Evaluation of the Tribological Behavior of Materials Used for the Production of Orthodontic Devices in 3D DLP Printing Technology, Due to Oral Cavity Environmental Factors

Abstract

1. Introduction

2. Materials and Methods

- 1.

- GR-10 Guide Resin with ASIGA UV Max Printer

- Material: GR-10 guide, manufactured by Pro3dure medical GmbH.

- Printer: ASIGA UV Max (ASM) (Asiga, Alexandria, NSW, Australia).

- -

- Technology: digital light processing (DLP)

- -

- Light Source: 385 nm

- -

- LCD Screen: 4.5-inch with an XY resolution of 1919 × 1081 dpi

- -

- Pixel Size (Resolution): 62 m

- 2.

- NextDent SG Resin with Phrozen Shuffle Lite Printer

- Material: NextDent SG, manufactured by NextDent.

- Printer: Phrozen Shuffle Lite (PSL) (Phrozen, Hsinchu City, Taiwan).

- -

- Technology: digital light processing (DLP)

- -

- LCD Screen: 5.5-inch with an XY resolution of 2560 × 1440 dpi

- -

- Pixel Size (Resolution): 47 m

2.1. Specimen Fabrication and Printing Parameters

2.1.1. GR-10 Resin with ASIGA UV Max Printer

- General Settings:

- -

- Material Profile Name: GR-10 clear-transparent—385

- -

- Heater Temperature: 30 °C

- -

- Heater Enabled: Yes

- Burn-In Layers:

- -

- Number of Layers: 1

- -

- Burn-In Exposure: 0.5 mm

- XY Scale Adjustment:

- -

- Scale Factor: 1.0085 (to compensate for resin shrinkage)

- Leveling Enabled: Yes

- -

- Leveling Height: 2.0 mm

- Tallest Feature Detection: Disabled

- Slope Angle: 20 °

- Side Feature Size: 2.0 mm

- Support Spacing: 3.0 mm

- Support Strength: 40

- Intersupport Connection: Enabled

- Contact Point Diameter: 0.5 mm

- Overshoot Length: 1.0 mm

- Maximum Support Width: 2.3 mm

- Side Faces on Supports: 8

- Aspect Ratio: 3.0

2.1.2. NextDent SG Resin with Phrozen Shuffle Lite Printer

- General Settings:

- -

- Layer Height: 0.05 mm

- -

- Retract Speed: 100 mm/min

- -

- Light-Off Delay: 3 s

- Bottom Layers (First 6 Layers):

- -

- Exposure Time: 35 s

- -

- Lift Height: 8 mm

- -

- Lift Speed: 50 mm/min

- Normal Layers:

- -

- Exposure Time: 3.5 s

- -

- Lift Height: 7 mm

- -

- Lift Speed: 50 mm/min

2.2. Justification of Parameters

- Manufacturer Recommendations: The printing parameters for both resins were selected based on the manufacturers’ guidelines, to ensure optimal curing and mechanical properties.

- -

- For GR-10 Resin: The manufacturer Pro3dure provides parameters specifically for the ASIGA UV Max printer.

- -

- For NextDent SG Resin: NextDent supplies parameters suitable for open 3D printing systems like the Phrozen Shuffle Lite.

- Reproducibility and Accuracy: Detailed printing parameters are provided, to ensure that the study can be accurately replicated by other researchers and to maintain consistency in specimen fabrication.

