Robotized Fabrication Strategy for Large-Scale 3D Conformal Electronics

Abstract

1. Introduction

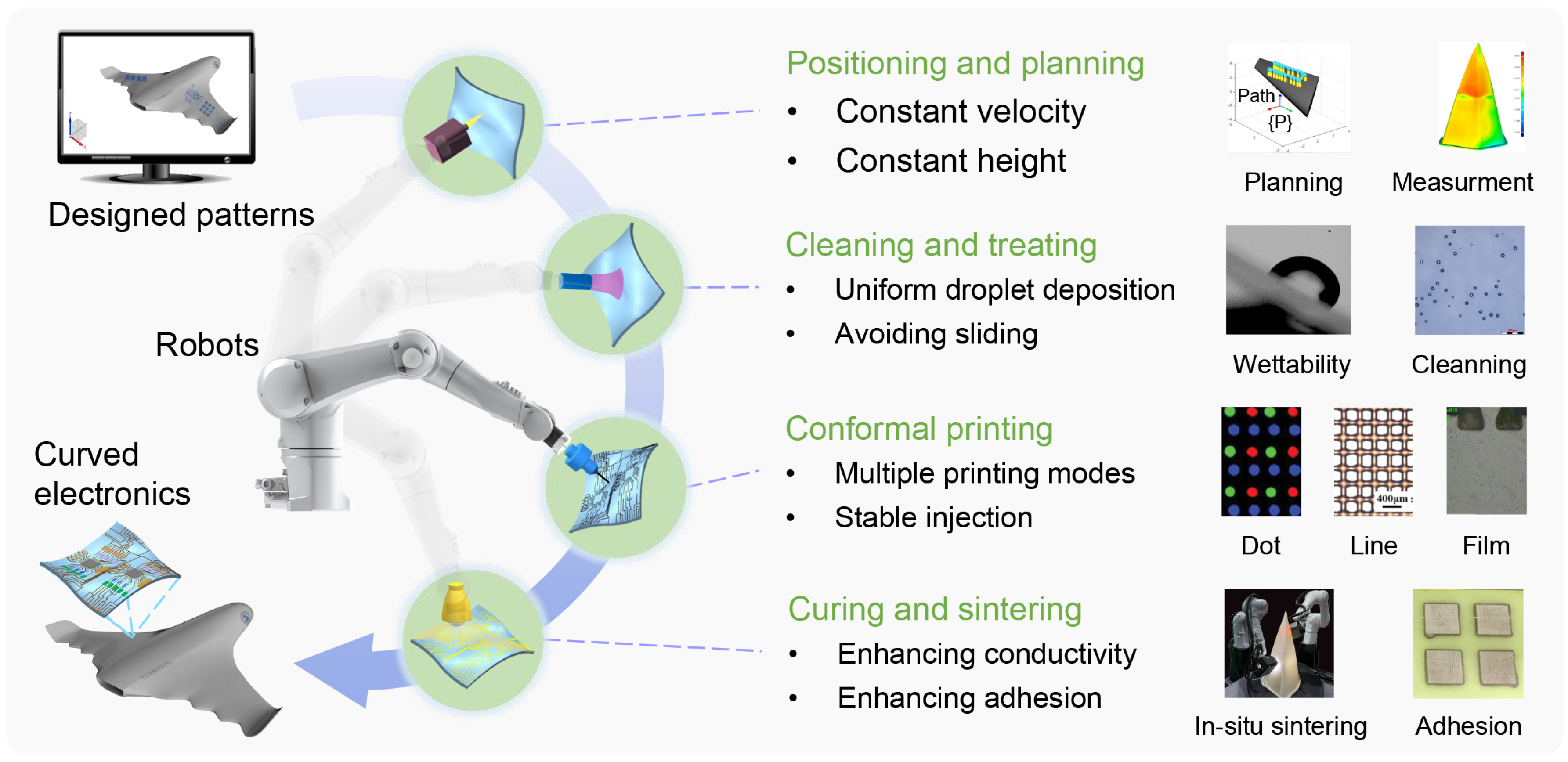

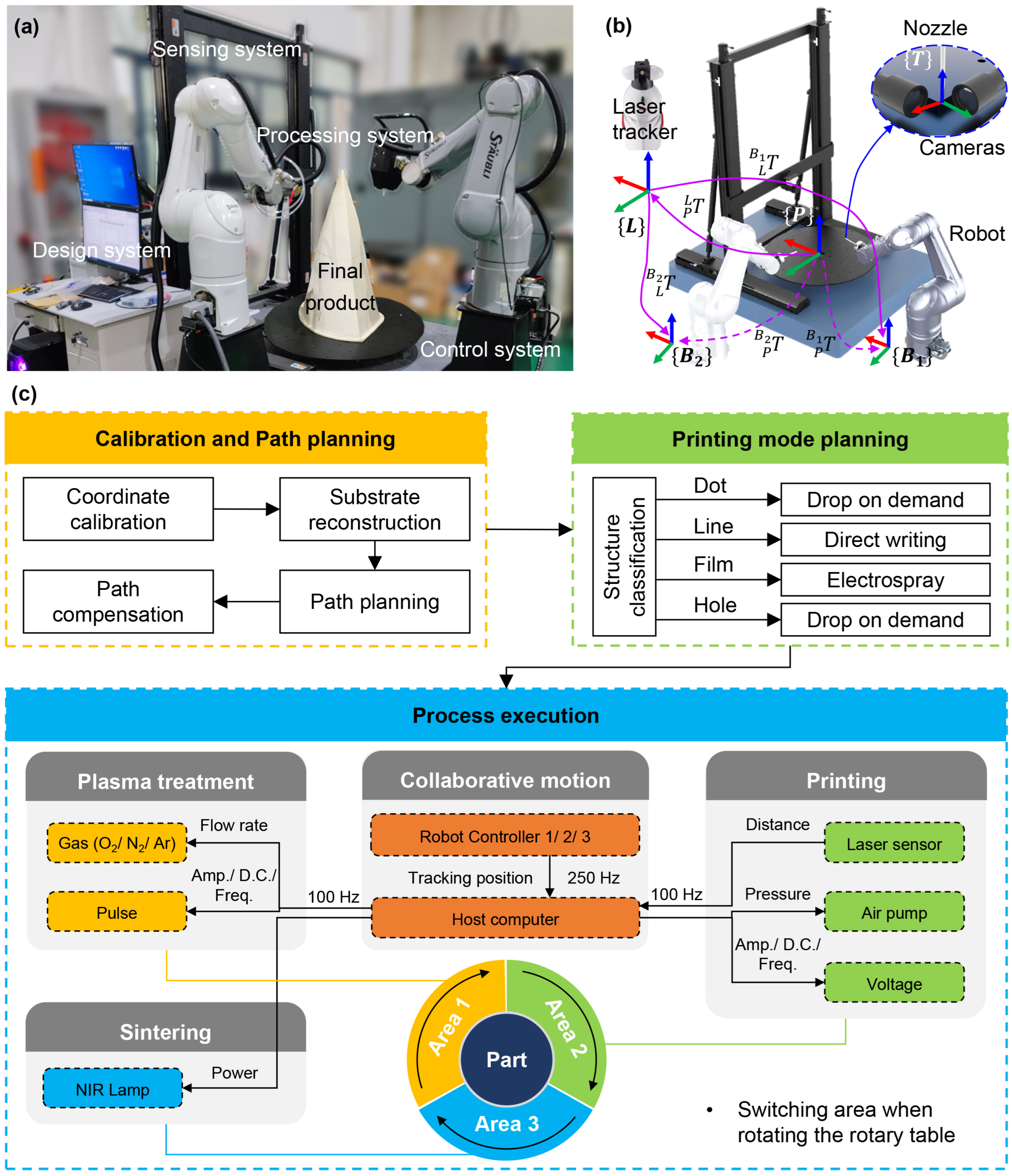

2. Fabrication Strategy for Large-Scale Conformal Electronics

3. Key Technologies of the Fabrication Strategy

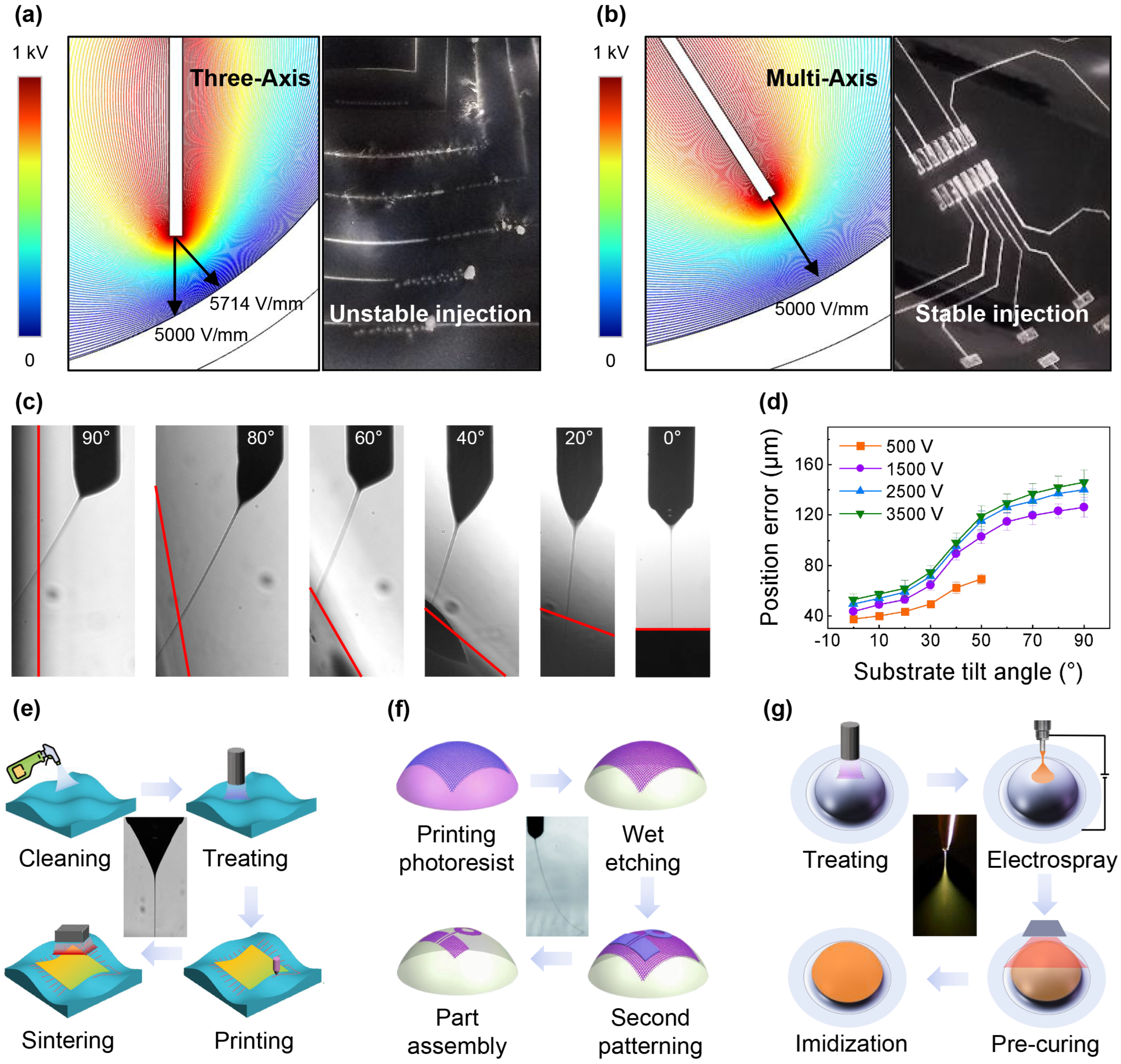

