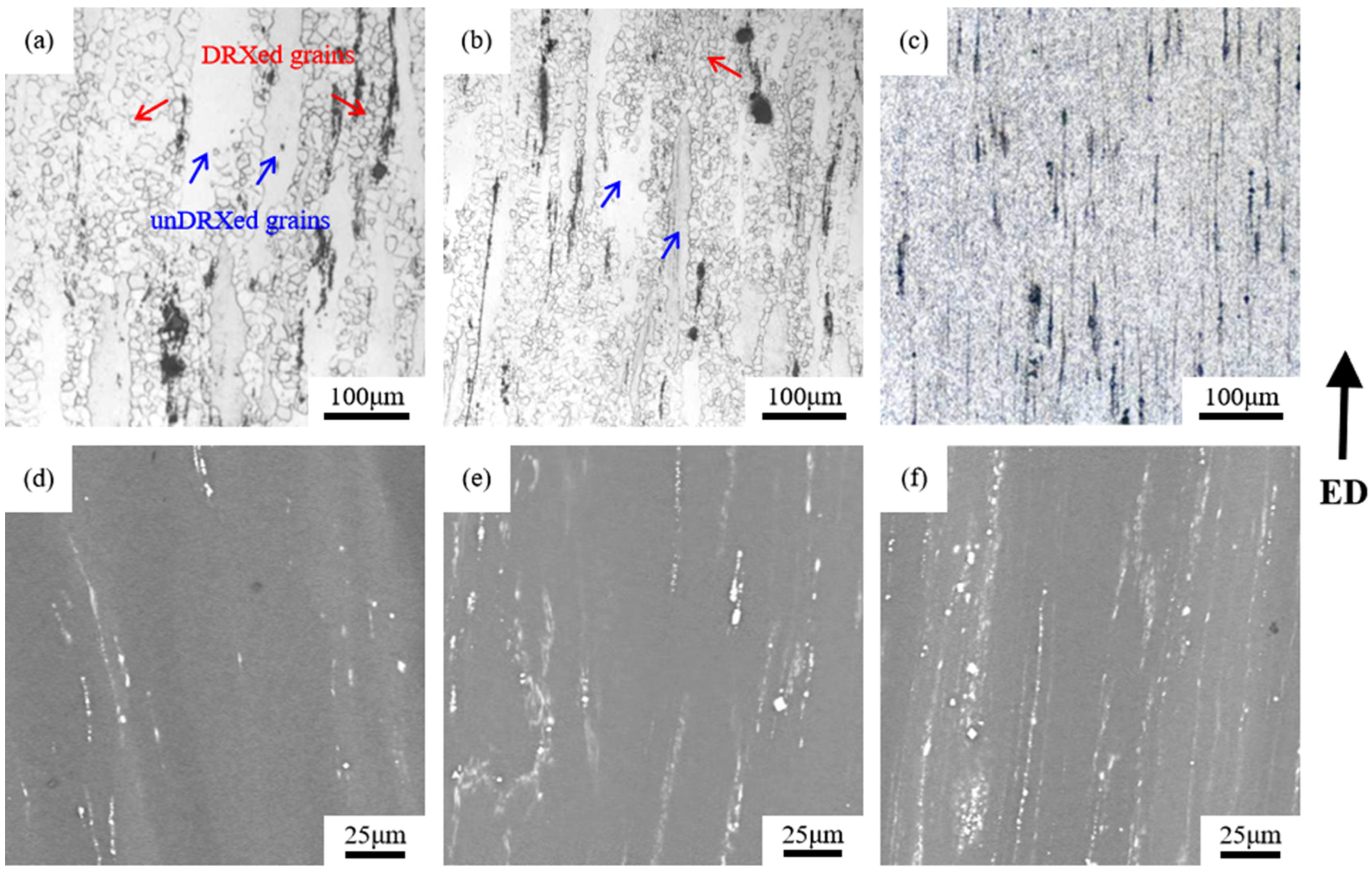

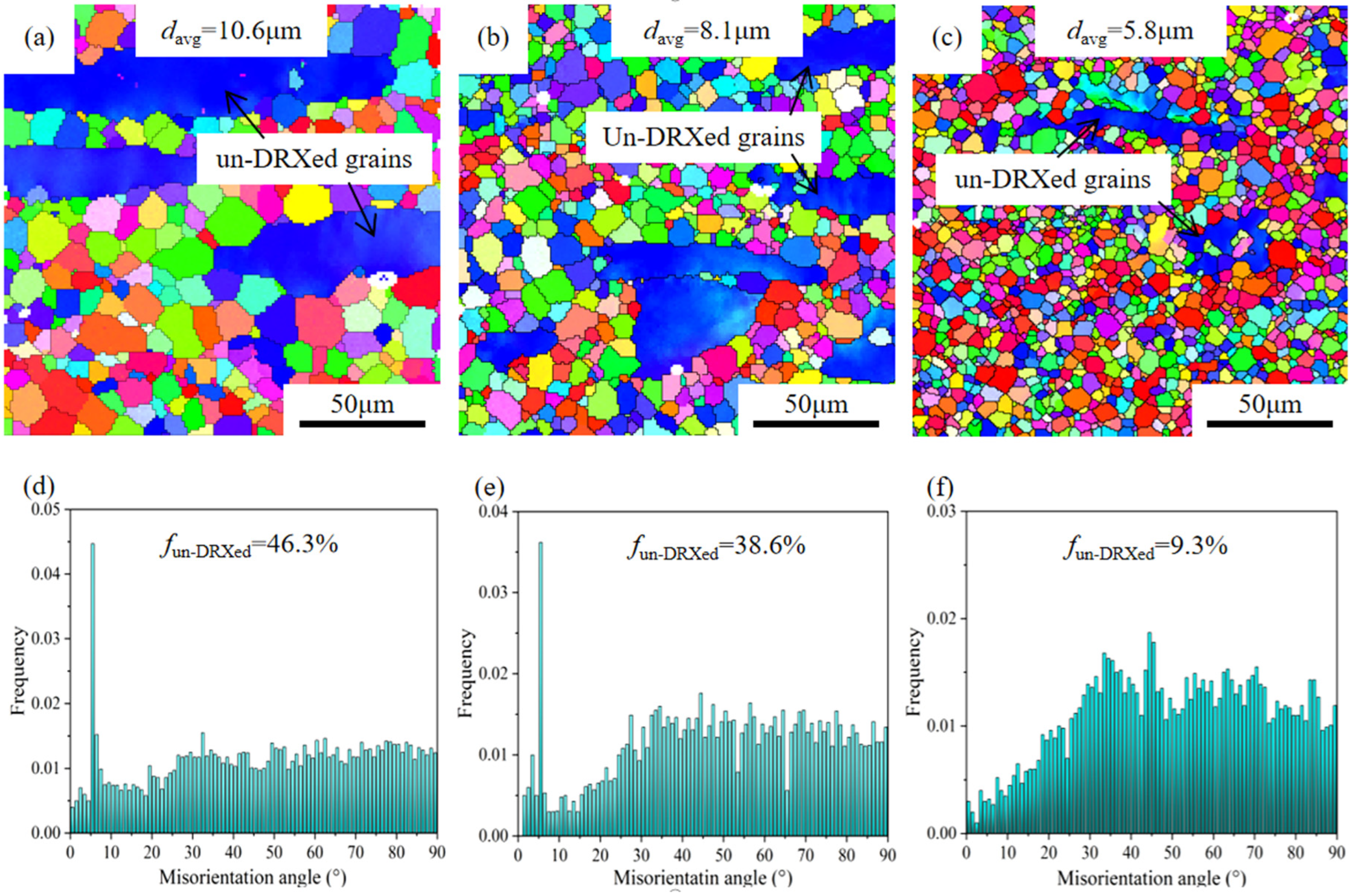

3.2. The Microstructure of Hot-Extruded Alloys

3.3. Age-Hardening and Microstructure Analysis of Peak-Aged Mg-xGd-4Y-1Sm-0.5Zr Alloys

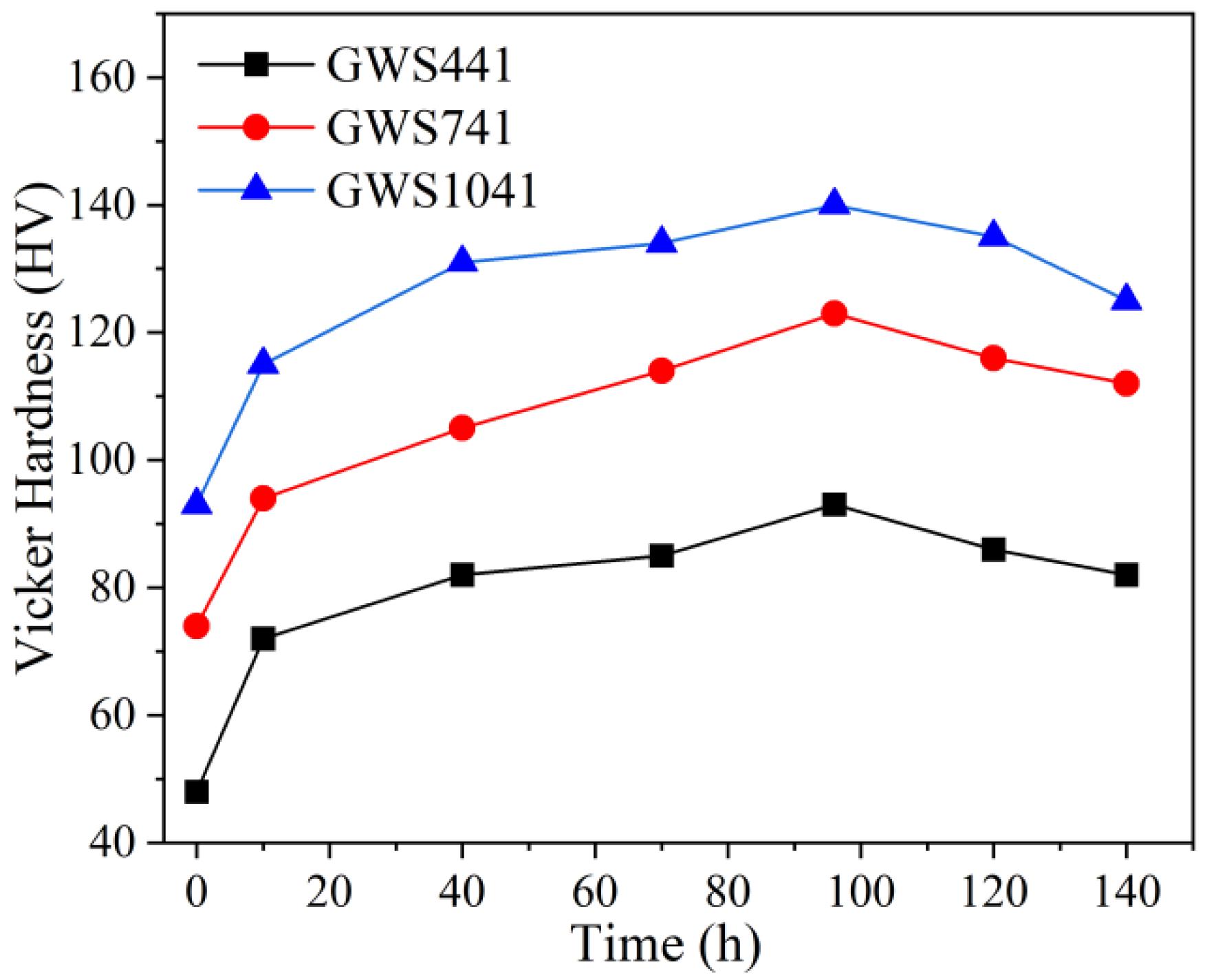

3.3.1. Age-Hardening Analysis

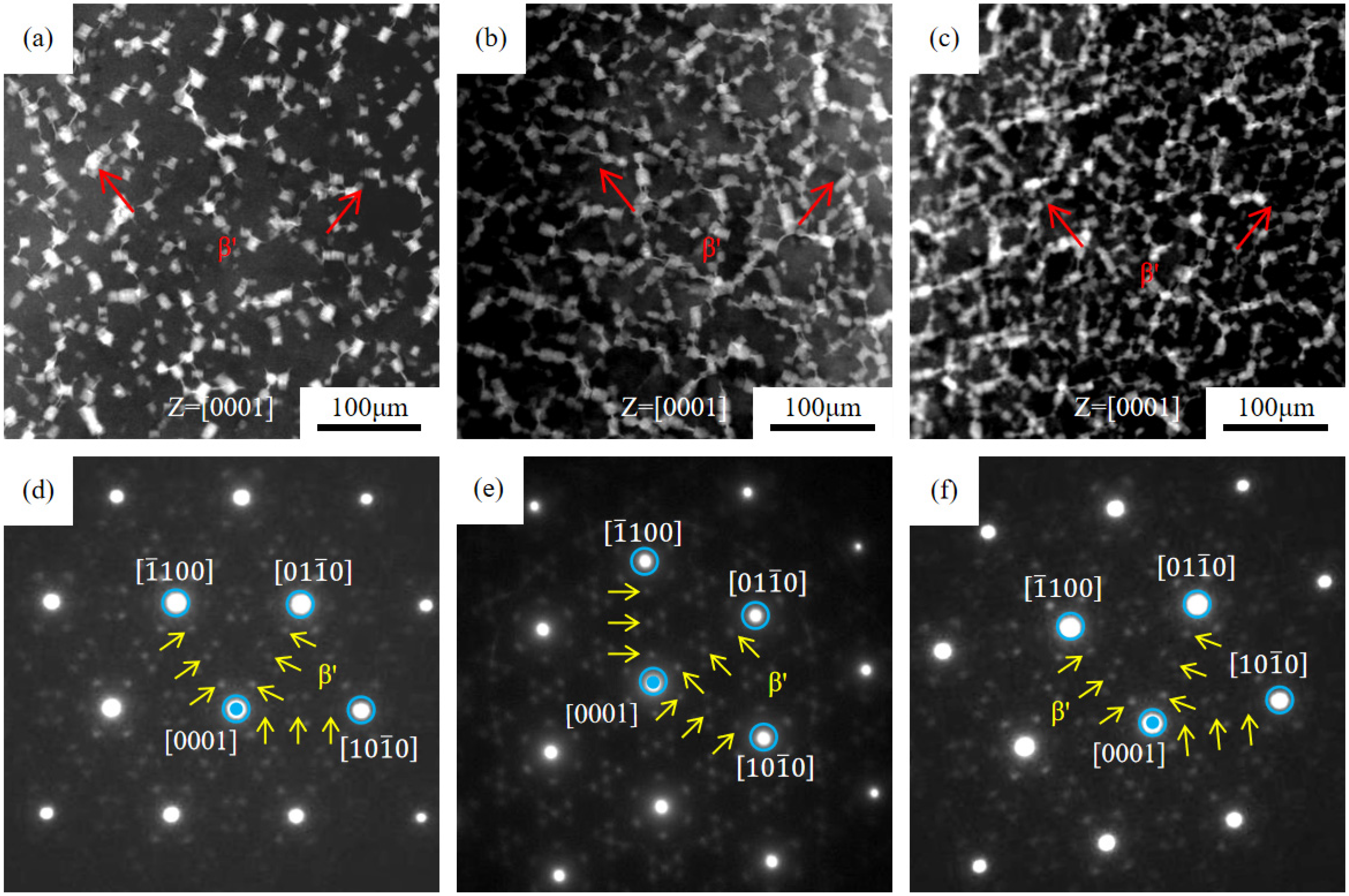

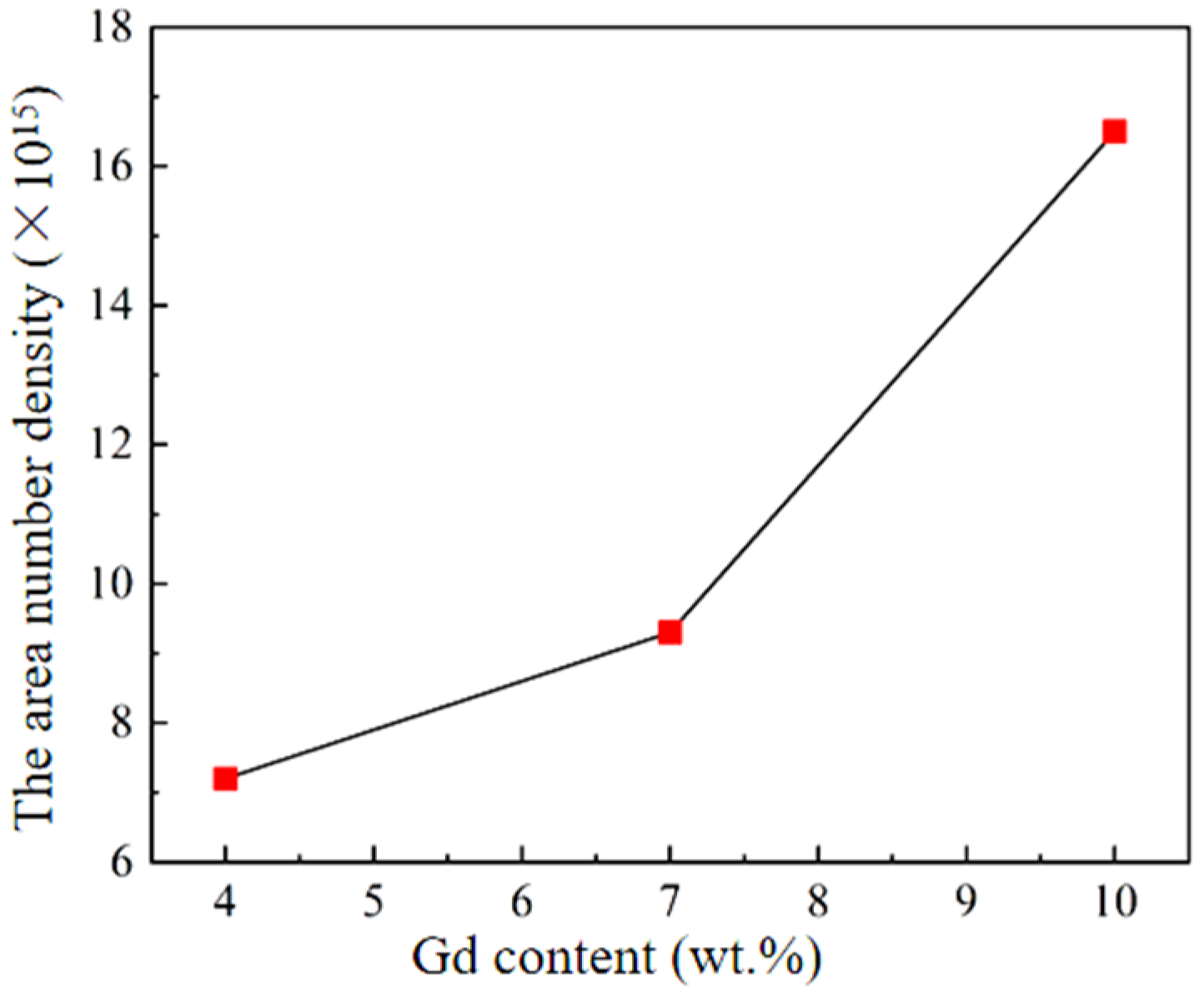

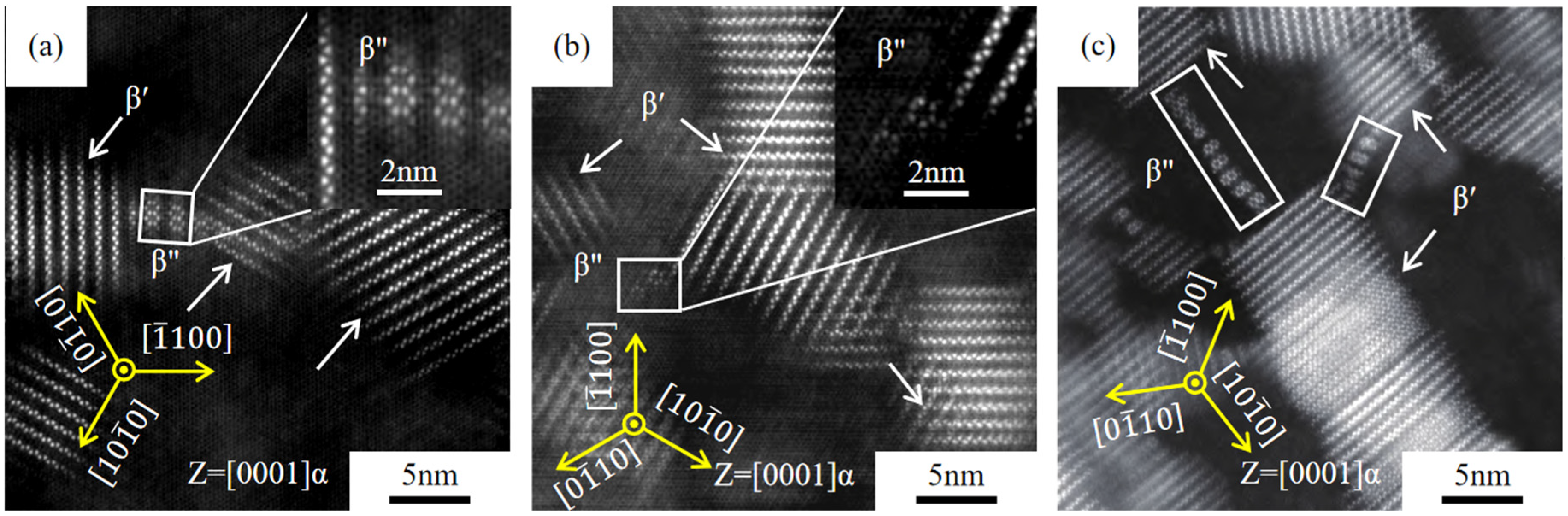

3.3.2. The Microstructure Analysis of Peak-Aged Mg-xGd-4Y-1Sm-0.5Zr Alloys

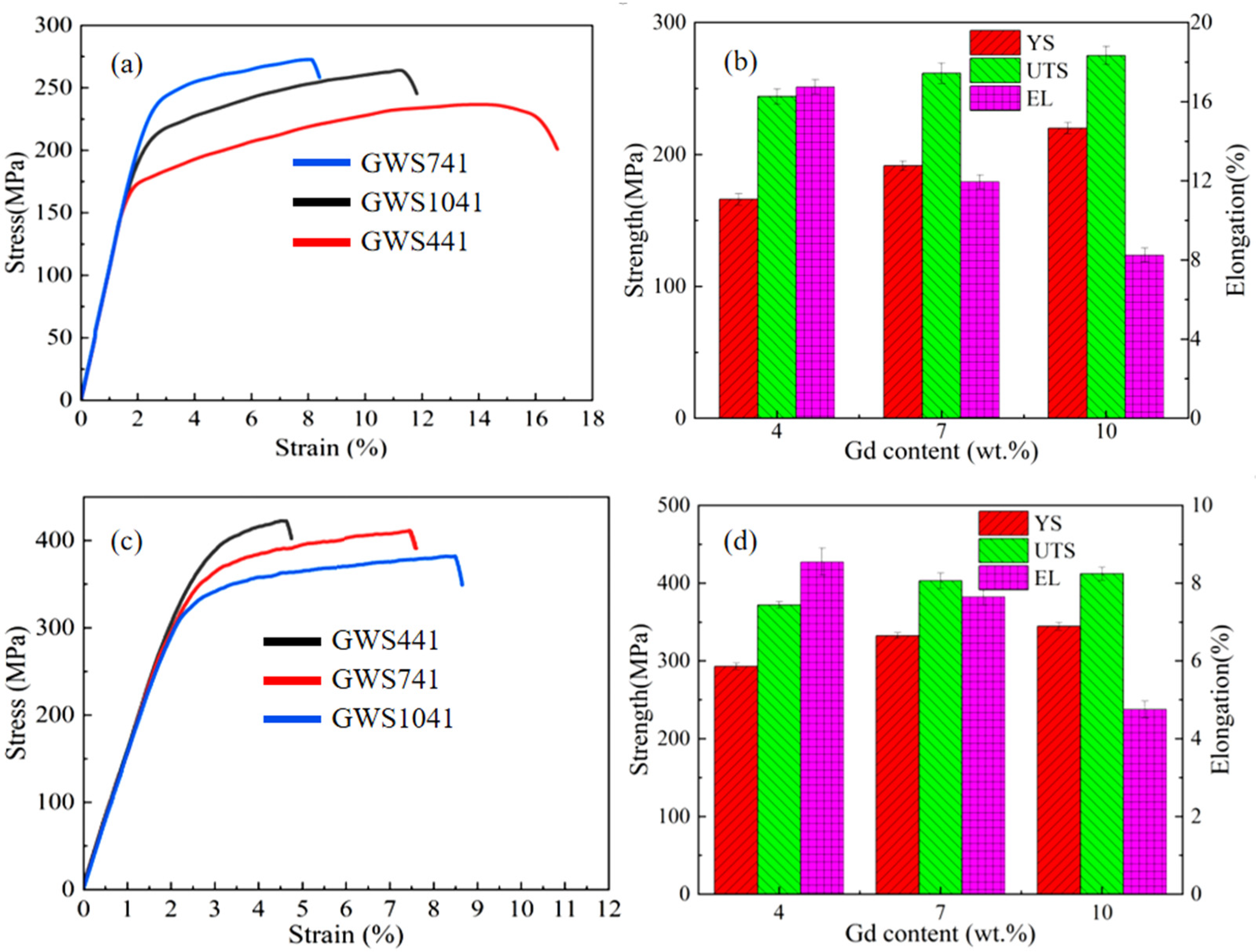

3.3.3. Analysis of Mechanical Properties

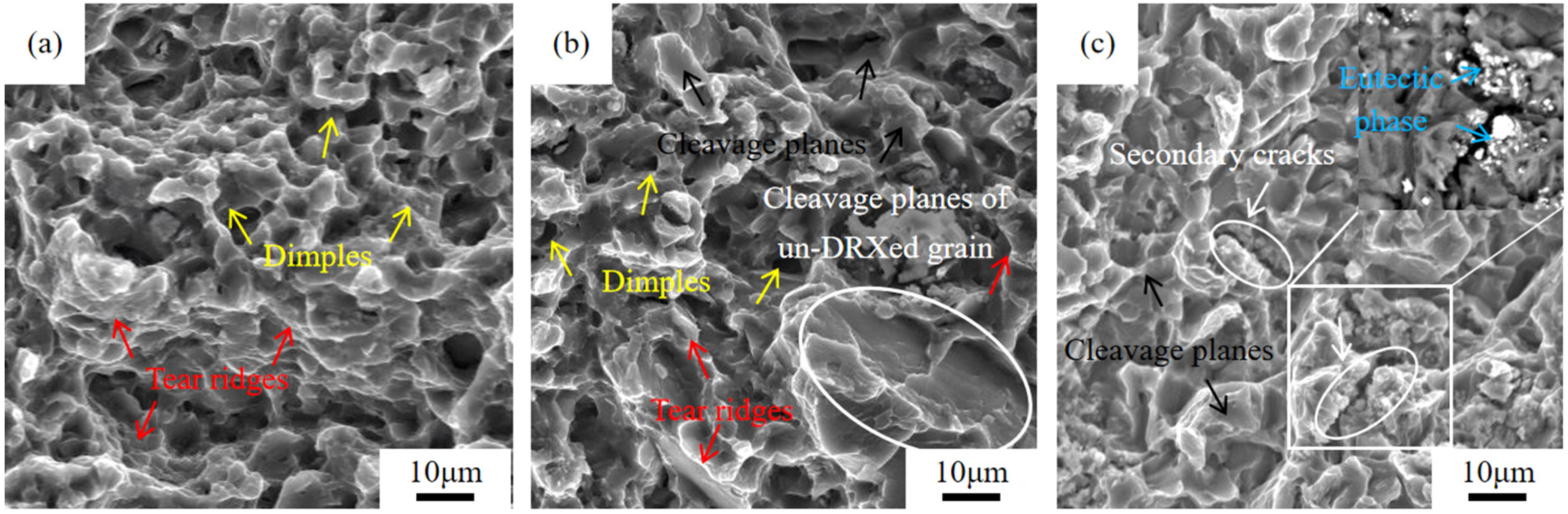

3.3.4. Tensile Fracture Morphology Analysis

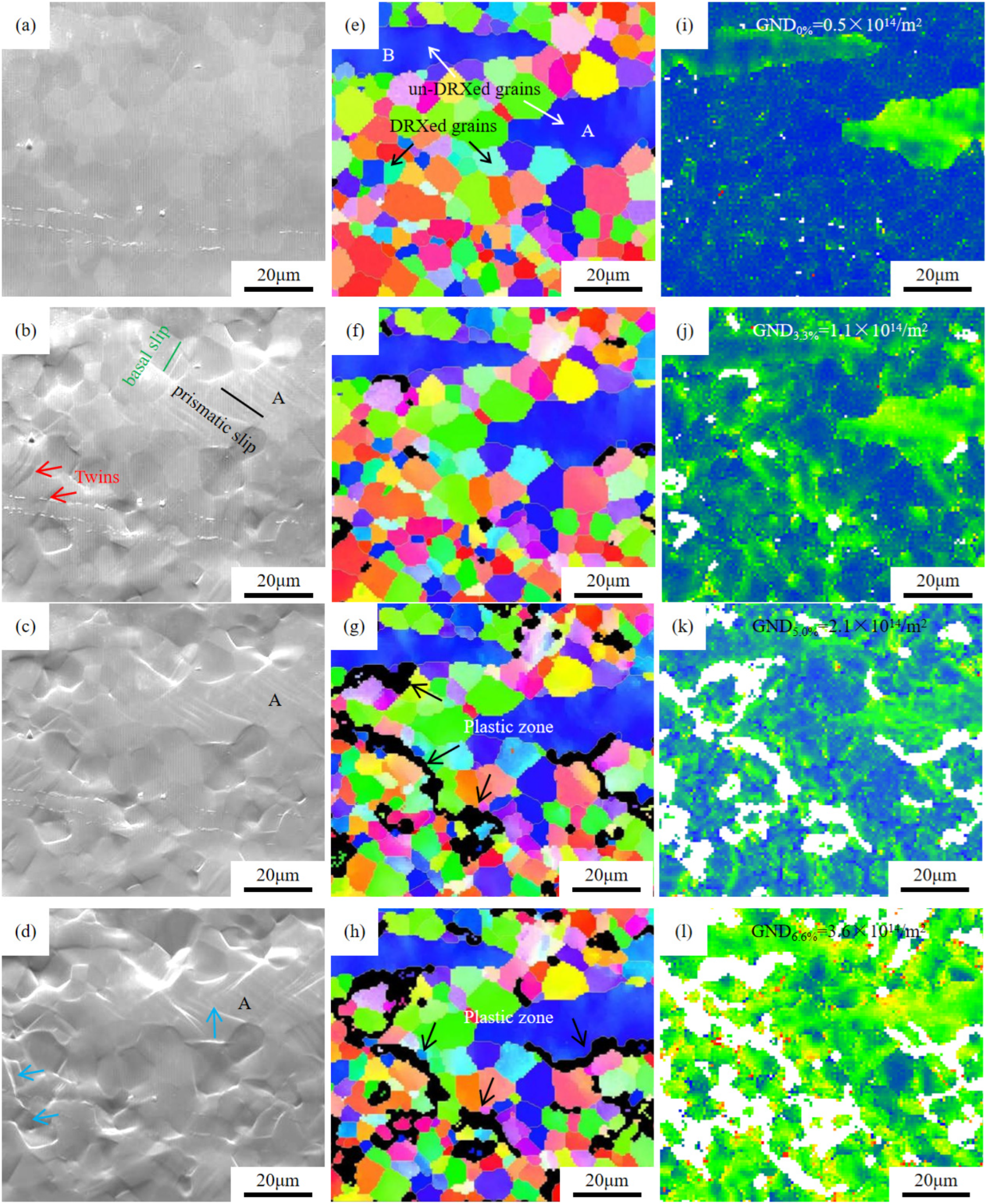

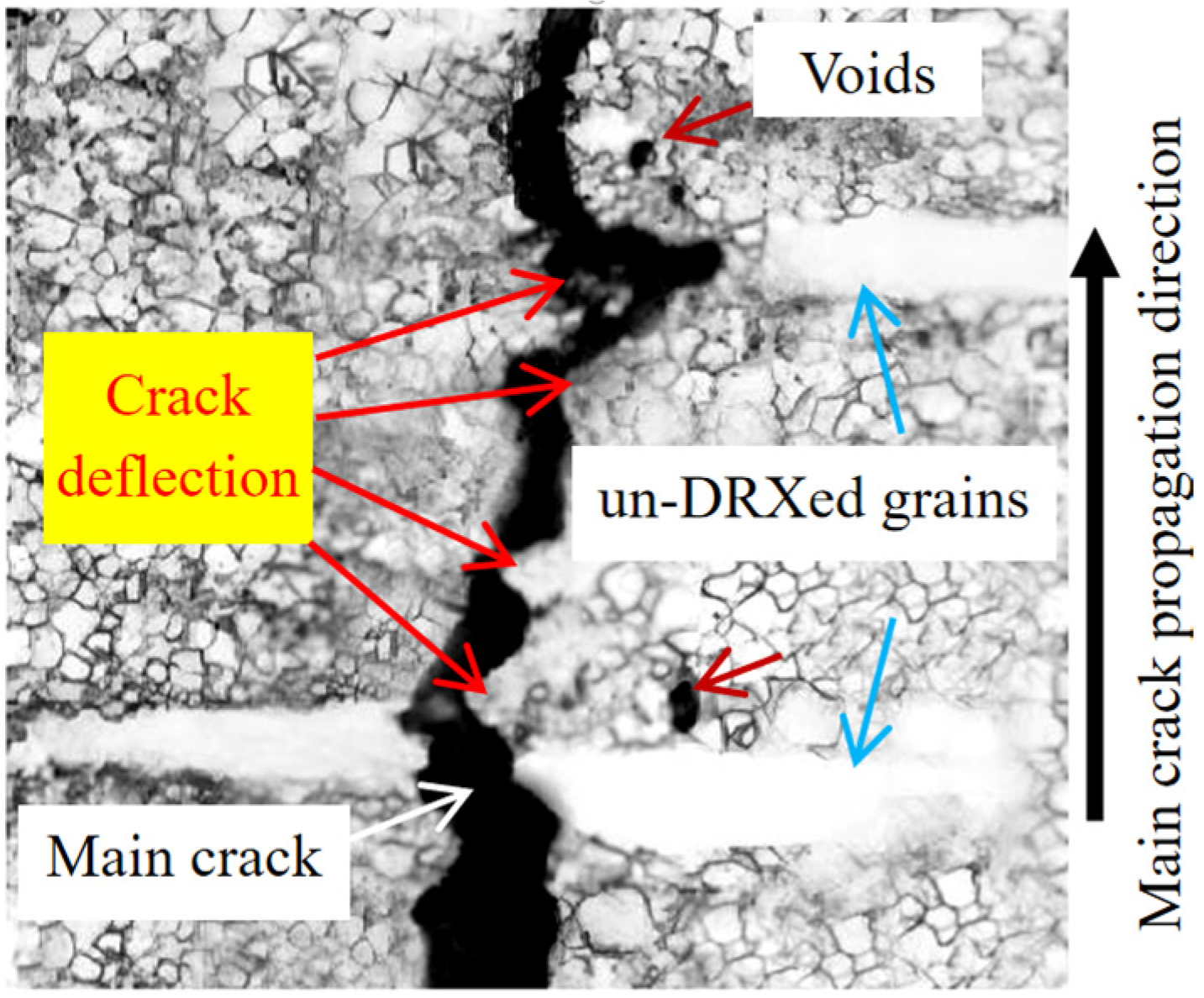

3.4. Deformation Behavior of Hot Extrusion Peak Aged GWS741 Alloy

4. Conclusions

