Investigation on the Microstructure and Mechanical Properties of X70 Pipeline Steel Fabricated by Laser-Directed Energy Deposition

Abstract

1. Introduction

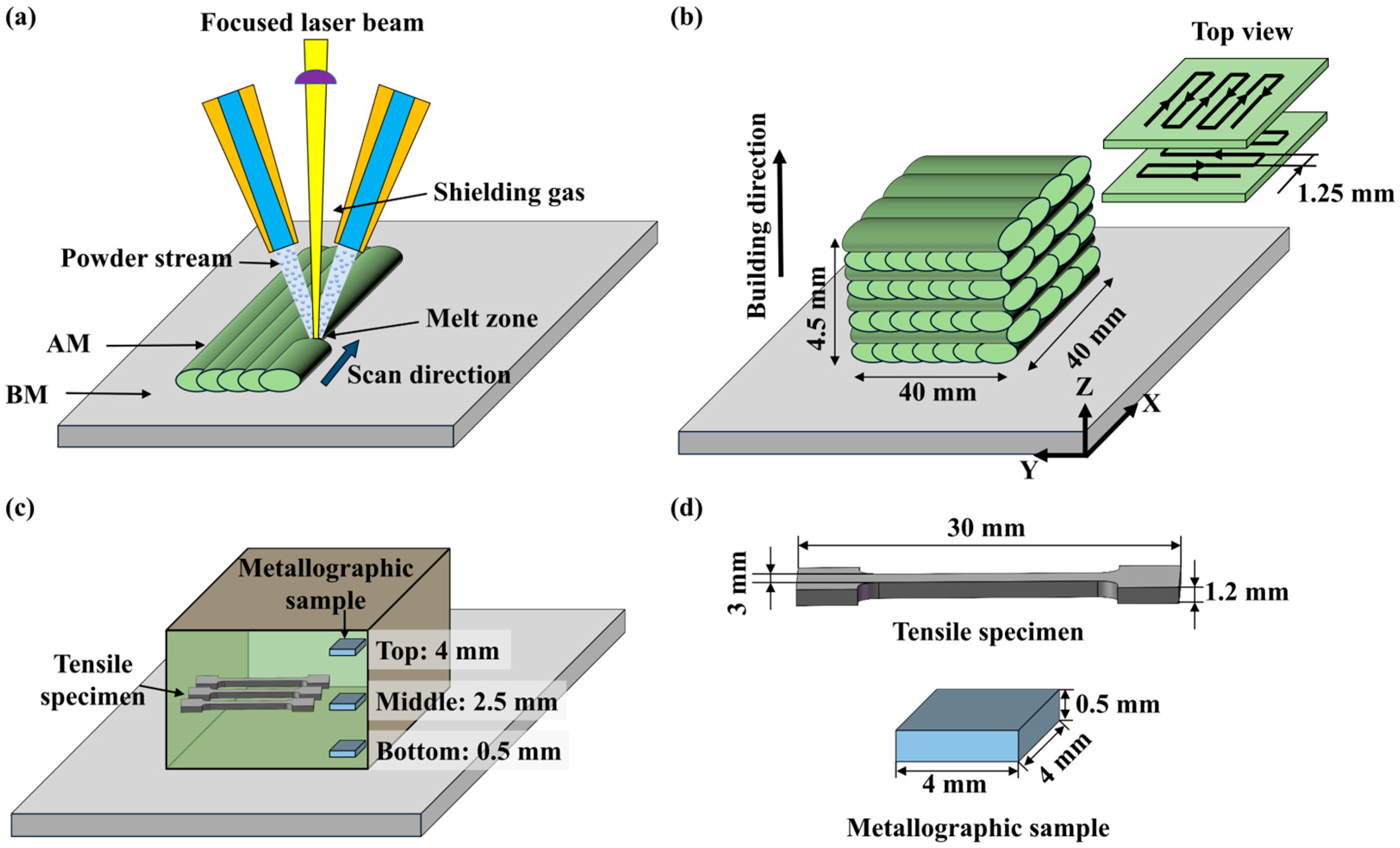

2. Experimental Procedure

2.1. Materials

2.2. L-DED Process

2.3. Microstructure Characterization

2.4. Microhardness and Tensile Testing

3. Results

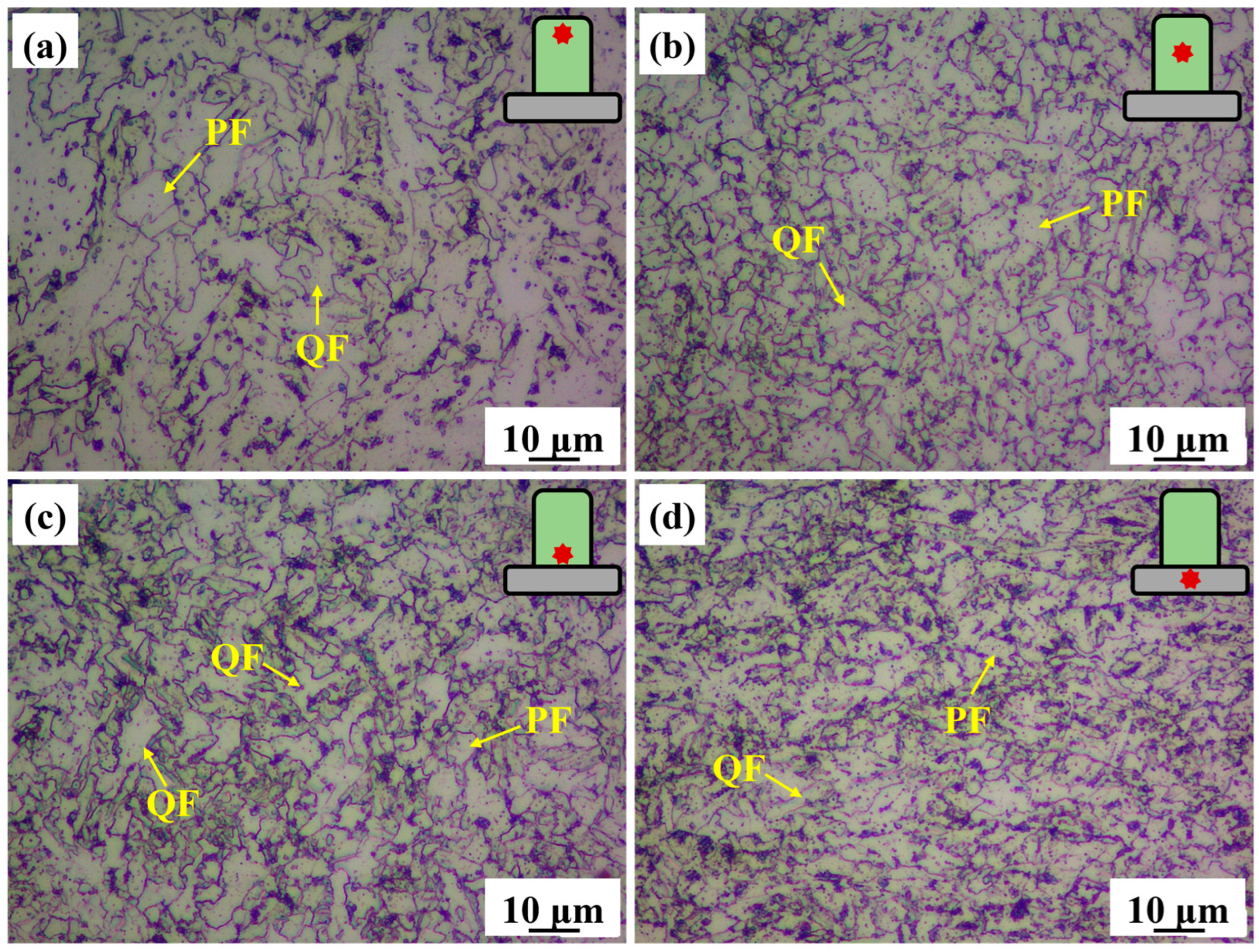

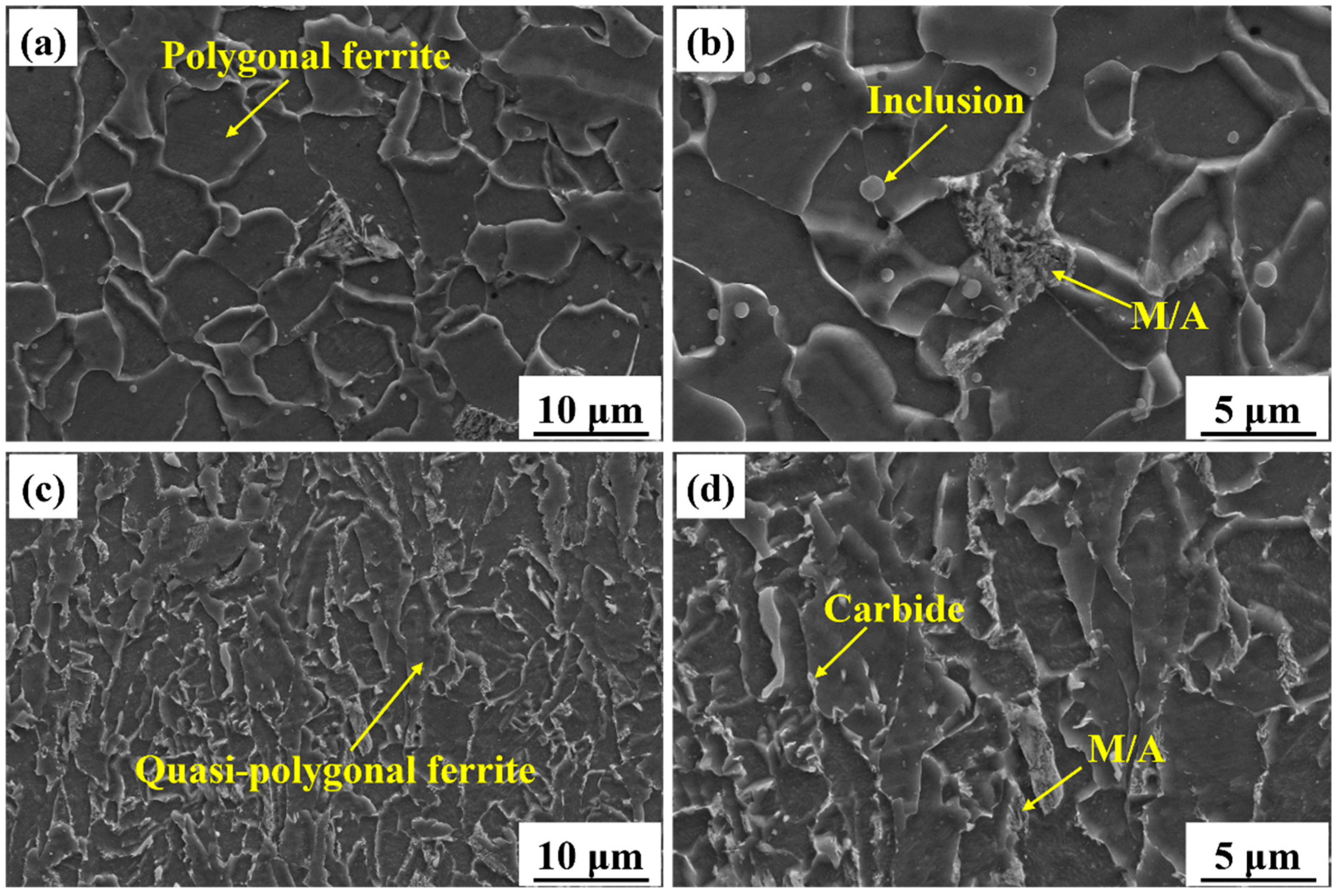

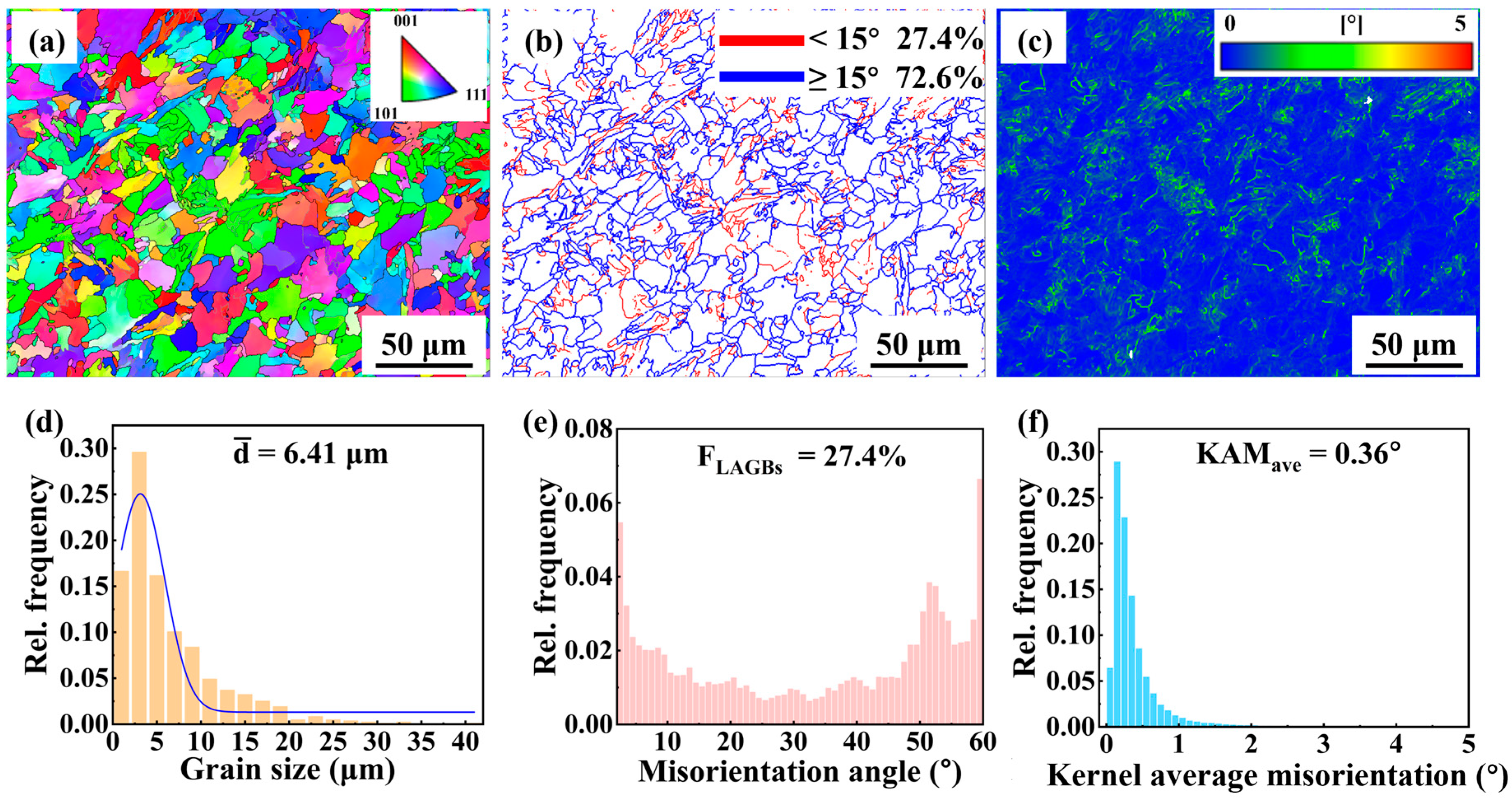

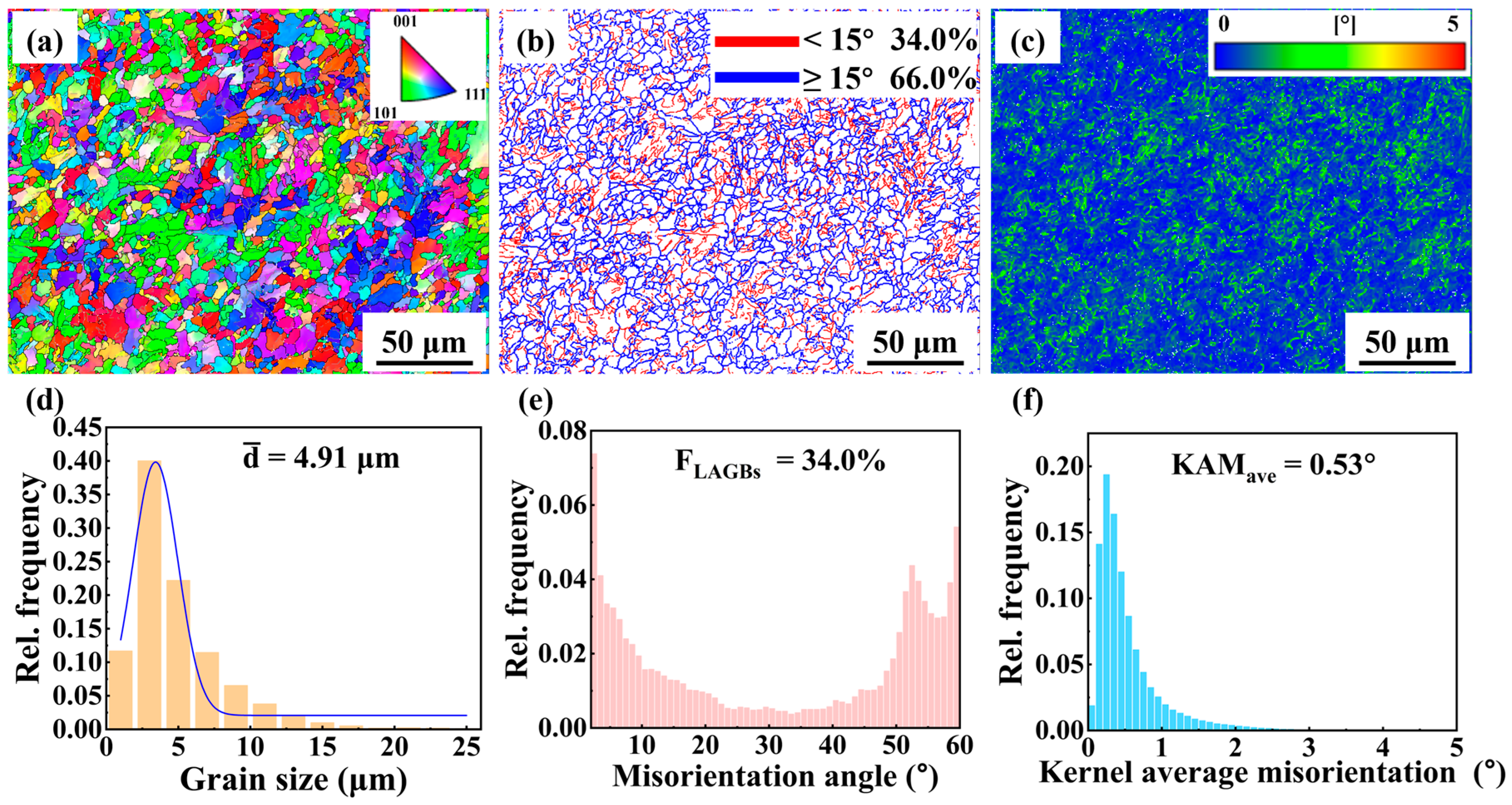

3.1. Microstructure

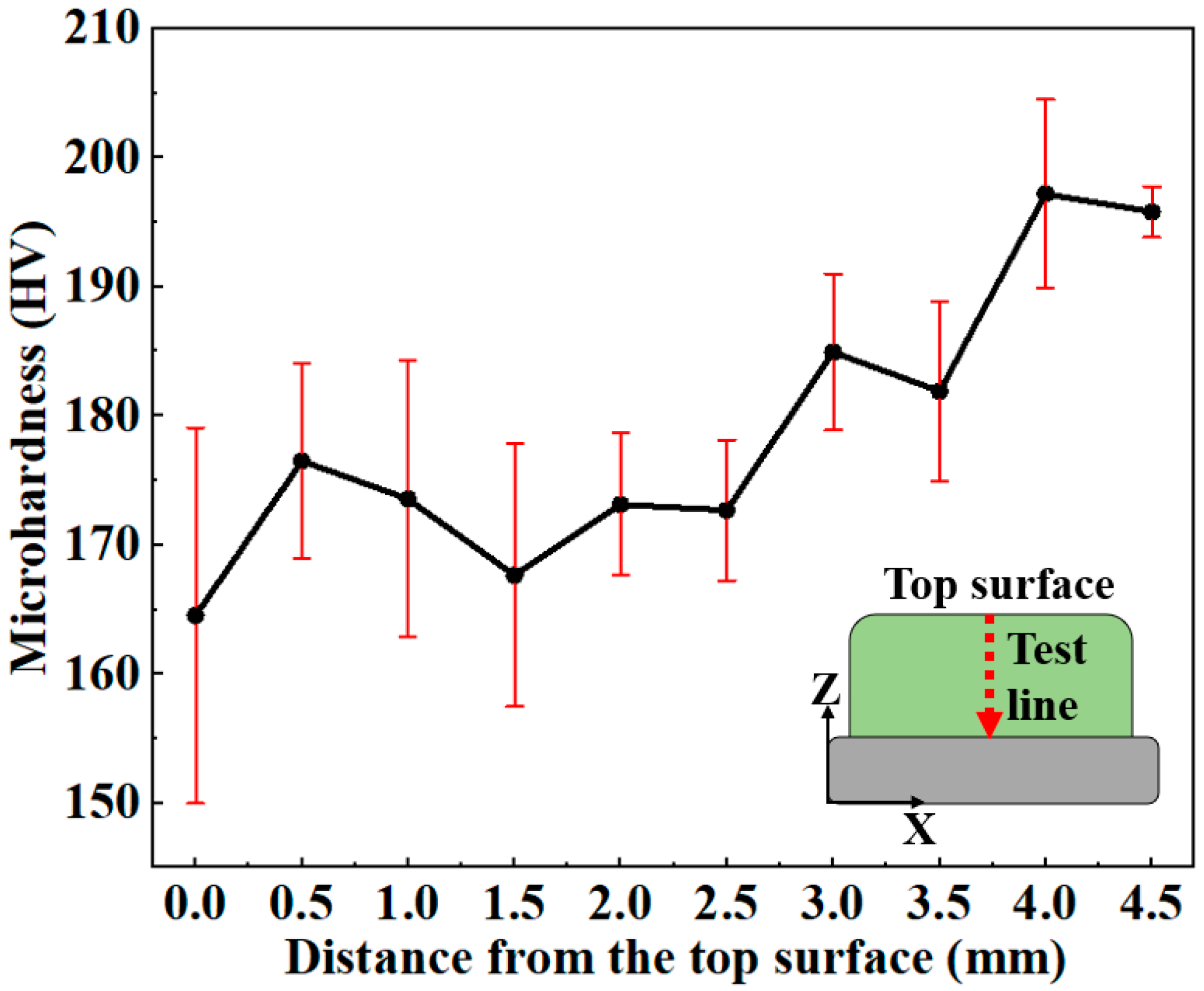

3.2. Microhardness

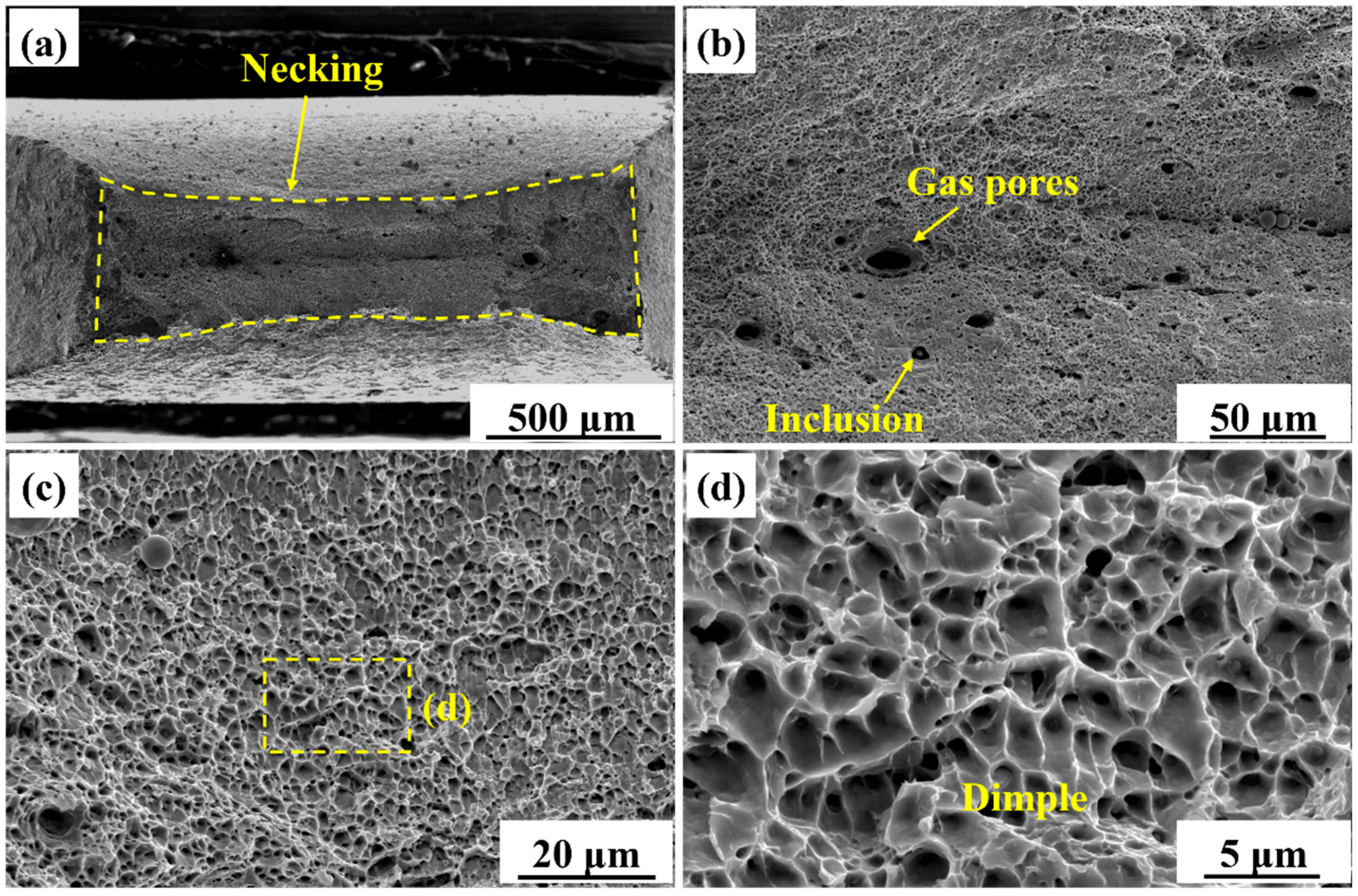

3.3. Tensile Properties

4. Discussion

4.1. Influence of L-DED Process on Microstructure Evolution

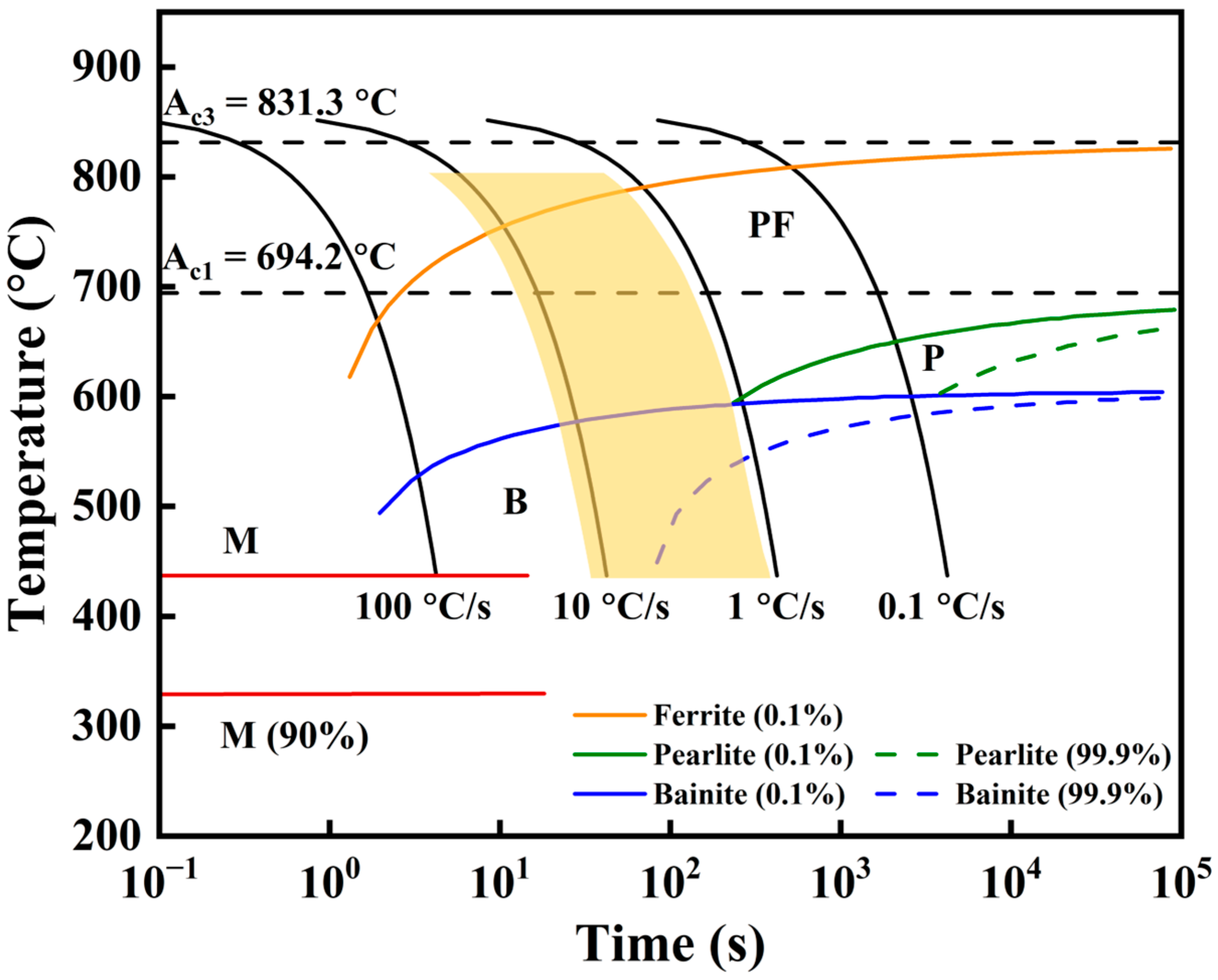

4.1.1. Thermal Process During L-DED

4.1.2. Phase Transformation of L-DED X70 Steel

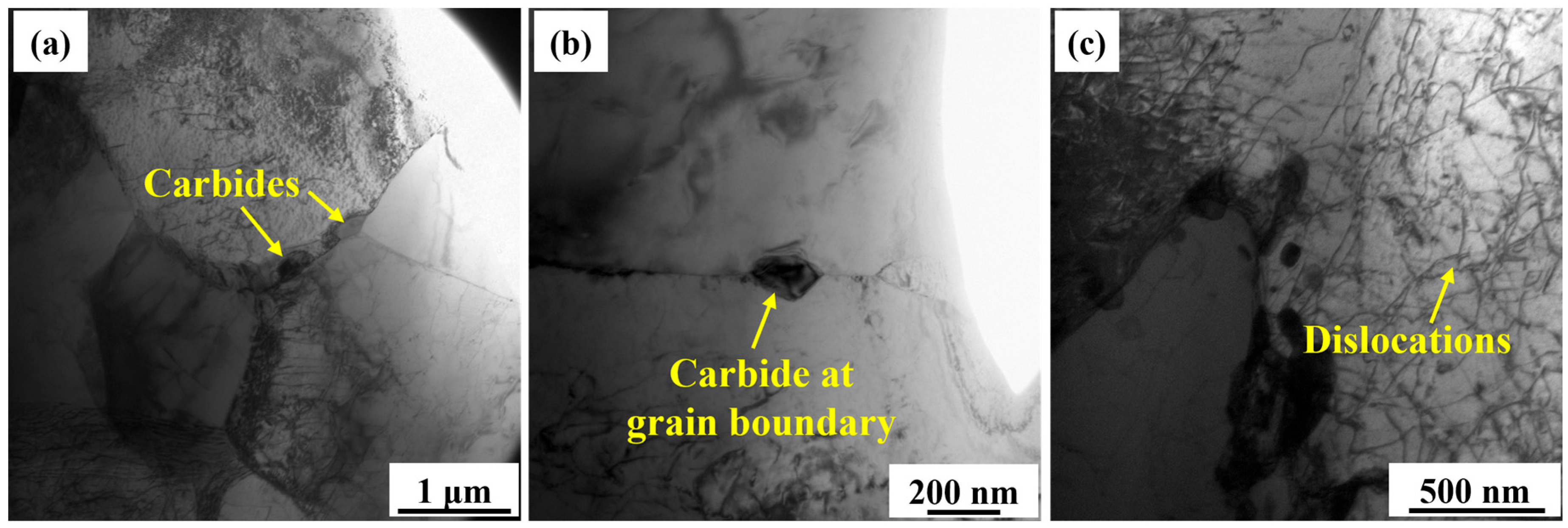

4.1.3. Carbide Precipitation

4.1.4. Grain Boundary and Dislocation Evolution

4.2. Influence of Microstructure on Microhardness