3.1. EHD Conformal Printing Technology

3.1.1. Comparison of Three-Axis and Multi-Axis Conformal Printing

3.1.2. EHD Printing Processes Corresponding to Three Printing Modes

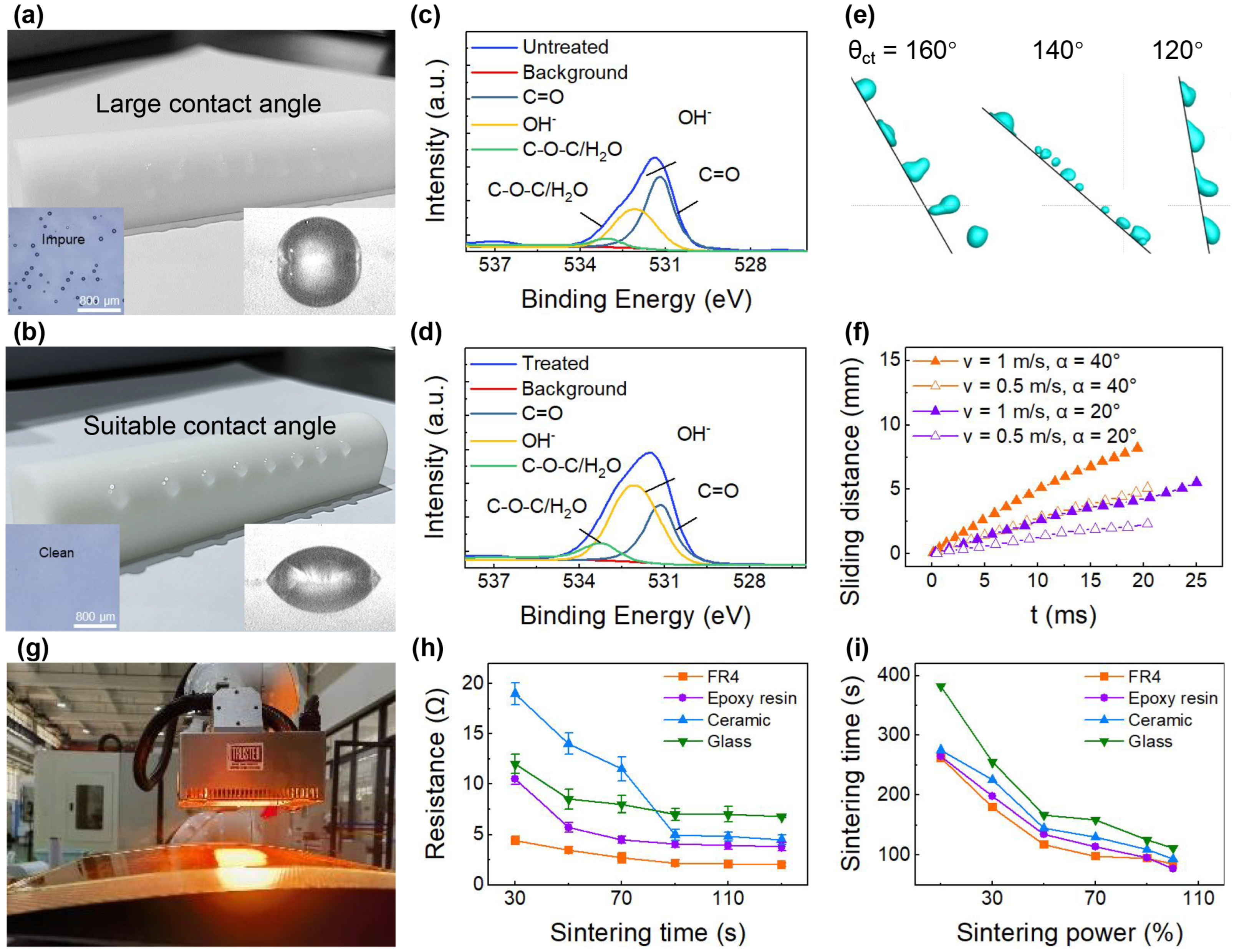

3.2. In Situ Plasma Pre-Treatment and NIR Sintering Post-Treatment Technology

3.2.1. Plasma Treatment Technology

3.2.2. NIR Sintering Technology

