Multiscale Prediction for Mechanical and Thermal Properties of Needled Composites Considering Pore and Their Application

Abstract

1. Introduction

2. Preparation Process of Specimens

- (1)

- Alternately stacking fiber composite materials such as 0° non-woven fiber cloth, short fiber web cloth and 90° non-woven fiber cloth until a specified thickness was achieved;

- (2)

- Performing needling on the stack surface, during which the carbon fiber preform moved horizontally along the conveyor belt while the needle plate reciprocated vertically at a predetermined frequency;

- (3)

- Rotating the composite stack horizontally by 90° and repeating the needling process to ensure uniform consistency of needle perforations along both the x- and y-axes of the material.

3. Microstructure Observation and Analysis

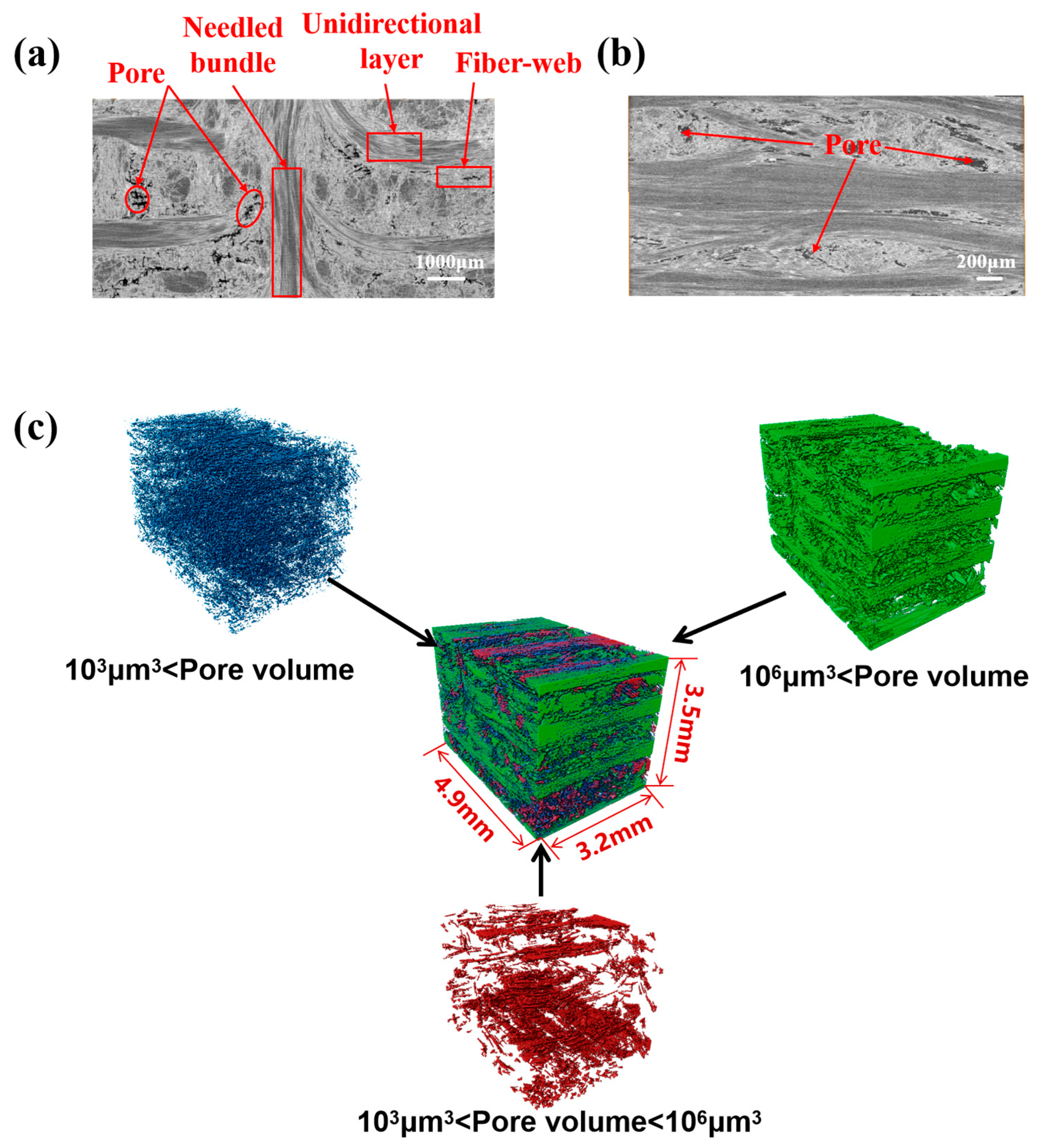

3.1. XCT Observation

3.2. IRT Observation

4. Multiscale Model Construction and Property Prediction

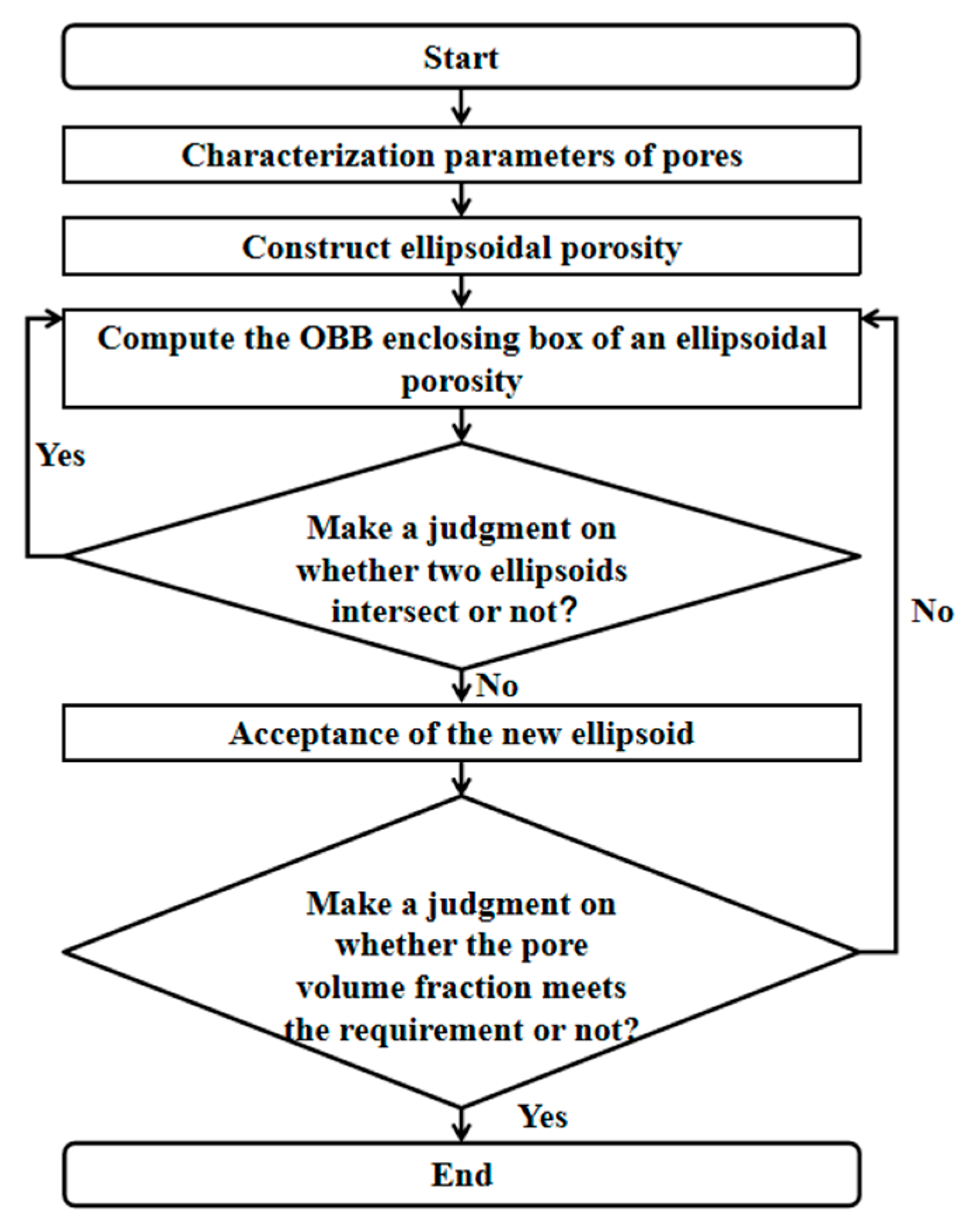

4.1. Multiscale Model Construction

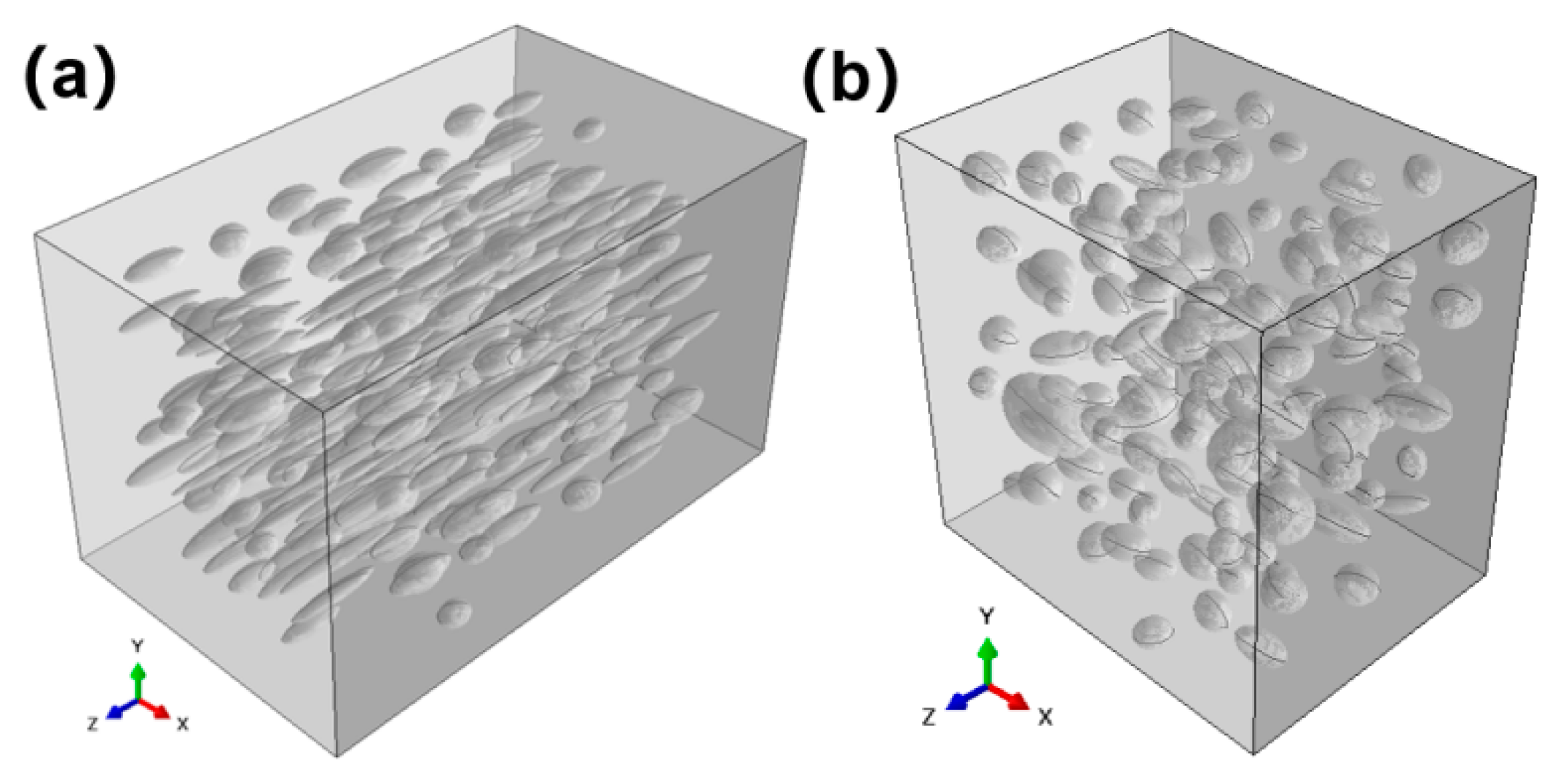

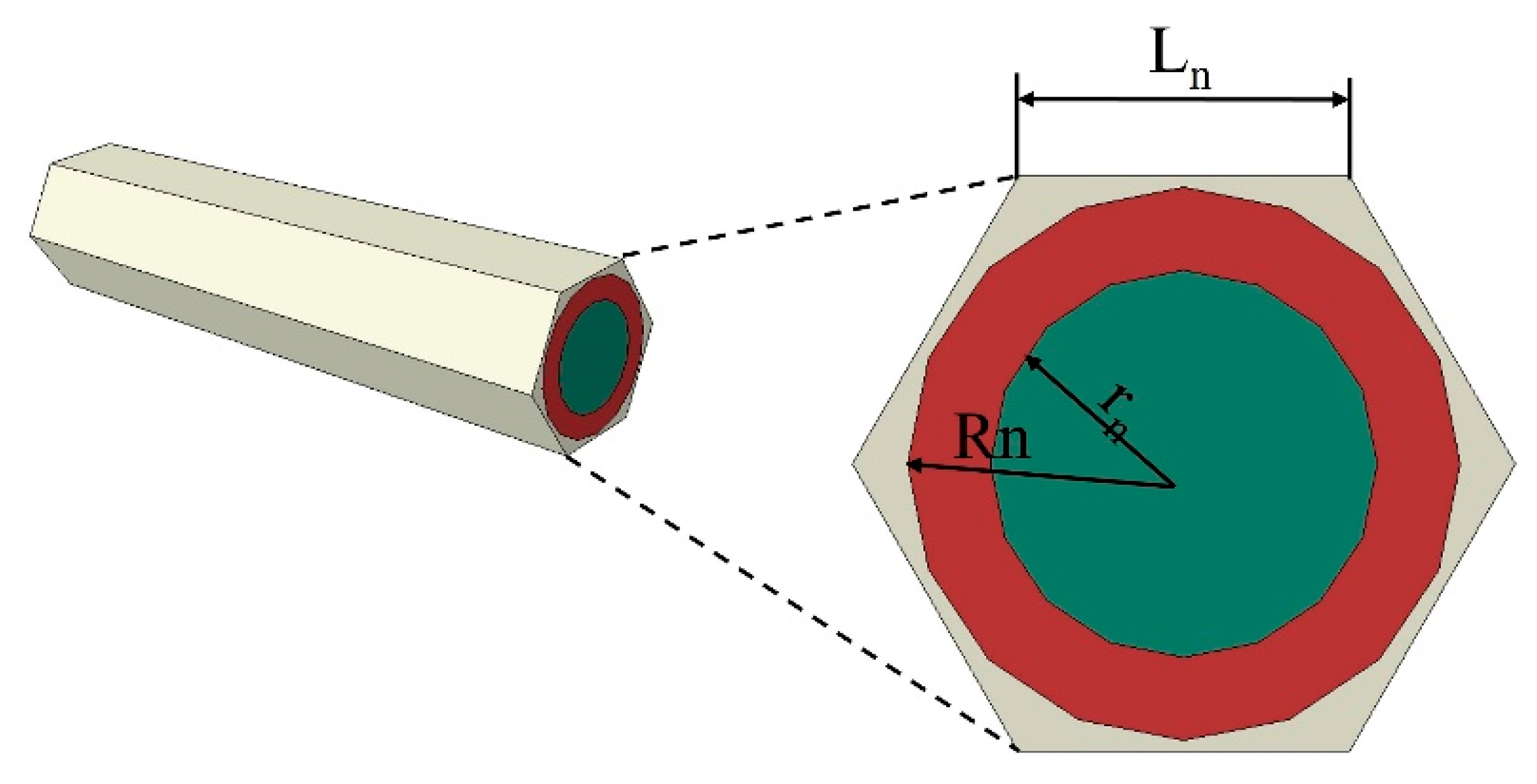

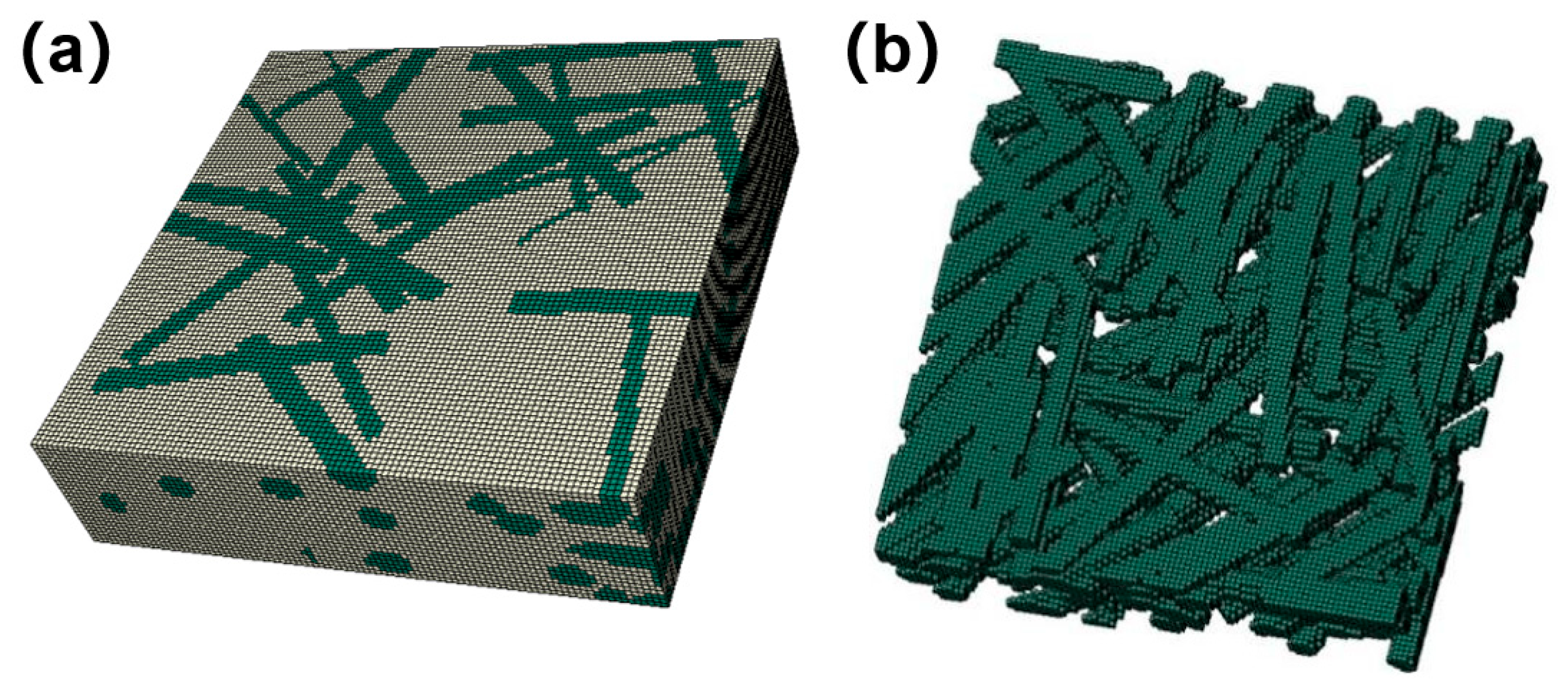

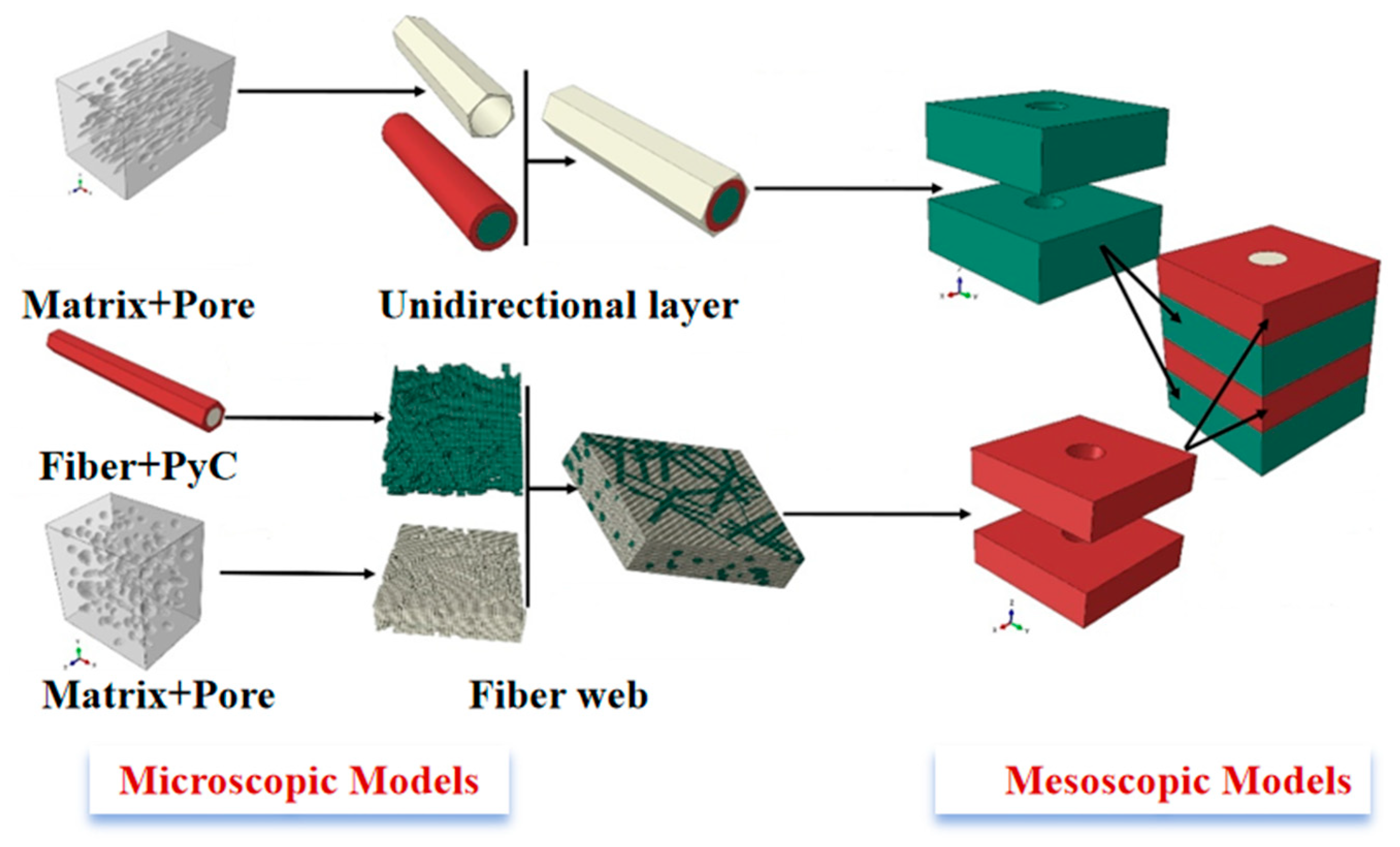

4.1.1. Microscale Model

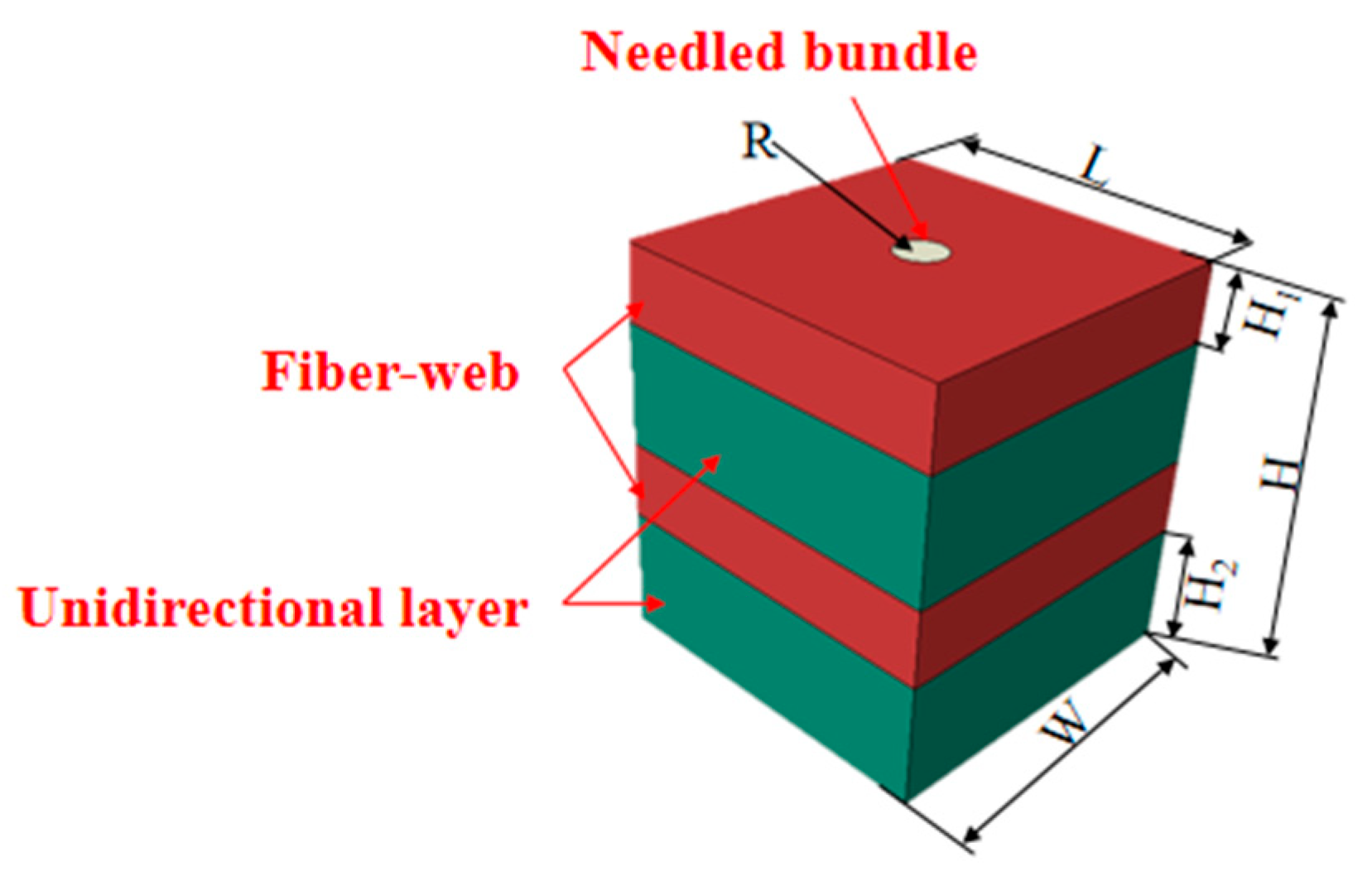

4.1.2. Mesoscale Model

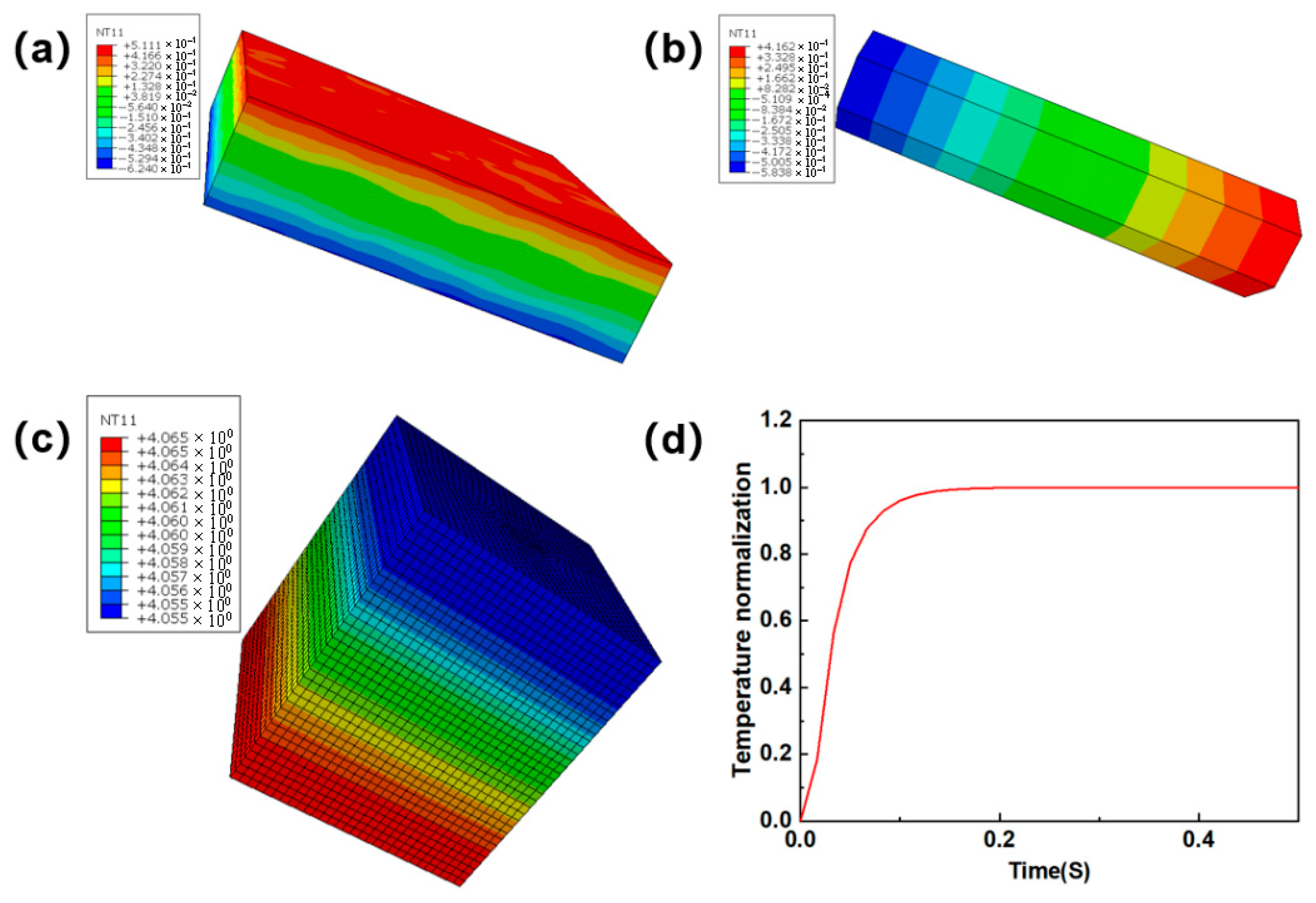

4.2. Property Prediction

5. Results and Discussion

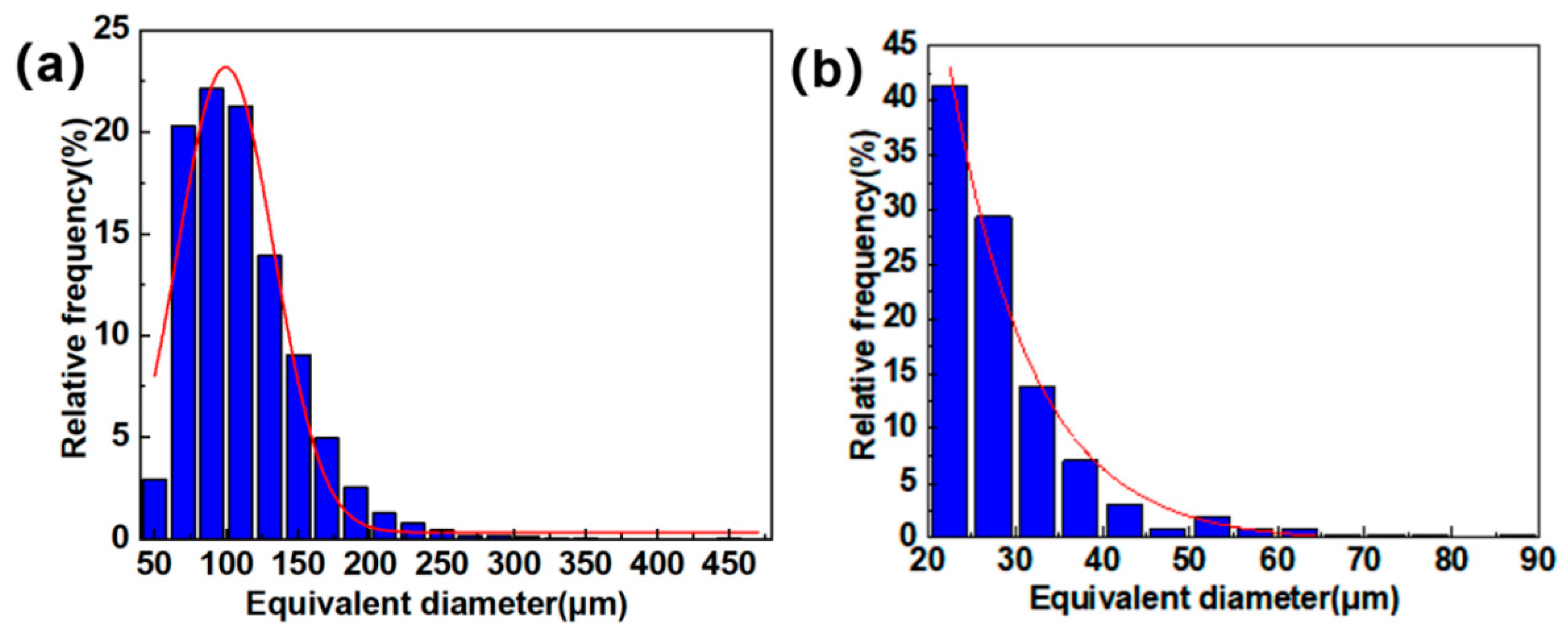

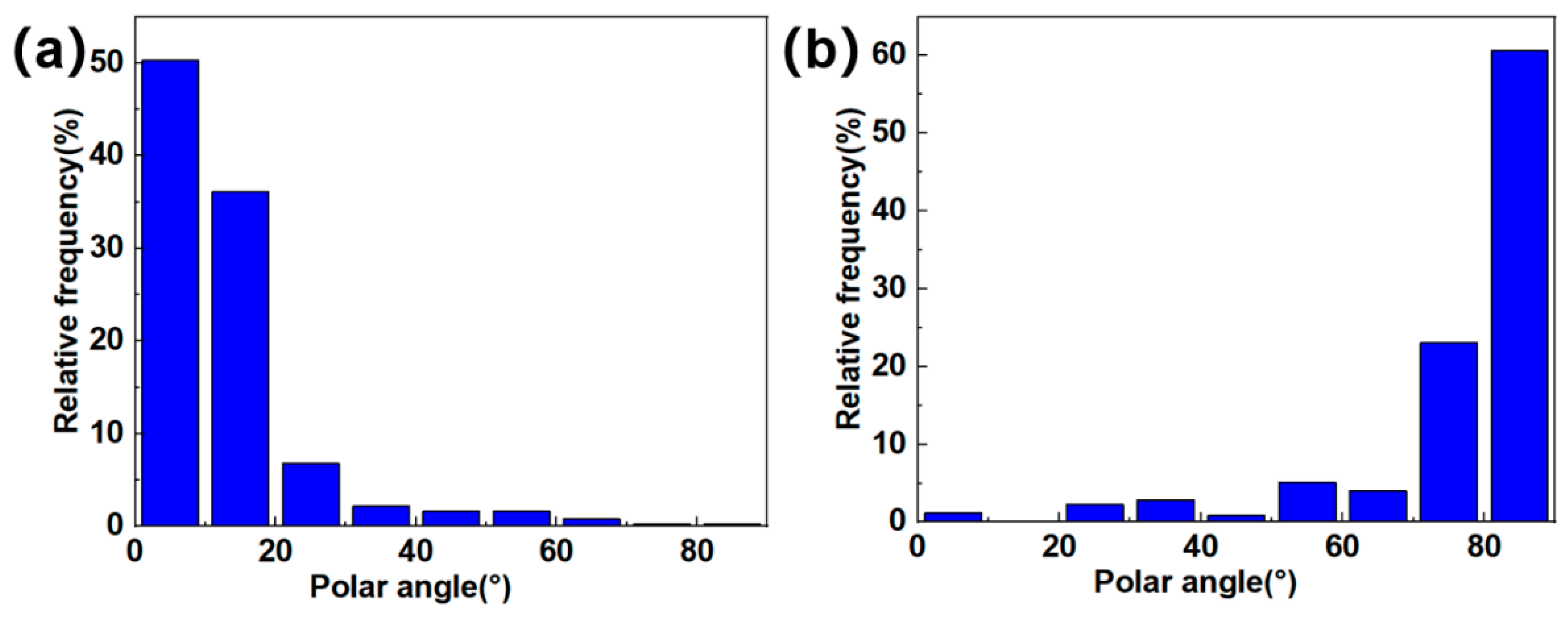

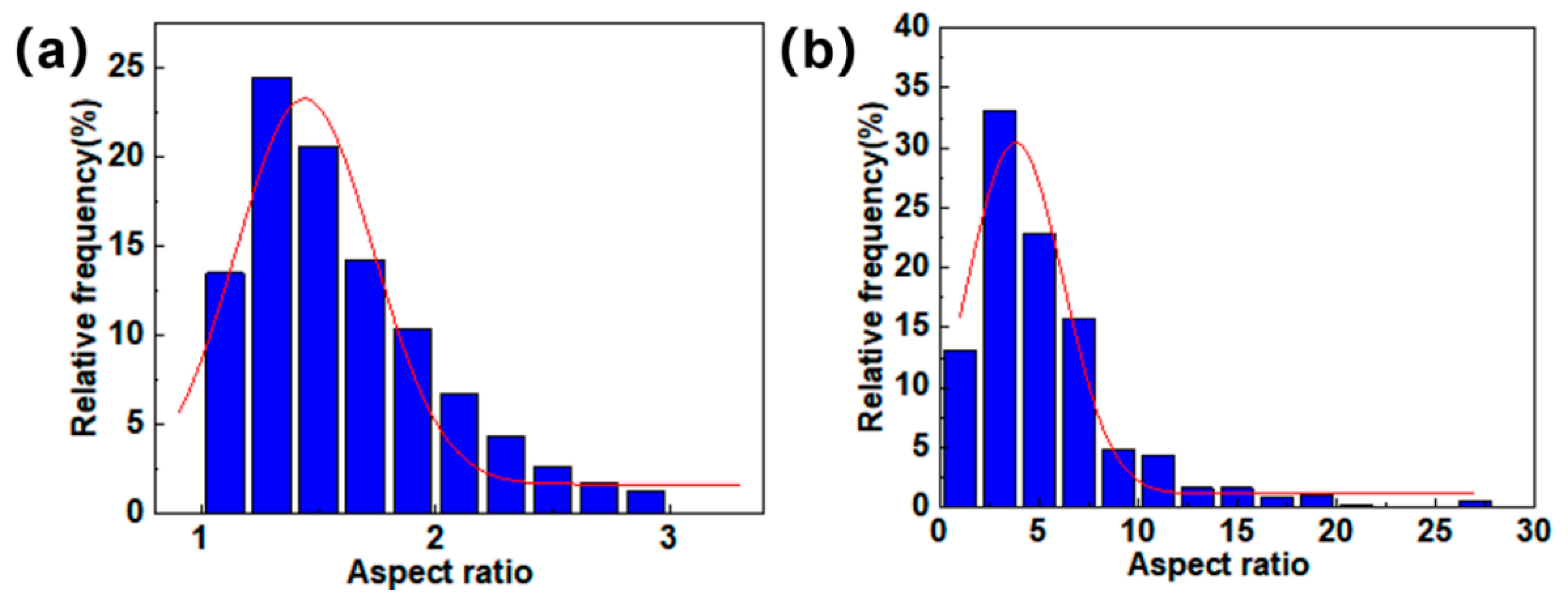

5.1. Defect Analysis and Parameter Characterization

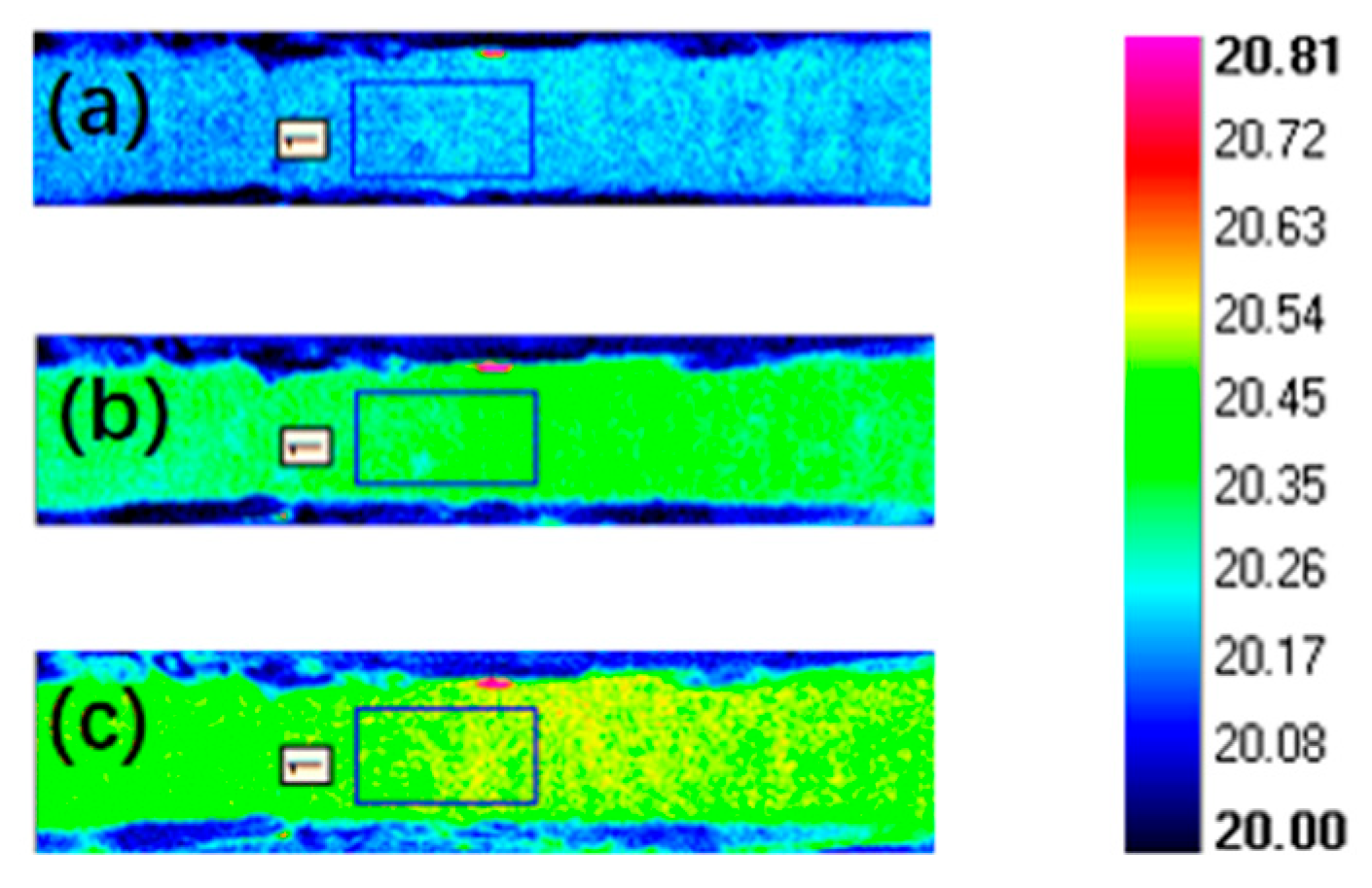

