Electrical Curing of Metakaolin- and GBFS-Based Geopolymers: A Sustainable Technology Aligned with the European Green Deal

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Characterization

2.2. Experimental Procedure

3. Results

3.1. Physical Properties

3.1.1. Bulk Density, Porosity, and Water Absorption

3.1.2. Ultrasonic Pulse Velocity

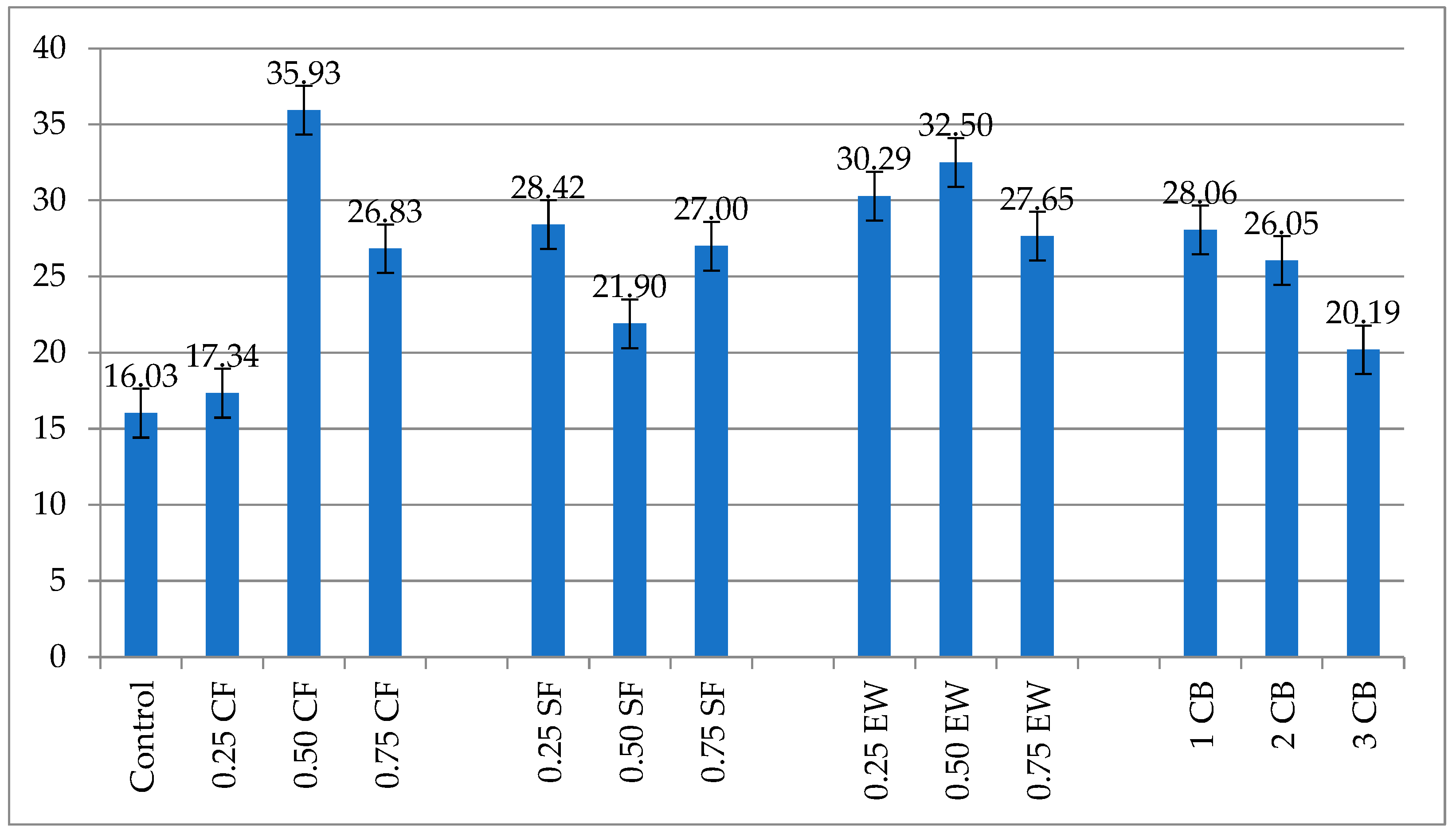

3.1.3. Abrasion Resistance

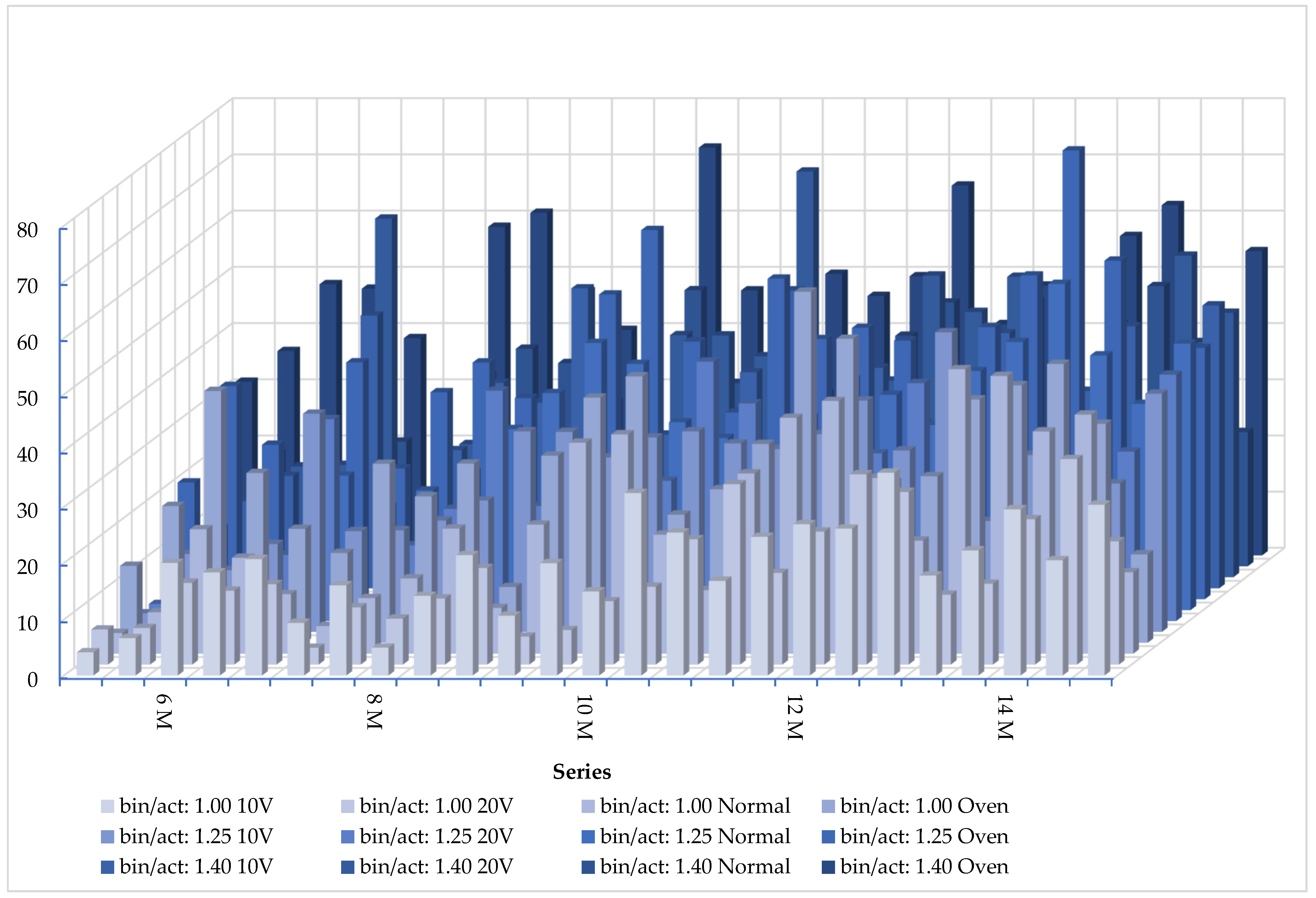

3.2. Compressive Strength Results for Samples with Different Molarities Within the Scope of Preliminary Tests

3.3. Mechanical Properties of Fiber-Added Samples

3.3.1. Compressive Strength

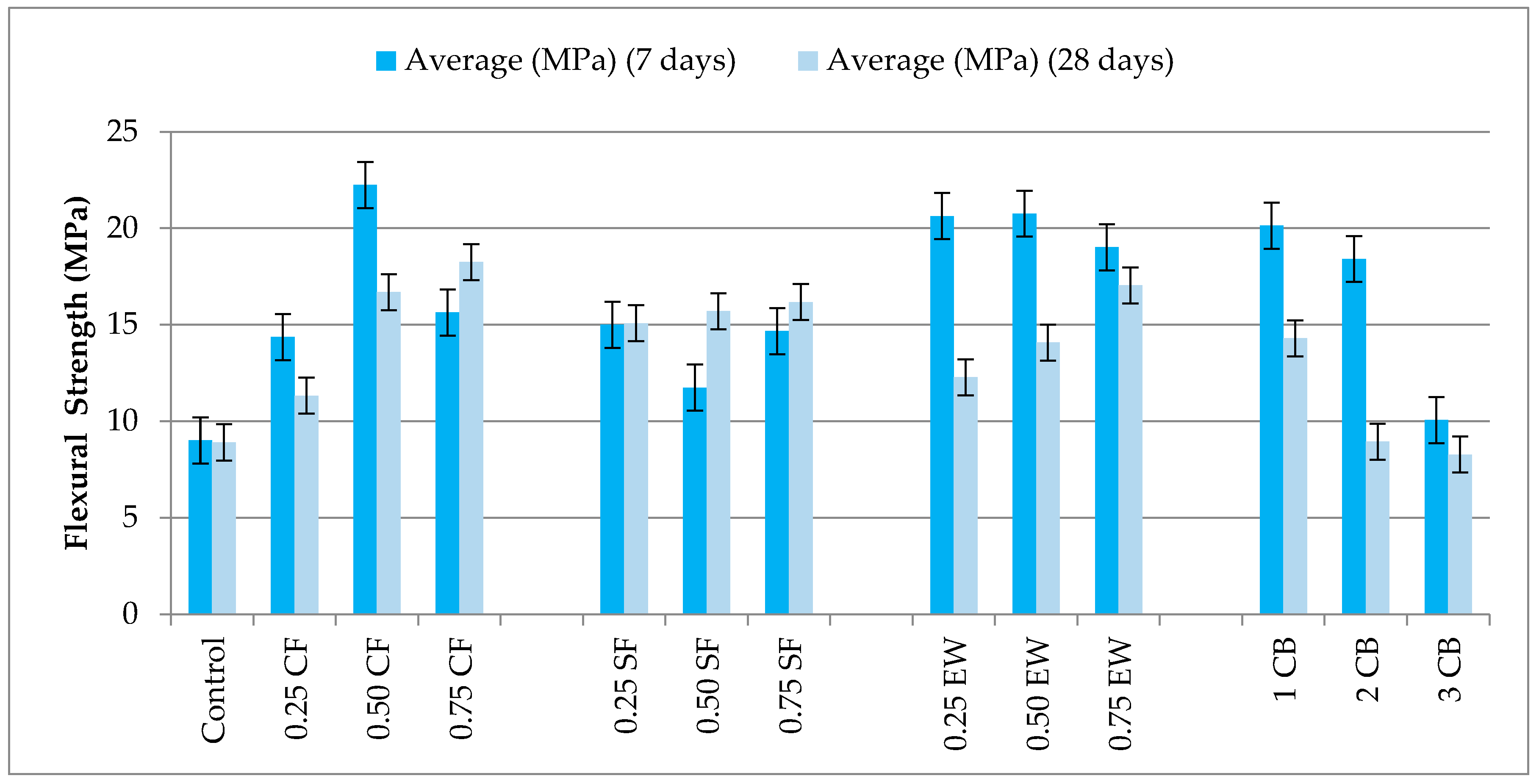

3.3.2. Flexural Strength

3.3.3. Splitting and Direct Tensile Strengths

3.3.4. Microstructural Analysis

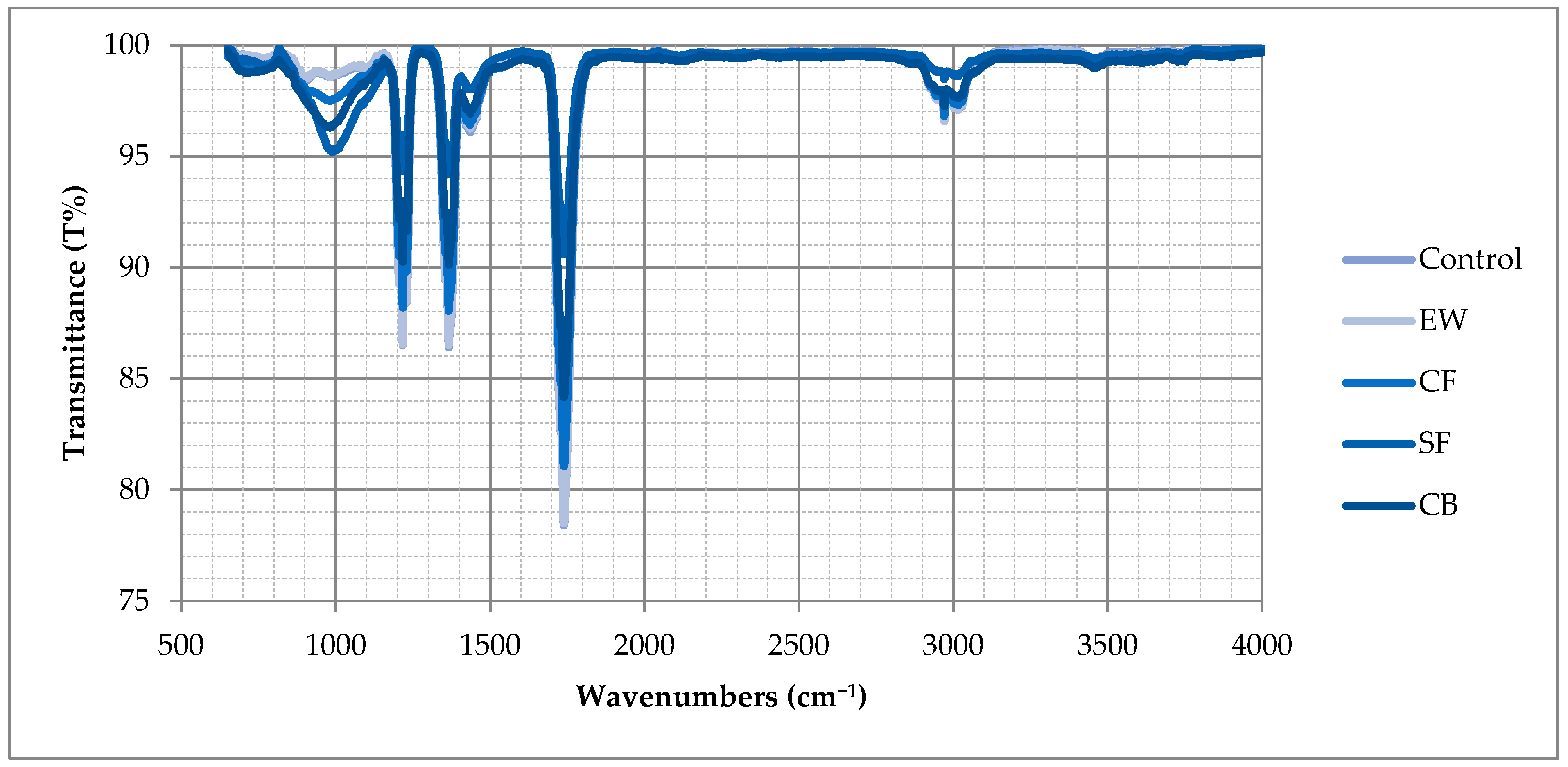

Fourier Transform Infrared Spectroscopy

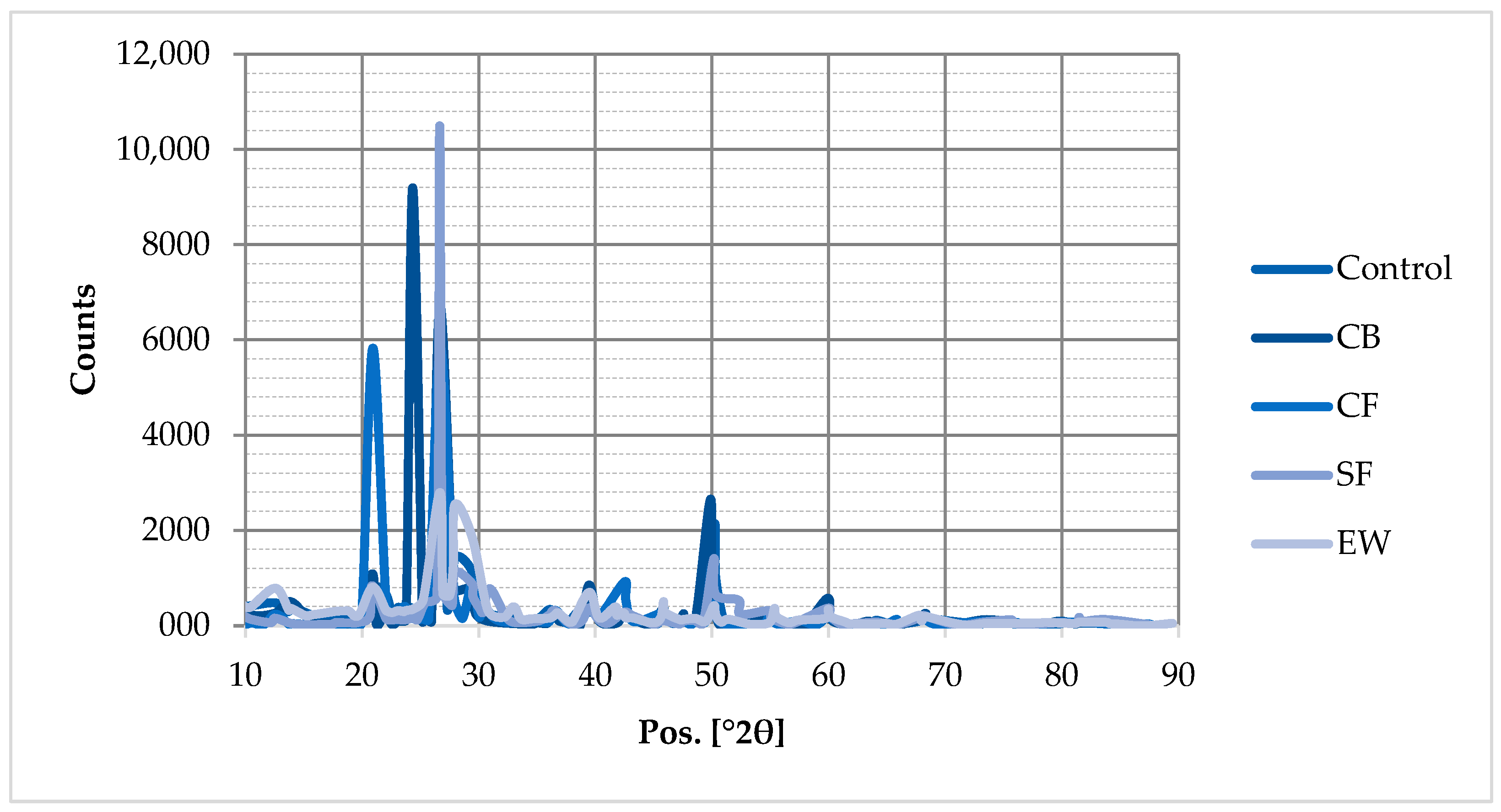

X-Ray Diffraction

Scanning Electron Microscope

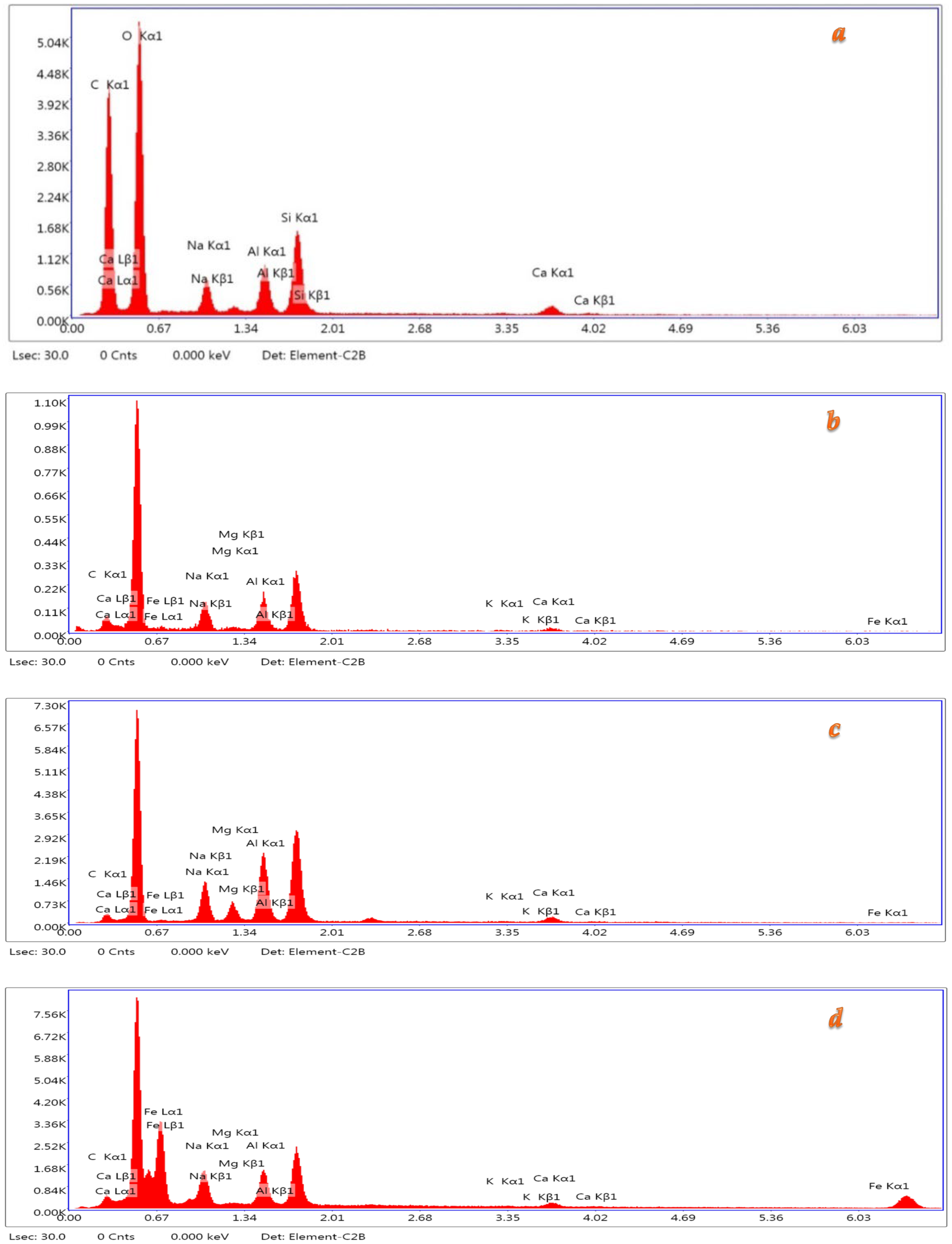

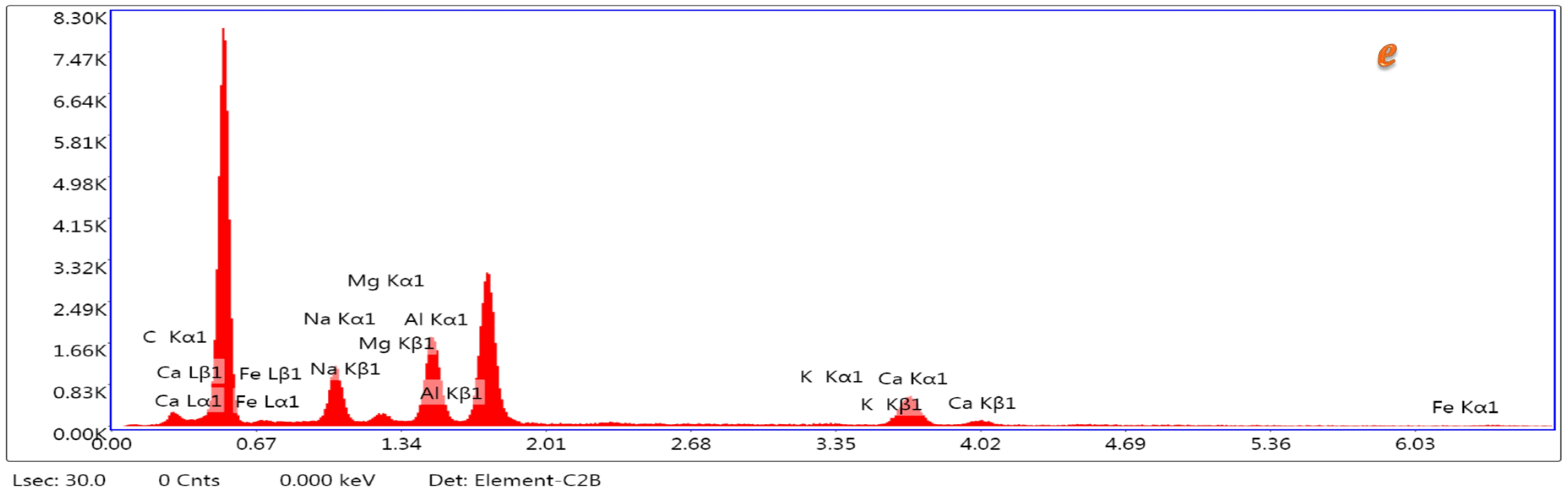

Energy-Dispersive X-Ray Spectroscopy