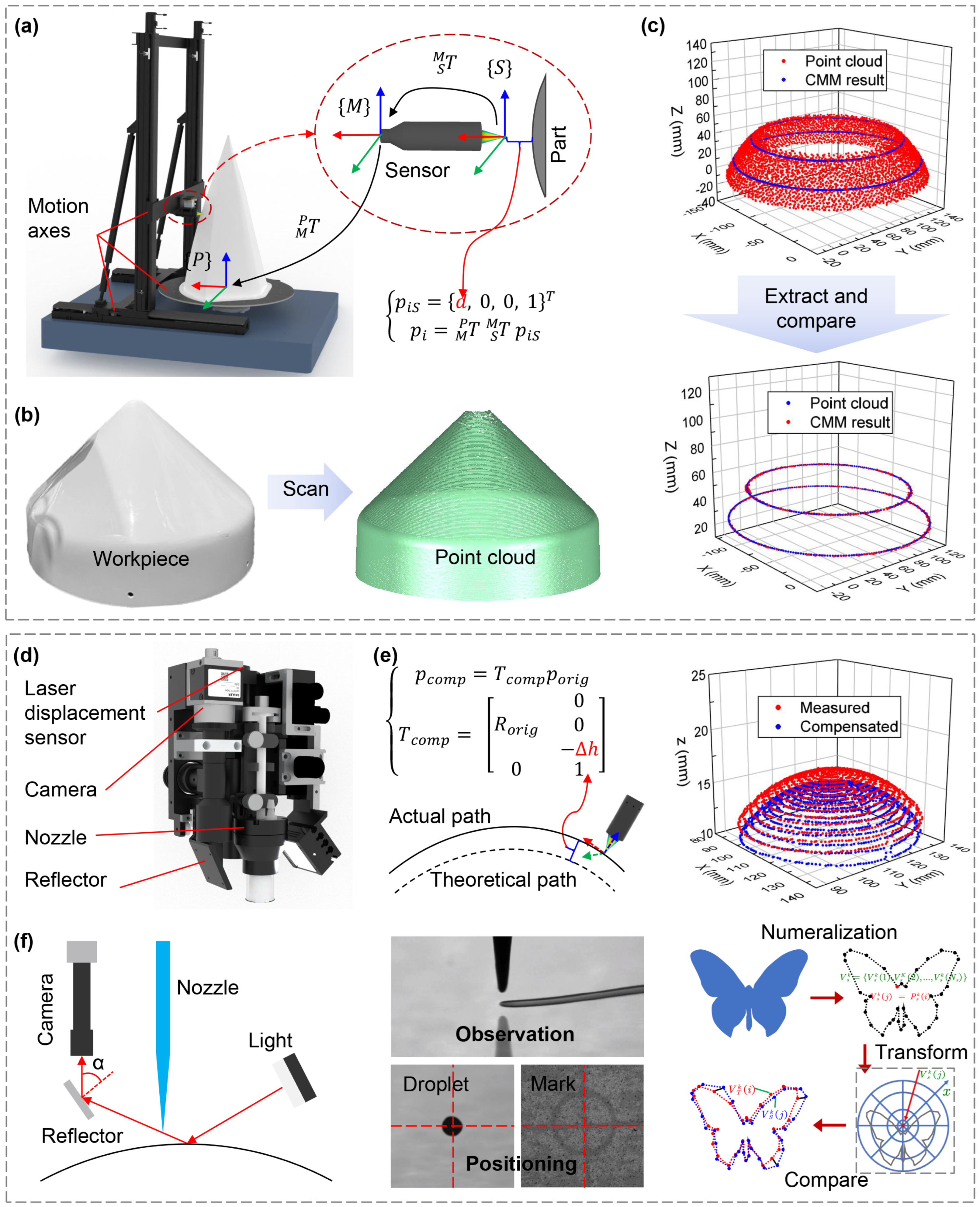

3.3. On Machine Measurement and Hybrid Positioning Technology

3.3.1. On Machine Measurement System

3.3.2. Laser and Vision Positioning Technology

4. Application of Fabrication Strategies to Equipment and Devices

4.1. Multi-Robot Collaborative Conformal Printing Equipment

4.1.1. Conformal Printing Equipment

