Cement-Based Grouting Materials Modified with GO/NS Hybrids

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

- 1.

- Cement:

- 2.

- Nano-silica (NS):

- 3.

- Graphene oxide (GO):

- 4.

- Superplasticizer:

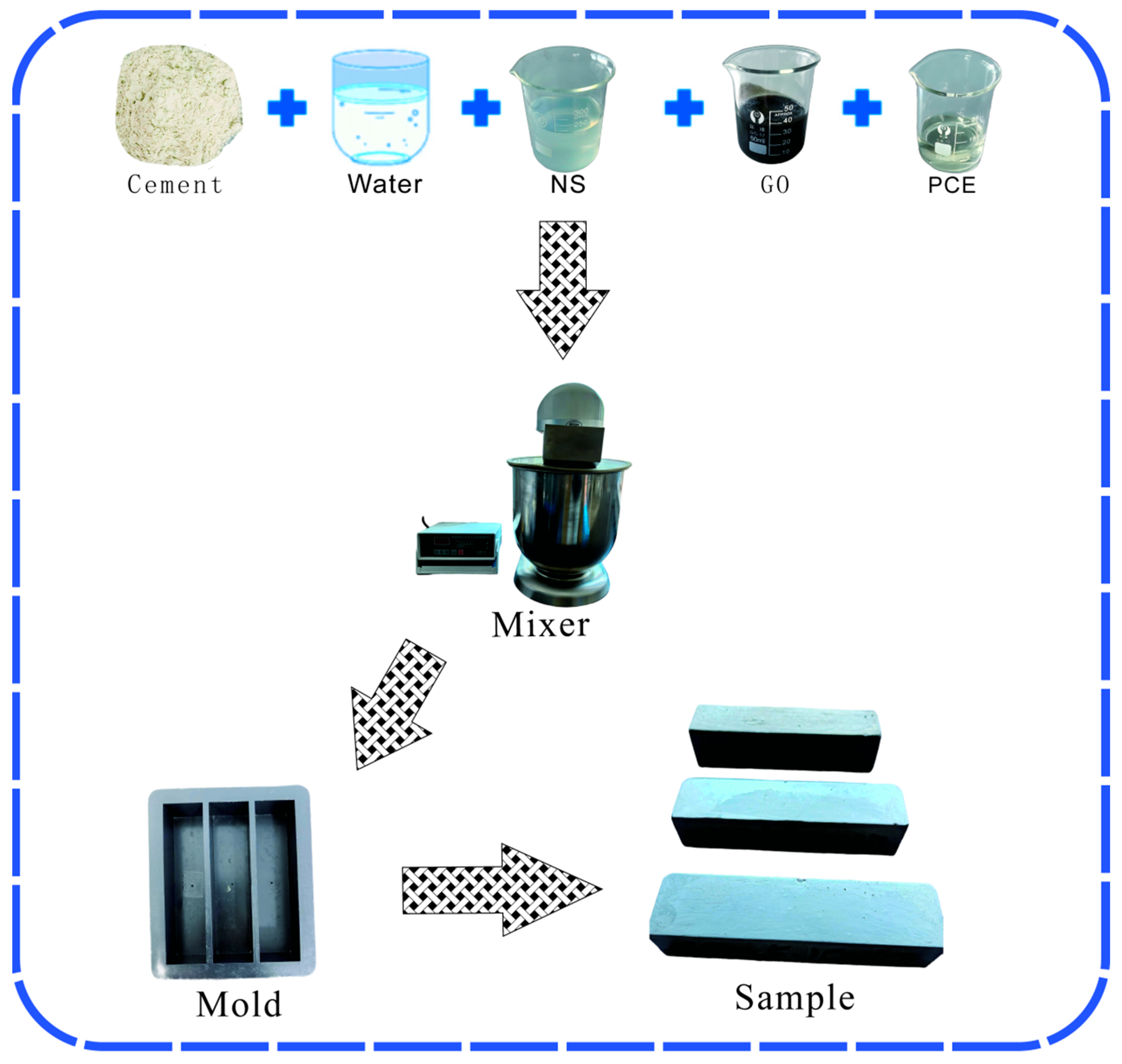

2.2. Sample Preparation

2.3. Testing Methods

- 1.

- Setting Time

- 2.

- Fluidity (Flowability)

- 3.

- Bleeding Rate

- 4.

- Mechanical Properties

- 5.

- Scanning Electron Microscopy (SEM)

- 6.

- X-ray Diffraction (XRD)

- 7.

- Fourier-Transform Infrared Spectroscopy (FTIR)

- 8.

- Mercury Intrusion Porosimetry (MIP)

