A Novel Strategy for Introducing Metal-Organic Frameworks into Carbon Fiber to Improve the Interfacial and Mechanical Properties of Carbon Fiber/Epoxy Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

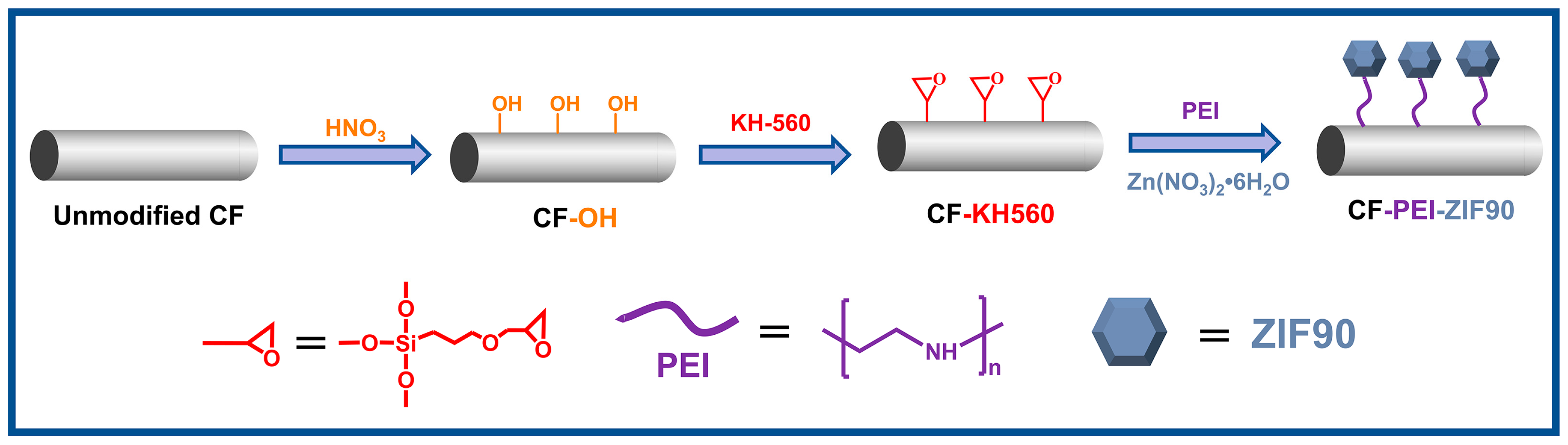

2.2. Preparation of Epoxy Group-Functionalized CF

2.3. Preparation of CF-PEI-ZIF90

2.4. Preparation of Composites