3.4. Evaluation of Test Results with the Multi-Criteria Decision Support Method (HD Method) and the Selection of the Best Geopolymer Mortars

3.5. Environmental Impact Assessment of Different Curing Regimes and Reinforcement Types

4. Conclusions

- (1)

- Electrical curing efficiency: Rapid electrical curing efficiently converted MK–GBFS geopolymer mortars from laboratory-grade experimental adhesive into field-deployable, high-performance concrete by facilitating accelerated geopolymerization instead of traditional thermal curing.

- (2)

- Comparable strength to thermal curing: Whereas oven curing provided the greatest compressive strength (79.81 MPa for 25MK–75GBFS at 14 M NaOH and 1.25 B/A), the GBFS-heavy mixtures electrically cured at 20 V reached as high as 72.18 MPa, affirming electrical curing’s ability to achieve a strength similar to that under the traditional methods.

- (3)

- Voltage influence: Raising the curing voltages from 10 V to a higher value of 20 V resulted in a considerable strength improvement for all activator molarities and B/A ratios.

- (4)

- Activator concentration: The optimal NaOH contents for electrocuring ranged between 10 M and 14 M, during which proper Na+ availability enabled increased the reaction kinetics acceleration.

- (5)

- The binder/activator ratio: Higher B/A ratios (1.25–1.40) resulted in increased compressive strength according to a higher precursor concentration but decreased the workability, suggesting that a compromise is necessary for workable applications.

- (6)

- Role of GBFS: Systems rich in slag had markedly improved strength and conduction compared to those for MK-rich mixes as a result of CaO encouraging more compact C–A–S–H/N–A–S–H gels under electrical fields.

- (7)

- Porosity and water absorption trends: CF and EW fibers increased the water absorption and porosity, especially at higher dosages. CB at 1–2% decreased the porosity through a microfiller effect, whereas 3% CB resulted in agglomeration and build-up of the void content.

- (8)

- The UPVs indicated these porosity variations, displaying a lower velocity for more heavily populated mixes and a higher velocity for low CB contents, evidencing the sensitivity of ultrasonic pulse velocity to matrix compactness.

- (9)

- Abrasion behavior: While the wear resistance decreased with increasing porosity for EW, SF achieved moderate success due to its finer tip and less disruptive network structure.

- (10)

- Mechanical enhancement through fibers: All of the fiber-reinforced concoctions showed increased compressive, bending, and tensile strength when compared to these values for the control. EW, particularly at 0.50%, resulted in the highest compressive strength (88.30 MPa at 7 days), which corresponded to its highest peak current (26.8 A).

- (11)

- Flexural and tensile improvements: SF exhibited significant improvements in flexural and tensile strength, which were caused by their crack-bridging capability and matrix densification.

- (12)

- Dosage optimization: Reasonable dosages (0.50% EW, 0.75% SF, 1% CB) offered the optimum compromise between conductivity and mechanical soundness. High fiber additions resulted in increased porosity and a lower performance for increased current conduction.

- (13)

- The SEM micrographs displayed dense and well-structured matrices in the electrocured samples, while the development of continuous gel phases and a void-reduced microstructure indicated that the microstructure was efficiently enhanced by the electric fields.

