Improving the Wear Resistance of Steel-Cutting Tools for Nuclear Power Facilities by Electrospark Alloying with Hard Transition Metal Borides

Abstract

1. Introduction

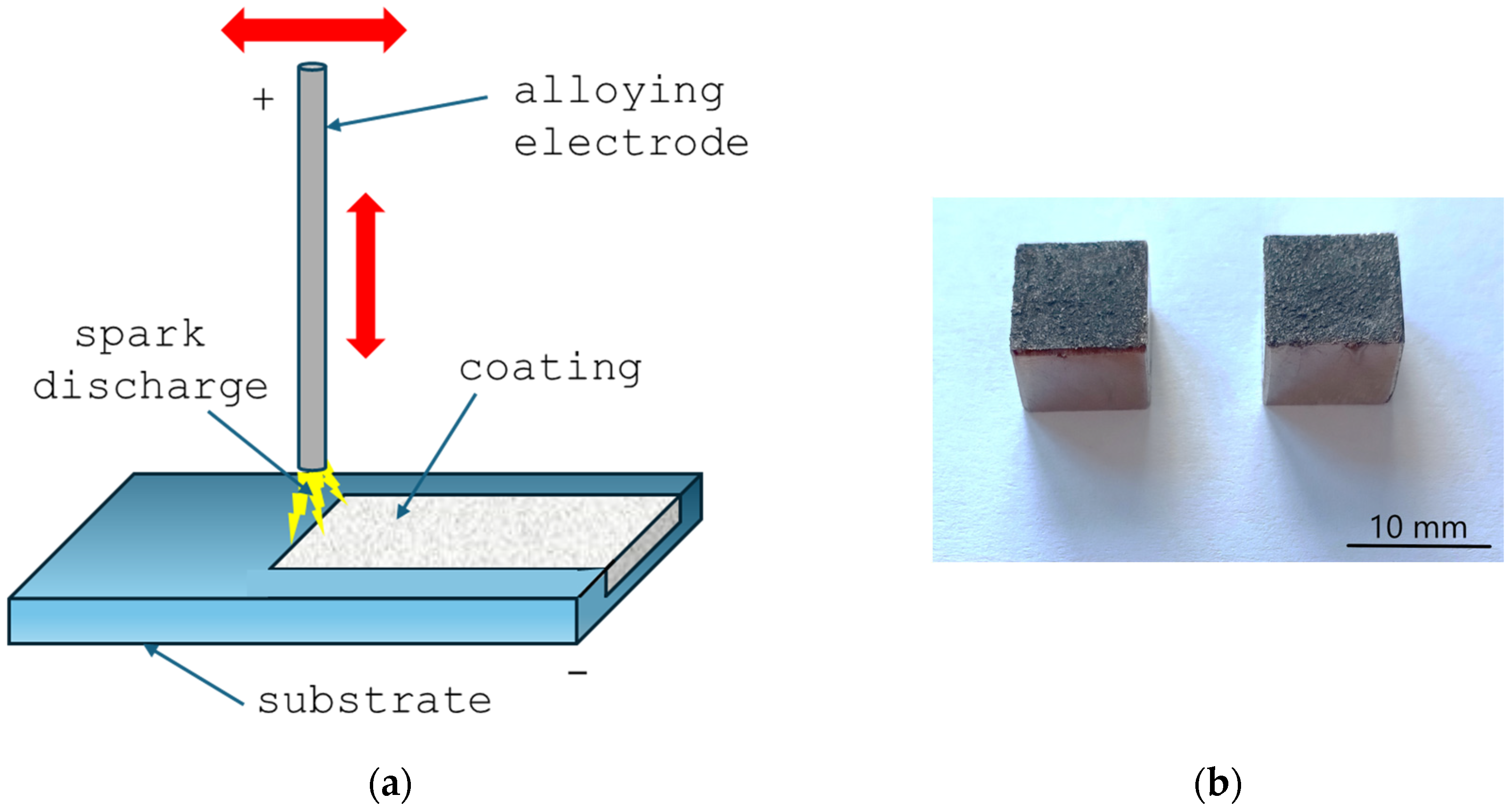

2. Materials and Methods

3. Results and Discussions

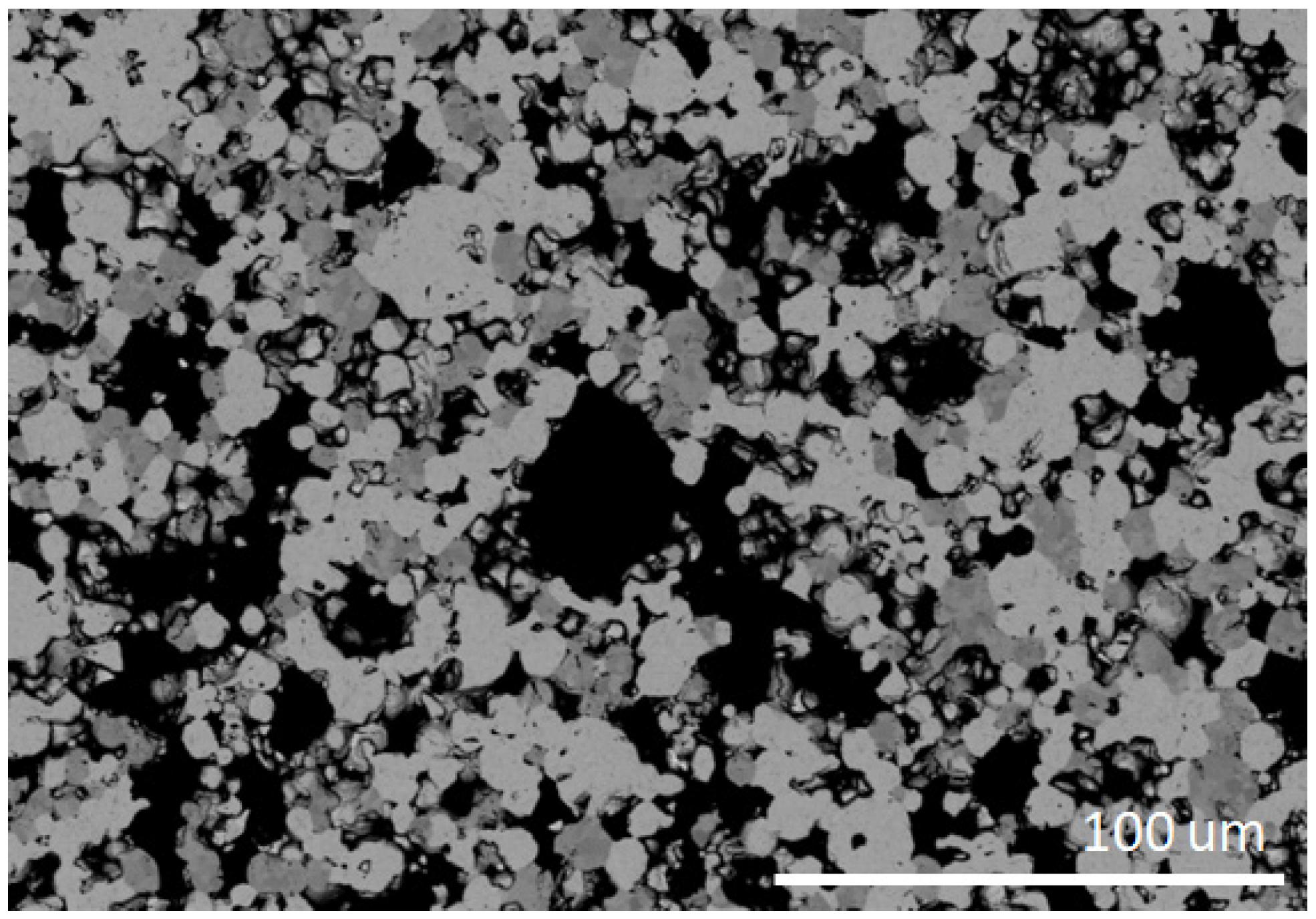

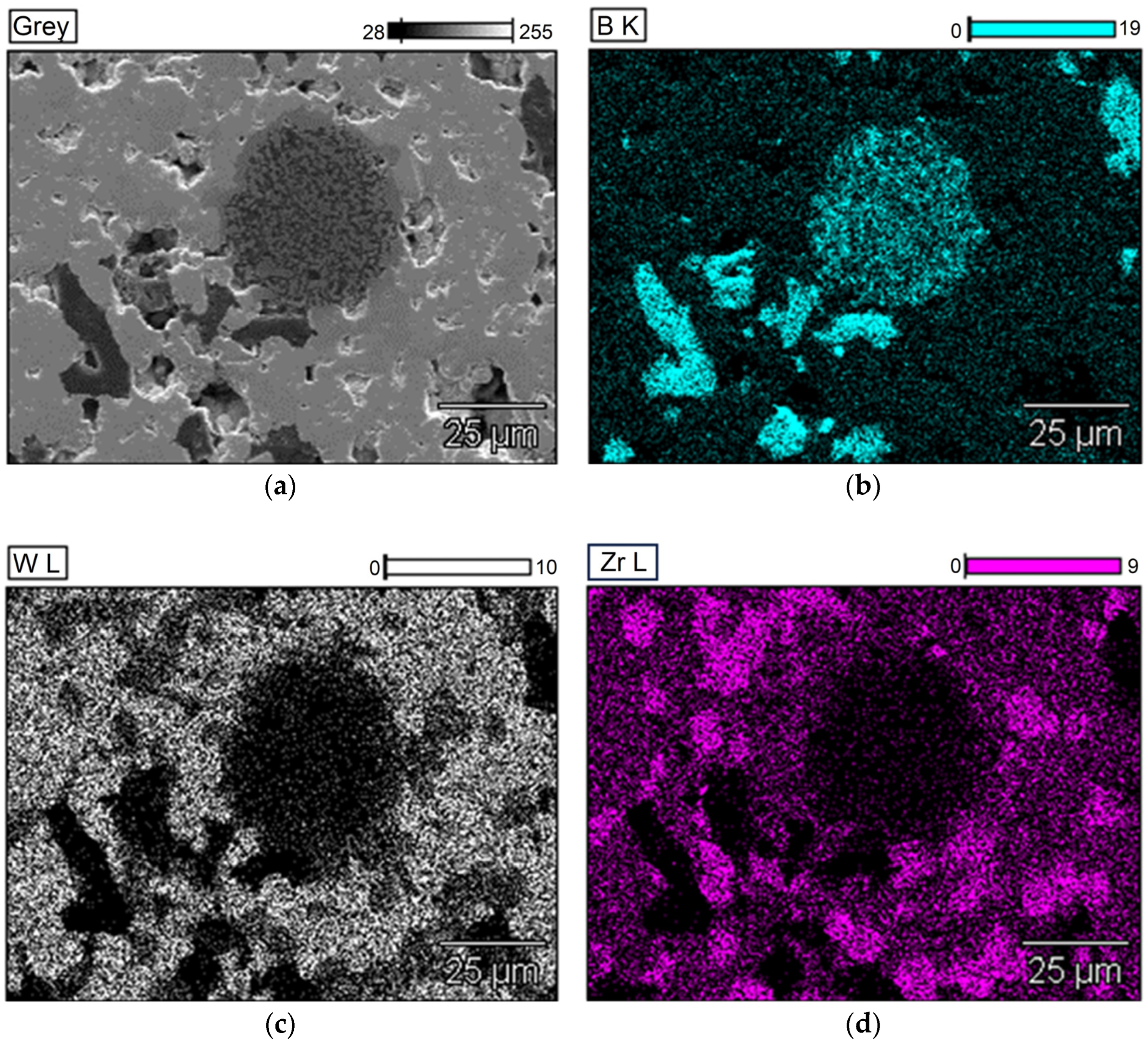

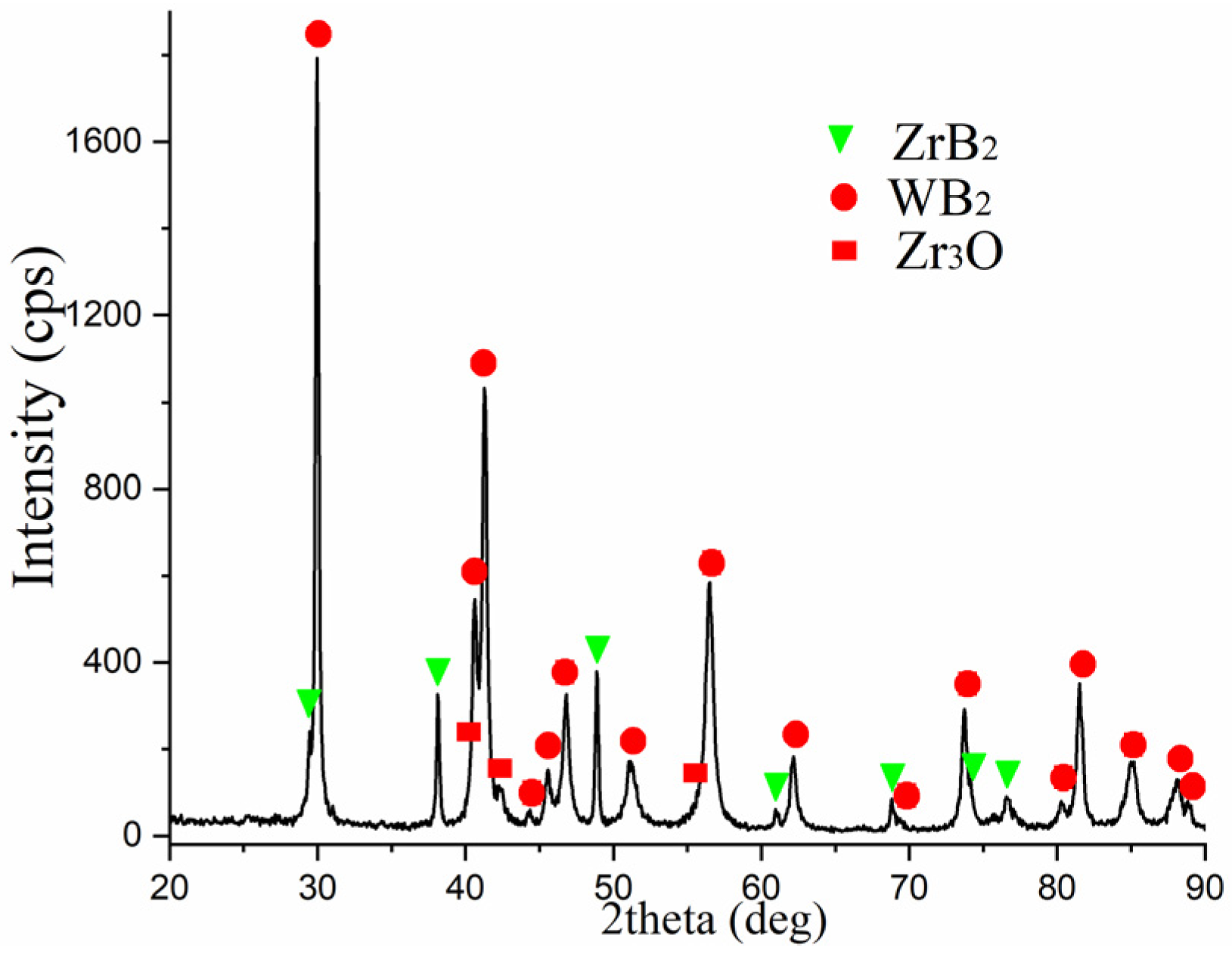

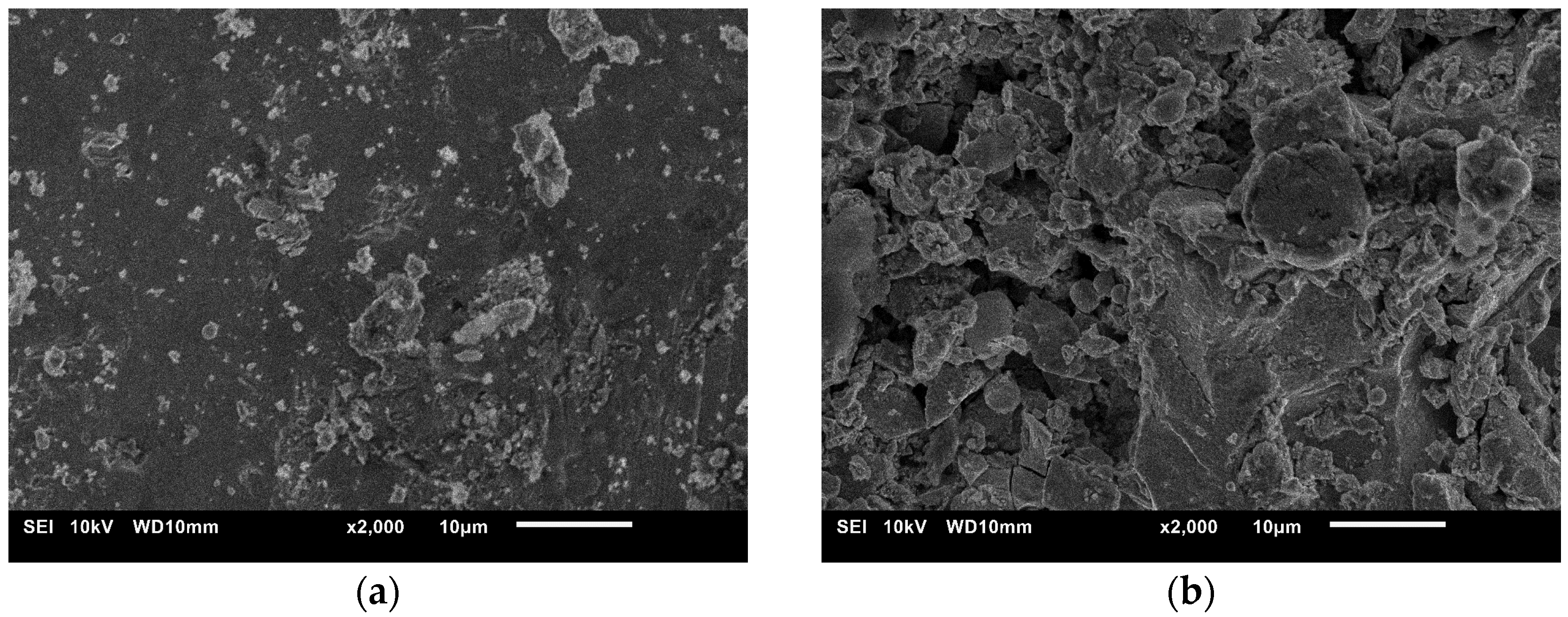

