Stress Concentration-Based Material Leakage Fault Online Diagnosis of Vacuum Pressure Vessels Based on Multiple FBG Monitoring Data

Abstract

1. Introduction

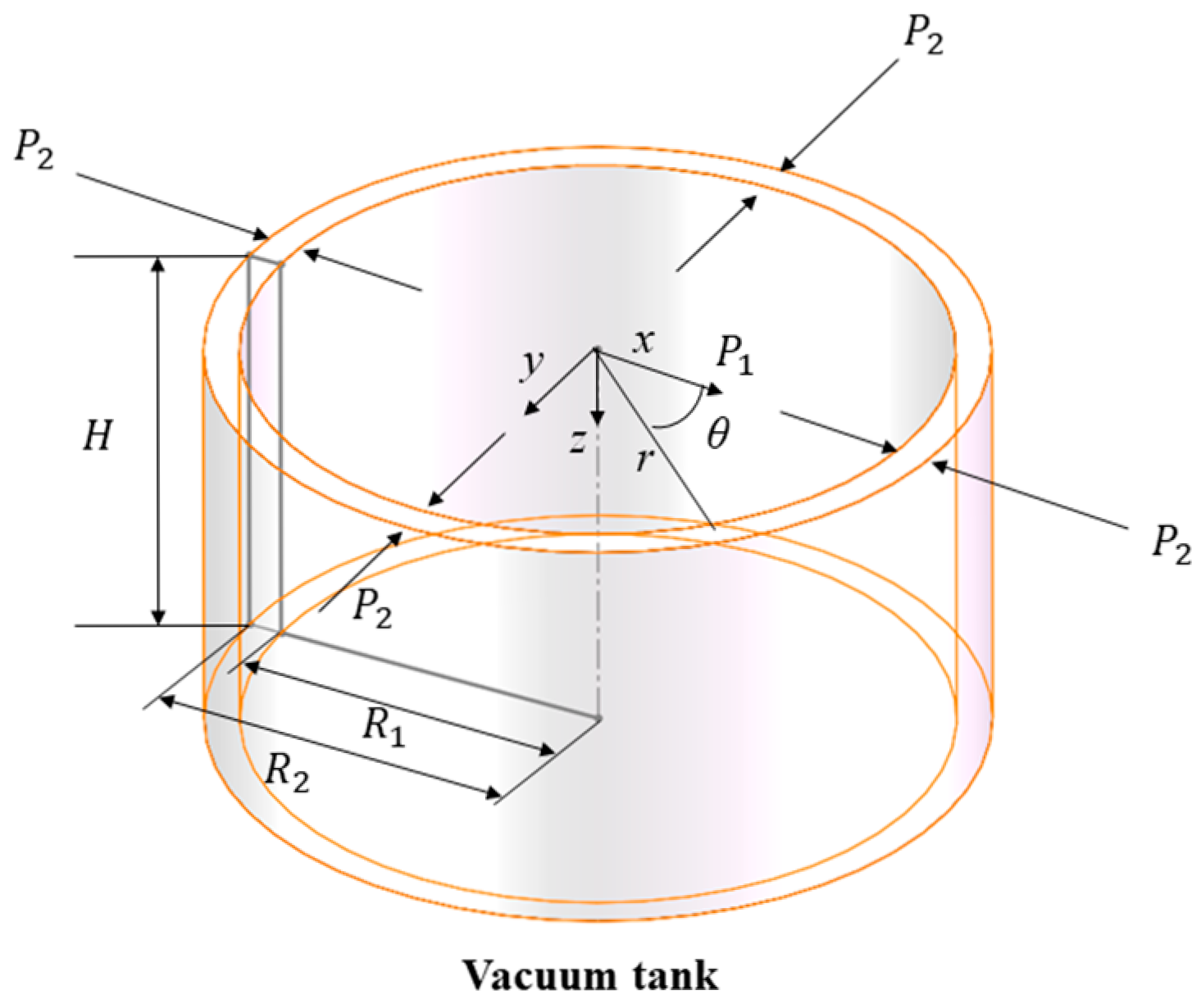

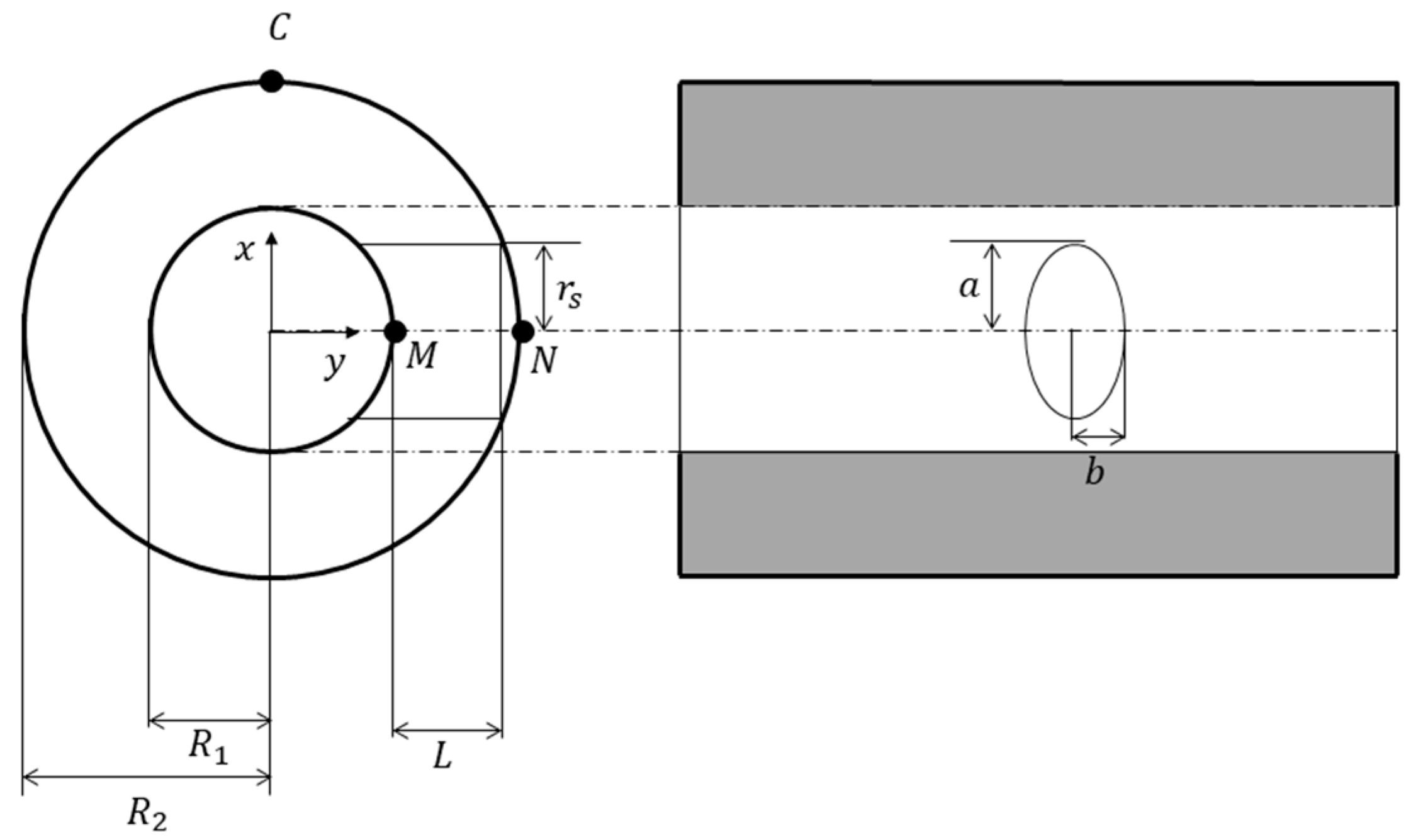

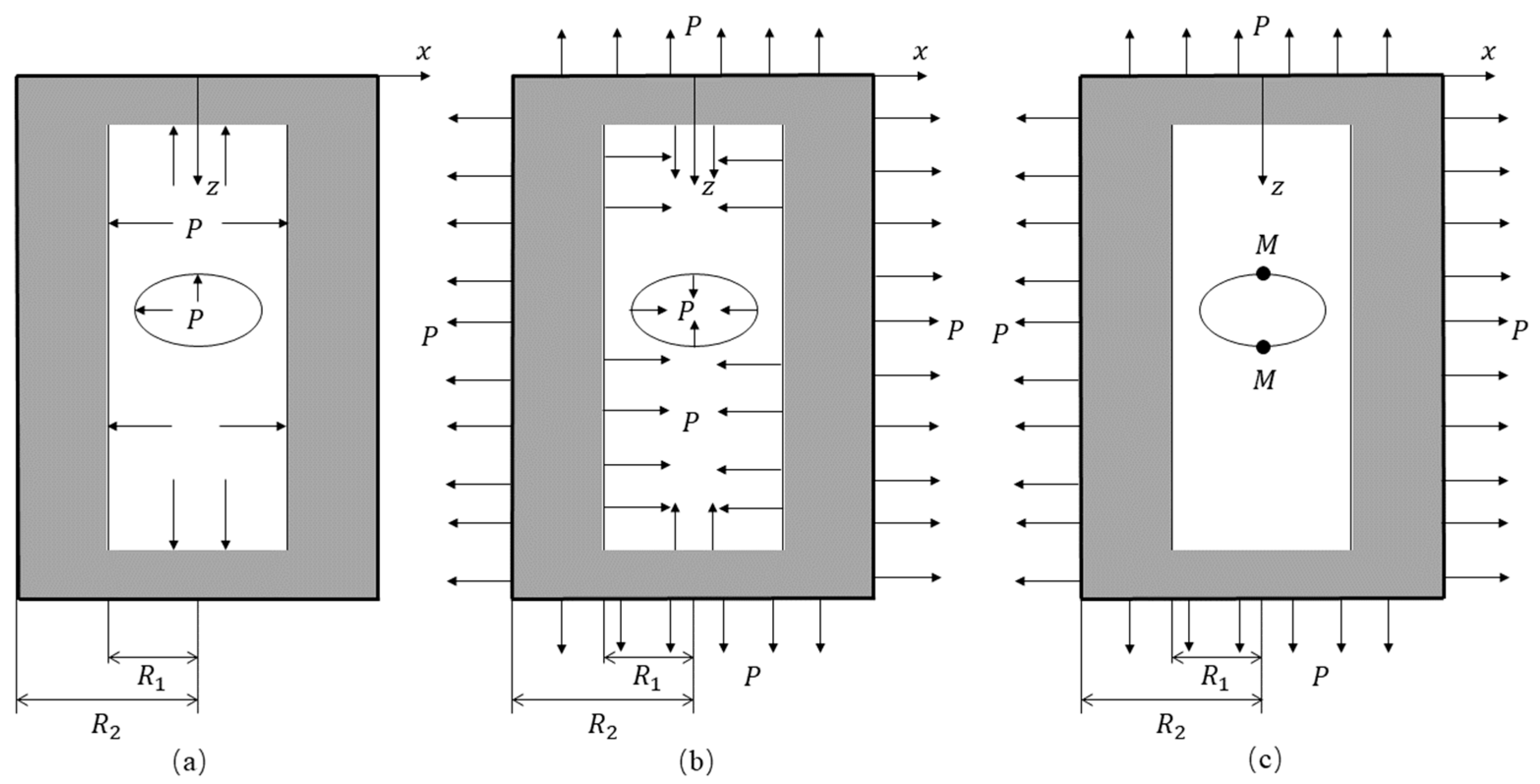

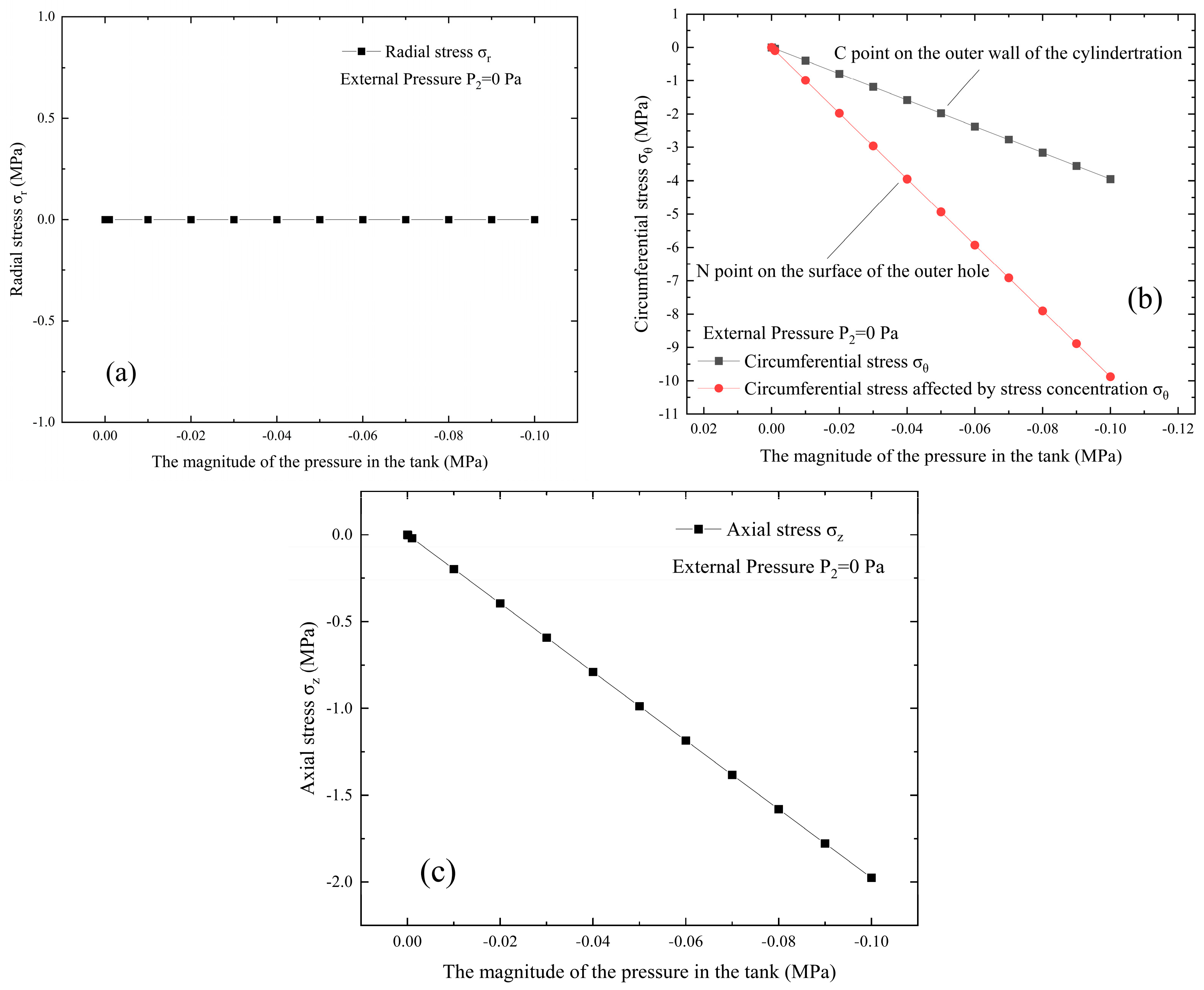

2. Structural Leakage Monitoring Mechanism of Pressure Vessels

2.1. Theoretical Description

2.2. Leakage-Induced Stress Concentration of Vacuum Pressure Vessels

3. Leakage Fault Identification Based on FBG Sensing Information

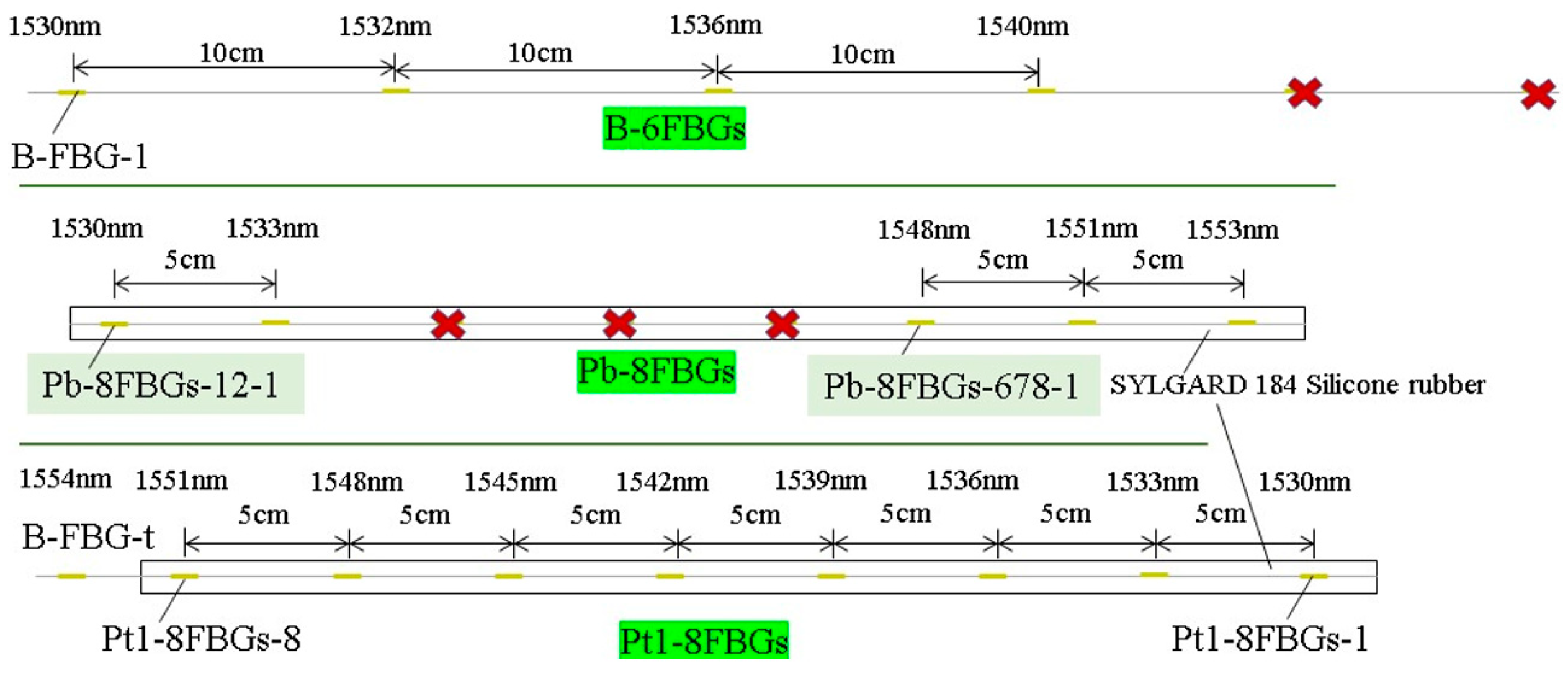