- The grain of hot extruded Mg-xGd-4Y-1Sm-0.5Zr (x = 4, 7, 10; wt.%) alloys is refined strongly and forms a bimodal structure. With Gd content increasing, the degree of DRXed increases and average grain size gradually decreases, which are 10.6 μm, 8.1 μm, and 5.8 μm, respectively. Both the fraction of non-dynamic recrystallized grains gradually decreases, with 46.3%, 38.6%, and 9.3%.

- After aging treatment (200 °C × 96 h), the hot extruded Mg-xGd-4Y-1Sm-0.5Zr alloys reach the peak hardness. As Gd content increases, the area number density of the β′ phase increases with Gd, being 7.1 × 1015/m2, 9.9 × 1015/m2, and 16.5 × 1015/m2, respectively. And the yield strength (YS) increases from 287 MPa to 345 MPa, the ultimate tensile strength (UTS) increases from 365 MPa to 418 MPa, and elongation (EL) decreases from 8.5% to 4.2%. The fracture mechanism is a quasi-cleavage fracture.

- The hot extrusion peak-aged GWS741 has the optimal performance, and the YS, UTS, and EL are 332 MPa, 409 MPa, and 7.8%, respectively. From the in situ experiment, the coarse un-DRXed grain occurs prismatic () slip, and the DRXed grains occur basal () slip and twin deformation. When the strain is 6.6%, there is still no micro-crack in the bimodal structure region, showing high plasticity. During the tensile failure process, the main crack propagates along a zigzag path, forming the crack deflection, and the main crack passes through the long un-DRXed grain and bypasses the un-DRXed grain.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Y.F.; Zhang, A.; Li, C.M.; Xie, H.C.; Jiang, B.; Dong, Z.H.; Jin, P.; Pan, F. Recent advances of high strength Mg-RE alloys: Alloy development, forming and application. J. Mater. Res. Technol. 2023, 26, 2919–2940. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, J.H.; Xie, J.S.; Liu, S.J.; Fu, W.; Wu, R.Z. Developing a Mg alloy with ultrahigh room temperature ductility via grain boundary segregation and activation of non-basal slips. Int. J. Plast. 2023, 162, 103548. [Google Scholar] [CrossRef]

