Study on Dynamic Mechanical Behavior of 34CrNi3MoA Alloy Steel Considering the Coupling Effect of Temperature and Strain Rate

Abstract

1. Introduction

2. SHPB Experiment

2.1. Experimental Design

2.2. SHPB Experimental Principle

3. Experimental Results and Analysis

3.1. Temperature Effect Analysis

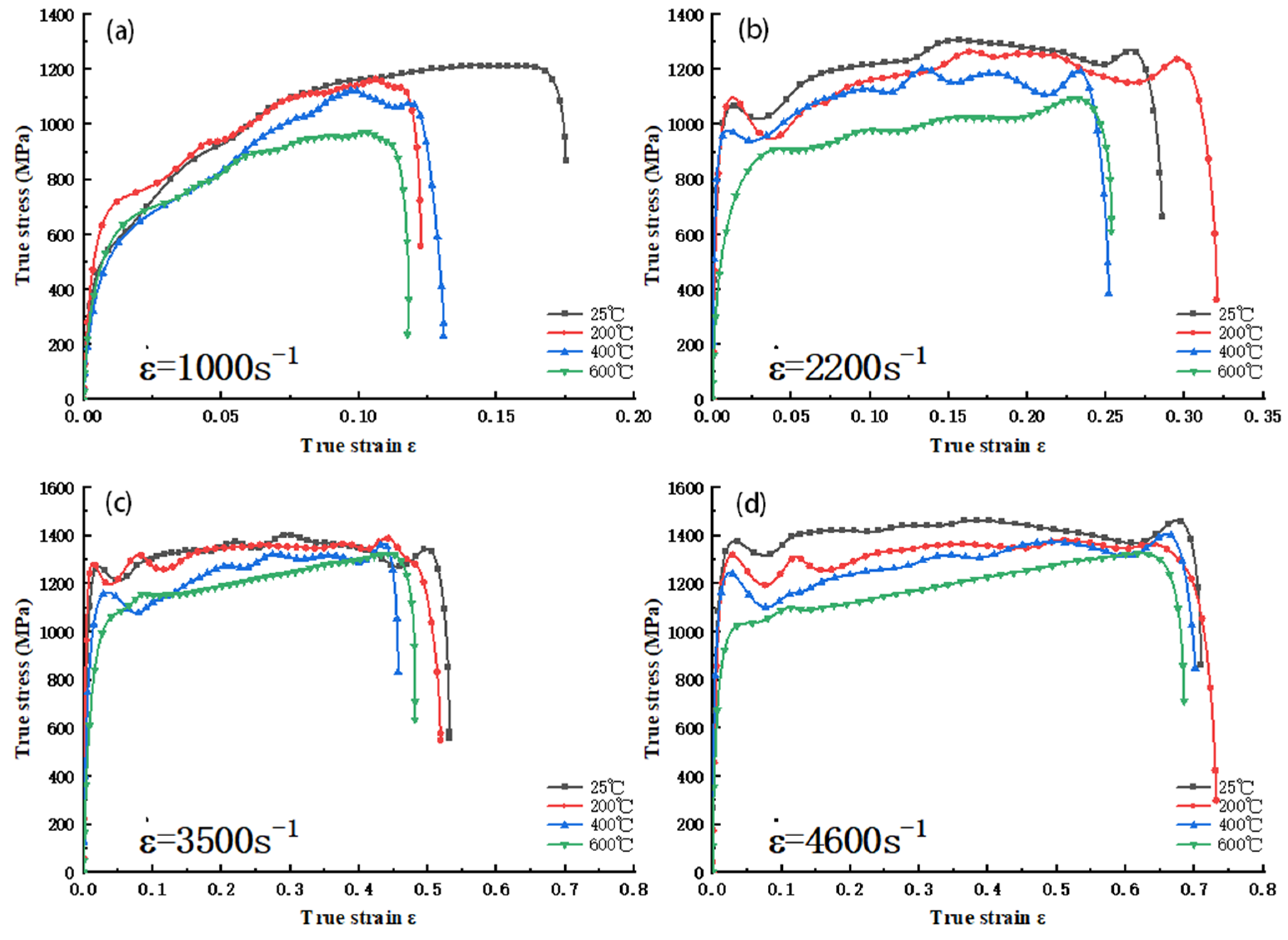

3.1.1. Analysis of Stress and Strain Curves at Different Temperatures Under the Same Strain Rate