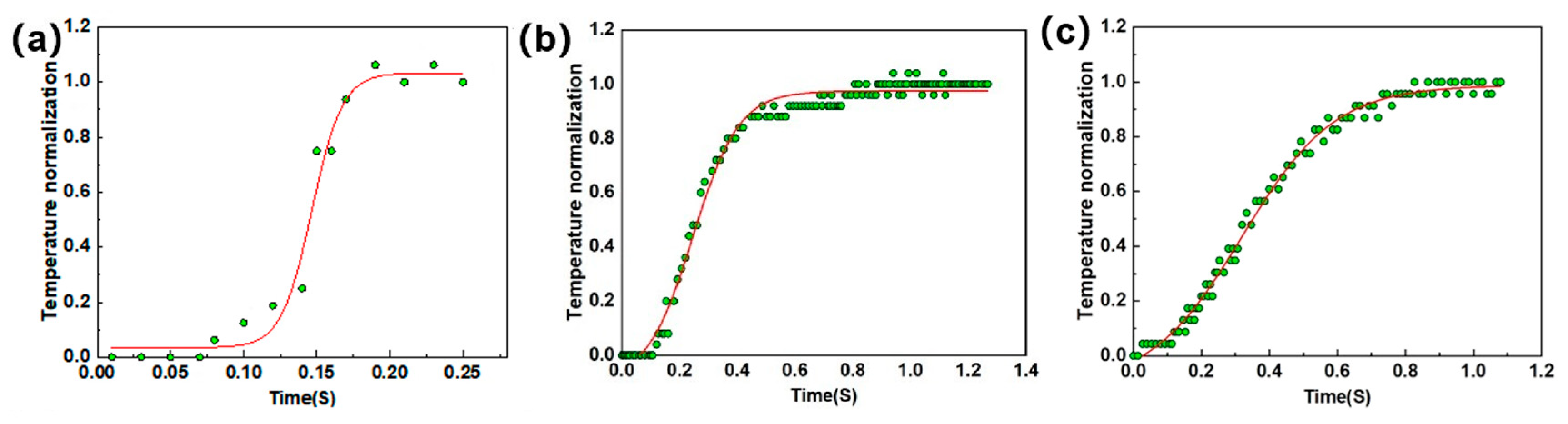

5.2. Thermal Diffusivity Detection

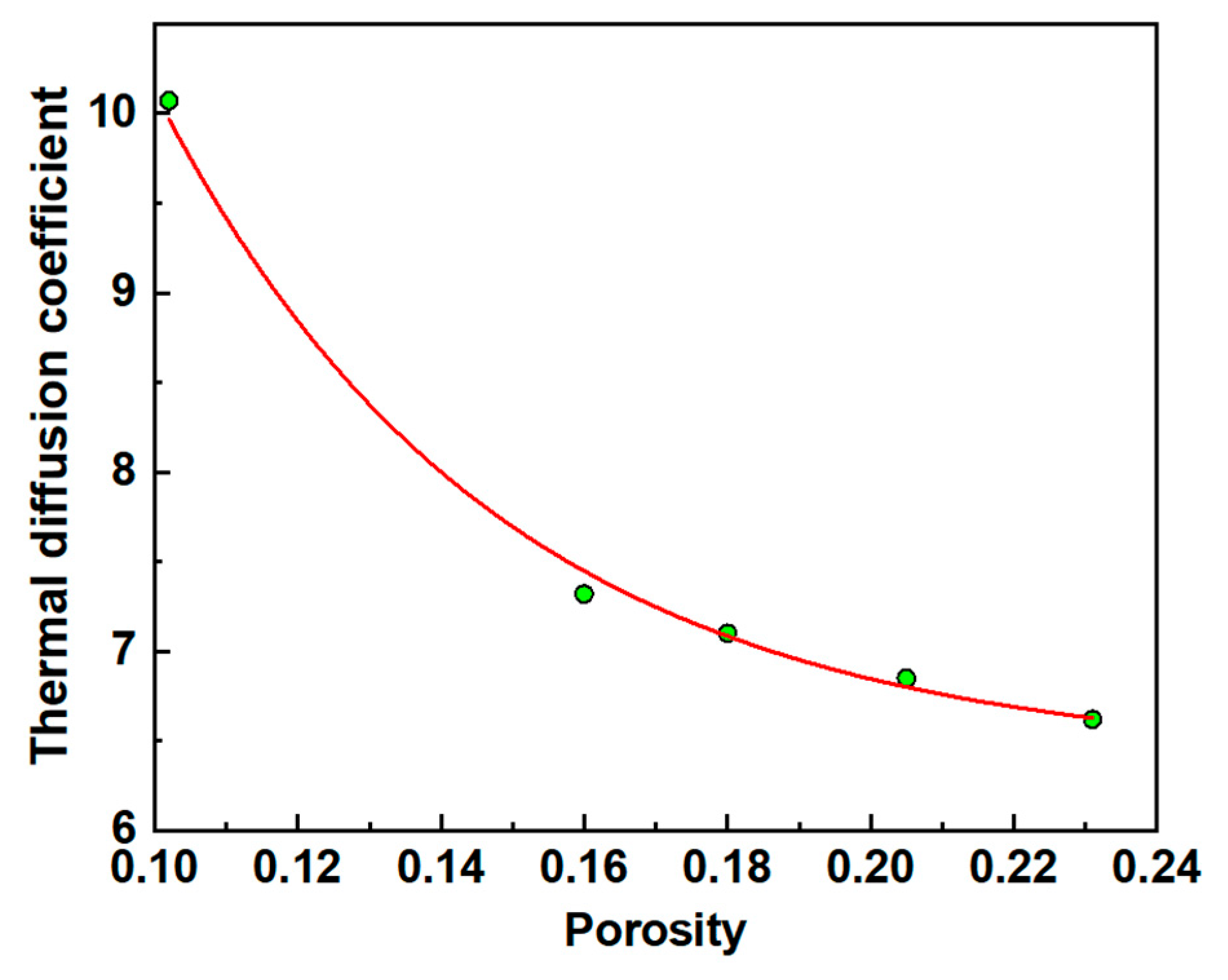

5.3. Thermal Diffusion Coefficient Simulation Analysis

5.4. Elastic Modulus Prediction

5.5. Correlation Analysis and Application

6. Conclusions

- (1)

- The pore shapes and sizes of N-CMCs exhibited strong multiscale characteristics and dispersion. However, due to the various fiber morphologies in different regions, the pore size, direction and aspect ratio corresponded to a certain function distribution.

- (2)

- The multiscale analysis method proposed in this paper, which fully considered the geometric and distributional characteristics of the pores, provided better accuracy in predicting the thermal diffusion coefficients and the elastic modulus. It should be noted that the