2.5. Characterization

3. Results and Discussion

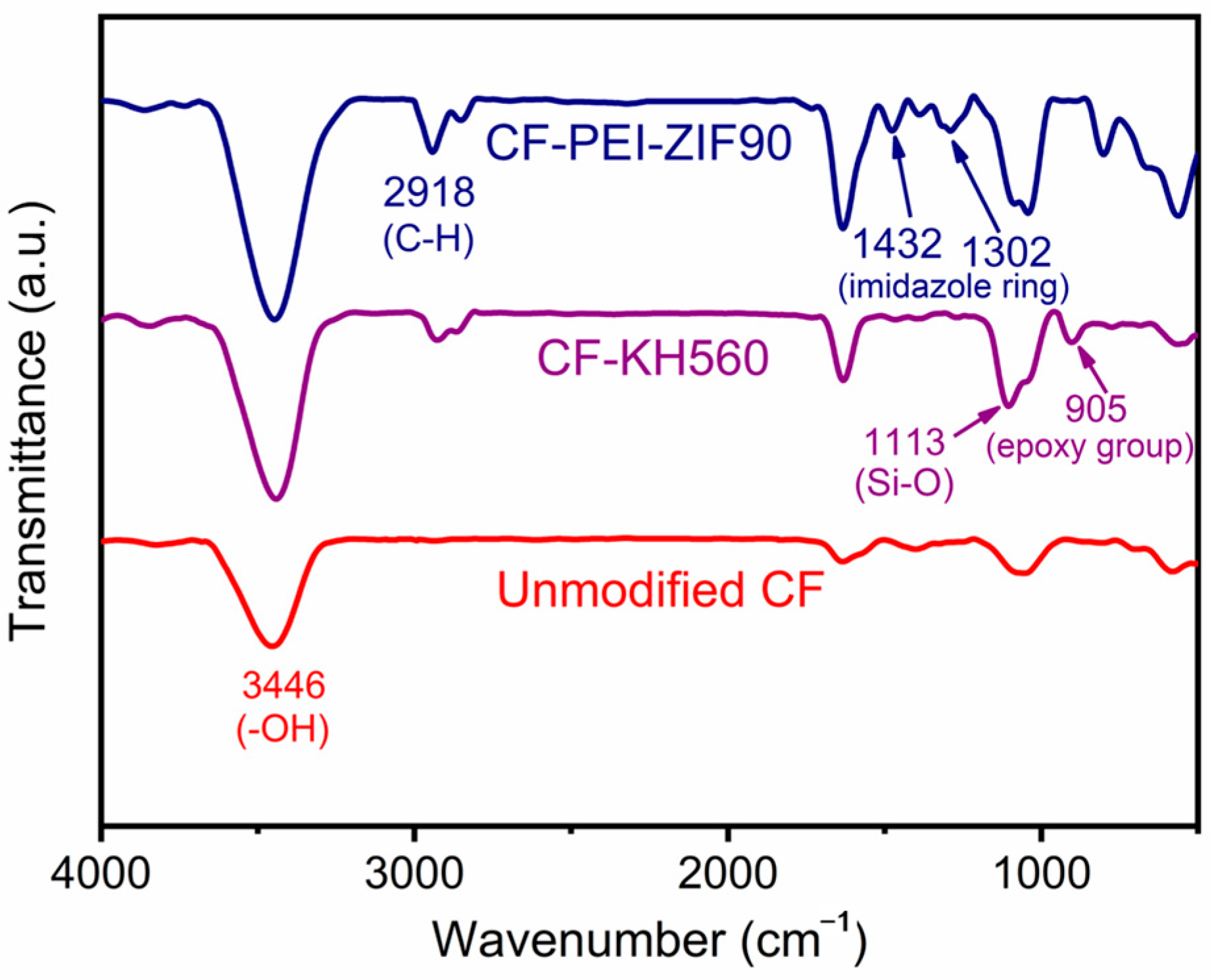

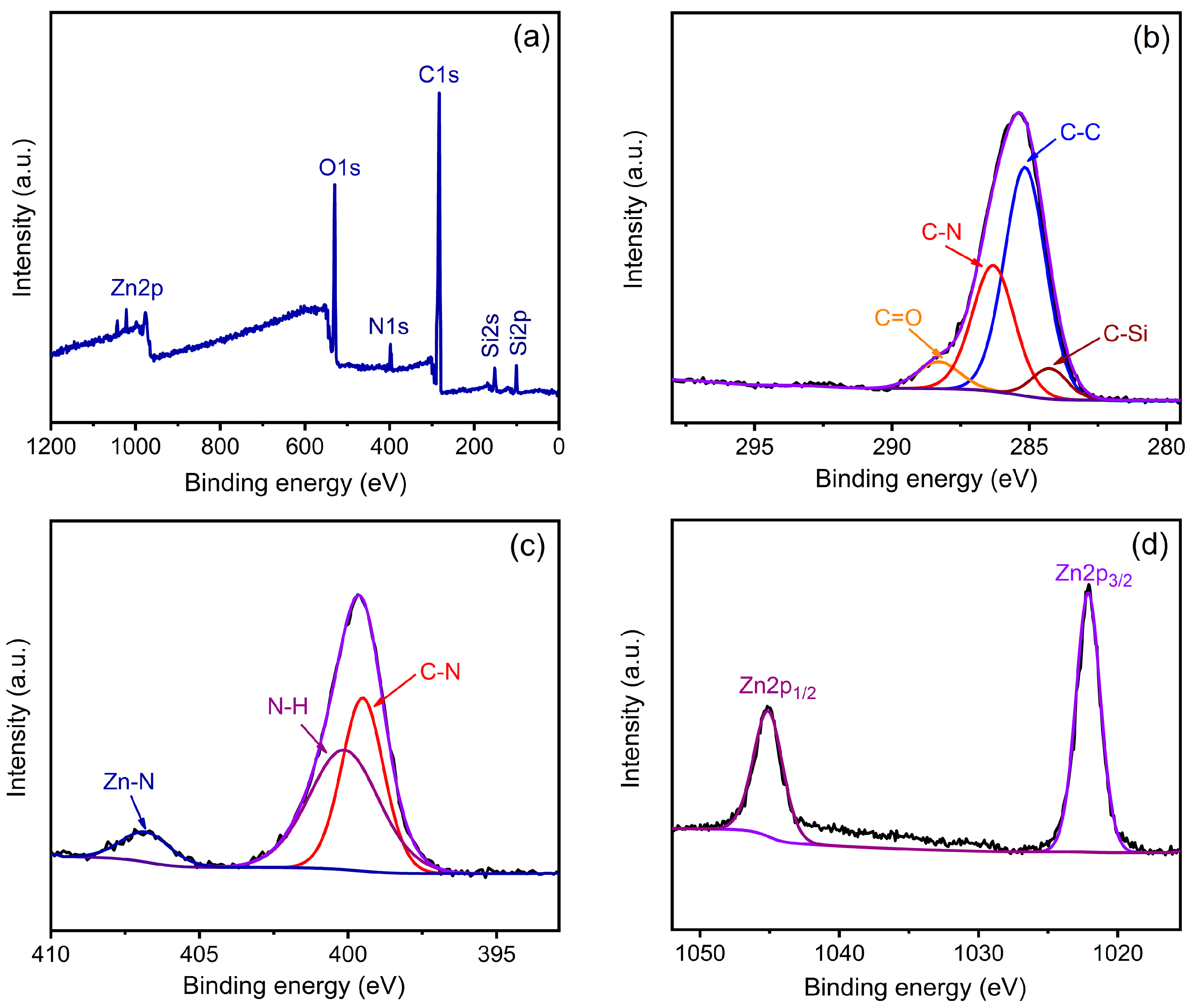

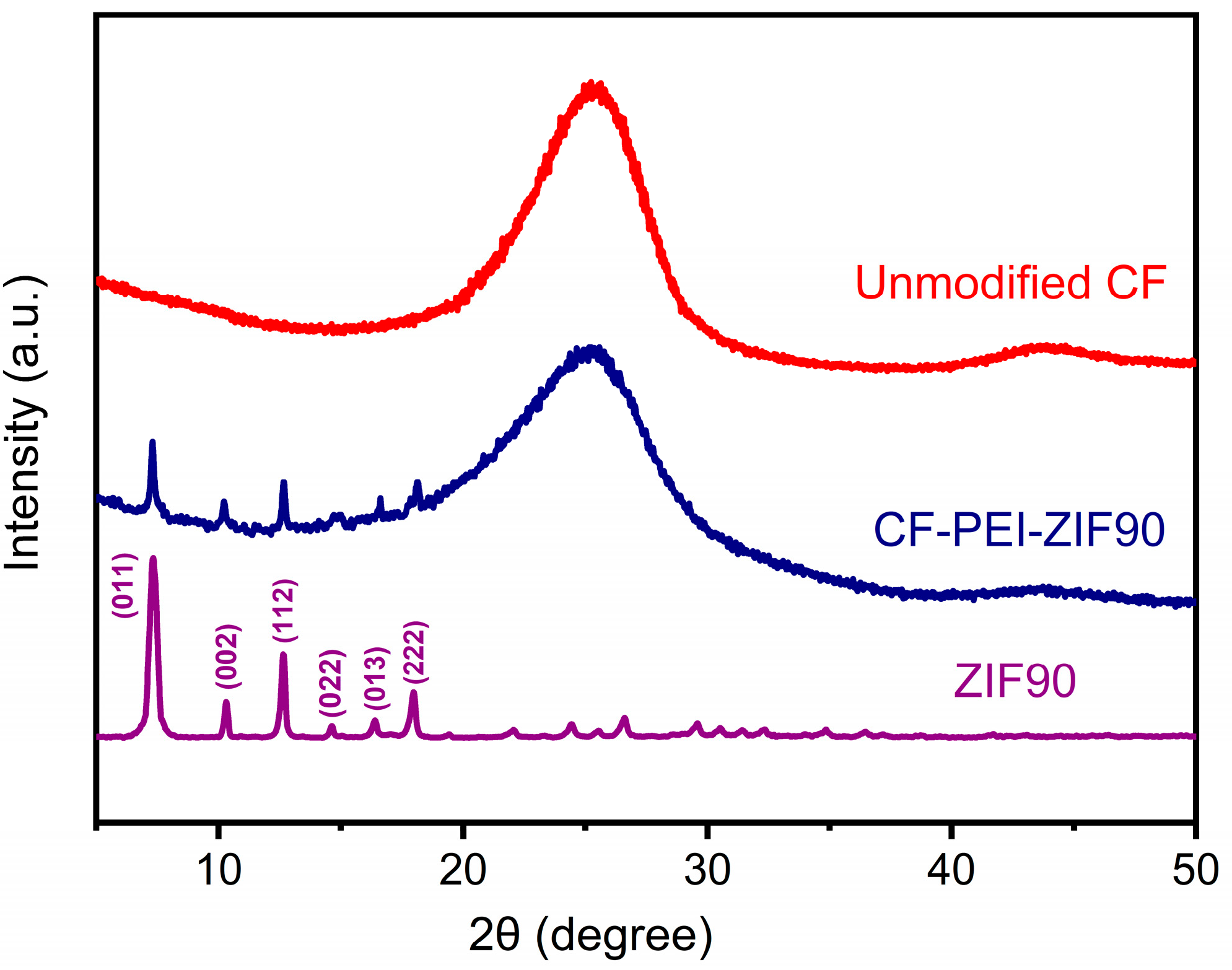

3.1. Physicochemical Characterizations for Modified CFs

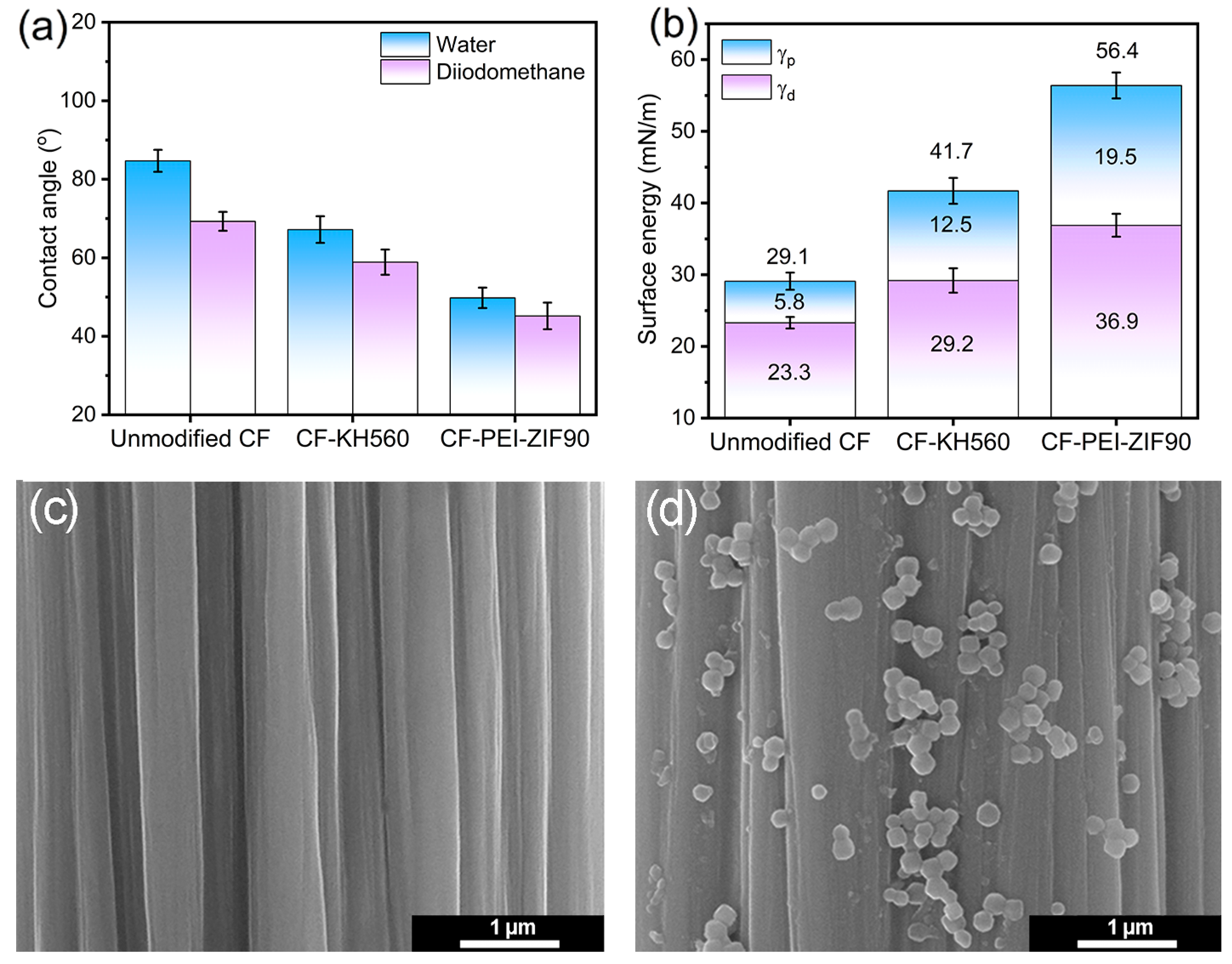

3.2. Surface Wettability and Morphology of CFs