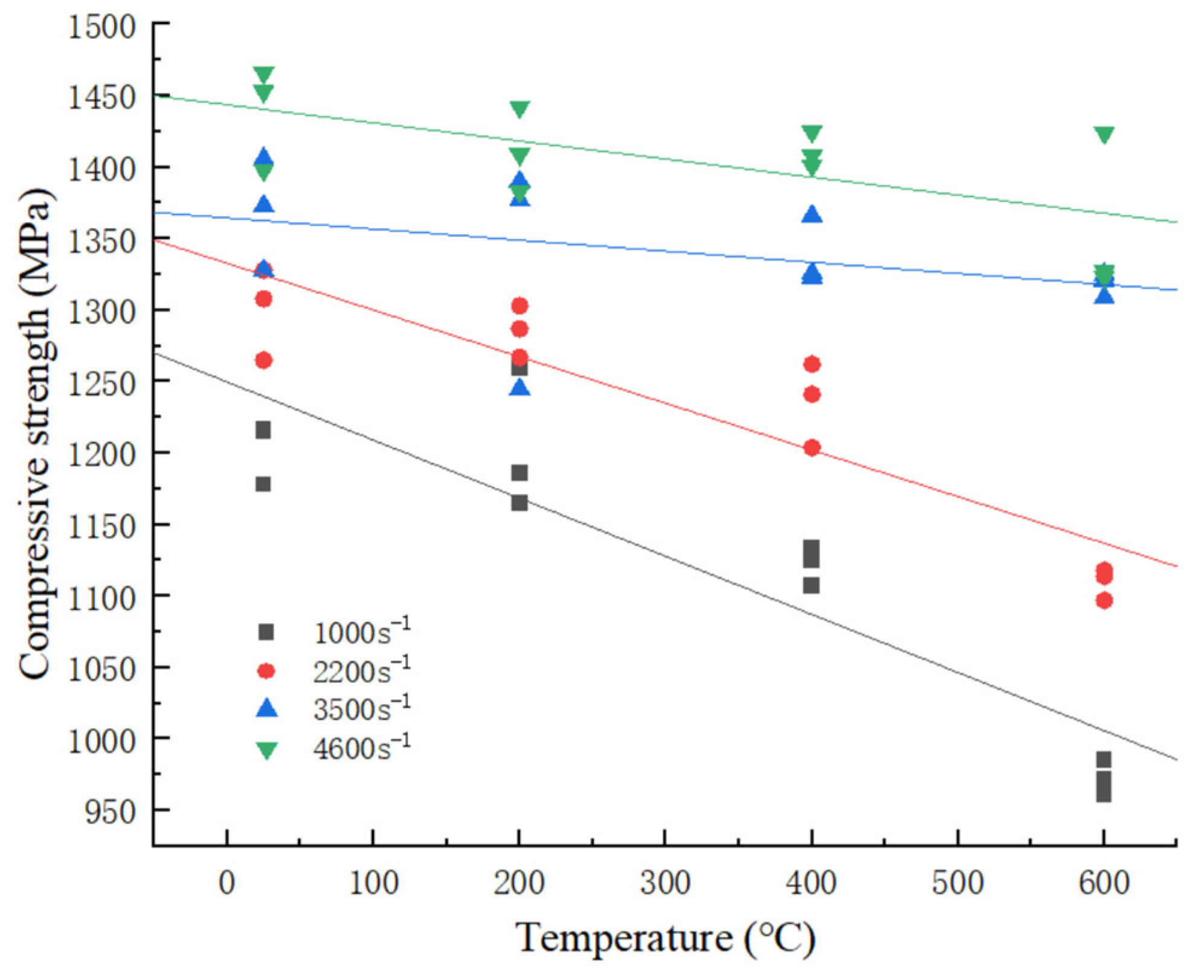

3.1.2. Effect of Temperature on the Compressive Strength of the Material

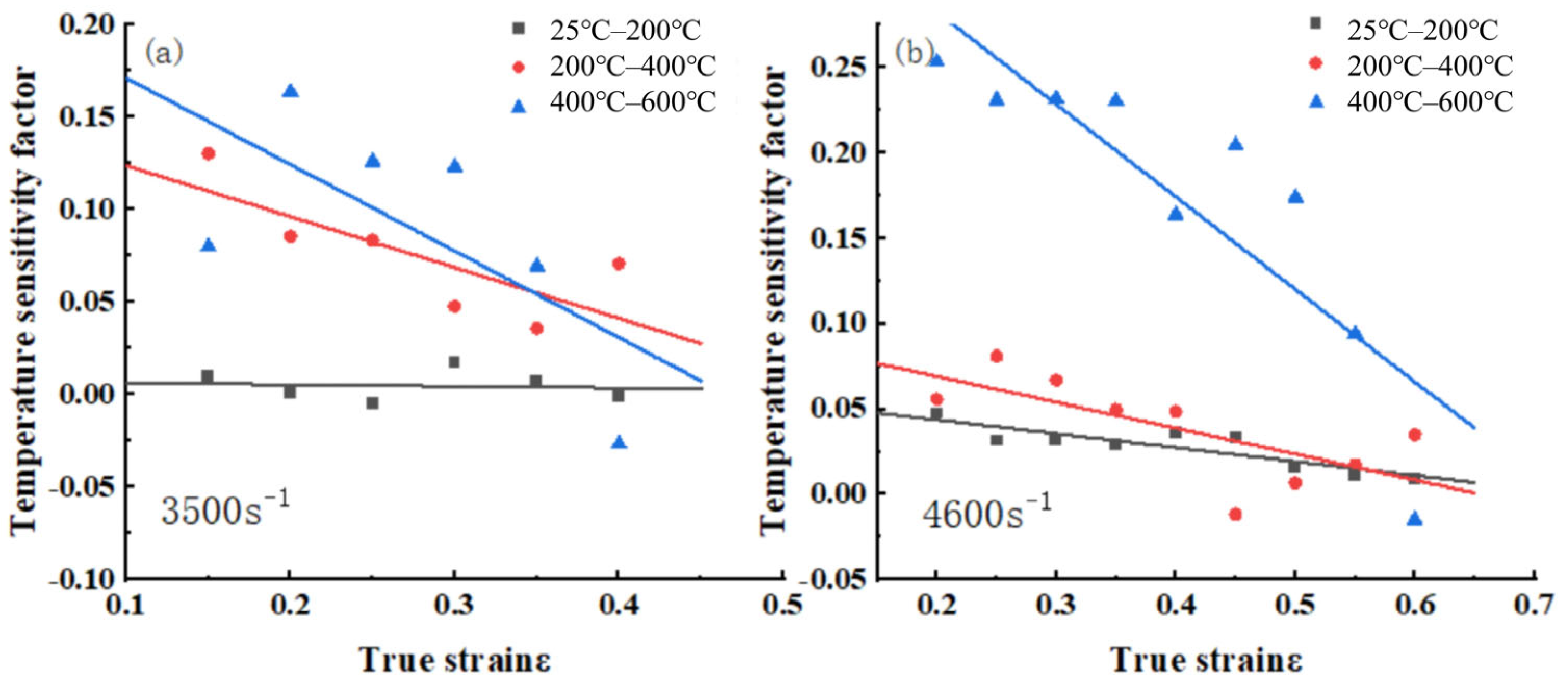

3.1.3. Temperature Sensitivity Analysis

3.2. Analysis of the Reinforcement Effect of the Strain Rate

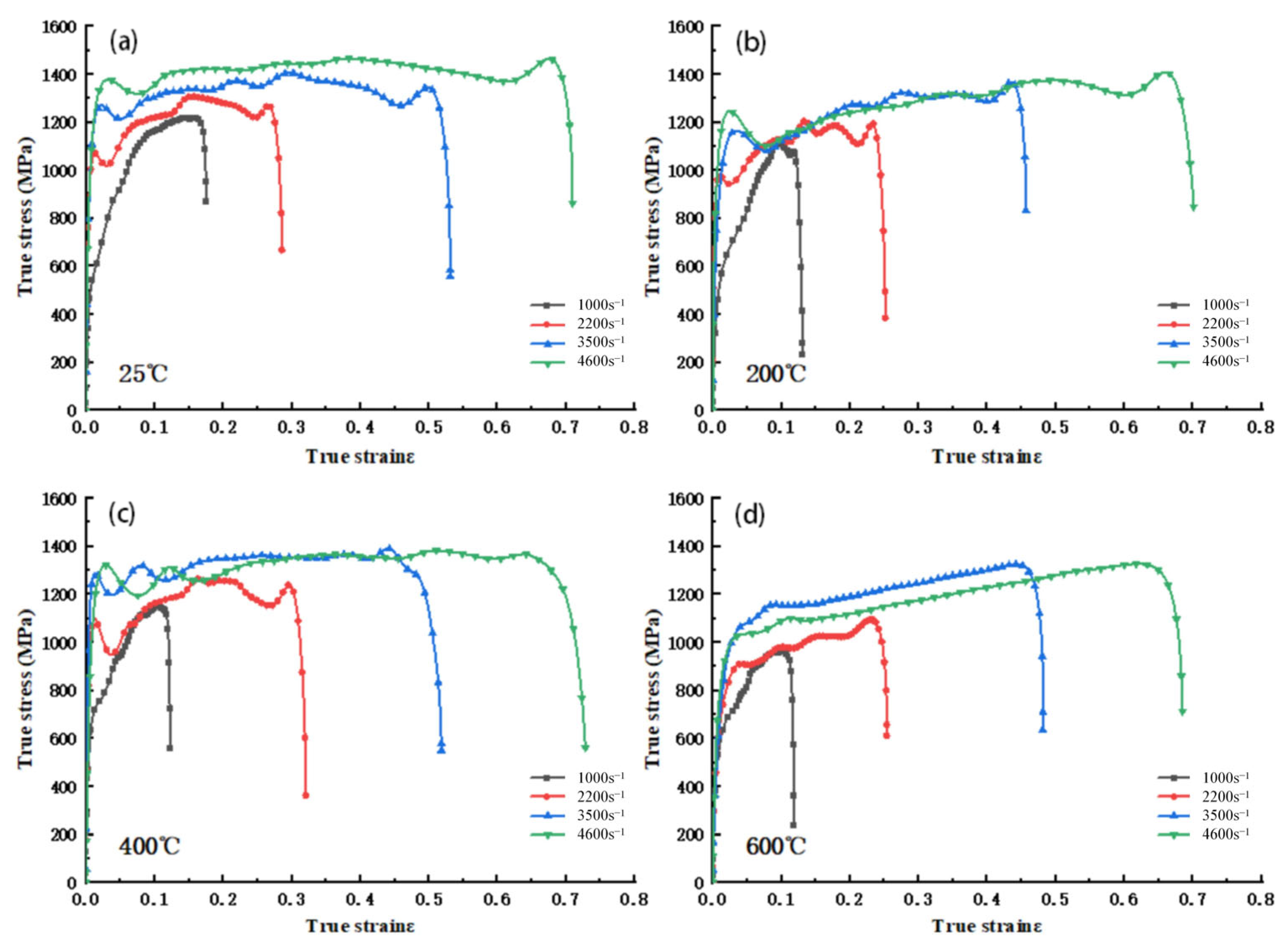

3.2.1. Analysis of Stress and Strain Curve of Different Strain Rates at the Same Temperature

3.2.2. Effect of the Strain Rate on the Compressive Strength of the Material