3. Results and Discussion

3.1. Fresh State Properties

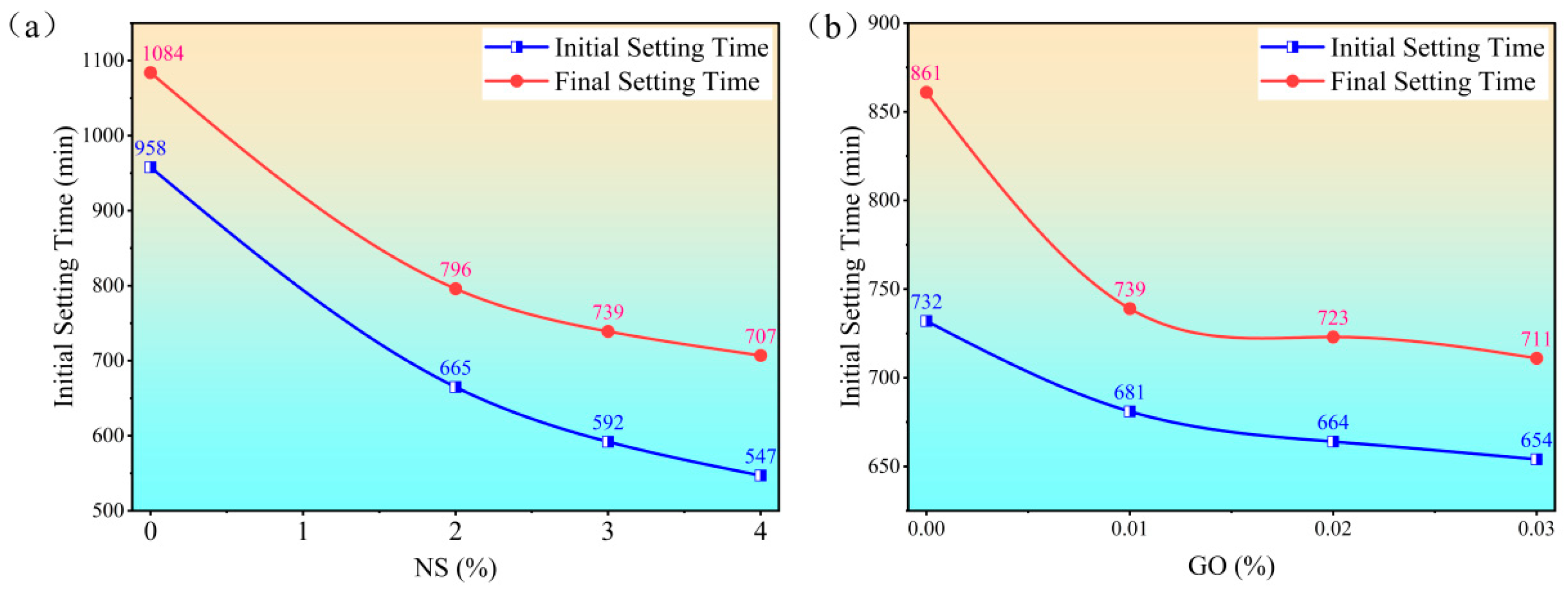

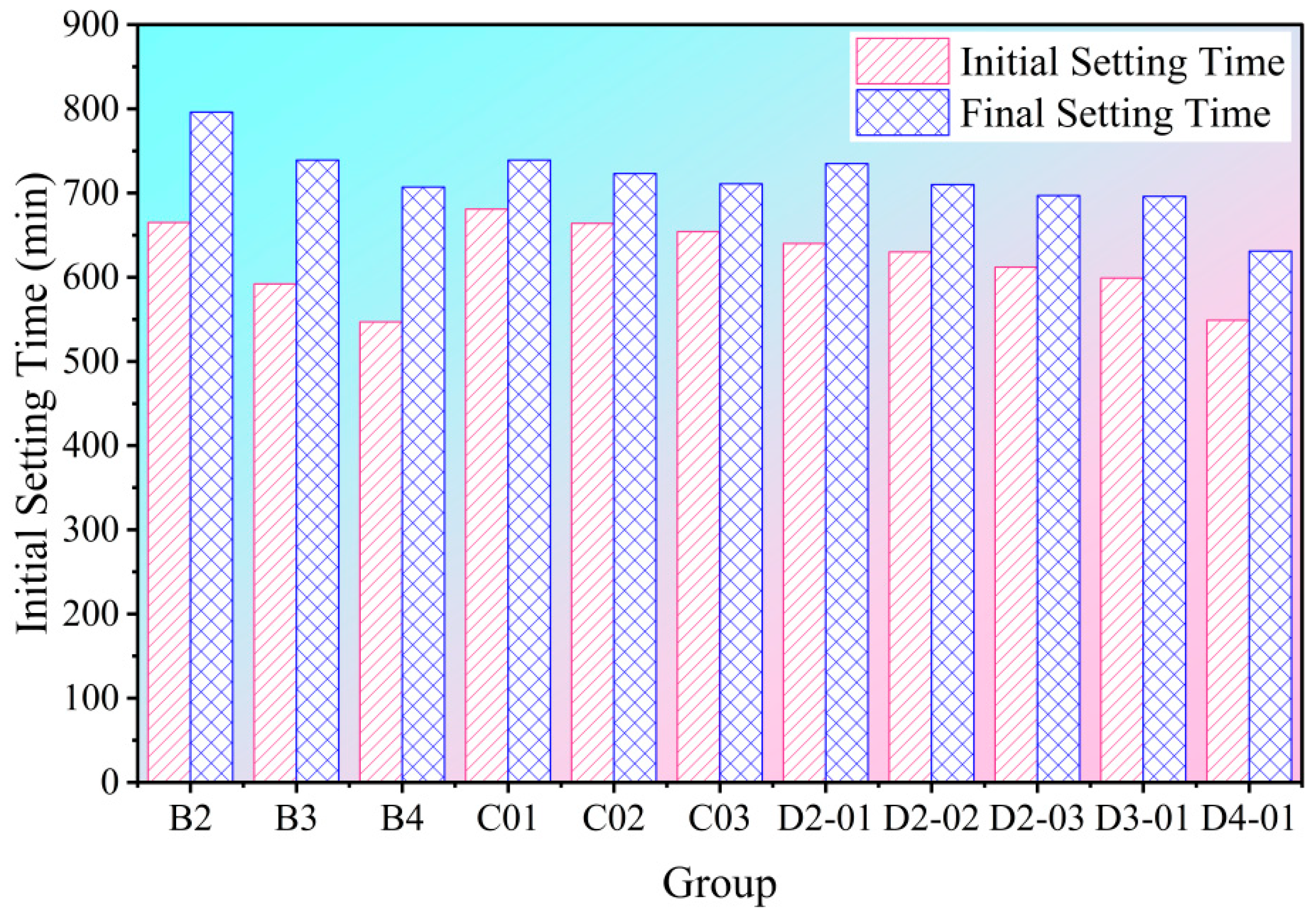

3.1.1. Setting Time

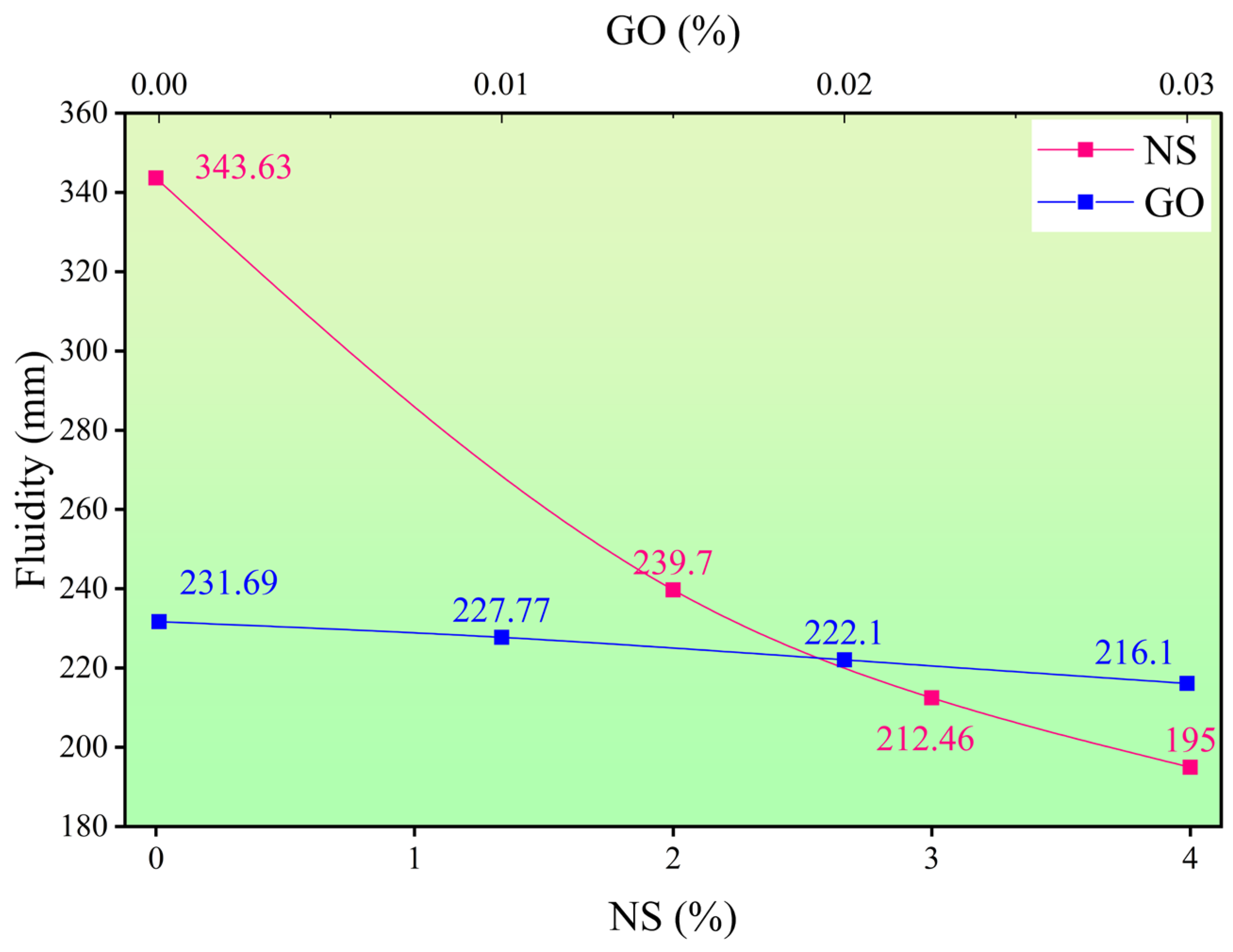

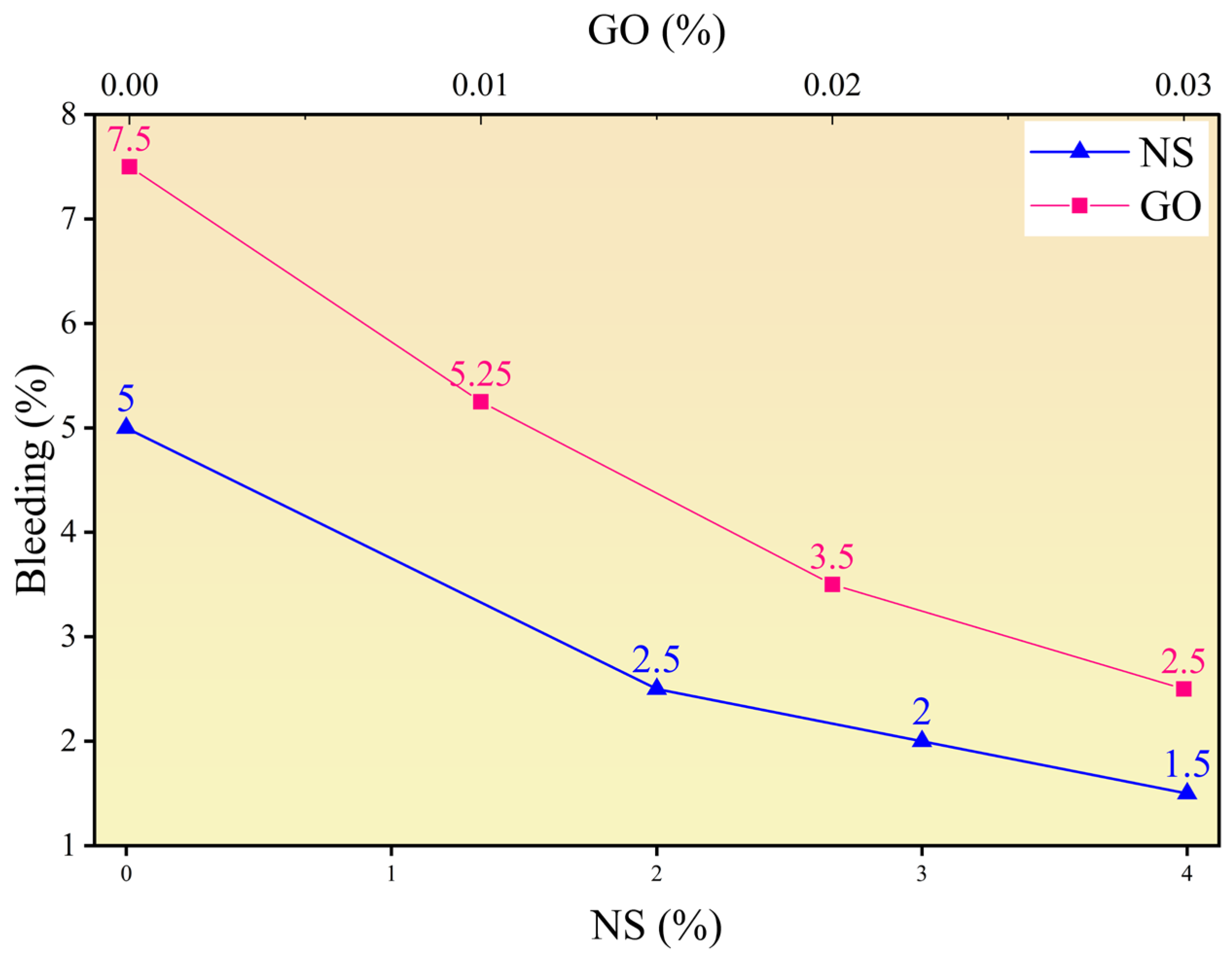

3.1.2. Bleeding Rate and Fluidity