- (14)

- The FTIR spectra showed typical Si–O–T bands (≈990–1000 cm−1) and C–O bands (1300–1400 cm−1), evidencing geopolymerization reactions.

- (15)

- The XRD patterns exhibited broad amorphous humps characteristic of geopolymer gels, as well as crystalline phases of calcite, indicative of both geopolymeric gel precipitation and incidental carbonation.

- (16)

- EDS verified the even distribution of Na, Al, Si, Ca, and Fe in slag-rich systems, favoring the coexistence of N–A–S–H and C–A–S–H gels. Although EDS cannot act as a phase identification tool, its tendency correlated well with the XRD and FT-IR results.

- (17)

- Fiber conductivity’s role: Conductive fibers functioned as percolation routes, enhancing the cure efficiency. Specifically, EW built stable current routes, accelerating the reaction rates and promoting matrix closure densification.

- (18)

- HD method evaluation: Analysis with the HD method, assigning equal weights to each of the parameters, resulted in the election of 0.50% CF, 0.75% SF, 0.75% EW, and 1% CB as the optimum compositions of each of their respective additives. Out of these, the overall best was 0.75% EW, which exceeded the control for 8 of 11 properties, with the porosity parameters being the sole points of relative weakness.

- (19)

- Multi-criteria decision advantage: The HD method struck a good balance in conflicting performance criteria, enabling optimization of the optimum blends, which were not necessarily at the top of the individual categories but provided the optimum overall performance.

- (20)

- The LCA proved 10 V electrical curing to provide the environmentally best performance, cutting the energy demand from 8000 kWh/m3 (oven) by as little as 1440 kWh/m3 (control) and CO2 emissions from 4000 kg/m3 to 720 kg/m3, by as much as 80%. Of the series, 0.25–0.50 CF and SF at 10 V offered the best balanced profiles for all impact categories, whereas EW at 10 V, despite the increased energy consumption (≈10,800–12,800 kWh/m3), scored high for waste valorization. By contrast, 20 V curing for highly conductive mixes like 0.50 EW produced the highest burdens, causing 25,728 kWh/m3 of energy use and 12,864 kg CO2/m3, beating oven curing in a few categories.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MK | Metakaolin |

| GBFS | Ground granulated blast furnace slag |

| SS | Sodium silicate |

| SH | Sodium hydroxide |

| SF | Steel fiber |

| CF | Carbon fiber |

| CB | Carbon black |

| EW | Waste erosion wire |

| UPV | Ultrasonic pulse velocity |

| SEM | Scanning Electron Microscope |

| EDS | Energy-Dispersive X-ray Spectroscopy |

| XRD | X-Ray diffraction |

| FTIR | Fourier Transform Infrared Spectroscopy |

Appendix A

References

- Dilbas, H.; Çakır, Ö. Physical and Mechanical Properties of Treated Recycled Aggregate Concretes-Combination of Mechanical Treatment and Silica Fume. J. Mater. Civ. Eng. 2021, 33, 04021096. [Google Scholar] [CrossRef]

- Kabirova, A.; Husem, M.; Dilbas, H. Metakaolin-Based and Blast Furnace Slag-Activated Geopolymer Cement with Waste Powders. Iran. J. Sci. Technol. Trans. Civ. Eng. 2023, 47, 891–907. [Google Scholar] [CrossRef]

- Barcelo, L.; Kline, J.; Walenta, G.; Gartner, E. Cement and carbon emissions. Mater. Struct. 2014, 47, 1055–1065. [Google Scholar] [CrossRef]

- Dan, H.; Ma, Z.; Li, M.; Ma, S.; Tan, J. Early performance and bonding mechanism of metakaolin (MK)- ground granulated blast furnace slag (GGBS) based geopolymer road repair mortar. Int. J. Pavement Eng. 2023 24, 2252156. [CrossRef]

- Liew, Y.M.; Kamarudin, H.; Al Bakri, A.M.M.; Luqman, M.; Nizar, I.K.; Ruzaidi, C.M.; Heah, C.Y. Processing and characterization of calcined kaolin cement powder. Constr. Build. Mater. 2012, 30, 794–802. [Google Scholar] [CrossRef]

- Payakaniti, P.; Pinitsoontorn, S.; Thongbai, P.; Amornkitbamrung, V.; Chindaprasirt, P. Electrical conductivity and compressive strength of carbon fiber reinforced fly ash geopolymeric composites. Constr. Build. Mater. 2017, 135, 164–176. [Google Scholar] [CrossRef]

- Ribeiro, R.A.S.; Ribeiro, M.G.S.; Kriven, W.M. A review of particle- and fiber-reinforced metakaolin-based geopolymer composites. J. Ceram. Sci. Technol. 2017, 8, 307–322. [Google Scholar] [CrossRef]

- Nergis, D.D.B.; Abdullah, M.M.A.B.; Vizureanu, P.; Tahir, M.F.M. Geopolymers and their uses: Review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 374, 012019. [Google Scholar] [CrossRef]

- Cai, J.; Pan, J.; Li, X.; Tan, J.; Li, J. Electrical resistivity of fly ash and metakaolin based geopolymers. Constr. Build. Mater. 2020, 234, 117868. [Google Scholar] [CrossRef]

- Huseien, G.F.; Mirza, J.; Ismail, M.; Ghoshal, S.K.; Ariffin, M.A.M. Effect of metakaolin replaced granulated blast furnace slag on fresh and early strength properties of geopolymer mortar. Ain Shams Eng. J. 2018, 9, 1557–1566. [Google Scholar] [CrossRef]

- Farhan, K.Z.; Johari, M.A.M.; Demirboga, R. Assessment of important parameters involved in synthesizing geopolymer composites: A review. Constr. Build. Mater. 2020, 264, 120276. [Google Scholar] [CrossRef]

- Cai, J.; Li, X.; Tan, J.; Vandevyvere, B. Fly ash-based geopolymer with self-heating capacity for accelerated curing. J. Clean. Prod. 2020, 261, 121119. [Google Scholar] [CrossRef]

- Heah, C.Y.; Kamarudin, H.; Al Bakri, A.M.M.; Binhussain, M.; Luqman, M.; Nizar, I.K.; Ruzaidi, C.M.; Liew, Y.M. Effect of curing profile on kaolin-based geopolymers. Phys. Procedia 2011, 22, 305–311. [Google Scholar] [CrossRef]

- Yun-Ming, L.; Cheng-Yong, H.; Al Bakri, M.M.; Hussin, K. Structure and properties of clay-based geopolymer cements: A review. Prog. Mater. Sci. 2016, 83, 595–629. [Google Scholar] [CrossRef]

- Heritage, I. Direct Electric Curing of Mortar and Concrete. Ph.D. Thesis, Napier University, Edinburgh, UK, 2001. [Google Scholar]

- Zhang, Y.; Chen, S.; Ruan, S.; Wang, W.; Wang, Q.; Chen, D.; Liu, Y.; Yan, D. Electrothermal effect of alternating current on hardening process of metakaolin-based geopolymer. Cem. Concr. Compos. 2023, 142, 105205. [Google Scholar] [CrossRef]

- Aygun, B.F.; Uysal, M.; Bilir, T.; Cosgun, T.; Dilbas, H. Alternating current curing of conductive fly ash-slag geopolymer mortars: Performance, characterization and optimization. Arch. Civ. Mech. Eng. 2024, 25, 46. [Google Scholar] [CrossRef]