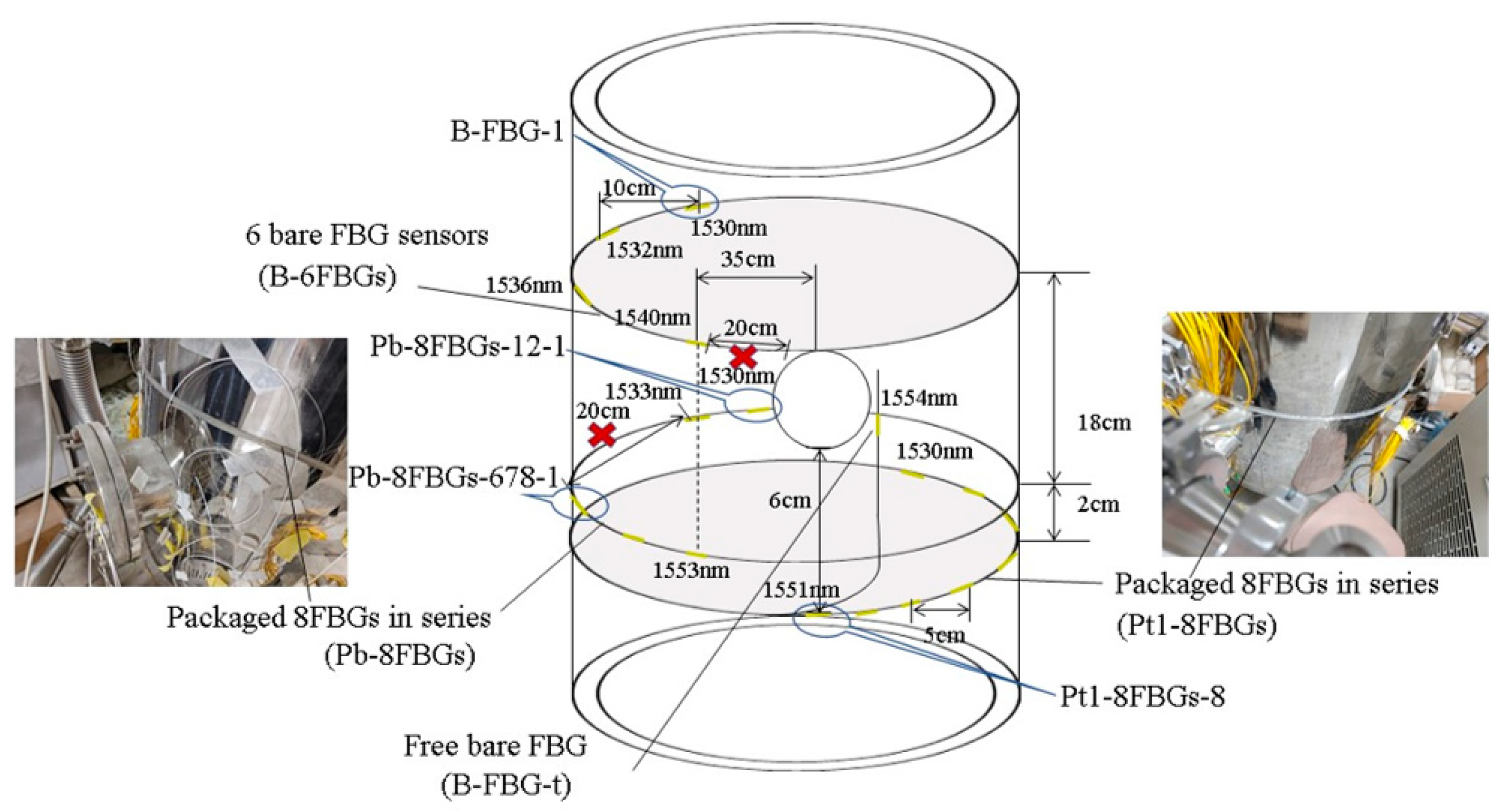

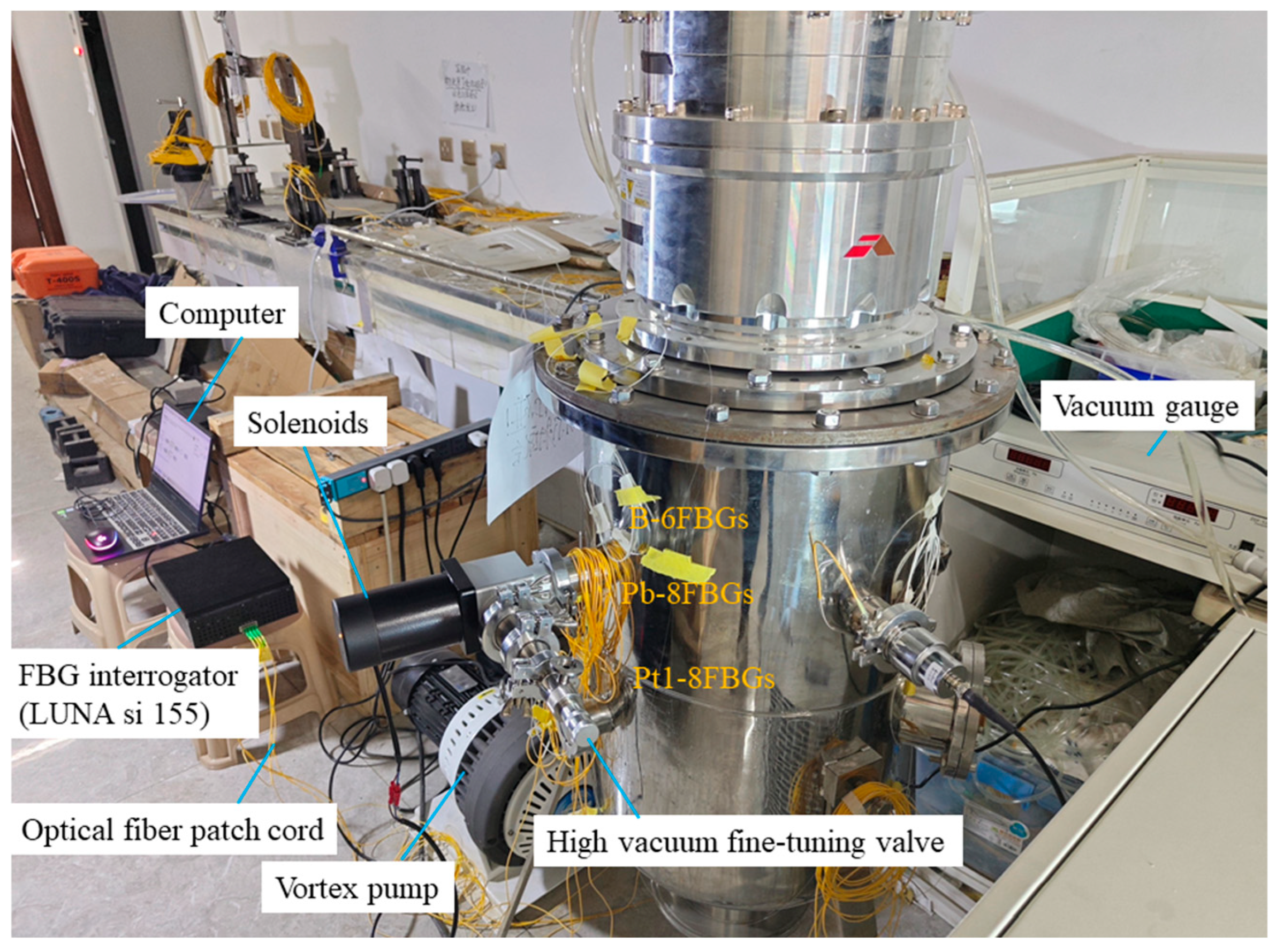

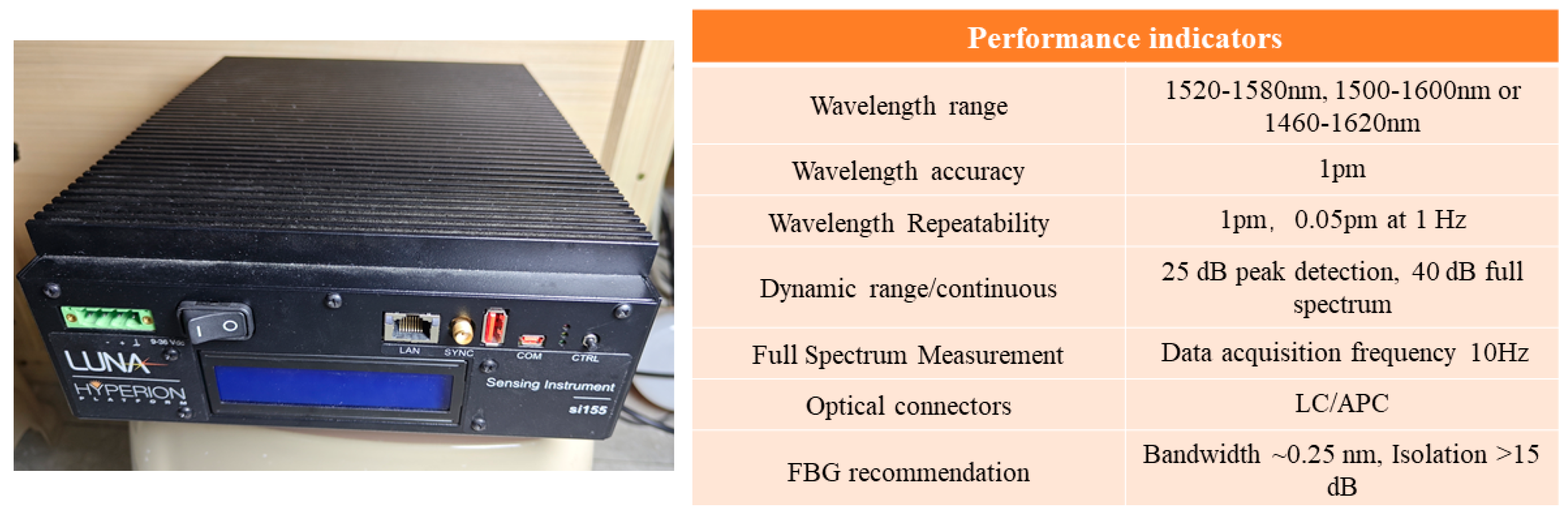

3.1. Experimental Investigation

3.2. Preliminary Data Analysis

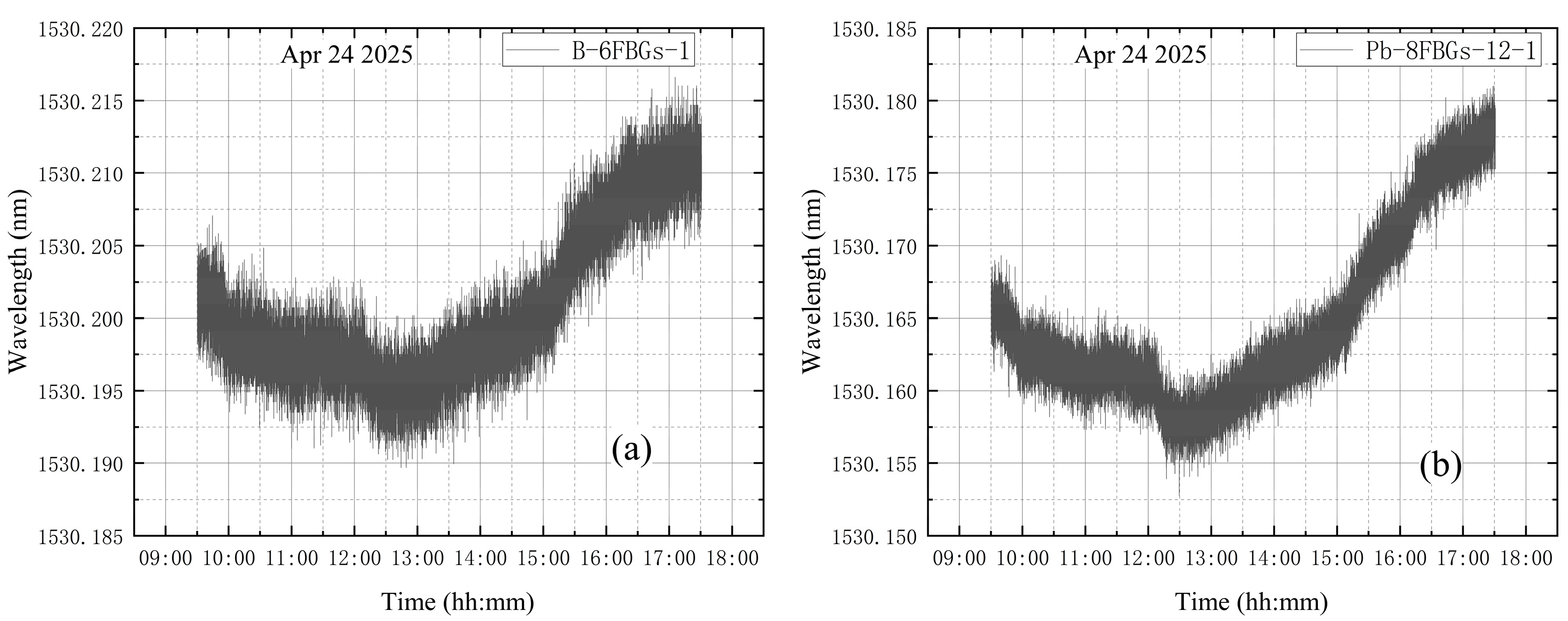

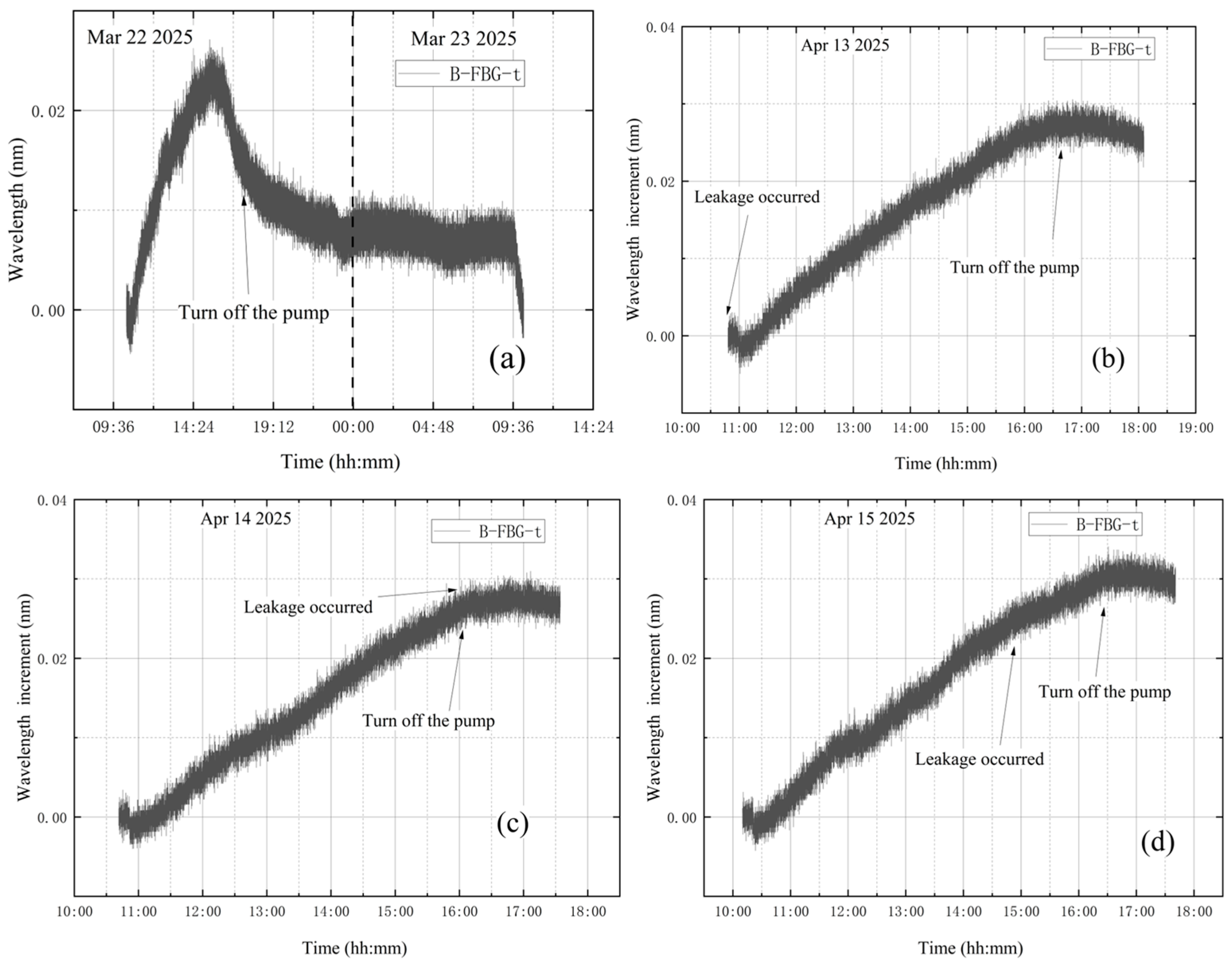

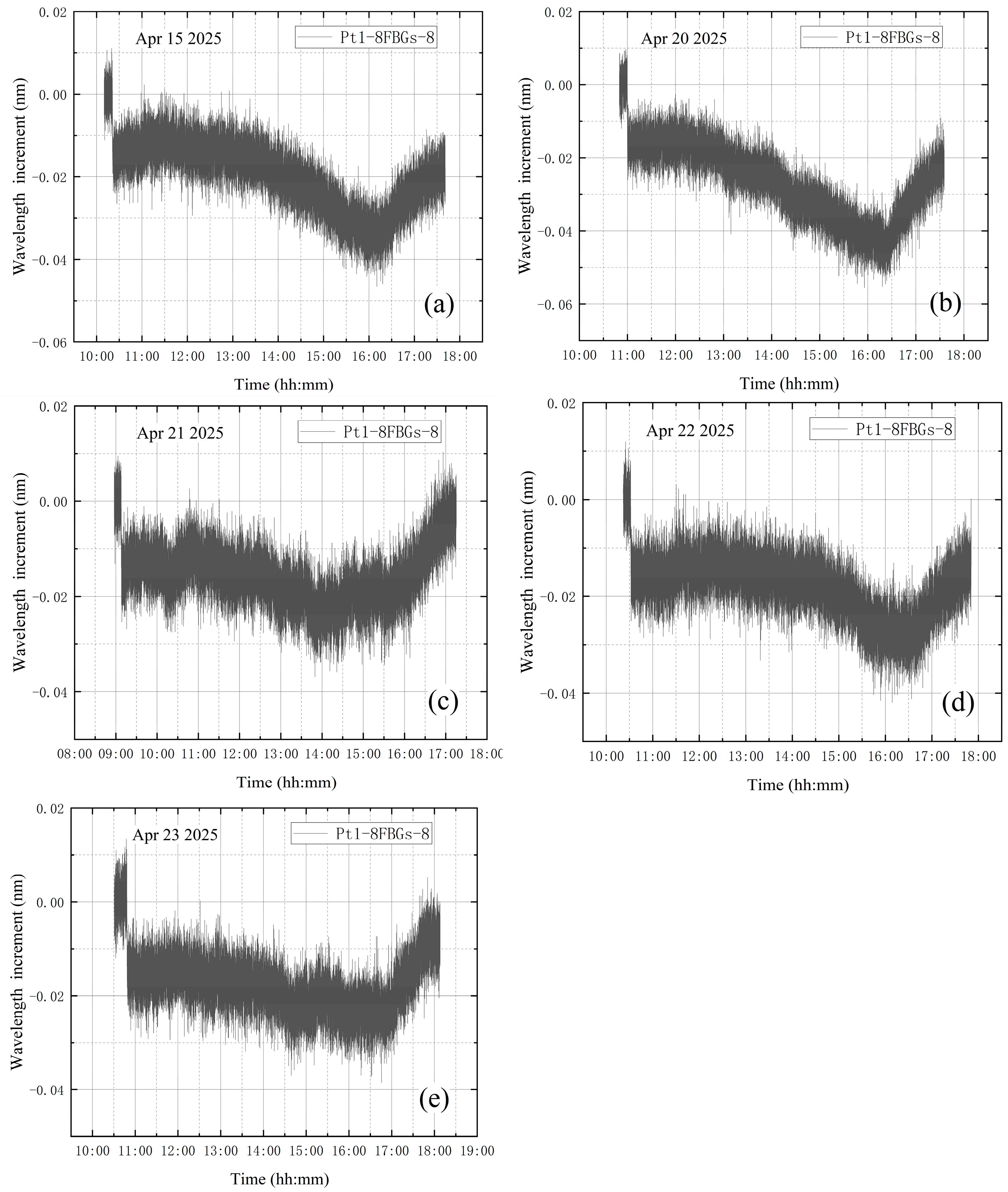

3.2.1. Temperature Influence Test

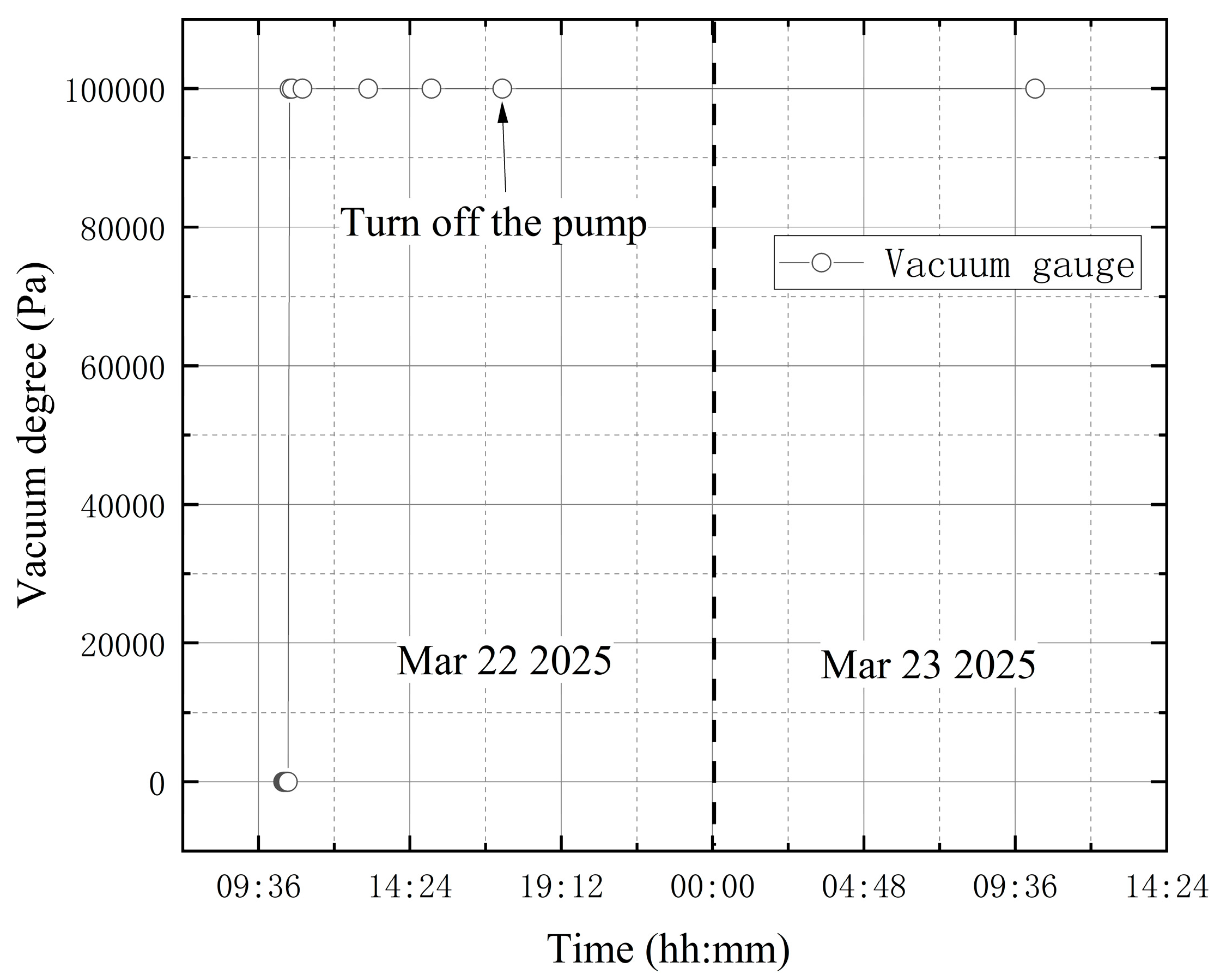

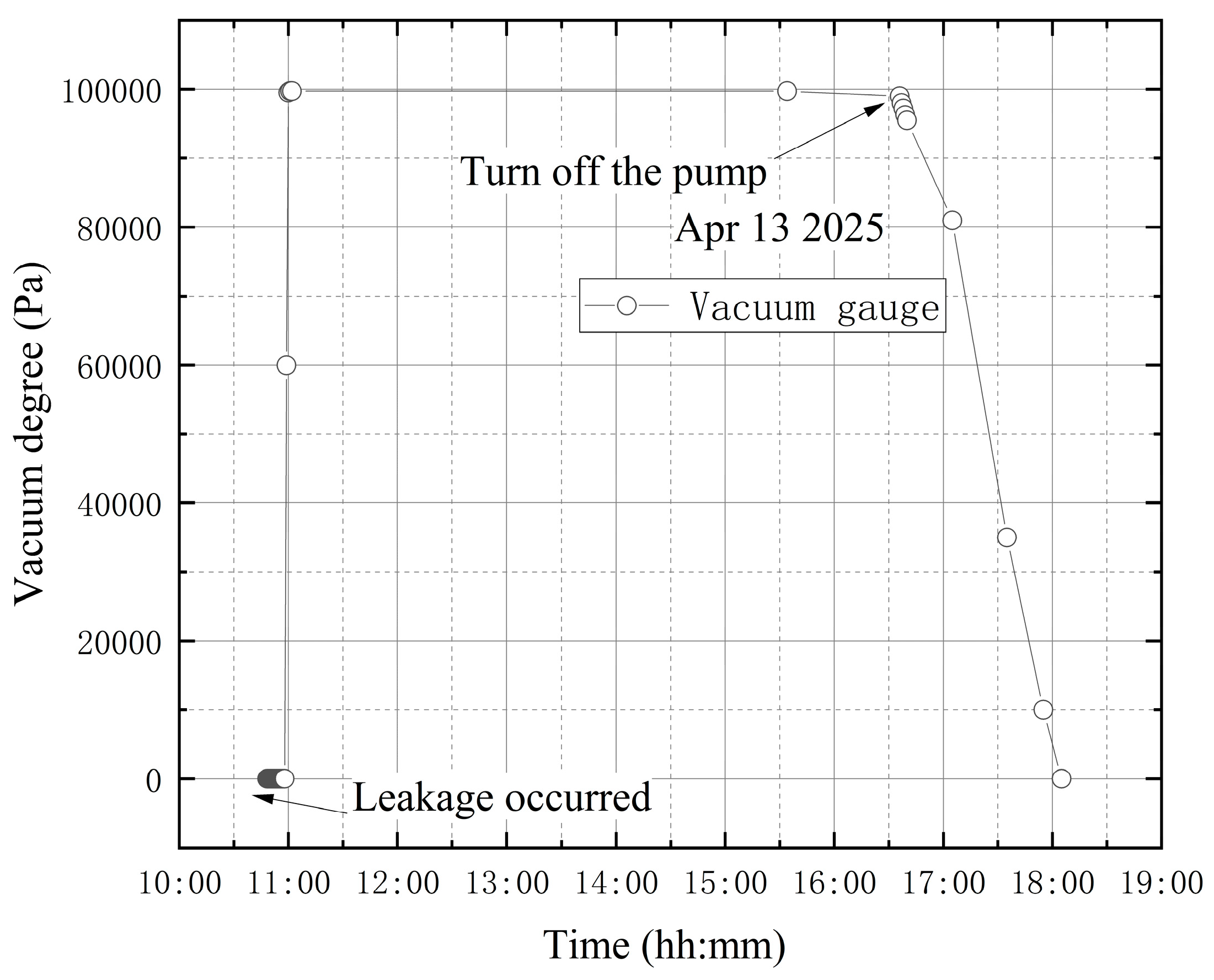

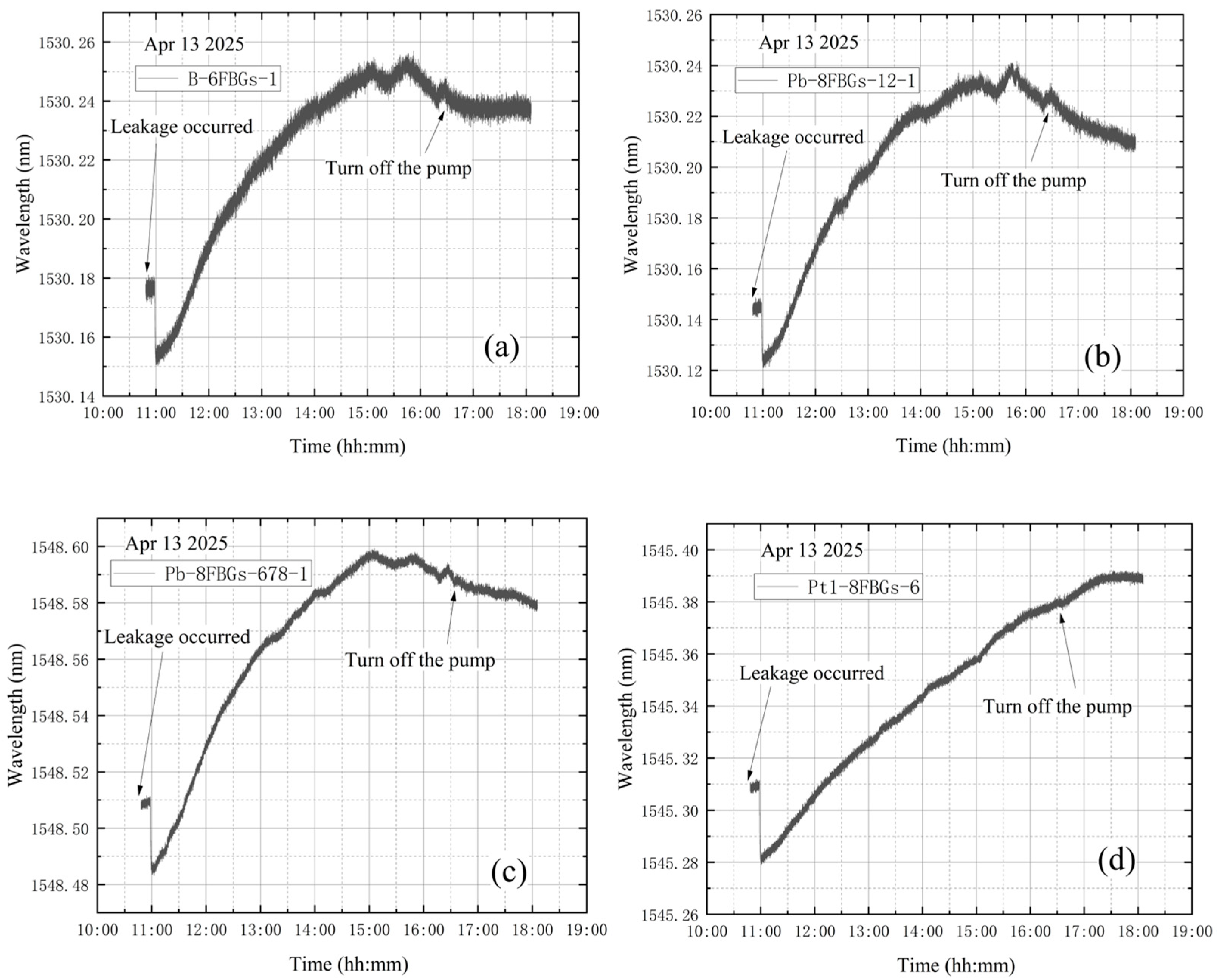

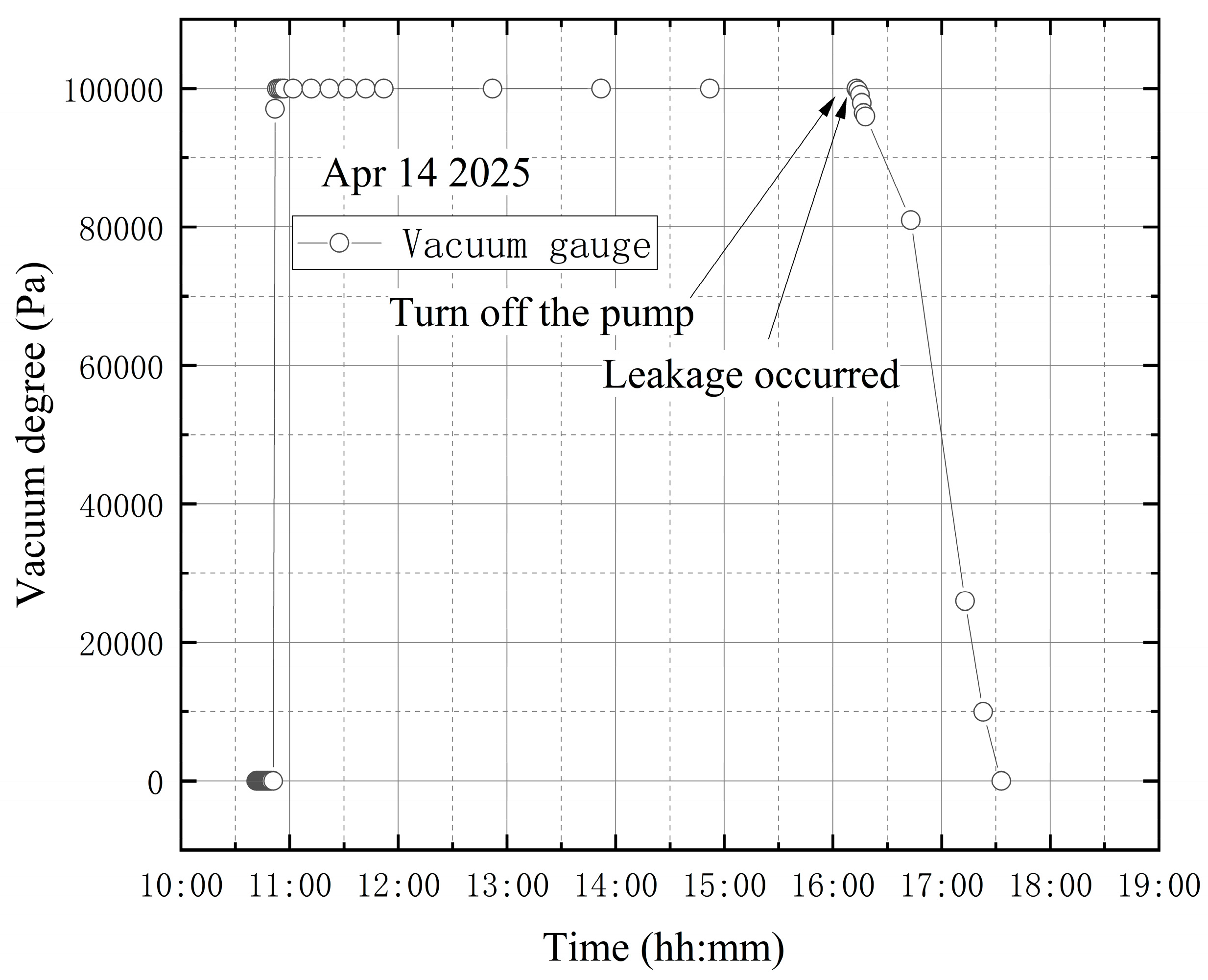

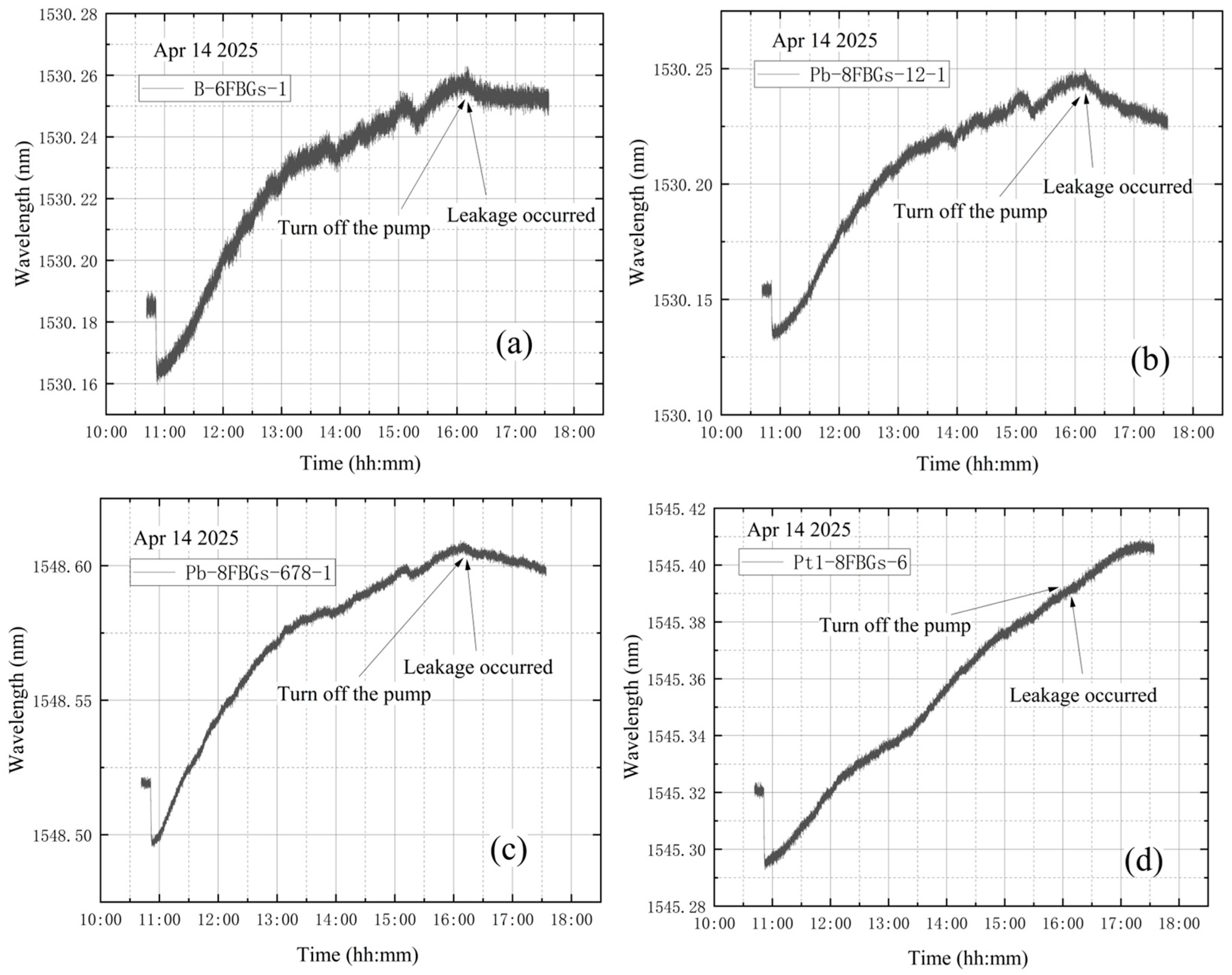

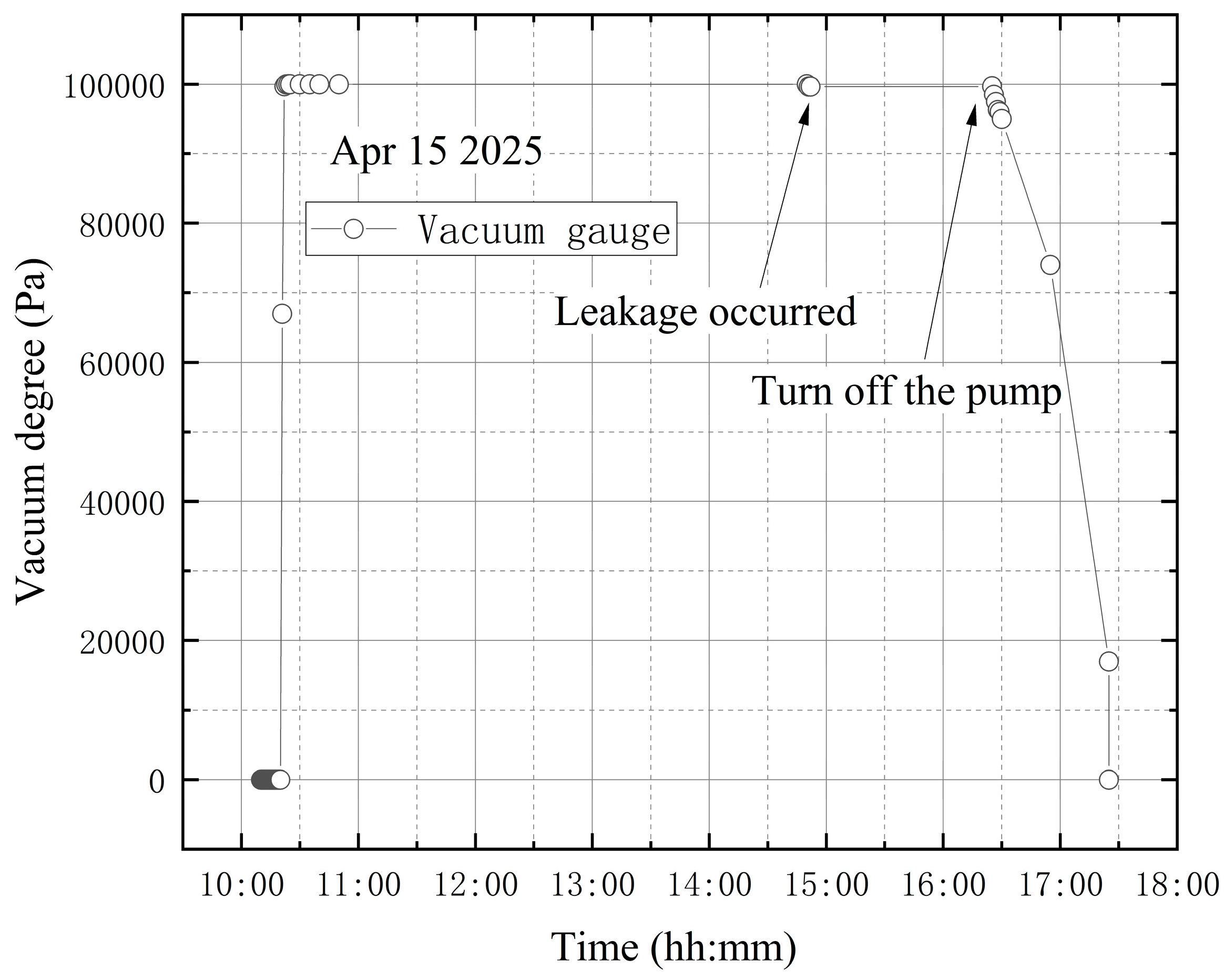

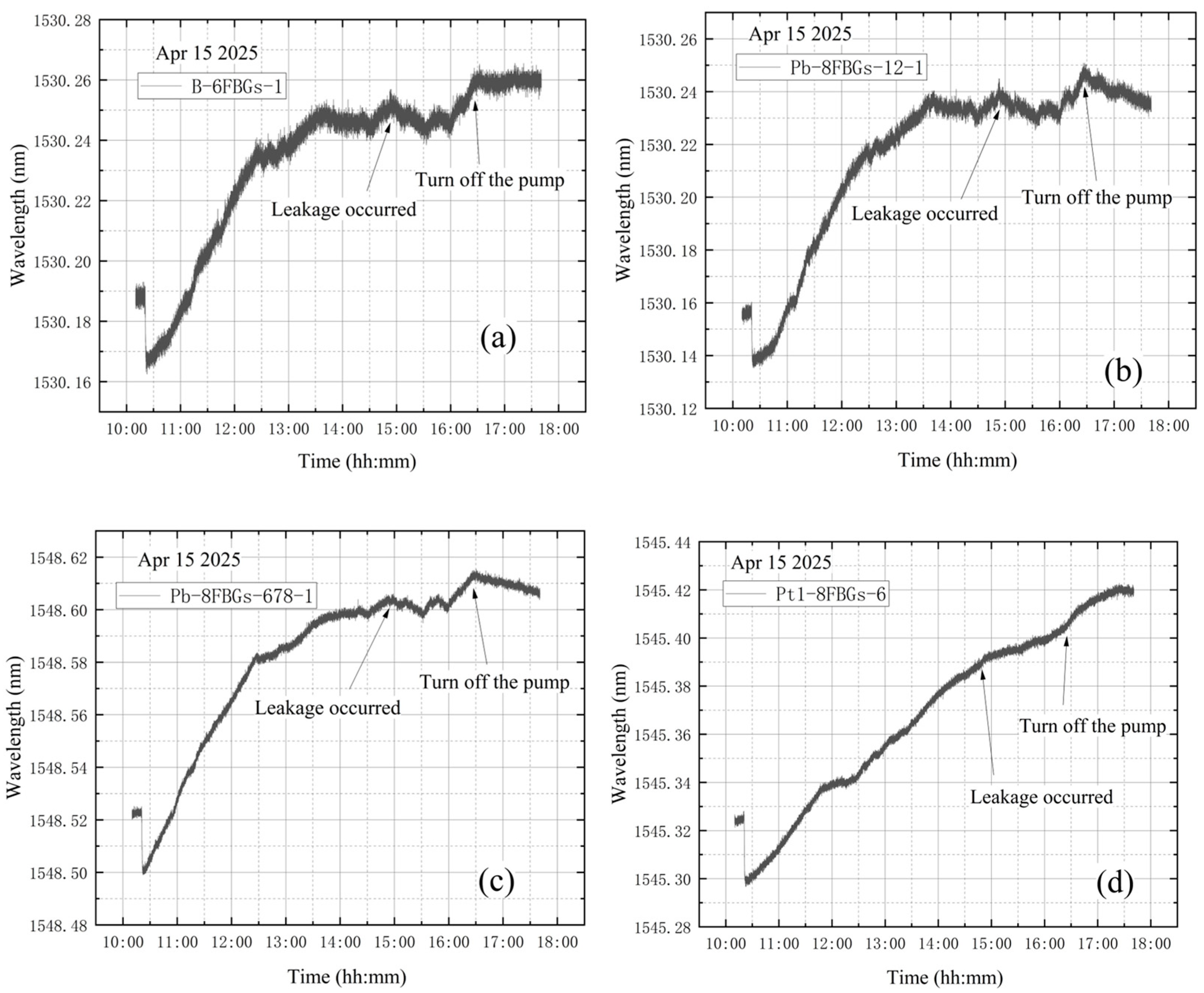

