Multimode Magneto-Optical Fiber Based on Borogermanate Glass Containing Tb3+ for Sensing Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Bulk Glass Preparation

2.2. Core-Cladding Glass Preform Preparation

- (I)

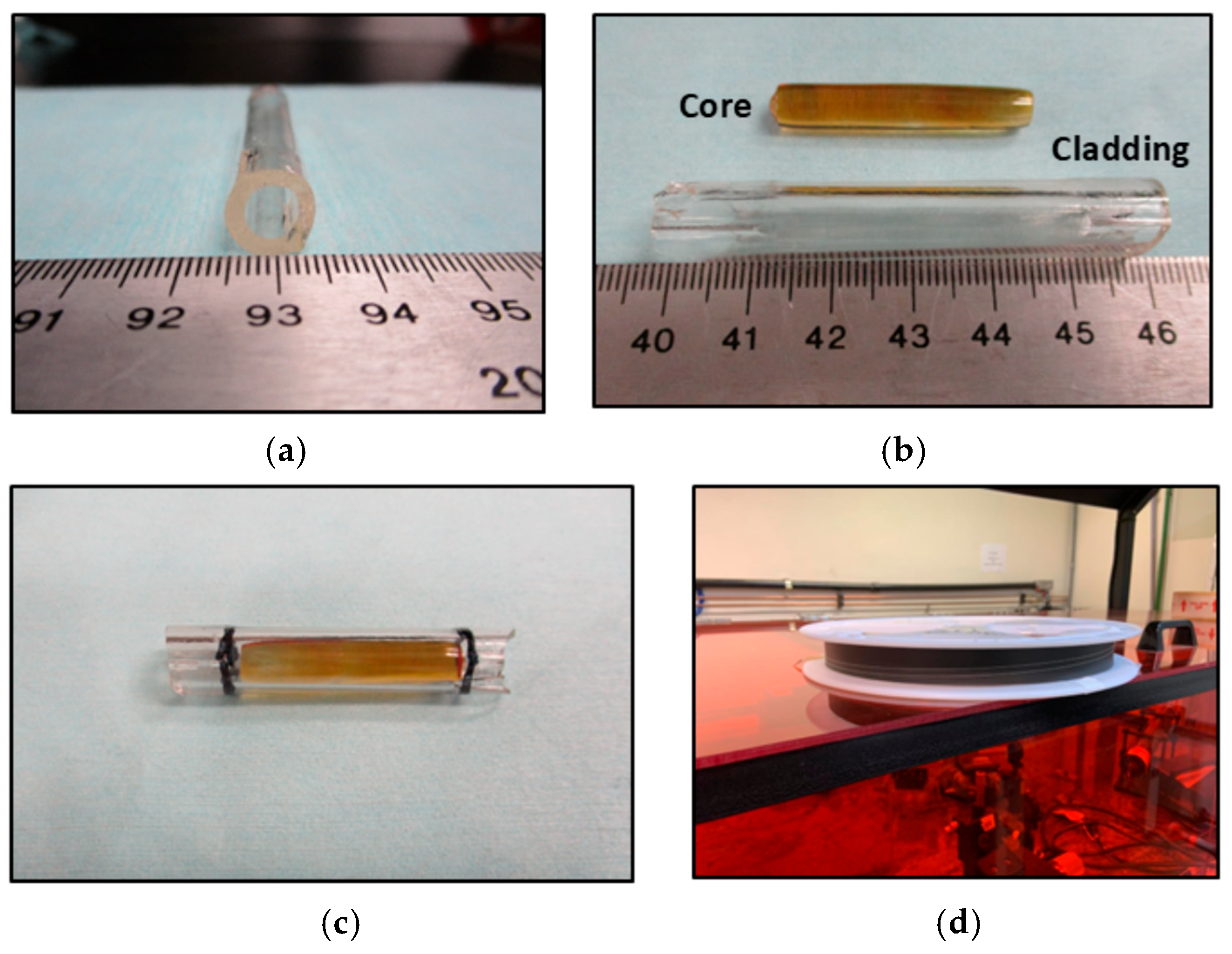

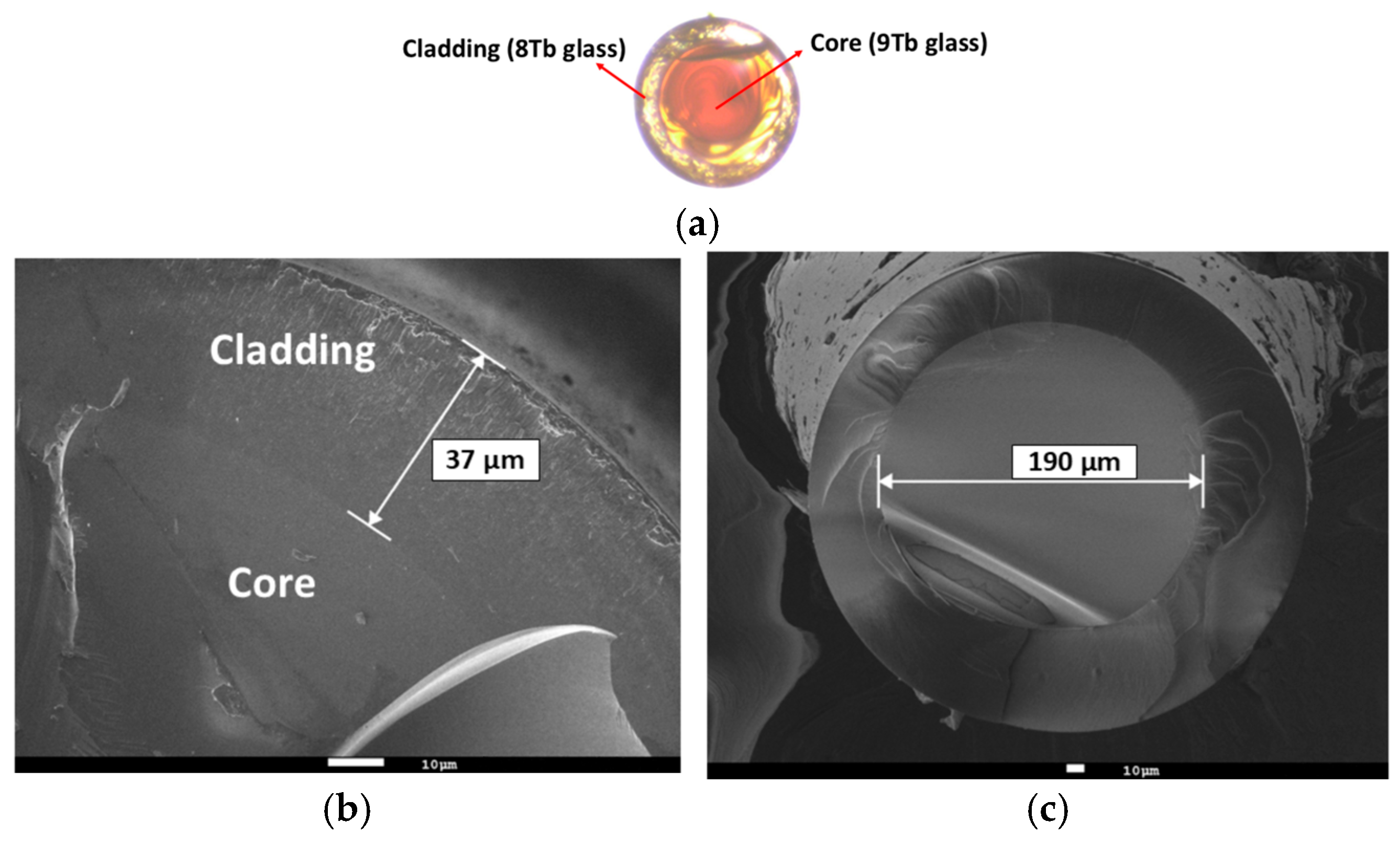

- Cladding preparation: Firstly, the cladding fiber was prepared using the glass composition containing 8 mol% Tb4O7 (BGB-8Tb). A glass tube measuring 6 cm in length, with an outer diameter of 10 mm and inner diameter of 6.5 mm, was fabricated using the rotational casting method (Figure 1a). For this, 25 g of BGB-8Tb glass was melted at 1400 °C for 1 h in a platinum crucible. After melting, the cladding composition was cast into a preheated cylindrical stainless-steel mold (maintained at 50 °C below Tg) mounted in a rotational casting furnace. Rotation was immediately performed for 15 s at 2500 rpm, forming the glass tube by centrifugal action (Figure 1a). The rotation system was then switched off, and thermal annealing of the glass tube was performed for 6 h at 550 °C (below Tg) to minimize structural stress of the tube. The glass tube was then cooled at a slow cooling rate of 0.5 °C min−1 until reaching room temperature. In the final step, the external surface of the glass tube was polished with silicon carbide (SiC) papers (600, 800, 1200, 2400, and 4000 mesh) using an automatic polishing machine, followed by a final polishing with an aluminum oxide suspension.

- (II)

- Core preparation: The core fiber was fabricated from a glass rod preform (4 cm length × 6.45 mm diameter) containing 9 mol% of Tb4O7 (BGB-9Tb), according to the experimental parameters detailed in Section 2.1 (Figure 1b). For this, 20 g of the BGB-9Tb glass composition was melted for 1 h in a platinum crucible at 1400 °C in a resistive furnace. The melt was cast into a cylindrical preheated mold maintained at 50 °C below Tg (564 °C), followed by thermal annealing for 6 h. The glass rod was cooled to room temperature at a rate of 0.5 °C min−1. A rod measuring 6.45 mm in diameter and 4 cm in length was prepared. The glass rod was polished using the same procedure described above for the glass tube.