- Zhao, J.; Jiang, B.; Xu, J.; He, W.; Huang, G.; Pan, F. The influence of Gd on the recrystallisation, texture and mechanical properties of Mg alloy. Mater. Sci. Eng. A 2022, 839, 142867. [Google Scholar] [CrossRef]

- Xiao, X.W.; Li, J.; Feng, H.W.; Jing, L.; Nan, Y.; Zhen, Y.Z.; Jie, D. High strength and ductility Mg-8Gd-3Y-0.5Zr alloy with bimodal structure and nano-precipitates. J. Mater. Sci. Technol. 2020, 44, 19–23. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, J.; Chen, X.; Huang, G.; Xia, D.; Tang, A.; Zhu, Y.T.; Jiang, B.; Pan, F.S. Improving mechanical properties of heterogeneous Mg-Gd alloy laminate via accumulated extrusion bonding. Mater. Sci. Eng. A 2020, 785, 139324. [Google Scholar] [CrossRef]

- Yu, S.; Wan, Y.; Liu, C.; Wang, J. Age-hardening and age-softening in nanocrystalline Mg-Gd-Y-Zr alloy. Mater. Charact. 2019, 156, 109841. [Google Scholar] [CrossRef]

- Rezaei, A.; Mahmudi, R.; Cayron, C.; Loge, R. Superplastic behavior of a severely deformed Mg-6Gd-3Y-0.5Ag alloy. Mater. Sci. Eng. A 2021, 802, 140616. [Google Scholar] [CrossRef]

- Yu, Z.J.; Huang, Y.D.; Gan, W.M.; Zhong, Z.Y.; Hort, N.; Meng, J. Effects of extrusion ratio and annealing treatment on the mechanical properties and microstructure of a Mg-11Gd-4.5Y-1Nd-1.5Zn-0.5Zr (wt%) alloy. J. Mater. Sci. 2017, 52, 6670–6685. [Google Scholar] [CrossRef]

- Deng, Y.F.; Yan, H.G.; Li, Q.; Chen, J.H.; Xia, W.J.; Su, B.; Wu, M.; Song, M. Enhancing strength and ductility of low RE content Mg-Gd-Y-Zr alloy via a novel thermomechanical treatment based on multi-directional forging. J. Alloys Compd. 2023, 958, 170535. [Google Scholar] [CrossRef]

- Alizadeh, R.; Mahmudi, R.; Ngan, A.H.; Langdon, T.G. Microstructural evolution during hot shear deformation of an extruded fine-grained Mg-Gd-Y-Zr alloy. J. Mater. Sci. 2017, 52, 7843–7857. [Google Scholar] [CrossRef]