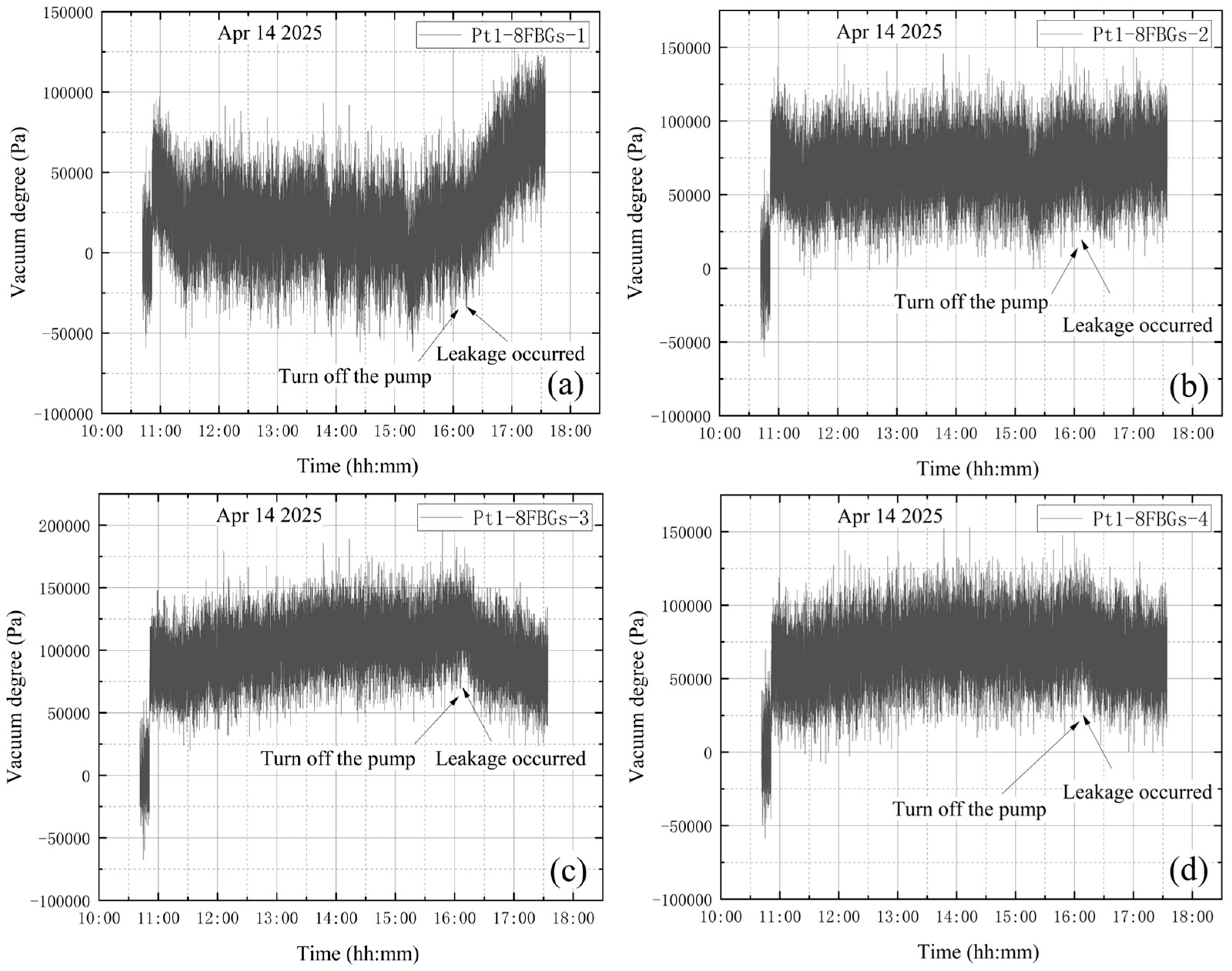

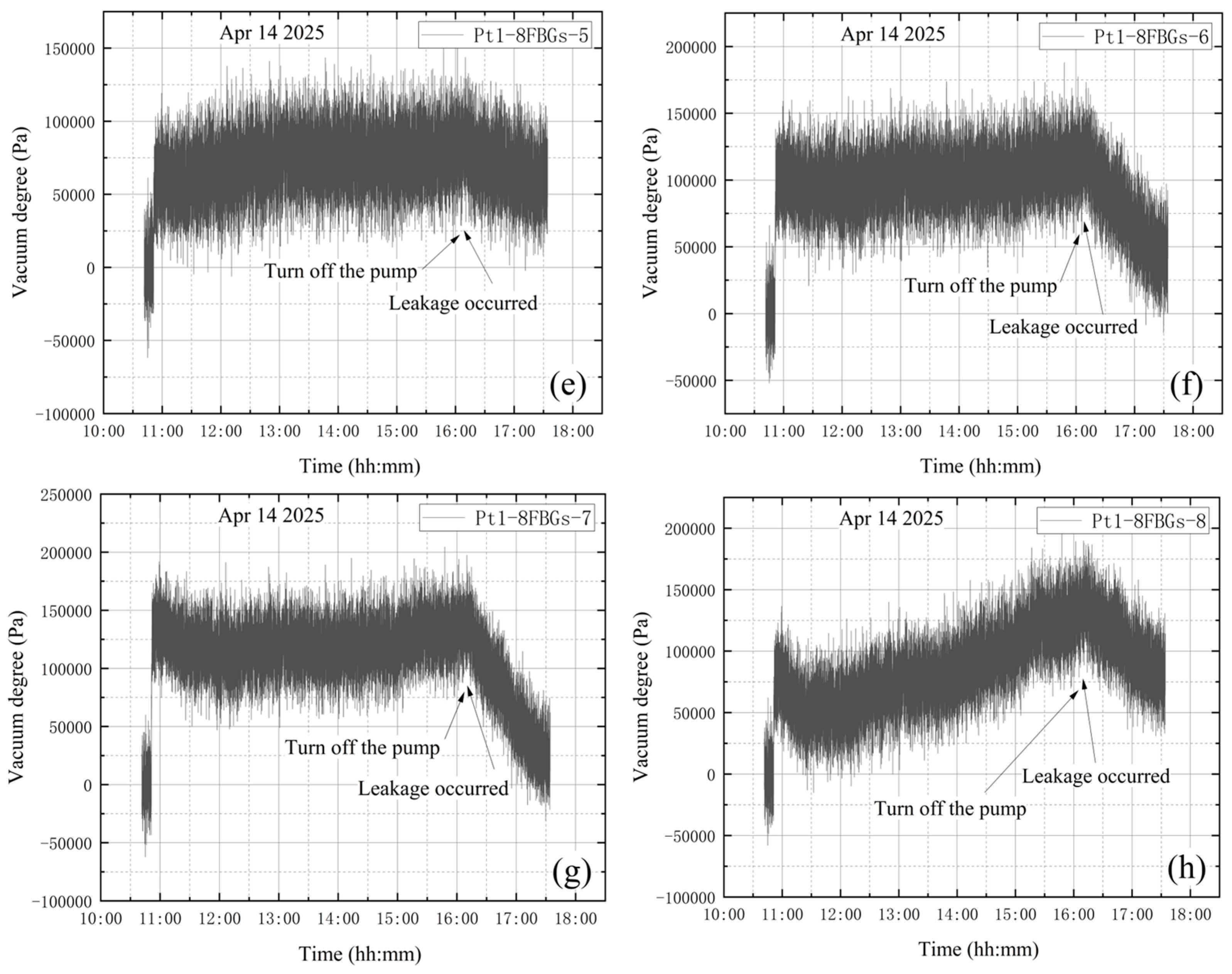

3.2.2. Leak Monitoring Tests

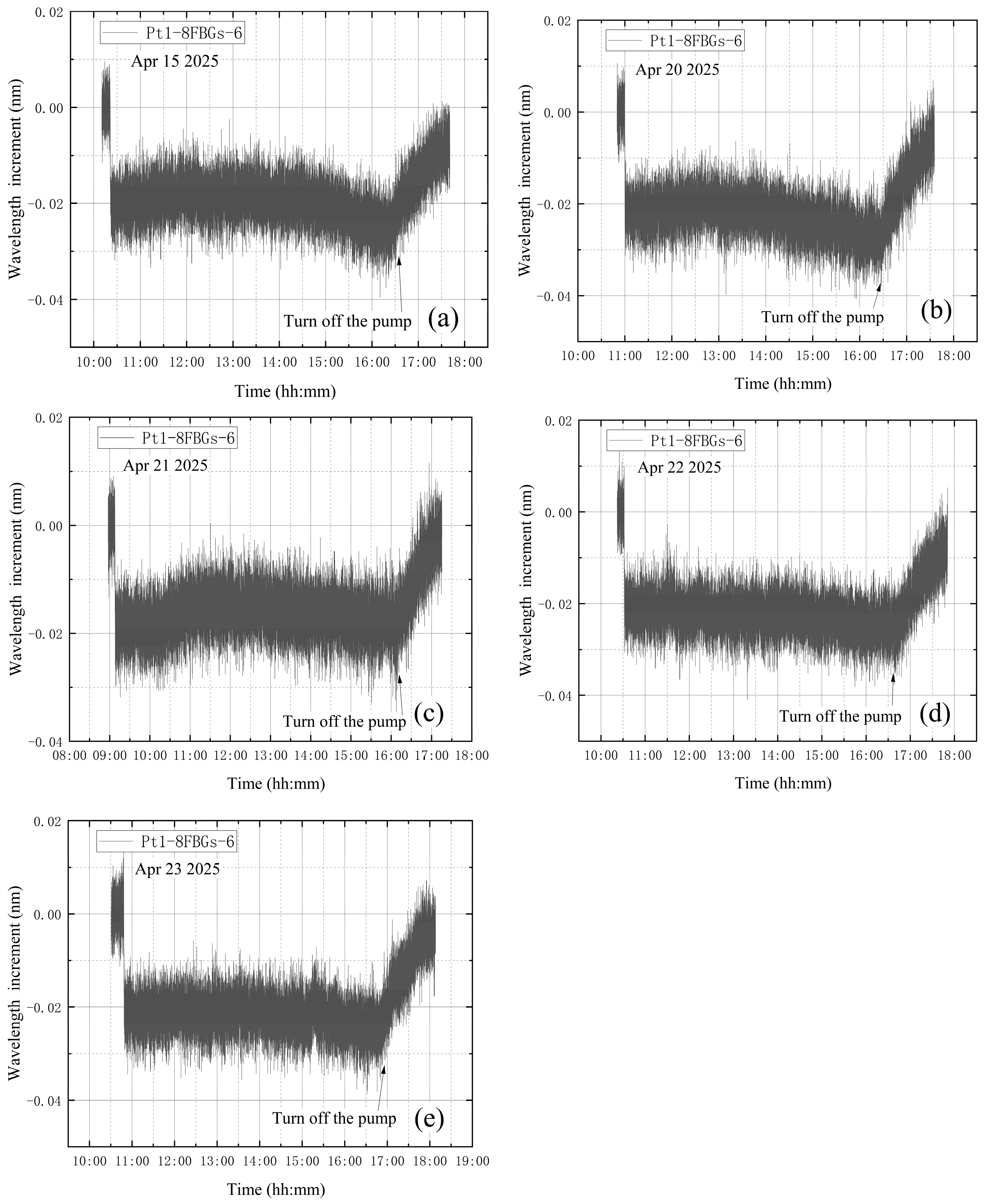

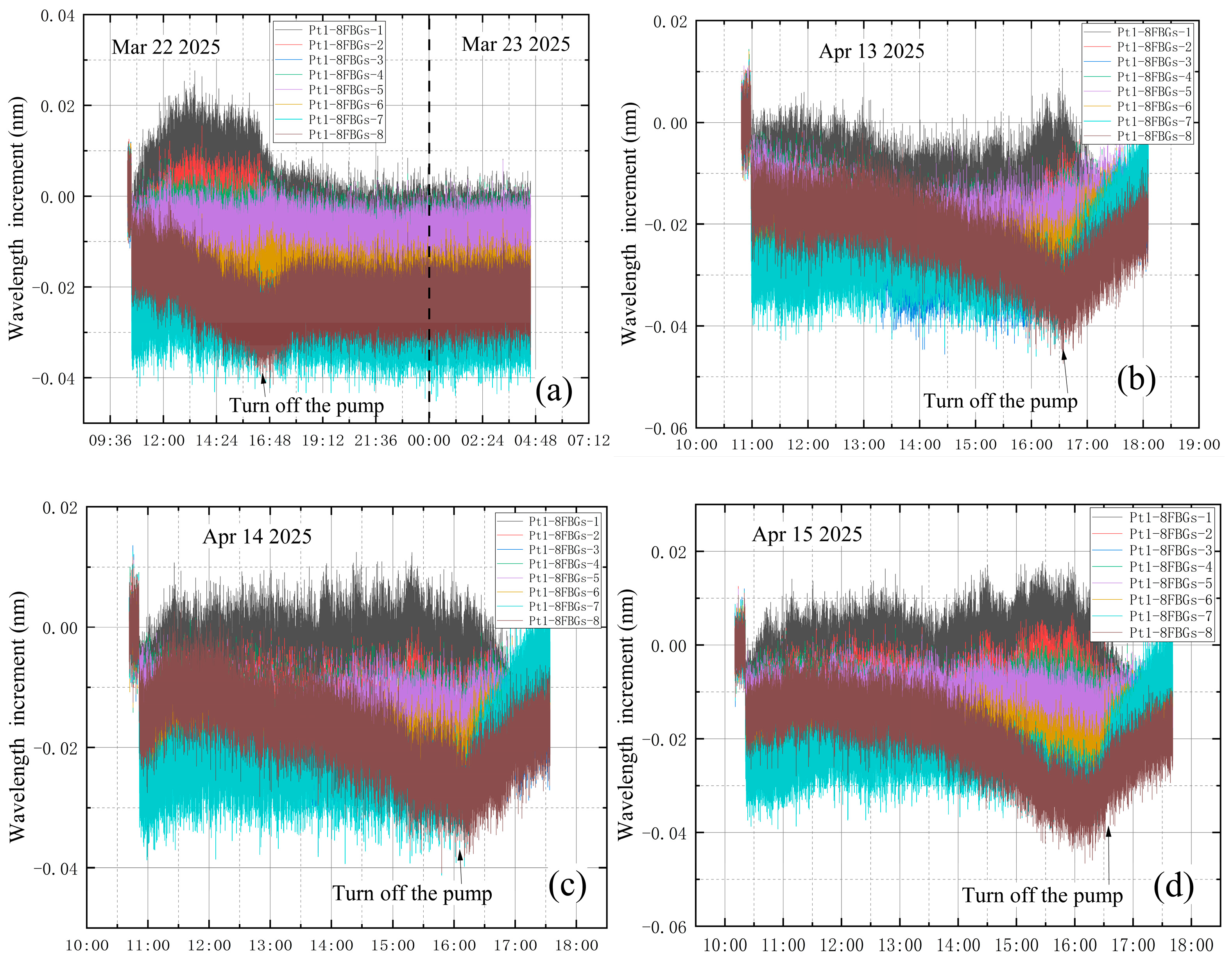

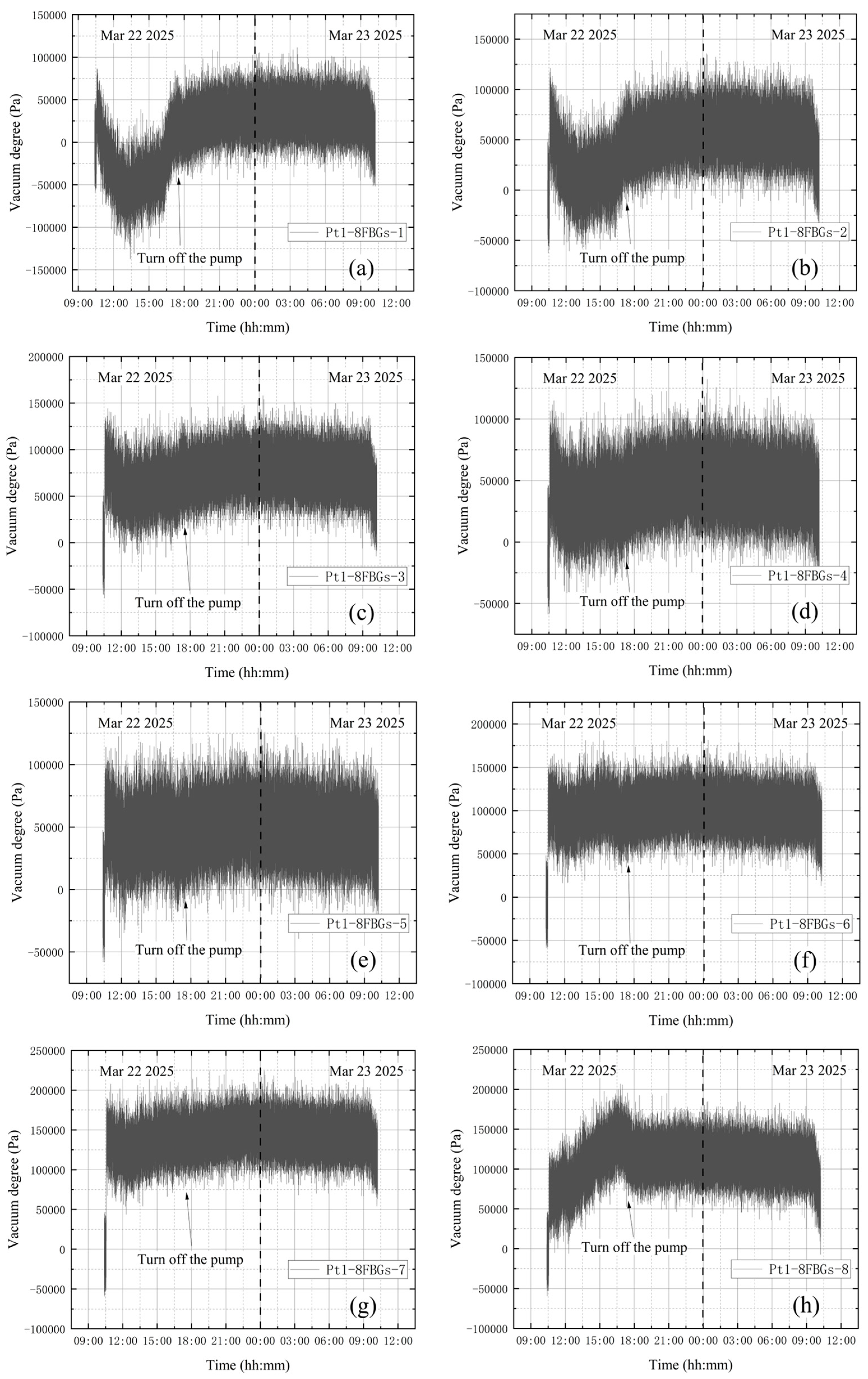

3.3. Vibration Influence Analysis

4. Leakage Identification After Vibration Correction

4.1. No Leakage During the Whole Experiment

4.2. Leakage Before Vacuum Extraction

4.3. Leakage at the End of Vacuum Extraction

4.4. Leakage During Vacuum Extraction

4.5. Construction of Fitting Equation

