Effect of Vibration Timing on Mechanical and Durability Properties of Early-Strength Cement-Based Composites for Bridge Wet Joints

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Proportion and Sample Preparation

2.3. Protocol of Vibration Timing

2.4. Experimental Methodology

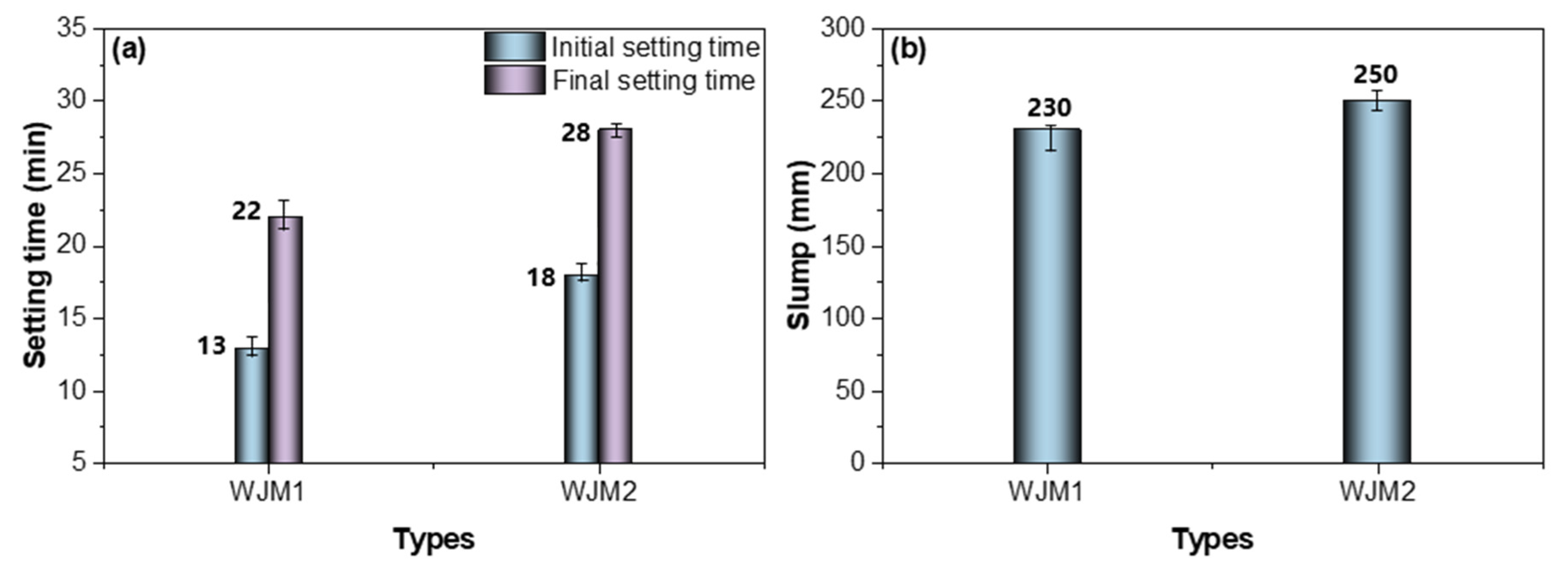

2.4.1. Setting Time and Workability

2.4.2. Compressive, Flexural and Bond Strength Test

2.4.3. Microscopic Test

3. Results and Discussion

3.1. Workability

3.2. Strength Performance

3.2.1. Compressive Strength

3.2.2. Flexural Strength

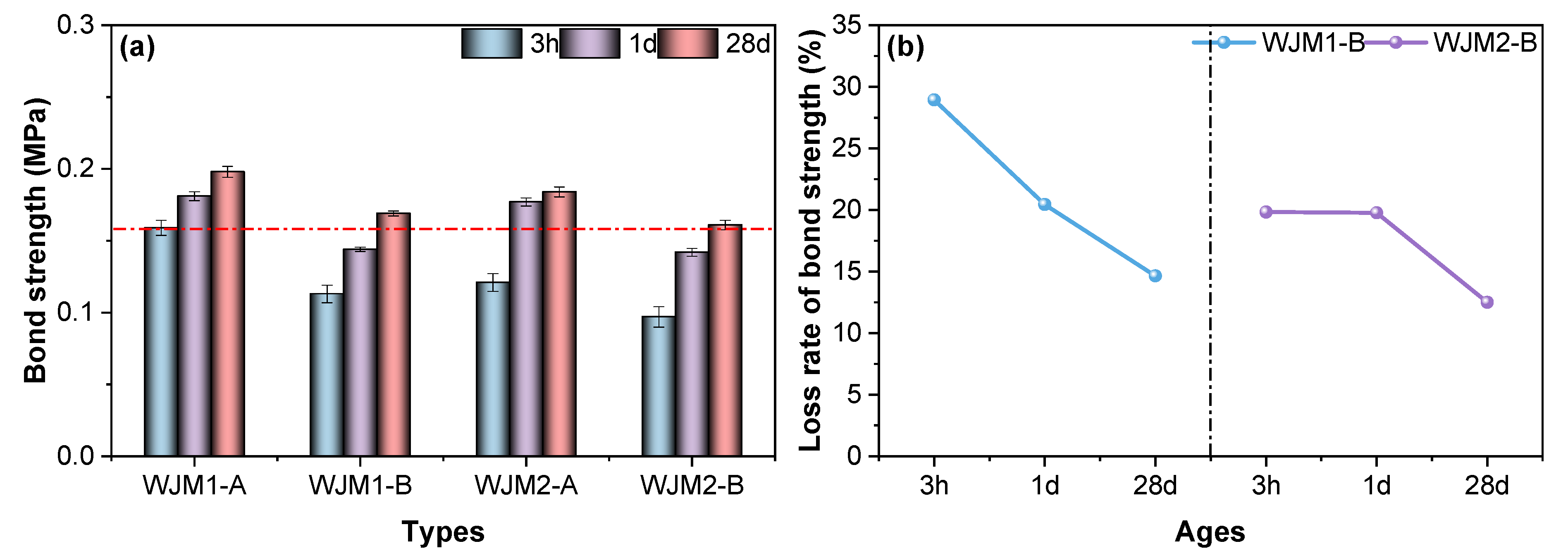

3.2.3. Bond Strength

3.3. Microscopic Performance

3.3.1. Chloride Penetration Resistance

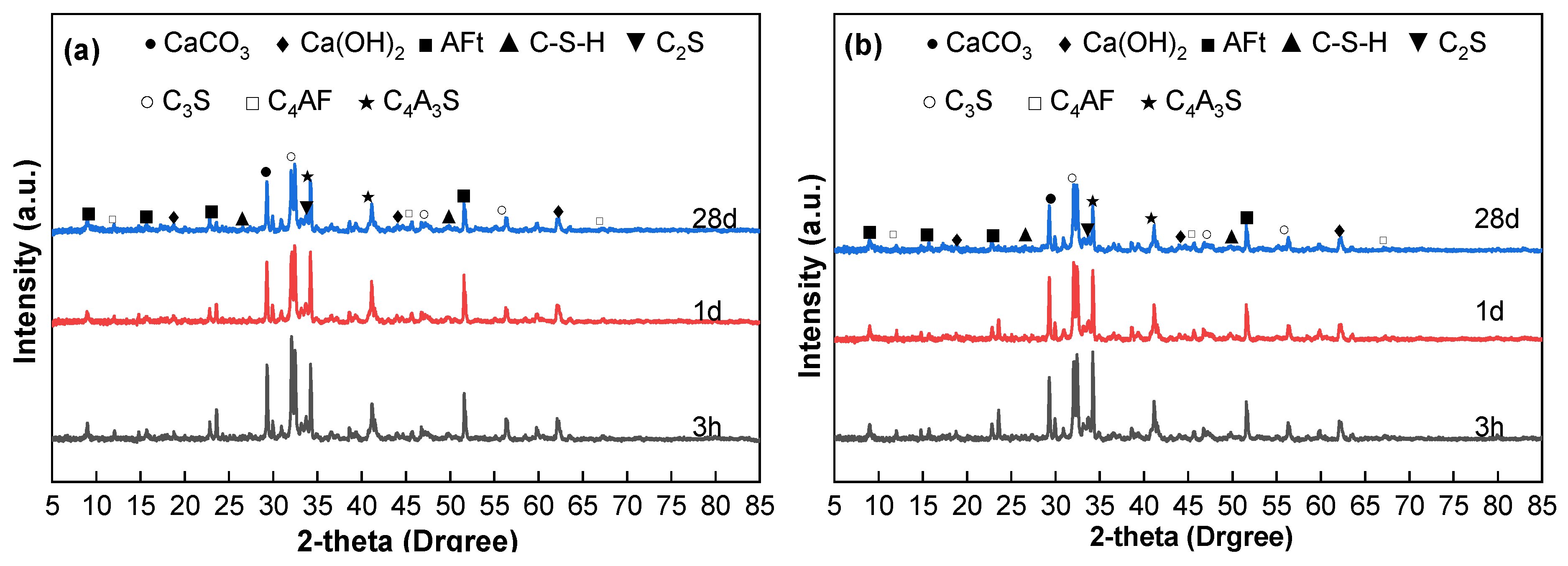

