Analysis of the Causes of Damage to the Steel Drive Shaft Used in a Paint Mixer

Abstract

1. Introduction

2. Materials and Methods

- Macroscopic studies of shaft fracture using a Delta Optical SZ-630B optical microscope (Delta Optical, Minsk Mazowiecki, Poland) with a magnification of 10×.

- Preparation of samples for microscopic observations: mounting the test specimens—Ecopress 100 device (Metkon INC., Mauldin, SC, USA); surface grinding—abrasive papers: 180, 500, 2000; surface polishing with diamond suspension—Scandimatic 33305 device (SCAN-DIA GmbH, Hagen, Germany); etching in 4% HNO3.

- Hardness measurements at the cross section of the subsurface layer of the drive shaft were conducted using a Vickers hardness tester (HV 0.1) and a Mitutoyo Micro-Vickers HM-210 A device (Model 810–401 D, Mitutoyo, Kawasaki, Japan) and Rockwell FENIX 300U device (Innovatest, Wiry, Poland). Microscopic examination of metallographic specimens was carried out using an Axiovert 100A optical microscope (Carl Zeiss GmbH, Oberkochen, Germany) with the use of the computer image analysis software ImageJ (version 1.54p) and an Axiocam 305 camera (Carl Zeiss GmbH, Oberkochen, Germany).

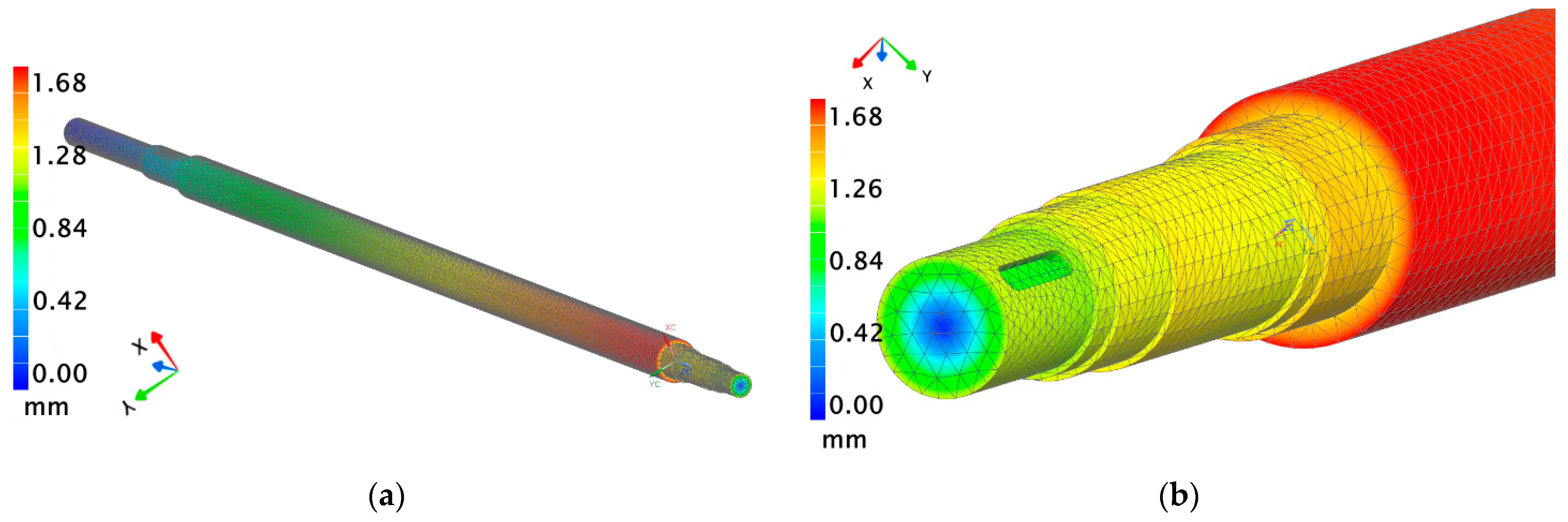

- FEM simulation—modeling and evaluation of stress distribution in individual shaft cross-sections, which identifies potential places most vulnerable to damage.