- (III)

- Conventional rod-in-tube technique: The third step in the preparation of the core-cladding glass preform involved the insertion of the BGB-9Tb glass rod (core) into the BGB-8Tb glass tube (cladding) to obtain the final assembled core-cladding glass preform system (Figure 1c). The glass rod was fitted into the glass tube, ensuring complete surface contact, since improper fitting of the core within the glass tube could lead to morphological defects in the resulting optical fiber.

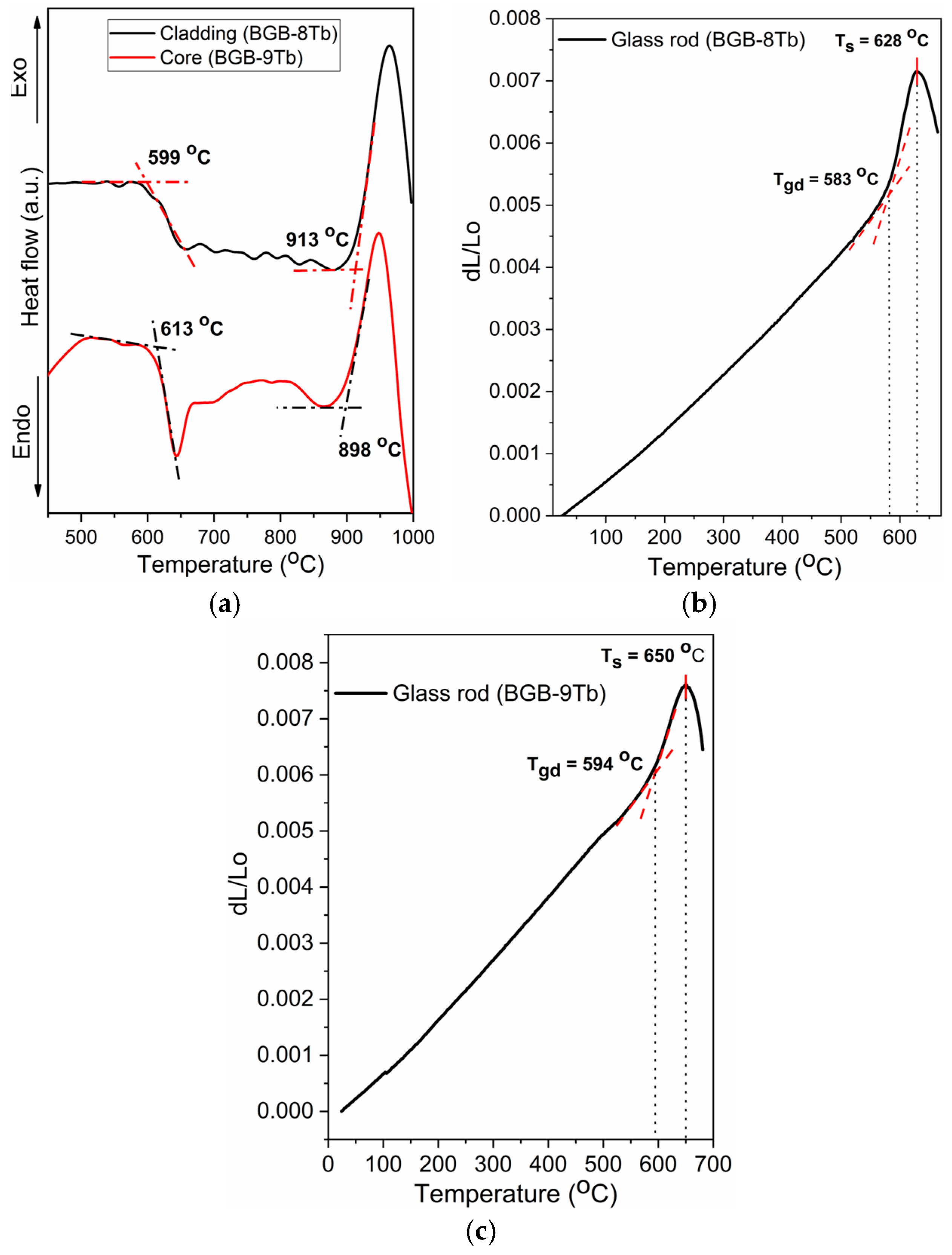

| Sample | Tg (±2 °C) | Tx (±2 °C) | ΔT (±4 °C) | Tgd (±2 °C) | Ts (±2 °C) | α(25–500 °C) (±0.05) (10−6 K−1) | Tfib |