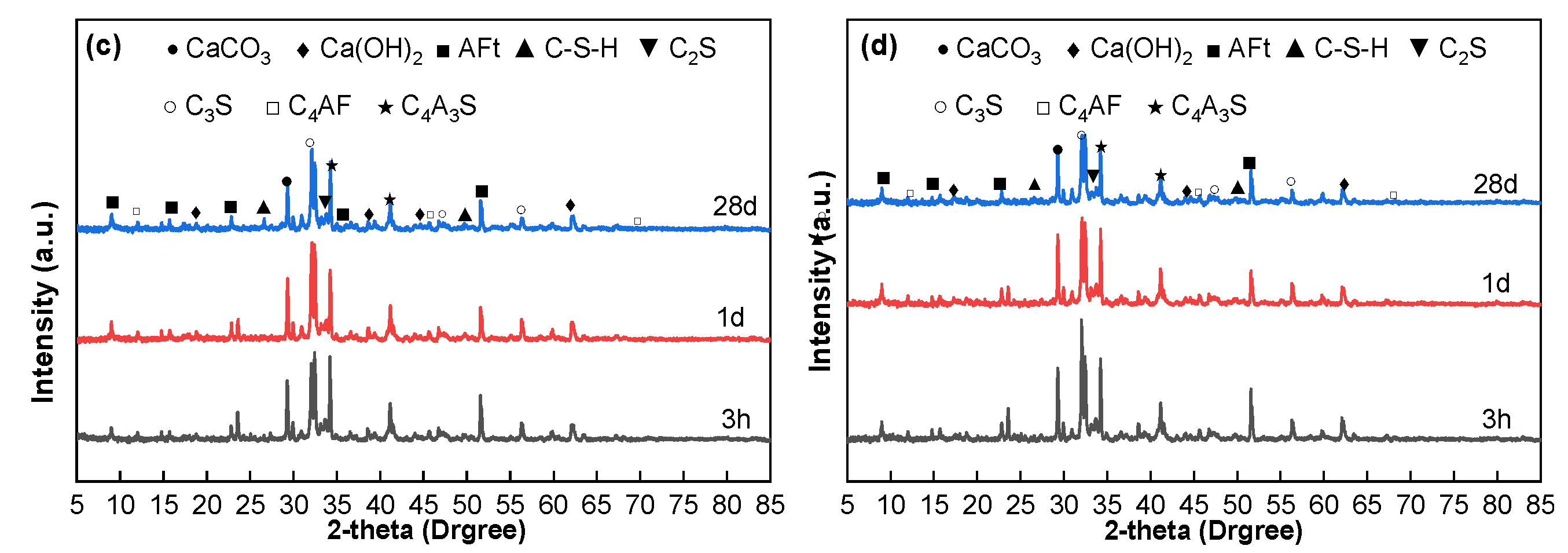

3.3.2. XRD Analysis

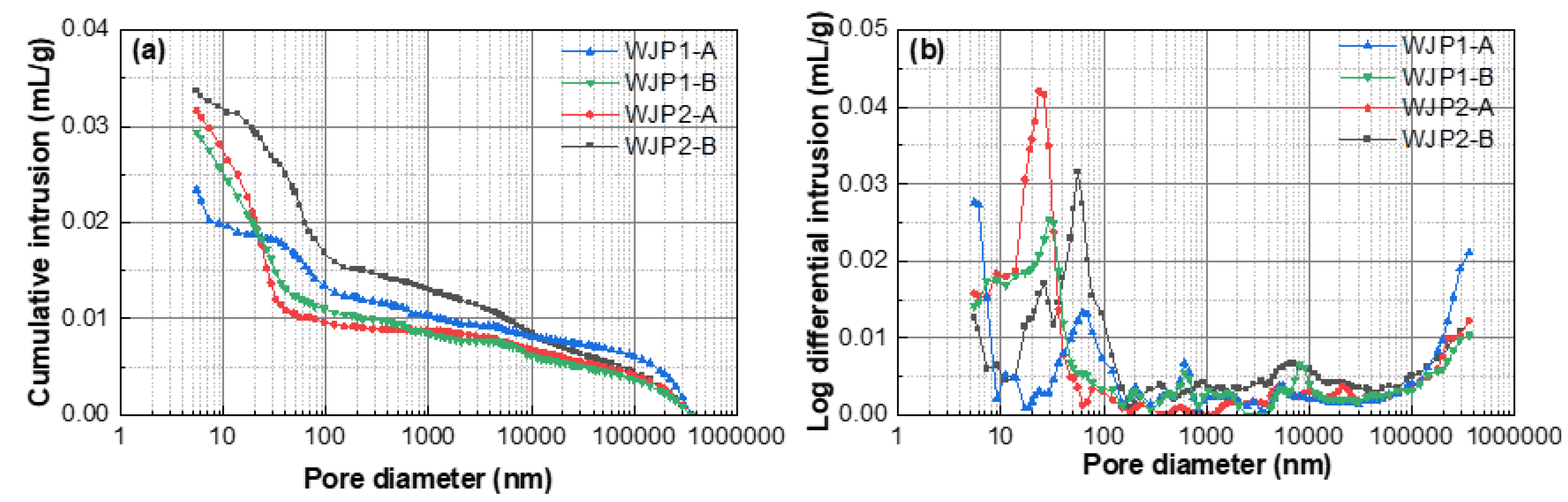

3.3.3. MIP Analysis

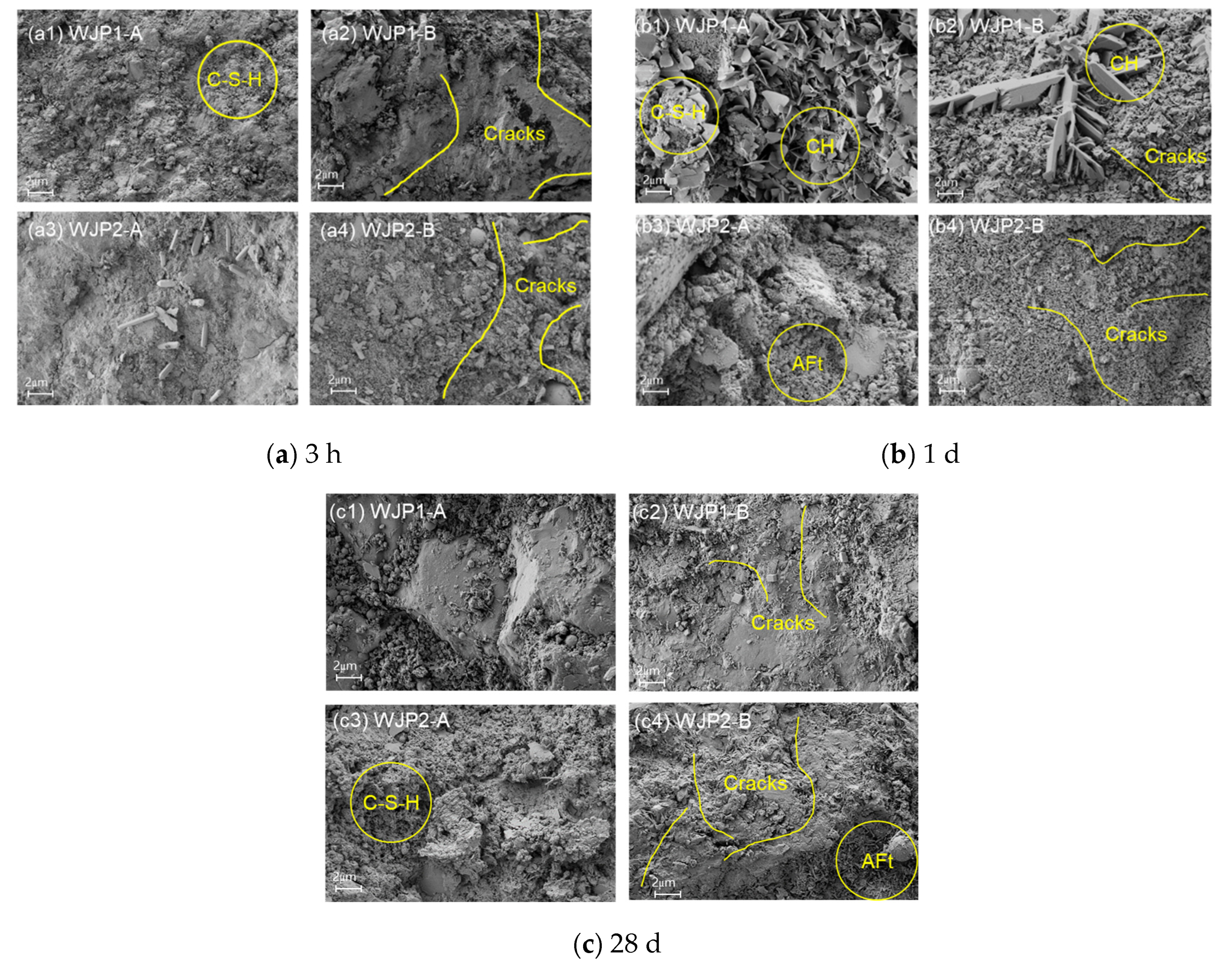

3.3.4. SEM Analysis

4. Conclusions

- (1)

- Vibration occurring between the initial and final setting periods has a pronounced adverse effect on the early-age mechanical properties, including compressive, flexural, and bond strengths. This finding emphasizes the necessity of minimizing or controlling vibration during this critical hydration stage to ensure structural integrity.

- (2)

- Microstructural characterization (SEM and MIP) demonstrated that vibration induces microcracks and increases pore connectivity in the cement matrix, leading to reduced compactness and long-term durability. Although partial