4.1.2. Conformal Printing Steps Based on the Equipment

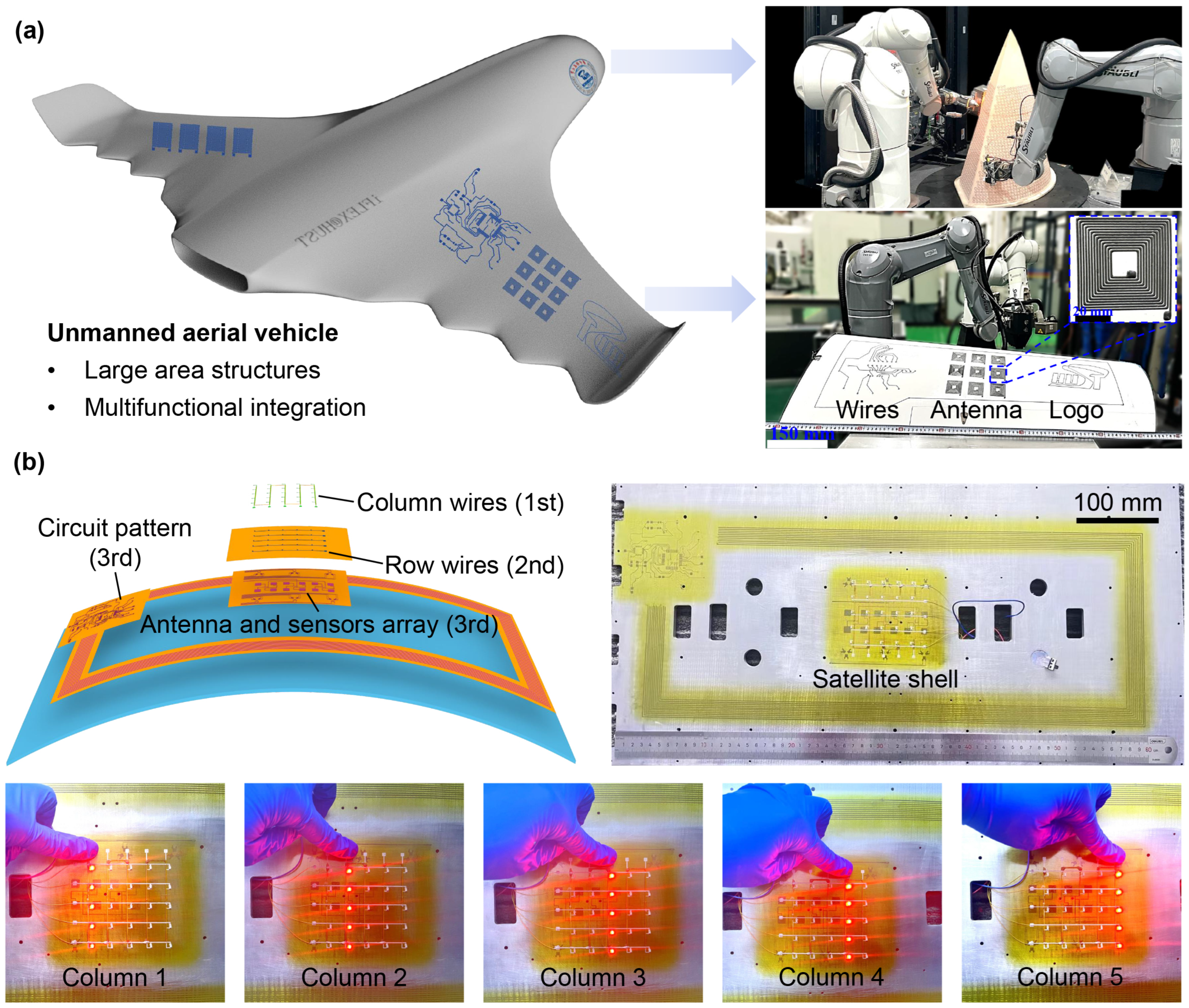

4.2. Conformal Electronics on Smart Skin and Satellite Shell

4.2.1. Conformal Electronics on Smart Skin

4.2.2. Conformal Electronics on Satellite Shell

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gao, Y.; Ge, Y.; Ma, L.; Hu, Y.; Chen, Y. Optimization design of configuration and layout for Queqiao relay satellite. Adv. Astronaut. Sci. Technol. 2019, 2, 33–38. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, S.; Xiong, T.; Huang, Y.; Qiu, L. Recent progress in aircraft smart skin for structural health monitoring. Struct. Health Monit. 2022, 21, 2453–2480. [Google Scholar] [CrossRef]