- Aygun, B.F.; Uysal, M.; Bilir, T.; Cosgun Dilbas, H. An investigation on physical, mechanical and microstructural properties of electricity-based cured GBFS-FA geopolymer. Constr. Build. Mater. 2024, 458, 139526. [Google Scholar] [CrossRef]

- Urunveren, H.; Beycioglu, A.; Resulogulları, E.C.; Disken, N.B. A comparative investigation of eco-friendly fly ash-based geopolymer mortar produced by using electrical and heat curing: Mechanical properties, energy consumption and cost. Constr. Build. Mater. 2024, 439, 137200. [Google Scholar] [CrossRef]

- Hanjitsuwan, S.; Chindaprasirt, P.; Pimraksa, K. Electrical conductivity and dielectric property of fly ash geopolymer pastes. Int. J. Miner. Metall. Mater. 2011, 18, 94–99. [Google Scholar] [CrossRef]

- Hanjitsuwan, S.; Hunpratub, S.; Thongbai, P.; Maensiri, S.; Sata, V.; Chindaprasirt, P. Effects of NaOH concentrations on physical and electrical properties of high calcium fly ash geopolymer paste. Cem. Concr. Compos. 2014, 45, 9–14. [Google Scholar] [CrossRef]

- Kovarik, T.; France, P.; Sestak, J.; Rieger, D.; Belsky, P.; Kadlec, J.; Roubicek, P. A novel approach to polyaluminosialates curing process using electric boosting and temperature profile investigation by DSC. J. Therm. Anal. Calorim. 2015, 121, 517–524. [Google Scholar] [CrossRef]

- Dehghanpour, H.; Yilmaz, K.; Ipek, M. Evaluation of recycled nano carbon black and waste erosion wires in electrically conductive concretes. Constr. Build. Mater. 2019, 221, 109–121. [Google Scholar] [CrossRef]

- Vaidya, S.; Allouche, E.N. Strain sensing of carbon fiber reinforced geopolymer concrete. Mater. Struct. 2011, 44, 1467–1475. [Google Scholar] [CrossRef]

- Baradan, B.; Yazici, H.; Aydin, S. Concrete (TR), 2nd ed.; Dokuz Eylul University Engineering Faculty Publications: Izmir, Turkey, 2015. [Google Scholar]

- Nazir, K.; Canpolat, O.; Uysal, M.; Nis, A.; Kuranli, O.F. Engineering properties of different fiber-reinforced metakaolin-red mud based geopolymer mortars. Constr. Build. Mater. 2023, 385, 131496. [Google Scholar] [CrossRef]

- Wen, S.; Chung, D.D.L. Partial replacement of carbon fiber by carbon black in multifunctional cement-matrix composites. Carbon 2007, 45, 505–513. [Google Scholar] [CrossRef]

- Monteiro, A.O.; Cachim, P.B.; Costa, P.M.F.J. Self-sensing piezoresistive cement composite loaded with carbon black particles. Cem. Concr. Compos. 2017, 81, 59–65. [Google Scholar] [CrossRef]

- Ipek, M. Analysis of usability of waste erosion wires as fiber in reactive powder concrete. J. Polytech. 2017, 20, 451–457. [Google Scholar]

- Dehghanpour, H.; Yilmaz, K. A more sustainable approach for producing less expensive electrically conductive concrete mixture: Experimental and FE study. Cold Reg. Sci. Technol. 2021, 184, 103231. [Google Scholar] [CrossRef]

- Torgal, F.P.; Gomes, J.C.; Jalali, S. Alkali-activated binders: A review part 2. About materials and binders manufacture. Constr. Build. Mater. 2008, 22, 1315–1322. [Google Scholar] [CrossRef]

- Jaya, N.A.; Yun-Ming, L.; Al Bakri, M.M.A.; Cheng-Yong, H.; Hussin, K. Effect of sodium hydroxide molarity on physical, mechanical and thermal conductivity of metakaolin geopolymers. IOP Conf. Ser. Mater. Sci. Eng. 2018, 343, 012015. [Google Scholar] [CrossRef]

- Heah, C.Y.; Kamarudin, H.; Al Bakri, A.M.M.; Binhussain, M.; Luqman, M.; Nizar, I.K.; Ruzaidi, C.M.; Liew, Y.M. Study on solids-to-liquid and alkaline activator ratios on kaolin-based geopolymers. Constr. Build. Mater. 2012, 35, 912–922. [Google Scholar] [CrossRef]

- Yahya, Z.; Al Bakri, M.M.A.; Hussin, K.; Nizar, K.N.; Razak, R.A.; Sandu, A.V. Effect of solids-to-liquids, Na2SiO3-to-NaOH and curing temperature on the palm oil boiler ash (Si + Ca) geopolymerisation system. Materials 2015, 8, 2227–2242. [Google Scholar] [CrossRef]

- ASTM C642 (2006); Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2006.

- ASTM C109/C109M-16a (2016); Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM C348-14 (2014); Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM C496-96 (1996); Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 1996.

- Pinto, A.T. Alkali-Activated Metakaolin Based Binders. Ph.D. Thesis, University of Minho, Braga, Portugal, 2008. [Google Scholar]

- Aziz, I.H.; Al Bakri, M.M.A.; Mohd Salleh, M.A.A.; Azimi, E.A.; Chaiprapa, J.; Sandu, A.V. Strength development of solely ground granulated blast furnace slag geopolymers. Constr. Build. Mater. 2020, 250, 118720. [Google Scholar] [CrossRef]

- Nazir, K.; Canpolat, O.; Uysal, M. Durability properties of steel, polyamide and polyethylene fiber reinforced geopolymer mortar made with recycled concrete aggregate and glass powder as fillers. J. Build. Eng. 2023, 76, 107313. [Google Scholar] [CrossRef]

- ASTM C597-16 (2016); Standard Test Method for Pulse Velocity Through Concrete. ASTM International: West Conshohocken, PA, USA, 2016.

- BS EN 1338 (2003); B. Standard, Concrete Paving Block-Requirements and Test Methods. British Standards Institution: London, UK, 2003.

- Mindess, S.; Young, J.F.; Darwin, D. Concrete, 2nd ed.; Prentice Hall Pearson Education: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- Arslan, A.A.; Uysal, M.; Yilmaz, A.; Al-Mashhadani, M.M.; Canpolat, O.; Sahin, F.; Aygormez, Y. Influence of wetting-drying curing system on the performance of fiber reinforced metakaolin-based geopolymer composites. Constr. Build. Mater. 2019, 225, 909–926. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications, 4th ed.; Institut Geopolymere: Saint-Quentin, France, 2015. [Google Scholar]

- Zhang, Y.; Sun, W.; Chen, Q.; Chen, L. Synthesis and heavy metal immobilization behaviors of slag based geopolymer. J. Hazard. Mater. 2007, 143, 206–213. [Google Scholar] [CrossRef]

- Tuyan, M.; Andıc-Cakır, O.; Ramyar, K. Effect of alkali activator concentration and curing condition on strength and microstructure of waste clay brick powder-based geopolymer. Compos. Part B Eng. 2018, 135, 242–252. [Google Scholar] [CrossRef]

- Dogan, F.; Dehghanpour, H.; Subasi, S.; Marasli, M. Characterization of carbon fiber reinforced conductive mortars filled with recycled ferrochrome slag aggregates. J. Sustain. Constr. Mater. Technol. 2022, 7, 145–157. [Google Scholar] [CrossRef]