|---|---|---|---|---|---|---|---|

| BGB-8Tb | 599 | 913 | 314 | 583 | 628 | 10.3 | 734 |

| BGB-9Tb | 614 | 896 | 282 | 590 | 650 | 10.2 | 744 |

2.3. Characterization Techniques

3. Results and Discussion

3.1. Thermal, Viscosity, and Morphological Analyses

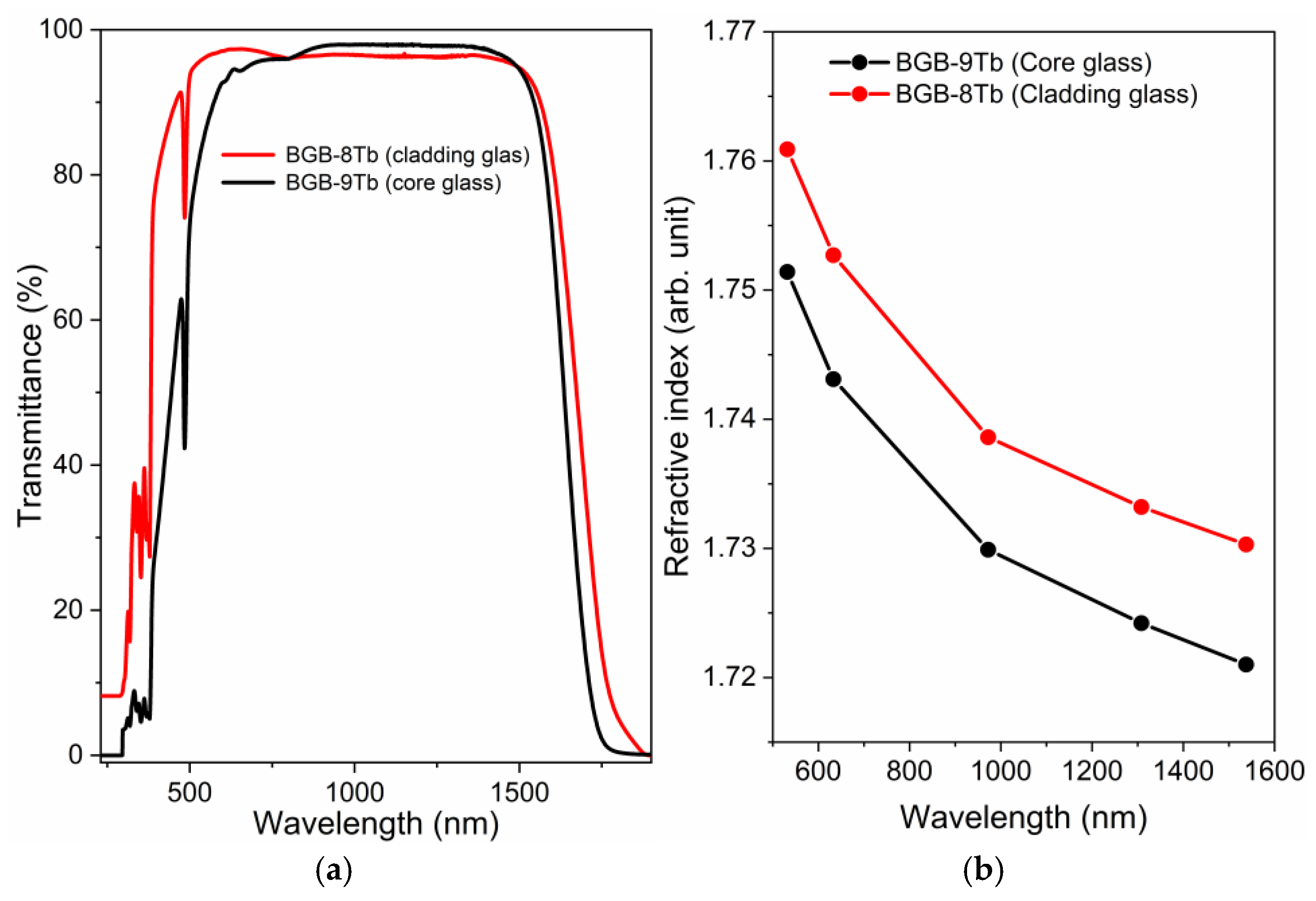

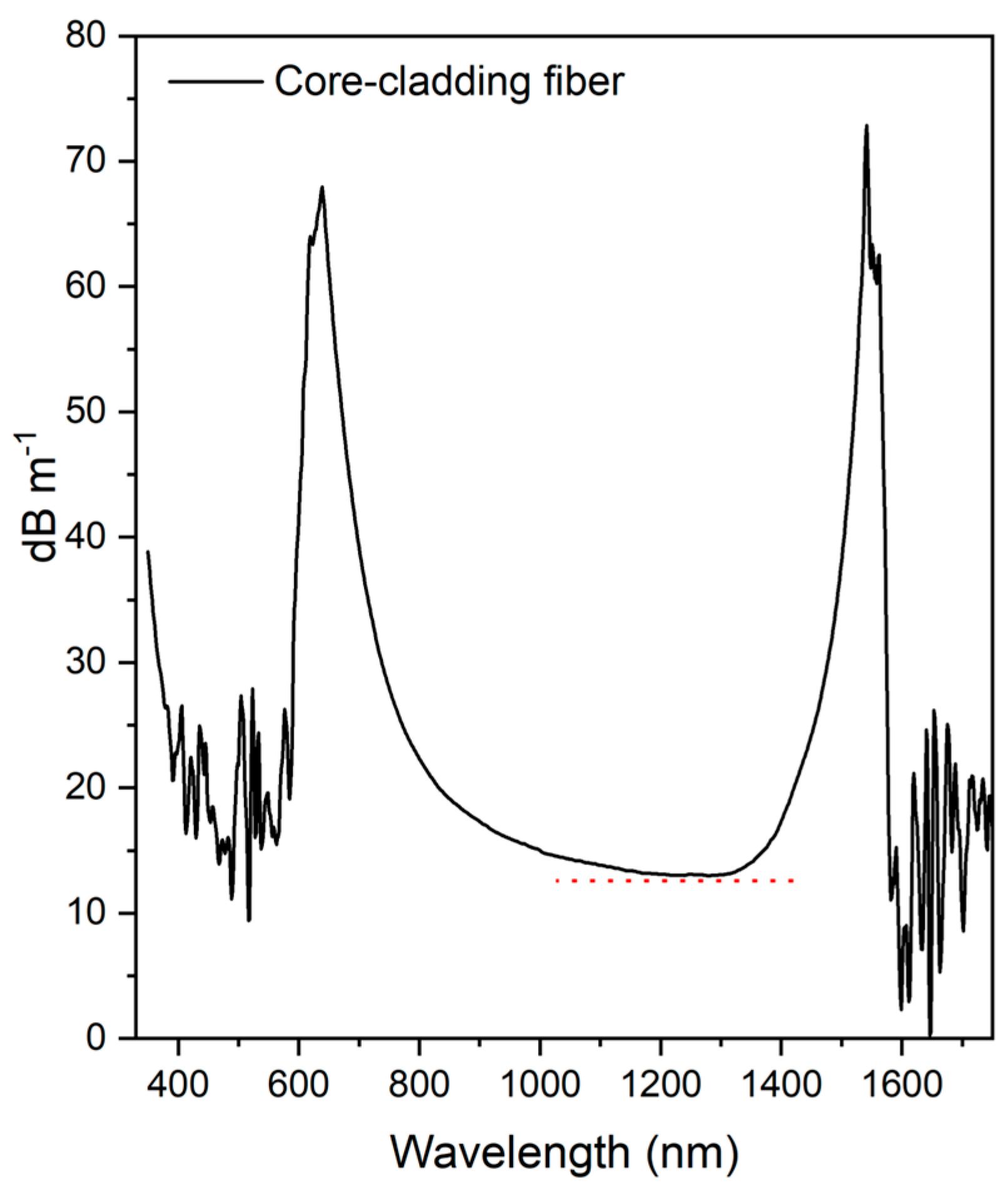

3.2. Optical Analysis

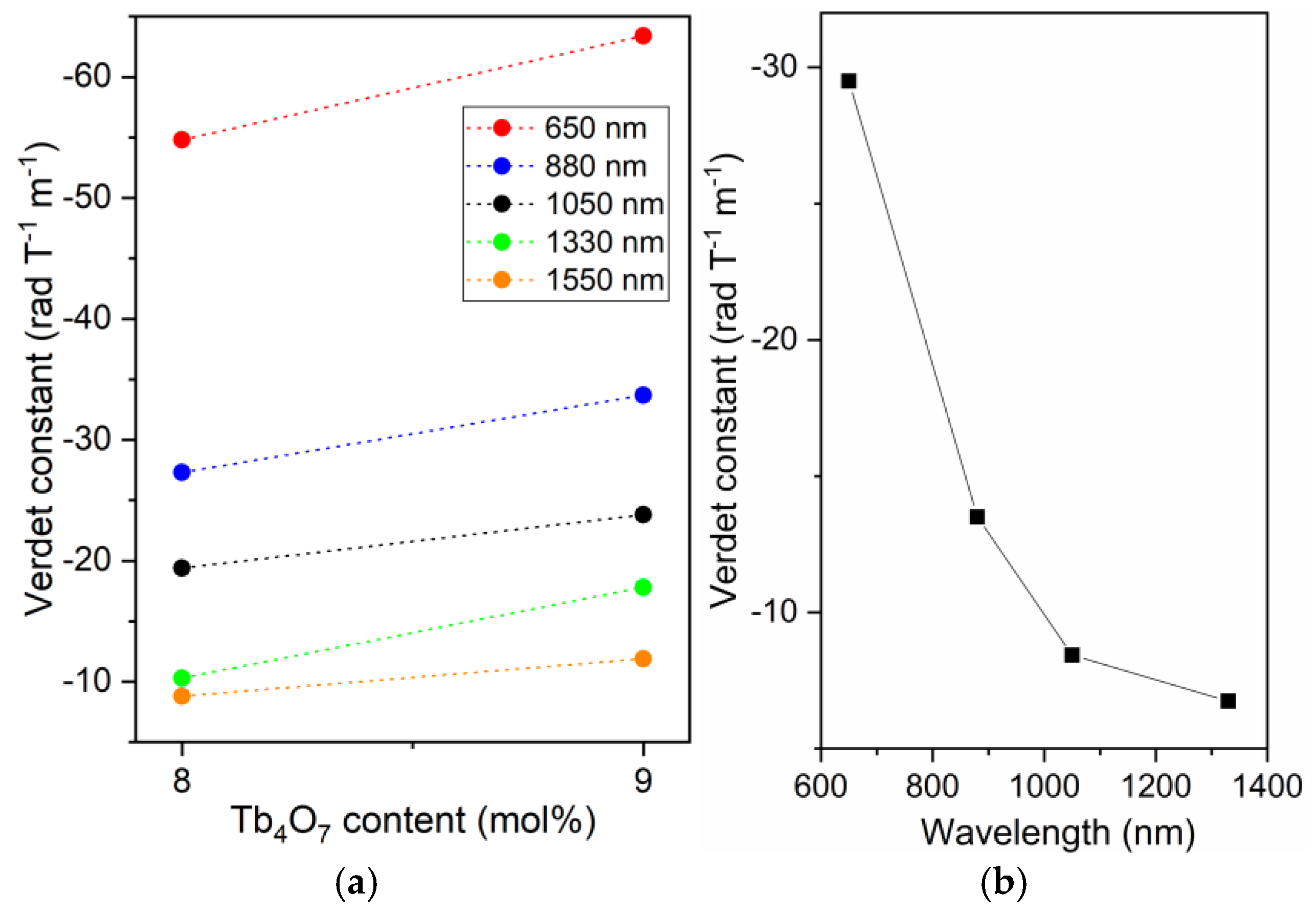

3.3. Magneto-Optical Measurements

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| RE | Rare-earth |

| SMF | Single-mode fiber |

| MMF | Multimode optical fiber |

| DSC | Differential scanning calorimetry |

| TMA | Thermomechanical analysis |

| UV-Vis-NIR | Ultraviolet-visible-near-infrared |

| NA | Numerical aperture |

| VB | Verdet constant |

| MO | Magneto-optical |

| TGG | Terbium gallium garnet |

| YIG | Yttrium iron garnet |

| NIR | Near-infrared |

| HMO | Heavy metal oxide |

| MCVD | Modified chemical vapor deposition |

| BGB | Borogermanate glass |

| PMMA | Poly(methyl methacrylate) |

| SEM | Scanning electron microscopy |