4.3. Influence of Microstructure on Tensile Properties

4.3.1. Tensile Strength and Ductility

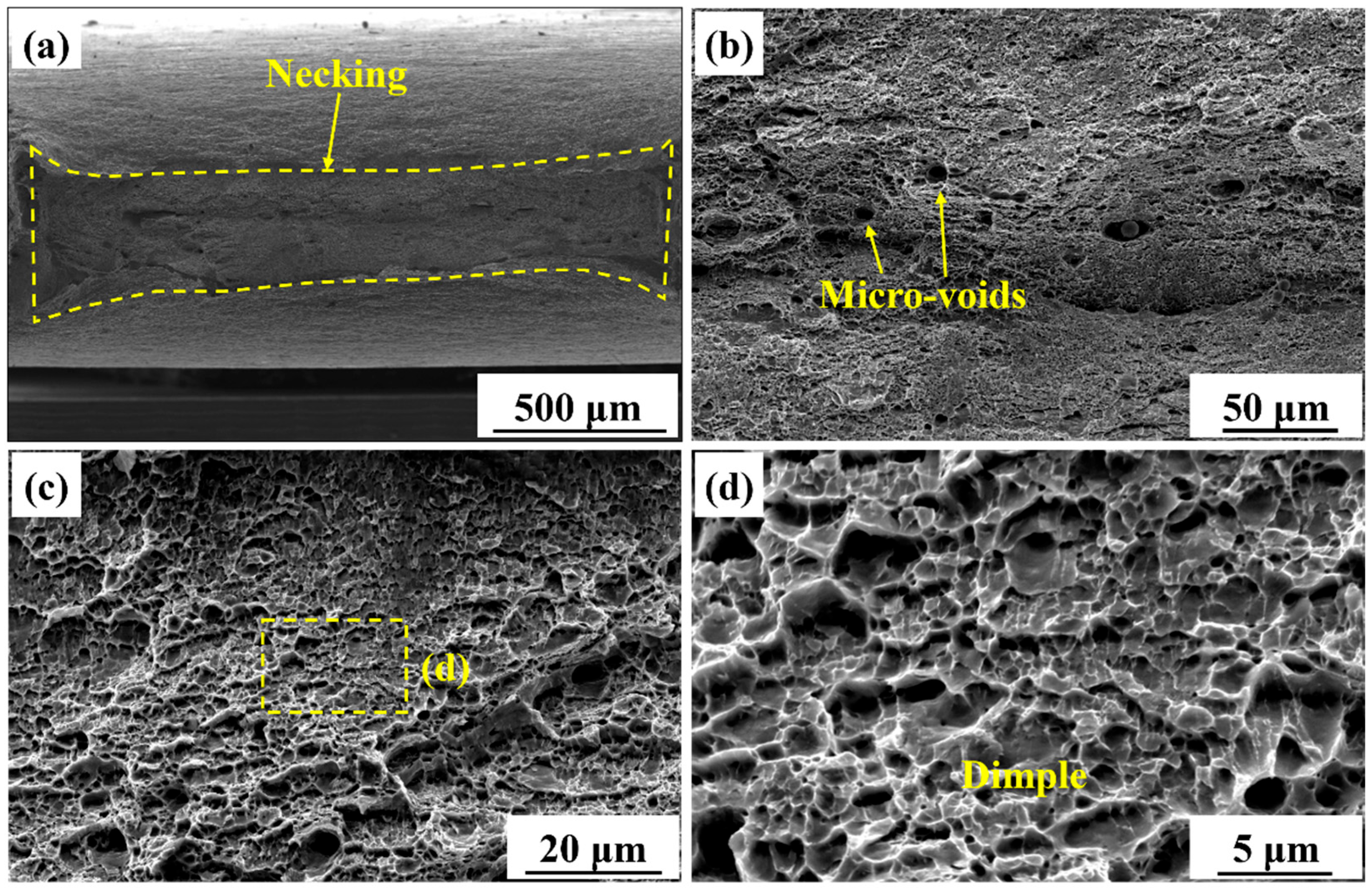

4.3.2. Fracture Morphology

4.4. Limitations

5. Conclusions

- (1)

- The microstructure exhibited inhomogeneity along the building direction. From the bottom to the top, the grains gradually coarsened, and the proportion of PF increased. From the bottom to the top, thermal accumulation increased, resulting in decreased cooling rates, which promoted grain coarsening and the formation of PF. The grain size of the AM X70 was larger than that of BM.

- (2)

- AM X70 exhibited a significantly reduced dislocation density. The high thermal input and slow cooling rates led to substantial annihilation of dislocation structures. Fe3C carbides were dispersed both within grains and along grain boundaries. Meanwhile, the intrinsic heat treatment provided favorable kinetic conditions for carbon diffusion, as well as for the nucleation and growth of Fe3C.

- (3)