3.2.3. Strain Rate Sensitivity Analysis

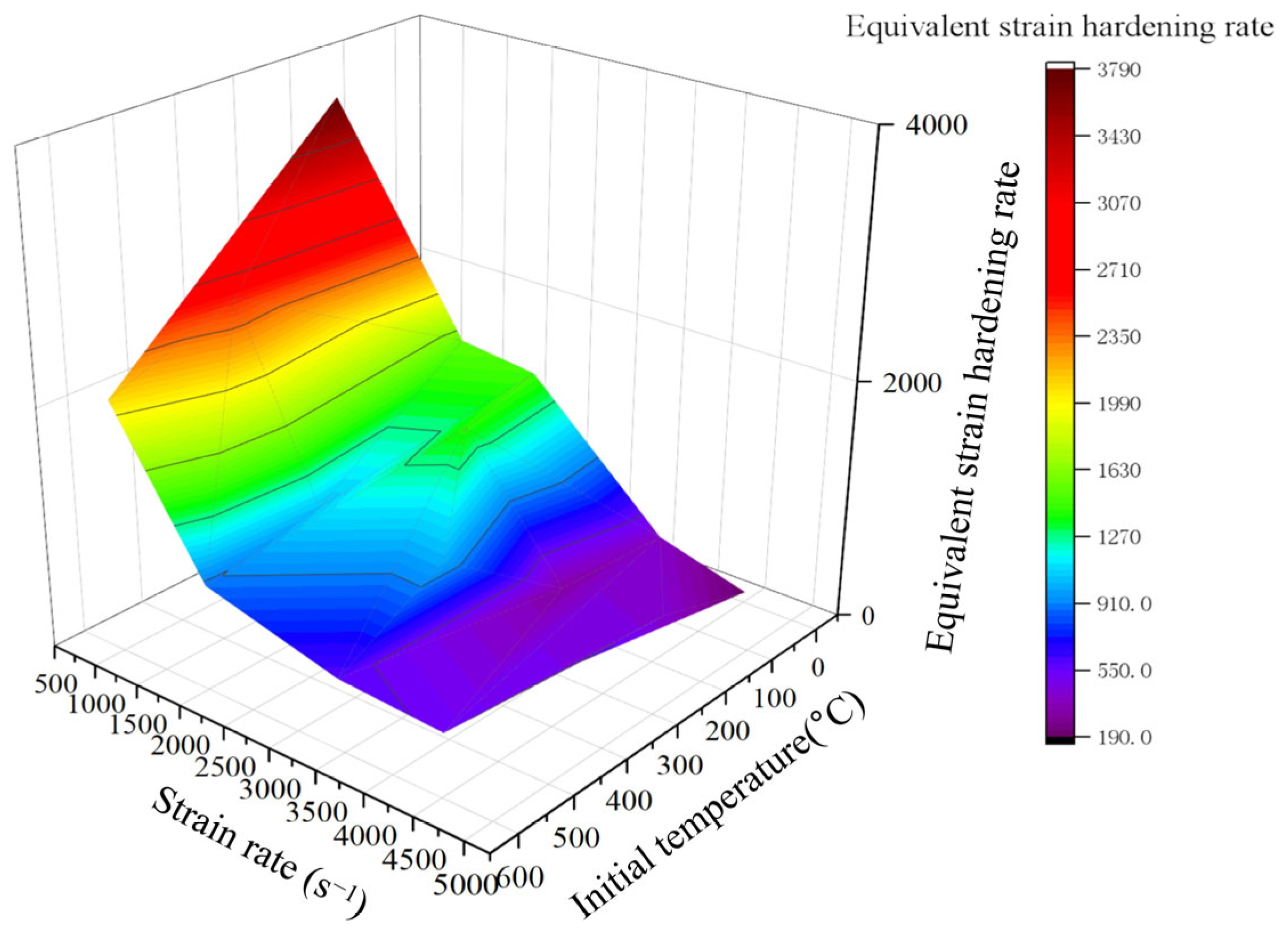

3.3. Analysis of the Processing-Hardening Effect

4. Constitutive Model of 34CrNi3MoA Low-Alloy Steel

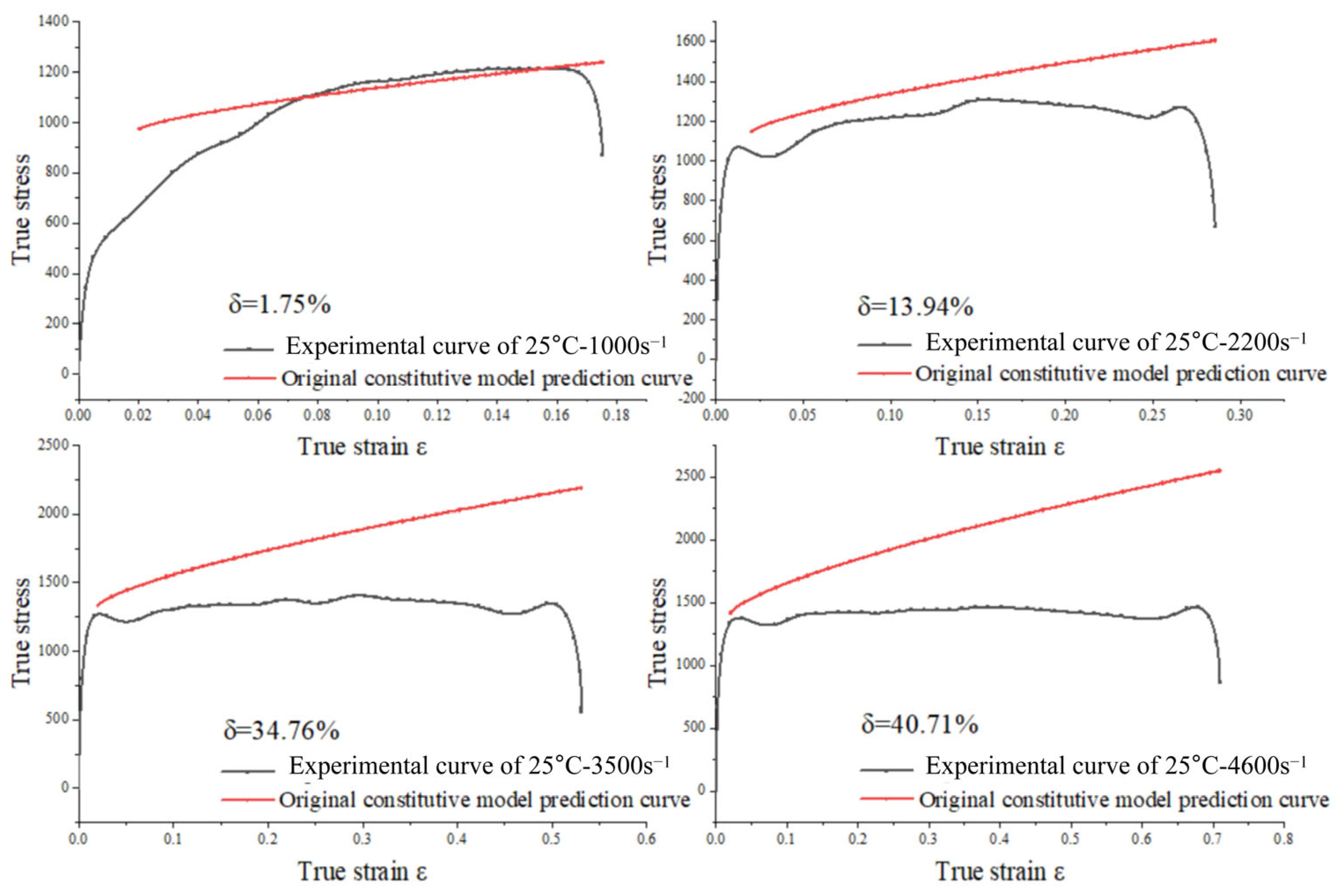

4.1. Original J-C Constitutive Model for 34CrNi3MoA Low-Alloy Steel

4.2. Modification of the Johnson–Cook Constitutive Model

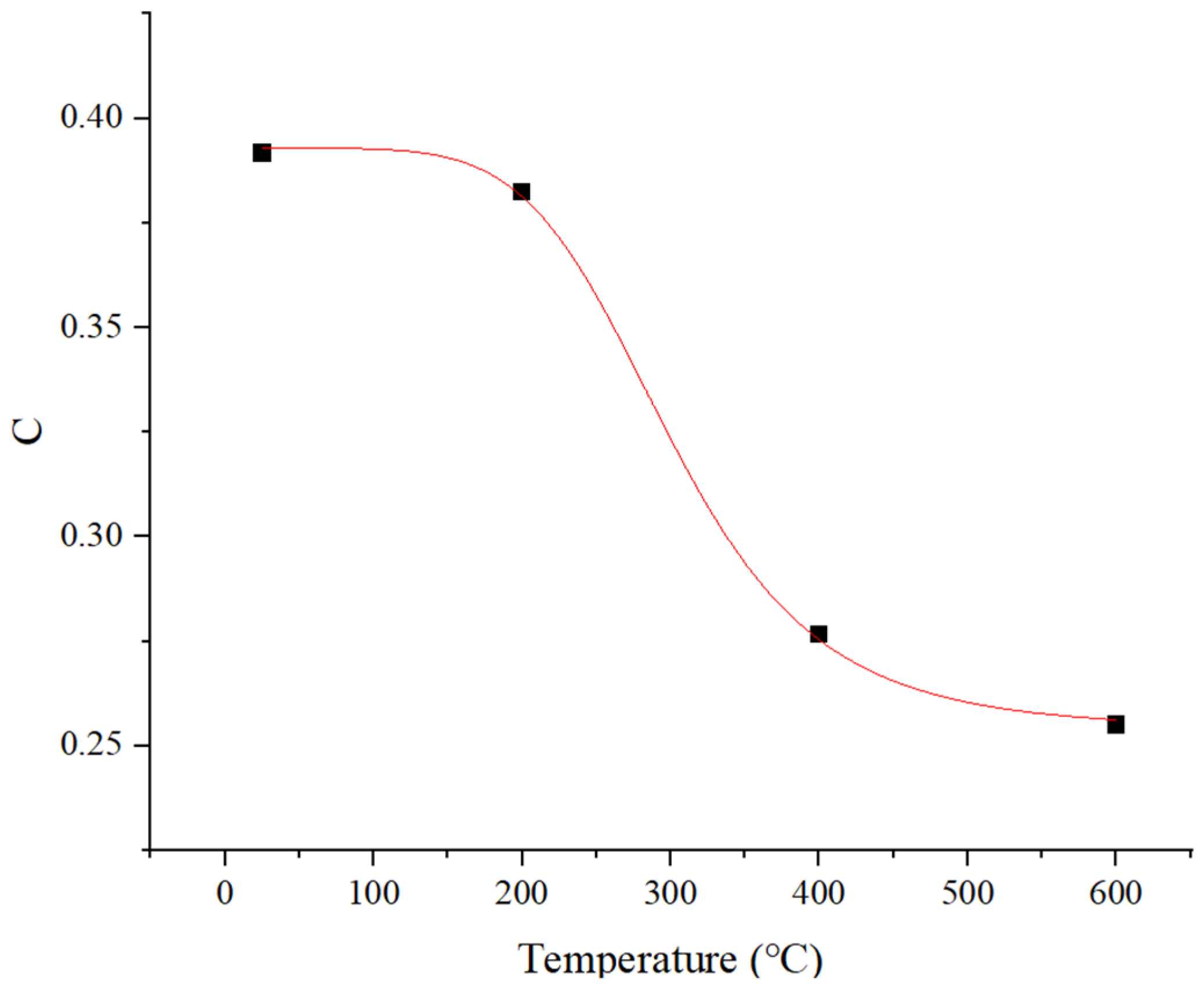

4.2.1. Strain Rate Reinforcement Function of the Coupling Temperature