- Dehghanpour, H.; Dogan, F.; Subasi, S.; Maraslı, M. Effects of single-walled carbon nanotubes and steel fiber on Effects of single-walled carbon nanotubes and steel fiber on recycled ferrochrome filled electrical conductive mortars. J. Sustain. Constr. Mater. Technol. 2022, 7, 250–265. [Google Scholar] [CrossRef]

- Polat, B.Y.; Uysal, M. Bacterial crack healing in metakaolin based geopolymer mortar. J. Build. Eng. 2021, 39, 102291. [Google Scholar] [CrossRef]

- Sahin, F.; Uysal, M.; Canpolat, O.; Cosgun, T.; Dehghanpour, H. The effect of polyvinyl fibers on metakaolin-based geopolymer mortars with different aggregate filling. Constr. Build. Mater. 2021, 300, 124257. [Google Scholar] [CrossRef]

- Uysal, M.; Kuranli, O.F.; Aygormez, Y.; Canpolat, O.; Cosgun, T. The Effect of various fibers on the red mud additive sustainable geopolymer composites. Constr. Build. Mater. 2022, 363, 129864. [Google Scholar] [CrossRef]

- Kuang, L.; Li, G.; Xiang, J.; Ma, W.; Cui, X. Effect of seawater on the properties and microstructure of metakaolin/slag-based geopolymers. Constr. Build. Mater. 2023, 397, 132418. [Google Scholar] [CrossRef]

| Sieve Size (mm) | Cumulative Retained (%) |

|---|---|

| 2.00 | 3.72 |

| 1.60 | 9.88 |

| 1.00 | 15.76 |

| 0.50 | 50.10 |

| 0.16 | 95.90 |

| 0.08 | 96.30 |

| Fiber Type | Diameter (mm) | Length (mm) | l/d Ratio | Electrical Resistivity (Ω·cm) |

|---|---|---|---|---|

| CF | 0.007 | 12 | 1714 | 0.00155 |

| SF | 0.4 | 25 | 62.5 | — |

| EW | 0.4 | 25 | 62.5 | 0.00256 |

| Molarity of NaOH | B/A Ratio | Mix ID | MK | GBFS | Fine Aggregate | Na2SiO3 | NaOH |

|---|---|---|---|---|---|---|---|

| 6 M, 8 M, 10 M, 12 M, 14 M | 1.40 | 100MK0S | 450.0 | 0 | 1125 | 210 | 105 |

| 75MK25S | 337.5 | 112.5 | 1125 | ||||

| 50MK50S | 225.0 | 225.0 | 1125 | ||||

| 25MK75S | 112.5 | 337.5 | 1125 | ||||

| 0MK100S | 0 | 450.0 | 1125 | ||||

| 1.25 | 100MK0S | 450.0 | 0 | 1125 | 240 | 120 | |

| 75MK25S | 337.5 | 112.5 | 1125 | ||||

| 50MK50S | 225.0 | 225.0 | 1125 | ||||

| 25MK75S | 112.5 | 337.5 | 1125 | ||||

| 0MK100S | 0 | 450.0 | 1125 | ||||

| 1.00 | 100MK0S | 450.0 | 0 | 1125 | 300 | 150 | |

| 75MK25S | 337.5 | 112.5 | 1125 | ||||

| 50MK50S | 225.0 | 225.0 | 1125 | ||||

| 25MK75S | 112.5 | 337.5 | 1125 | ||||

| 0MK100S | 0 | 450.0 | 1125 |

| Mix ID | Bulk Density (kg/m3) | Change in Porosity (%) | Change in Water Absorption (%) | |

|---|---|---|---|---|

| Control | 1900 | - | - | |

| CF | 0.25 CF | 2020 | 35.24 | 27.32 |

| 0.50 CF | 2100 | 70.13 | 54.22 | |

| 0.75 CF | 1970 | 88.99 | 82.43 | |

| SF | 0.25 SF | 2000 | 7.49 | 2.55 |

| 0.50 SF | 2060 | 16.04 | 7.09 | |

| 0.75 SF | 2080 | 44.41 | 32.30 | |

| EW | 0.25 EW | 2060 | 31.85 | 21.68 |

| 0.50 EW | 2110 | 78.77 | 61.18 | |

| 0.75 EW | 2140 | 121.59 | 97.47 | |

| CB | 1 CB | 2060 | −15.86 | −22.11 |

| 2 CB | 1920 | −11.67 | −12.30 | |

| 3 CB | 1800 | 37.89 | 45.79 | |

| Mixture | UPV (km/s) (28 Days) | Change in UPV | |

|---|---|---|---|

| Control | 3.12 | - | |

| CF | 0.25 CF | 2.66 | −14.60% |

| 0.50 CF | 3.32 | 6.50% | |

| 0.75 CF | 2.91 | −6.84% | |

| SF | 0.25 SF | 3.21 | 2.98% |

| 0.50 SF | 3.59 | 15.11% | |

| 0.75 SF | 3.34 | 6.95% | |

| EW | 0.25 EW | 3.03 | −2.97% |

| 0.50 EW | 3.47 | 11.24% | |

| 0.75 EW | 3.54 | 13.33% | |

| CB | 1 CB | 3.08 | −1.38% |

| 2 CB | 2.95 | −5.56% | |

| 3 CB | 2.97 | −4.77% | |

| Content | Percentage, % | ||||

|---|---|---|---|---|---|

| Control | EW | CF | SF | CB | |

| C | 42.5 | 0.2 | 0.0 | 0.0 | 0.0 |

| O | 40.1 | 0.0 | 0.0 | 0.0 | 0.0 |

| Na | 3.5 | 34.3 | 24.9 | 31.0 | 24.5 |

| Al | 4.3 | 45.7 | 45.5 | 25.4 | 35.6 |

| Si | 7.2 | 0.0 | 0.0 | 0.0 | 0.0 |

| Ca | 2.5 | 13.2 | 13.5 | 7.8 | 34.4 |

| Fe | 0.0 | 0.1 | 0.0 | 34.4 | 0.1 |

| Mg | 0.0 | 3.9 | 12.3 | 0.4 | 4.9 |

| K | 0.0 | 2.5 | 3.8 | 0.9 | 0.5 |

| Main Content | Mixture | K * | The Best Series in the Group | The Best of All |

|---|---|---|---|---|

| CF | 0.25 CF | 5.62 × 10−11 | 0.50 CF | 0.75 EW |

| 0.50 CF | 6.25 × 10−16 | |||

| 0.75 CF | 1.17 × 10−15 | |||

| SF | 0.25 SF | 6.30 × 10−16 | 0.75 SF | |

| 0.50 SF | 5.42 × 10−16 | |||

| 0.75 SF | 1.02 × 10−16 | |||

| EW | 0.25 EW | 7.54 × 10−17 | 075 EW | |

| 0.50 EW | 2.51 × 10−17 | |||

| 0.75 EW | 1.74 × 10−17 | |||

| CB | 1 CB | 2.34 × 10−15 | 1 CB | |

| 2 CB | 3.97 × 10−15 | |||

| 3 CB | 1.05 × 10−14 |

| Mixture | Bulk Density (kg/m3) | Porosity, (%) | Water Absorption, (%) | UPV (km/s) @ (28 Days) | Abrasion Resistance cm3/50 cm2 | Comp. Str., 7 Days, MPa | Comp. Str., 28 Days, MPa | Bend. Str., 7 Days, MPa | Bend. Str., 28 Days, MPa | Spl. Tens. Str., 28 Days, MPa | Dir. Tens. Str., 28 Days, MPa |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Control | 1900 | 9.08 | 4.77 | 3.12 | 16.03 | 50.8 | 52.29 | 9.0 | 8.9 | 1.34 | 1.08 |

