Coarse Aggregate Induced Fiber Dispersion and Its Role in UHPC Mechanics Across Flexural and Compressive Loading

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Mix Proportions

2.3. Specimen Preparation and Curing

2.4. Testing Methods

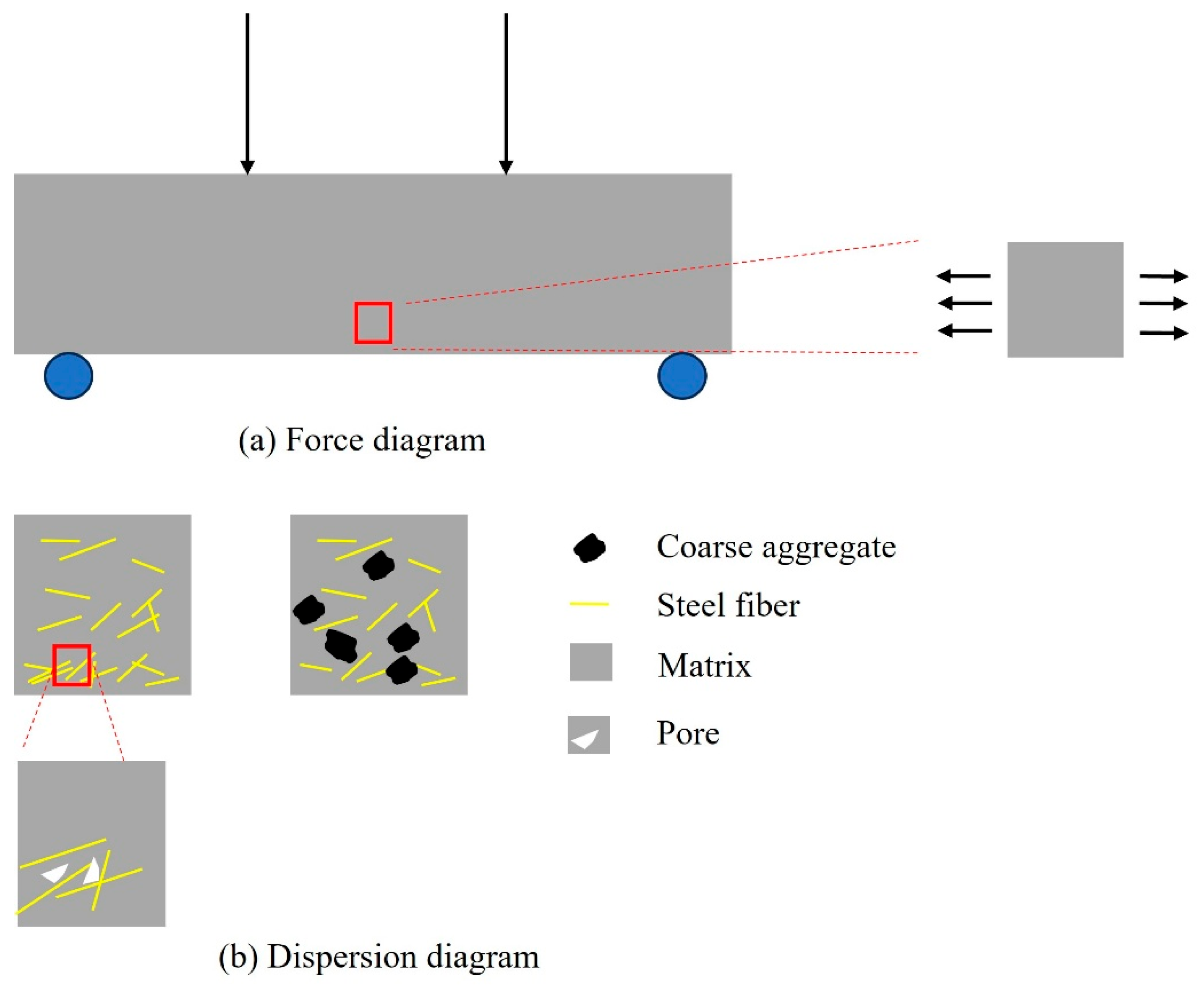

2.4.1. Four-Point Bending Test

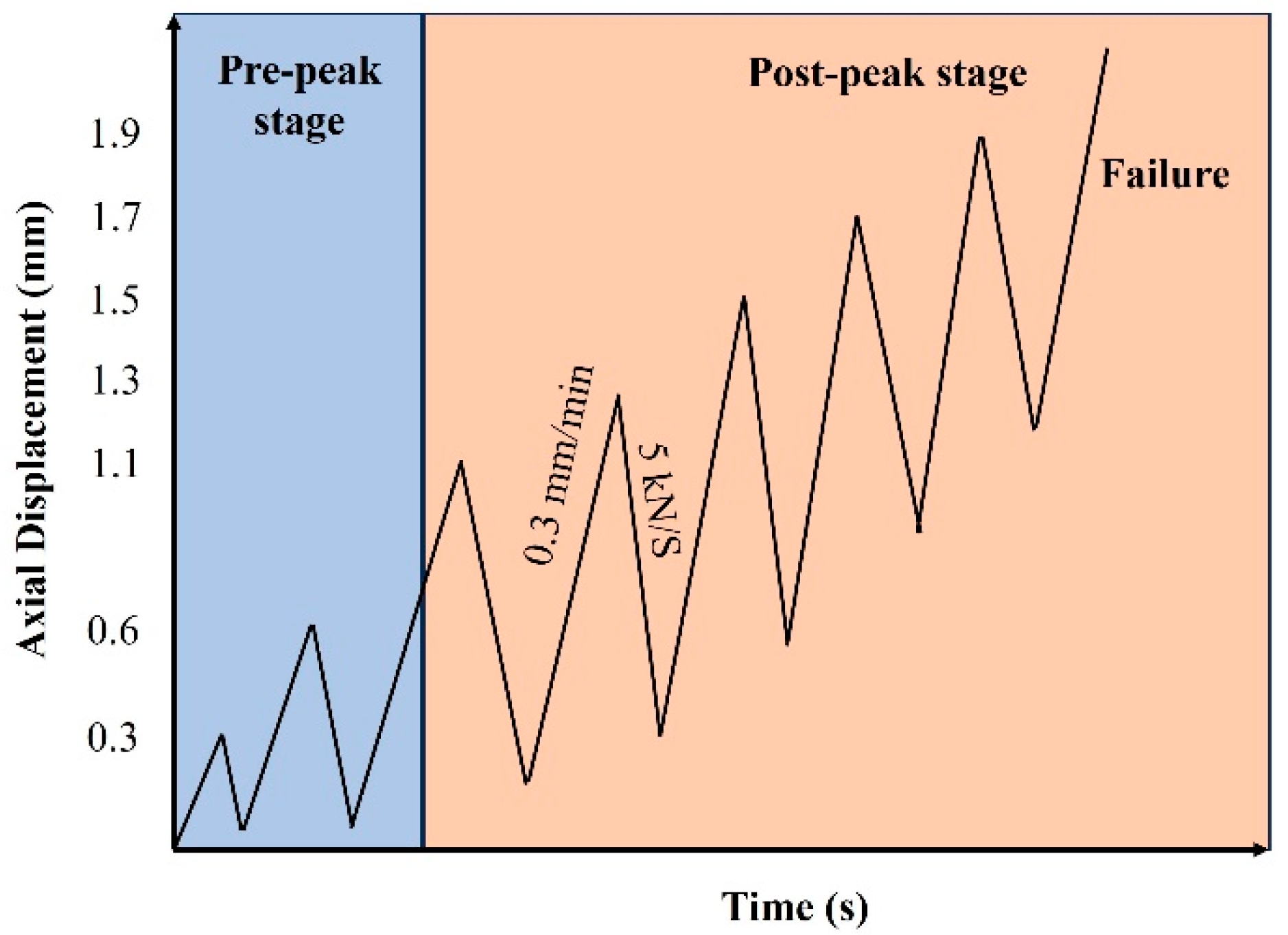

2.4.2. Compressive Strength Test

2.4.3. Fiber Dispersion Test

3. Results

3.1. Flexural Properties

3.1.1. Load-Deflection and Key Parameters

3.1.2. Distribution of Fiber

3.2. Compressive Properties

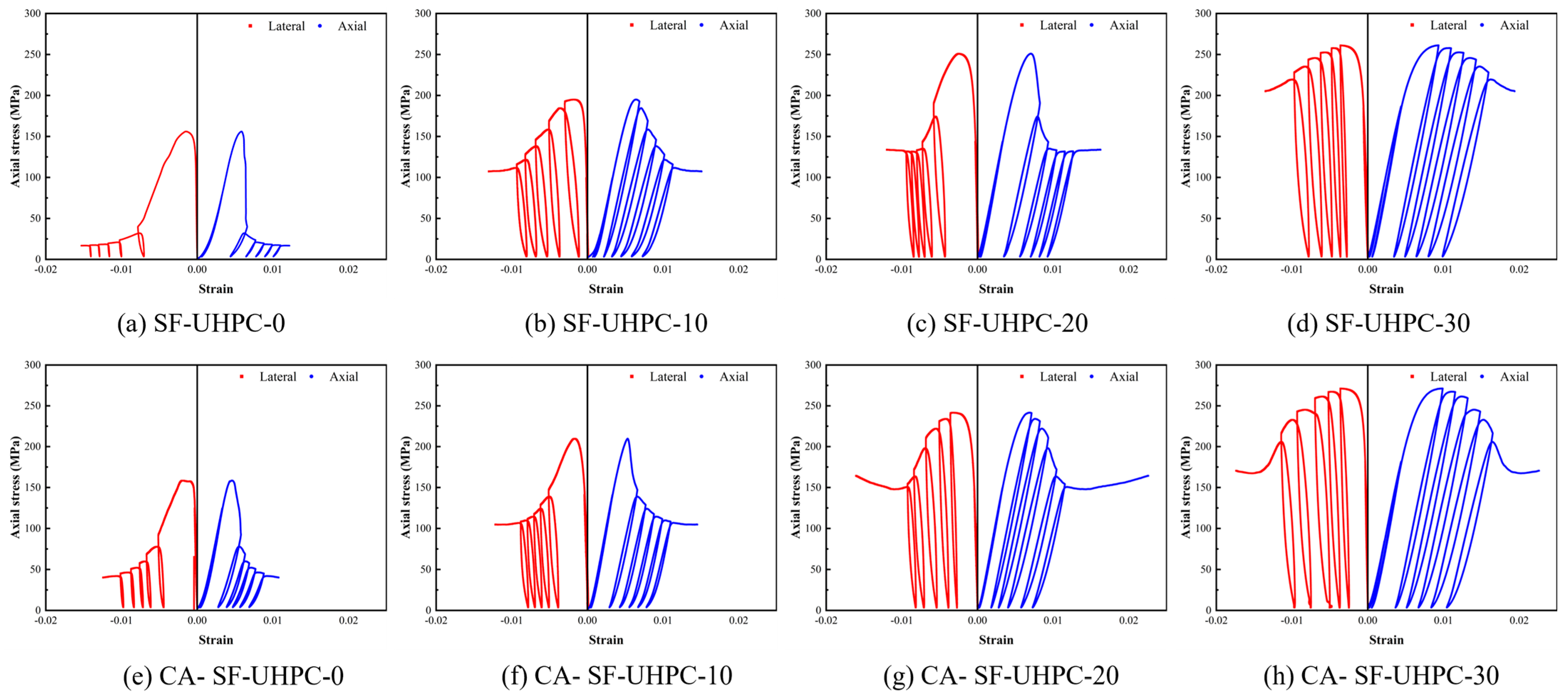

3.2.1. Stress–Strain

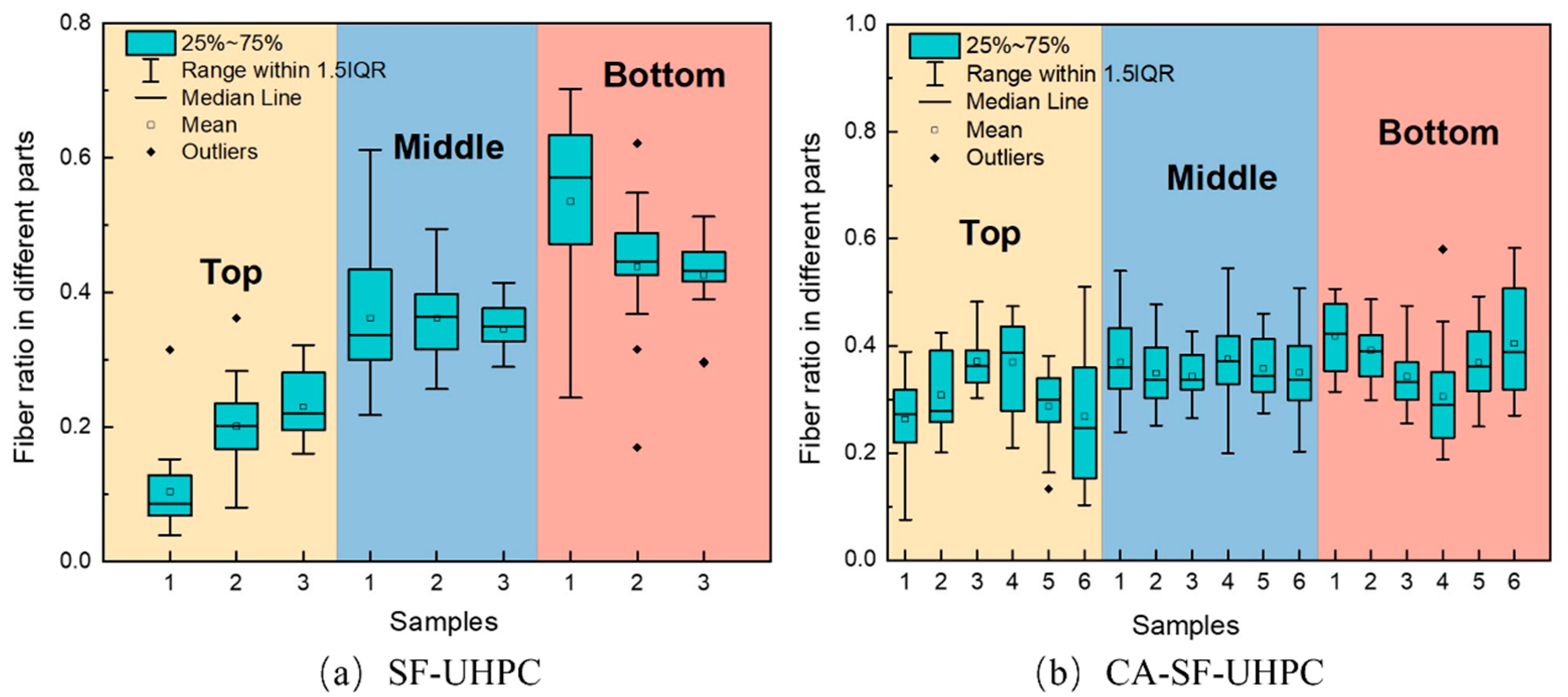

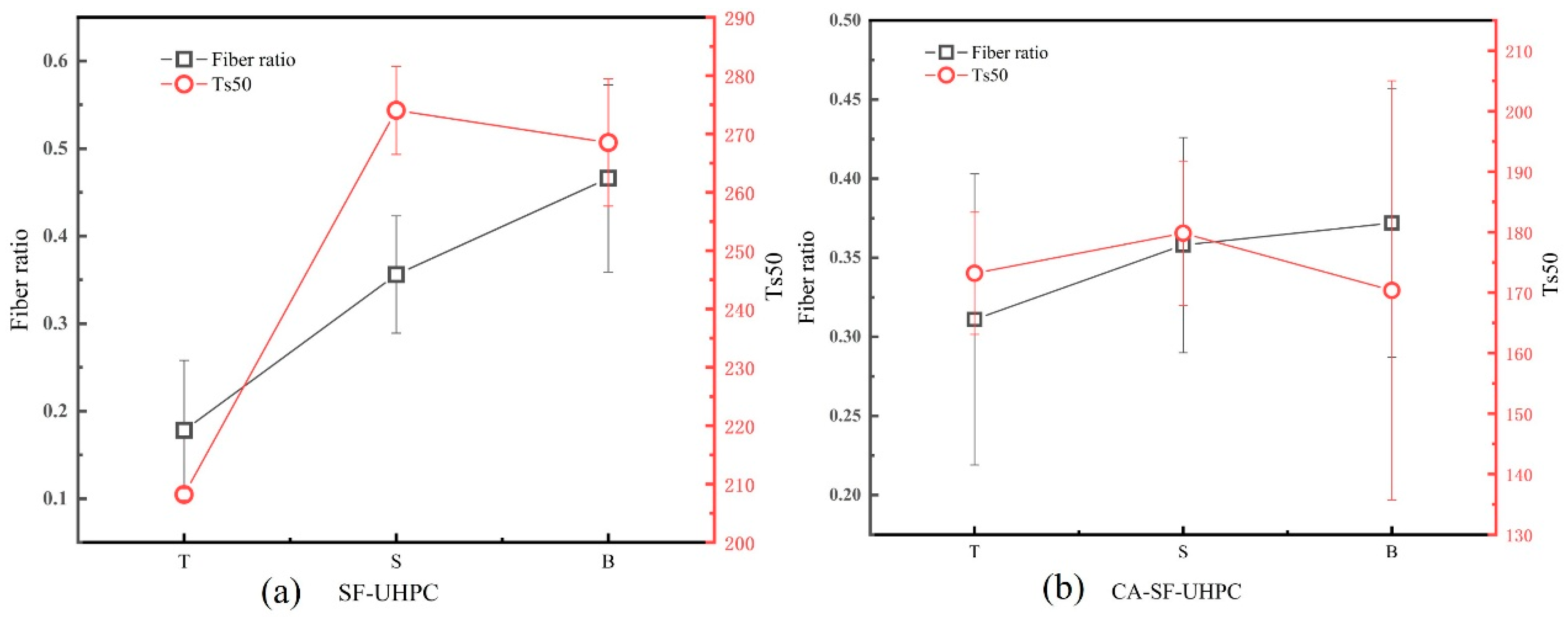

3.2.2. Distribution of Fiber

4. Discussion

4.1. Effect of Fiber Distribution on Four-Point Bending Response of UHPC