- Wan, Y.; Tang, B.; Gao, Y.; Tang, L.; Zhao, Y. Bulk nanocrystalline high-strength magnesium alloys prepared via rotary swaging. Acta Mater. 2020, 200, 274–286. [Google Scholar] [CrossRef]

- Dobatkin, S.V.; Rokhlin, L.L.; Lukyanova, E.A.; Murashkin, M.Y.; Rokhlin, L.L.; Dobatkin, S.V.; Estrin, Y.Z. Structure and mechanical properties of the Mg-Y-Gd-Zr alloy after high pressure torsion. Mater. Sci. Eng. A 2016, 667, 217–223. [Google Scholar] [CrossRef]

- Zheng, J.; Chen, Z.; Yan, Z.; Qiang, W.A.; Yong, X.A. Preparation of ultra-high strength Mg-Gd-Y-Zn-Zr alloy by pre-ageing treatment prior to extrusion. J. Alloys Compd. 2022, 894, 162490. [Google Scholar] [CrossRef]

- Rokhlin, L.L.; Dobatkina, T.V.; Tarytina, I.E.; Luk’yanova, E.A.; Ovchinnikova, O.A. Effect of samarium on the strength properties of Mg-Y-Gd-Zr alloys. Russ. Metall. 2021, 2021, 267–271. [Google Scholar] [CrossRef]

