Surface Finishing of Additive Manufactured Titanium Alloy by Plasma Electrolytic Polishing Without Pretreatments

Abstract

1. Introduction

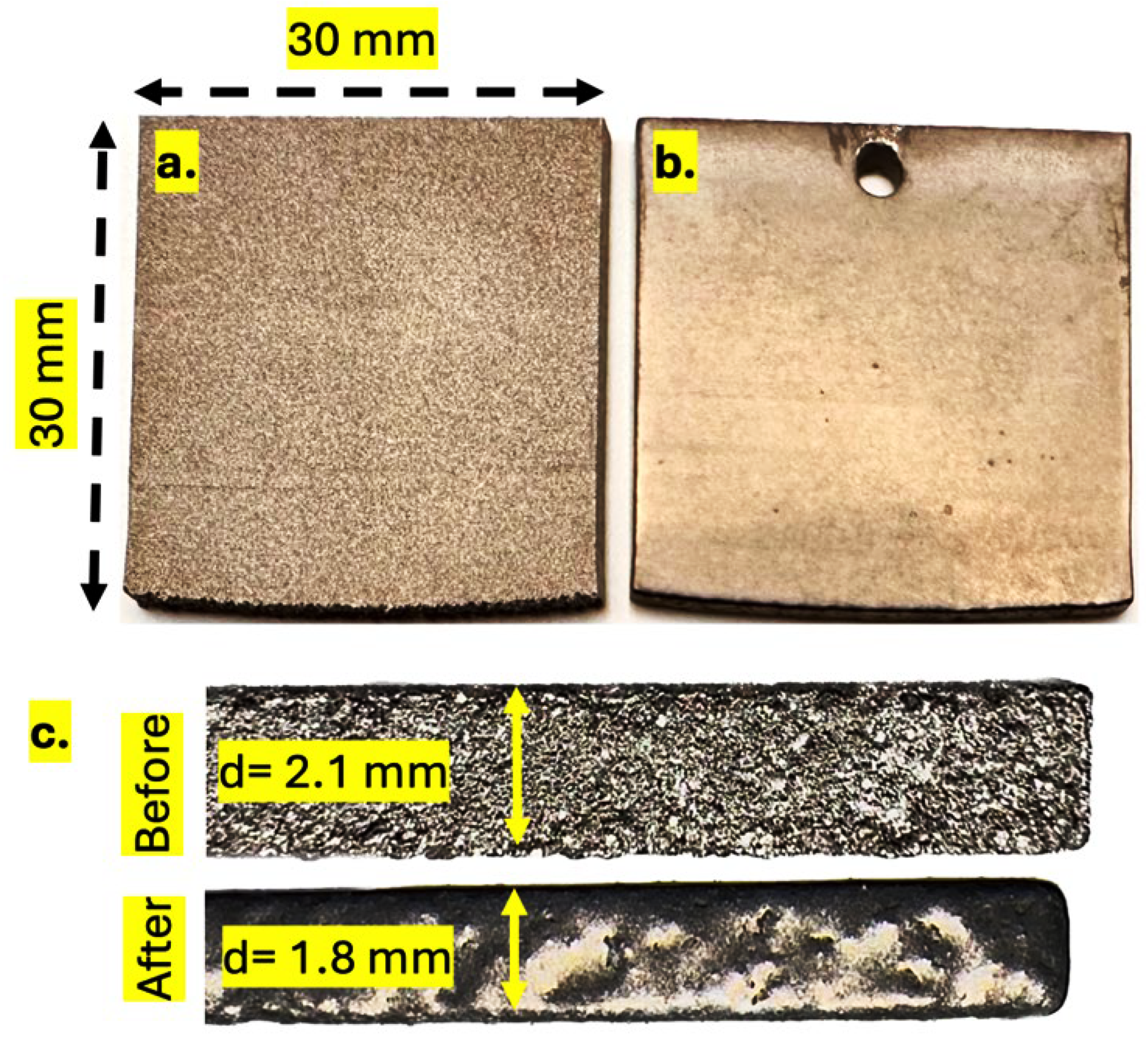

2. Materials and Methods

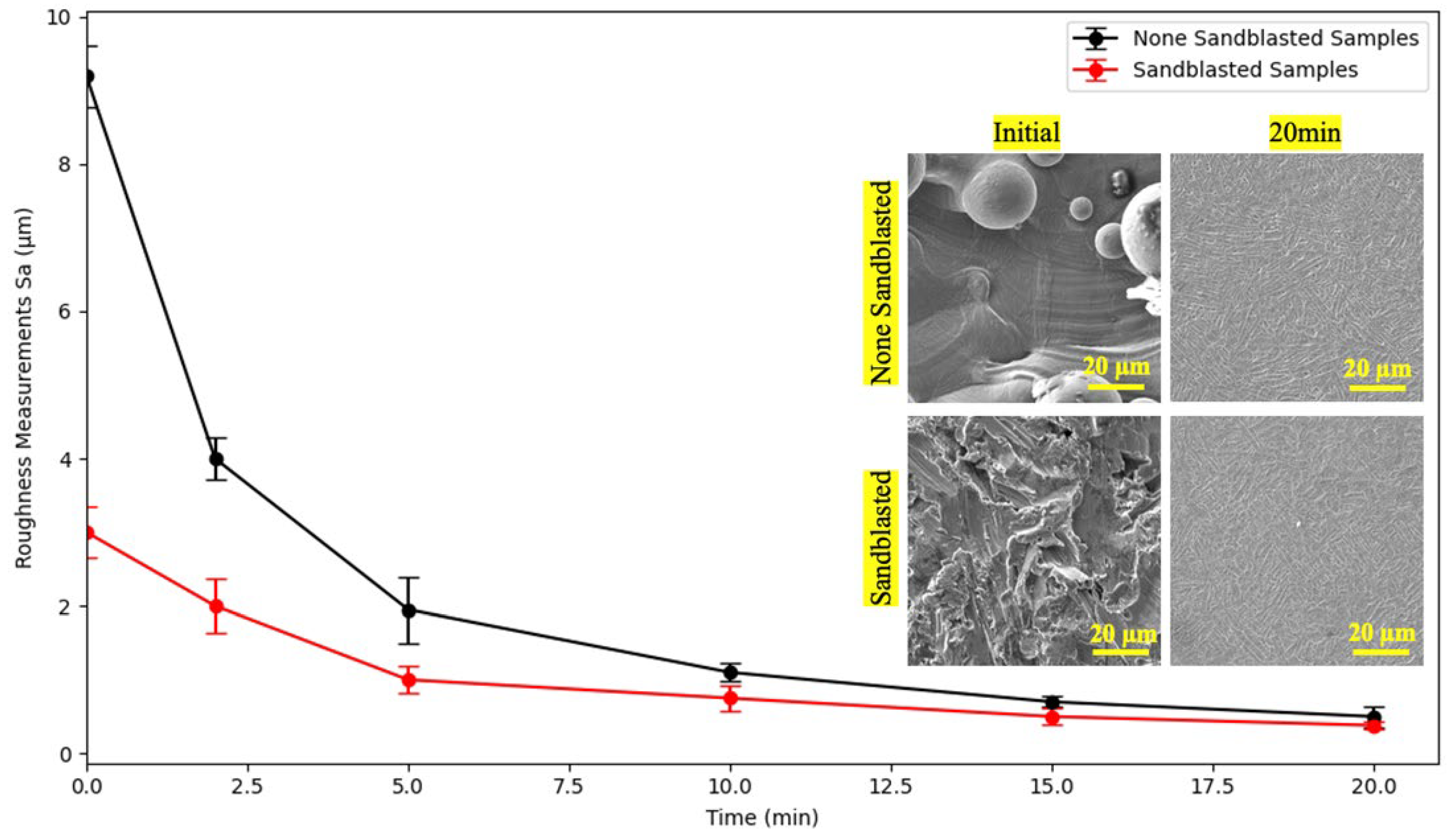

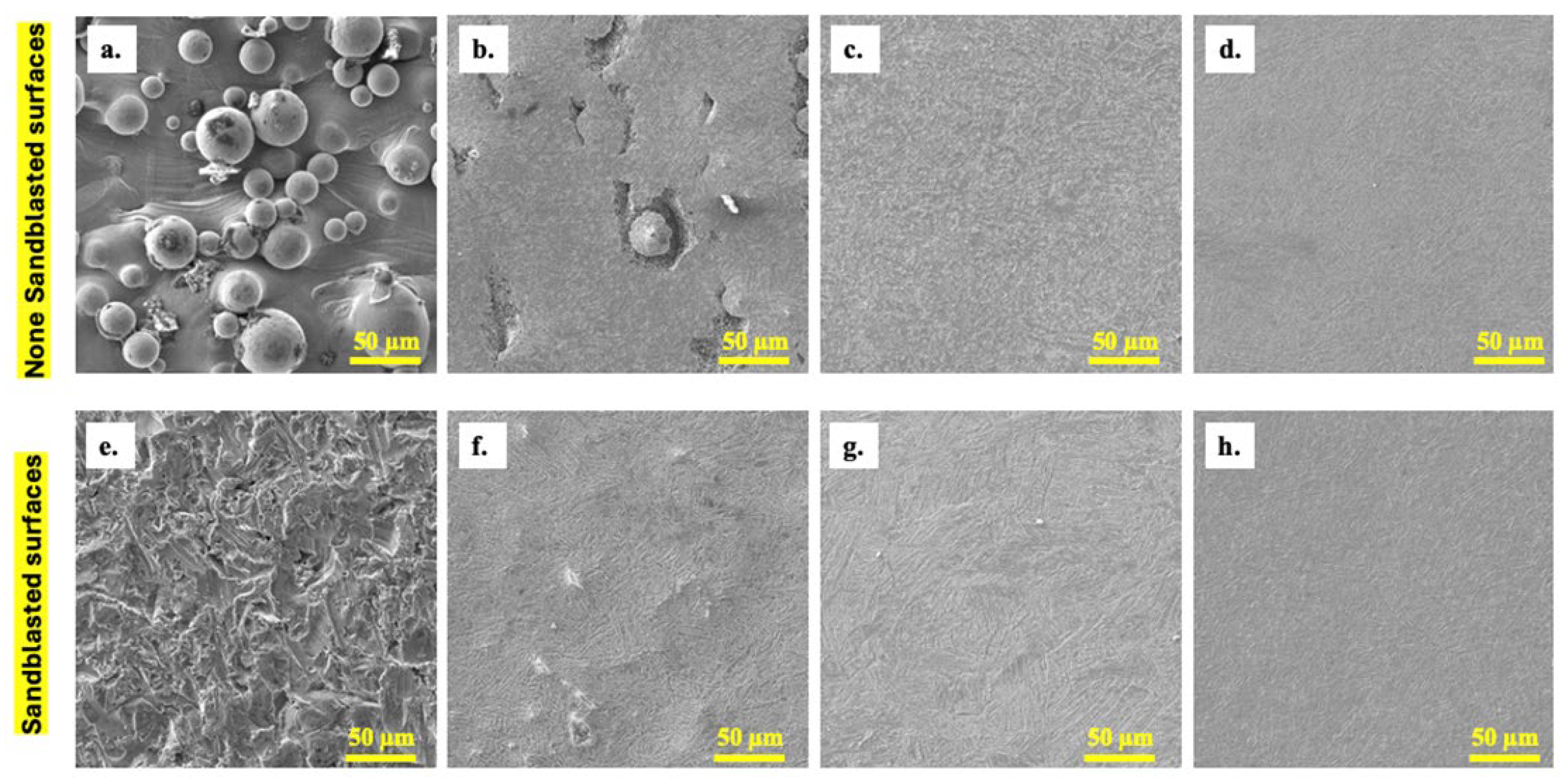

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gibson, I.; Rosen, D.; Stucker, B. Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing, 1st ed.; Springer: New York, NY, USA, 2015. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Boyer, R.R. An overview on the use of titanium in the aerospace industry. Mater. Sci. Eng. A 1996, 213, 103–114. [Google Scholar] [CrossRef]