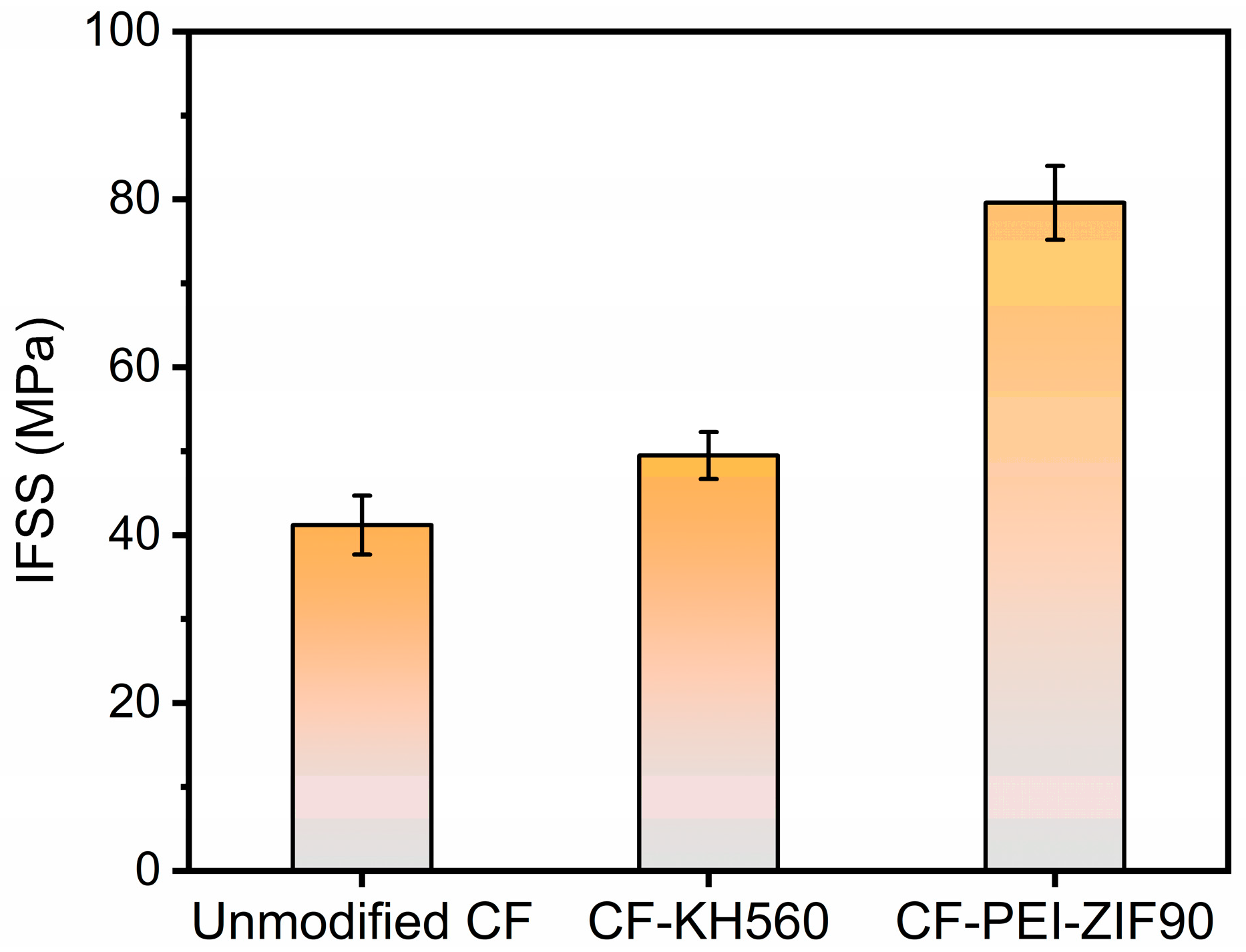

3.3. Interfacial Properties of Composites

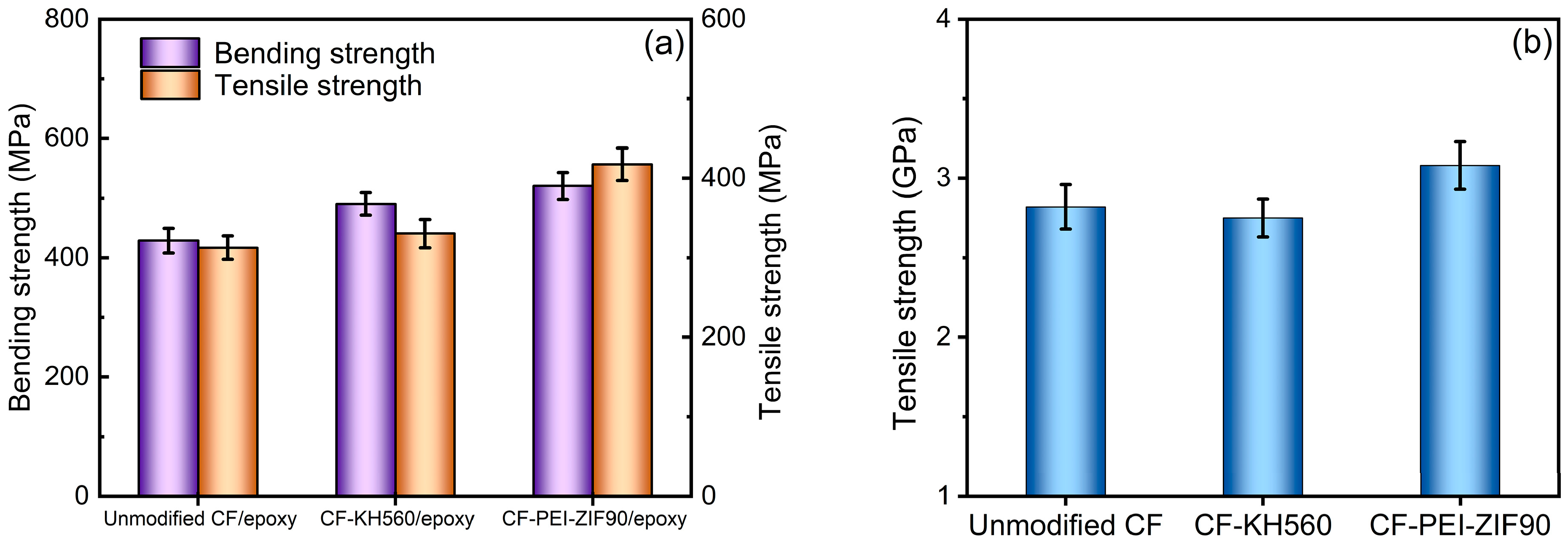

3.4. Mechanical Properties of Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- González, C.; Vilatela, J.J.; Molina-Aldareguía, J.M.; Lopes, C.S.; Llorca, J. Structural composites for multifunctional applications: Current challenges