Mechanical Performance of Plywood TIE Joints Under Tension and Shear in the WikiHouse Skylark Modular System

Abstract

1. Introduction

2. Materials and Methods

2.1. Plywood Panels

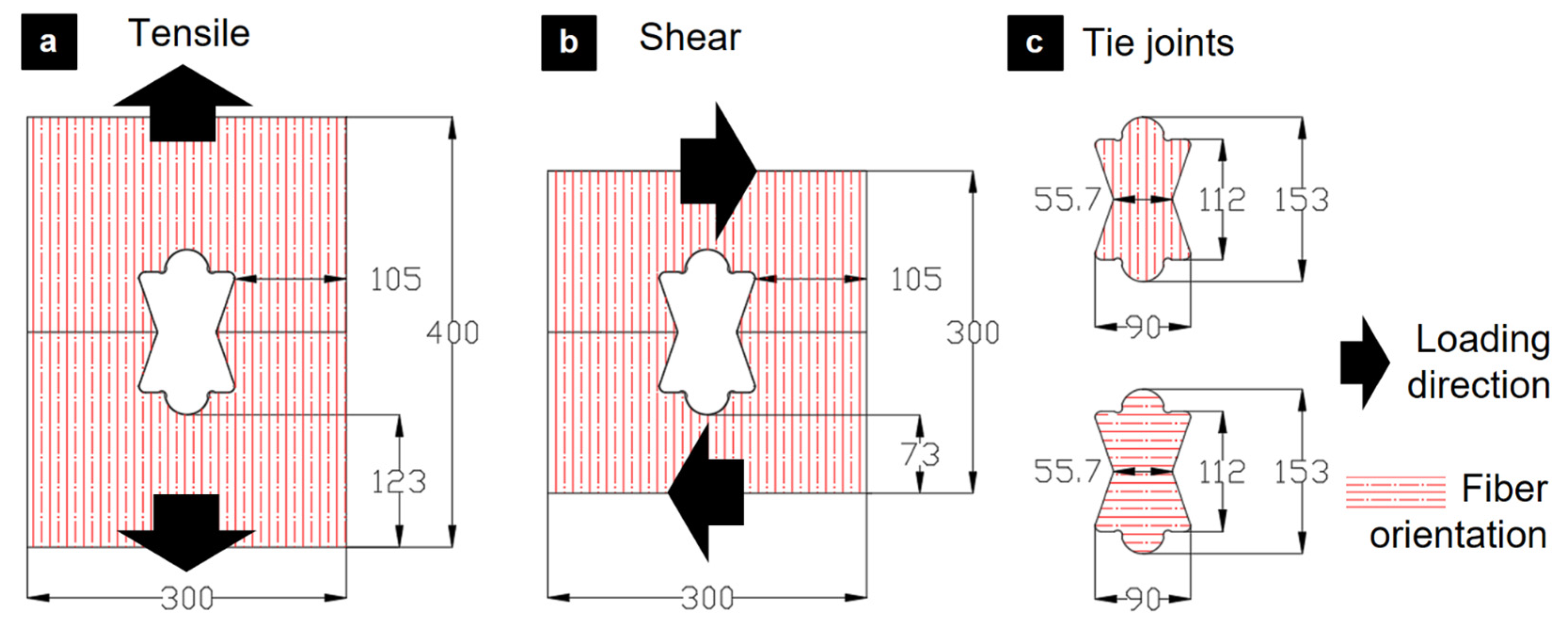