| OSA | Optical spectrum analyzer |

| CTE | Coefficient of thermal expansion |

| CFS | Cationic field strength |

References

- Suzuki, F.; Furuyama, T.; Sato, F.; Masuda, N.; Yoshida, H.; Ogino, J.; Yogo, A.; Kawaguchi, H.; Yasuhara, R.; Tokita, S.; et al. Faraday isolators for high-power lasers using magneto-optical glass. Proc. SPIE 2025, 13344, 133440C. [Google Scholar]

- Al-Zahrani, J.S.; Alrowaili, Z.A.; Eke, C.; Al-Qaisi, S.; Alsufyani, S.J.; Olarinoye, I.O.; Boukhris, I.; Al-Buriahi, M.S. Tb3+-doped GeO2–B2O3–P2O5–ZnO magneto-optical glasses: Potential application as gamma-radiation absorbers. Radiat. Phys. Chem. 2023, 208, 110874. [Google Scholar] [CrossRef]

- Guo, Y.; Canning, J.; Chaczko, Z.; Peng, G.-D. A magneto-optical fibre transducer. Proc. SPIE 2025, 13639, 136399E. [Google Scholar]

- Liu, C.; Shen, T.; Wu, H.-B.; Feng, Y.; Chen, J.-J. Applications of magneto-strictive, magneto-optical, magnetic fluid materials in optical fiber current sensors and optical fiber magnetic field sensors: A review. Opt. Fiber Technol. 2021, 65, 102634. [Google Scholar] [CrossRef]