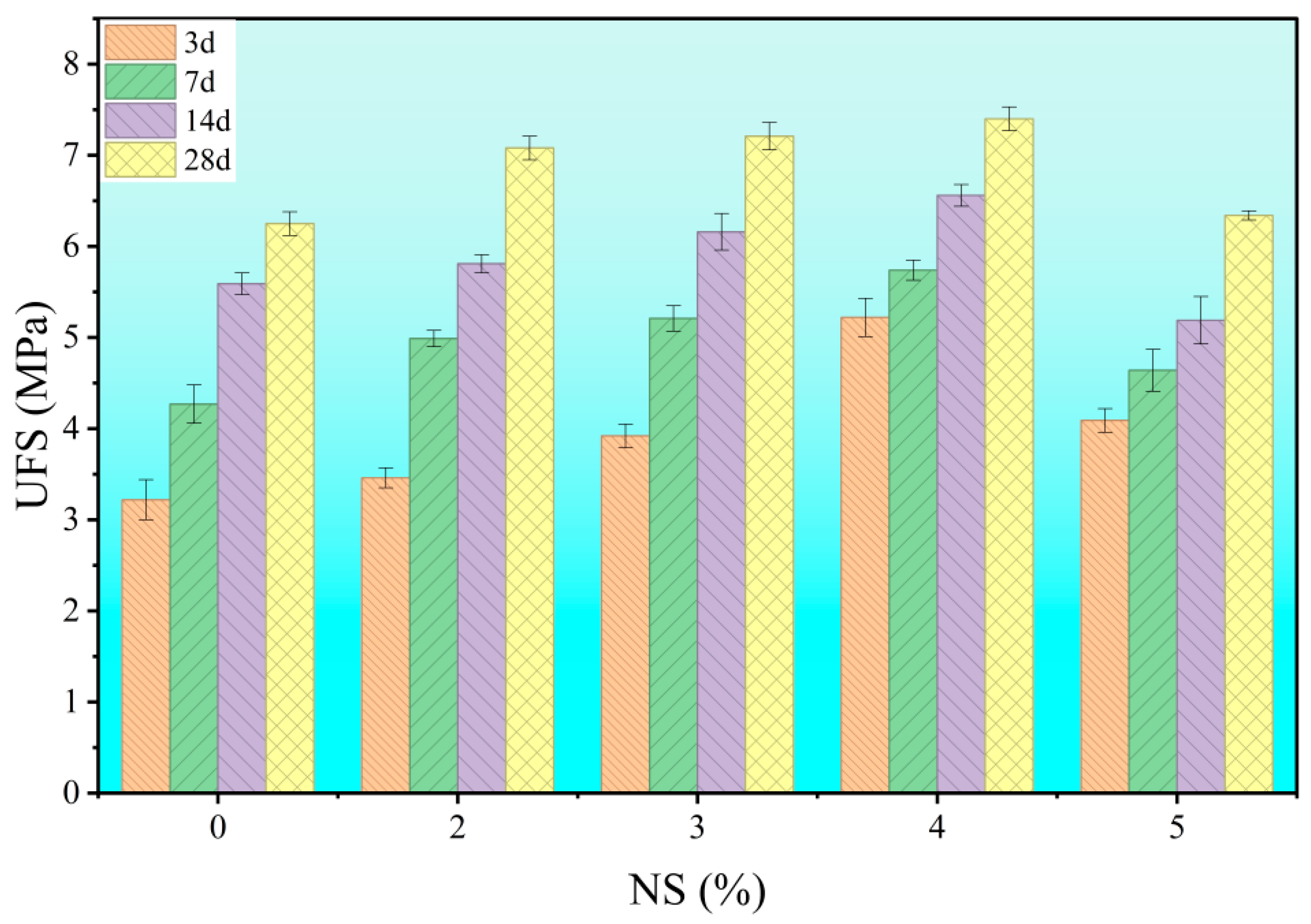

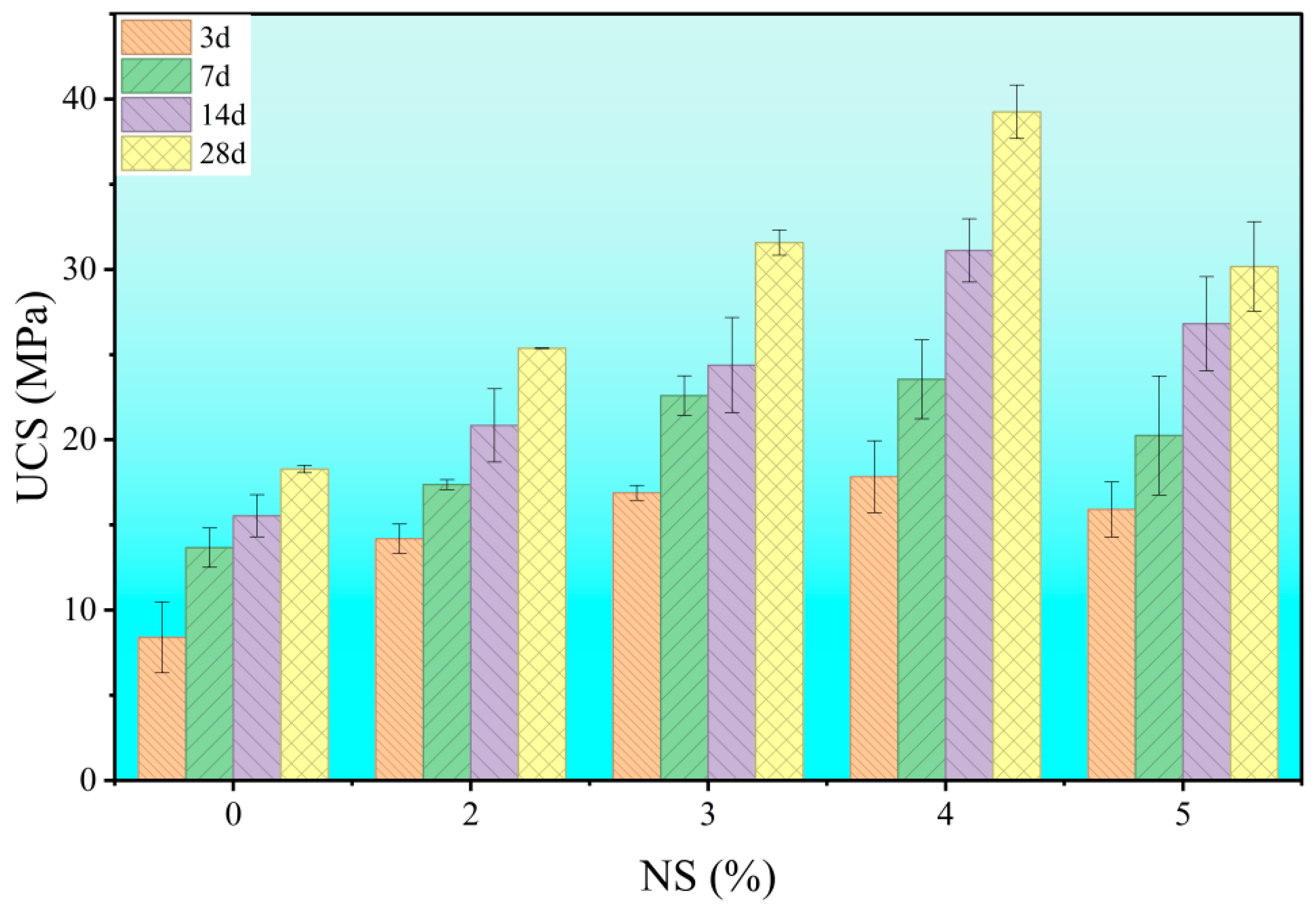

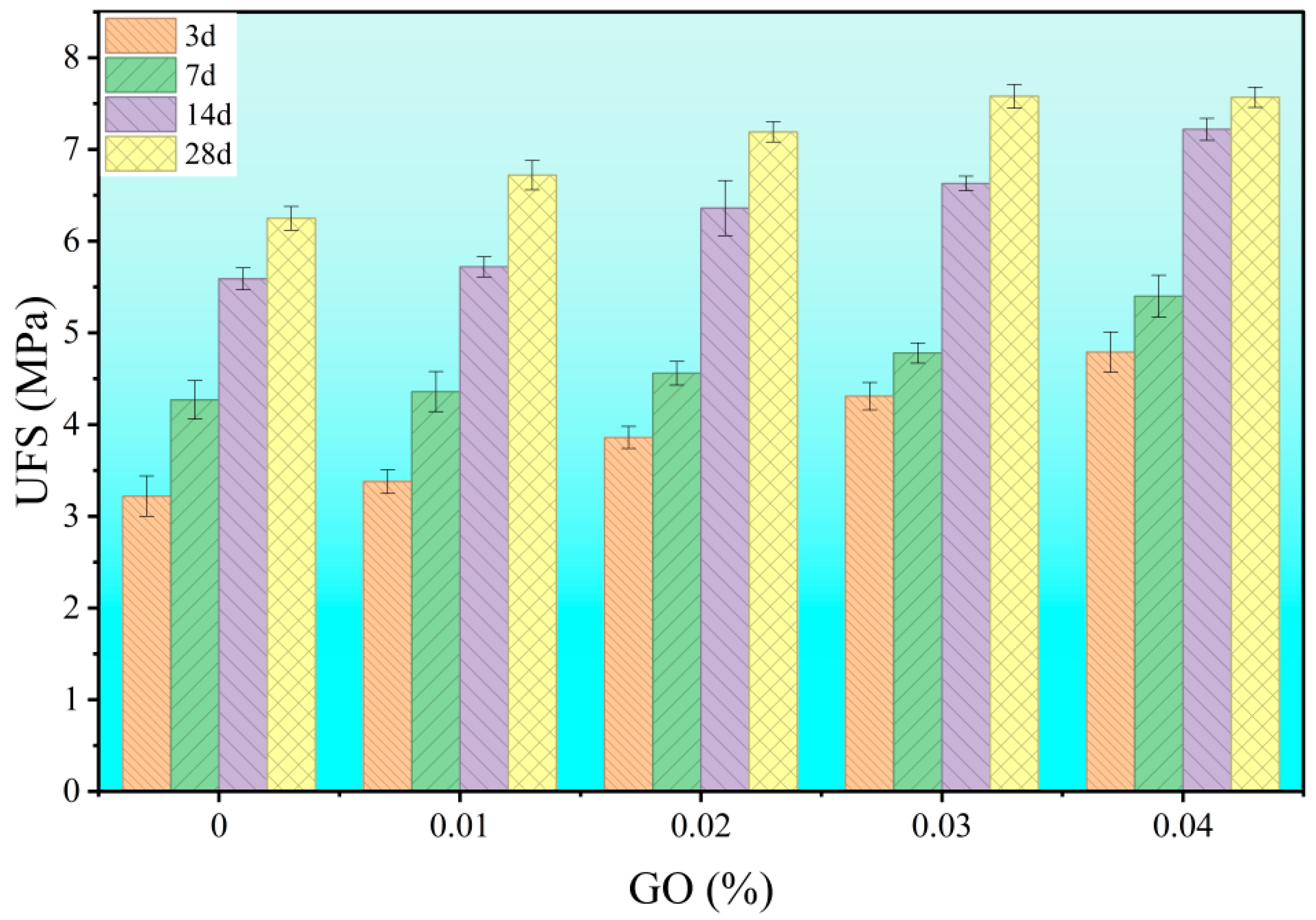

3.2. Mechanical Properties

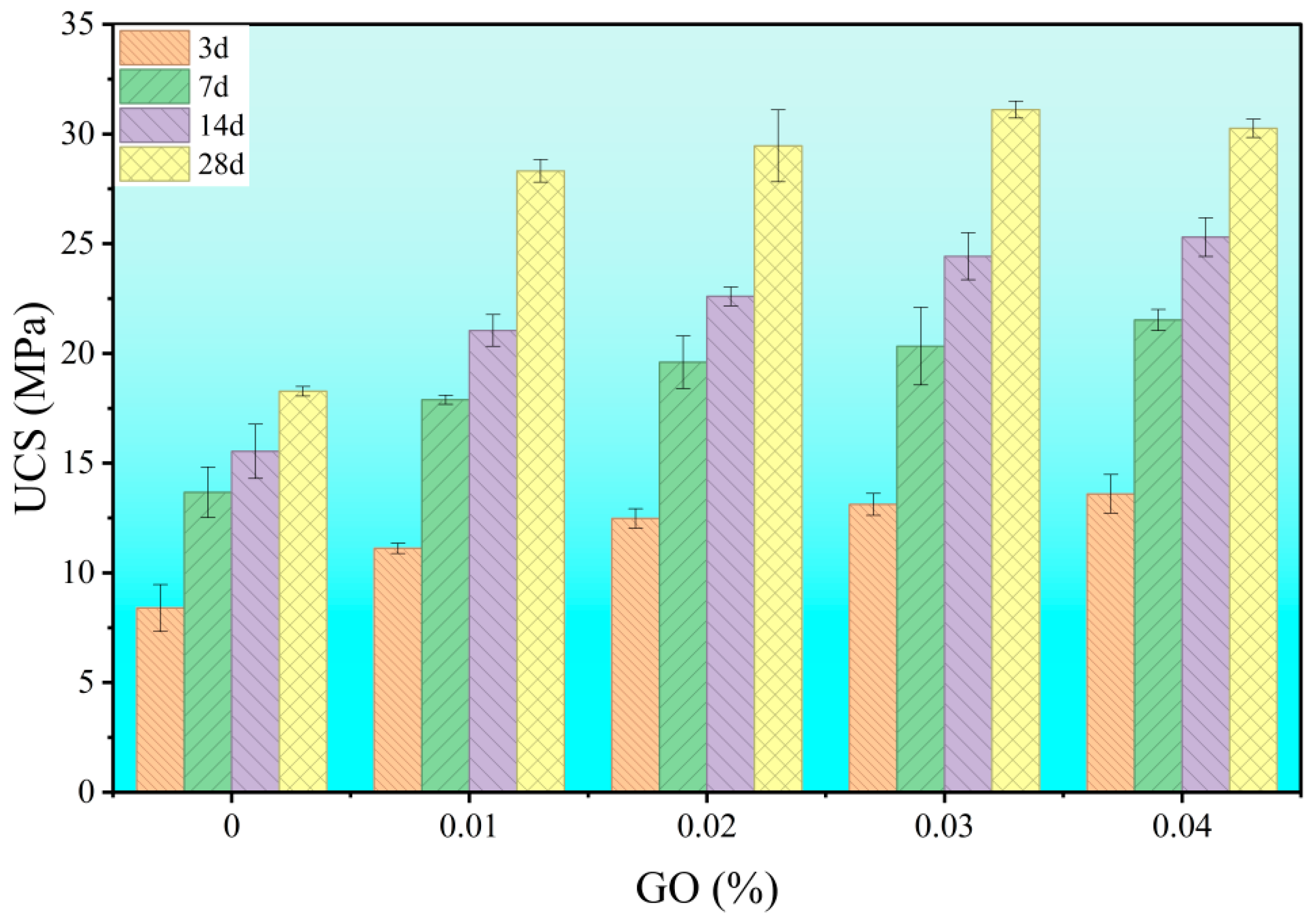

3.2.1. Effect of NS and GO

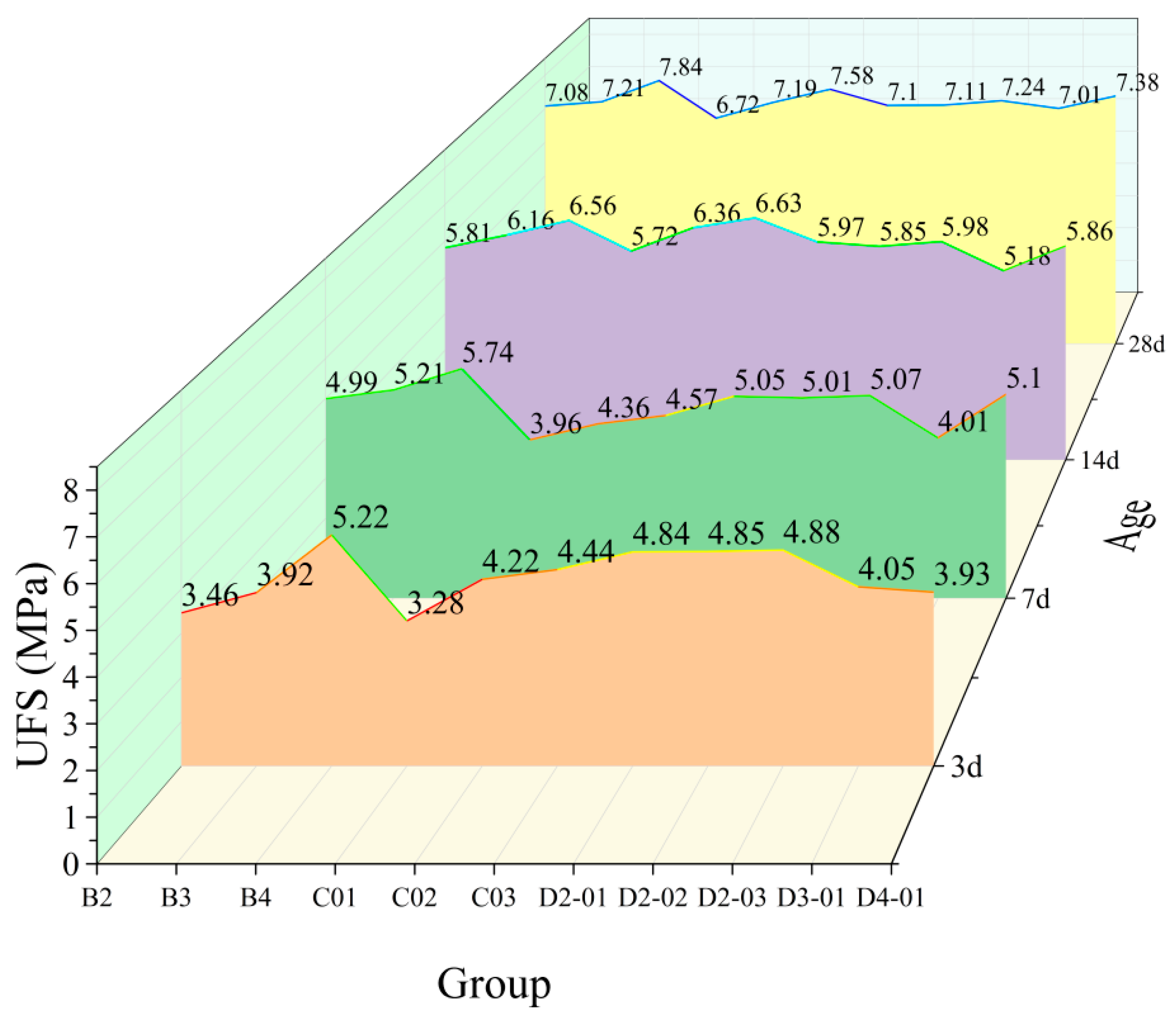