- Xie, H.B.; Liu, B.S.; Bai, J.Y.; Guan, C.L.; Qin, G. Re-recognition of the aging precipitation behavior in the Mg-Sm binary alloy. J. Alloy Compd. 2020, 814, 152320. [Google Scholar] [CrossRef]

- Yan, L.P.; Li, Q.A.; Zhu, L.M.; Chen, X.Y.; Yang, L.D.; Chen, J.; Li, W.H. Investigation of hot extruded GW84 alloy on high temperature tensile properties and microstructure evolution. J. Mater. Res. Technol. 2021, 13, 408–416. [Google Scholar] [CrossRef]

- Pei, Y.; Yuan, M.; Wei, E.; Teng, B. Effects of Sm element addition on the workability and microstructure evolution of Mg-Gd-Y-Zr alloy during hot deformation. Mater. Des. 2023, 230, 111962. [Google Scholar] [CrossRef]

- Li, K.J.; Xu, H.J.; Tong, Z.M. Effects of Sm on microstructure of Mg-12Gd-2Y-0.5Zr Alloy. IOP Conf. Ser. Mater. Sci. Eng. 2019, 569, 022017. [Google Scholar] [CrossRef]

- Chen, X.W.; Yang, H.Y.; Dong, B.X.; Liu, T.; Liu, L.; Tian, Z.; Zhan, L.; Wang, C.; Li, Z.; Meng, J. The development of high-strength flame-retardant magnesium alloys. J. Mater. Res. Technol. 2025, 36, 5797–5823. [Google Scholar] [CrossRef]

- Yan, L.P.; Li, Q.A.; Chen, X.Y. Microstructure evolution and dynamic precipitation behavior of Mg-10Gd-4Y-1Sm-0.5Zr during backward hot extrusion, metals and materials international. Met. Mater. Int. 2021, 27, 3522–3528. [Google Scholar] [CrossRef]

- Mirzadeh, H. Grain refinement of magnesium alloys by dynamic recrystallization (DRX): A review. J. Mater. Res. Technol. 2023, 25, 7050–7077. [Google Scholar] [CrossRef]

- Ding, N.; Du, W.B.; Li, S.B.; Liu, K.; Du, X.; Yu, Z.Y. Strain rate dependence of dynamic recrystallization and texture evolution in hot compressed Mg-Gd-Er-Zr alloy. J. Magnes. Alloy 2025, 13, 161–171. [Google Scholar] [CrossRef]

- Li, J.L.; Wen, C.; Han, X.Z. Unveiling anomalous strengthening and deformation mechanism evolution in a Mg-Gd-Y-Zr alloy under rate-temperature coupling effects. J. Magnes. Alloy 2025, 13, 2913–2926. [Google Scholar] [CrossRef]

- Tang, C.P.; Cui, L.; Jiang, H.C.; Liu, W.H.; Li, J.; Liu, X.; Li, H. The role of initial grain size on bimodal-grained microstructure and mechanical properties of an extruded Mg-Gd-Y-Nd-Zr alloy. J. Mater. Res. Technol. 2023, 23, 4663–4677. [Google Scholar] [CrossRef]

- Guan, K.; Ma, R.; Zhang, J.; Wu, R.; Yang, Q.; Meng, J. Modifying microstructures and tensile properties of Mg-Sm based alloy via extrusion ratio. J. Magnes. Alloy 2021, 9, 1098–1109. [Google Scholar] [CrossRef]

- Xu, N.; Ren, Z.K.; Fan, Y.; Gu, B.K.; Shen, J.; Song, Q.N.; Zhao, Z.; Bao, Y. Microstructural evolution and mechanical properties of cooling medium assistant friction stir processed AZ31B Mg alloy. Trans. Nonferrous Met. Soc. China 2023, 33, 1729–1741. [Google Scholar] [CrossRef]

- Xia, X.S.; Zhang, K.; Ma, M.L.; Li, T. Constitutive modeling of flow behavior and processing maps of Mg-8.1Gd-4.5Y-0.3Zr alloy. J. Magnes. Alloy 2020, 8, 917–928. [Google Scholar] [CrossRef]

- Wu, Q.Y.; Wu, Y.J.; Deng, Q.C.; Ding, C.Y.; Zhang, Y.; Peng, N.; Jia, L.; Chang, Z.; Peng, L. Effect of Gd content on microstructure and mechanical properties of Mg-xGd-Zr alloys via semicontinuous casting. J. Magnes. Alloy 2024, 12, 4045–4050. [Google Scholar] [CrossRef]

- Jia, J.J.; Zhang, H.L.; Meng, M.; Yang, X.; Zhang, X.H.; Zhang, Z.M. Strain-induced heterogeneous bimodal microstructure behavior of Mg-Gd-Y-Zn-Zr alloy containing LPSO phase during hot compression. J. Mater. Res. Technol. 2023, 27, 4264–4277. [Google Scholar] [CrossRef]

- Li, C.; Wei, J.; Jin, J.; Yan, H.; Shan, Z.; Mao, Y.; Chen, R. The effect of precipitates on the fracture behavior and tensile properties of Mg-14Gd-0.5Zr (wt.%) alloy. J. Mater. Sci. Technol. 2024, 180, 226–242. [Google Scholar] [CrossRef]

- Wang, C.H.; Dong, Z.H.; Jiang, B.; Wang, L.; Zheng, Z.; Zhang, A.; Levente, V. Low thermal expansion in conjunction with improved mechanical properties achieved in Mg-Gd solid solutions. Mater. Des. 2025, 251, 113685. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, J.L.; Wang, M.; Wang, W.Z.; Zhao, D.; Huang, H.; Zhao, Q.; Xu, X.; Zhang, H.; Huang, G. Research progress of heterogeneous structure magnesium alloys: A review. J. Magnes. Alloy 2024, 12, 2147–2180. [Google Scholar] [CrossRef]

- Pang, H.; Tang, L.; Wang, X.; Ma, M.; Lu, L. The Influence of Aging Temperature and Cryogenic Treatment on the Mechanical Properties and Microstructure of Extruded Mg-8Gd-3Y-0.4Zr Alloy. Materials 2025, 18, 2922. [Google Scholar] [CrossRef]

- Wang, D.; Fu, P.H.; Peng, L.M.; Wang, Y.X.; Ding, W.J. Development of high strength sand cast Mg-Gd-Zn alloy by co-precipitation of the prismatic β′ and β1 phases. Mater. Charact. 2019, 153, 157–168. [Google Scholar] [CrossRef]

- Wang, D.; He, Y.; Yu, Y.; Fan, P.; Gao, H.; Fu, P.; Peng, L. Microstructure and mechanical properties of cast Mg-6Gd-Zr alloy with different Y addition. J. Mater. Res. Technol. 2023, 27, 4494–4502. [Google Scholar] [CrossRef]

- Rong, W.; Wu, Y.; Zhang, Y.; Sun, M.; Chen, J.; Peng, L.; Ding, W.J. Characterization and strengthening effects of γ′ precipitates in a high-strength casting Mg-15Gd-1Zn-0.4Zr (wt.%) alloy. Mater. Charact. 2017, 126, 1–9. [Google Scholar] [CrossRef]