- The microhardness gradually decreased along the building direction. The bottom region had a high content of QF, resulting in higher microhardness. In contrast, the top region was predominantly composed of coarse PF, leading to lower microhardness. The average microhardness of the AM specimen was 179 ± 11 HV which was 23.8% lower than that of the BM specimen (235 ± 7 HV).

- (4)

- The AM X70 exhibited a YS of 435 MPa and an UTS of 513 MPa. Both the YS and UTS of the AM X70 were lower than those of the BM and API 5L standard. The elongation of AM X70 reached 42.9%, which was 58% higher than that of the BM. The reduction in strength stemmed from the grain coarsening and decreased dislocation density induced by the L-DED thermal cycles. Meanwhile, the plastic accommodation ability was enhanced, resulting in substantially improved ductility. In harsh service environments characterized by complex stress states, the strength of repaired pipeline steel becomes critically important. Given the current limitations in mechanical performance, future work will primarily focus on enhancing the strength of the deposited X70 steel.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nguyen, T.T.; Park, J.; Kim, W.S.; Nahm, S.H.; Beak, U.B. Effect of low partial hydrogen in a mixture with methane on the mechanical properties of X70 pipeline steel. Int. J. Hydrogen Energy 2020, 45, 2368–2381. [Google Scholar] [CrossRef]

- Beidokhti, B.; Dolati, A.; Koukabi, A.H. Effects of alloying elements and microstructure on the susceptibility of the welded HSLA steel to hydrogen-induced cracking and sulfide stress cracking. Mater. Sci. Eng. A 2009, 507, 167–173. [Google Scholar] [CrossRef]

- Fekete, J.R.; Sowards, J.W.; Amaro, R.L. Economic impact of applying high strength steels in hydrogen gas pipelines. Int. J. Hydrogen Energy 2015, 40, 10547–10558. [Google Scholar] [CrossRef]

- Zhang, S.B.; Hou, P.J.; Kang, J.Y.; Li, T.Y.; Mooraj, S.; Ren, Y.; Chen, C.H.; Hart, A.J.; Gerasimidis, S.; Chen, W. Laser additive manufacturing for infrastructure repair: A case study of a deteriorated steel bridge beam. J. Mater. Sci. Technol. 2023, 154, 149–158. [Google Scholar] [CrossRef]