- Leyens, C.; Peters, M. (Eds.) Titanium and Titanium Alloys Fundamentals and Applications, 1st ed.; Wiley: Weinheim, Germany, 2003. [Google Scholar] [CrossRef]

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Delgado, P.; Cuesta, I.; Alegre, J.; Díaz, A. State of the art of Deep Rolling. Precis. Eng. 2016, 46, 1–10. [Google Scholar] [CrossRef]

- Bauereiß, A.; Scharowsky, T.; Körner, C. Defect generation and propagation mechanism during additive manufacturing by selective beam melting. J. Mech. Work. Technol. 2014, 214, 2522–2528. [Google Scholar] [CrossRef]

- Kim, J.-C.; Cheong, S.-K.; Noguchi, H. Evolution of residual stress redistribution associated with localized surface microcracking in shot-peened medium-carbon steel during fatigue test. Int. J. Fatigue 2013, 55, 147–157. [Google Scholar] [CrossRef]

- Gåhlin, R.; Jacobson, S. A novel method to map and quantify wear on a micro-scale. Wear 1998, 222, 93–102. [Google Scholar] [CrossRef]

- Wang, M.; Yang, C.; Li, Z.; Zhao, S.; Zhang, Y.; Lu, X. Effects of surface roughness on the aerodynamic performance of a high subsonic compressor airfoil at low Reynolds number. Chin. J. Aeronaut. 2021, 34, 71–81. [Google Scholar] [CrossRef]