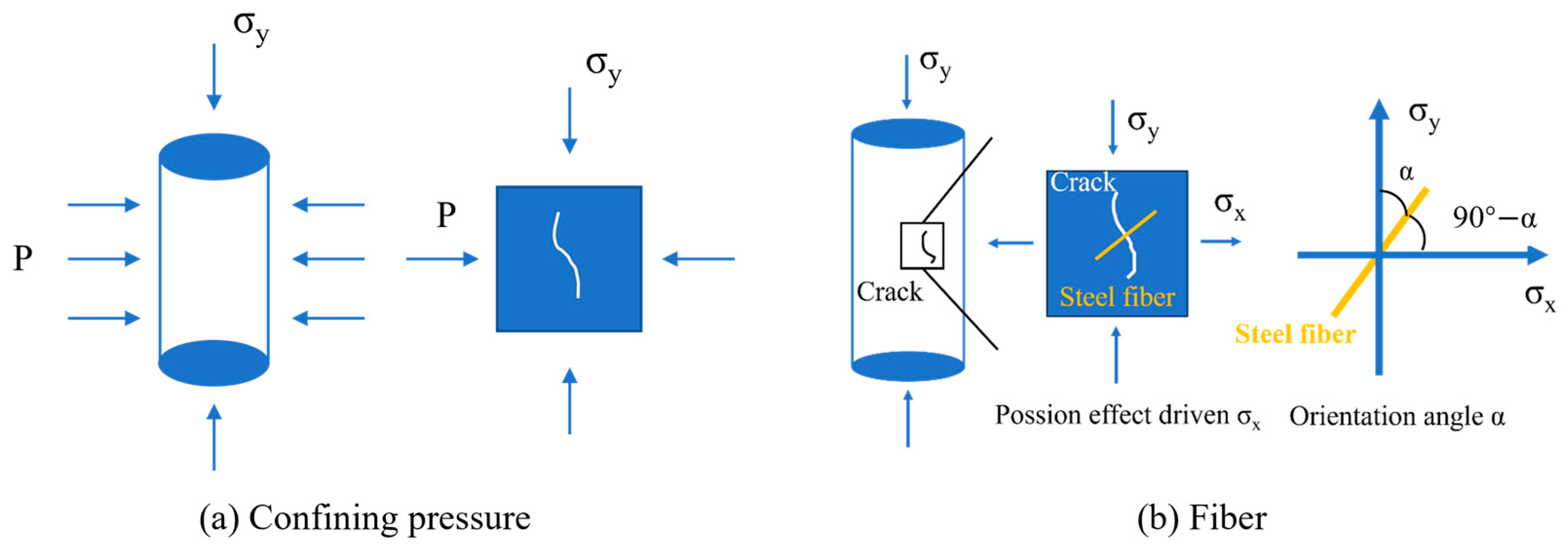

4.2. The Role of Confining Pressure and Fibers in the Compressive Behavior of UHPC

5. Conclusions

- Tension-zone fibers govern flexural response. Flexural capacity and post-cracking toughness are governed predominantly by the local steel-fiber fraction within the tensile zone.

- Coarse aggregate has a relatively small influence on both flexural and compressive strength but a pronounced influence on toughness. Although its addition reduces flexural toughness, it also narrows the differences in measured toughness among specimens tested with different faces serving as the tensile zone.

- CA addition mitigates fiber settlement. Introducing CA (10 mm, 20 vol%) attenuates fiber settlement and modestly improves vertical uniformity: the distribution coefficient increases from 0.651 to 0.673, while the orientation angle rises from 48.77° to 48.90°.