- Han, X.; Liu, C.; Niu, L.; Zheng, X.; Duan, C.; Sun, X.; Ren, J.; Zhang, J. Tb3+-doped fluoro-borosilicate magneto-optical glass with a large Verdet constant for current sensing. Ceram. Int. 2025, 51, 798–806. [Google Scholar] [CrossRef]

- Nalin, M.; Albino, L.V.; Lodi, T.A.; Orives, J.R.; Marcondes, L.M.; Habib, A.A.; Acosta, M.H.R.; Zanotto, E.D.; Franco, D.F. Novel scalable synthesis of luminescent and magnetic single crystal garnets. Mater. Horiz. 2025, 12, 4709–4713. [Google Scholar] [CrossRef] [PubMed]

- Franco, D.F.; Fernandes, R.G.; Felix, J.F.; Mastelaro, V.R.; Eckert, H.; Afonso, C.R.; Messaddeq, Y.; Messaddeq, S.H.; Morency, S.; Nalin, M. Fundamental studies of magneto-optical borogermanate glasses and derived optical fibers containing Tb3+. J. Mater. Res. Technol. 2021, 11, 312–327. [Google Scholar] [CrossRef]

- Lin, H.; Li, G.; Hao, C.; Zhou, L.; Li, N.; Yang, H.; Wang, L. Study on the physical properties and luminescent properties of Tb3+-doped GBBS magneto-optical glass. Opt. Mater. 2024, 150, 115072. [Google Scholar] [CrossRef]