model developed in this study was primarily validated against laboratory-scale standard specimens. When applied to large components with complex geometries, challenges such as increased blind spots in infrared detection and potential distortions in thermal conduction simulations may arise, which could have a certain impact on the prediction accuracy.

- (3)

- Based on the prediction results, it can be seen that there is a mapping relationship between porosity, thermal diffusion coefficient and elastic modulus. By using IRT to test the thermal diffusion coefficient in combination with the multiscale analysis method, the rapid identification and accurate prediction of the porosity and elastic modulus of the composites can be achieved.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ge, J.; Chao, X.; Tian, W.; Li, W.; Qi, L. Numerical evaluation of temperature-dependent mechanical behaviors of needled carbon/carbon composites from 25 °C to 1200 °C. J. Eur. Ceram. Soc. 2026, 46, 117818. [Google Scholar] [CrossRef]

- Quan, H.; Wang, L.; Huang, J.; Luo, H.; Zheng, K.; Yang, H.; Yang, X.; Dong, X.; Cui, G.; Song, J.; et al. Durable protection and failure mechanism of the multilayer coating system for SiCf/SiC composites under high-temperature oxidation. Compos. Part B Eng. 2022, 244, 110197. [Google Scholar] [CrossRef]

- Wang, R.; He, C.; Zhang, J.; Zhang, J.; Fei, J.; Fu, Q. 2.5D woven vs. 2.5D needled Preforms: Influencing microstructure evolution, mechanical properties and ablation behavior in C/C–ZrC–SiC based composites. Compos. Part B Eng. 2025, 307, 112908. [Google Scholar] [CrossRef]