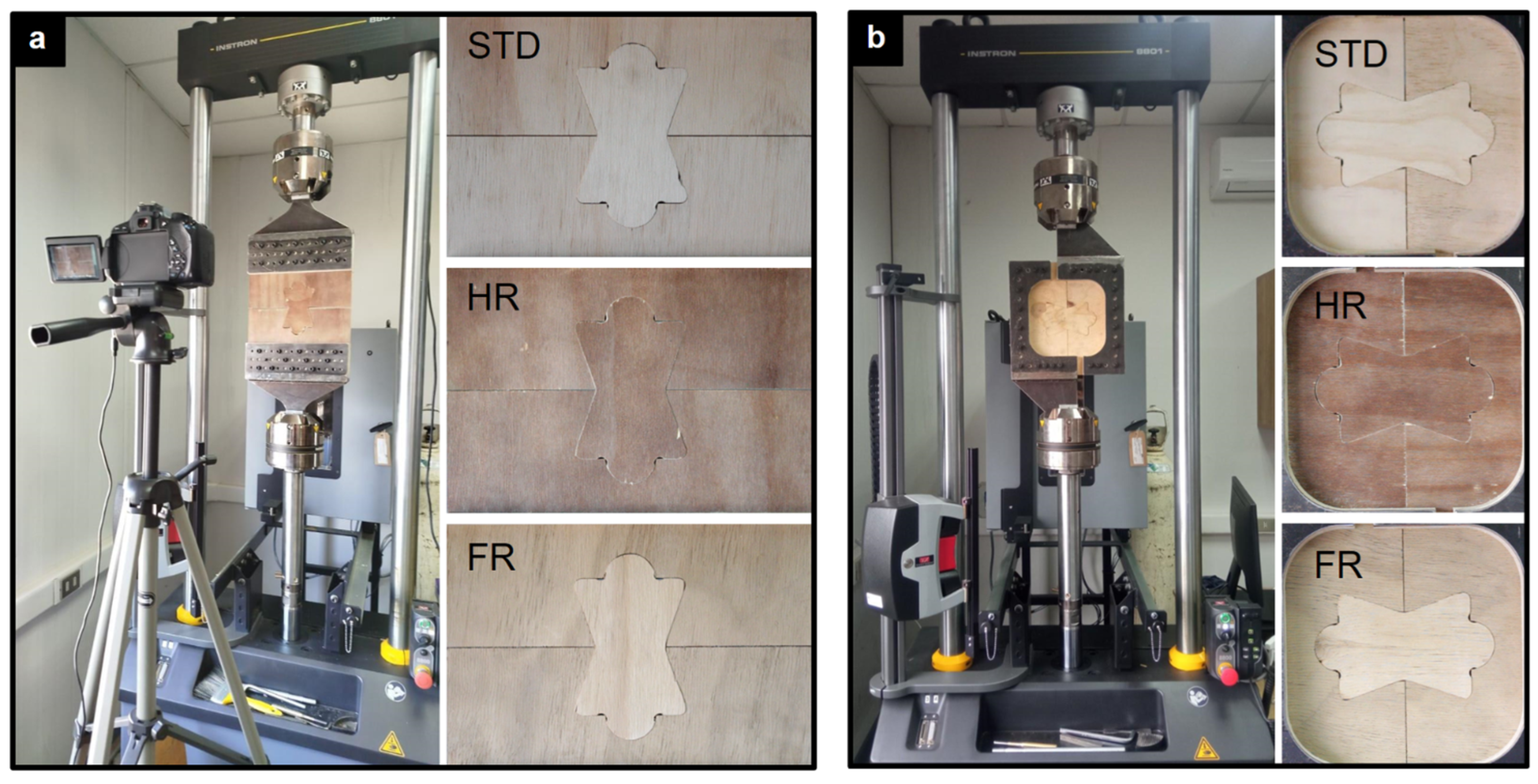

2.2. Specimen Design and Fabrication

2.3. Testing Setup and Protocol

3. Results

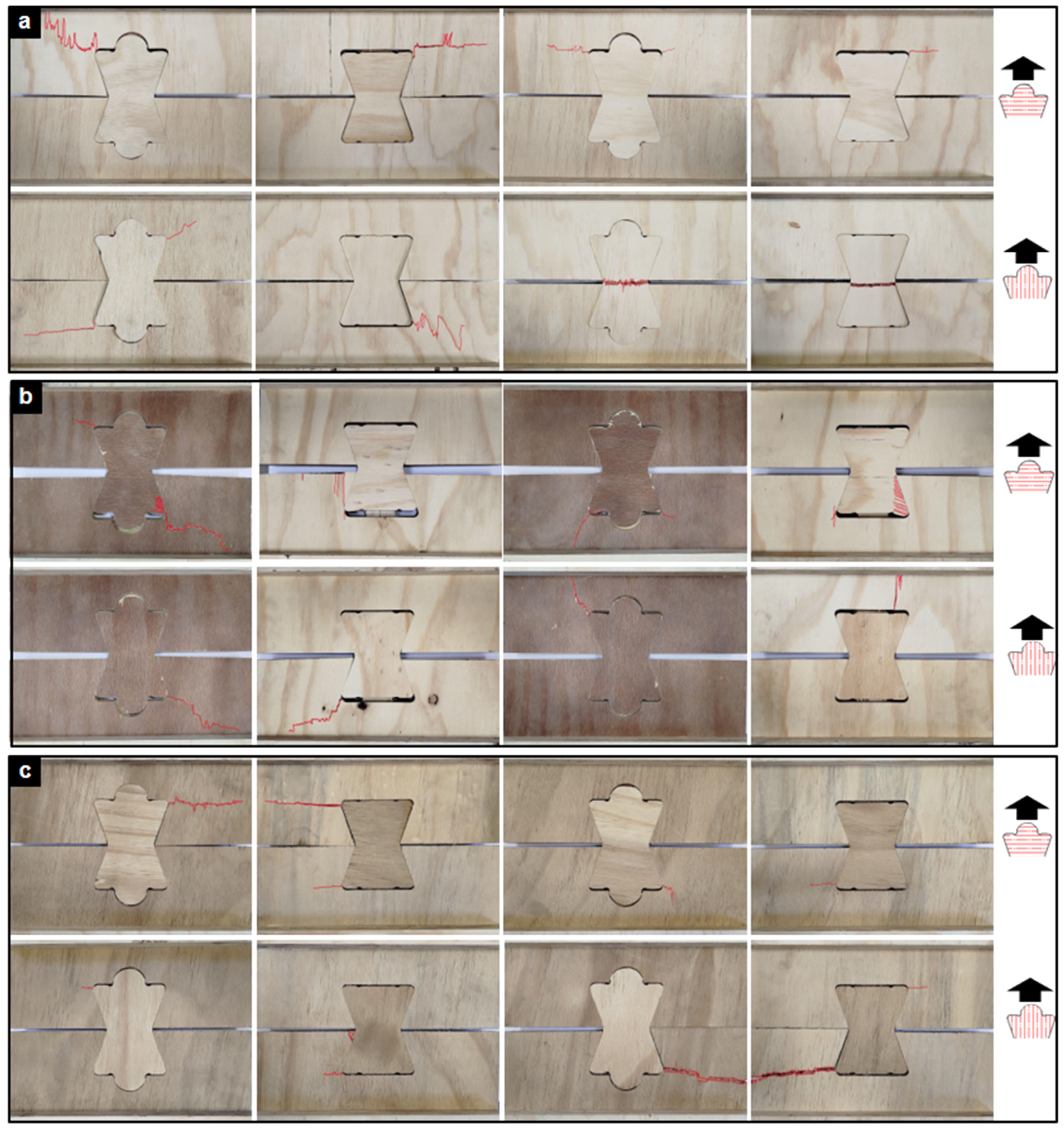