3. Results

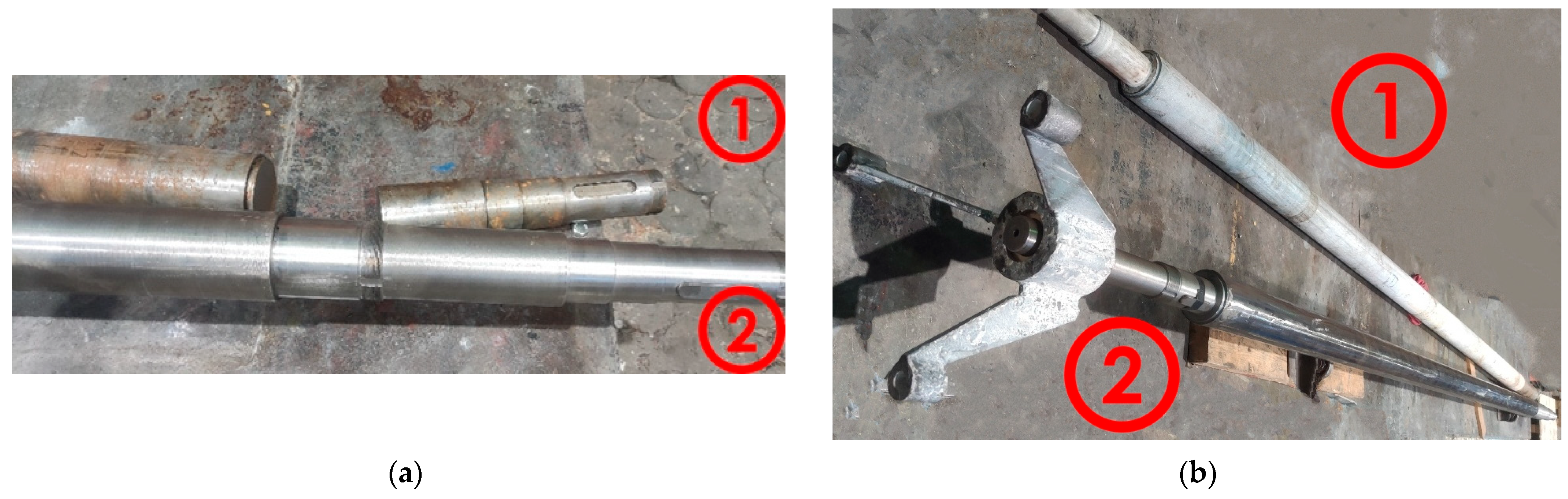

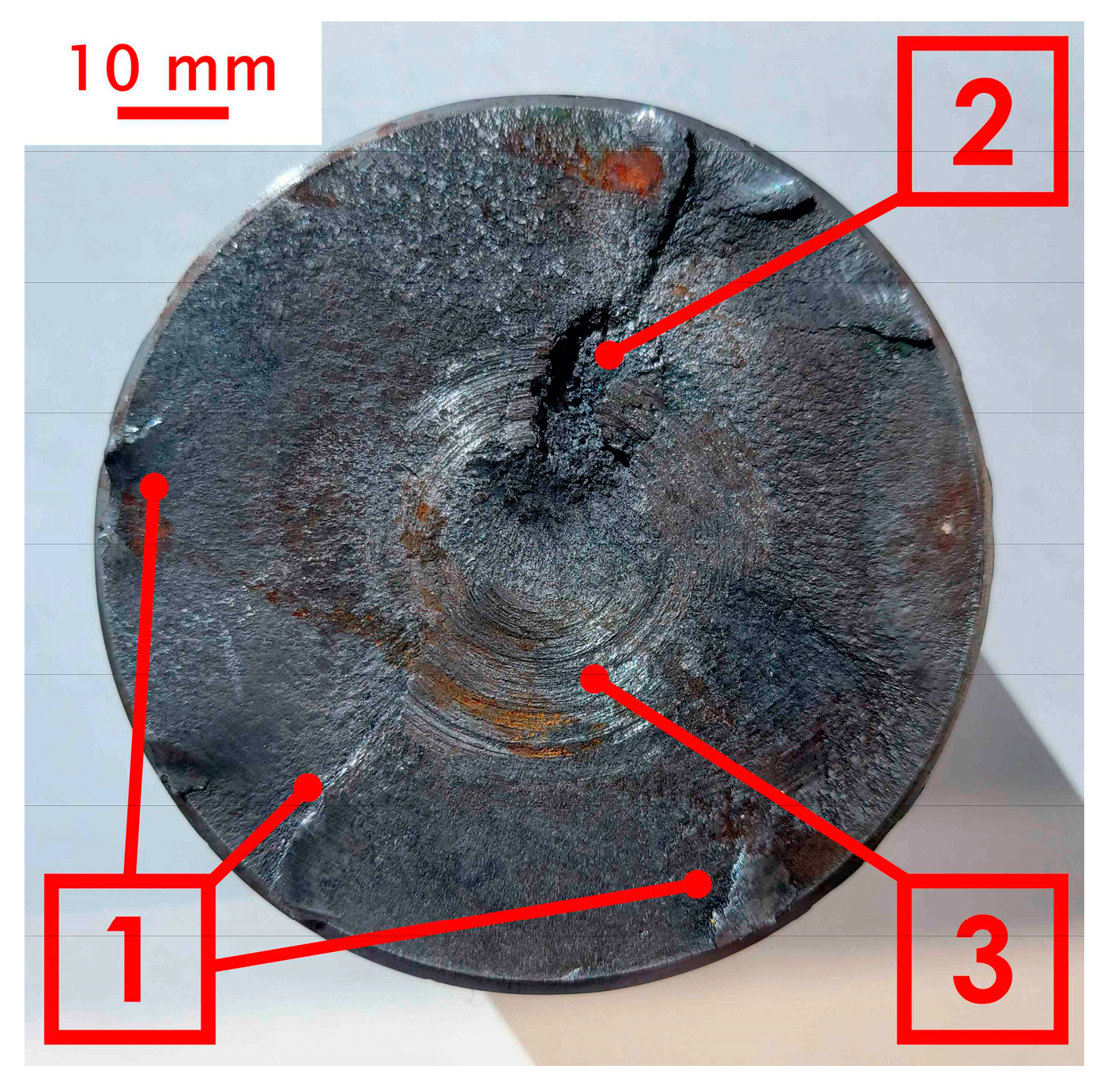

3.1. Macroscopic Observations

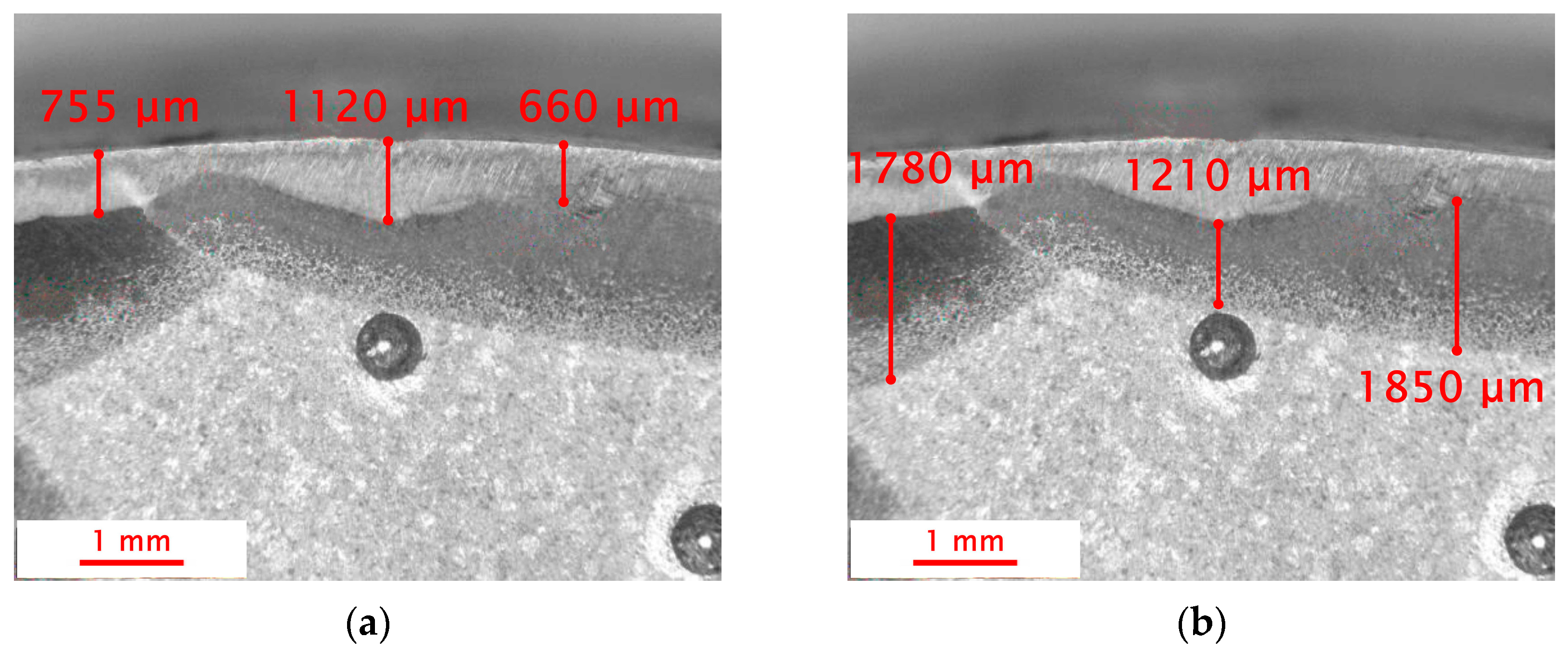

3.2. Microscopic Observations and Hardness Measurements

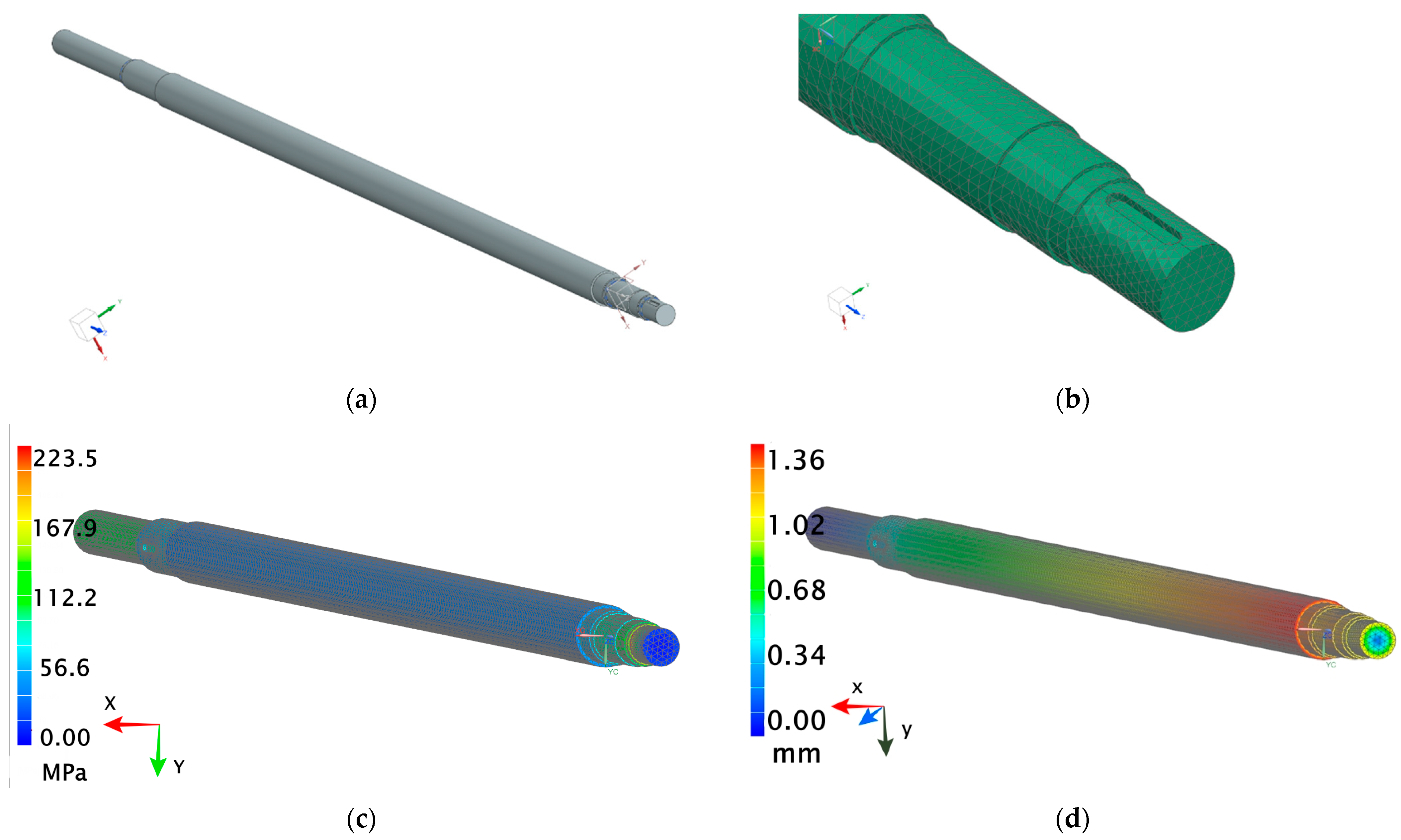

3.3. FEM Analysis of the Paint Mixer Shaft

- Identification of areas of potential torsion that may affect the structural integrity of the shaft and its ability to transmit torques.

- Assessment of the impact of various loads, both static and dynamic, on the strength and durability of the structure.

4. Conclusions

- In less heavily loaded structures, the use of carbon steel as the material for the drive shaft is entirely sufficient and economically justified. The achieved service life of the analyzed paint mixer drive shaft, amounting to 20 years, should be considered satisfactory.