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ladd, M.E.; Quick, H.H.; Scheffler, K.; Speck, O. Design requirements for human UHF magnets from the perspective of MRI scientists. Supercond. Sci. Technol. 2024, 37, 113001. [Google Scholar] [CrossRef]

- Ge, L.; Zhao, J.; Li, H.; Dong, J.; Geng, H.; Zu, L.; Lin, S.; Jia, X.; Yang, X. A three-dimensional progressive failure analysis of filament-wound composite pressure vessels with void defects. Thin Walled Struct. 2024, 199, 111858. [Google Scholar] [CrossRef]

- Sharma, P.; Sharma, S.; Bera, T.; Semwal, K.; Badhe, R.M.; Sharma, A.; Kapur, G.S.; Ramakumar, S.S.V.; Neogi, S. Effects of dome shape on burst and weight performance of a type-3 composite pressure vessel for storage of compressed hydrogen. Compos. Struct. 2022, 293, 115732. [Google Scholar] [CrossRef]

- Nebe, M.; Soriano, A.; Braun, C.; Middendorf, P.; Walther, F. Analysis on the mechanical response of composite pressure vessels during internal pressure loading: FE modeling and experimental correlation. Compos. Part B Eng. 2021, 212, 108550. [Google Scholar] [CrossRef]

- Lainé, E.; Dupré, J.C.; Grandidier, J.C.; Cruz, M. Instrumented tests on composite pressure vessels (type IV) under internal water pressure. Int. J. Hydrogen Energy 2021, 46, 1334–1346. [Google Scholar] [CrossRef]