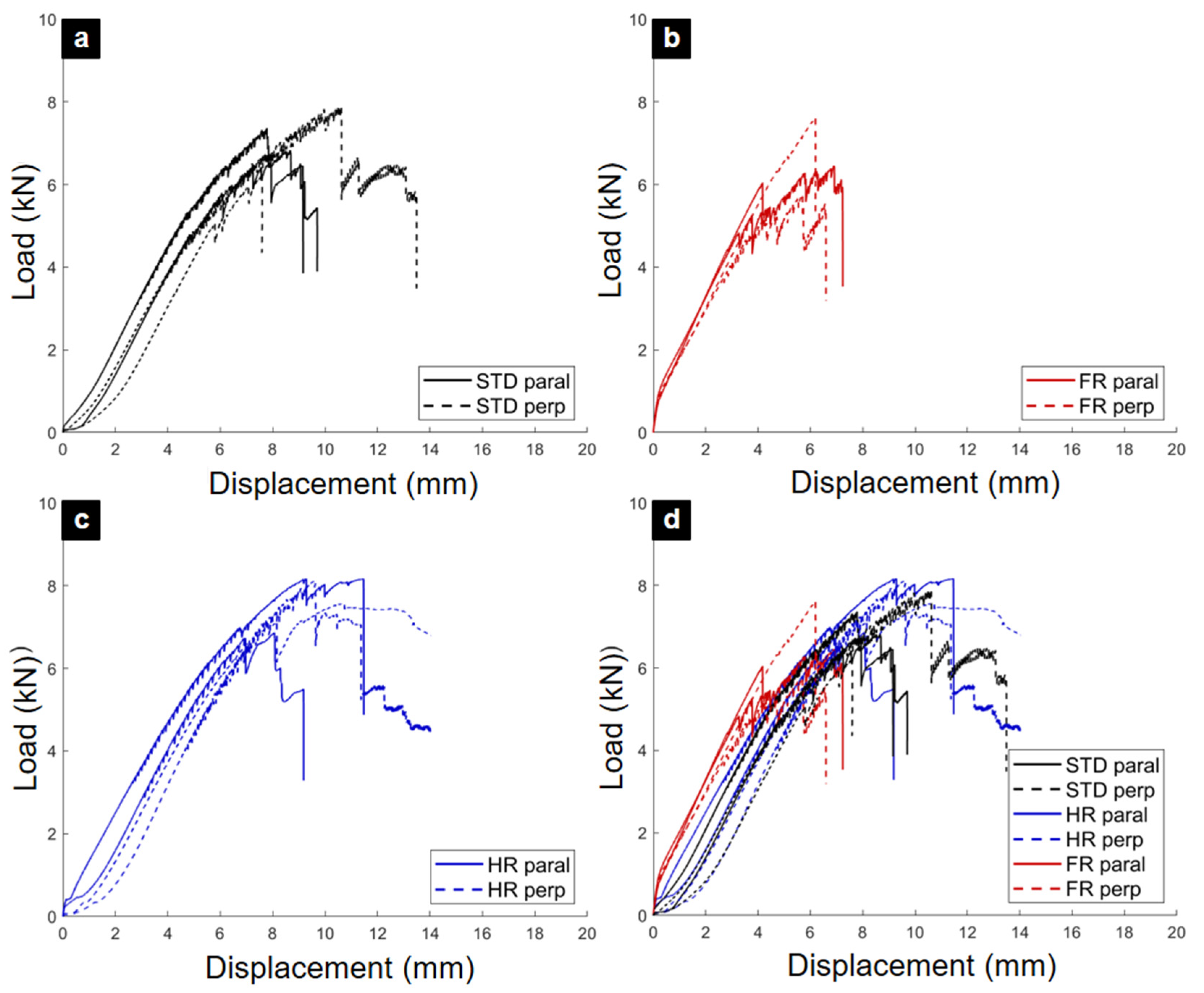

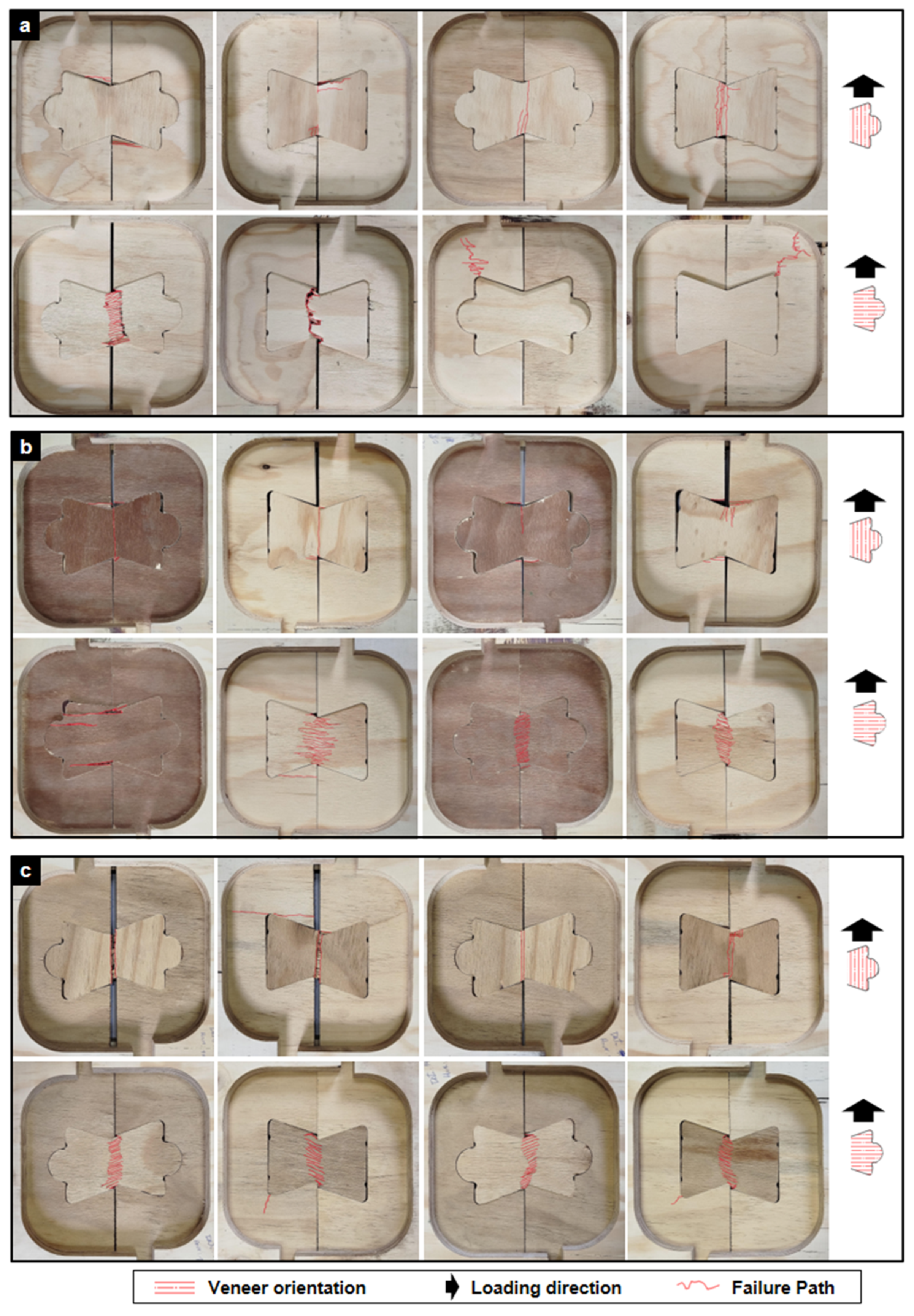

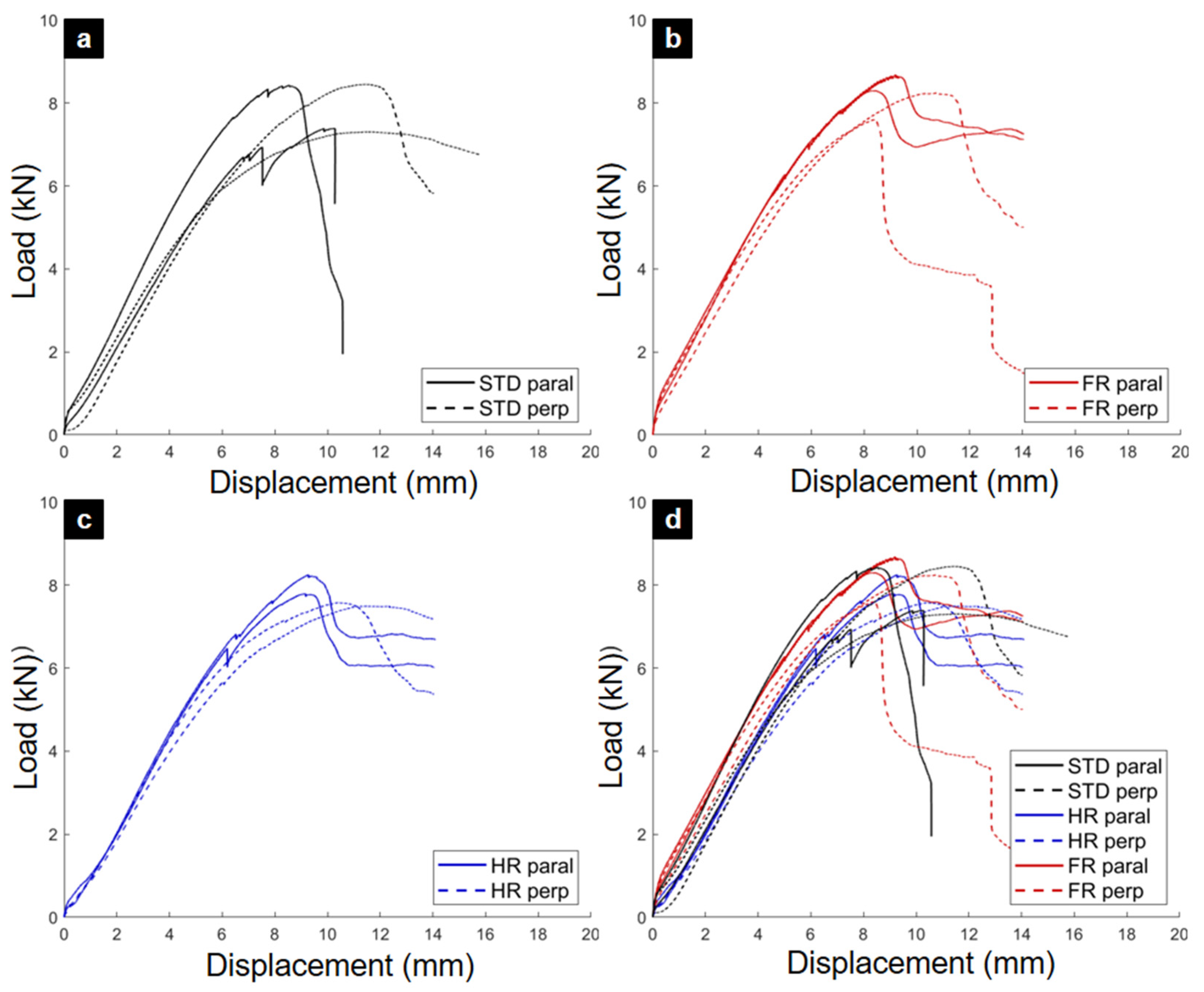

3.1. Monotonic Tensile Response

3.2. Monotonic Shear Response

4. Discussion

5. Conclusions

- Performance-enhancing treatments significantly influence joint behavior, particularly the failure mode and ductility. Their selection must balance durability and fire resistance against structural impact.