3.1. The Structure and Properties of Electrode Material

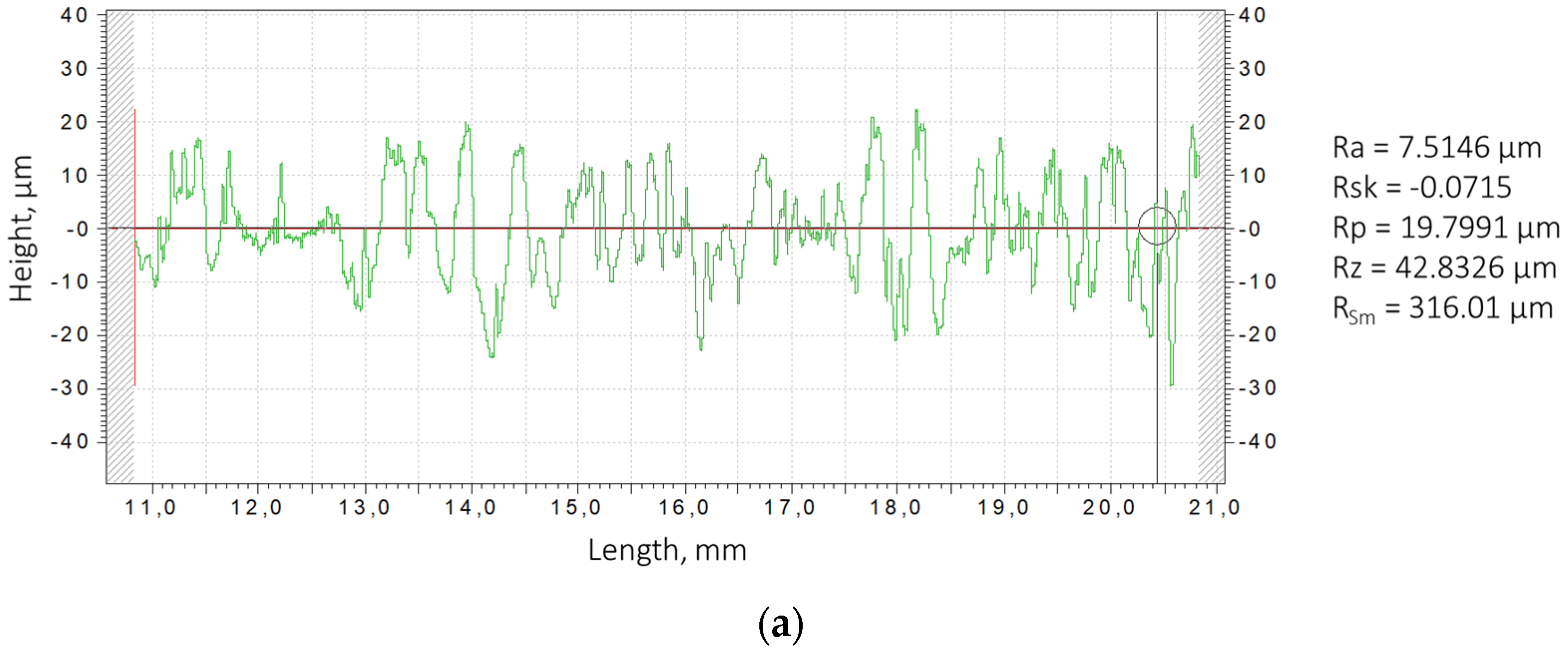

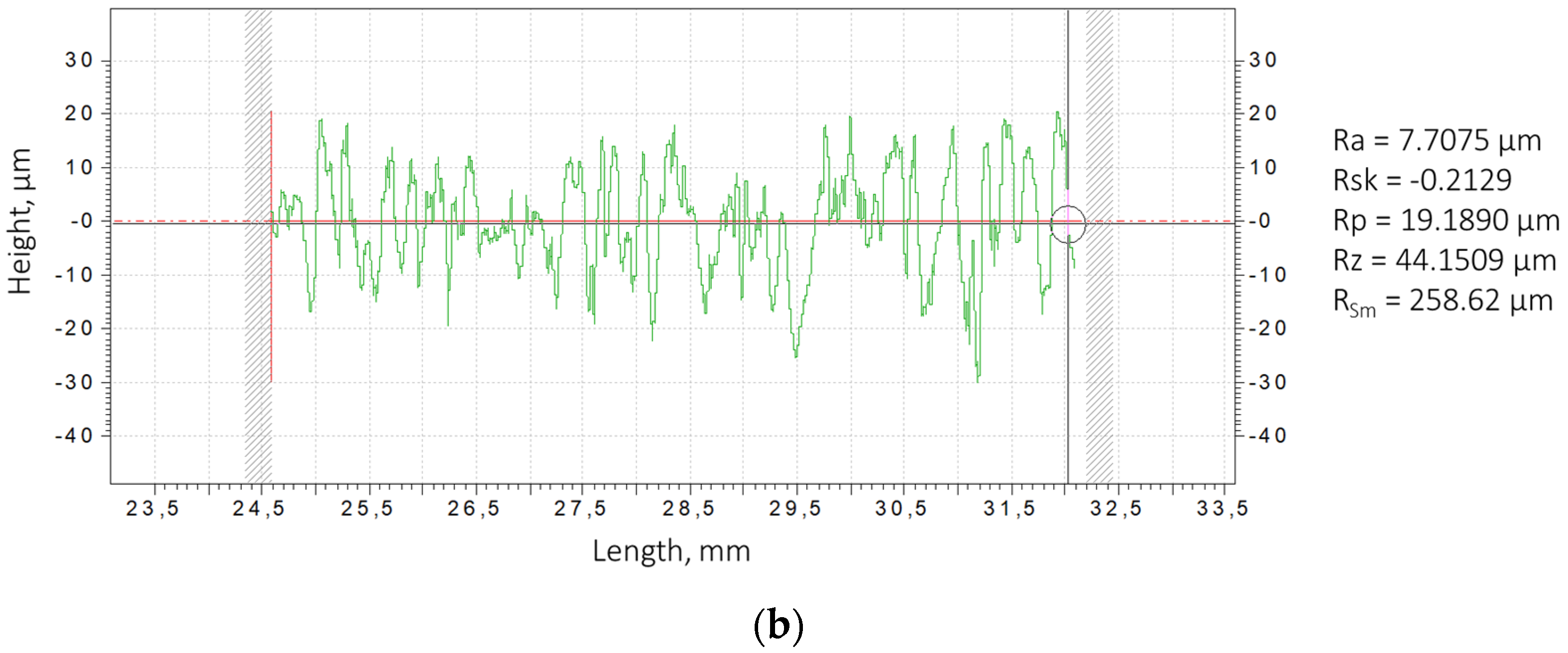

3.2. Study of Surface Topography of Samples After ESA

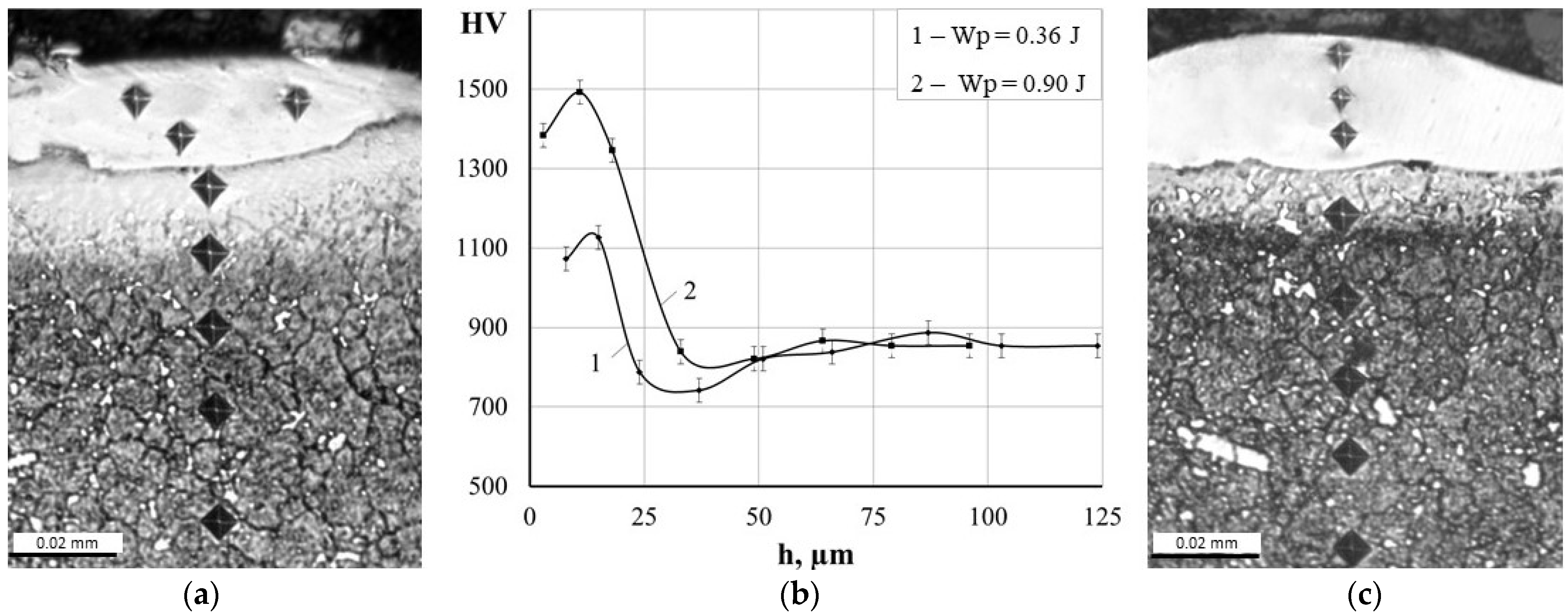

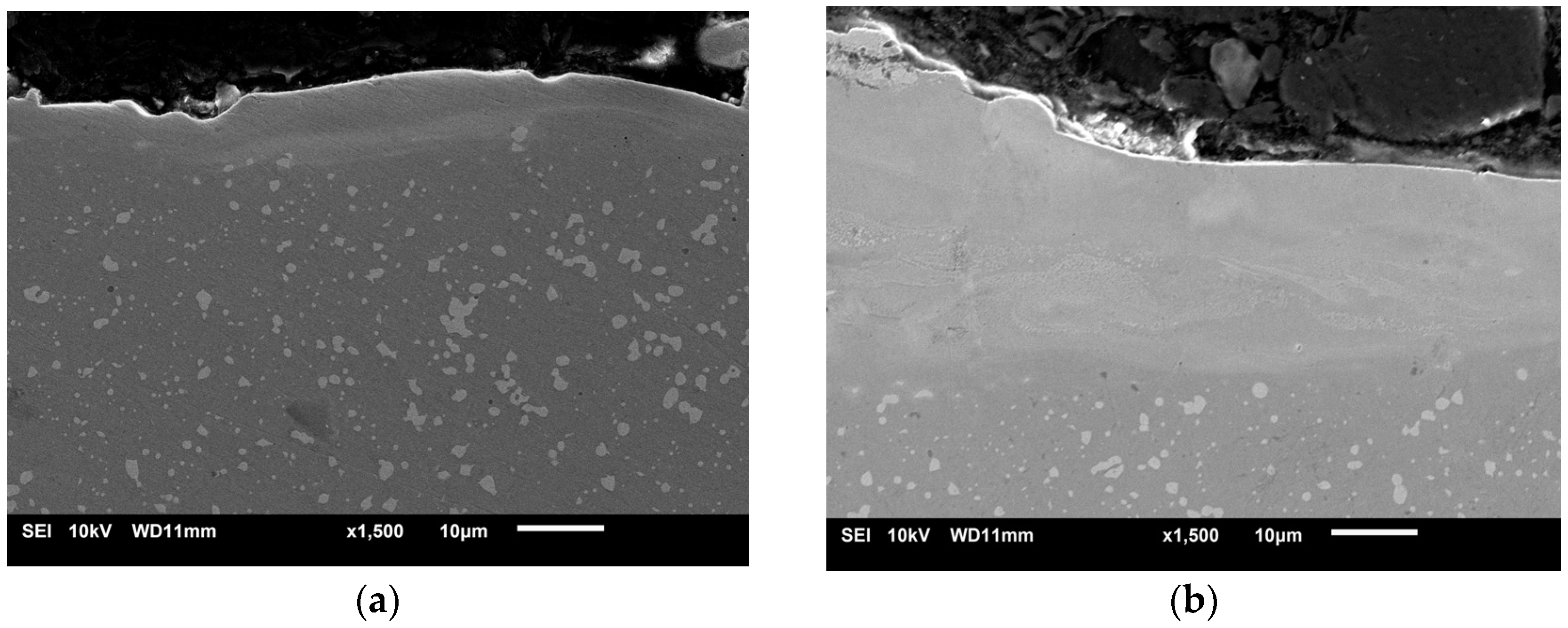

3.3. Microstructural Analysis of ESA Coatings

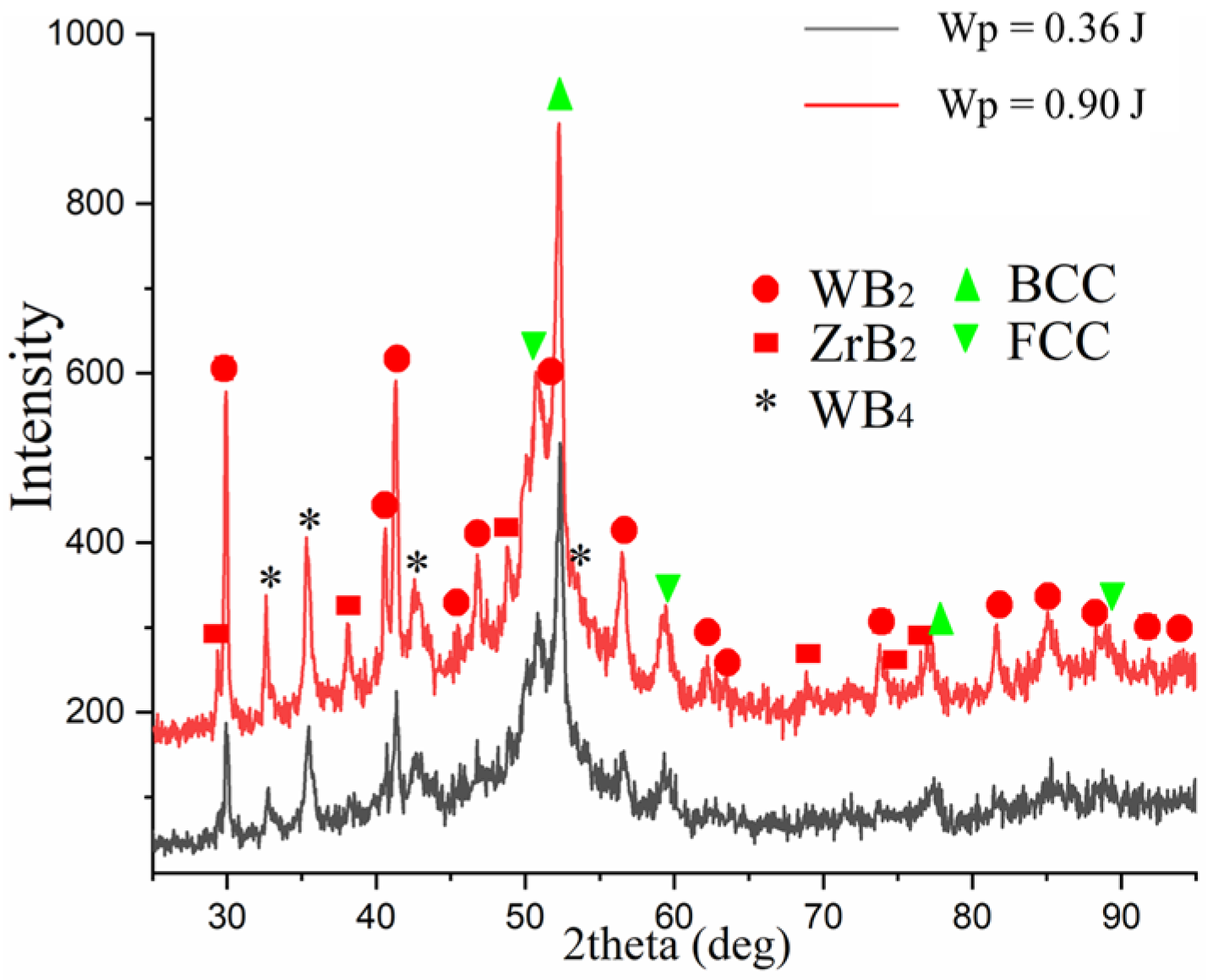

3.4. X-Ray Analysis of ESA Coatings