- Zhou, H.; Xu, W.Z.; Jian, W.W.; Cheng, G.W.; Ma, X.L.; Guo, W.; Mathaudhu, S.N.; Wang, Q.D.; Zhu, Y.T. A new metastable precipitate phase in Mg-Gd-Y-Zr alloy. Philos. Mag. 2014, 94, 2403–2411. [Google Scholar] [CrossRef]

- Matsuoka, Y.; Matsuda, K.; Watanabe, K.; Nakamura, J.; Lefebvre, W.; Nakagawa, D.; Saikawa, S.; Ikeno, S. Precipitation sequence in the Mg-Gd-Y system investigated by HRTEM and HAADFSTEM. Mater. Trans. 2014, 55, 1051–1057. [Google Scholar] [CrossRef]

- Xie, J.S.; Zhang, J.H.; You, Z.H.; Liu, S.J.; Guan, K.; Wu, R.Z.; Wang, J.; Jing, F. Towards developing Mg alloys with simultaneously improved strength and corrosion resistance via RE alloying. J. Magnes. Alloy 2021, 9, 41–56. [Google Scholar] [CrossRef]

- Zheng, J.X.; Li, Z.; Tan, L.D.; Xu, X.S.; Luo, R.C.; Chen, B. Precipitation in Mg-Gd-Y-Zr alloy: Atomic-scale insights into structures and transformations. Mater. Charact. 2016, 117, 76–83. [Google Scholar] [CrossRef]

- Liu, K.; Wang, X.D.; Wen, K. Effect of isothermal homogenization on microstructure and mechanical properties of the Mg-5Y-4Gd-0.5Zn-0.4Zr alloy. Mater. Des. 2013, 52, 1035–1042. [Google Scholar] [CrossRef]

- Xie, H.B.; Pan, H.C.; Ren, Y.P.; Sun, S.N.; Wang, L.Q.; He, Y.F.; Qin, G.W. Co-existences of the two types of β’ precipitations in peak-aged Mg-Gd binary alloy. J. Alloys Compd. 2018, 738, 32–38. [Google Scholar] [CrossRef]

- Nie, J.F. Effects of precipitate shape and orientation on dispersion strengthening in magnesium alloys. Scripta Mater. 2003, 48, 1009–1023. [Google Scholar] [CrossRef]

- Peng, P.; Tang, A.T.; Jia, S.; Zhang, J.Y.; Zhou, S.B.; Song, K.; Pan, F. Significant improvement in yield stress of Mg-Gd-Mn alloy by forming bimodal grain structure. Mater. Sci. Eng. A 2021, 803, 140569. [Google Scholar] [CrossRef]

- Pan, H.; Qin, G.; Huang, Y.; Ren, Y.; Sha, X.; Han, X.; Liu, Z.Q.; Li, C.; Wu, X.; Chen, H. Development of low-alloyed and rare-earth-free magnesium alloys having ultra-high strength. Acta Mater. 2018, 149, 350–363. [Google Scholar] [CrossRef]

- Jin, Z.Z.; Zha, M.; Yu, Z.Y.; Ma, P.K.; Li, Y.K.; Liu, J.M. Exploring the Hall-Petch relation and strengthening mechanism of bimodal-grained Mg-Al-Zn alloys. J. Alloys Compd. 2020, 833, 155004. [Google Scholar] [CrossRef]

- Li, R.G.; Yan, Y.; Pan, H.C.; Zhang, H.; Li, J.R.; Qin, G.W.; Liu, B.S. Achieving a high-strength binary Mg-15Gd alloy by nano substructure with Gd segregation and nano clusters. Mater. Res. Lett. 2022, 10, 682–689. [Google Scholar] [CrossRef]

- Zhang, H.; Gao, Y.; Li, R.G.; Liu, B.S.; Li, S.S.; Tang, Y.; Zhang, Y.H.; Qin, G. Comparative study on contribution of bimodal microstructure and heterogeneous microstructure to mechanical properties of ZK60 alloy. J. Mater. Res. Technol. 2024, 33, 8687–8697. [Google Scholar] [CrossRef]

- Ji, Z.K.; Qiao, X.G.; Sun, W.T.; Yuan, L.; Cong, F.G.; Wang, G.J.; Zheng, M.Y. Effect of bimodal microstructure on the tensile properties and fracture toughness of extruded Mg-9Gd-4Y-0.5Zr alloy. Mater. Sci. Eng. A 2023, 885, 145587. [Google Scholar] [CrossRef]

- Wang, Z.; Lin, X.; Kang, N.; Wang, Y.; Yu, X.; Tan, H.; Huang, W. Making selective-laser-melted high-strength Al-Mg-Sc-Zr alloy tough via ultrafine and heterogeneous microstructure. Scr. Mater. 2021, 203, 114052. [Google Scholar] [CrossRef]

- Ji, Z.K.; Qiao, X.G.; Yuan, L.; Cong, F.G.; Wang, G.J.; Zheng, M.Y. Exceptional fracture toughness in a high-strength Mg alloy with the synergetic effects of bimodal structure, LPSO, and nanoprecipitates. Scr. Mater. 2023, 236, 115675. [Google Scholar] [CrossRef]

| Gd | Y | Sm | Zr | |

|---|---|---|---|---|

| Mg-4Gd-4Y-1Sm-0.5Zr (GWS441) | 3.95 | 3.88 | 0.91 | 0.51 |

| Mg-7Gd-4Y-1Sm-0.5Zr (GWS741) | 6.91 | 3.75 | 0.87 | 0.48 |

| Mg-10Gd-4Y-1Sm-0.5Zr (GWS1041) | 9.87 | 3.92 | 0.94 | 0.46 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, L.; Zhu, X.; Qiu, R.; Wang, N.; Zhang, X. Effect of Gd Content on the Microstructure and Mechanical Properties of Hot Extruded Mg-xGd-4Y-1Sm-0.5Zr Alloys. Materials 2025, 18, 5023. https://doi.org/10.3390/ma18215023

Yan L, Zhu X, Qiu R, Wang N, Zhang X. Effect of Gd Content on the Microstructure and Mechanical Properties of Hot Extruded Mg-xGd-4Y-1Sm-0.5Zr Alloys. Materials. 2025; 18(21):5023. https://doi.org/10.3390/ma18215023

Chicago/Turabian StyleYan, Lipeng, Xinglin Zhu, Ranfeng Qiu, Nannan Wang, and Xiaoke Zhang. 2025. "Effect of Gd Content on the Microstructure and Mechanical Properties of Hot Extruded Mg-xGd-4Y-1Sm-0.5Zr Alloys" Materials 18, no. 21: 5023. https://doi.org/10.3390/ma18215023

APA StyleYan, L., Zhu, X., Qiu, R., Wang, N., & Zhang, X. (2025). Effect of Gd Content on the Microstructure and Mechanical Properties of Hot Extruded Mg-xGd-4Y-1Sm-0.5Zr Alloys. Materials, 18(21), 5023. https://doi.org/10.3390/ma18215023