- Piscopo, G.; Iuliano, L. Current research and industrial application of laser powder directed energy deposition. Int. J. Adv. Manuf. Technol. 2022, 119, 6893–6917. [Google Scholar] [CrossRef]

- Kang, L.; Song, P. Bending behaviour of surface corroded and perforated corroded steel tubes repaired by laser cladding additive manufacturing. Thin-Walled Struct. 2024, 203, 112213. [Google Scholar] [CrossRef]

- Ning, J.; Wen, J.H.; Zhang, L.J.; Na, S.J. Assessment of the universality of duplex stainless steel powder in laser additive repair based on Schaeffler diagram. Addit. Manuf. 2022, 55, 102864. [Google Scholar] [CrossRef]

- Cheng, H.; Lei, B.L.; Liu, X.; Deng, Z.R.; Chen, K.Q.; Wei, S.Y.; Luo, X.C.; Wu, X. Development of low transformation temperature alloys for laser additive manufacturing repairing the defects in HSLA-100 plates: Focusing on the microstructure, residual stress and performance. J. Mater. Res. Technol. 2025, 38, 1472–1486. [Google Scholar] [CrossRef]

- Rashid, R.A.R.; Nazari, K.A.; Barr, C.; Palanisamy, S.; Orchowski, N.; Matthews, N.; Dargusch, M.S. Effect of laser reheat post-treatment on the microstructural characteristics of laser-cladded ultra-high strength steel. Surf. Coat. Technol. 2019, 372, 93–102. [Google Scholar] [CrossRef]

- Ning, J.; Yu, Z.S.; Sun, K.; Hu, M.J.; Zhang, L.X.; Zhang, Y.B.; Zhang, L.J. Comparison of microstructures and properties of X80 pipeline steel additively manufactured based on laser welding with filler wire and cold metal transfer. J. Mater. Res. Technol. 2021, 10, 752–768. [Google Scholar] [CrossRef]

- Seede, R.; Shoukr, D.; Zhang, B.; Whitt, A.; Gibbons, S.; Flater, P.; Elwany, A.; Arroyave, R.; Karaman, I. An ultra-high strength martensitic steel fabricated using selective laser melting additive manufacturing: Densification, microstructure, and mechanical properties. Acta Mater. 2020, 186, 199–214. [Google Scholar] [CrossRef]