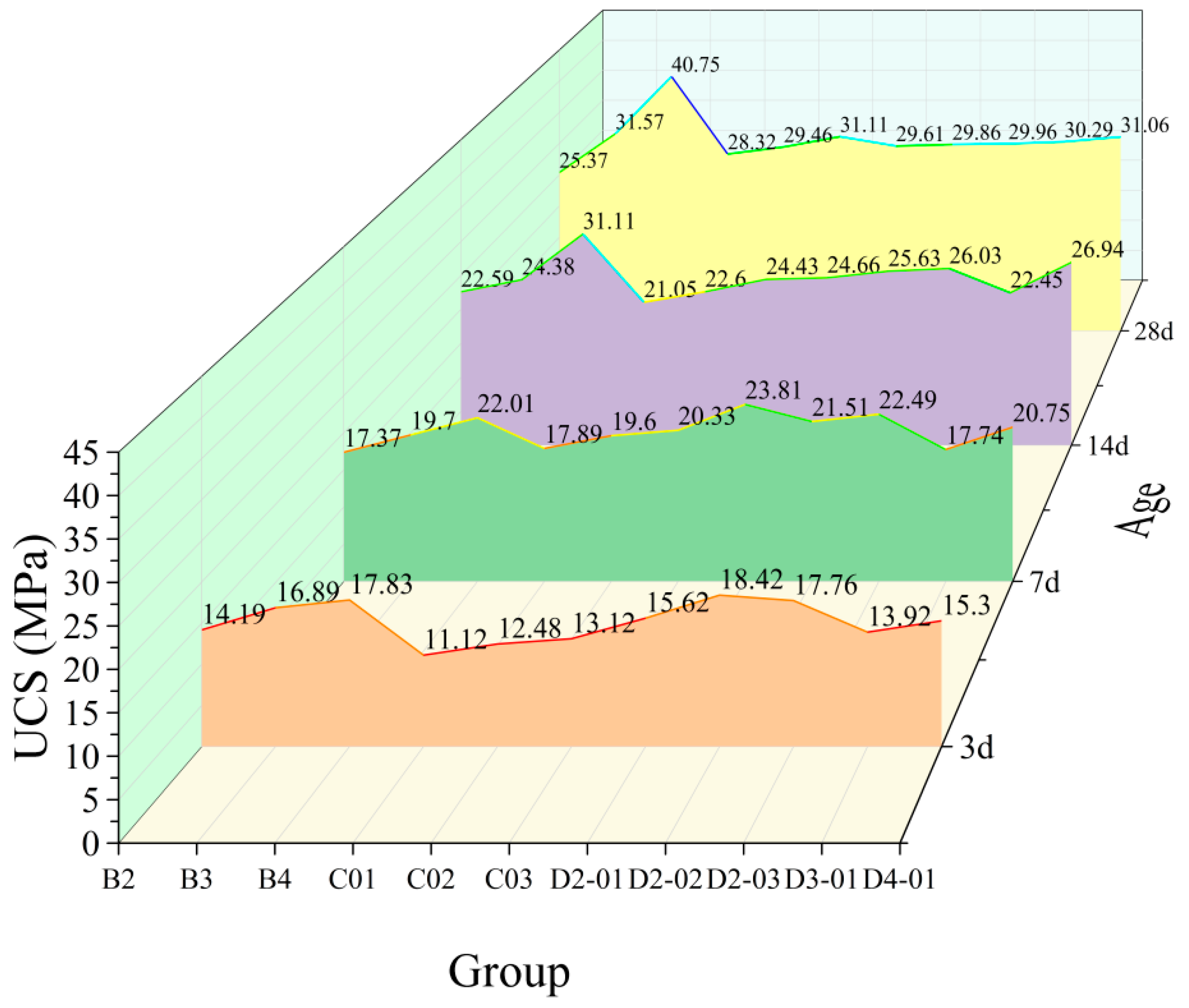

3.2.2. Effect of NS/GO Hybrids

3.3. Analysis of Hydration Products and Solidification Mechanisms in Grouting Materials

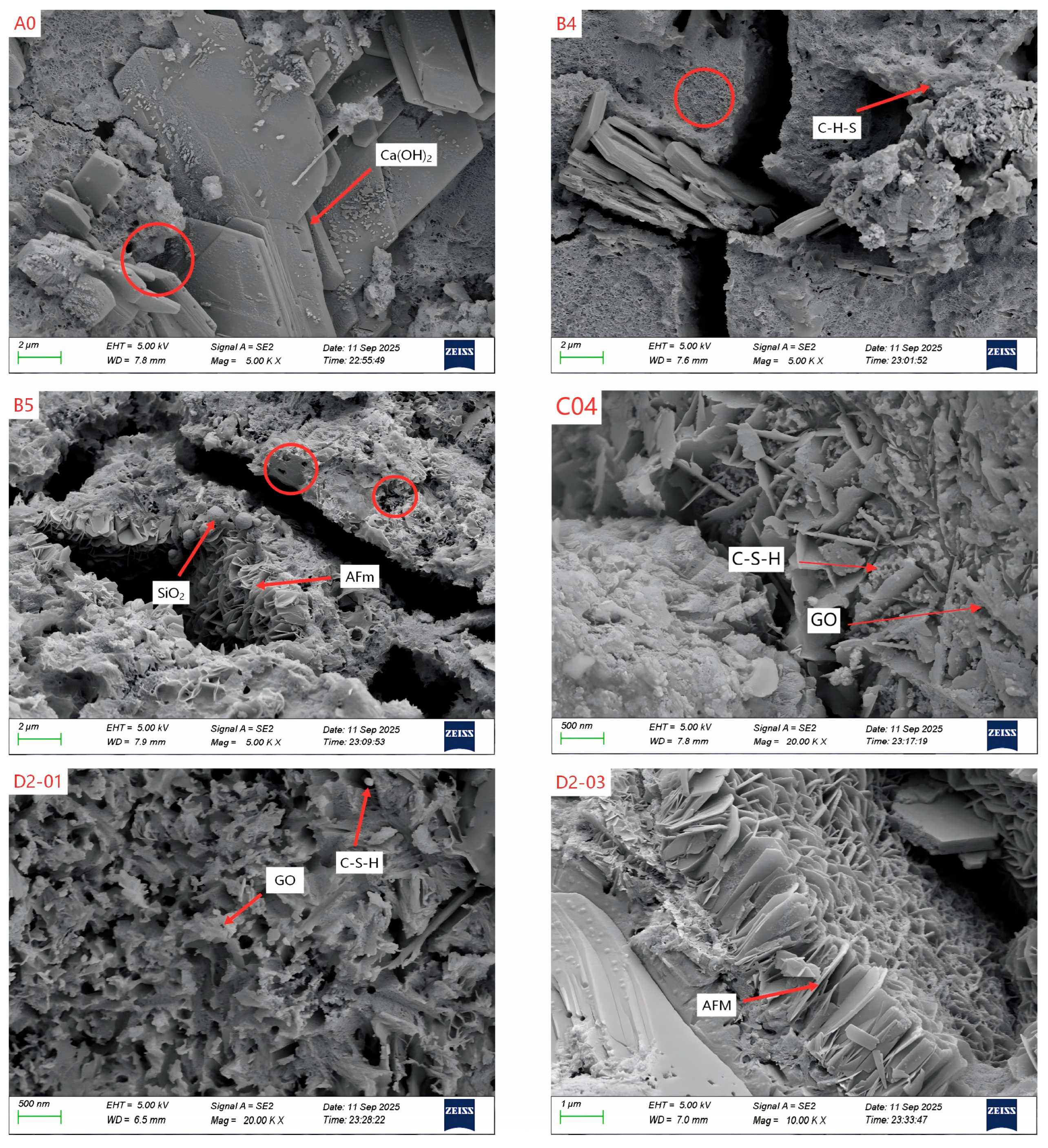

3.3.1. SEM Analysis

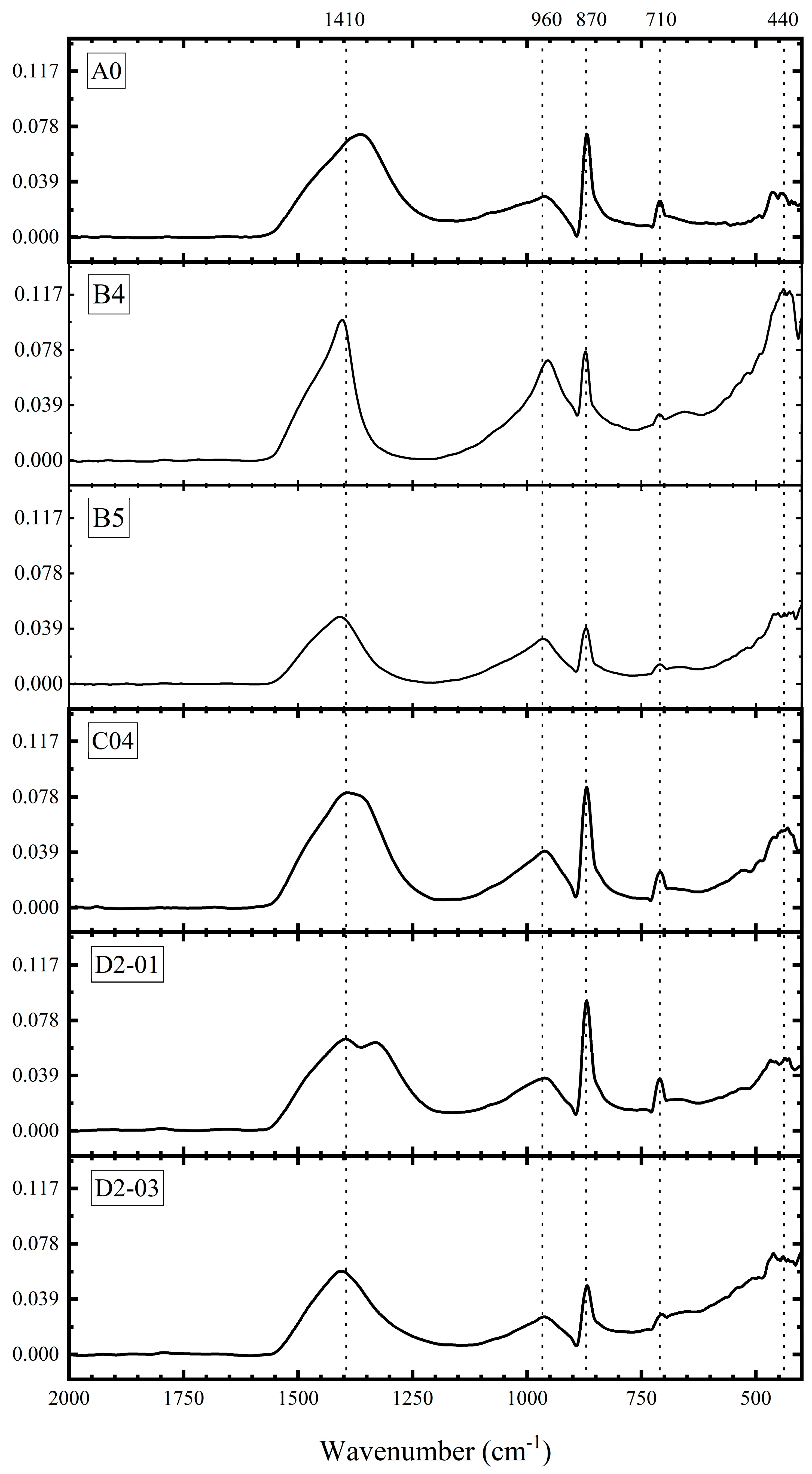