and future trends. Prog. Mater. Sci. 2017, 89, 194–251. [Google Scholar] [CrossRef]

- Zhou, H.W.; Mishnaevsky, L.; Yi, H.Y.; Liu, Y.Q.; Hu, X.; Warrier, A.; Dai, G.M. Carbon fiber/carbon nanotube reinforced hierarchical composites: Effect of CNT distribution on shearing strength. Compos. Part B Eng. 2016, 88, 201–211. [Google Scholar] [CrossRef]

- Xiong, K.; Xiong, L.; Liu, F.; Xiong, M.; Chen, T. Simultaneous grafting of carbon nanotube and hyperbranched poly(thioether-yne) onto carbon fiber via thiol-alkyne click chemistry to improve interface properties of carbon fiber/epoxy composite. Polym. Compos. 2024, 45, 2646–2655. [Google Scholar] [CrossRef]

- Chand, S. Review Carbon fibers for composites. J. Mater. Sci. 2000, 35, 1303–1313. [Google Scholar] [CrossRef]

- Li, Y.; Xiong, L.; Zhu, W.; Liu, F. Bio-inspired design of an electricity-triggered self-healing interface for carbon fiber/bismaleimide composite by grafting graphene oxide and furfuramine onto carbon fiber. Ind. Crops Prod. 2025, 236, 121917. [Google Scholar] [CrossRef]