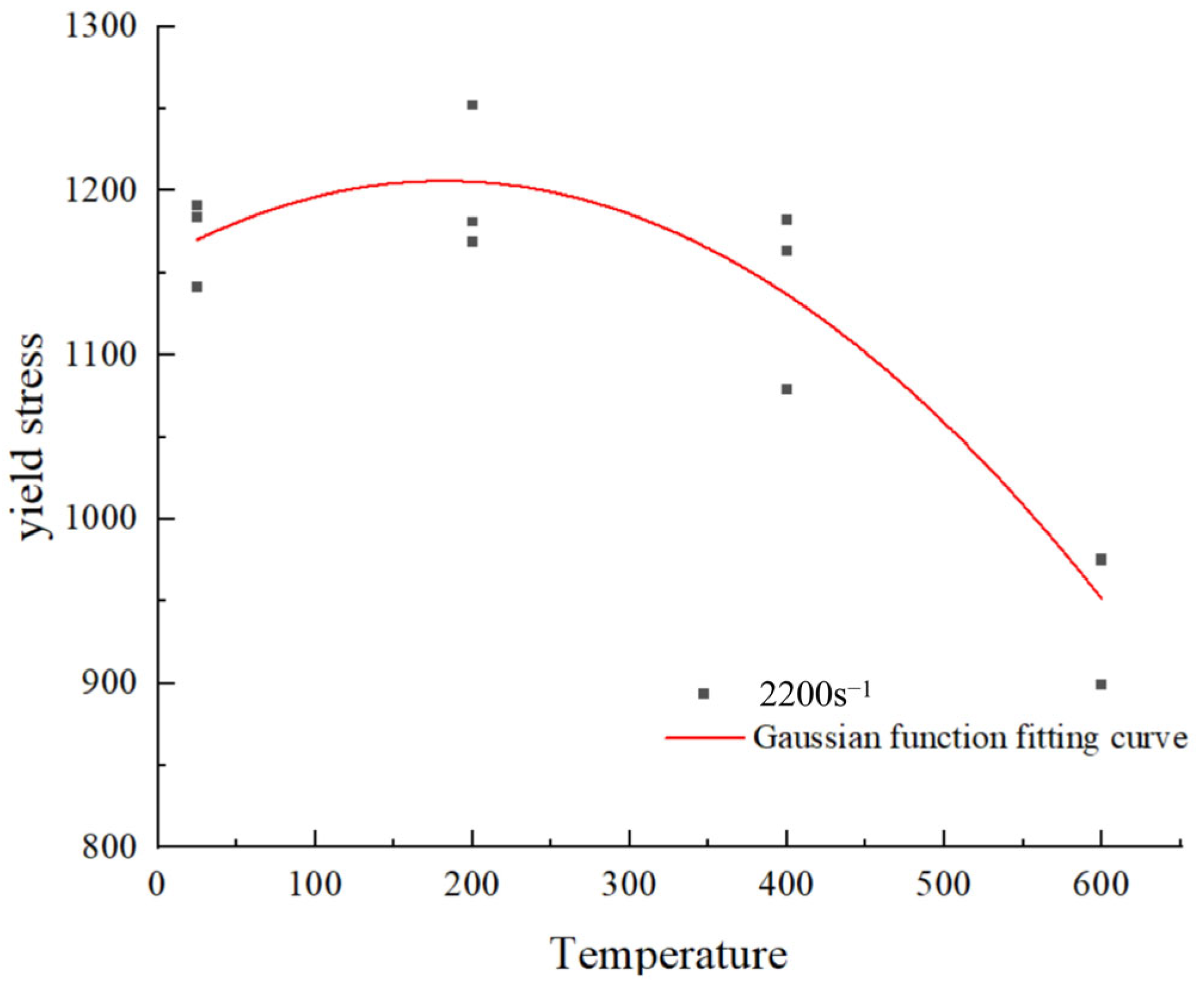

4.2.2. Temperature Softening Function Based on the Dynamic Strain Aging Phenomenon

4.2.3. Strain Hardening Correction Function for Coupling Strain Rate and Temperature Under Low Strain

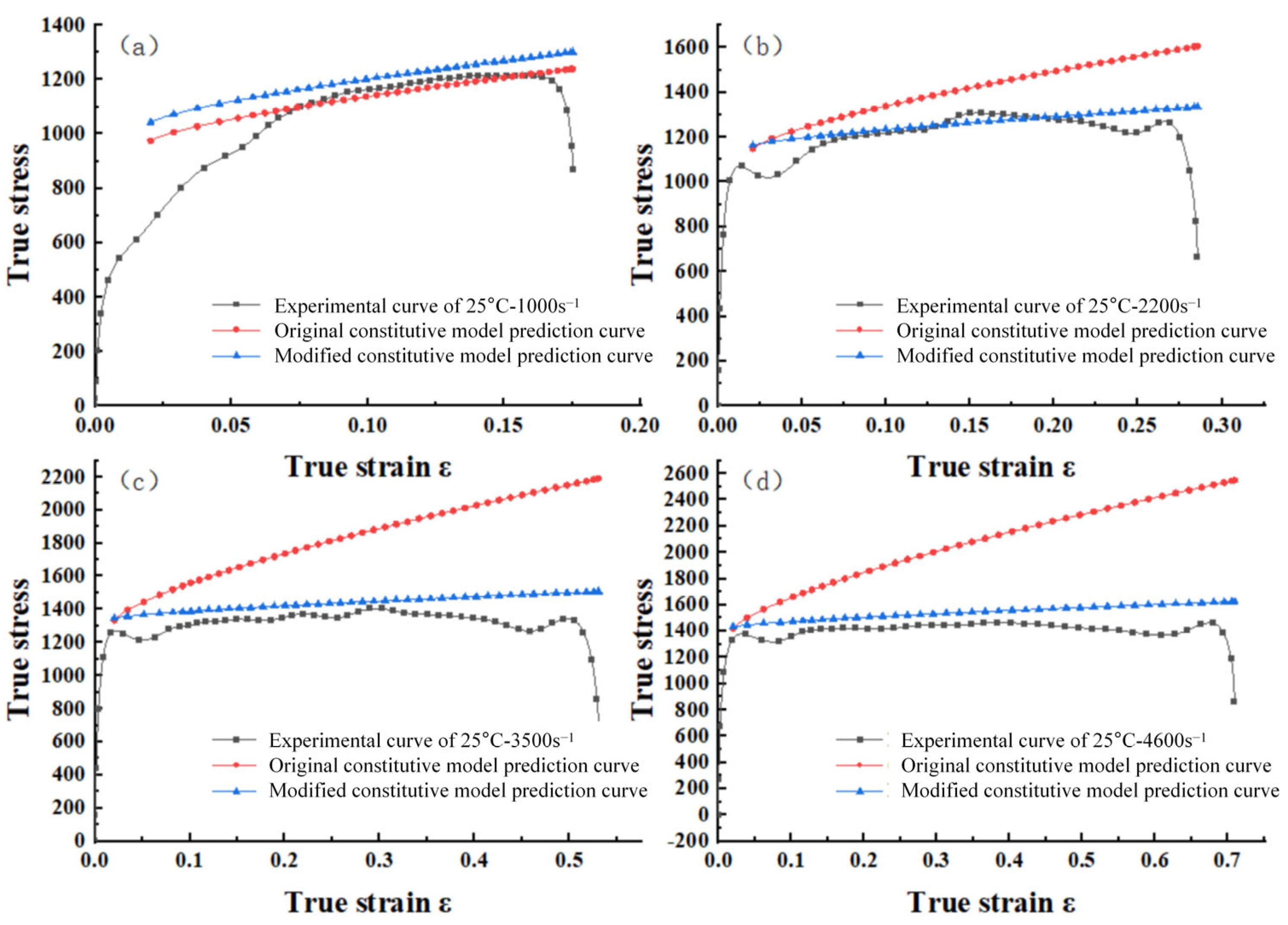

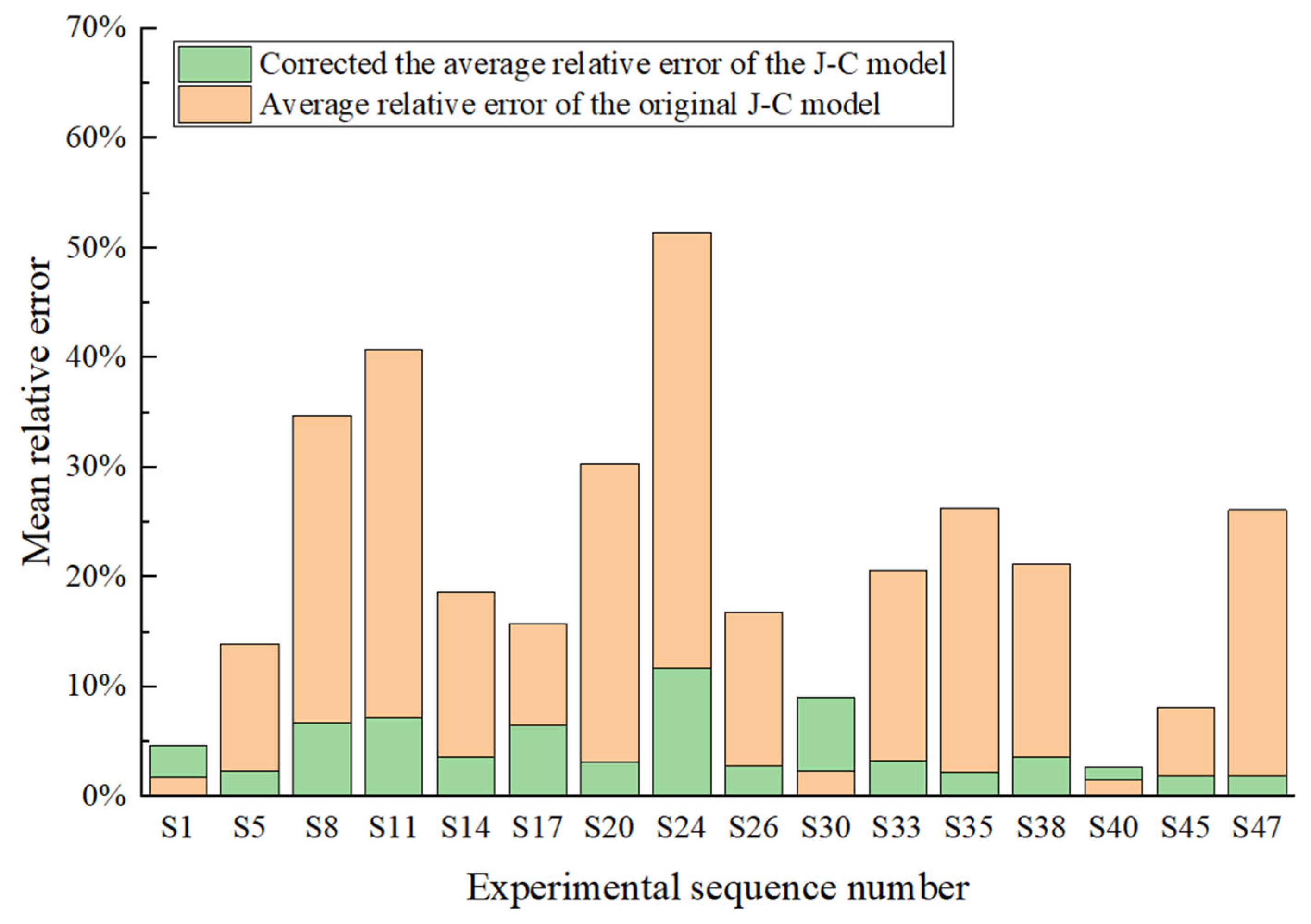

4.3. Modified Constitutive Model Fitting Results and Error Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bao, Z.; Zhang, Y.; Zhang, Y.; Fan, W.; Meng, L. Dynamic mechanical properties of 38CrMoAl high-strength steel and its J-C constitutive model. Mech. Eng. Mater. 2021, 45, 76–83. [Google Scholar]

- Jia, X.D.; Zhou, Y.; Wang, Y.N. Deformation Behavior and Constitutive Model of 34CrNi3Mo during Thermo-Mechanical Deformation Process. Materials 2022, 15, 5220. [Google Scholar] [CrossRef] [PubMed]

- Niu, Q.; Chen, M.; Ming, W. Study on the dynamic compression mechanical behavior of TC17 titanium alloy at high temperature and high strain rate. China Mech. Eng. 2017, 28, 2888–2892+2897. [Google Scholar]

- Zhang, Z.; Li, Y.; Li, C.; Han, G.Z.; Wang, G.; Zhao, M.H.; Chen, Z.; Xu, T. Determination and verification of Johnson-Cook dynamic constitutive model for surface-modified layer of carburized 18CrNiMo7-6 alloy steel. J. Mater. Res. Technol. 2025, 36, 364819–364837. [Google Scholar] [CrossRef]