- Berno, A.E.; Caixeta, F.J.; Ruzene, J.P.C.; Feltran, A.M.; Albino, L.V.; Abuçafy, M.P.; Silva, O.D.B.; Rodrigues, J.P.P.; Ferreira-Neto, E.P.; Rosa, A.P.A.; et al. Recycled Rare Earth Ions from E-Waste in Borogermanate Glasses for Magneto-Optical Applications. Chem. Asian J. 2025, 20, e202401613. [Google Scholar] [CrossRef]

- Albino, L.V.; Dussauze, M.; Toulemonde, O.; Duttine, M.; Jubera, V.; Franco, D.F.; Cardinal, T.; Nalin, M. Paramagnetic borotungstate glasses with high terbium concentration for magneto-optical applications. J. Non-Cryst. Solids 2024, 627, 122811. [Google Scholar] [CrossRef]

- Lin, H.; Jia, H.; Zhou, L.; Li, N.; Liu, B.; He, J.; Yao, G.; Li, S.; Zhou, Y.; Li, C.; et al. Magneto-optical and fluorescence properties of Tb3+ doped glass-ceramics containing AlPO4. J. Non-Cryst. Solids 2022, 579, 121377. [Google Scholar] [CrossRef]

- Huang, Y.; Chen, H.; Dong, W.; Pang, F.; Wen, J.; Chen, Z.; Wang, T. Fabrication of europium-doped silica optical fiber with high Verdet constant. Opt. Express 2016, 24, 18709–18717. [Google Scholar] [CrossRef] [PubMed]

- Henrique, F.R.; Pelosi, A.G.; Almeida, J.M.P.; Franco, D.F.; Cocca, L.H.Z.; Clabel H., J.L.; Nalin, M.; Mastelaro, V.R.; De Boni, L. Nonlinear refraction in high terbium content borogermanate glass bulk and fiber. Opt. Mater. 2024, 147, 114635. [Google Scholar] [CrossRef]

- Cabral, T.D.; Franco, D.F.; Fujiwara, E.; Nalin, M.; Cordeiro, C.M.B. Magnetic Field Fiber Specklegram Sensors Based on Tb3+-Doped Magneto-Optical Glasses with High Verdet Constants. IEEE Sens. J. 2023, 23, 6872–6879. [Google Scholar] [CrossRef]

- Jin, W.; Ding, J.; Guo, L.; Gu, Q.; Li, C.; Su, L.; Wu, A.; Zeng, F. Growth and performance research of Tb3Ga5O12 magneto-optical crystal. J. Cryst. Growth 2018, 484, 17–20. [Google Scholar] [CrossRef]

- Block, A.D.; Dulal, P.; Stadler, B.J.; Seaton, N.C. Growth parameters of fully crystallized YIG, Bi:YIG, and Ce:YIG films with high Faraday rotations. IEEE Photonics J. 2014, 6, 1–8. [Google Scholar] [CrossRef]

- Ikesue, A.; Aung, Y.L. Development of optical grade polycrystalline YIG ceramics for Faraday rotator. J. Am. Ceram. Soc. 2018, 101, 5120–5126. [Google Scholar] [CrossRef]

- Watanabe, M.; Maruyama, Y.; Nagao, K.; Anzai, Y.; Nagao, M.; Watauchi, S.; Tanaka, I. Czochralski growth and composition control of Tb3Ga5O12 single crystals. J. Cryst. Growth 2025, 665, 128205. [Google Scholar] [CrossRef]

- Gao, G.; Winterstein-Beckmann, A.; Surzhenko, O.; Dubs, C.; Dellith, J.; Schmidt, M.A.; Wondraczek, L. Faraday rotation and photoluminescence in heavily Tb3+-doped GeO2-B2O3-Al2O3-Ga2O3 glasses for fiber-integrated magneto-optics. Sci. Rep. 2015, 5, 8942. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, Z.; Chen, N.; Huang, Y.; Liu, S.; Shang, Y.; Wang, T. Study of the Verdet constant of the holmium-doped silica fiber. OSA Contin. 2020, 3, 1096–1104. [Google Scholar] [CrossRef]

- Linganna, K.; Ju, S.; Lee, Y.; Han, W.-T. Development of aluminosilicate glass fiber doped with high Pr3+ concentration for all-optical fiber isolator application. J. Mater. Sci. Mater. Electron. 2019, 30, 12790–12795. [Google Scholar] [CrossRef]

- Franco, D.F.; Ledemi, Y.; Correr, W.; Morency, S.; Afonso, C.R.M.; Messaddeq, S.H.; Messaddeq, Y.; Nalin, M. Magneto-optical borogermanate glasses and fibers containing Tb3+. Sci. Rep. 2021, 11, 9906. [Google Scholar] [CrossRef] [PubMed]