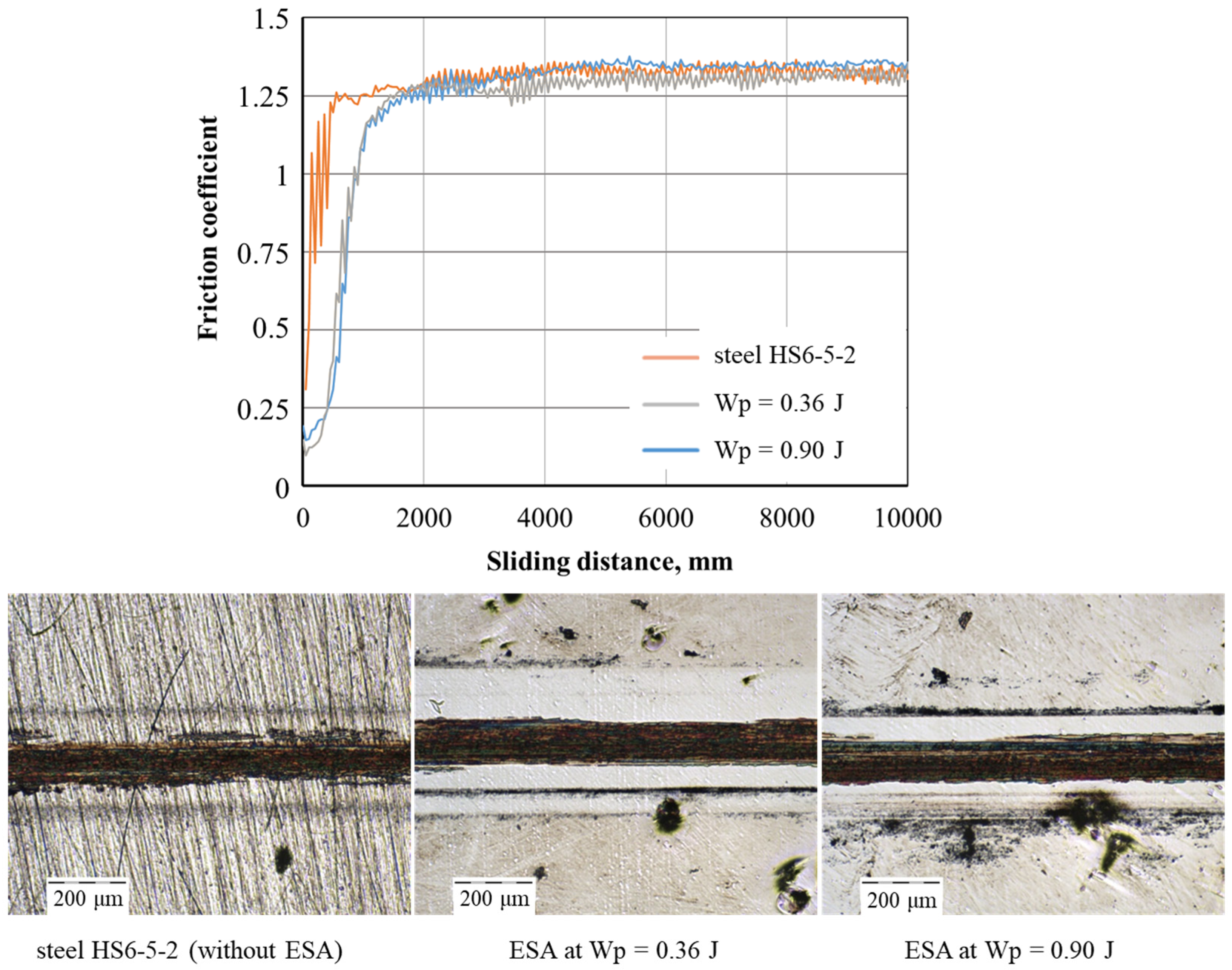

3.5. Wear Resistance of ESA Coatings

4. Conclusions

- This research confirmed that W–Zr–B system materials are promising for use as coatings for cutting tools designed to operate under conditions of increased mechanical, thermal and radiation loads. These coatings hold promise for use in repair and installation operations at nuclear power facilities. Moreover, W-Zr-B ceramics are characterized by good electrical conductivity, which allows for the effective use of electrospark alloying (ESA) for the preparation of coatings.

- The studied electrode materials of the W–Zr–B system, synthesised by the SPS method, are characterised by a heterogeneous microstructure with areas enriched with tungsten, zirconium and excess boron. X-ray analysis confirmed the presence of the main phases WB2 (~72% by mass) and ZrB2 (~23% by mass), as well as a small amount of zirconium oxide (~5% by mass) formed as a result of high-temperature sintering. The samples obtained are characterised by high hardness (26.6 ± 1.8 GPa), density (8.88 g/cm3) and rationally low porosity (<10%). The preservation of mechanical integrity and the absence of brittleness indicate the high structural stability of the material and confirm its practical application as electrodes for ESA.