3.3.2. FTIR Analysis

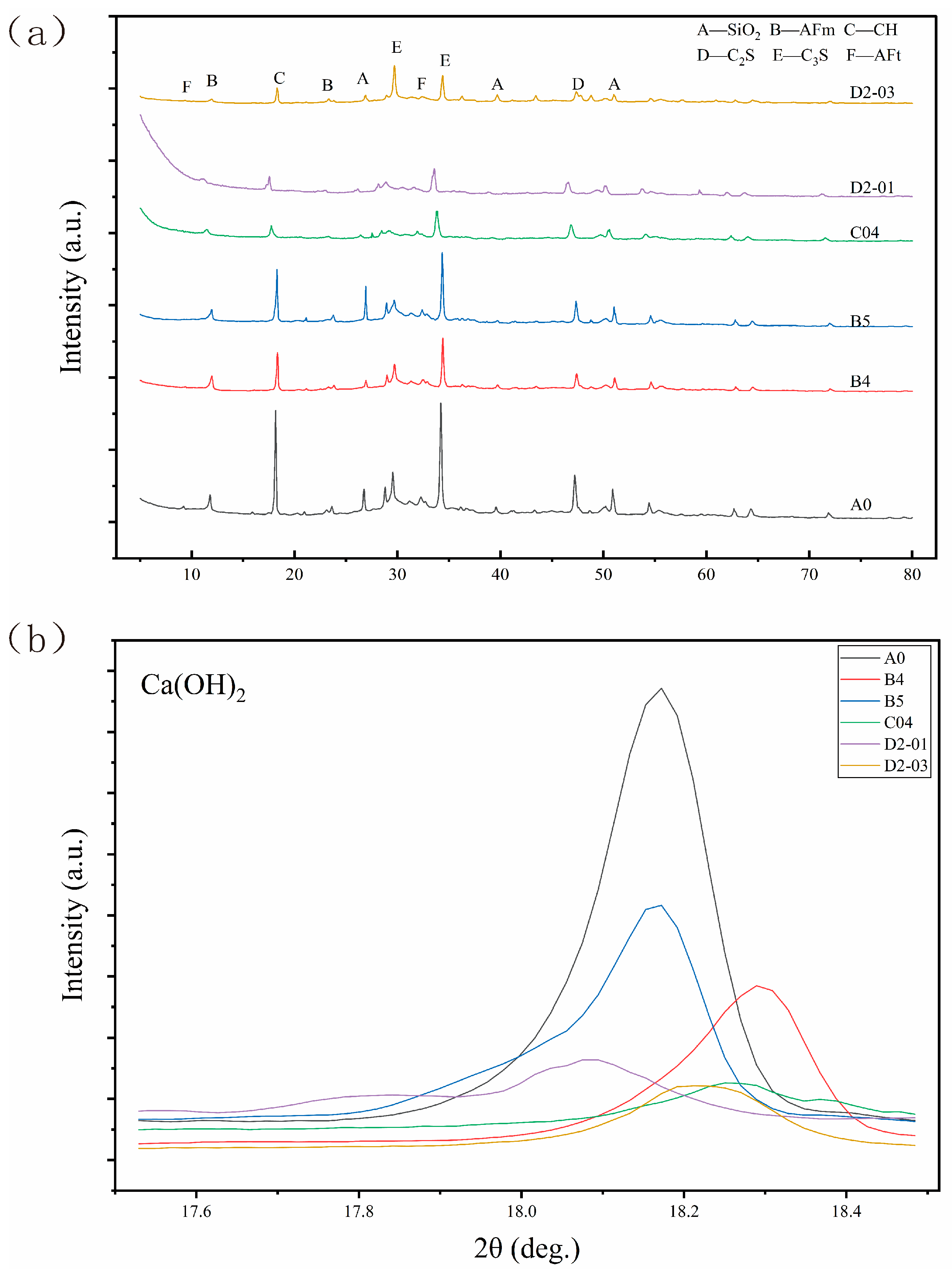

3.3.3. XRD Analysis

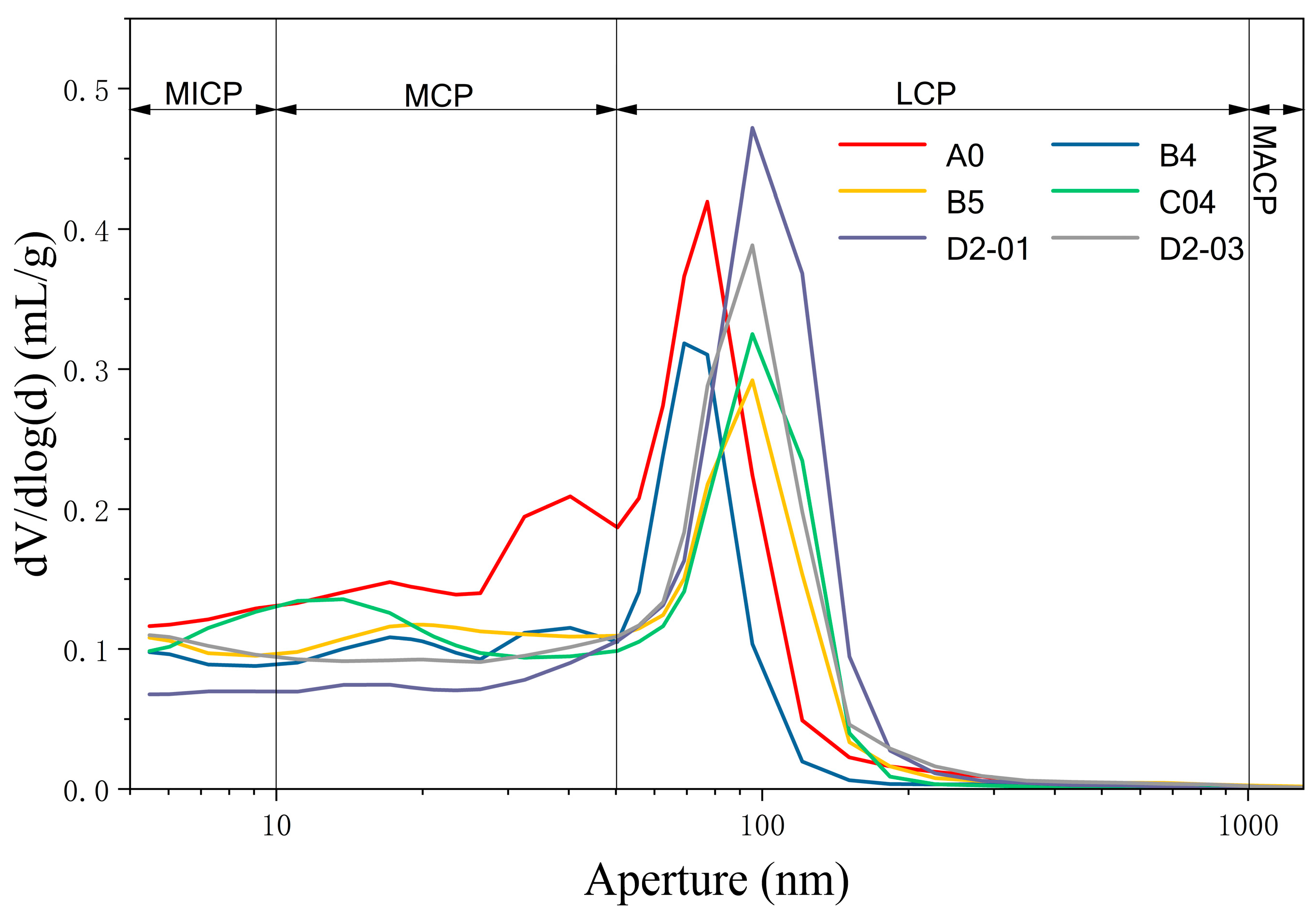

3.3.4. MIP Analysis

4. Conclusions

- Fresh State Properties: Both NS and GO significantly accelerated the setting time of cement paste and effectively reduced the bleeding rate. However, NS had a more detrimental impact on fluidity compared to GO. The hybrid system further shortened the setting process and improved stability, albeit at the cost of a more substantial reduction in fluidity.