- Triaxial compression behavior is confinement-dominated. Due to the overlapping crack suppression mechanisms, the contribution of steel fibers to strength enhancement is gradually diminished as confinement increases.

- Coarse aggregate and steel fibers have both complementary and competing effects. Coarse aggregate limits fiber settlement but disrupts fiber continuity. When confinement is present, the confining pressure diminishes their complementary and competing interaction.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix design and properties assessment of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Graybeal, B.A. Compressive Behavior of Ultra-High-Performance Fiber-Reinforced Concrete. ACI Mater. J. 2007, 104, 146–152. [Google Scholar]

- Shi, Z.; Su, Q.; Kavoura, F.; Velijkovic, M. Uniaxial tensile response and tensile constitutive model of ultra-high performance concrete containing coarse aggregate (CA-UHPC). Cem. Concr. Compos. 2023, 136, 104878. [Google Scholar] [CrossRef]

- Su, X.; Ren, Z.; Li, P. Review on physical and chemical activation strategies for ultra-high performance concrete (UHPC). Cem. Concr. Compos. 2024, 149, 105519. [Google Scholar] [CrossRef]

- Zhu, Y.; Hussein, H.; Kumar, A.; Chen, G. A review: Material and structural properties of UHPC at elevated temperatures or fire conditions. Cem. Concr. Compos. 2021, 123, 104212. [Google Scholar] [CrossRef]

- Mahjoubi, S.; Barhemat, R.; Meng, W.; Bao, Y. AI-guided auto-discovery of low-carbon cost-effective ultra-high performance concrete (UHPC). Resour. Conserv. Recycl. 2023, 189, 106741. [Google Scholar] [CrossRef]

- Yin, T.; Liu, K.; Fan, D.; Yu, R. Derivation and verification of multilevel particle packing model for Ultra-High Performance Concrete (UHPC): Modelling and experiments. Cem. Concr. Compos. 2023, 136, 104889. [Google Scholar] [CrossRef]

- Yoo, D.; Banthia, N. Mechanical properties of ultra-high-performance fiber-reinforced concrete: A review. Cem. Concr. Compos. 2016, 73, 267–280. [Google Scholar] [CrossRef]

- Fan, J.; Shao, Y.; Bandelt, M.; Adams, M.; Ostertag, C. Sustainable reinforced concrete design: The role of ultra-high performance concrete (UHPC) in life-cycle structural performance and environmental impacts. Eng. Struct. 2024, 316, 118585. [Google Scholar] [CrossRef]