- Coatings on HS6-5-2 tool steel obtained by ESA under different processing conditions were studied. Surface topography analysis showed that increased discharge energy forms a more developed micro-relief with craters and micro-protrusions. Despite similar Ra values (~7.5–7.7 μm), the nature of irregularities varies, reflecting the ESA coating formation mechanism and indicating opportunities for further optimization using hybrid techniques.

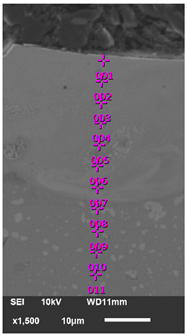

- Metallographic analysis revealed the formation of a hardened surface layer (“white layer”) with a thickness of 10–30 μm and microhardness of 1125.9–1492.1 HV. A diffusion zone beneath the layer shows a gradient decrease in microhardness to the substrate, indicating strong metallurgical bonding without cracks or delamination. Elemental analysis confirmed that the coating is enriched with the main components of the alloying electrode material: tungsten, zirconium and boron. These elements decrease in concentration with depth, forming a diffusion-strengthened transition layer.

- Coatings after ESA have a more complex phase composition compared to the electrode. In addition to ZrB2 and WB2, WB4 phases and BCC/FCC solid solutions form due to diffusion and intensive mixing during ESA. Higher discharge energy leads to multiphase layers with high-boron compounds, reflecting intensified diffusion and chemical activity.

- ESA coatings demonstrated superior wear resistance compared to the uncoated HS6-5-2 steel substrate. The test results showed a significant reduction in wear depth for the ESA-treated samples, with average values of 0.88 ± 0.33 μm (Wp = 0.36 J) and 0.69 ± 0.03 μm (Wp = 0.90 J), compared to 1.52 ± 0.12 μm for the uncoated steel, while the friction coefficient remained approximately 1.2.

- The results demonstrate ESA is a simple, portable, and energy-efficient method for local strengthening of cutting tools, producing coatings with high adhesion, increased hardness, and overall high quality.

- Further development of this work should be directed towards optimising hybrid technologies based on ESA (surface plastic deformation, laser treatment, magnetron sputtering), which will reduce roughness, increase the uniformity of the coating structure and improve their performance characteristics.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Eickelpasch, N.; Kalwa, H.; Steiner, H.; Priesmeyer, U. The application of mechanical and thermal cutting tools for the dismantling of activated internals of the reactor pressure vessels in the Versuchsatomkraftwerk, Kahl and the Gundremmingen Unit A. Nucl. Eng. Des. 1997, 170, 173–180. [Google Scholar] [CrossRef]

- Lee, G.-R.; Lim, B.-J.; Cho, D.-W.; Park, C.-D. Selection methodology of the optimal cutting technology for dismantling of components in nuclear power plants. Ann. Nucl. Energy 2022, 166, 108808. [Google Scholar] [CrossRef]

- Matteucci, P.; Cepolina, F. A robotic cutting tool for contaminated structure maintenance and decommissioning. Autom. Constr. 2015, 58, 109–117. [Google Scholar] [CrossRef]

- Rizzo, A.; Goel, S.; Grilli, M.L.; Iglesias, R.; Jaworska, L.; Lapkovskis, V.; Novak, P.; Postolnyi, B.O.; Valerini, D. The Critical Raw Materials in Cutting Tools for Machining Applications: A Review. Materials 2020, 13, 1377. [Google Scholar] [CrossRef]

- Pogrebnjak, O.D.; Dyadyura, K.O.; Gaponova, O.P. Features of Thermodynamic Processes on Contact Surfaces of Multicomponent Nanocomposite Coatings with Hierarchical and Adaptive Behaviour. Metallofiz. Noveishie Tekhnol. 2015, 37, 899–919. [Google Scholar] [CrossRef]

- Kang, K.; Su, S.; Yu, B.; Sun, Z.; Hu, S.; Wang, Z.; Zhao, C.; Wu, L.; Luo, G.; Wei, R. The review and prospect of tool coating technology. Int. J. Adv. Manuf. Technol. 2025, 137, 3107–3139. [Google Scholar] [CrossRef]

- Wang, X.-X.; Wang, Y.-H.; Ling, Z.-C.; Yuan, Z.-P.; Shi, J.-J.; Qin, J.; Sun, H.-W.; Pan, K.-M.; Geng, Z.-M.; Ma, H.-L.; et al. Strategies for superhard tool coating materials: Focus on preparation methods and properties. J. Iron Steel Res. Int. 2025, 32, 2232–2266. [Google Scholar] [CrossRef]

- Berladir, K.; Hovorun, T.; Botko, F.; Radchenko, S.; Oleshko, O. Thin Modified Nitrided Layers of High-Speed Steels. Materials 2025, 18, 2434. [Google Scholar] [CrossRef]

- Alves, U.C.; Ricci, V.P.; Mota, I.G.C.; Koga, G.Y.; Hassui, A.; Ventura, C.E.H. Mechanical and tribological characterization of TiAlN/TiN and TiSiN/AlTiN coating systems for cutting tools. J. Manuf. Process. 2025, 145, 522–535. [Google Scholar] [CrossRef]

- Drnovšek, A.; Rebelo de Figueiredo, M.; Vo, H.; Xia, A.; Vachhani, S.J.; Kolozsvári, S.; Hosemann, P.; Franz, R. Correlating high temperature mechanical and tribological properties of CrAlN and CrAlSiN hard coatings. Surf. Coat. Technol. 2019, 372, 361–368. [Google Scholar] [CrossRef]

- Twardowska, A.; Ślusarczyk, Ł.; Kowalski, M. Impact of Deposition of the (TiBx/TiSiyCz) x3 Multilayer on M2 HSS on the Cutting Force Components and Temperature Generated in the Machined Area during the Milling of 316L Steel. Materials 2022, 15, 746. [Google Scholar] [CrossRef]

- Nunthavarawong, P.; Rangappa, S.M.; Siengchin, S.; Dohda, K. (Eds.) Diamond-Like Carbon Coatings: Technologies and Applications, 1st ed.; CRC Press: Boca Raton, FL, USA, 2022. [Google Scholar] [CrossRef]

- Liu, X.-L.; Lin, Z.; Zhao, H.-J.; Sun, F. Study on Microstructure, Mechanical Properties, Tribological Properties and Service Performance of CrAlN and CrAlBN Coatings Deposited on Powder Metallurgy High-Speed Steel (PM-HSS) and Shaper Cutter by Arc Ion Plating Technique. Coatings 2024, 14, 486. [Google Scholar] [CrossRef]

- Tarelnyk, V.B.; Gaponova, O.P.; Konoplianchenko, I.V.; Tarelnyk, N.V.; Mikulina, M.A.; Gerasimenko, V.A.; Vasylenko, O.O.; Zubko, V.M.; Melnyk, V.I. Properties of Surfaces Parts from X10CrNiTi18-10 Steel Operating in Conditions of Radiation Exposure Retailored by Electrospark Alloying. Pt. 3. X-ray Spectral Analysis of Retailored Coatings. Metallofiz. Noveishie Tekhnol. 2022, 44, 1323–1333. [Google Scholar] [CrossRef]

- Chen, L.; Lan, Y.; Cheng, Y.; Zeng, J.; Ma, Y.; Yu, S.; Ding, Z.; Liu, B.; Zhang, J.; Peng, H.; et al. Friction behavior and wear mechanism of laser cladded FeNiCr-WC composite coatings in comparison with different friction pairs. J. Mater. Res. Technol. 2024, 31, 1956–1973. [Google Scholar] [CrossRef]

- Xian, G.; Xiong, J.; Fan, H.; Jiang, F.; Guo, Z.; Zhao, H.; Xian, L.; Jing, Z.; Liao, J.; Liu, Y. Investigations on microstructure, mechanical and tribological properties of TiN coatings deposited on three different tool materials. Int. J. Refract. Met. Hard Mater. 2022, 102, 105700. [Google Scholar] [CrossRef]