- The hydro-repellent (HR) treatment did not negatively impact the joint’s mechanical performance. Both STD and HR joints exhibited a desirable ductile failure mode with gradual load decay, though no statistically significant difference in their ultimate strengths was found.

- The fire-retardant (FR) treatment introduced a critical strength–ductility trade-off. While the mean shear strength was the highest observed (8207 N), the treatment induced a brittle fracture mode and a significant loss of ductility. This change from a ductile to brittle failure raises important considerations for structural design, especially in seismic regions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- UN. Global Status Report for Buildings and Construction 2024/25: Not Just Another Brick in the Wall; United Nations: New York, NY, USA, 2025. [CrossRef]

- Valenzuela, M.; Ciudad, G.; Cárdenas, J.P.; Medina, C.; Salas, A.; Oñate, A.; Pincheira, G.; Attia, S.; Tuninetti, V. Towards the Development of Performance-Efficient Compressed Earth Blocks from Industrial and Agro-Industrial By-Products. Renew. Sustain. Energy Rev. 2024, 194, 114323. [Google Scholar] [CrossRef]

- Miranda, A.; Muñoz, R.; Aedo, C.; Bustos, F.; Tuninetti, V.; Valenzuela, M.; Medina, C.; Oñate, A. High-Performance Concrete from Rubber and Shell Waste Materials: Experimental and Computational Analysis. Materials 2024, 17, 5516. [Google Scholar] [CrossRef]

- Cuellar, S.; Grisales, S.; Castaneda, D.I. Constructing tomorrow: A multifaceted exploration of Industry 4.0 scientific, patents, and market trend. Autom. Constr. 2023, 156, 105113. [Google Scholar] [CrossRef]

- Olawumi, T.O.; Chan, D.W.M.; Ojo, S.; Yam, M.C.H. Automating the modular construction process: A review of digital technologies and future directions with blockchain technology. J. Build. Eng. 2022, 46, 103720. [Google Scholar] [CrossRef]

- Pillai, R.G.; Gettu, R.; Santhanam, M.; Rengaraju, S.; Dhandapani, Y.; Rathnarajan, S.; Basavaraj, A.S. Service life and life cycle assessment of reinforced concrete systems with limestone calcined clay cement (LC3). Cem. Concr. Res. 2019, 118, 111–119. [Google Scholar] [CrossRef]

- Cadavid-Giraldo, N.; Velez-Gallego, M.C.; Restrepo-Boland, A. Carbon emissions reduction and financial effects of a cap and tax system on an operating supply chain in the cement sector. J. Clean. Prod. 2020, 275, 122583. [Google Scholar] [CrossRef]

- Chinzorigt, G.; Lim, M.K.; Yu, M.; Lee, H.; Enkbold, O.; Choi, D. Strength, shrinkage and creep and durability aspects of concrete including CO2 treated recycled fine aggregate. Cem. Concr. Res. 2020, 136, 106062. [Google Scholar] [CrossRef]

- Cheng, D.; Reiner, D.M.; Yang, F.; Cui, C.; Meng, J.; Shan, Y.; Liu, Y.; Tao, S.; Guan, D. Projecting future carbon emissions from cement production in developing countries. Nat. Commun. 2023, 14, 8213. [Google Scholar] [CrossRef]

- Parracho, D.F.R.; El-Din, M.N.; Esmaeili, I.; Freitas, S.S.; Rodrigues, L.; Martins, J.P.; Corvacho, H.; Delgado, J.M.P.Q.; Guimarães, A.S. Modular construction in the digital age: A systematic review on smart and sustainable innovations. Buildings 2025, 15, 765. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K.; Sadiq, R. Conventional versus modular construction methods: A comparative cradle-to-gate LCA for residential buildings. Energy Build. 2019, 204, 109479. [Google Scholar] [CrossRef]

- Shahpari, M.; Saradj, F.M.; Pishvaee, M.S.; Piri, S. Assessing the productivity of prefabricated and in-situ construction systems using hybrid multi-criteria decision making method. J. Build. Eng. 2020, 27, 100979. [Google Scholar] [CrossRef]

- Peiris, A.; Hui, F.K.P.; Duffield, C.; Wang, J.; Gil Garcia, M.; Chen, Y.; Ngo, T. Digitalising modular construction: Enhancement of off-site manufacturing productivity via a manufacturing execution & control (MEC) system. Comput. Ind. Eng. 2023, 178, 109117. [Google Scholar] [CrossRef]

- Greer, F.; Horvath, A. Modular construction’s capacity to reduce embodied carbon emissions in California’s housing sector. Build. Environ. 2023, 240, 110432. [Google Scholar] [CrossRef]

- Jayawardana, J.; Sandanayake, M.; Kulatunga, A.K.; Jayasinghe, J.A.S.C.; Zhang, G.; Osadith, S.A.U. Evaluating the circular economy potential of modular construction in developing economies—A life cycle assessment. Sustainability 2023, 15, 16336. [Google Scholar] [CrossRef]

- Wasim, M.; Han, T.M.; Huang, H.; Madiyev, M.; Ngo, T.D. An approach for sustainable, cost-effective and optimised material design for the prefabricated non-structural components of residential buildings. J. Build. Eng. 2020, 32, 101474. [Google Scholar] [CrossRef]

- Tavares, V.; Soares, N.; Raposo, N.; Marques, P.; Freire, F. Prefabricated versus conventional construction: Comparing life-cycle impacts of alternative structural materials. J. Build. Eng. 2021, 41, 102705. [Google Scholar] [CrossRef]

- Hu, R.; Chen, K.; Fang, W.; Zheng, L.; Xu, J. The technology–environment relationship revisited: Evidence from the impact of prefabrication on reducing construction waste. J. Clean. Prod. 2022, 341, 130883. [Google Scholar] [CrossRef]