- Wang, X.; Yu, R.; Song, Q.; Shui, Z.; Liu, Z.; Wu, S.; Hou, D. Optimized design of ultra-high performance concrete (UHPC) with a high wet packing density. Cem. Concr. Res. 2019, 126, 105921. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Wagner, P.; Frohlich, D.; Weinberg, K. Dynamic fracture investigations of ultra-high performance concrete by spalling tests. Eng. Struct. 2019, 201, 109844. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K.H. Investigation of mechanical properties and shrinkage of ultra-high performance concrete: Influence of steel fiber content and shape. Compos. Part B 2019, 174, 107021. [Google Scholar] [CrossRef]

- Wille, K.; Cotulio, C.B. Material efficiency in the design of ultra-high performance concrete. Constr. Build. Mater. 2015, 86, 33–43. [Google Scholar] [CrossRef]

- Li, P.P.; Yu, Q.L.; Brouwers, H.J.H.; Chen, W. Conceptual design and performance evaluation of two-stage ultra-low binder ultra-high performance concrete. Cem. Concr. Res. 2019, 125, 105858. [Google Scholar] [CrossRef]

- Zhang, F.; Pang, K.; Zhong, R.; Li, J.; Liu, Q.; Zhang, J. Effect of key design parameters on the physical/mechanical properties of coarse aggregated UHPC and its structural response subjected to bending. Constr. Build. Mater. 2024, 448, 138189. [Google Scholar] [CrossRef]

- Hans, B.; Thomas, D. The influence of aggregate type on the strength and elastic modulus of high strength concrete. Constr. Build. Mater. 2015, 74, 132–139. [Google Scholar] [CrossRef]

- Lv, Y.; Zhang, W.; Wu, F.; Wu, P.; Zeng, W.; Yang, F. Static mechanical properties and mechanism of C200 ultra-high performance concrete (UHPC) containing coarse aggregates. Sci. Eng. Compos. Mater. 2020, 27, 186–195. [Google Scholar] [CrossRef]

- Akcaoglu, T.; Tokyay, M.; Celik, T. Effect of coarse aggregate size and matrix quality on ITZ and failure behavior of concrete under uniaxial compression. Cem. Concr. Compos. 2004, 26, 633–638. [Google Scholar] [CrossRef]

- Xu, L.; Wu, F.; Chi, Y.; Cheng, P.; Zeng, Y.; Chen, Q. Effects of coarse aggregate and steel fibre contents on mechanical properties of high performance concrete. Constr. Build. Mater. 2019, 206, 97–110. [Google Scholar] [CrossRef]

- Xue, C.; Xu, H.; Yu, M.; Mao, X.; Ding, X.; Ye, J. Study on compressive stress-strain relationship of ultra-high performance concrete with coarse aggregates under and after high temperatures. Constr. Build. Mater. 2019, 206, 97–110. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, J.; Zhou, H.; Liu, J.; Zhang, Q.; Han, F. Effect of Coarse Aggregate and Steel Fiber on Uniaxial Tensile Property of Ultra-high Performance Concrete. Mater. Rev. 2017, 31, 5. [Google Scholar]

- Wu, F.; Xu, L.; Chi, Y.; Zeng, Y.; Deng, F.; Chen, Q. Compressive and flexural properties of ultra-high performance fiber-reinforced cementitious composite: The effect of coarse aggregate. Compos. Struct. 2020, 236, 111810. [Google Scholar]

- Deng, F.; Xu, L.; Chi, Y.; Wu, F.; Chen, Q. Effect of steel-polypropylene hybrid fiber and coarse aggregate inclusion on the stress–strain behavior of ultra-high performance concrete under uniaxial compression. Compos. Struct. 2020, 252, 112685. [Google Scholar] [CrossRef]

- Yuan, C.; Chen, W.; Pham, T.; Hao, H. Effect of aggregate size on bond behaviour between basalt fibre reinforced polymer sheets and concrete. Compos. Part B Eng. 2019, 158, 459–474. [Google Scholar] [CrossRef]

- Cheng, J.; Liu, J.; Liu, J.; Zhang, Q.; Zhang, L.; Lin, W.; Han, F. An experimental study and a mechanism analysis on mechanical properties of Ultra-high performance concrete with coarse aggregate. Mater. Rev. 2017, 31, 115–119. [Google Scholar]

- Huang, Z.; Li, S. Study on Mechanical Properties of Ultra High Performance Concrete with Coarse Aggregate. J. Hunan Univ. (Nat. Sci.) 2018, 45, 8. [Google Scholar]

- Yang, F.; Ji, Y.; Liu, W.; Zhang, C.; Fang, D. Experimental Study on Ultra-high Performance Concrete with Coarse Aggregate. Concrete 2018, 12, 110–113. [Google Scholar]