- The regeneration of the drive shaft by weld-surfacing enabled its further operation for a relatively short period (3 years) and led to a change in the nature of its failure due to microstructural changes in the steel caused by thermal effects.

- The cause of damage to the drive shaft prior to regeneration was chipping/wear of the outer surface, whereas the direct cause of failure after regeneration was cracking originating from initiation points in the outer zone of the surface layer. Therefore, the quality of the layer added during surfacing is a key factor in this case.

- The failure of the shaft was also influenced by the excessive hardness of the added material (325 HV 0.1). Although no further surface abrasion wear was observed, the multisite, circumferential cracking mechanism suggests the excessive brittleness of the outer layer as a reason for destruction.

- The radial expansion direction of the observed cracks indicated that the drive shaft experienced fatigue failure during service and the main reason for failure was rotation-bending fatigue.

- The hardness of the core of the drive shaft was found to be typical for the standard value during the mechanical property test, which was due to the pearlitic–ferritic structure (with 60% pearlite).

- The heat-affected zone formed as a result of the weld-surfacing process exhibited hardness only slightly lower than that of the newly added layer (by approximately 50 HV0.01) and consisted of very fine pearlite.

- Finite element analysis showed that the drive shaft lifetime can be extended by using different materials: steel with higher carbon content or hollow shaft construction. The use of a hollow shaft can lead to a reduction in initial weight by up to 14%, which should result in a significant extension of the analyzed structure’s service life and enable its production from a higher-grade steel without increasing material costs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gronostajski, Z.; Kuziak, R. Metalurgiczne, technologiczne i funkcjonalne podstawy zaawansowanych wysokowytrzymałych stali dla przemysłu motoryzacyjnego. Pr. Inst. Metal. Żelaza 2010, 62, 22–26. [Google Scholar]

- Poloszyk, S.; Różański, L. Termowizyjna diagnostyka maszyn technologicznych. Pomiary Autom. Kontrola 2000, 46, 15–18. [Google Scholar]

- Marek, F. Metody diagnozowania obiektów technicznych i procesów przemysłowych. Politechnika Śląska. 2015. Available online: https://www.axonmedia.pl/konferencje/archiwalne/prezentacje/Marek%20Fidali.pdf (accessed on 1 September 2025).

- Huang, Z.; Wang, J.; Hu, Y.; Jiang, Y.; Xu, Y.; Wan, X. Failure Mechanism of Rear Drive Shaft in a Modified Pickup Truck. Metals 2024, 14, 641. [Google Scholar] [CrossRef]

- Hou, N.; Ding, N.; Qu, S.; Guo, W.; Liu, L.; Xu, N.; Tian, L.; Xu, H.; Chen, X.; Zaïri, F.; et al. Failure Modes, Mechanisms and Causes of Shafts in Mechanical Equipment. Eng. Fail. Anal. 2022, 136, 106216. [Google Scholar] [CrossRef]

- Zhao, L.H.; Xing, Q.K.; Wang, J.Y.; Li, S.L.; Zheng, S.L. Failure and Root Cause Analysis of Vehicle Drive Shaft. Eng. Fail. Anal. 2019, 99, 225–234. [Google Scholar] [CrossRef]

- Anoop, M.S.; Dhanesh, S. Failure Analysis and Design Optimization of Alternator Shaft Used in Rail Coaches. Mater. Today Proc. 2021, 45, 1403–1410. [Google Scholar] [CrossRef]

- Cui, T.; Li, Y.; Luo, F.; Wang, C. Fracture Mechanism of Transmission Spindle System for High-Speed Tracked Vehicle. Eng. Fail. Anal. 2022, 136, 106174. [Google Scholar] [CrossRef]

- Zhang, Z.; Yin, Z.; Han, T.; Tan, A.C.C. Fracture Analysis of Wind Turbine Main Shaft. Eng. Fail. Anal. 2013, 34, 129–139. [Google Scholar] [CrossRef]

- Zhu, C.; He, J.; Peng, J.; Ren, Y.; Lin, X.; Zhu, M. Failure Mechanism Analysis on Railway Wheel Shaft of Power Locomotive. Eng. Fail. Anal. 2019, 104, 25–38. [Google Scholar] [CrossRef]

- Xu, Z.; Cui, Y.; Li, B.; Liu, K.; Shi, F.; Cao, P. Impact Analysis of Initial Cracks’ Angle on Fatigue Failure of Flange Shafts. Coatings 2022, 12, 276. [Google Scholar] [CrossRef]