- Sun, S.D.; Liu, Q.C.; Brandt, M.; Luzin, V.; Cottam, R.; Janardhana, M.; Clark, G. Effect of laser clad repair on the fatigue behaviour of ultra-high strength AISI 4340 steel. Mater. Sci. Eng. A 2014, 606, 46–57. [Google Scholar] [CrossRef]

- Zhan, X.H.; Fang, Y.C.; Gao, Q.Y.; Guan, X.H.; Ci, S.W.; Cai, X.K.; Guan, S.Z. Study on the microstructure evolution performance improvement of Invar alloy repaired by laser cladding Aermet100 ultra-high strength steel. J. Mater. Process. Technol. 2024, 331, 118517. [Google Scholar] [CrossRef]

- Jing, G.Y.; Wang, Z.M. Influence of molten pool mode on microstructure and mechanical properties of heterogeneously tempered 300M steel by selective laser melting. J. Mater. Process. Technol. 2021, 296, 117188. [Google Scholar] [CrossRef]

- Sun, G.F.; Yao, S.; Wang, Z.D.; Shen, X.T.; Yan, Y.; Zhou, R.; Ni, Z.H. Microstructure and mechanical properties of HSLA-100 steel repaired by laser metal deposition. Surf. Coat. Technol. 2018, 351, 198–211. [Google Scholar] [CrossRef]

- Shang, F.M.; Chen, S.Y.; Zhou, L.; Jia, W.M.; Cui, T.; Liang, J.; Liu, C.S.; Wang, M. Effect of laser energy volume density on wear resistance and corrosion resistance of 30Cr15MoY alloy steel coating prepared by laser direct metal deposition. Surf. Coat. Technol. 2021, 421, 127382. [Google Scholar] [CrossRef]

- Claeys, L.; Deconinck, L.; Verbeken, K.; Depover, T. Effect of additive manufacturing and subsequent heat and/or surface treatment on the hydrogen embrittlement sensitivity of 316L austenitic stainless steel. Int. J. Hydrogen Energy 2023, 48, 36142–36157. [Google Scholar] [CrossRef]

- American Petroleum Institute. API Specification 5L: Specification for Line Pipe, 46th ed.; American Petroleum Institute: Washington, DC, USA, 2018. [Google Scholar]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components-process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Müller, J.; Goulas, C.; Hensel, J. Analysis of thermal cycles during DED-Arc of high-strength low-alloy steel and microstructural evolution. J. Mater. Res. Technol. 2024, 31, 3661–3674. [Google Scholar] [CrossRef]

- Zhang, X.T.; Wang, L.; Zhao, N.; Liu, R.C.; Zhang, L.; Wu, W.D.; Yang, D.Q.; Huang, Y.; Wang, K.H. The effect of thermal cycle on microstructure evolution and mechanical properties of Co-free maraging steel produced by wire arc additive manufacturing. J. Mater. Process. Technol. 2024, 332, 118582. [Google Scholar] [CrossRef]

- Lazić, V.N.; Sedmak, A.S.; Živković, M.M.; Aleksandrović, S.M.; Čukić, R.D.; Jovičić, R.D.; Ivanović, I.B. Theoretical-experimental determining of cooling time (t8/5) in hard facing of steels for forging dies. Therm. Sci. 2010, 14, 235–246. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Duarte, V.; Avila, J.A.; Santos, T.G.; Miranda, R.M.; Oliveira, J.P. Wire and arc additive manufacturing of HSLA steel: Effect of thermal cycles on microstructure and mechanical properties. Addit. Manuf. 2019, 27, 440–450. [Google Scholar] [CrossRef]

- Liang, C.; Song, G.X.; Wang, W.L.; Sohn, I.L.; Zeng, J. In situ observation of the austenite to ferrite transformation in low-carbon steels from different initial phases at defined cooling rates. J. Mater. Res. Technol. 2024, 28, 2116–2126. [Google Scholar] [CrossRef]

- Xie, H.; Du, L.X.; Hu, J.; Sun, G.S.; Wu, H.Y.; Misra, R.D.K. Effect of thermo-mechanical cycling on the microstructure and toughness in the weld CGHAZ of a novel high strength low carbon steel. Mater. Sci. Eng. A 2015, 639, 482–488. [Google Scholar] [CrossRef]

- Wang, G.; Wang, J.; Yin, L.; Hu, H.; Yao, Z. Quantitative correlation between thermal cycling and the microstructures of X100 pipeline steel laser-welded joints. Materials 2020, 13, 121. [Google Scholar] [CrossRef]

- Bertsch, K.M.; Meric de Bellefon, G.; Kuehl, B.; Thoma, D.J. Origin of dislocation structures in an additively manufactured austenitic stainless steel 316L. Acta Mater. 2020, 199, 19–33. [Google Scholar] [CrossRef]

- Xiao, F.R.; Liao, B.; Shan, Y.Y.; Qiao, G.Y.; Zhong, Y.; Zhang, C.L.; Yang, K. Challenge of mechanical properties of an acicular ferrite pipeline steel. Mater. Sci. Eng. A 2006, 431, 41–52. [Google Scholar] [CrossRef]

- Lobanov, M.L.; Zorina, M.A.; Karabanalov, M.S.; Urtsev, N.V.; Redikultsev, A.A. Phase transformation crystallography in pipeline HSLA steel after TMCP. Metals 2023, 13, 1121. [Google Scholar] [CrossRef]

- Odqvist, J.; Hillert, M.; Ågren, J. Effect of alloying elements on the γ to α transformation in steel. I. Acta Mater. 2002, 50, 3213–3227. [Google Scholar] [CrossRef]

- Danoix, F.; Sauvage, X.; Huin, D.; Germain, L.; Gouné, M. A direct evidence of solute interactions with a moving ferrite/austenite interface in a model Fe-C-Mn alloy. Scr. Mater. 2016, 121, 61–65. [Google Scholar] [CrossRef]

- Biro, E.; McDermid, J.R.; Vignier, S.; Zhou, Y.N. Decoupling of the softening processes during rapid tempering of a martensitic steel. Mater. Sci. Eng. A 2014, 615, 395–404. [Google Scholar] [CrossRef]

- Xue, H.Y.; Li, X.; Zhang, Z.H.; Xiao, S.J.; Yan, M.Z. The effect of tempering temperature on reheating cracks in the coarse-grained heat-affected zone of 15Cr1Mo1V steel pipe after repair welding. Int. J. Press. Vessel. Pip. 2025, 218, 105590. [Google Scholar] [CrossRef]

- Zhao, L.Y.; Wang, Q.M.; Shi, G.H.; Hu, B.; Wang, S.B.; Qiao, M.L.; Wang, Q.F.; Liu, R.P. The impacts of M/A constituents decomposition and complex precipitation on mechanical properties of high-strength weathering steel subjected to tempering treatment. J. Mater. Res. Technol. 2023, 23, 2504–2526. [Google Scholar] [CrossRef]

- Tang, Z.H.; Stumpf, W. The role of molybdenum additions and prior deformation on acicular ferrite formation in microalloyed Nb-Ti low-carbon line-pipe steels. Mater. Charact. 2008, 59, 717–728. [Google Scholar] [CrossRef]

- Zhou, Y.; Chen, S.Y.; Chen, X.T.; Cui, T.; Liang, J.; Liu, C.S. The evolution of bainite and mechanical properties of direct laser deposition 12CrNi2 alloy steel at different laser power. Mater. Sci. Eng. A 2019, 742, 150–161. [Google Scholar] [CrossRef]