- Wang, Y. Properties of Ultra-high Performance Concrete Containing Coarse Dolomite Aggregate. J. Yangtze River Sci. Res. Inst. 2020, 37, 149–155. [Google Scholar]

- Huang, W.; Yang, Y.; Liu, Y.; Cui, T. Mechanical Properties of Ultra-high Performance Concrete Containing Coarse Aggregate. J. Chin. Ceram. Soc. 2020, 48, 1747–1755. (In Chinese) [Google Scholar]

- Liu, J.; Han, F.; Cui, G.; Zhang, Q.; LV, J.; Zhang, L.; Yang, Z. Combined effect of coarse aggregate and fiber on tensile behavior of ultra-high performance concrete. Constr. Build. Mater. 2016, 121, 310–318. [Google Scholar] [CrossRef]

- Shen, C.; Wang, H.; Tang, D.; Lyu, Z.; Zhang, H.; Yu, L.; Yang, C. Investigating the influence of coarse aggregate characteristics and fiber dispersion on the flexural performance of ultra-high performance concrete (UHPC). J. Build. Eng. 2024, 97, 110738. [Google Scholar] [CrossRef]

- Shen, C.; Tang, D.; Lyu, Z.; Yang, C.; Yu, L. Distribution of coarse aggregate and steel fibers in ultra-high performance concrete containing coarse aggregate (UHPC-CA) and their effect on the flexural performance. Constr. Build. Mater. 2024, 421, 135666. [Google Scholar] [CrossRef]

- Donnini, J.; Lancioni, G.; Chiappini, G.; Corinaldesi, V. Uniaxial tensile behavior of ultra-high performance fiber-reinforced concrete (uhpfrc): Experiments and modeling. Compos. Struct. 2021, 258, 113433. [Google Scholar] [CrossRef]

- Li, S.; Jensen, O.M.; Yu, Q. Influence of steel fiber content on the rate-dependent flexural performance of ultra-high performance concrete with coarse aggregates. Constr. Build. Mater. 2022, 318, 125935. [Google Scholar] [CrossRef]

- ASTM C1609; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam With Third-Point Loading). ASTM International: West Conshohocken, PA, USA, 2012.

- Abrishambaf, A.; Pimentel, M.; Nunes, S. Influence of fibre orientation on the tensile behaviour of ultra-high performance fibre reinforced cementitious composites. Cem. Concr. Res. 2017, 97, 28–40. [Google Scholar] [CrossRef]

- Zou, Y.; Jiang, J.; Yang, J.; Zhang, Z.; Guo, J. Enhancing the toughness of bonding interface in steel-UHPC composite structure through fiber bridging. Cem. Concr. Compos. 2023, 137, 104947. [Google Scholar] [CrossRef]

- Wang, R.; Gao, X.; Zhang, J.; Han, G. Spatial distribution of steel fibers and air bubbles in UHPC cylinder determined by X-ray CT method. Constr. Build. Mater. 2018, 160, 39–47. [Google Scholar] [CrossRef]

- Meng, K.; Xu, L.; Yin, C. Experimental investigation on the mechanical behavior of hybrid steel-polypropylene fiber reinforced concrete under conventional triaxial cyclic compression. Constr. Build. Mater. 2021, 291, 123262. [Google Scholar] [CrossRef]

- Ke, L.; Han, B.; Chen, Z.; Feng, Z.; Qi, J.; Yoo, D. Failure criteria and stress-strain constitutive envelope surfaces for UHPFRC with different volume fractions of steel fibers under triaxial compression. Eng. Struct. 2025, 330, 119856. [Google Scholar] [CrossRef]

- Wang, Z.; Li, B.; Li, L.; Nong, Q.; Mo, S.; Zhang, Z. Experimental investigation on the damage behavior of high-performance engineered cementitious composites subjected to triaxial monotonic and cyclic compression. Constr. Build. Mater. 2025, 458, 139589. [Google Scholar] [CrossRef]

- Teng, L.; Huang, H.; Du, J.; Khayat, K. Prediction of fiber orientation and flexural performance of UHPC based on suspending mortar rheology and casting method. Cem. Concr. Compos. 2021, 122, 104142. [Google Scholar] [CrossRef]

- Shen, X.; Bruhwiler, E. Influence of local fiber distribution on tensile behavior of strain hardening UHPFRC using NDT and DIC. Cem. Concr. Res. 2020, 132, 106042. [Google Scholar] [CrossRef]

- Islam, M.M.; Zhang, Q.; Jin, Q. A review of existing codes and standards on design factors for UHPC placement and fiber orientation. Constr. Build. Mater. 2022, 345, 128308. [Google Scholar] [CrossRef]

- Kang, S.; Kim, J. The relation between fiber orientation and tensile behavior in an Ultra High Performance Fiber Reinforced Cementitious Composites (UHPFRCC). Cem. Concr. Res. 2011, 41, 1001–1014. [Google Scholar] [CrossRef]