- Michel, A.; Singh, R.K.; Nepa, P. A compact and wideband dashboard antenna for vehicular LTE/5G wireless communications. Electronics 2022, 11, 1923. [Google Scholar] [CrossRef]

- Liu, F.; Deswal, S.; Christou, A.; Sandamirskaya, Y.; Kaboli, M.; Dahiya, R. Neuro-inspired electronic skin for robots. Sci. Robot. 2022, 7, eabl7344. [Google Scholar] [CrossRef]

- Zhu, P.; Li, Z.; Pang, J.; He, P.; Zhang, S. Latest developments and trends in electronic skin devices. Soft Sci. 2024, 4, 17. [Google Scholar] [CrossRef]

- Qu, J.; Cui, G.; Li, Z.; Fang, S.; Zhang, X.; Liu, A.; Han, M.; Liu, H.; Wang, X.; Wang, X. Advanced flexible sensing technologies for soft robots. Adv. Funct. Mater. 2024, 34, 2401311. [Google Scholar] [CrossRef]

- Kim, J.H.; Chun, H.J.; Hong, I.P.; Kim, Y.J.; Park, Y.B. Analysis of FSS radomes based on physical optics method and ray tracing technique. IEEE Antennas Wirel. Propag. Lett. 2014, 13, 868–871. [Google Scholar] [CrossRef]

- Knoll, M.; Offenzeller, C.; Jakoby, B.; Hilber, W. Embedded temperature and anti-icing monitoring systems directly printed on 3d shaped substrates. IEEE Sens. J. 2020, 20, 5314–5321. [Google Scholar] [CrossRef]

- Huang, Y.; Zhu, C.; Xiong, W.; Wang, Y.; Jiang, Y.; Qiu, L.; Guo, D.; Hou, C.; Jiang, S.; Yang, Z.; et al. Flexible smart sensing skin for “Fly-by-Feel” morphing aircraft. Sci. China Technol. Sci. 2022, 65, 1–29. [Google Scholar] [CrossRef]

- Tian, S.; Wang, Y.; Deng, H.; Wang, Y.; Zhang, X. Flexible pressure and temperature sensors towards e-skin: Material, mechanism, structure and fabrication. Soft Sci. 2023, 3, 30. [Google Scholar] [CrossRef]

- Ye, D.; Xie, H.; Tian, Y.; Wen, J.; Shi, Z.; An, K.; Zhang, Y.; Huang, Y. Electrohydrodynamic lithography of metallic mesh for optically transparent flexible and conformal antennas. Sci. China Technol. Sci. 2023, 66, 2–12. [Google Scholar] [CrossRef]

- Paulsen, J.A.; Renn, M.; Christenson, K.; Plourde, R. Printing conformal electronics on 3D structures with Aerosol Jet technology. In Proceedings of the 2012 Future of Instrumentation International Workshop (FIIW) Proceedings, Gatlinburg, TN, USA, 8–9 October 2012; pp. 1–4. [Google Scholar]

- Choi, S.; Shin, J.; Park, G.; Eo, J.S.; Jang, J.; Yang, J.J.; Wang, G. 3D-integrated multilayered physical reservoir array for learning and forecasting time-series information. Nat. Commun. 2024, 15, 2044. [Google Scholar] [CrossRef] [PubMed]

- Zhou, L.; Liu, R.; Yi, X. Research and development of anti-icing/deicing techniques for vessels. Ocean Eng. 2022, 260, 112008. [Google Scholar] [CrossRef]

- Xiong, W.; Zhu, C.; Guo, D.; Hou, C.; Yang, Z.; Xu, Z.; Qiu, L.; Yang, H.; Li, K.; Huang, Y. Bio-inspired, intelligent flexible sensing skin for multifunctional flying perception. Nano Energy 2021, 90, 106550. [Google Scholar] [CrossRef]

- Chen, J.; Yang, S.; Li, Y.; Huang, Y.; Yin, Z. Active curved surface deforming of flexible conformal electronics by multi-fingered actuator. Robot. Comput.-Integr. Manuf. 2020, 64, 101942. [Google Scholar] [CrossRef]

- Liu, J.; Jiang, S.; Xiong, W.; Zhu, C.; Li, K.; Huang, Y. Self-healing kirigami assembly strategy for conformal electronics. Adv. Funct. Mater. 2022, 32, 2109214. [Google Scholar] [CrossRef]