- Forouzan, F.; Vuorinen, E.; Mücklich, F. Post weld-treatment of laser welded AHSS by application of quenching and partitioning technique. Mater. Sci. Eng. A 2017, 698, 174–182. [Google Scholar] [CrossRef]

- Saha, D.C.; Biro, E.; Gerlich, A.P.; Zhou, Y. Martensite tempering kinetics: Effects of dislocation density and heating rates. Mater. Charact. 2020, 168, 110564. [Google Scholar] [CrossRef]

- Ren, T.; Mohammadijoo, M.; Wiskel, J.B.; Lazor, R.; Willett, E.; Ivey, D.G.; Henein, H. Effect of cold wire addition in tandem submerged arc welding on weld geometry and micro-hardness of heavy gauge X70 steel. Int. J. Adv. Manuf. Technol. 2022, 121, 7607–7625. [Google Scholar] [CrossRef]

- Sharma, L.; Chhibber, R. Mechanical properties and hydrogen induced cracking behaviour of API X70 SAW weldments. Int. J. Press. Vessel. Pip. 2018, 165, 193–207. [Google Scholar] [CrossRef]

- Gordienko, A.I.; Derevyagina, L.S.; Malikov, A.G.; Orishich, A.M.; Surikova, N.S.; Volochaev, M.N. The effect of the initial microstructure of the X70 low-carbon microalloyed steel on the heat affected zone formation and the mechanical properties of laser welded joints. Mater. Sci. Eng. A 2020, 797, 140075. [Google Scholar] [CrossRef]

- Chen, Y.B.; Feng, J.C.; Li, L.Q.; Chang, S.; Ma, G.L. Microstructure and mechanical properties of a thick-section high-strength steel welded joint by novel double-sided hybrid fibre laser-arc welding. Mater. Sci. Eng. A 2013, 582, 284–293. [Google Scholar] [CrossRef]

- Hayes, B.J.; Martin, B.W.; Welk, B.; Kuhr, S.J.; Ales, T.K.; Brice, D.A.; Ghamarian, I.; Baker, A.H.; Haden, C.V.; Harlow, D.G.; et al. Predicting tensile properties of Ti-6Al-4V produced via directed energy deposition. Acta Mater. 2017, 133, 120–133. [Google Scholar] [CrossRef]

- Qin, Y.Q.; Feng, Q.S.; Hu, Y.B.; Zhong, F.L.; Zhao, Z.F.; Yu, Q.C.; Yin, S.B.; Jia, S.J. Effect of Cr microalloying on microstructure evolution and toughness in SCGHAZ of X80 pipeline steel. J. Iron Steel Res. Int. 2025, 32, 3573–3586. [Google Scholar] [CrossRef]

- Ju, Y.Z.; Li, S.; Ba, L.Z.; Yang, X.C.; Li, C.N.; Di, X.J. Effect of cyclic heat treatment on microstructure and mechanical properties of ultra-high strength steel fabricated by wire + arc additive manufacturing with cold metal transfer. Mater. Sci. Eng. A 2025, 927, 147986. [Google Scholar] [CrossRef]

- Wang, W.; Shan, Y.Y.; Yang, K. Study of high strength pipeline steels with different microstructures. Mater. Sci. Eng. A 2009, 502, 38–44. [Google Scholar] [CrossRef]

- Zhao, M.C.; Hanamura, T.; Qiu, H.; Yang, K. Lath boundary thin-film martensite in acicular ferrite ultralow carbon pipeline steels. Mater. Sci. Eng. A 2005, 395, 327–332. [Google Scholar] [CrossRef]

- Xiao, F.R.; Liao, B.; Ren, D.L.; Shan, Y.Y.; Yang, K. Acicular ferritic microstructure of a low-carbon Mn-Mo-Nb microalloyed pipeline steel. Mater. Charact. 2005, 54, 305–314. [Google Scholar] [CrossRef]

- Lee, H.J.; Narayana, P.L.; Kim, J.H.; Park, C.H.; Hong, J.-K.; Yeom, J.-T.; Lee, T.; Lee, S.W. Effect of interlayer cooling on the microstructure and mechanical properties of titanium alloys fabricated using directed energy deposition. J. Alloys Compd. 2023, 953, 170202. [Google Scholar] [CrossRef]

- da Silva, L.J.; Souza, D.M.; de Araújo, D.B.; Reis, R.P.; Scotti, A. Concept and validation of an active cooling technique to mitigate heat accumulation in WAAM. Int. J. Adv. Manuf. Technol. 2020, 107, 2513–2523. [Google Scholar] [CrossRef]

- Kuprienko, A.; Stickle, J.; Harwig, D.; Carney, M.; Fink, C. Effect of liquid nitrogen cryogenic cooling during wire arc directed energy deposition of nickel aluminum bronze. Weld. World 2024, 68, 515–524. [Google Scholar] [CrossRef]

| Element | C | Mn | Ni | Cr | Si | Mo | V | Cu | Nb | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X70 plate | 0.085 | 1.57 | 0.02 | 0.27 | 0.21 | 0.003 | 0.003 | 0.024 | 0.05 | 0.010 | 0.005 | Bal. |

| X70 powder | 0.057 | 1.47 | 0.08 | 0.36 | 0.20 | 0.013 | 0.002 | 0.02 | 0.04 | 0.012 | 0.008 | Bal. |

| Parameter | Value |

|---|---|

| Laser power (W) | 2000 |

| Laser spot diameter (mm) | 2 |

| Scanning speed (mm/min) | 1000 |

| Powder feed rate (g/min) | 10 |

| Hatching distance (mm) | 1.25 |

| ΔZ increment (mm) | 0.75 |

| Layer number | 8 |

| Material | Yield Strength (MPa) | Ultimate Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| X70 AM | 434.8 ± 36.4 | 512.6 ± 24.2 | 42.9 ± 3.5 |

| X70 BM | 549.7 ± 46.4 | 643.7 ± 10.9 | 27.1 ± 7.1 |

| X70 API 5L | ≥485 | ≥570 | ≥20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Wang, C.; Wu, L.; Sun, G. Investigation on the Microstructure and Mechanical Properties of X70 Pipeline Steel Fabricated by Laser-Directed Energy Deposition. Materials 2025, 18, 4997. https://doi.org/10.3390/ma18214997

Wang Z, Wang C, Wu L, Sun G. Investigation on the Microstructure and Mechanical Properties of X70 Pipeline Steel Fabricated by Laser-Directed Energy Deposition. Materials. 2025; 18(21):4997. https://doi.org/10.3390/ma18214997

Chicago/Turabian StyleWang, Zhandong, Chunke Wang, Linzhong Wu, and Guifang Sun. 2025. "Investigation on the Microstructure and Mechanical Properties of X70 Pipeline Steel Fabricated by Laser-Directed Energy Deposition" Materials 18, no. 21: 4997. https://doi.org/10.3390/ma18214997

APA StyleWang, Z., Wang, C., Wu, L., & Sun, G. (2025). Investigation on the Microstructure and Mechanical Properties of X70 Pipeline Steel Fabricated by Laser-Directed Energy Deposition. Materials, 18(21), 4997. https://doi.org/10.3390/ma18214997