- Alam, S.; Yandek, G.R.; Lee, R.C.; Mabry, J.M. Design and development of a filament wound composite overwrapped pressure vessel. Compos. Part C Open Access 2020, 2, 100045. [Google Scholar] [CrossRef]

- Meemary, B.; Vasiukov, D.; Deléglise-Lagardère, M.; Chaki, S. Sensors integration for structural health monitoring in composite pressure vessels: A review. Compos. Struct. 2024, 351, 118546. [Google Scholar] [CrossRef]

- Yang, G.; Xu, S.; Jiang, P.; Zhang, X.; Li, X.F.; Chen, Y. Feasibility of persistent-mode operation of HTS magnet with flux pump compensation for MRI. Supercond. Sci. Technol. 2025, 38, 065010. [Google Scholar] [CrossRef]

- McCarville, D.A.; Guzman, J.C.; Jackson, J.R.; Birkland, J.O. Design, manufacture and test of cryotank components. Compr. Compos. Mater. II 2017, 3, 1–27. [Google Scholar]

- Gao, D.; Wu, Z.; Yang, L.; Zheng, Y.; Yin, W. Structural health monitoring for long-term aircraft storage tanks under cryogenic temperature. Aerosp. Sci. Technol. 2019, 92, 881–891. [Google Scholar] [CrossRef]

- Wilson, W.C.; Coffey, N.C.; Madaras, E.I. Leak Detection and Location Technology Assessment for Aerospace Applications, NASA/TM-2008-215347; NASA: Washington, DC, USA, 2008.