- Huang, H.; Gao, X.; Khaya, K.H. Contribution of fiber orientation to enhancing dynamic properties of UHPC under impact loading. Cem. Concr. Compos. 2021, 121, 104108. [Google Scholar] [CrossRef]

- Wu, Z.; Khayat, K.H.; Shi, C. How do fiber shape and matrix composition affect fiber pullout behavior and flexural properties of UHPC? Cem. Concr. Compos. 2018, 90, 193–201. [Google Scholar] [CrossRef]

- Gong, M.; Pan, A.; Zhang, Z.; Wang, T.; Rao, X.; Chen, C.; Huang, W. Pull-out behaviour of steel fiber in ultra-high performance fiber reinforced concrete. Bull. Chin. Ceram. Soc. 2023, 42, 2764–2772. (In Chinese) [Google Scholar]

- Qi, J.; Wu, Z.; Ma, Z.; Wang, J. Pullout behavior of straight and hooked-end steel fibers in UHPC matrix with various embedded angles. Constr. Build. Mater. 2018, 191, 764–774. [Google Scholar] [CrossRef]

- Lee, Y.; Kang, S.; Kim, J. Pullout behavior of inclined steel fiber in an ultra-high strength cementitious matrix. Constr. Build. Mater. 2010, 24, 2030–2041. [Google Scholar] [CrossRef]

- Lin, S.; Liu, J.; Liu, C.; Liu, K.; Liu, P.; Su, Y. Triaxial compressive behaviour of ultra-high performance geopolymer concrete (UHPGC) and its applications in contact explosion and projectile impact analysis. Constr. Build. Mater. 2024, 449, 138394. [Google Scholar] [CrossRef]

- Li, B.; Chen, Z.; Wang, S.; Xu, L. A review on the damage behavior and constitutive model of fiber reinforced concrete at ambient temperature. Constr. Build. Mater. 2024, 412, 134919. [Google Scholar] [CrossRef]

| SiO2 | Al2O3 | CaO | Fe2O3 | SO3 | MgO | Na2O | K2O | LOI | |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 19.41 | 4.32 | 65.29 | 3.06 | 2.89 | 2.47 | 0.068 | 0.71 | 2.3 |

| Silica fume | 91.87 | 0.21 | 0.19 | 0.12 | 1.68 | 3.05 | 0.073 | 0.18 | 1.6 |

| Basalt aggregate | 49.11 | 15.82 | 10.57 | 11.20 | - | 7.13 | 2.27 | 0.70 | - |

| Specimen Name | C | SF1 | QF | QS | BA | W | SP | SF | W/C |

|---|---|---|---|---|---|---|---|---|---|

| SF-UHPC | 685 | 60 | 220 | 1165 | 0 | 150 | 26.1 | 195 | 0.2 |

| CA-SF-UHPC | 695.7 | 31.6 | 79 | 977 | 600 | 145.5 | 25.5 | 195 | 0.2 |

| Group | Distribution Coefficient | Orientation Angle (°) |

|---|---|---|

| SF-UHPC | 0.651 | 48.77 |

| CA-SF-UHPC | 0.673 | 48.90 |

| Group | Distribution Coefficient | Orientation Angle (°) |

|---|---|---|

| SF-UHPC-0 | 0.644 | 48.55 |

| SF-UHPC-10 | 0.664 | 44.52 |

| SF-UHPC-20 | 0.744 | 43.03 |

| SF-UHPC-30 | 0.627 | 44.77 |

| CA-SF-UHPC-0 | 0.599 | 43.33 |

| CA-SF-UHPC-10 | 0.502 | 48.01 |

| CA-SF-UHPC-20 | 0.491 | 48.16 |

| CA-SF-UHPC-30 | 0.665 | 48.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, C.; Zhang, Y.; Li, J.; Zeng, H.; Yang, C.; Yu, L. Coarse Aggregate Induced Fiber Dispersion and Its Role in UHPC Mechanics Across Flexural and Compressive Loading. Materials 2025, 18, 4796. https://doi.org/10.3390/ma18204796

Shen C, Zhang Y, Li J, Zeng H, Yang C, Yu L. Coarse Aggregate Induced Fiber Dispersion and Its Role in UHPC Mechanics Across Flexural and Compressive Loading. Materials. 2025; 18(20):4796. https://doi.org/10.3390/ma18204796

Chicago/Turabian StyleShen, Chen, Yue Zhang, Jianlin Li, Haonan Zeng, Changhui Yang, and Linwen Yu. 2025. "Coarse Aggregate Induced Fiber Dispersion and Its Role in UHPC Mechanics Across Flexural and Compressive Loading" Materials 18, no. 20: 4796. https://doi.org/10.3390/ma18204796

APA StyleShen, C., Zhang, Y., Li, J., Zeng, H., Yang, C., & Yu, L. (2025). Coarse Aggregate Induced Fiber Dispersion and Its Role in UHPC Mechanics Across Flexural and Compressive Loading. Materials, 18(20), 4796. https://doi.org/10.3390/ma18204796