- Lee, Y.M.; You, J.; Kim, M.; Kim, T.A.; Lee, S.-S.; Bang, J.; Park, J.H. Highly improved interfacial affinity in carbon fiber-reinforced polymer composites via oxygen and nitrogen plasma-assisted mechanochemistry. Compos. Part B Eng. 2019, 165, 725–732. [Google Scholar] [CrossRef]

- Luo, Y.; Shi, Z.; Qiao, S.; Tong, A.; Liao, X.; Zhang, T.; Bai, J.; Xu, C.; Xiong, X.; Chen, F.; et al. Advances in nanomaterials as exceptional fillers to reinforce carbon fiber-reinforced polymers composites and their emerging applications. Polym. Compos. 2025, 46, 54–80. [Google Scholar] [CrossRef]

- Xiong, K.; Liu, F.; Chen, T.; Xiong, L. Facile and efficient grafting of graphene oxide onto carbon fiber with hyperbranched poly(thioether-yne) via click chemistry to improve interface and mechanical properties of composite. Surf. Interfaces 2024, 46, 104038. [Google Scholar] [CrossRef]

- Jin, S.Y.; Young, R.J.; Eichhorn, S.J. Hybrid carbon fibre–carbon nanotube composite interfaces. Compos. Sci. Technol. 2014, 95, 114–120. [Google Scholar] [CrossRef]

- Han, P.; Hu, S.; Wei, G. Precisely adjusting the interface adhesion of carbon fiber/epoxy composites by regulating the micro-configuration of graphene oxide nanosheets on the fiber surface. Appl. Surf. Sci. 2024, 665, 160327. [Google Scholar] [CrossRef]

- Ma, J.; Dai, S.; Guo, Z.; Shang, L.; Ao, Y.; Jin, L. Impact of graphene oxide lateral sizes on the mechanical and thermal properties of carbon fiber composites. Polym. Compos. 2025, 46, 2061–2072. [Google Scholar] [CrossRef]

- Xiong, M.; Xiong, L.; Xiong, K.; Liu, F. A new strategy for improvement of interface and mechanical properties of carbon fiber/epoxy composites by grafting graphene oxide onto carbon fiber with hyperbranched polymers via thiol-ene click chemistry. Polym. Compos. 2023, 44, 5490–5498. [Google Scholar] [CrossRef]

- Wu, D.; Yao, Z.; Sun, X.; Liu, X.; Liu, L.; Zhang, R.; Wang, C. Mussel-tailored carbon fiber/carbon nanotubes interface for elevated interfacial properties of carbon fiber/epoxy composites. Chem. Eng. J. 2022, 429, 132449. [Google Scholar] [CrossRef]

- Zhang, W.; Dai, M.; Liang, X.; Wang, X.; Wei, W.; Zhou, Z. Interfacial Enhancement by CNTs Grafting towards High-Performance Mechanical Properties of Carbon Fiber-Reinforced Epoxy Composites. Materials 2023, 16, 3825. [Google Scholar] [CrossRef]

- Wang, X.; Li, S.-C.; Xiang, D.-W.; Gao, M.; Zuo, H.-M.; Li, D.-S. Flexural Properties and Failure Mechanisms of Short-Carbon-Fiber-Reinforced Polylactic Acid Composite Modified with MXene and GO. Materials 2024, 17, 1389. [Google Scholar] [CrossRef]

- Zhang, F.; Li, N.; Shi, J.-F.; Wang, Y.-Y.; Yan, D.-X.; Li, Z.-M. Cation Bimetallic MOF Anchored Carbon Fiber for Highly Efficient Microwave Absorption. Small 2024, 20, 2312135. [Google Scholar] [CrossRef]

- Ayyagari, S.; Al-Haik, M.; Ren, Y.; Abbott, A.; Trigg, E.B.; Zheng, B.; Koerner, H. Metal organic frameworks modification of carbon fiber composite interface. Compos. Part B Eng. 2021, 224, 109197. [Google Scholar] [CrossRef]

- Li, Q.; Sun, Y.; Li, G.; Yang, X.; Zuo, X. Enhancing Interfacial and Electromagnetic Interference Shielding Properties of Carbon Fiber Composites via the Hierarchical Assembly of the MWNT/MOF Interphase. Langmuir ACS J. Surf. Colloids 2022, 38, 14277–14289. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, B.; Huang, Y. Constructing nanosheet-like MOF on the carbon fiber surfaces for improving the interfacial properties of carbo fiber/epoxy composites. Appl. Surf. Sci. 2020, 514, 145870. [Google Scholar] [CrossRef]