recovery occurs with further hydration, the persistence of fine cracks and elevated porosity highlights the lasting influence of early vibration.

- (3)

- Chloride penetration tests confirmed that vibration significantly elevates the chloride diffusion coefficient, particularly in mixtures with higher water-to-binder ratios (WJM2). This increased permeability accelerates the risk of chloride ingress and reinforcement corrosion, underscoring the importance of vibration control in durability design.

- (4)

- Comparative evaluation of different mix proportions under various vibration protocols revealed that mixtures with higher water content (WJM2) exhibit relatively better resistance to strength loss. Nevertheless, the detrimental effects of vibration remain evident, suggesting that optimization of both mix design and vibration timing is essential for achieving durable and reliable bridge wet joint connections.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Murtagh, N.; Scott, L.; Fan, J. VSI Editorial—Sustainable and Resilient Construction: Current Status and Future Challenges. J. Clean. Prod. 2020, 268, 122264. [Google Scholar]

- Das, J.T.; Banerjee, A.; Puppala, A.J.; Chakraborty, S. Sustainability and Resilience in Pavement Infrastructure: A Unified Assessment Framework. Environ. Geotech. 2022, 9, 360–372. [Google Scholar] [CrossRef]

- Dan, D.; Ying, Y.; Ge, L. Digital Twin System of Bridges Group Based on Machine Vision Fusion Monitoring of Bridge Traffic Load. IEEE Trans. Intell. Transp. Syst. 2022, 23, 22190–22205. [Google Scholar] [CrossRef]

- Deng, S.; Yan, B.; Shen, L.; Yuan, J.; Li, H. Experimental Investigations on the Flexural Behavior of UHPC Wet Joints for UHPC Light-Weight Rigid Frame Arch Bridges. Constr. Build. Mater. 2024, 446, 137994. [Google Scholar] [CrossRef]

- Ye, M.; Li, L.; Li, H.; Zhou, C. Shear Behavior of Joints in Precast UHPC Segmental Bridges under Direct Shear Loading. Constr. Build. Mater. 2022, 357, 129212. [Google Scholar] [CrossRef]

- Han, F.; Wang, J.; Ji, X.; Chen, S.; Liu, J.; Wu, M.; Liu, J. Insights into the Hydration Kinetics and Microstructural Evolution of Ultra-High Performance Cementitious Composite at Mid-to-Low Curing Temperatures. Constr. Build. Mater. 2025, 468, 140403. [Google Scholar]