- Pantazopoulos, G.; Zormalia, S.; Vazdirvanidis, A. Investigation of Fatigue Failure of Roll Shafts in a Tube Manufacturing Line. J. Fail. Anal. Prev. 2010, 10, 358–362. [Google Scholar] [CrossRef]

- Zhang, P.; Jiang, Y.; Li, Y.; Gong, J.; Sun, N. Experimental and Simulative Failure Analysis of AISI 316L Stainless Steel Screw Shaft. J. Fail. Anal. Prev. 2018, 18, 799–808. [Google Scholar] [CrossRef]

- Xiaolei, X.; Zhiwei, Y. Failure Analysis of a Locomotive Turbocharger Main-Shaft. Eng. Fail. Anal. 2009, 16, 495–502. [Google Scholar] [CrossRef]

- Ghosh, D.; Roy, H.; Mondal, A. Failure Investigation of Condensate Pump Shaft. J. Fail. Anal. Prev. 2014, 14, 450–453. [Google Scholar] [CrossRef]

- Sitthipong, S.; Towatana, P.; Sitticharoenchai, A. Failure Analysis of Metal Alloy Propeller Shafts. Mater. Today Proc. 2017, 4, 6491–6494. [Google Scholar] [CrossRef]

- Diler, A.A.; Gurgen, S.; Sert, A. Failure analysis of an axle shaft in an airport ground support vehicle. Proc. Inst. Mech. Eng. Part L J. Mater.-Des. Appl. 2023, 237, 925–940. [Google Scholar] [CrossRef]

- Bian, X.; Liu, Y.; Zhang, J. Fracture Analysis on Involute Spline of Large Tunnel Boring Machine. Eng. Fail. Anal. 2022, 142, 106728. [Google Scholar] [CrossRef]

- Kowalski, S.; Barta, D.; Dižo, J.; Dittrich, A. Assessment of the Wear of a Repeatedly Disassembled Interference-Fit Joint Operating under Rotational Bending Conditions. Appl. Sci. 2023, 13, 3902. [Google Scholar] [CrossRef]

- Miranda, R.S.; Cruz, C.; Cheung, N.; Cunha, A.P.A. Fatigue Failure Analysis of a Speed Reduction Shaft. Metals 2021, 11, 856. [Google Scholar] [CrossRef]

- Hou, X.Q.; Li, Y.; Liu, C.K.; He, Y.H. Fracture Failure Analysis of a 30CrMnSiA Steel Shaft. J. Fail. Anal. Prev. 2012, 12, 485–489. [Google Scholar] [CrossRef]

- Nassef, G.A.; Elkhatib, A.; Yakout, M. Analysis of a Failed Rocker Arm Shaft of a Passenger Car Engine. Case Stud. Eng. Fail. Anal. 2016, 5–6, 10–14. [Google Scholar] [CrossRef]

- Jarrett, W.; Jeffs, S.P.; Korkees, F. The opportunities and challenges of hybrid composite driveshafts and their couplings in the aerospace industry: A review. Compos. Struct. 2023, 320, 117203. [Google Scholar] [CrossRef]

- Muni, K.; Jaligam, K.; Vinay, K. Design and Analysis of Drive Shaft of an Automobile. Int. J. Eng. Trends Technol. (IJETT). 2016, 38, 6. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, P.; Sharma, S. Material selection for automotive drive shafts: A review. J. Mech. Eng. Res. 2018, 10, 45–55. [Google Scholar]

- Cander, D.; Geneix, J.; Depouhon, P. Advanced concept of drive shaft system for hybrid high speed helicopter. In Proceedings of the 45th European Rotorcraft Forum, Warsaw, Poland, 17–20 September 2019; p. 156. Available online: https://dspace-erf.nlr.nl/server/api/core/bitstreams/bb837cad-4a5c-4274-8442-98348d0f15a1/content (accessed on 1 September 2025).

- Tuninetti, V.; Martínez, D.; Narayan, S.; Menacer, B.; Oñate, A. Design Optimization of a Marine Propeller Shaft for Enhanced Fatigue Life: An Integrated Computational Approach. J. Mar. Sci. Eng. 2024, 12, 2227. [Google Scholar] [CrossRef]

- Top Entry Mixers—Product Calalog of REDOR Company. Available online: http://karbo-eko-masz.pl/katalogi/REDOR1.pdf (accessed on 1 September 2025).