- Benkerroum, N.; Bouhlal, Y.; El Attar, A.; Marhaben, A. Occurrence of Shiga Toxin–Producing Escherichia coli O157 in Selected Dairy and Meat Products Marketed in the City of Rabat, Morocco. J. Food Prot. 2004, 67, 1234–1237. [Google Scholar] [CrossRef]

- Albrektsson, T.; Wennerberg, A. On osseointegration in relation to implant surfaces. Clin. Implant. Dent. Relat. Res. 2019, 21, 4–7. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.-D.; Zhang, L.-L.; Fei, Y.-H.; Liu, X.-Y.; Li, M.-X. On the formation mechanisms of fine granular area (FGA) on the fracture surface for high strength steels in the VHCF regime. Int. J. Fatigue 2016, 82, 402–410. [Google Scholar] [CrossRef]

- Mu, J.; Sun, T.; Leung, C.L.A.; Oliveira, J.; Wu, Y.; Wang, H.; Wang, H. Application of electrochemical polishing in surface treatment of additively manufactured structures: A review. Prog. Mater. Sci. 2023, 136, 101109. [Google Scholar] [CrossRef]

- Pauzon, C.; Forêt, P.; Hryha, E.; Arunprasad, T.; Nyborg, L. Argon-helium mixtures as Laser-Powder Bed Fusion atmospheres: Towards increased build rate of Ti-6Al-4V. J. Mech. Work. Technol. 2020, 279, 116555. [Google Scholar] [CrossRef]

- Belkin, P.; Kusmanov, S.; Parfenov, E. Mechanism and technological opportunity of plasma electrolytic polishing of metals and alloys surfaces. Appl. Surf. Sci. Adv. 2020, 1, 100016. [Google Scholar] [CrossRef]

- An, F.; Zhang, L.; Na, S.J. Effects of plasma electrolytic polishing on the surface and mechanical properties of Ti-6.5Al-3.5Mo-1.5Zr-0.3Si specimen fabricated by laser powder bed fusion. J. Manuf. Process. 2024, 131, 283–296. [Google Scholar] [CrossRef]

- Ghezri, A.; Pratama, K.; Scholl, Y.; Küenzi, A.; Nelis, T.; Burger, J.; Bessire, C. Energy Efficient Jet Polishing via Electrolytic Plasma Enhances Corrosion Resistance in Stainless Steel. J. Manuf. Mater. Process. 2024, 8, 289. [Google Scholar] [CrossRef]

- Küenzi, A.; Goetschi, M.; Nelis, T.; Bessire, C. Jet Application of Plasma Electrolyte Polishing. Procedia CIRP 2022, 113, 525–529. [Google Scholar] [CrossRef]

- Cornelsen, M.; Deutsch, C.; Seitz, H. Electrolytic Plasma Polishing of Pipe Inner Surfaces. Metals 2017, 8, 12. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, C.; Ding, F.; Yang, Y.; Zhang, T.; He, X.; Zheng, L.; Li, N. Principle, process, and application of metal plasma electrolytic polishing: A review. Int. J. Adv. Manuf. Technol. 2021, 114, 1893–1912. [Google Scholar] [CrossRef]

- Zeidler, H.; Boettger-Hiller, F.; Edelmann, J.; Schubert, A. Surface Finish Machining of Medical Parts Using Plasma Electrolytic Polishing. Procedia CIRP 2016, 49, 83–87. [Google Scholar] [CrossRef]

- Parfenov, E.; Farrakhov, R.; Mukaeva, V.; Gusarov, A.; Nevyantseva, R.; Yerokhin, A. Electric field effect on surface layer removal during electrolytic plasma polishing. Surf. Coat. Technol. 2016, 307, 1329–1340. [Google Scholar] [CrossRef]

- Nestler, K.; Böttger-Hiller, F.; Adamitzki, W.; Glowa, G.; Zeidler, H.; Schubert, A. Plasma Electrolytic Polishing–An Overview of Applied Technologies and Current Challenges to Extend the Polishable Material Range. Procedia CIRP 2016, 42, 503–507. [Google Scholar] [CrossRef]

- Danilov, I.; Hackert-Oschätzchen, M.; Zinecker, M.; Meichsner, G.; Edelmann, J.; Schubert, A. Process Understanding of Plasma Electrolytic Polishing through Multiphysics Simulation and Inline Metrology. Micromachines 2019, 10, 214. [Google Scholar] [CrossRef]