- Wang, D.; Wang, X.; Ye, H.; Yu, F.; Han, B. Dynamic Behaviors of Nickel Coated Carbon Nanotubes Reinforced Ultra-High Performance Cementitious Composites under High Strain Rate Impact Loading. Cem. Concr. Compos. 2024, 149, 105525. [Google Scholar] [CrossRef]

- Sun, G.; Ma, T.; Jiang, Y.; Hu, M.; Lu, T.; Siwainao, D.H. Dual Self-Repairing Enhancement Mechanisms of Blocked Dynamic Isocyanate Prepolymer on Aging Degradation and Fatigue Damages of High-Content SBS-Modified Asphalt. Constr. Build. Mater. 2025, 472, 140855. [Google Scholar] [CrossRef]

- Xi, B.; Huang, Z.; Al-Obaidi, S.; Ferrara, L. Healing Capacity of Ultra High Performance Concrete under Sustained through Crack Tensile Stresses and Aggressive Environments. Cem. Concr. Compos. 2024, 145, 105355. [Google Scholar]

- Zhao, L.; Cui, W.; Shen, X.; Xu, S.; Ding, Y.; Ge, Y. A Fast On-Site Measure-Analyze-Suppress Response to Control Vortex-Induced-Vibration of a Long-Span Bridge. Structures 2022, 35, 192–201. [Google Scholar]

- Wang, H.; Feng, P.; Liu, X.; Shi, J.; Wang, C.; Wang, W.; Li, H.; Hong, J. The Role of Ettringite Seeds in Enhancing the Ultra-Early Age Strength of Portland Cement Containing Aluminum Sulfate Accelerator. Compos. Part B Eng. 2024, 287, 111856. [Google Scholar] [CrossRef]

- Boukhatem, A.; Bouarab, K.; Yahia, A. Kappaphycus Alvarezii Seaweed as Novel Viscosity-Modifying Admixture for Cement-Based Materials. ACI Mater. J. 2023, 120, 15–28. [Google Scholar]

- Leng, J.; Yang, J.; Zhang, Z.; Du, J.; Zou, Y.; Zhou, J. Effect of Vehicle-Induced Vibration on the Strength, Nano-Mechanical Properties, and Microstructural Characteristics of Ultra-High-Performance Concrete during Hardening Process. Cem. Concr. Compos. 2024, 148, 105487. [Google Scholar] [CrossRef]

- Gao, X.; Liu, Q.; Cai, Y.; Tong, L.; Peng, Z.; Xiong, Q.X.; De Schutter, G. A New Model for Investigating the Formation of Interfacial Transition Zone in Cement-Based Materials. Cem. Concr. Res. 2025, 187, 107675. [Google Scholar] [CrossRef]

- Chen, L.; Zhu, X.; Zhang, Y.; Wang, L.; Ma, B.; Zheng, Y.; Poon, C.S.; Yan, J.; Tsang, D.C.W. Carbonation-Enhanced Interfacial Transition Zone in Biochar-Cement Mortar. Constr. Build. Mater. 2024, 451, 138606. [Google Scholar] [CrossRef]

- Gao, X.; Peng, Z.; Tong, L.; Cai, Y.; Xiao, J.; Geng, X.; Liu, Q. Effect of Global Aggregate Distribution on Interfacial Transition Zones in Cement-Based Materials: An Analytical-Numerical Study. Constr. Build. Mater. 2025, 458, 138278. [Google Scholar] [CrossRef]

- Zhang, Z.; Jia, Z.; Shi, J.; Jiang, Y.; Banthia, N.; Zhang, Y. Clarifying and Quantifying the Driving Force for the Evolution of Static Yield Stress of Cement Pastes. Cem. Concr. Res. 2023, 167, 107129. [Google Scholar] [CrossRef]

- Kong, L.; Su, S.; Wang, Z.; Wu, P.; Zhang, Y.; Chen, Z.; Ren, D.; Ai, C. Microscale Mechanism and Key Factors of Waterborne Epoxy Resin Emulsified Asphalt Enhancing Interlayer Bonding Performance and Shear Resistance of Bridge Deck Pavement. Constr. Build. Mater. 2024, 419, 135570. [Google Scholar] [CrossRef]

- Wei, Y.; Guo, W.; Ma, L.; Liu, Y.; Yang, B. Materials, Structure, and Construction of a Low-Shrinkage UHPC Overlay on Concrete Bridge Deck. Constr. Build. Mater. 2023, 406, 133353. [Google Scholar] [CrossRef]