- Smith, J.; Lee, K. Lightweight aluminum drive shafts for sports cars. Mater. Des. 2020, 188, 108–115. [Google Scholar]

- Lee, D.G.; Kim, H.S.; Kim, J.W.; Kim, J.K. Design and manufacture of an automotive hybrid aluminum/composite drive shaft. Compos. Struct. 2004, 63, 87–99. [Google Scholar] [CrossRef]

- Elanchezhian, C.; Vijaya Ramnath, B.; Sripada Raghavendra, K.N.; Mithun Muralidharan Rekha, G. Design and Comparison of the Strength and Efficiency of Drive Shaft made of Steel and Composite Materials. Mater. Today Proc. 2018, 5, 1000–1007. [Google Scholar] [CrossRef]

- Nalini Kumari, J.; Murthy, B.S.R. A Literature Review on composite Material For Drive Shaft. J. Sci. Technol. 2017, 2, 1–4. [Google Scholar]

- Raushan, R.; Dhande, K.K.; Jamadar, N.I.; Malwe, P.D. Material characterization, design and analysis of CF/PA66 drive shaft with high strength carbon steel. Mater. Today Proc. 2022, 64, 51–58. [Google Scholar] [CrossRef]

- Sun, S.; Yu, X.; Chen, X. Study of Component Structural Equivalent Fatigue Based on a Combined Stress Gradient Approach and the Theory of Critical Distance. Eng. Fail. Anal. 2016, 60, 199–208. [Google Scholar] [CrossRef]

- Trifkovic, D.; Stupar, S.; Bosnjak, S.; Milovancevic, M.; Krstic, B.; Rajic, Z.; Dunjic, M. Failure Analysis of the Combat Jet Aircraft Rudder Shaft. Eng. Fail. Anal. 2011, 18, 1998–2007. [Google Scholar] [CrossRef]

- Negru, R.; Muntean, S.; Pasca, N.; Marsavina, L. Failure Assessment of the Shaft of a Pumped Storage Unit. Fatigue Fract. Eng. Mater. Struct. 2014, 37, 807–820. [Google Scholar] [CrossRef]

- Lee, D.W.; Lee, S.J.; Cho, S.S.; Joo, W.S. Failure of Rocker Arm Shaft for 4-Cylinder SOHC Engine. Eng. Fail. Anal. 2005, 12, 405–412. [Google Scholar] [CrossRef]

- Iskandar, N.; Sulardjaka; Arif, I.N. Maintenance and Repair of Ship Propeller Shafts. IRJIET 2023, 7, 589–594. Available online: https://irjiet.com/Volume-7/Issue-11-November-2023/Maintenance-and-Repair-of-Ship-Propeller-Shafts/1997 (accessed on 1 September 2025).

- Miller, B.A.; Taylor, R.O.; Swartzentruber, P.D.; Kelly, B.P. Failure of Steel Shafts Due to Improper Repair Welding. J. Fail. Anal. Prev. 2023, 23, 894–909. [Google Scholar] [CrossRef]

- Kupiec, B.; Opiekun, Z.; Dec, A. Rebuilding of Turbocharger Shafts by Hardfacing. Materials 2022, 15, 5761. [Google Scholar] [CrossRef]

- Bridigum, T. Welding: Everything You Need to Know; Motorbooks International: Osceola, WI, USA, 2022; 160p. [Google Scholar]

- Singh, R. Applied Welding Engineering, Processes, Codes and Standards; Butterworth-Heinemann: Oxford, UK, 2020. [Google Scholar]

- PN-EN 10083-2; Quenching Steels—Part 2: Technical Conditions for the Supply of Alloy Steels’. Polish Committee for Standardization: Warsaw, Poland, 2018.

- Wires for Surface by Welding. Available online: https://bendam.pl/druty-do-napawania/ (accessed on 17 September 2025).

- Chen, J.; Cao, R. Micromechanism of Cleavage Fracture of Metals: A Comprehensive Microphysical Model for Cleavage Cracking in Metals; Butterworth-Heinemann: Oxford, UK, 2014. [Google Scholar]

- Safonov, E.N. Research of features of structure formation in case of surface steel hardening. 15th International Conference on Industrial Manufacturing and Metallurgy. IOP Conf. Ser. Mater. Sci. Eng. 2020, 966, 012066. [Google Scholar] [CrossRef]

- Dobrzański, L.A. Materiały Inżynierskie z Podstawami Technologii Procesów Materiałowych; PWN: Warsaw, Poland, 2024. [Google Scholar]

- Toth, L. The possibilities of the retained austenite reduction on tool steels. Cryst. Eng. 2021, 6, 99–105. [Google Scholar] [CrossRef]

- Zhang, L.Y.; Rong, M.; Purushothaman, R. Microstructure and Property Predictions by Using a Heat-Treatment Planning System, CHT-q/t. In Proceedings of the 24th ASM Heat Treating Society Conference, Detroit, MI, USA, 17–19 September 2007. [Google Scholar]