- Gao, F.; Lin, J.; Ge, Y.; Lu, S.; Zhang, Y. A mechanism and method of leak detection for pressure vessel: Whether, when, and how. IEEE Trans. Instrum. Meas. 2020, 69, 6004–6015. [Google Scholar] [CrossRef]

- Palaniappan, M.; Thomas, P.V.; Rao, B.S.C.; Chandramohan, R. Mass spectrometer helium leak testing of large volume pipelines and pressure vessels of a nuclear power plant. Int. J. Press. Vessel. Pip. 1997, 73, 39–44. [Google Scholar] [CrossRef]

- Nuthalapati, S.; Kee, K.E.; Pedapati, S.R.; Jumbri, K. A review of chloride induced stress corrosion cracking characterization in austenitic stainless steels using acoustic emission technique. Nucl. Eng. Technol. 2024, 56, 688–706. [Google Scholar] [CrossRef]

- Brunner, A.J. Structural health and condition monitoring with acoustic emission and guided ultrasonic waves: What about long-term durability of sensors, sensor coupling and measurement chain? Appl. Sci. 2021, 11, 11648. [Google Scholar] [CrossRef]

- Gholizadeh, S.; Leman, Z.; Baharudin, B.H.T. A review of the application of acoustic emission technique in engineering. Struct. Eng. Mech. 2015, 54, 1075–1095. [Google Scholar] [CrossRef]

- Prager, J.; Kitze, J.; Acheroy, C.; Brackrock, D.; Brekow, G.; Kreutzbruck, M. SAFT and TOFD—A comparative study of two defect sizing techniques on a reactor pressure vessel mock-up. J. Nondestruct. Eval. 2013, 32, 1–13. [Google Scholar] [CrossRef]

- Moon, C.; Brown, W.C.; Mellen, S.; Lovelace, D. Ultrasound Techniques for Leak Detection in Vehicle and Pressure Vessel Production Lines. In INTER-NOISE and NOISE-CON Congress and Conference Proceedings, Dearborn, MI, USA, 28–30 July 2008; Institute of Noise Control Engineering: Wakefield, MA, USA, 2008; Volume 2008, pp. 1332–1340. [Google Scholar]

- Graue, R.; Krisson, M.; Erdmann, M.; Reutlinger, A. Integrated health monitoring approach for reusable cryogenic tank structures. J. Spacecr. Rocket. 2000, 37, 580–585. [Google Scholar] [CrossRef]

- Dudić, S.; Ignjatović, I.; Šešlija, D.; Blagojević, V.; Stojiljković, M. Leakage quantification of compressed air using ultrasound and infrared thermography. Measurement 2012, 45, 1689–1694. [Google Scholar] [CrossRef]

- Yang, H.; Yao, X.F.; Wang, S.; Yuan, L.; Ke, Y.C.; Liu, Y.H. Simultaneous determination of gas leakage location and leakage rate based on local temperature gradient. Measurement 2019, 133, 233–240. [Google Scholar] [CrossRef]

- Saworski, B.; Zielinski, O. Comparison of machine vision based methods for online in situ oil seep detection and quantification. In Proceedings of the OCEANS 2009-EUROPE, Bremen, Germany, 11–14 May 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 1–4. [Google Scholar]

- Suresh, G.; Heygster, G.; Melsheimer, C.; Bohrmann, G. Natural oil seep location estimation in SAR images using direct and contextual information. In Proceedings of the 2014 IEEE Geoscience and Remote Sensing Symposium, Quebec City, QC, Canada, 13–18 July 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 1678–1681. [Google Scholar]

- Suresh, G.; Melsheimer, C.; Körber, J.H.; Bohrmann, G. Automatic estimation of oil seep locations in synthetic aperture radar images. IEEE Trans. Geosci. Remote Sens. 2015, 53, 4218–4230. [Google Scholar] [CrossRef]

- Sun, L.; Chen, F.; Yao, G.; Chen, K.; Xie, H. November. Research of leak detection and exclusion system based on pressure differential discrimination method. In Proceedings of the 2010 International Conference on E-Product E-Service and E-Entertainment, Henan, China, 7–9 November 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 1–4. [Google Scholar]

- Gillis, K.A.; Moldover, M.R.; Mehl, J.B. Detecting leaks in gas-filled pressure vessels using acoustic resonances. Rev. Sci. Instrum. 2016, 87, 054901. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Xiang, P.; Jiang, L. Strain transfer theory of industrialized optical fiber-based sensors in civil engineering: A review on measurement accuracy, design and calibration. Sens. Actuators A Phys. 2019, 285, 414–426. [Google Scholar] [CrossRef]

- Ansari, F. Practical implementation of optical fiber sensors in civil structural health monitoring. J. Intell. Mater. Syst. Struct. 2007, 18, 879–889. [Google Scholar] [CrossRef]

- Rocha, H.; Semprimoschnig, C.; Nunes, J.P. Sensors for process and structural health monitoring of aerospace composites: A review. Eng. Struct. 2021, 237, 112231. [Google Scholar] [CrossRef]

- Ma, J.; Gong, Z.; Yan, C.L.; Cao, P.F.; Wang, H.P. Wavelet denoising analysis on vacuum-process monitoring signals of aerospace vacuum vessel structures. Meas. Sci. Technol. 2024, 35, 126008. [Google Scholar] [CrossRef]

- Cheng, W.Z. Flight test technique for helicopter blade strain measurements based on fiber Bragg grating. Chin. J. Appl. Mech. 2016, 33, 466–471+549. [Google Scholar]

- Liu, R.M.; Liang, D.K. Test attempt to shear strength of interface for embedded optical fiber sensors. Chin. J. Appl. Mech. 2009, 26, 820–823+844. [Google Scholar]

- Gao, C.; Wang, D.; Yu, Y.; Zheng, Y.; Jiang, S.; Deng, Z. Measurement technique of mechanical parameters for tubular workpiece based on fiber Bragg grating. Chin. J. Appl. Mech. 2015, 32, 817–822+898. [Google Scholar]

- Chen, C.; Wang, H.P.; He, S.Z.; Chen, J.; Sun, L. Random vibration and fatigue performance analysis of carbon-fiber composite antenna beams based on fiber-Bragg-grating sensor arrays. Chin. J. Appl. Mech. 2025, 1–12, accept. [Google Scholar]

- Degrieck, J.; De Waele, W.; Verleysen, P. Monitoring of fibre reinforced composites with embedded optical fibre Bragg sensors, with application to filament wound pressure vessels. NDT Int. 2001, 34, 289–296. [Google Scholar]

- Zhang, W.E.I. Non-destructive evaluation of composite pressure vessel by using FBG sensors. Chin. J. Aeronaut. 2007, 20, 120–123. [Google Scholar] [CrossRef]

- Gąsior, P.; Kaleta, J.; Sankowska, A. Optical fiber sensors in health monitoring of composite high-pressure vessels for hydrogen. In Proceedings of the Optical Measurement Systems for Industrial Inspection V, Munich, Germany, 17–21 June 2007; SPIE: Bellingham, WA, USA, 2007; Volume 6616, pp. 1007–1016. [Google Scholar]

- Chen, K.C.; Hsieh, T.S.; Wu, C.W.; Hsu, C.Y.; Chiang, C.C. Fiber Bragg grating technology to construct the strain variation sensing system of an underwater pressure vessel. Sens. Mater. 2018, 30, 2383–2390. [Google Scholar] [CrossRef]

- Saeter, E.; Lasn, K.; Nony, F.; Echtermeyer, A.T. Embedded optical fibres for monitoring pressurization and impact of filament wound cylinders. Compos. Struct. 2019, 210, 608–617. [Google Scholar] [CrossRef]

- Gong, Z.; Yan, G.; Ma, J.; Yan, C.L.; Shen, F.K.; Li, H.; Wang, H.P. Vacuum loss state monitoring of aerospace vacuum pressure vessels based on quasi-distributed FBG sensing technology. Struct. Durab. Health Monit. 2025, 19, 473–498. [Google Scholar] [CrossRef]

- Faupel, J.H.; Harris, D.B. Stress concentration in heavy-walled cylindrical pressure vessels-effect of elliptic and circular side holes. Ind. Eng. Chem. 1957, 49, 1979–1986. [Google Scholar] [CrossRef]

- Xu, Z.L. Elasticity, 5th ed.; Higher Education Press: Beijing, China, 2016. [Google Scholar]

- Wang, H.P.; Dai, J.G.; Wang, X.Z. Improved temperature compensation of fiber Bragg grating-based sensors applied to structures under different loading conditions. Opt. Fiber Technol. 2001, 63, 102506. [Google Scholar] [CrossRef]

- Zhang, C.; Lai, S.X.; Wang, H.P. Structural modal parameter recognition and related damage identification methods under environmental excitations: A review. Struct. Durab. Health Monit. 2025, 19, 25–54. [Google Scholar] [CrossRef]

- Do, V.-D.; Le Grognec, P.; Rohart, P. A new analytical tool for the elastic/plastic buckling design of pressure vessels subjected to external pressure. Int. J. Press. Vessel. Pip. 2024, 210, 105221. [Google Scholar] [CrossRef]

- Mihaljec, B.; Vukelić, G.; Božić, Ž.; Bakhtiari, R. Pressure vessel failure analysis and numerical optimization of a composite repair patch with experimental validation. Int. J. Press. Vessel. Pip. 2025, 215, 105454. [Google Scholar] [CrossRef]

| Contents | Tags | Value | Unit |

|---|---|---|---|

| Inner radius | R1 | 0.2 | m |

| Outer radius | R2 | 0.205 | m |

| External pressure | P2 | 0 | Pa |

| Modulus of elasticity | E | 200 | GPa |

| Poisson ratio | μ | 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, Z.; Shen, F.-K.; Liu, Y.-H.; Yan, C.-L.; Rui, J.; Cao, P.-F.; Wang, H.-P.; Xiang, P. Stress Concentration-Based Material Leakage Fault Online Diagnosis of Vacuum Pressure Vessels Based on Multiple FBG Monitoring Data. Materials 2025, 18, 4697. https://doi.org/10.3390/ma18204697

Gong Z, Shen F-K, Liu Y-H, Yan C-L, Rui J, Cao P-F, Wang H-P, Xiang P. Stress Concentration-Based Material Leakage Fault Online Diagnosis of Vacuum Pressure Vessels Based on Multiple FBG Monitoring Data. Materials. 2025; 18(20):4697. https://doi.org/10.3390/ma18204697

Chicago/Turabian StyleGong, Zhe, Fu-Kang Shen, Yong-Hao Liu, Chang-Lin Yan, Jia Rui, Peng-Fei Cao, Hua-Ping Wang, and Ping Xiang. 2025. "Stress Concentration-Based Material Leakage Fault Online Diagnosis of Vacuum Pressure Vessels Based on Multiple FBG Monitoring Data" Materials 18, no. 20: 4697. https://doi.org/10.3390/ma18204697

APA StyleGong, Z., Shen, F.-K., Liu, Y.-H., Yan, C.-L., Rui, J., Cao, P.-F., Wang, H.-P., & Xiang, P. (2025). Stress Concentration-Based Material Leakage Fault Online Diagnosis of Vacuum Pressure Vessels Based on Multiple FBG Monitoring Data. Materials, 18(20), 4697. https://doi.org/10.3390/ma18204697