- Wei, W.; Lu, P. Designing Dual-Responsive Drug Delivery Systems: The Role of Phase Change Materials and Metal-Organic Frameworks. Materials 2024, 17, 3070. [Google Scholar] [CrossRef]

- Zhang, G.; Xu, H.; Zhu, Y.; Yan, C.; Liu, D.; Chen, G.; Xiao, Z. Simultaneously improving interfacial adhesion and toughness of carbon fiber reinforced epoxy composites by grafting polyethyleneimine on the carbon fiber surface to construct a rigid-flexible interface. Polym. Compos. 2024, 45, 12044–12056. [Google Scholar] [CrossRef]

- Pu, G.; Yang, A.; Li, Y.; Jiang, Z.; Li, X.; Chen, Z.; He, R.; Zhang, K.; Yang, W. Carbon fiber in situ grown ZIF-67 nanocrystals with excellent electrochemical and interfacial property. Polym. Compos. 2024, 45, 972–988. [Google Scholar] [CrossRef]

- Shan, Z.; Jia, X.; Lin, Z.; Yang, J.; Wang, S.; Li, Y.; Shao, D.; Feng, L.; Song, H.J. In-situ growth strategy of ZIF-8 nanocrystals on carbon fibers achieved high-efficient interface enhancement. Surf. Interfaces 2022, 33, 102230. [Google Scholar] [CrossRef]

- Wu, G.; Fan, Q.; Sun, W.; Yu, Z.; Jia, Z.; Ma, J.J.C.J.o.C.E. Regulatable pervaporation performance of Zn-MOFs/polydimethylsiloxane mixed matrix pervaporation membranes. Chin. J. Chem. Eng. 2022, 42, 312–318. [Google Scholar] [CrossRef]

- Yang, T.; Chung, T.-S. Room-temperature synthesis of ZIF-90 nanocrystals and the derived nano-composite membranes for hydrogen separation. J. Mater. Chem. A 2013, 1, 6081–6090. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, B.; Huang, Y. Interfacial self-healing performance of carbon fiber/epoxy based on postsynthetic modification of metal-organic frameworks. Compos. Sci. Technol. 2022, 227, 109564. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, Y.; Li, N.; Zhao, X.; Han, X.; Li, S.; Lu, W.; Wang, K.; Du, S. Enhanced interfacial strength of carbon fiber/PEEK composites using a facile approach via PEI&ZIF-67 synergistic modification. J. Mater. Res. Technol. 2019, 8, 6289–6300. [Google Scholar] [CrossRef]

- Zhao, M.; Sun, Z.; Guo, J.; Qu, Q.; Jiang, T.; Wang, G.; Wang, J. Strengthening and Toughening Epoxy Composites by Constructing MOF/CF Multi-Scale Reinforcement. Coatings 2023, 13, 170. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, J.; Ma, H.; Deng, Q.; Li, H.; Xiong, L. A Novel Strategy for Introducing Metal-Organic Frameworks into Carbon Fiber to Improve the Interfacial and Mechanical Properties of Carbon Fiber/Epoxy Composites. Materials 2025, 18, 4856. https://doi.org/10.3390/ma18214856

Yan J, Ma H, Deng Q, Li H, Xiong L. A Novel Strategy for Introducing Metal-Organic Frameworks into Carbon Fiber to Improve the Interfacial and Mechanical Properties of Carbon Fiber/Epoxy Composites. Materials. 2025; 18(21):4856. https://doi.org/10.3390/ma18214856

Chicago/Turabian StyleYan, Jin, Hongyi Ma, Qiyu Deng, Hongyun Li, and Lei Xiong. 2025. "A Novel Strategy for Introducing Metal-Organic Frameworks into Carbon Fiber to Improve the Interfacial and Mechanical Properties of Carbon Fiber/Epoxy Composites" Materials 18, no. 21: 4856. https://doi.org/10.3390/ma18214856

APA StyleYan, J., Ma, H., Deng, Q., Li, H., & Xiong, L. (2025). A Novel Strategy for Introducing Metal-Organic Frameworks into Carbon Fiber to Improve the Interfacial and Mechanical Properties of Carbon Fiber/Epoxy Composites. Materials, 18(21), 4856. https://doi.org/10.3390/ma18214856