- Sahmaran, M.; Al-Emam, M.; Yildirim, G.; Simsek, Y.E.; Erdem, T.K.; Lachemi, M. High-Early-Strength Ductile Cementitious Composites with Characteristics of Low Early-Age Shrinkage for Repair of Infrastructures. Mater. Struct. 2013, 48, 1389–1403. [Google Scholar] [CrossRef]

- Zhang, Z.; Wu, Y.; Chen, M.; Zhou, H.; Dong, B.; Ma, C. Synergistic Hybrid Fiber Reinforcement in Early-Strength High-Performance Cementitious Composite: Mechanical Performance, Fracture Mechanisms, and Environmental Sustainability. Constr. Build. Mater. 2025, 494, 143493. [Google Scholar] [CrossRef]

- Wang, J.; Guo, R.; Ma, L.; Long, Z.; Zhou, P.; Xu, X. Experimental Study on Static and Dynamic Mechanical Properties of Engineered Cementitious Composite-Coral Mortar Reinforced with Nano-SiO2. Constr. Build. Mater. 2025, 492, 142950. [Google Scholar] [CrossRef]

- Hanwen, D.; Shunzhi, Q. Utilization of Local Ingredients for the Production of High-Early-Strength Engineered Cementitious Composites. Adv. Mater. Sci. Eng. 2018, 2018, 8159869. [Google Scholar]

- Shanmugasundaram, N.; Praveenkumar, S.; Ashwin, K.P.S. Structural Behavior of Engineered Cementitious Composite Substrate Slab Overlays for Bridge Deck and Pavement Applications. Constr. Build. Mater. 2025, 459, 139736. [Google Scholar] [CrossRef]

- Wang, L.; Strangwood, M.; Balint, D.; Lin, J.; Dean, T.A. Formability and Failure Mechanisms of AA2024 under Hot Forming Conditions. Mater. Sci. Eng. A 2011, 528, 2648–2656. [Google Scholar] [CrossRef]

- Chen, F.X.; Leng, Y.; Zhang, G.Z.; Wei, K.; Jin, L.; Yin, T.Y.; Yu, R. Revealing the Effect of Hydroxyethyl Methyl Cellulose Ether on Rheological Characteristics and Hydration Kinetics of Ultra-High Performance Concrete with High Thixotropy. Constr. Build. Mater. 2024, 457, 139388. [Google Scholar] [CrossRef]

- Alomari, A.; Dahlberg, J.; Phares, B.M.; Liu, Z. Evaluation of the Performance of UHPC-and HCSC-Filled Noncontact Lap Splice Closure Joint Used for Lateral Slide-in Bridge Construction. J. Bridg. Eng. 2025, 30, 4025028. [Google Scholar] [CrossRef]

- Zhao, J.; Ahmed, A.H.; Liebscher, M.; Bartsch, A.; Ivaniuk, E.; Butler, M.; Kohout, J.; Hájková, P.; Mechtcherine, V. Thermomechanical Behavior of Textile-Reinforced Geopolymer Concrete Based on Mineral-Impregnated Carbon-Fibers (MCFs) Composites. Cem. Concr. Compos. 2024, 150, 105555. [Google Scholar] [CrossRef]

- Huang, K.; Zhou, Y.; Zhang, Z.; Zhang, H.; Lü, C.; Luo, J.; Shen, L. A Real-Time Quantitative Acceleration Monitoring Method Based on Triboelectric Nanogenerator for Bridge Cable Vibration. Nano Energy 2023, 118, 108960. [Google Scholar] [CrossRef]

- Su, J.; Li, J.; Wu, D.; Lu, G.; Wang, L.; Ma, J.; Li, Z.X. Lifetime Seismic Damage Evolution and Resilience Assessment of Offshore Bridges under Height-Varying Corrosion and Scour. Ocean Eng. 2025, 326, 120883. [Google Scholar] [CrossRef]

- Yang, K.; Wang, H.; Liu, Z. Evaluation on Mechanical Properties of High-Performance Biocomposite Bridge Deck Structure: A Review. Polym. Compos. 2021, 42, 6265–6297. [Google Scholar] [CrossRef]