- Hou, G.; Shang, D.G.; Zuo, L.X.; Qu, L.F.; Xia, M.; Wu, S.D.; Yin, X. Fatigue life prediction approach for through-hole of needled ceramic matrix composite based on volume fraction. Ceram. Int. 2023, 49, 34269–34276. [Google Scholar] [CrossRef]

- Zhang, P.; Yang, C.; Tong, Y.; Yin, L.; Hu, Y.; Liang, X.; Li, Y.; Zhang, Z. Multi-scale modeling and tensile failure prediction of 3D needled C/C–SiC composites considering real microstructure. J. Mater. Res. Technol. 2023, 25, 120–137. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, H.; Dong, S.; Zhao, X.; Peng, Y.; Chen, J. Progressive failure analysis of needle-punched C/SiC composites based on multiscale finite element model. Compos. Struct. 2023, 310, 116774. [Google Scholar] [CrossRef]

- Liang, C.; Gao, X.; Fu, L.; Mei, H.; Cheng, L.; Zhang, L. Pore evolution and mechanical response under locally varying density defects in ceramic matrix composites. Compos. Part B Eng. 2024, 279, 111459. [Google Scholar] [CrossRef]

- Mei, H.; Tan, Y.F.; Chen, T. Designable density defect influencing the mechanical property of 3D needled C/SiC composites. J. Alloys Compd. 2019, 806, 1453–1464. [Google Scholar] [CrossRef]

- Gowayed, Y.; Ojard, G.; Prevost, E.; Santhosh, U.; Jefferson, G. Defects in ceramic matrix composites and their impact on elastic properties. Compos. Part B Eng. 2013, 55, 167–175. [Google Scholar] [CrossRef]

- Lim, H.J.; Choi, H.; Lee, M.J.; Yun, G.J. An efficient multiscale model for needle-punched Cf/SiCm composite materials with experimental validation. Compos. Part B Eng. 2021, 217, 108890. [Google Scholar] [CrossRef]