- Zhou, H.; Peng, Z.; Li, G.; Guan, X.Y.; Chen, J.Z.; Shi, X.N.; Sun, L. A Novel Built-Up Constitutive Model of 40Cr Alloy Steel Considering the Geometric Effect with Simulation Verification. J. Mater. Eng. Perform. 2023, 34, 1–12. [Google Scholar] [CrossRef]

- Jiang, T.; Zhou, W.; Tang, J.; Zhao, X.; Zhao, J.; Liu, H. Constitutive modelling of AISI 9310 alloy steel and numerical calculation of residual stress after shot peening. Int. J. Impact Eng. 2022, 166, 104235. [Google Scholar] [CrossRef]

- Bian, Y.; Jin, G.; Wang, L.; Xue, R.; Li, Z.; Deng, X. Mechanical properties and JC constitutive modification of tungsten alloys under high strain rates and high/low temperatures. Mater. Today Commun. 2024, 41, 110542. [Google Scholar] [CrossRef]

- Yu, H.; Ding, Z.L.; Linzhi, X.; Sun, T.; Zhang, P.; Lei, J. Effect of notch on fatigue performance of marine shaft made of 34CrNi3Mo alloy steel under torsional loading. Int. J. Fatigue 2023, 175, 107790. [Google Scholar] [CrossRef]

- Yang, Y.; Li, Q.; Qiao, L. Review of SHPB Dynamic Load Impact Test Characteristics and Energy Analysis Methods. Processes 2023, 11, 3029. [Google Scholar] [CrossRef]

- Kolsky, H. An Investigation of the Mechanical Properties of Materials at Very High Rates of Loading. Proc. Phys. Soc. B 1949, 62, 676–700. [Google Scholar] [CrossRef]

- Priest, J.; Ghadbeigi, H.; Ayvar-Soberanis, S.; Liljerehn, A.; Way, M. A modified Johnson-Cook constitutive model for improved thermal softening prediction of machining simulations in C45 steel. Procedia CIRP 2022, 108, 106–111. [Google Scholar] [CrossRef]

- Morrone, A.A. Strain Rate and Temperature Effects During Dynamic Deformation of Polycrystalline and Monocrystalline High Purity Aluminum Including TEM Studies; Brown University: Providence, RI, USA, 1986; pp. 34–37. [Google Scholar]

- Zeng, S.; Hu, S.; Peng, B.; Hu, K.; Xiao, M. The constitutive relations and thermal deformation mechanism of nickel aluminum bronze. Mater. Des. 2022, 220, 110853. [Google Scholar] [CrossRef]

- Prasad, G.; Goerdeler, M.; Gottstein, G. Work hardening model based on multiple dislocation densities. Mater. Sci. Eng. A 2005, 400–401, 231–233. [Google Scholar] [CrossRef]

- Guo, W. Study on the plastic rheological behavior of a novel austenitic stainless steel. J. Northwestern Polytech. Univ. 2001, 19, 476479. [Google Scholar]

- Johnson, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. Eng. Fract. Mech. 1983, 21, 541–548. [Google Scholar]

- Wang, J.; Yuan, K.; Zhang, X.; Wang, R.; Gao, M.; Guo, W.G. Proposal and research progress of third-type strain aging. Explos. Impact 2021, 41, 4–14. [Google Scholar]

- Peng, S.; Wu, Y.; Zhang, T.; Xie, Q.; Yuan, Z.; Yin, L. Dynamic Constitutive Relationship of Mg–Gd–Y–Zr–Ag alloy during High Temperature Deformation Process. Materials 2023, 16, 2587. [Google Scholar] [CrossRef]

- Wang, J.J.; Guo, W.G.; Gao, X.S.; Su, J. The third-type of strain aging and the constitutive modeling of a Q235B steel over a wide range of temperatures and strain rates. Int. J. Plast. 2015, 65, 85–107. [Google Scholar] [CrossRef]

- Ren, Q.; Zhang, Y.; Hu, L.; Yin, Q.; Tang, L. Achieving synchronous compression-shear loading on SHPBby utilizing mechanical metamaterial. Int. J. Impact Eng. 2024, 186, 104888. [Google Scholar] [CrossRef]

- Yang, H.; Wang, X.; Ni, P.; Li, Z.; Liu, H. Construction of High Strain Rate Loading Constitutive Model and Failure Model and Prediction of Forming Limit for LA103Z Magnesium alloy. Met. Mater. Int. 2021, 28, 1938–1947. [Google Scholar] [CrossRef]

- Taek, J.J.; Yoon, J.W.; Kim, J.B. Determination of Johnson-Cook constitutive model coefficients considering initial gap between contact faces in SHPB test. J. Mater. Res. Technol. 2023, 24, 7242–7257. [Google Scholar] [CrossRef]

- Deshpande, V.M.; Chakraborty, P.; Chakraborty, T.; Tiwari, V. Application of copper as a pulse shaper in SHPB tests on brittle materials- experimental study, constitutive parameters identification, and numerical simulations. Mech. Mater. 2022, 171, 104336. [Google Scholar] [CrossRef]

- Li, P.; Yuan, K.; Guo, W.; Wang, R.; Chen, L.; Gao, M.; Du, P. Dynamic compressive behavior of a single crystal nickel-base superalloy at ultra-high temperature: Mechanism investigation with a modified electric synchronous SHPB technique. J. Mater. Res. Technol. 2022, 18, 637–657. [Google Scholar] [CrossRef]

- Shayanpoor, A.A.; Rezaei Ashtiani, H.R. The phenomenological and physical constitutive analysis of hot flow behavior of Al/Cu bimetal composite. Appl. Phys. A 2022, 128, 636. [Google Scholar] [CrossRef]

- Wang, C.; Ding, F.; Tang, D.; Zheng, L.; Li, S.; Xie, Y. Modeling and simulation of the high-speed milling of hardened steel SKD11 (62 HRC) based on SHPB technology. Int. J. Mach. Tools Manuf. 2016, 108, 13–26. [Google Scholar] [CrossRef]

- Yan, L.; Jiang, A.; Wang, Z.; Jiang, F.; Wang, F.; Wu, X.; Zhang, Y. Size effect during dynamic shear tests with hat-shaped specimens. J. Mater. Res. Technol. 2023, 27, 3231–3242. [Google Scholar] [CrossRef]

- Kamble, A.; Tandaiya, P. Modeling and simulation of dynamic compression of Bulk Metallic Glasses at room and elevated temperatures using split Hopkinson pressure bar setup. Int. J. Plast. 2024, 174, 103915. [Google Scholar] [CrossRef]

- Li, H.; Li, F.H.; Zhang, R.; Zhi, X.D. High strain rate experiments constitutive model for Q390D steel. J. Constr. Steel Res. 2023, 206, 107933. [Google Scholar] [CrossRef]