- Kumar, V.; Lo Ricco, M.; Bergman, R.D.; Nepal, P.; Poudyal, N.C. Environmental impact assessment of mass timber, structural steel, and reinforced concrete buildings based on the 2021 International Building Code provisions. Build. Environ. 2024, 251, 111195. [Google Scholar] [CrossRef]

- Kim, S. Prefabricated and modularized residential construction: A review of present status, opportunities, and future challenges. Buildings 2025, 15, 2889. [Google Scholar] [CrossRef]

- Zohourian, M.; Pamidimukkala, A.; Kermanshachi, S.; Almaskati, D. Modular construction: A comprehensive review. Buildings 2025, 15, 2020. [Google Scholar] [CrossRef]

- Wu, Y.; Li, Y. Development of transportation loading spectra for building modules based on a vehicle–module interaction model. Eng. Struct. 2022, 270, 114828. [Google Scholar] [CrossRef]

- Lacey, A.W.; Chen, W.; Hao, H.; Bi, K. Structural response of modular buildings—An overview. J. Build. Eng. 2018, 16, 45–56. [Google Scholar] [CrossRef]

- Ahmed, F.; Gkantou, M.; Nikitas, G.; Ferentinou, M.; Bras, A.; Riley, M. A review of recent developments in structural elements of modular steel building systems. J. Build. Eng. 2025, 111, 113087. [Google Scholar] [CrossRef]

- Thai, H.T.; Ngo, T.; Uy, B. A review on modular construction for high-rise buildings. Structures 2020, 28, 1265–1290. [Google Scholar] [CrossRef]

- Swami, G.; Thai, H.T.; Liu, X. Robustness analysis for innovative tall composite modular buildings with composite shear walls. J. Build. Eng. 2025, 107, 112712. [Google Scholar] [CrossRef]

- Ruiz, S.; Madariaga, R. Historical and recent large megathrust earthquakes in Chile. Tectonophysics 2018, 733, 37–56. [Google Scholar] [CrossRef]

- USGS. 20 Largest Earthquakes in the World Since 1900. Available online: https://www.usgs.gov/programs/earthquake-hazards/science/20-largest-earthquakes-world-1900 (accessed on 30 April 2023).

- Branco, J.M.; Descamps, T. Analysis and strengthening of carpentry joints. Constr. Build. Mater. 2015, 97, 34–47. [Google Scholar] [CrossRef]

- Chand, B.; Kaushik, H.B.; Das, S. Lateral load behavior of connections in Assam-type wooden houses in the Himalayan region of India. Constr. Build. Mater. 2020, 261, 119904. [Google Scholar] [CrossRef]

- Song, D.; Xue, J.; Wu, C. Experimental and theoretical study on seismic behavior of Dou-Gong brackets on column under the load in overhanging and width directions. Eng. Struct. 2024, 299, 117138. [Google Scholar] [CrossRef]

- Fujita, K.; Chiba, K. Long-term earthquake response monitoring of nineteenth-century timber temple Kencho-ji, Japan. Int. J. Archit. Herit. 2023, 17, 1240–1255. [Google Scholar] [CrossRef]

- Pan, Y.; Yi, D.; Khennane, A.; Chen, J. Seismic performance of a historic timber structure on a slope. J. Build. Eng. 2023, 71, 106434. [Google Scholar] [CrossRef]

- Kłosowski, P.; Lubowiecka, I.; Pestka, A.; Szepietowska, K. Historical carpentry corner log joints—Numerical analysis within stochastic framework. Eng. Struct. 2018, 176, 64–73. [Google Scholar] [CrossRef]

- van Nimwegen, S.E.; Latteur, P. A state-of-the-art review of carpentry connections: From traditional designs to emerging trends in wood–wood structural joints. J. Build. Eng. 2023, 78, 107089. [Google Scholar] [CrossRef]

- Rezaei Rad, A.; Burton, H.; Weinand, Y. Performance assessment of through-tenon timber joints under tension loads. Constr. Build. Mater. 2019, 207, 706–721. [Google Scholar] [CrossRef]

- Sokołowski, P.K.; Kossakowski, P.G. Static Analysis of Wooden Beams Strengthened with FRCM-PBO Composite in Bending. Materials 2023, 16, 1870. [Google Scholar] [CrossRef] [PubMed]

- CEN. EN 789; Timber Structures—Test Methods—Determination of Mechanical Properties of Wood-Based Panels. European Committee for Standardization: Brussels, Belgium, 2004.

- Voluntary Product Standard PS 1-22; Structural Plywood. National Institute of Standards and Technology (NIST): Gaithersburg, MD, USA, 2023.

- Tuninetti, V.; Alzugaray, R.; González, J.; Valenzuela, M.; Jaramillo, A.; Diez, E. Root cause and vibration analysis to increase veneer manufacturing process efficiency: A case study on an industrial peeling lathe. Eur. J. Wood Wood Prod. 2021, 79, 951–966. [Google Scholar] [CrossRef]

- Charuk, A.; Gawdzińska, K.; Dunaj, P. Finite element modeling of the dynamic response of plywood. Materials 2024, 17, 4358. [Google Scholar] [CrossRef]

- Tuninetti, V.; Sandoval, M.; Cárdenas-Ramírez, J.P.; Oñate, A.; Miranda, A.; Soto-Zúñiga, P.; Arnett, M.; Leiva, J.; Cancino, R. Miniaturized Shear Testing: In-Plane and Through-Thickness Characterization of Plywood. Materials 2024, 17, 5621. [Google Scholar] [CrossRef]

- Granello, G.; Reynolds, T.; Prest, C. Structural performance of composite WikiHouse beams from CNC-cut timber panels. Eng. Struct. 2022, 252, 113639. [Google Scholar] [CrossRef]

- Braun, K.; Kropp, C. Building a better world? Competing promises, visions, and imaginaries-in-the-making of the digitalization of architecture and construction. Futures 2023, 154, 103262. [Google Scholar] [CrossRef]

- Romero, A.; Odenbreit, C. Experimental Investigation on Strength and Stiffness Properties of Laminated Veneer Lumber (LVL). Materials 2023, 16, 7194. [Google Scholar] [CrossRef] [PubMed]

- CEN. EN 314; Plywood—Bonding Quality—Test Methods. European Committee for Standardization: Brussels, Belgium, 1993.