- Wang, Y.; Chen, C.; Yang, X.Y.; Zhang, Z.-R.; Wang, J.; Li, Z.; Chen, L.; Mu, W.-Z. Solidification modes and delta-ferrite of two types of 316L stainless steels: A combination of as-cast microstructure and HT-CLSM research. J. Iron Steel Res. Int. 2025, 32, 426–436. [Google Scholar] [CrossRef]

- Bęczkowski, R.; Cebulski, J.; Pasek, D. Properties of the deposited layers of Fe-Cr-Nb-C by using directional receiving heat. Przegląd Spaw. 2017, 89, 32–35. [Google Scholar]

- Bęczkowski, R.; Gucwab, M.; Wróbel, J.; Kulawik, A. The Adam Impact of the Bead Width on the Properties of the Anti-Abrasion Surfacing Weld. AIP Conf. Proc. 2016, 1738, 480095. [Google Scholar] [CrossRef]

- Dobrzeński, L.A. Podstawy Nauki o Materiałach i Metaloznawstwo: Materiały Inżynierskie z Podstawami Projektowania Materiałowego; Wydawnictwa Naukowo-Techniczne: Warszawa, Poland, 2002. [Google Scholar]

- Available online: https://plm.sw.siemens.com/en-US/nx/ (accessed on 1 September 2025).

- Płuciennik, P.; Maciejczyk, A. Wykorzystanie systemów CAD w procesie konstruowania maszyn i urządzeń. Autobusy 2016, 6, 1481–1485. [Google Scholar]

- PN-EN 10083-1:2008 Standard; Quenching Steels—Part 1: General Technical Delivery Conditions. Polish Committee for Standardization: Warsaw, Poland, 2013.

- Online Steel Wholesaler. Available online: https://moris.eu/pl/stal/c/STEEL (accessed on 1 September 2025).

- Gupta, A.; Yadav, V.S.; Chauhan, S. Investigation of dynamic behavior of Hollow Rotor Shaft System through FEM. J. Phys. Conf. Ser. 2021, 2007, 012066. [Google Scholar] [CrossRef]

- Cao, X.; Wang, B.; Guo, W.; Ju, Z. A New Method of Manufacturing Hollow Shafts via Flexible Skew Rolling. J. Phys. Conf. Ser. 2021, 2101, 012010. [Google Scholar] [CrossRef]

- Zhang, S.; Shu, X.; Wang, J.; Li, Z.; Xu, H.; Xia, Y.; Pater, Z.; Tomczak, J.; Bulzak, T. The Mechanism of Forming Hollow Shafts with Constant Wall Thickness by Three-Roll Skew Rolling. Metals 2024, 14, 702. [Google Scholar] [CrossRef]

| Chemical Composition of Steel, % | ||||||||

|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Ni | Mo | |

| PN-EN 10083-2 | 0.32–0.39 | max 0.4 | 0.5–0.8 | max 0.045 | max 0.045 | max 0.4 | max 0.4 | max 0.1 |

| C | Si | Mn | P | S | Cr | Ni | Mo | |

| Analysis | 0.34 | 0.25 | 0.64 | 0.025 | 0.020 | 0.25 | 0.20 | 0.1 |

| Mechanical Properties of Tested Steel | |||

|---|---|---|---|

| Steel Grade | Yield Strength, MPa | Tensile Strength, MPa | Torsional Strength, MPa |

| 1.0501 | 300–450 | 450–600 | 220–250 |

| 1.0503 | 450–600 | 600–800 | 550–700 |

| 1.0601 | 550–700 | 700–850 | 650–800 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skotnicki, W.; Jędrzejczyk, D. Analysis of the Causes of Damage to the Steel Drive Shaft Used in a Paint Mixer. Materials 2025, 18, 4798. https://doi.org/10.3390/ma18204798

Skotnicki W, Jędrzejczyk D. Analysis of the Causes of Damage to the Steel Drive Shaft Used in a Paint Mixer. Materials. 2025; 18(20):4798. https://doi.org/10.3390/ma18204798

Chicago/Turabian StyleSkotnicki, Wojciech, and Dariusz Jędrzejczyk. 2025. "Analysis of the Causes of Damage to the Steel Drive Shaft Used in a Paint Mixer" Materials 18, no. 20: 4798. https://doi.org/10.3390/ma18204798

APA StyleSkotnicki, W., & Jędrzejczyk, D. (2025). Analysis of the Causes of Damage to the Steel Drive Shaft Used in a Paint Mixer. Materials, 18(20), 4798. https://doi.org/10.3390/ma18204798