- Mechanical Properties: Both NS and GO significantly enhanced the compressive and flexural strength of cement paste at optimal dosages. The optimal dosage of NS was 4 wt%, while GO exhibited notable reinforcing effects within the range of 0.01–0.03 wt%. The hybrid system displayed a distinct transition from synergistic to antagonistic effects: a low-dosage combination (e.g., 2 wt% NS + 0.01 wt% GO) synergistically improved mechanical properties, increasing flexural and compressive strength by 13.5% and 45.5%, respectively, compared to the reference group. However, excessive dosage of either component (e.g., 5 wt% NS or 0.03 wt% GO in combination) resulted in reduced reinforcement efficiency, with performance even inferior to that of samples incorporating a single nanomaterial.

- Microstructure:

- NS enhances the matrix primarily through the pozzolanic reaction—consuming Ca(OH)2 to form additional C–S–H gel—and a nano-filling effect that optimizes the pore structure. In contrast, GO improves performance via a templating effect and by providing nucleation sites that promote dense deposition of hydration products, along with a bridging effect that enhances overall integrity.

- Excessive NS led to agglomeration, increasing the volume of harmful pores. Excessive GO resulted in abnormal morphology of hydration products (e.g., stacked plate-like AFm phases), inhibiting the formation of C–S–H gel.

- In the hybrid system, GO improved the dispersion of NS and enhanced its pozzolanic effect. However, excessive GO induced hetero-agglomeration, which weakened the activity of NS and caused a transition from synergy to antagonism.

- Pore Structure: NS mainly reduced medium and large capillary pores (>50 nm) and increased the proportion of fine pores (<50 nm), significantly decreasing total porosity. GO uniformly reduced pores across all size ranges, resulting in a more homogeneous pore size distribution. Although the hybrid system reduced total porosity, it also increased the proportion of large pores, the long-term durability implications of which require further investigation.

- This study demonstrates that both NS and GO offer significant potential for modifying cement-based grouting materials, but their dosages must be strictly optimized. It is recommended that the NS dosage should not exceed 4 wt%, and the GO dosage should remain below 0.03 wt%. For hybrid systems, a low-to-medium dosage combination (e.g., 2 wt% NS + 0.01 wt% GO) is recommended to avoid agglomeration and antagonistic effects, thereby achieving synergistic performance enhancement.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| NS | Nano-silica |

| GO | Graphene Oxide |

| PCE | Polycarboxylate Ether |

| FTIR | Fourier-Transform Infrared Spectroscopy |

| XRD | X-ray Diffraction |

| SEM | Scanning Electron Microscopy |

| MIP | Mercury Intrusion Porosimetry |

| UFS | Ultimate Flexural Strength |

| UCS | Ultimate Compressive Strength |

References

- Mehta, P.K.; Monteiro, P.J. Concrete Microstructure, Properties, and Materials; McGraw-hill: New York, NY, USA, 2006. [Google Scholar]

- Scrivener, K.L.; Juilland, P.; Monteiro, P.J. Advances in understanding hydration of portland cement. Cem. Concr. Res. 2015, 78, 38–56. [Google Scholar] [CrossRef]

- Sanchez, F.; Sobolev, K. Nanotechnology in concrete–a review. Constr. Build. Mater. 2010, 24, 2060–2071. [Google Scholar] [CrossRef]

- Raki, L.; Beaudoin, J.; Alizadeh, R.; Makar, J.; Sato, T. Cement and concrete nanoscience and nanotechnology. Materials 2010, 3, 918–942. [Google Scholar] [CrossRef]

- Du, H.; Dai Pang, S. Enhancement of barrier properties of cement mortar with graphene nanoplatelet. Cem. Concr. Res. 2015, 76, 10–19. [Google Scholar] [CrossRef]

- Sanchez, F.; Zhang, L. Molecular dynamics modeling of the interface between surface functionalized graphitic structures and calcium–silicate–hydrate: Interaction energies, structure, and dynamics. J. Colloid Interface Sci. 2008, 323, 349–358. [Google Scholar] [CrossRef]

- Shah, S.P.; Hou, P.; Cheng, X. Durability of cement-based materials and nano-particles: A review. In Nanotechnology in Construction: Proceedings of NICOM5 2015; Springer: Cham, Switzerland, 2015; pp. 15–24. [Google Scholar]

- Du, M.; Yang, Y.; Miao, J.; Hou, R.; Zhai, K.; Yao, X. A deep learning-based study of the role of graphene oxide nanosheets on the microstructure of cement paste. ACS Appl. Nano Mater. 2025, 8, 14297–14306. [Google Scholar] [CrossRef]

- Hu, J.; Lu, S.; Mao, X.; Luo, J.; Wang, S.; Gao, Y. Influence of nanosheet size and oxygen-containing functional group content on the reinforcing efficiency of graphene oxide on cementitious composites. J. Mater. Sci. 2025, 60, 7289–7306. [Google Scholar] [CrossRef]

- Fan, L.; Zheng, J.; Wu, C.; Wang, H.; Li, F.; Song, F. Graphene oxide at carbon nanotubes/cement matrix abnormally enhance its hydration products and interlayer stress transfer at an important hydration accelerated period: Experimental study and molecular dynamics simulation. Colloids Surf. A Physicochem. Eng. Asp. 2025, 717, 136830. [Google Scholar] [CrossRef]

- Zhang, H.; Gan, X.; Lu, Z.; Li, L.; Lu, L. Polycarboxylate superplasticizer-modified graphene oxide: Dispersion and performance enhancement in cement paste. Nanomaterials 2025, 15, 419. [Google Scholar] [CrossRef]

- Hu, Z.; Wan, Y.; Duan, Y.; Shi, Y.; Gu, C.; Ma, R.; Dong, J.; Cui, D. A review of the impact of graphene oxide on cement composites. Nanomaterials 2025, 15, 216. [Google Scholar] [CrossRef]

- Pan, Z.; He, L.; Qiu, L.; Korayem, A.H.; Li, G.; Zhu, J.W.; Collins, F.; Li, D.; Duan, W.H.; Wang, M.C. Mechanical properties and microstructure of a graphene oxide–cement composite. Cem. Concr. Compos. 2015, 58, 140–147. [Google Scholar] [CrossRef]

- Lv, S.; Ma, Y.; Qiu, C.; Sun, T.; Liu, J.; Zhou, Q. Effect of graphene oxide nanosheets of microstructure and mechanical properties of cement composites. Constr. Build. Mater. 2013, 49, 121–127. [Google Scholar] [CrossRef]

- Zhang, P.; Sun, Y.; Wei, J.; Zhang, T. Research progress on properties of cement-based composites incorporating graphene oxide. Rev. Adv. Mater. Sci. 2023, 62, 20220329. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.M.; Li, W.G.; Li, C.Y.; Sanjayan, J.G.; Duan, W.H.; Li, Z. Effects of graphene oxide agglomerates on workability, hydration, microstructure and compressive strength of cement paste. Constr. Build. Mater. 2017, 145, 402–410. [Google Scholar] [CrossRef]

- Vijayan, D.S.; Devarajan, P.; Sivasuriyan, A. A review on eminent application and performance of nano based silica and silica fume in the cement concrete. Sustain. Energy Technol. Assess. 2023, 56, 103105. [Google Scholar] [CrossRef]

- Qing, Y.; Zenan, Z.; Deyu, K.; Rongshen, C. Influence of nano-sio2 addition on properties of hardened cement paste as compared with silica fume. Constr. Build. Mater. 2007, 21, 539–545. [Google Scholar] [CrossRef]

- Ji, T. Preliminary study on the water permeability and microstructure of concrete incorporating nano-SiO2. Cem. Concr. Res. 2005, 35, 1943–1947. [Google Scholar] [CrossRef]

- Kim, G.; Suh, H.; Cho, S.; Im, S.; Nezhad, E.Z.; Seok, S.; Choi, C.; Bae, S. Synergistic strengthening mechanism of portland cement paste reinforced by a triple hybrid of graphene oxide, functionalized carbon nanotube, and nano-silica. Constr. Build. Mater. 2022, 352, 129017. [Google Scholar] [CrossRef]

- Nguyen, H.D.; Zhang, Q.; Sagoe-Crentsil, K.; Duan, W. Graphene oxide-coated sand for improving performance of cement composites. Cem. Concr. Compos. 2021, 124, 104279. [Google Scholar] [CrossRef]

- Bouibed, A.; Doufnoune, R. Synthesis and characterization of hybrid materials based on graphene oxide and silica nanoparticles and their effect on the corrosion protection properties of epoxy resin coatings. J. Adhes. Sci. Technol. 2019, 33, 834–860. [Google Scholar] [CrossRef]