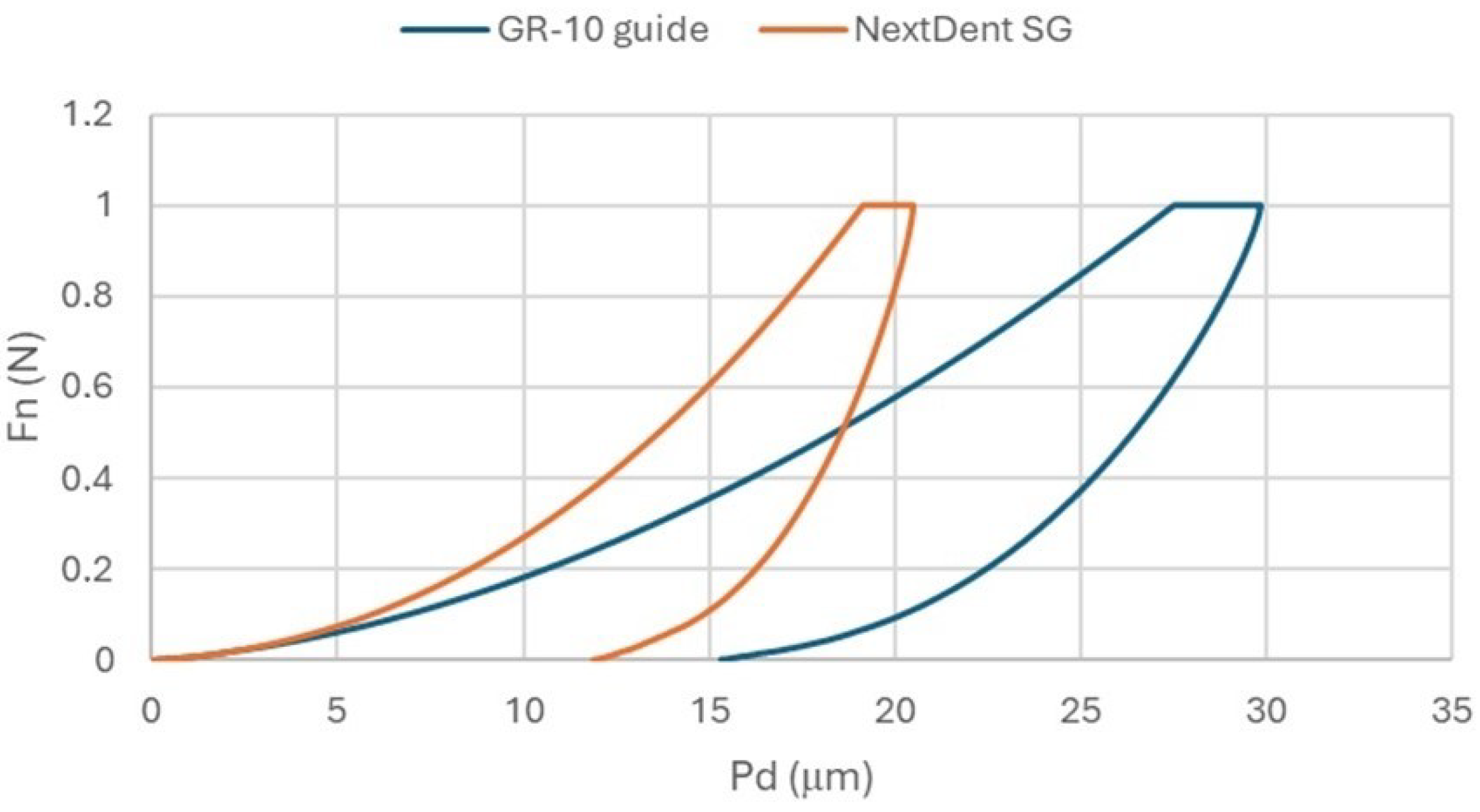

2.3. Indentation Properties