- Ge, L.; Li, H.M.; Zhong, J.H.; Zhang, C.; Fang, D.N. Micro-CT based trans-scale damage analysis of 3D braided composites with pore defects. Compos. Sci. Technol. 2021, 211, 108830. [Google Scholar] [CrossRef]

- Li, Y.H.; Ma, Y.; Guan, T.H.; Wang, Z.; Zhang, C.; Suo, T. A meso-scale stochastic model for tensile behavior of 2D woven ceramic composites considering void defects and stacking mode. Compos. Part A Appl. Sci. Manuf. 2024, 176, 107838. [Google Scholar] [CrossRef]

- Wang, J.L.; Yang, R.; Qu, L.F.; Li, H.L.; Sun, S.Y. A cross-scale method for predicting equivalent elastic constants of needled C/SiC composite considering manufacturing defects. J. Reinf. Plast. Compos. 2023, 44, 419–431. [Google Scholar] [CrossRef]

- Han, M.; Zhou, C.W.; Zhang, H.J. A mesoscale beam-spring combined mechanical model of needle-punched carbon/carbon composite. Compos. Sci. Technol. 2018, 168, 371–380. [Google Scholar] [CrossRef]

- Wang, G.Q.; Zhou, C.W.; Yu, J.; Ni, Y.; Li, X.; Zhang, Z.X. Mechanical model of needle-punched (NP) carbon/carbon (C/C) composites with isogeometric beams-extended springs at mesoscale. Compos. Struct. 2023, 318, 117038. [Google Scholar] [CrossRef]

- Mayr, G.; Plank, B.; Sekelja, J.; Hendorfer, G. Active thermography as a quantitative method for non-destructive evaluation of porous carbon fiber reinforced polymers. NDT Int. 2011, 44, 537–543. [Google Scholar] [CrossRef]

- Gao, Y.; Gao, M.; Wang, F.; Liu, J.; Yang, F.; Sheng, J.; Chen, M.; Wang, Y.; Yue, H. Convolution neural network fusion high power halogen lamp induced thermal-wave diffusion multidimensional features: An intelligent defect identification approach for aviation honeycomb sandwich composites. Infrared Phys. Technol. 2023, 133, 104772. [Google Scholar] [CrossRef]

- Zhang, D.D.; Ren, J.J.; Gu, J.; Li, L.J.; Zhang, J.Y.; Xiong, W.H.; Zhong, Y.F.; Zhou, T.Y. Nondestructive testing of bonding defects in multilayered ceramic matrix composites using THz time domain spectroscopy and imaging. Compos. Struct. 2020, 251, 112624. [Google Scholar] [CrossRef]

- Roy, S.; Gebert, J.M.; Stasiuk, G.; Piat, R.; Weidenmann, K.A.; Wanner, A. Complete determination of elastic moduli of interpenetrating metal/ceramic composites using ultrasonic techniques and micromechanical modelling. Mater. Sci. Eng. A-Struct. 2011, 528, 8226–8235. [Google Scholar] [CrossRef]

- Gao, X.G.; Wei, T.T.; Dong, H.N.; Song, Y.D. Damage detection in 2.5D C/SiC composites using electrical resistance tomography. J. Eur. Ceram. Soc. 2019, 39, 3583–3593. [Google Scholar] [CrossRef]

- Goulmy, J.P.; Caty, O.; Rebillat, F. Characterization of the oxidation of C/C/SiC composites by X-ray micro-tomography. J. Eur. Ceram. Soc. 2020, 40, 5120–5131. [Google Scholar] [CrossRef]

- Galizia, P.; Sciti, D.; Binner, J.; Venkatachalam, V.; Lagos, M.; Servadei, F.; Vinci, A.; Zoli, L.; Reimer, T. Elevated temperature tensile and bending strength of ultra-high temperature ceramic matrix composites obtained by different processes. J. Eur. Ceram. Soc. 2023, 43, 4588–4601. [Google Scholar] [CrossRef]

- Parker, W.J.; Jenkins, R.J.; Butler, C.P.; Abbott, G.L. Flash method of determining thermal diffusivity, heat capacity, and thermal conductivity. J. Appl. Phys. 1961, 32, 1679–1684. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, H.; Dong, S.; Zhao, X.; Peng, Y.; Chen, J. Multiscale model construction and modulus prediction of needle-punched carbon/carbon composites. Polym. Compos. 2023, 31, 1–12. [Google Scholar] [CrossRef]

- Rumayshah, K.K.; Dirgantara, T.; Judawisastra, H.; Wicaksono, S. Numerical micromechanics model of carbon fiber-reinforced composite using various periodical fiber arrangement. J. Mech. Sci. Technol. 2021, 35, 1401–1406. [Google Scholar] [CrossRef]

- Huang, H.; Hadigheh, S.A.; Baghaei, K.A. Influences of fibre shape on the transverse modulus of unidirectional fibre reinforced composites using finite element and machine learning methods. Compos. Struct. 2023, 312, 116872. [Google Scholar] [CrossRef]

| Voltage (kV) | Electricity (μA) | Angle (°) | Exposure Time (ms) | Pixel Size (μm) |

|---|---|---|---|---|

| 50.0 | 90 | 5.32 | 1000 | 5.0 |

| Porosity | Thickness (mm) | t1/2 (s) | Thermal Diffusion Coefficient (mm2/s) |

|---|---|---|---|

| 10% | 3.60 | 0.175 | 10.36 |

| 20.5% | 3.63 | 0.27 | 6.82 |

| 23% | 3.61 | 0.30 | 6.07 |

| Properties | Longitudinal Thermal Conductivity W/(m·K) | Transverse Thermal Conductivity W/(m·K) | Specific Thermal (J/kg·K) | Density kg/m3 |

|---|---|---|---|---|

| Carbon fiber | 9.4 | 3.6 | 752 | 1800 |

| Matrix | 23.4 | 700 | 3200 | |

| Pyrolysis carbon | 25 | 717 | 1800 | |

| Pore | 0.023 | 1005 | 1.29 | |

| Porosity | Thermal Diffusion Coefficient (mm2/s) | Experimental Value (mm2/s) | Error |

|---|---|---|---|

| 10% | 10.07 | 10.36 | 2.85% |

| 23% | 6.62 | 6.07 | 9.06% |

| Model | E1/(GPa) | E2/(GPa) | E3/(GPa) |

|---|---|---|---|

| Fiber-web layers | 56.76 | 52.52 | 58.90 |

| Unidirectional layers | 111.56 | 16.09 | 14.19 |

| RVE model | 55.96 | 52.92 | 26.09 |

| Experiment value | 57.76 |

| Porosity | E1 (GPa) | E2 (GPa) |

|---|---|---|

| Fiber-web layers | 40.77 | 31.01 |

| Unidirectional layers | 81.24 | 8.38 |

| RVE model | 39.56 | 35.55 |

| Experiment value | 40.69 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, S.; Wang, J.; Li, H.; Yang, R.; Zhou, L. Multiscale Prediction for Mechanical and Thermal Properties of Needled Composites Considering Pore and Their Application. Materials 2025, 18, 4855. https://doi.org/10.3390/ma18214855

Sun S, Wang J, Li H, Yang R, Zhou L. Multiscale Prediction for Mechanical and Thermal Properties of Needled Composites Considering Pore and Their Application. Materials. 2025; 18(21):4855. https://doi.org/10.3390/ma18214855

Chicago/Turabian StyleSun, Shiyong, Junlong Wang, Hailin Li, Rui Yang, and Liming Zhou. 2025. "Multiscale Prediction for Mechanical and Thermal Properties of Needled Composites Considering Pore and Their Application" Materials 18, no. 21: 4855. https://doi.org/10.3390/ma18214855

APA StyleSun, S., Wang, J., Li, H., Yang, R., & Zhou, L. (2025). Multiscale Prediction for Mechanical and Thermal Properties of Needled Composites Considering Pore and Their Application. Materials, 18(21), 4855. https://doi.org/10.3390/ma18214855