- Yi, N.; Gao, Y.; Verso, A.L., Jr.; Zhu, J.; Erdely, D.; Xue, C.; Lavelle, R.; Cheng, H. Fabricating functional circuits on 3D freeform surfaces via intense pulsed light-induced zinc mass transfer. Mater. Today 2021, 50, 24–34. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, B.; Jiang, J.; Wu, K.; Guo, C.F.; Wu, Z. High-fidelity conformal printing of 3D liquid alloy circuits for soft electronics. ACS Appl. Mater. Interfaces 2019, 11, 7148–7156. [Google Scholar] [CrossRef]

- Pfeiffer, C.; Xu, X.; Forrest, S.R.; Grbic, A. Patterning: Direct transfer patterning of electrically small antennas onto three-dimensionally contoured substrates. Adv. Mater. 2012, 24, 1138. [Google Scholar] [CrossRef][Green Version]

- Ko, H.C.; Stoykovich, M.P.; Song, J.; Malyarchuk, V.; Choi, W.M.; Yu, C.J.; Geddes, J.B., III; Xiao, J.; Wang, S.; Huang, Y.; et al. A hemispherical electronic eye camera based on compressible silicon optoelectronics. Nature 2008, 454, 748–753. [Google Scholar] [CrossRef] [PubMed]

- Kwok, T.H.; Wang, C.C.L.; Deng, D.; Zhang, Y.; Chen, Y. Four-dimensional printing for freeform surfaces: Design optimization of origami and kirigami structures. J. Mech. Des. 2015, 137, 111413. [Google Scholar] [CrossRef]

- Kim, Y.; Yuk, H.; Zhao, R.; Chester, S.A.; Zhao, X. Printing ferromagnetic domains for untethered fast-transforming soft materials. Nature 2018, 558, 274–279. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Yang, Y.; He, Z.; Chen, B.; Liu, J. A personal desktop liquid-metal printer as a pervasive electronics manufacturing tool for society in the near future. Engineering 2015, 1, 506–512. [Google Scholar] [CrossRef]

- Ganguly, S.; Margel, S. Fabrication and applications of magnetic polymer composites for soft robotics. Micromachines 2023, 14, 2173. [Google Scholar] [CrossRef]

- Zhang, H.; Huang, J.; Wang, J.; Zhao, J.; Liu, D. Development of a path planning algorithm for reduced dimension patch printing conductive pattern on surfaces. Int. J. Adv. Manuf. Technol. 2018, 95, 1645–1654. [Google Scholar] [CrossRef]

- Meng, F.; Huang, J.; Zhao, P. 3D-printed conformal array patch antenna using a five-axes motion printing system and flash light sintering. 3D Print. Addit. Manuf. 2019, 6, 118–125. [Google Scholar] [CrossRef]

- Wu, H.; Tian, Y.; Luo, H.; Zhu, H.; Duan, Y.; Huang, Y. Fabrication techniques for curved electronics on arbitrary surfaces. Adv. Mater. Technol. 2020, 5, 2000093. [Google Scholar] [CrossRef]

- Blumenthal, T.; Fratello, V.; Nino, G.; Ritala, K. Conformal printing of sensors on 3D and flexible surfaces using aerosol jet deposition. In Proceedings of the Nanosensors, Biosensors, and Info-Tech Sensors and Systems 2013, San Diego, CA, USA, 10–14 March 2013; Volume 8691, pp. 118–126. [Google Scholar]

- Ye, D.; Ding, Y.; Duan, Y.; Su, J.; Yin, Z.; Huang, Y.A. Large-scale direct-writing of aligned nanofibers for flexible electronics. Small 2018, 14, 1703521. [Google Scholar] [CrossRef]

- Huang, Y.; Wu, H.; Zhu, C.; Xiong, W.; Chen, F.; Xiao, L.; Liu, J.; Wang, K.; Li, H.; Ye, D.; et al. Programmable robotized ‘transfer-and-jet’printing for large, 3D curved electronics on complex surfaces. Int. J. Extrem. Manuf. 2021, 3, 045101. [Google Scholar] [CrossRef]

- Wu, H.; Luo, H.; Wang, K.; Ye, D.; Huang, Y. Enhanced geometric precision of non-contact, conformal 3D printing via “error-transferred” towards jetting-direction. Precis. Eng. 2021, 72, 1–12. [Google Scholar] [CrossRef]

- Ye, D.; Peng, Z.; Liu, J.; Huang, Y. Self-Limited ultraviolet laser sintering of liquid metal particles for μm-Thick flexible electronics devices. Mater. Des. 2022, 223, 111189. [Google Scholar] [CrossRef]

- Day, C.P. Robotics in industry—Their role in intelligent manufacturing. Engineering 2018, 4, 440–445. [Google Scholar] [CrossRef]

- Wang, B. The future of manufacturing: A new perspective. Engineering 2018, 4, 722–728. [Google Scholar] [CrossRef]