- Wada, T.; Hanyu, H. Tool wear of (Ti, Al) N-coated polycrystalline cubic boron nitride compact in cutting of hardened steel. IOP Conf. Ser. Mater. Sci. Eng. 2017, 264, 012017. [Google Scholar] [CrossRef]

- Sousa, V.F.C.; Silva, F.J.G. Recent Advances in Turning Processes Using Coated Tools-A Comprehensive Review. Metals 2020, 10, 170. [Google Scholar] [CrossRef]

- Tan, D.-W.; Zhu, L.-L.; Wei, W.-X.; Yu, J.-J.; Zhou, Y.-Z.; Guo, W.-M.; Lin, H.-T. Performance improvement of Si3N4 ceramic cutting tools by tailoring of phase composition and microstructure. Ceram. Int. 2020, 46, 26182–26189. [Google Scholar] [CrossRef]

- Kumar, B.P.; Rao, P.S.; Ravi Kiran, D.S.S.; Venkatesh, D.J.; Rao, C.V. Parametric optimization of Al2O3-ZrO2 (Y2O3) based self-lubricating composite cutting tool materials for turning operations using TOPSIS method. Int. J. Interact. Des. Manuf. 2025, 19, 2727–2749. [Google Scholar] [CrossRef]

- Manokhin, A.; Klymenko, S.; Beresnev, V.; Zakiev, V.; Klymenko, S. To the Question of the Mechanism of the Effect of Coating on the Durability of Tools from PCBN. In Advanced Manufacturing Processes. InterPartner 2019; Tonkonogyi, V., Ivanov, V., Trojanowska, J., Oborskyi, G., Edl, M., Kuric, I., Pavlenko, I., Dasic, P., Eds.; Springer: Cham, Switzerland, 2020; pp. 206–215. [Google Scholar] [CrossRef]

- AbuAlRoos, N.J.; Azman, M.N.; Baharul Amin, N.A.; Zainon, R. Tungsten-based material as promising new lead-free gamma radiation shielding material in nuclear medicine. Phys. Medica 2020, 78, 48–57. [Google Scholar] [CrossRef]

- Windsor, C.G.; Astbury, J.O.; Davidson, J.J.; McFadzean, C.J.R.; Morgan, J.G.; Wilson, C.L.; Humphry-Baker, S.A. Tungsten boride shields in a spherical tokamak fusion power plant. Nucl. Fusion 2021, 61, 086018. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, X.; Lai, C.; Ma, J.; Meng, X.; Zhang, L.; Xu, G.; Lu, Y.; Li, H.; Wang, J.; et al. Boriding of tungsten by the powder-pack process: Phase formation, growth kinetics and enhanced neutron shielding. Int. J. Refract. Met. Hard Mater. 2023, 110, 106049. [Google Scholar] [CrossRef]

- McAlister, D. Neutron Shielding Materials; PG Research Foundation: Naperville, IL, USA, 2016. [Google Scholar]

- Windsor, C.G.; Astbury, J.O.; Morgan, J.G.; Wilson, C.L.; Humphry-Baker, S.A. Activation and transmutation of tungsten boride shields in a spherical tokamak. Nucl. Fusion 2022, 62, 036009. [Google Scholar] [CrossRef]

- Lin, Y.; McFadzean, C.; Humphry-Baker, S.A. Oxidation resistance of WB and W2B-W neutron shields. J. Nucl. Mater. 2022, 565, 153762. [Google Scholar] [CrossRef]

- Pangilinan, L.E.; Turner, C.L.; Akopov, G.; Anderson, M.; Mohammadi, R.; Kaner, R.B. Superhard Tungsten Diboride-Based Solid Solutions. Inorg. Chem. 2018, 57, 15305–15313. [Google Scholar] [CrossRef]

- Akopov, G.; Yeung, M.T.; Turner, C.L.; Mohammadi, R.; Kaner, R.B. Extrinsic hardening of superhard tungsten tetraboride alloys with group 4 transition metals. J. Am. Chem. Soc. 2016, 138, 5714–5721. [Google Scholar] [CrossRef]

- Mościcki, T.; Chrzanowska-Giżyńska, J.; Psiuk, R.; Denis, P.; Mulewska, K.; Kurpaska, Ł.; Chmielewski, M.; Wiśniewska, M.; Garbiec, D. Thermal and mechanical properties of (W,Zr)B2−z coatings deposited by RF magnetron sputtering method. Int. J. Refract. Met. Hard Mater. 2022, 105, 105811. [Google Scholar] [CrossRef]

- Mościcki, T.; Psiuk, R.; Radziejewska, J.; Wiśniewska, M.; Garbiec, D. Properties of spark plasma sintered compacts and magnetron sputtered coatings made from Cr, Mo, Re and Zr alloyed tungsten diboride. Coatings 2021, 11, 1378. [Google Scholar] [CrossRef]

- Khor, K.; Yu, L.; Sundararajan, G. Formation of hard tungsten boride layer by spark plasma sintering boriding. Thin Solid Films 2005, 478, 232–237. [Google Scholar] [CrossRef]

- Maździarz, M.; Psiuk, R.; Krawczyńska, A.; Lewandowska, M.; Mościcki, T. Effect of zirconium doping on the mechanical properties of W1−xZrxB2 on the basis of first-principles calculations and magnetron sputtered films. Arch. Civ. Mech. Eng. 2022, 22, 193. [Google Scholar] [CrossRef]

- Psiuk, R.; Milczarek, M.; Jenczyk, P.; Denis, P.; Jarząbek, D.M.; Bazarnik, P.; Pisarek, M.; Mościcki, T. Improved mechanical properties of W-Zr-B coatings deposited by hybrid RF magnetron–PLD method. Appl. Surf. Sci. 2021, 570, 151239. [Google Scholar] [CrossRef]

- Rzempołuch, J.; Stasiak, T.; Maździarz, M.; Jasiński, J.; Woy, U.; Psiuk, R.; Kowal, M.; Kosińska, A.; Wilczopolska, M.; Mulewska, K.; et al. Characterization of He⁺ implanted W-Zr-B thin films deposited by HiPIMS on additively manufactured Inconel 617 as a candidate system for nuclear components. J. Nucl. Mater. 2025, 616, 156091. [Google Scholar] [CrossRef]

- Storozhenko, M.S.; Umanskyi, O.P.; Tarelnyk, V.B.; Koval, O.Y.; Gubin, Y.V.; Mikulina, M.O.; Martsenyuk, I.S.; Kostenko, O.D.; Kurinna, T.V. Structure and Wear Resistance of FeNiCrBSiC–MeB2 Electrospark Coatings. Powder Metall. Met. Ceram. 2020, 59, 330–341. [Google Scholar] [CrossRef]

- Benkovsky, I.; Tsyntsaru, N.; Silkin, S.; Petrenko, V.; Pakstas, V.; Cesiulis, H.; Dikusar, A. Synthesis, Wear and Corrosion of Novel Electrospark and Electrospark–Electrochemical Hybrid Coatings Based on Carbon Steels. Lubricants 2023, 11, 205. [Google Scholar] [CrossRef]

- Gaponova, O.P.; Tarelnyk, V.B.; Tarelnyk, N.V.; Myslyvchenko, O.M. Nanostructuring of Metallic Surfaces by Electrospark Alloying Method. JOM 2023, 75, 3400–3412. [Google Scholar] [CrossRef]

- Tarelnyk, V.B.; Gaponova, O.P.; Konoplianchenko, Y.V.; Martsynkovskyy, V.S.; Tarelnyk, N.V.; Vasylenko, O.O. Improvement of Quality of the Surface Electroerosive Alloyed Layers by the Combined Coatings and the Surface Plastic Deformation. III. The Influence of the Main Technological Parameters on Microgeometry, Structure and Properties of Electrolytic Erosion Coatings. Metallofiz. Noveishie Tekhnol. 2019, 41, 313–335. [Google Scholar] [CrossRef]