- Pang, Y.; He, W.; Zhong, J. Risk-Based Design and Optimization of Shape Memory Alloy Restrained Sliding Bearings for Highway Bridges under near-Fault Ground Motions. Eng. Struct. 2021, 241, 112421. [Google Scholar] [CrossRef]

| Chemical | CaO | SiO2 | Fe2O3 | MgO | Al2O3 | K2O | Na2O | SO3 | TiO2 | MnO | Others |

|---|---|---|---|---|---|---|---|---|---|---|---|

| OPC | 62.52 | 19.66 | 3.37 | 0.85 | 4.29 | 0.62 | 0.08 | 2.61 | 0.24 | 0.17 | 5.59 |

| SAC | 43.40 | 8.50 | 1.90 | 1.80 | 33.60 | — | — | 8.20 | 1.50 | 1.1 | |

| SF | — | 93 | — | — | — | — | — | — | — | 7 | |

| GMb | 8 | 55 | 5 | — | 20 | — | — | 3 | — | 9 |

| Agents | Appearance | Bulk Density (g/L) | Fineness (Passing 0.3 mm Sieve) (%) | Residual Moisture (%) | Water Reduction Rate (%) | Dry Loss (%) | Residual on 40 Mesh Sieve (%) | Ash Content (%) |

|---|---|---|---|---|---|---|---|---|

| Defoamer | White powder | 500–700 | ≥90 | ≤3 | ≥25 | — | — | — |

| Water-Reducing Agent | White powder | 500–700 | ≥90 | ≤3 | ≥25 | — | — | — |

| Retarder | — | — | — | — | — | 1.26 | 0.39 | 3.12 |

| Type | Cement | SAC | CAM | Water | Sand | CAD | W/B |

|---|---|---|---|---|---|---|---|

| WJM1 | 365 | 91 | 104 | 95.2 | 560 | 9.1 | 0.17 |

| WJM2 | 365 | 91 | 104 | 106.4 | 560 | 9.1 | 0.19 |

| WJP1 | 365 | 91 | 104 | 95.2 | — | 9.1 | 0.17 |

| WJP2 | 365 | 91 | 104 | 106.4 | — | 9.1 | 0.19 |

| Type | No Vibration | Vibration for 10 min | ||

|---|---|---|---|---|

| Between Initial Setting to Final Setting | 10 min After Final Setting | 3 h After Final Setting | ||

| WJM1, WJM2, WJP1 or WJP2 | A | — | — | — |

| — | B | — | — | |

| — | — | C | — | |

| — | — | — | D | |

| Types | Porosity (%) | Total Porosity Volume (mL/g) | Total Porosity Area (nm) | Most Probable Pore Size (nm) | Average Pore Size (nm) |

|---|---|---|---|---|---|

| WJP1-A | 5.5638 | 0.0234 | 3.074 | 5.48 | 30.50 |

| WJP1-B | 6.8259 | 0.0294 | 4.997 | 55.78 | 23.51 |

| WJP2-A | 7.2592 | 0.0316 | 5.782 | 23.41 | 21.88 |

| WJP2-B | 7.7014 | 0.0337 | 3.013 | 29.03 | 44.78 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Li, J.; Tian, X.; Pang, Y.; Fu, B.; Zhou, S. Effect of Vibration Timing on Mechanical and Durability Properties of Early-Strength Cement-Based Composites for Bridge Wet Joints. Materials 2025, 18, 4645. https://doi.org/10.3390/ma18204645

Li X, Li J, Tian X, Pang Y, Fu B, Zhou S. Effect of Vibration Timing on Mechanical and Durability Properties of Early-Strength Cement-Based Composites for Bridge Wet Joints. Materials. 2025; 18(20):4645. https://doi.org/10.3390/ma18204645

Chicago/Turabian StyleLi, Xiaodong, Jianxin Li, Xiang Tian, Yafeng Pang, Bing Fu, and Shuangxi Zhou. 2025. "Effect of Vibration Timing on Mechanical and Durability Properties of Early-Strength Cement-Based Composites for Bridge Wet Joints" Materials 18, no. 20: 4645. https://doi.org/10.3390/ma18204645

APA StyleLi, X., Li, J., Tian, X., Pang, Y., Fu, B., & Zhou, S. (2025). Effect of Vibration Timing on Mechanical and Durability Properties of Early-Strength Cement-Based Composites for Bridge Wet Joints. Materials, 18(20), 4645. https://doi.org/10.3390/ma18204645