- Goh, G.L.; Zhang, H.; Chong, T.H.; Yeong, W.Y. 3D printing of multilayered and multimaterial electronics: A review. Adv. Electron. Mater. 2021, 7, 2100445. [Google Scholar] [CrossRef]

- Kucukdeger, E.; Tong, Y.; Singh, M.; Zhang, J.; Harding, L.K.; Salado, A.; Ellingson, S.W.; Johnson, B.N. Conformal 3D printing of non-planar antennas on wrinkled and folded kapton films using point cloud data. Flex. Print. Electron. 2021, 6, 044002. [Google Scholar] [CrossRef]

- Park, J.U.; Hardy, M.; Kang, S.J.; Barton, K.; Adair, K.; Mukhopadhyay, D.K.; Lee, C.Y.; Strano, M.S.; Alleyne, A.G.; Georgiadis, J.G.; et al. High-resolution electrohydrodynamic jet printing. Nat. Mater. 2007, 6, 782–789. [Google Scholar] [CrossRef]

- Onses, M.S.; Sutanto, E.; Ferreira, P.M.; Alleyne, A.G.; Rogers, J.A. Mechanisms, capabilities, and applications of high-resolution electrohydrodynamic jet printing. Small 2015, 11, 4237–4266. [Google Scholar] [CrossRef]

- Mkhize, N.; Bhaskaran, H. Electrohydrodynamic jet printing: Introductory concepts and considerations. Small Sci. 2022, 2, 21. [Google Scholar] [CrossRef]

- Ding, Y.; Zhu, C.; Liu, J.; Duan, Y.; Yi, Z.; Xiao, J.; Wang, S.; Huang, Y.; Yin, Z. Flexible small-channel thin-film transistors by electrohydrodynamic lithography. Nanoscale 2017, 9, 19050–19057. [Google Scholar] [CrossRef] [PubMed]

- Garcia-Geijo, P.; Riboux, G.; Gordillo, J.M. Inclined impact of drops. J. Fluid Mech. 2020, 897, A12. [Google Scholar] [CrossRef]

- Lv, C.J.; Shi, S.L. Wetting states of two-dimensional drops under gravity. Phys. Rev. E 2018, 98, 042802. [Google Scholar] [CrossRef]

- Guan, Y.; Fu, J.W.; Wu, S.; Chen, X.Y.; Zhou, C. The post-impact dynamics of drop rebound on inclined hydrophobic surfaces of various wettabilities. Phys. Fluids 2021, 33, 72108. [Google Scholar] [CrossRef]

- Guan, Y.; Fu, J.W.; Wu, S.; Yu, C.P.; Chen, X.Y.; Zhou, C. The dynamical behaviors of water drop impacting and bouncing on an inclined hydrophobic surface. Colloids Surfaces A Physicochem. Eng. Asp. 2021, 627, 127087. [Google Scholar] [CrossRef]

- Chen, J.K.; Liu, T.; Yang, H.; Zhang, Z.; Huang, Y.A.; Yin, Z.P. Polygonal-feature-based shape context for flexible surface vision positioning. Meas. Sci. Technol. 2019, 30, 055403. [Google Scholar] [CrossRef]

| Conformal Printing Strategy | Process Integration | Surface Type | Cost | Efficiency | Resolution (µm) | Ink Viscosity (cP) |

|---|---|---|---|---|---|---|

| Piezoelectric inkjet [26,27] | Printing only | Low curvature | Middle | High | >30 | 10–20 |

| Extrusion [36,37] | Printing only | Low curvature | Low | Low | >70 | – |

| Aerosol [28,29] | Printing only | High curvature | High | Middle | 10–200 | 1–2500 |

| EHD (other works) [31,32,33] | Printing only | Middle curvature | Low | Middle | >3 | 1–10,000 |

| Multi-robots EHD (this work) | Whole process | High curvature, large scale | Lowest | High | 5 | 1–10,000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ge, J.; Wu, H.; Wang, H.; Ye, D. Robotized Fabrication Strategy for Large-Scale 3D Conformal Electronics. Materials 2025, 18, 5015. https://doi.org/10.3390/ma18215015

Ge J, Wu H, Wang H, Ye D. Robotized Fabrication Strategy for Large-Scale 3D Conformal Electronics. Materials. 2025; 18(21):5015. https://doi.org/10.3390/ma18215015

Chicago/Turabian StyleGe, Jiaying, Hao Wu, Hongyang Wang, and Dong Ye. 2025. "Robotized Fabrication Strategy for Large-Scale 3D Conformal Electronics" Materials 18, no. 21: 5015. https://doi.org/10.3390/ma18215015

APA StyleGe, J., Wu, H., Wang, H., & Ye, D. (2025). Robotized Fabrication Strategy for Large-Scale 3D Conformal Electronics. Materials, 18(21), 5015. https://doi.org/10.3390/ma18215015