- Garbiec, D.; Wiśniewska, M.; Psiuk, R.; Denis, P.; Levintant-Zayonts, N.; Leshchynsky, V.; Rubach, R.; Mościcki, T. Zirconium alloyed tungsten borides synthesized by spark plasma sintering. Arch. Civ. Mech. Eng. 2021, 21, 37. [Google Scholar] [CrossRef]

- Vander Voort, G.F. Metallography and Microstructures; ASM International: Materials Park, OH, USA, 2004; ISBN 978-0-87170-706-2. [Google Scholar]

- Gaponova, O.P.; Tarelnyk, V.B.; Martsynkovskyy, V.S.; Konoplianchenko, I.V.; Melnyk, V.I.; Vlasovets, V.M.; Sarzhanov, O.A.; Tarelnyk, N.V.; Mikulina, M.O.; Polyvanyi, A.D.; et al. Combined Electrospark Running-in Coatings of Bronze Parts. Part 1. Structure and Mechanical Properties. Metallofiz. Noveishie Tekhnol. 2021, 43, 1121–1138. [Google Scholar] [CrossRef]

- Haponova, O.; Tarelnyk, V.; Mościcki, T.; Tarelnyk, N. Hybrid Surface Treatment Technologies Based on the Electrospark Alloying Method: A Review. Coatings 2025, 15, 721. [Google Scholar] [CrossRef]

- Kumar, A.; Batham, H.; Das, A.K. Microhardness of Fe-TiB2 composite coating on AISI 304 stainless steel by TIG coating technique. Mater. Today Proc. 2021, 39, 1291–1295. [Google Scholar] [CrossRef]

- Zhao, S.; Xu, S.; Yang, L.; Huang, Y. WC-Fe metal-matrix composite coatings fabricated by laser wire cladding. J. Mater. Process. Tech. 2022, 301, 117438. [Google Scholar]

- Penyashki, T.; Kostadinov, G.; Kandeva, M. Improvement of Surface Properties of Carbon Steel Through Electrospark Coatings from Multicomponent Hard Alloys. Materials 2025, 18, 2211. [Google Scholar] [CrossRef] [PubMed]

- Tarelnyk, V.; Konoplianchenko, I.; Gaponova, O.; Tarelnyk, N.; Martsynkovskyy, V.; Sarzhanov, B.; Sarzhanov, O.; Antoszewski, B. Effect of Laser Processing on the Qualitative Parameters of Protective Abrasion-Resistant Coatings. Powder Metall. Met. Ceram. 2020, 58, 703–713. [Google Scholar] [CrossRef]

- Ciski, A. Deep Cryogenic Treatment and Tempering at Different Temperatures of HS6-5-2 High Speed Steel. Arch. Metall. Mater. 2018, 63, 929–934. [Google Scholar] [CrossRef] [PubMed]

| C | Si | Mn | P | S | Cr | Mo | W | V |

|---|---|---|---|---|---|---|---|---|

| 0.8–0.88 | max 0.45 | max 0.4 | max 0.03 | max 0.03 | 3.8–4.5 | 4.7–5.2 | 5.9–6.7 | 1.7–2.1 |

| Type of Generator | Capacitance, C, µF | Voltage, U, V | Frequency, Hz | Pulse Duration, s | Discharge Energy, Wp, J | Productivity, cm2/min |

|---|---|---|---|---|---|---|

| Transistor–thyristor (TT) | 120 | 100 | 100 | 10−7–10−8 | 0.36 | 1.0–1.3 |

| 300 | 0.90 |

| WB2 | ZrB2 | Zr3O |

|---|---|---|

| 72 | 23 | 5 |

| Discharge Energy, J | Roughness, µm | Strengthened Layer | Continuity, % | ||

|---|---|---|---|---|---|

| Ra | Rz | HV | h, µm | ||

| 0.36 | 7.5146 | 42.8326 | 1125.9 | 10–20 | 75 |

| 0.90 | 7.7075 | 44.1509 | 1492.1 | 15–30 | 90 |

| Point | Elements Mass % | |||||||||

| B | C | Cr | Zr | W | Mo | V | Ni | Fe | Total | ||

| 1 | 5.78 | 1.42 | 1.06 | 11.69 | 57.46 | 1.07 | 0.09 | 0.16 | 21.27 | 100 | |

| 2 | 3.79 | 1.23 | 2.2 | 9.39 | 46.28 | 1.23 | 0.11 | 0.12 | 35.65 | 100 | |

| 3 | 4.38 | 1.35 | 2.51 | 6.58 | 31.85 | 2.05 | 0.06 | 0.21 | 51.01 | 100 | |

| 4 | 3.04 | 1.53 | 4.11 | 5.03 | 24.08 | 3.45 | 0.58 | 0.19 | 57.99 | 100 | |

| 5 | 4.37 | 1.24 | 3.15 | 4.67 | 43.26 | 2.32 | 0.65 | 0.15 | 40.19 | 100 | |

| 6 | 3.96 | 1.25 | 2.65 | 3.78 | 26.39 | 2.65 | 0.89 | 0.15 | 58.28 | 100 | |

| 7 | 2.18 | 1.29 | 2.77 | 1.76 | 23.27 | 3.74 | 0.76 | 0.27 | 63.96 | 100 | |

| 8 | 2.13 | 1.02 | 3.72 | 1.22 | 25.3 | 2.73 | 1.02 | 0.29 | 62.57 | 100 | |

| 9 | 1.78 | 0.9 | 3.58 | 0.24 | 13.24 | 3.56 | 1.14 | 0.6 | 74.96 | 100 | |

| 10 | 1.53 | 0.88 | 3.17 | 0.27 | 7.17 | 3.87 | 1.86 | 0.49 | 80.76 | 100 | |

| 11 | 0.55 | 0.97 | 3.13 | 0.21 | 5.12 | 4.72 | 1.72 | 0.68 | 82.9 | 100 | |

| Samples | Roughness, µm | |

|---|---|---|

| Ra | Rz | |

| HS6-5-2 steel without ESA | 1.19 | 8.00 |

| ESA at Wp = 0.36 J | 0.46 | 4.18 |

| ESA at Wp = 0.90 J | 0.49 | 3.61 |

| Samples | Average Wear Depth, μm |

|---|---|

| HS6-5-2 steel without ESA | 1.52 ± 0.12 |

| ESA at Wp = 0.36 J | 0.88 ± 0.33 |

| ESA at Wp = 0.90 J | 0.69 ± 0.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haponova, O.; Tarelnyk, V.; Mościcki, T.; Zielińska, K.; Myslyvchenko, O.; Bochenek, K.; Garbiec, D.; Laponog, G.; Jasinski, J.J. Improving the Wear Resistance of Steel-Cutting Tools for Nuclear Power Facilities by Electrospark Alloying with Hard Transition Metal Borides. Materials 2025, 18, 5005. https://doi.org/10.3390/ma18215005

Haponova O, Tarelnyk V, Mościcki T, Zielińska K, Myslyvchenko O, Bochenek K, Garbiec D, Laponog G, Jasinski JJ. Improving the Wear Resistance of Steel-Cutting Tools for Nuclear Power Facilities by Electrospark Alloying with Hard Transition Metal Borides. Materials. 2025; 18(21):5005. https://doi.org/10.3390/ma18215005

Chicago/Turabian StyleHaponova, Oksana, Viacheslav Tarelnyk, Tomasz Mościcki, Katarzyna Zielińska, Oleksandr Myslyvchenko, Kamil Bochenek, Dariusz Garbiec, Gennadii Laponog, and Jaroslaw Jan Jasinski. 2025. "Improving the Wear Resistance of Steel-Cutting Tools for Nuclear Power Facilities by Electrospark Alloying with Hard Transition Metal Borides" Materials 18, no. 21: 5005. https://doi.org/10.3390/ma18215005

APA StyleHaponova, O., Tarelnyk, V., Mościcki, T., Zielińska, K., Myslyvchenko, O., Bochenek, K., Garbiec, D., Laponog, G., & Jasinski, J. J. (2025). Improving the Wear Resistance of Steel-Cutting Tools for Nuclear Power Facilities by Electrospark Alloying with Hard Transition Metal Borides. Materials, 18(21), 5005. https://doi.org/10.3390/ma18215005