- Bahari-Sambran, F.; Cepeda-Jiménez, M.C.; Orozco-Caballero, A.; Carreño, F. Dynamic and static strain aging in AlFeCrX alloys processed by laser powder bed fusion. J. Mater. Sci. 2025; 1–18, prepublished. [Google Scholar] [CrossRef]

- Bai, X.; Wu, S.; Wei, L.; Luo, S.; Xie, X.; Liaw, P.K. Effect of strain rate and temperature on the serration behavior of SA508-III RPV steel in the dynamic strain aging process. J. Iron Steel Res. Int. 2018, 25, 767–775. [Google Scholar] [CrossRef]

- Shaarbaf, M.; Toroghinejad, M.R.; Shafyei, A.; Asqardoust, S.; Salimyanfard, F. Influence of high strain rate deformation on the microstructure and mechanical behavior of NiCoCrFe high entropy alloy. J. Mater. Res. Technol. 2023, 27, 2264–2279. [Google Scholar] [CrossRef]

- Li, X.; Wei, Z.; Wang, X.; Yang, L.; Hao, X.; Wang, M.; Guo, M.; Guo, J. Effect of cryogenic temperatures on the mechanical behavior and deformation mechanism of AISI 316H stainless steel. J. Mater. Res. Technol. 2023, 22, 3375–3386. [Google Scholar] [CrossRef]

- Arab, A.; Guo, Y.; Sktani, Z.D.I.; Chen, P. Effect of strain rate and temperature on deformation and recrystallization behaviour of BCC structure AlCoCrFeNi high entropy alloy. Intermetallics 2022, 147, 107601. [Google Scholar] [CrossRef]

- Chakraborty, P.; Singha, M.K.; Tiwari, V. Dynamic tensile and compressive behaviour of AA7475-T7351 alloy under different strain rates and temperatures. Structures 2022, 46, 49–63. [Google Scholar] [CrossRef]

- Nath, S.; Konkati, C.; Kumar Gupta, R.; Chauhan, A. Quasi-static and dynamic response of AA-2219-T87 aluminium alloy. Mater. Today Commun. 2024, 38, 108443. [Google Scholar] [CrossRef]

- Song, P.; Liu, J.; Li, W.; Li, Y. Plastic deformation behavior of a Cu–10Ta alloy under strong impact loading. Def. Technol. 2024, 32, 368–382. [Google Scholar] [CrossRef]

- Kumar Pandouria, A.; Yadav, K.; Tiwari, V. Compressive and tensile behavior of AA2014-T6 under different strain rates and different temperatures. Structures 2023, 49, 12–25. [Google Scholar] [CrossRef]

| C | Mn | Si | Cr | Ni | P | S | Mo |

|---|---|---|---|---|---|---|---|

| 0.32 | 0.69 | 0.17 | 0.98 | 2.9 | 0.005 | 0.004 | 0.32 |

| Experimental Serial Number | Temperature (°C) | Strain Rate (s−1) |

|---|---|---|

| S1–3 | 25 | 1000 |

| S4–6 | 25 | 2200 |

| S7–9 | 25 | 3500 |

| S10–12 | 25 | 4600 |

| S13–15 | 200 | 1000 |

| S16–18 | 200 | 2200 |

| S19–21 | 200 | 3500 |

| S22–24 | 200 | 4600 |

| S25–27 | 400 | 1000 |

| S28–30 | 400 | 2200 |

| S31–33 | 400 | 3500 |

| S34–36 | 400 | 4600 |

| S37–39 | 600 | 1000 |

| S40–42 | 600 | 2200 |

| S43–45 | 600 | 3500 |

| S46–48 | 600 | 4600 |

| Parameter Name | Tm | ||||||

|---|---|---|---|---|---|---|---|

| price | 963 | 1010 | 0.718 | 0.39165 | 1.54 | 1400 | 1420 |

| parameter name | |||||||||

| price | 901 | 0.14 | 5 | 0.26 | 300 | 2.08 | 0.21 | −90 | 249 |

| parameter name | |||||||||

| price | 1.01 | 79.8 | 279 | 1375 | −1007 | 0.89 | 1420 | 25 | 1400 |

| Experimental Serial Number | Temperature | Strain Rate | The Original J-C Model | Correct the J-C Model |

|---|---|---|---|---|

| S1 | 25 | 1434 | 1.75% | 1.50% |

| S5 | 25 | 2261 | 13.94% | 4.19% |

| S8 | 25 | 3705 | 34.76% | 2.69% |

| S11 | 25 | 4621 | 40.71% | 2.96% |

| S14 | 200 | 1038 | 18.63% | 3.57% |

| S17 | 200 | 2467 | 15.71% | 2.17% |

| S20 | 200 | 3543 | 30.31% | 2.59% |

| S24 | 200 | 4594 | 51.39% | 6.50% |

| S26 | 400 | 1105 | 16.80% | 2.84% |

| S30 | 400 | 2006 | 2.36% | 5.43% |

| S33 | 400 | 3361 | 20.60% | 2.96% |

| S35 | 400 | 4755 | 26.28% | 1.80% |

| S38 | 600 | 990 | 21.19% | 3.24% |

| S40 | 600 | 2014 | 1.49% | 1.22% |

| S45 | 600 | 3438 | 8.07% | 0.62% |

| S47 | 600 | 4515 | 26.11% | 0.76% |

| mean | 20.63% | 2.82% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, X.; Zhang, Z.; Wu, H.; Chen, J.; Sun, L.; Li, G. Study on Dynamic Mechanical Behavior of 34CrNi3MoA Alloy Steel Considering the Coupling Effect of Temperature and Strain Rate. Materials 2025, 18, 4658. https://doi.org/10.3390/ma18204658

Guan X, Zhang Z, Wu H, Chen J, Sun L, Li G. Study on Dynamic Mechanical Behavior of 34CrNi3MoA Alloy Steel Considering the Coupling Effect of Temperature and Strain Rate. Materials. 2025; 18(20):4658. https://doi.org/10.3390/ma18204658

Chicago/Turabian StyleGuan, Xiaoyan, Zhengyuan Zhang, Hengheng Wu, Jianzhi Chen, Li Sun, and Guochao Li. 2025. "Study on Dynamic Mechanical Behavior of 34CrNi3MoA Alloy Steel Considering the Coupling Effect of Temperature and Strain Rate" Materials 18, no. 20: 4658. https://doi.org/10.3390/ma18204658

APA StyleGuan, X., Zhang, Z., Wu, H., Chen, J., Sun, L., & Li, G. (2025). Study on Dynamic Mechanical Behavior of 34CrNi3MoA Alloy Steel Considering the Coupling Effect of Temperature and Strain Rate. Materials, 18(20), 4658. https://doi.org/10.3390/ma18204658