- CEN. EN 310; Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization: Brussels, Belgium, 1993.

- Tuninetti, V.; Medina, C.; Salas, A.; Valdivia, I.; Fernández, E.; Meléndrez, M.; Pincheira, G.; Flores, P. Fiber-Reinforced Composite Materials: Characterization and Computational Predictions of Mechanical Performance; Springer Nature: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Tuninetti, V.; Mariqueo, M. Performance of Combined Woven Roving and Mat Glass-Fiber Reinforced Polymer Composites Under Absorption Tower Lifting Loads. Polymers 2024, 16, 2937. [Google Scholar] [CrossRef] [PubMed]

- Rojas-Ulloa, C.; Tuninetti, V.; Sepúlveda, H.; Betaieb, E.; Pincheira, G.; Gilles, G.; Duchêne, L.; Habraken, A.M. Accurate Numerical Prediction of Ductile Fracture and Micromechanical Damage Evolution for Ti6Al4V Alloy. Comput. Mech. 2024, 73, 177–198. [Google Scholar] [CrossRef]

- Romero, F.; Méndez, F.; González, J.; Tuninetti, V.; Medina, C.; Valin, M.; Valin, J.; Salas, A.; Vicuña, C. Acoustic Emission-Based Method for IFSS Characterization in Single-Fiber Fragmentation Tests. Appl. Sci. 2025, 15, 4517. [Google Scholar] [CrossRef]

- Hernández, R.; Hinojosa, J.; Fuenzalida-Henríquez, I.; Tuninetti, V. Implementation of a Non-Intrusive Primal–Dual Method with 2D-3D-Coupled Models for the Analysis of a DCB Test with Cohesive Zones. Appl. Sci. 2025, 15, 6924. [Google Scholar] [CrossRef]

- Tuninetti, V.; Oñate, A.; Valenzuela, M.; Sepúlveda, H.; Pincheira, G.; Medina, C.; García-Herrera, C.; Duchêne, L.; Habraken, A.M. Characterization Approaches Affect Asymmetric Load Predictions of Hexagonal Close-Packed Alloy. J. Mater. Res. Technol. 2023, 26, 5028–5036. [Google Scholar] [CrossRef]

- EAGON Lautaro S.A. Tablero Estructural. Available online: https://www.eagon.cl/producto/estructural/ (accessed on 17 September 2025).

- ASTM G154-23; Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials. ASTM International: West Conshohocken, PA, USA, 2023. [CrossRef]

- ASTM D5590-17(2021); Standard Test Method for Determining the Resistance of Paint Films and Related Coatings to Fungal Defacement by Accelerated Four-Week Agar Plate Assay. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- EAGON Lautaro S.A. Tablero Estructural HR. Available online: https://www.eagon.cl/producto/estructural-hidrorepelente/ (accessed on 17 September 2025).

- ASTM E84-22; Standard Test Method for Surface Burning Characteristics of Building Materials. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- EAGON Lautaro S.A. Tablero Estructural FR. Available online: https://www.eagon.cl/producto/estructural-retardante-al-fuego/ (accessed on 17 September 2025).

- ASTM A36/A36M-19; Standard Specification for Carbon Structural Steel. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- Tuninetti, V.; Gilles, G.; Milis, O.; Pardoen, T.; Habraken, A.M. Anisotropy and tension–compression asymmetry modeling of the room temperature plastic response of Ti-6Al-4V. Int. J. Plast. 2015, 67, 53–68. [Google Scholar] [CrossRef]

- Tuninetti, V.; Flores, P.; Valenzuela, M.; Pincheira, G.; Medina, C.; Duchêne, L.; Habraken, A.-M. Experimental characterization of the compressive mechanical behaviour of Ti6Al4V alloy at constant strain rates over the full elastoplastic range. Int. J. Mater. Form. 2020, 13, 709–724. [Google Scholar] [CrossRef]

- Granello, G. Experimental Testing of Bow Ties in Tension; University of Strathclyde: Glasgow, UK, 2023; Available online: https://www.wikihouse.cc/research/bow-ties-subjected-to-tensile-forces (accessed on 17 September 2025).

- Granello, G. Experimental Testing of Bow Ties in Shear; University of Strathclyde: Glasgow, UK, 2022; Available online: https://www.wikihouse.cc/research/bow-ties-subjected-to-shear-forces (accessed on 17 September 2025).

- Bernaczyk, A.; Wagenführ, A.; Terfloth, C.; Lincke, J.; Krystofiak, T.; Niemz, P. Investigations into the Influence of Temperature on the Tensile Shear Strength of Various Adhesives. Materials 2023, 16, 6173. [Google Scholar] [CrossRef]

- Metsä. Metsä Wood—Producer and Seller of Premium Quality Kerto® LVL, Plywood and other Wood Products. Available online: https://www.metsagroup.com/metsawood (accessed on 8 September 2025).

- He, X.; Yam, M.C.H.; Zhou, Z.; Zayed, T.; Ke, K. Inhomogeneity in mechanical properties of ductile iron pipes: A comprehensive analysis. Eng. Fail. Anal. 2024, 163, 108459. [Google Scholar] [CrossRef]

- EN 1995-1-1:2004+A 1; Eurocode 5: Design of Timber Structures—Part 1-1: General—Common Rules and Rules for Buildings. European Committee for Standardization (CEN): Brussels, Belgium, 1995.