| 0.75 EW | 2140 (+) | 20.12 (-) | 9.42 (-) | 3.54 (+) | 27.65 (-) | 68.86 (+) | 76.8 (+) | 19.01 (+) | 17.04 (+) | 2.24 (+) | 1.8 (+) |

| Series | Curing | Energy (kWh/m3) | CO2 (kg) | Water (L) | Soil (kg) | Eutro (kg PO4 eq) | Ozone (kg CFC-11) | Toxicity (kg DCB) |

|---|---|---|---|---|---|---|---|---|

| Control | 10 V | 1440 | 720 | 100,800 | 1728 | 288 | 0.0288 | 21.6 |

| Control | 20 V | 2880 | 1440 | 201,600 | 3456 | 576 | 0.0576 | 43.2 |

| Control | Oven | 8000 | 4000 | 560,000 | 9600 | 1600 | 0.1600 | 120 |

| 0.25 CF | 10 V | 6096 | 3048 | 426,720 | 7315 | 1219 | 0.122 | 91.4 |

| 0.25 CF | 20 V | 12,192 | 6096 | 853,440 | 14,630 | 2438 | 0.244 | 182.9 |

| 0.25 CF | Oven | 8000 | 4000 | 560,000 | 9600 | 1600 | 0.160 | 120 |

| 0.50 CF | 10 V | 7164 | 3582 | 501,480 | 8597 | 1433 | 0.143 | 107.5 |

| 0.50 CF | 20 V | 14,328 | 7164 | 1,002,960 | 17,194 | 2866 | 0.287 | 215.0 |

| 0.50 CF | Oven | 8000 | 4000 | 560,000 | 9600 | 1600 | 0.160 | 120 |

| 0.75 CF | 10 V | 8184 | 4092 | 573,000 | 9821 | 1637 | 0.164 | 122.8 |

| 0.75 CF | 20 V | 16,368 | 8184 | 1,146,000 | 19,642 | 3274 | 0.327 | 245.5 |

| 0.75 CF | Oven | 8000 | 4000 | 560,000 | 9600 | 1600 | 0.160 | 120 |

| 0.25 SF | 10 V | 7020 | 3510 | 491,400 | 8424 | 1404 | 0.140 | 105.3 |

| 0.25 SF | 20 V | 14,040 | 7020 | 982,800 | 16,848 | 2808 | 0.281 | 210.6 |

| 0.25 SF | Oven | 8000 | 4000 | 560,000 | 9600 | 1600 | 0.160 | 120.0 |

| 0.50 SF | 10 V | 8220 | 4110 | 575,400 | 9864 | 1644 | 0.164 | 123.3 |

| 0.50 SF | 20 V | 16,440 | 8220 | 1,150,800 | 19,728 | 3288 | 0.329 | 246.6 |

| 0.50 SF | Oven | 8000 | 4000 | 560,000 | 9600 | 1600 | 0.160 | 120.0 |

| 0.75 SF | 10 V | 9600 | 4800 | 672,000 | 11,520 | 1920 | 0.192 | 144.0 |

| 0.75 SF | 20 V | 19,200 | 9600 | 1,344,000 | 23,040 | 3840 | 0.384 | 288.0 |

| 0.75 SF | Oven | 8000 | 4000 | 560,000 | 9600 | 1600 | 0.160 | 120.0 |

| 0.25 EW | 10 V | 9072 | 4536 | 635,040 | 10,886 | 1814 | 0.181 | 136.1 |

| 0.25 EW | 20 V | 18,144 | 9072 | 1,270,080 | 21,772 | 3628 | 0.363 | 272.2 |

| 0.25 EW | Oven | 8000 | 4000 | 560,000 | 9600 | 1600 | 0.160 | 120.0 |

| 0.50 EW | 10 V | 12,864 | 6432 | 900,480 | 15,437 | 2573 | 0.257 | 193.0 |

| 0.50 EW | 20 V | 25,728 | 12,864 | 1,800,960 | 30,874 | 5146 | 0.515 | 386.0 |

| 0.50 EW | Oven | 8000 | 4000 | 560,000 | 9600 | 1600 | 0.160 | 120.0 |

| 0.75 EW | 10 V | 10,848 | 5424 | 759,360 | 13,018 | 2170 | 0.217 | 162.7 |

| 0.75 EW | 20 V | 21,696 | 10,848 | 1,518,720 | 26,035 | 4339 | 0.434 | 325.4 |

| 0.75 EW | Oven | 8000 | 4000 | 560,000 | 9600 | 1600 | 0.160 | 120.0 |

| 1% CB | 10 V | 9252 | 4626 | 647,640 | 11,102 | 1850 | 0.185 | 138.8 |

| 1% CB | 20 V | 18,504 | 9252 | 1,295,280 | 22,205 | 3700 | 0.370 | 277.5 |

| 1% CB | Oven | 8000 | 4000 | 560,000 | 9600 | 1600 | 0.160 | 120.0 |

| 2% CB | 10 V | 9900 | 4950 | 693,000 | 11,880 | 1980 | 0.198 | 148.5 |

| 2% CB | 20 V | 19,800 | 9900 | 1,386,000 | 23,760 | 3960 | 0.396 | 297.0 |

| 2% CB | Oven | 8000 | 4000 | 560,000 | 9600 | 1600 | 0.160 | 120.0 |

| 3% CB | 10 V | 10,560 | 5280 | 739,200 | 12,672 | 2112 | 0.211 | 158.4 |

| 3% CB | 20 V | 21,120 | 10,560 | 1,478,400 | 25,344 | 4224 | 0.422 | 316.8 |

| 3% CB | Oven | 8000 | 4000 | 560,000 | 9600 | 1600 | 0.160 | 120.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gokcegoz, Y.; Uysal, M.; Canpolat, O.; Arikan, O.; Dilbas, H.; Aygun, B. Electrical Curing of Metakaolin- and GBFS-Based Geopolymers: A Sustainable Technology Aligned with the European Green Deal. Materials 2025, 18, 4811. https://doi.org/10.3390/ma18204811

Gokcegoz Y, Uysal M, Canpolat O, Arikan O, Dilbas H, Aygun B. Electrical Curing of Metakaolin- and GBFS-Based Geopolymers: A Sustainable Technology Aligned with the European Green Deal. Materials. 2025; 18(20):4811. https://doi.org/10.3390/ma18204811

Chicago/Turabian StyleGokcegoz, Yusuf, Mucteba Uysal, Orhan Canpolat, Oktay Arikan, Hasan Dilbas, and Beyza Aygun. 2025. "Electrical Curing of Metakaolin- and GBFS-Based Geopolymers: A Sustainable Technology Aligned with the European Green Deal" Materials 18, no. 20: 4811. https://doi.org/10.3390/ma18204811

APA StyleGokcegoz, Y., Uysal, M., Canpolat, O., Arikan, O., Dilbas, H., & Aygun, B. (2025). Electrical Curing of Metakaolin- and GBFS-Based Geopolymers: A Sustainable Technology Aligned with the European Green Deal. Materials, 18(20), 4811. https://doi.org/10.3390/ma18204811