- Praneeth, J.; Venatesh, S.; Ramarishna, L.S. Optimization of Processing Parameters and Mechanical Properties of SLM Titanium Alloy. In Proceedings of the 2nd International Conference on Emerging Trends in Engineering (ICETE 2023), Hyderabad, India, 28–30 April 2023; Raj, B., Gill, S., Calderon, C.A.G., Cihan, O., Tukkaraja, P., Venkatesh, S., Mudigonda, M., Gaddam, M., Dasari, R.K., Eds.; Advances in Engineering Research. Atlantis Press International BV: Dordrecht, The Netherlands, 2023; Volume 23, pp. 1150–1158. [Google Scholar] [CrossRef]

- Mullen, L.; Stamp, R.C.; Brooks, W.K.; Jones, E.; Sutcliffe, C.J. Selective Laser Melting: A regular unit cell approach for the manufacture of porous, titanium, bone in-growth constructs, suitable for orthopedic applications. J. Biomed. Mater. Res. Part B: Appl. Biomater. 2008, 89, 325–334. [Google Scholar] [CrossRef] [PubMed]

- Pauzon, C.; Mishurova, T.; Evsevleev, S.; Goff, S.D.-L.; Murugesan, S.; Bruno, G.; Hryha, E. Residual stresses and porosity in Ti-6Al-4V produced by laser powder bed fusion as a function of process atmosphere and component design. Addit. Manuf. 2021, 47, 102340. [Google Scholar] [CrossRef]

- Elsayed, M.; Ghazy, M.; Youssef, Y.; Essa, K. Optimization of SLM process parameters for Ti6Al4V medical implants. Rapid Prototyp. J. 2018, 25, 433–447. [Google Scholar] [CrossRef]

- Grabarczyk, J.; Jastrzębski, K.; Wrotniak, M. Post-processing of titanium 3D printouts with radio frequency plasma. Eng. Biomater. 2021, 24, 102340. [Google Scholar] [CrossRef]

- Ginestra, P.; Ceretti, E.; Lobo, D.; Lowther, M.; Cruchley, S.; Kuehne, S.; Villapun, V.; Cox, S.; Grover, L.; Shepherd, D.; et al. Post Processing of 3D Printed Metal Scaffolds: A Preliminary Study of Antimicrobial Efficiency. Procedia Manuf. 2020, 47, 1106–1112. [Google Scholar] [CrossRef]

- Liu, D.; Zong, X.; Xue, P.; Gao, Z.; Wu, W.; Song, Z.; Ye, F.; Pang, Y.; Zhang, Y.; Zhou, H.; et al. Effects of plasma electrolytic polishing treatment on the surface morphology, microstructure and corrosion resistance of additively manufactured TC4 titanium alloy. J. Mater. Res. Technol. 2025, 35, 7008–7017. [Google Scholar] [CrossRef]

- Zeidler, H.; Böttger-Hiller, F.; Wunderlich, A.H. Surface Finish of Additively Manufactured Parts Using Plasma Electrolytic Polishing, Octobre 2017. [En ligne]. Available online: https://www.euspen.eu/knowledge-base/AM17159.pdf (accessed on 2 October 2025).

- Yerokhin, A.L.; Nie, X.; Leyland, A.; Matthews, A.; Dowey, S.J. Plasma electrolysis for surface engineering. Surf. Coat. Technol. 1999, 122, 73–93. [Google Scholar] [CrossRef]

- Lv, Z.; Wang, L.; Hu, X.; Bu, Z.; Li, Y. Leveling mechanism of plasma electrolytic polishing of titanium alloy with aqueous fluoride-type solution. Int. J. Electrochem. Sci. 2024, 19, 100749. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ghezri, A.; Nelis, T.; Burger, J.; Bessire, C. Surface Finishing of Additive Manufactured Titanium Alloy by Plasma Electrolytic Polishing Without Pretreatments. Materials 2025, 18, 4719. https://doi.org/10.3390/ma18204719

Ghezri A, Nelis T, Burger J, Bessire C. Surface Finishing of Additive Manufactured Titanium Alloy by Plasma Electrolytic Polishing Without Pretreatments. Materials. 2025; 18(20):4719. https://doi.org/10.3390/ma18204719

Chicago/Turabian StyleGhezri, Adel, Thomas Nelis, Jürgen Burger, and Cedric Bessire. 2025. "Surface Finishing of Additive Manufactured Titanium Alloy by Plasma Electrolytic Polishing Without Pretreatments" Materials 18, no. 20: 4719. https://doi.org/10.3390/ma18204719

APA StyleGhezri, A., Nelis, T., Burger, J., & Bessire, C. (2025). Surface Finishing of Additive Manufactured Titanium Alloy by Plasma Electrolytic Polishing Without Pretreatments. Materials, 18(20), 4719. https://doi.org/10.3390/ma18204719