- Yenidogan, C.; Nishi, R.; Uwadan, S.; Nagae, T.; Isoda, H.; Tsuchimoto, T.; Inoue, T.; Kajiwara, K. Full-scale shake table tests of P&B type of Japanese three-story wood dwellings for the collapse characterization. Soil Dyn. Earthq. Eng. 2021, 150, 106898. [Google Scholar] [CrossRef]

- Chen, J.; Wu, Z.; Zheng, Y.; Furuta, T.; Xiong, H. Full-scale shaking table tests of cross-laminated timber structures adopting dissipative angle brackets and hold-downs with soft-steel and rubber. Eng. Struct. 2024, 313, 118292. [Google Scholar] [CrossRef]

- Yenidogan, C.; Nishi, R.; Nagae, T.; Inoue, T.; Kajiwara, K. Full-scale cyclic test of a Japanese post and beam wood shearwall assembly. Bull. Earthq. Eng. 2020, 18, 4985–5008. [Google Scholar] [CrossRef]

- Takeuchi, T.; Terazawa, Y.; Komuro, S.; Kurata, T.; Sitler, B. Performance and failure modes of mass timber buckling-restrained braces under cyclic loading. Eng. Struct. 2022, 266, 114462. [Google Scholar] [CrossRef]

- Cao, J.; Xiong, H.; Chen, J. Mechanical performance of timber–concrete bolted connections under cyclic loading. Structures 2021, 34, 3464–3477. [Google Scholar] [CrossRef]

- Baleca, V.; Barsotti, R.; Bennati, S.; Oliveira, D.V. Experimental investigation of in-plane loaded timber-framed rammed earth panels. Part II: Cyclic shear–compression tests. Structures 2023, 58, 1463–1477. [Google Scholar] [CrossRef]

- Zhang, E.; Chen, G.; Wang, C.; Zhu, W.; Yang, W. Experimental investigation on lateral performance of southern pine nailed connections under monotonic and cyclic loading. Structures 2024, 69, 107334. [Google Scholar] [CrossRef]

- Poletti, E.; Vasconcelos, G.; Branco, J.M.; Koukouviki, A.M. Performance evaluation of traditional timber joints under cyclic loading and their influence on the seismic response of timber frame structures. Constr. Build. Mater. 2016, 127, 321–334. [Google Scholar] [CrossRef]

- Xu, F.; Geng, M.; Meng, X.; Diao, Y.; Gao, Y. Out-of-plane shear performance of a novel non-metallic CLT dovetail joint subjected to monotonic and cyclic loading. Ind. Crops Prod. 2024, 208, 117780. [Google Scholar] [CrossRef]

- Porras, E.; Esenarro, D.; Chang, L.; Morales, W.; Vargas, C.; Sucasaca, J. Toward Cost-Effective Timber Shell Structures through the Integration of Computational Design, Digital Fabrication, and Mechanical Integral ‘Half-Lap’ Joints. Buildings 2024, 14, 1735. [Google Scholar] [CrossRef]

| Property | STD | HR | FR | Method/Reference |

|---|---|---|---|---|

| Nominal Thickness (mm) | 18 | 18 | 18 | Manufacturer Specification |

| Number of Plies | 7 | 7 | 7 | |

| Veneer Grade (Face/Back) | C/D | C/D | B/C | |

| Special Treatment | None | Hydro-repellent | Fire-retardant | |

| Standards Met | PS 1–22 | ASTM G154, ASTM D5590 | ASTM E84 (Class B) | |

| Mean Density (kg/m3) | 520 | 525 | 580 | |

| Moisture Content (%) | 10.5 ± 0.5 | 10.5 ± 0.5 | 10.5 ± 0.5 | Conditioned Lab Env. |

| Orthotropic Shear Properties | See Ref. [42] | Tuninetti et al., 2024 | ||

| Plywood Type | Loading Mode | Mean Fmax (N) | Std. Dev. (N) | CV (%) |

|---|---|---|---|---|

| Standard | Tension | 7076 | 724 | 10.2 |

| Shear | 7897 | 633 | 8 | |

| Fire-Resistant | Tension | 6470 | 822 | 12.7 |

| Shear | 8207 | 445 | 5.4 | |

| Weather-Resistant | Tension | 7674 | 606 | 7.9 |

| Shear | 7779 | 338 | 4.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sandoval, M.; Cárdenas-Ramírez, J.P.; Soto-Zúñiga, P.; Arnett, M.; Oñate, A.; Leiva, J.; Cancino, R.; Tuninetti, V. Mechanical Performance of Plywood TIE Joints Under Tension and Shear in the WikiHouse Skylark Modular System. Materials 2025, 18, 4738. https://doi.org/10.3390/ma18204738

Sandoval M, Cárdenas-Ramírez JP, Soto-Zúñiga P, Arnett M, Oñate A, Leiva J, Cancino R, Tuninetti V. Mechanical Performance of Plywood TIE Joints Under Tension and Shear in the WikiHouse Skylark Modular System. Materials. 2025; 18(20):4738. https://doi.org/10.3390/ma18204738

Chicago/Turabian StyleSandoval, Moisés, Juan Pablo Cárdenas-Ramírez, Paula Soto-Zúñiga, Michael Arnett, Angelo Oñate, Jorge Leiva, Rodrigo Cancino, and Víctor Tuninetti. 2025. "Mechanical Performance of Plywood TIE Joints Under Tension and Shear in the WikiHouse Skylark Modular System" Materials 18, no. 20: 4738. https://doi.org/10.3390/ma18204738

APA StyleSandoval, M., Cárdenas-Ramírez, J. P., Soto-Zúñiga, P., Arnett, M., Oñate, A., Leiva, J., Cancino, R., & Tuninetti, V. (2025). Mechanical Performance of Plywood TIE Joints Under Tension and Shear in the WikiHouse Skylark Modular System. Materials, 18(20), 4738. https://doi.org/10.3390/ma18204738