- Liu, C.; Chen, F.; Wu, Y.; Zheng, Z.; Yang, J.; Yang, B.; Yang, J.; Hui, D.; Luo, Y. Research progress on individual effect of graphene oxide in cement-based materials and its synergistic effect with other nanomaterials. Nanotechnol. Rev. 2021, 10, 1208–1235. [Google Scholar] [CrossRef]

- Bai, S.; Jiang, L.; Xu, N.; Jin, M.; Jiang, S. Enhancement of mechanical and electrical properties of graphene/cement composite due to improved dispersion of graphene by addition of silica fume. Constr. Build. Mater. 2018, 164, 433–441. [Google Scholar] [CrossRef]

- Mowlaei, R.; Lin, J.; de Souza, F.B.; Fouladi, A.; Korayem, A.H.; Shamsaei, E.; Duan, W. The effects of graphene oxide-silica nanohybrids on the workability, hydration, and mechanical properties of portland cement paste. Constr. Build. Mater. 2021, 266, 121016. [Google Scholar] [CrossRef]

- Mohammed, A.; Sanjayan, J.G.; Duan, W.H.; Nazari, A. Incorporating graphene oxide in cement composites: A study of transport properties. Constr. Build. Mater. 2015, 84, 341–347. [Google Scholar] [CrossRef]

- Li, H.; Zhang, Q.; Feng, G.; Mei, L.; Wang, Y.; Long, W. Multi-scale improved damping of high-volume fly ash cementitious composite: Combined effects of polyvinyl alcohol fiber and graphene oxide. Constr. Build. Mater. 2020, 260, 119901. [Google Scholar] [CrossRef]

- Wang, D.; Fang, J.; Wang, Q.; Liu, Y. Utilizing desulphurized electrolytic-manganese residue as a mineral admixture: A feasibility study. Cem. Concr. Compos. 2022, 134, 104822. [Google Scholar] [CrossRef]

- Kavussi, A.; Qazizadeh, M.J. Fatigue characterization of asphalt mixes containing electric arc furnace (EAF) steel slag subjected to long term aging. Constr. Build. Mater. 2014, 72, 158–166. [Google Scholar] [CrossRef]

- GB/T 17671-2021; Methods of Testing Cements—Determination of Strength. Standards Press of China: Beijing, China, 2021.

- Senff, L.; Labrincha, J.A.; Ferreira, V.M.; Hotza, D.; Repette, W.L. Effect of nano-silica on rheology and fresh properties of cement pastes and mortars. Constr. Build. Mater. 2009, 23, 2487–2491. [Google Scholar] [CrossRef]

- Kong, D.; Su, Y.; Du, X.; Yang, Y.; Wei, S.; Shah, S.P. Influence of nano-silica agglomeration on fresh properties of cement pastes. Constr. Build. Mater. 2013, 43, 557–562. [Google Scholar] [CrossRef]

- Jo, B.; Kim, C.; Tae, G.; Park, J. Characteristics of cement mortar with nano-SiO2 particles. Constr. Build. Mater. 2007, 21, 1351–1355. [Google Scholar] [CrossRef]

- Land, G.; Stephan, D. The influence of nano-silica on the hydration of ordinary portland cement. J. Mater. Sci. 2012, 47, 1011–1017. [Google Scholar] [CrossRef]

- Wang, Q.; Li, S.; Pan, S.; Cui, X.; Corr, D.J.; Shah, S.P. Effect of graphene oxide on the hydration and microstructure of fly ash-cement system. Constr. Build. Mater. 2019, 198, 106–119. [Google Scholar] [CrossRef]

- Liu, C.; Huang, X.; Wu, Y.; Deng, X.; Zheng, Z. The effect of graphene oxide on the mechanical properties, impermeability and corrosion resistance of cement mortar containing mineral admixtures. Constr. Build. Mater. 2021, 288, 123059. [Google Scholar] [CrossRef]

- Suhendro, B. Toward green concrete for better sustainable environment. Procedia Eng. 2014, 95, 305–320. [Google Scholar] [CrossRef]

- Cho, Y.; Yoo, S.; Jung, S.; Lee, K.; Kwon, S. Effect of Na2O content, SiO2/Na2O molar ratio, and curing conditions on the compressive strength of fa-based geopolymer. Constr. Build. Mater. 2017, 145, 253–260. [Google Scholar] [CrossRef]

- Wyrzykowski, M.; Terrasi, G.; Lura, P. Expansive high-performance concrete for chemical-prestress applications. Cem. Concr. Res. 2018, 107, 275–283. [Google Scholar] [CrossRef]

- Kedir, A.; Gamachu, M.; Alex, A.G. Cement-based graphene oxide composites: A review on their mechanical and microstructure properties. J. Nanomater. 2023, 2023, 6741000. [Google Scholar] [CrossRef]

- Alex, A.G.; Kedir, A.; Tewele, T.G. Review on effects of graphene oxide on mechanical and microstructure of cement-based materials. Constr. Build. Mater. 2022, 360, 129609. [Google Scholar] [CrossRef]

- Murmu, P.P.; Kennedy, J.; Ruck, B.J.; Williams, G.V.M.; Markwitz, A.; Rubanov, S.; Suvorova, A.A. Effect of annealing on the structural, electrical and magnetic properties of Gd-implanted ZnO thin films. J. Mater. Sci. 2012, 47, 1119–1126. [Google Scholar] [CrossRef]

- Rouquerol, J.; Avnir, D.; Fairbridge, C.W.; Everett, D.H.; Haynes, J.M.; Pernicone, N.; Ramsay, J.D.; Sing, K.S.W.; Unger, K.K. Recommendations for the characterization of porous solids (technical report). Pure Appl. Chem. 1994, 66, 1739–1758. [Google Scholar] [CrossRef]

| Compound | Content (%) | Phase Name | Approximate Content |

|---|---|---|---|

| CaO | 54.36% | C3S | 45–60% |

| SiO2 | 22.31% | C2S | 15–30% |

| Al2O3 | 9.76% | C3A | 6–12% |

| SO3 | 3.16% | C4AF | 6–8% |

| Fe2O3 | 3.13% | Gypsum | 3–5% |

| K2O | 1.03% | Additives | 5–20% |

| MgO | 1.01% | ||

| TiO2 | 0.43% |

| Property | Value |

|---|---|

| SiO2 content | 40.1 wt% |

| Na2O | 0.22 wt% |

| pH value | 9.6 |

| Average particle size | 10 nm |

| Density(at 25 °C) | 1.295 g/cm3 |

| Appearance | Semi-translucent, milky-white colloid |

| Property | Value |

|---|---|

| Number of layers | Single-layer |

| Single-layer ratio | >99.9% |

| Thickness | ~1 nm |

| Flake diameter | 10–50 μm |

| Oxidation degree | ~36% |

| Specific surface area | 50–150 m2/g |

| Group | w/c | Cement | SP (wt%) | NS (wt%) | GO (wt%) |

|---|---|---|---|---|---|

| A0 | 0.6 | 100% | 0.6 | / | / |

| B2 | 0.6 | 100% | 0.6 | 2 | / |

| B3 | 0.6 | 100% | 0.6 | 3 | / |

| B4 | 0.6 | 100% | 0.6 | 4 | / |

| B5 | 0.6 | 100% | 0.6 | 5 | / |

| C01 | 0.6 | 100% | / | / | 0.01 |

| C02 | 0.6 | 100% | / | / | 0.02 |

| C03 | 0.6 | 100% | / | / | 0.03 |

| C04 | 0.6 | 100% | / | / | 0.04 |

| D2-01 | 0.6 | 100% | 0.6 | 2 | 0.01 |

| D2-02 | 0.6 | 100% | 0.6% | 2 | 0.02 |

| D2-03 | 0.6 | 100% | 0.6 | 2 | 0.03 |

| D3-01 | 0.6 | 100% | 0.6 | 3 | 0.01 |

| D4-01 | 0.6 | 100% | 0.6 | 4 | 0.01 |

| Wavenumber (cm−1) | Vibration Assignment | Compound/Structure Indicated |

|---|---|---|

| ~1410 | C–O asymmetric stretching | Calcium carbonate (CaCO3) |

| ~960 | Si–O stretching | Calcium silicate hydrate (C–S–H) gel |

| ~870–880 | C–O out-of-plane bending | Calcium carbonate (CaCO3) |

| ~710 | C–O in-plane bending | Calcium carbonate (CaCO3) |

| ~430–450 | Si–O bending | SiO44− tetrahedron (in C2S, C3S, or quartz) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, L.; Yang, G.; Ai, Y.; Qu, J.; Duan, J.; Yang, K.; Sun, W. Cement-Based Grouting Materials Modified with GO/NS Hybrids. Materials 2025, 18, 4820. https://doi.org/10.3390/ma18214820

Lu L, Yang G, Ai Y, Qu J, Duan J, Yang K, Sun W. Cement-Based Grouting Materials Modified with GO/NS Hybrids. Materials. 2025; 18(21):4820. https://doi.org/10.3390/ma18214820

Chicago/Turabian StyleLu, Longfei, Guoxiang Yang, Yan Ai, Jingkai Qu, Jinrui Duan, Kun Yang, and Wenbin Sun. 2025. "Cement-Based Grouting Materials Modified with GO/NS Hybrids" Materials 18, no. 21: 4820. https://doi.org/10.3390/ma18214820

APA StyleLu, L., Yang, G., Ai, Y., Qu, J., Duan, J., Yang, K., & Sun, W. (2025). Cement-Based Grouting Materials Modified with GO/NS Hybrids. Materials, 18(21), 4820. https://doi.org/10.3390/ma18214820