- Cruz, J.L.; Andres, M.V.; Hernandez, M.A. Faraday effect in standard optical fibers: Dispersion of the effective Verdet constant. Appl. Opt. 1996, 35, 922–927. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Jiang, S.; Zuegel, J.D.; Marciante, J.R. Effective Verdet constant in a terbium-doped-core phosphate fiber. Opt. Lett. 2009, 34, 1699–1701. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Jiang, S.; Marciante, J.R. Compact all-fiber optical Faraday components using 65-wt%-terbium–doped fiber with a record Verdet constant of −32 rad/(Tm). Opt. Express 2010, 18, 12191–12196. [Google Scholar] [CrossRef]

- Skopak, T.; Calzavara, F.; Ledemi, Y.; Célarié, F.; Allix, M.; Véron, E.; Dussauze, M.; Cardinal, T.; Fargin, E.; Messaddeq, Y. Properties, structure and crystallization study of germano-gallate glasses in the Ga2O3–GeO2–BaO–K2O system. J. Non-Cryst. Solids 2019, 514, 98–107. [Google Scholar] [CrossRef]

- Galstyan, A.; Messaddeq, S.H.; Skripachev, I.; Galstian, T.; Messaddeq, Y. Role of iodine in the solubility of Tm3+ ions in As2S3 glasses. Opt. Mater. Express 2016, 6, 230–243. [Google Scholar] [CrossRef]

- Wang, M.-T.; Cheng, J.-S. Viscosity and thermal expansion of rare earth containing soda–lime–silicate glass. J. Alloys Compd. 2010, 504, 273–276. [Google Scholar] [CrossRef]

- Nemilov, S.V. Thermodynamic and Kinetic Aspects of the Vitreous State; CRC Press: Boca Raton, FL, USA, 1995; 222p. [Google Scholar]

- Chen, Q.; Chen, Q.; Wang, H.; Wang, G.; Yin, S. Magneto optical properties of rare earth Tb2O3 doped PbO–Bi2O3–B2O3 glass. J. Non-Cryst. Solids 2017, 470, 99–107. [Google Scholar] [CrossRef]

- Sontakke, A.D.; Annapurna, K. Study on Tb3+-containing high silica and low silica calcium aluminate glasses: Impact of optical basicity. Spectrochim. Acta A 2012, 94, 180–185. [Google Scholar] [CrossRef]

- Savinkov, V.; Sigaev, V.; Golubev, N.; Sarkisov, P.; Masalov, A.; Sergeev, A. Borogermanate glasses with a high terbium oxide content. J. Non-Cryst. Solids 2010, 356, 1655–1659. [Google Scholar] [CrossRef]

- Wan, X.; Zhong, Q.; Tie, S.; Shen, J. Synthesis and luminescence properties of Tb3+ activated CaO–Al2O3–B2O3 glass. Optoelectron. Adv. Mater. 2011, 5, 538–544. [Google Scholar]

- Manzani, D.; Ferrari, J.L.; Polachini, F.C.; Messaddeq, Y.; Ribeiro, S.J.L. 1.5 μm and visible up-conversion emissions in Er3+/Yb3+ co-doped tellurite glasses and optical fibers for photonic applications. J. Mater. Chem. 2012, 22, 16540–16545. [Google Scholar] [CrossRef]

- Stone, J.; Walrafen, G.E. Overtone vibrations of OH groups in fused silica optical fibers. J. Chem. Phys. 1982, 76, 1712–1722. [Google Scholar] [CrossRef]

- Buck, J.A. Fundamentals of Optical Fibers, 2nd ed.; Wiley: Hoboken, NJ, USA, 2004; ISBN 978-0-471-22191-3. [Google Scholar]

- Yoshino, T. Theory for the Faraday effect in optical fiber. J. Opt. Soc. Am. B 2005, 22, 1856–1860. [Google Scholar] [CrossRef]

- Barczak, K.; Cimek, J.; Stępień, R.; Buczyński, R. Measurements of Verdet constant in heavy metal oxide glasses for magneto-optic fiber current sensors. Opt. Mater. 2022, 123, 111942. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Franco, D.F.; Morency, S.; Messaddeq, Y.; Nalin, M. Multimode Magneto-Optical Fiber Based on Borogermanate Glass Containing Tb3+ for Sensing Applications. Materials 2025, 18, 4736. https://doi.org/10.3390/ma18204736

Franco DF, Morency S, Messaddeq Y, Nalin M. Multimode Magneto-Optical Fiber Based on Borogermanate Glass Containing Tb3+ for Sensing Applications. Materials. 2025; 18(20):4736. https://doi.org/10.3390/ma18204736

Chicago/Turabian StyleFranco, Douglas F., Steeve Morency, Younès Messaddeq, and Marcelo Nalin. 2025. "Multimode Magneto-Optical Fiber Based on Borogermanate Glass Containing Tb3+ for Sensing Applications" Materials 18, no. 20: 4736. https://doi.org/10.3390/ma18204736

APA StyleFranco, D. F., Morency, S., Messaddeq, Y., & Nalin, M. (2025). Multimode Magneto-Optical Fiber Based on Borogermanate Glass Containing Tb3+ for Sensing Applications. Materials, 18(20), 4736. https://doi.org/10.3390/ma18204736