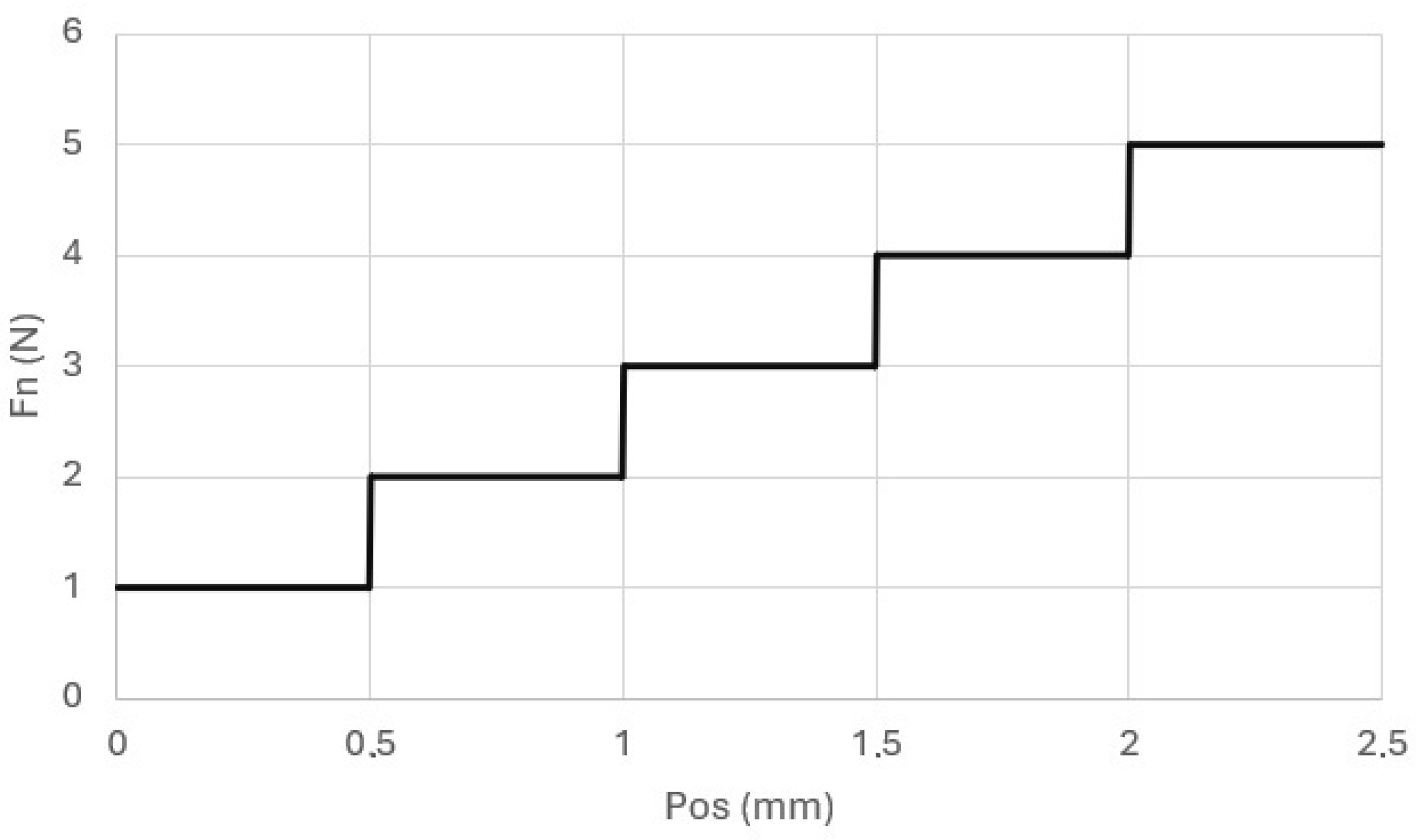

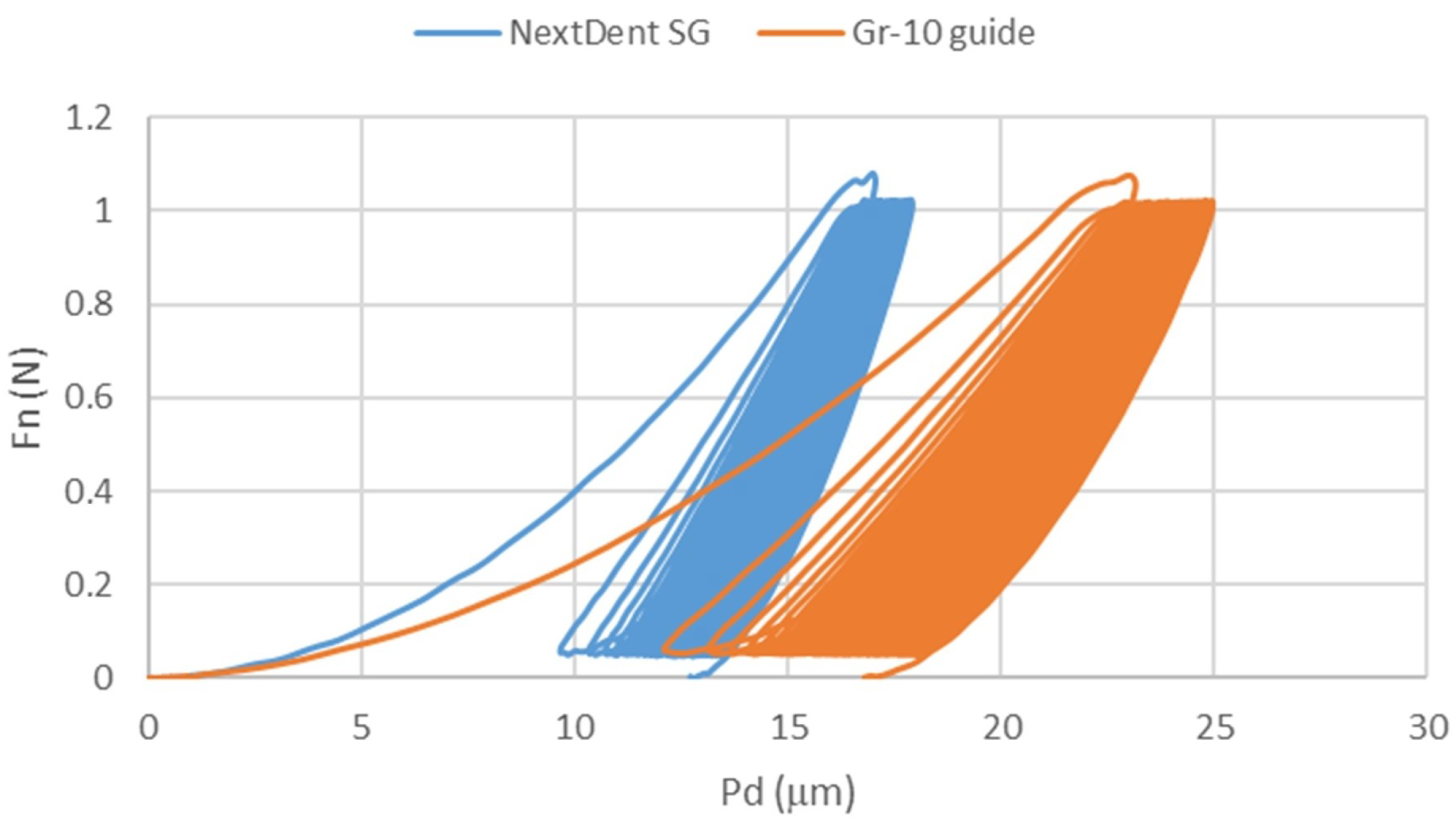

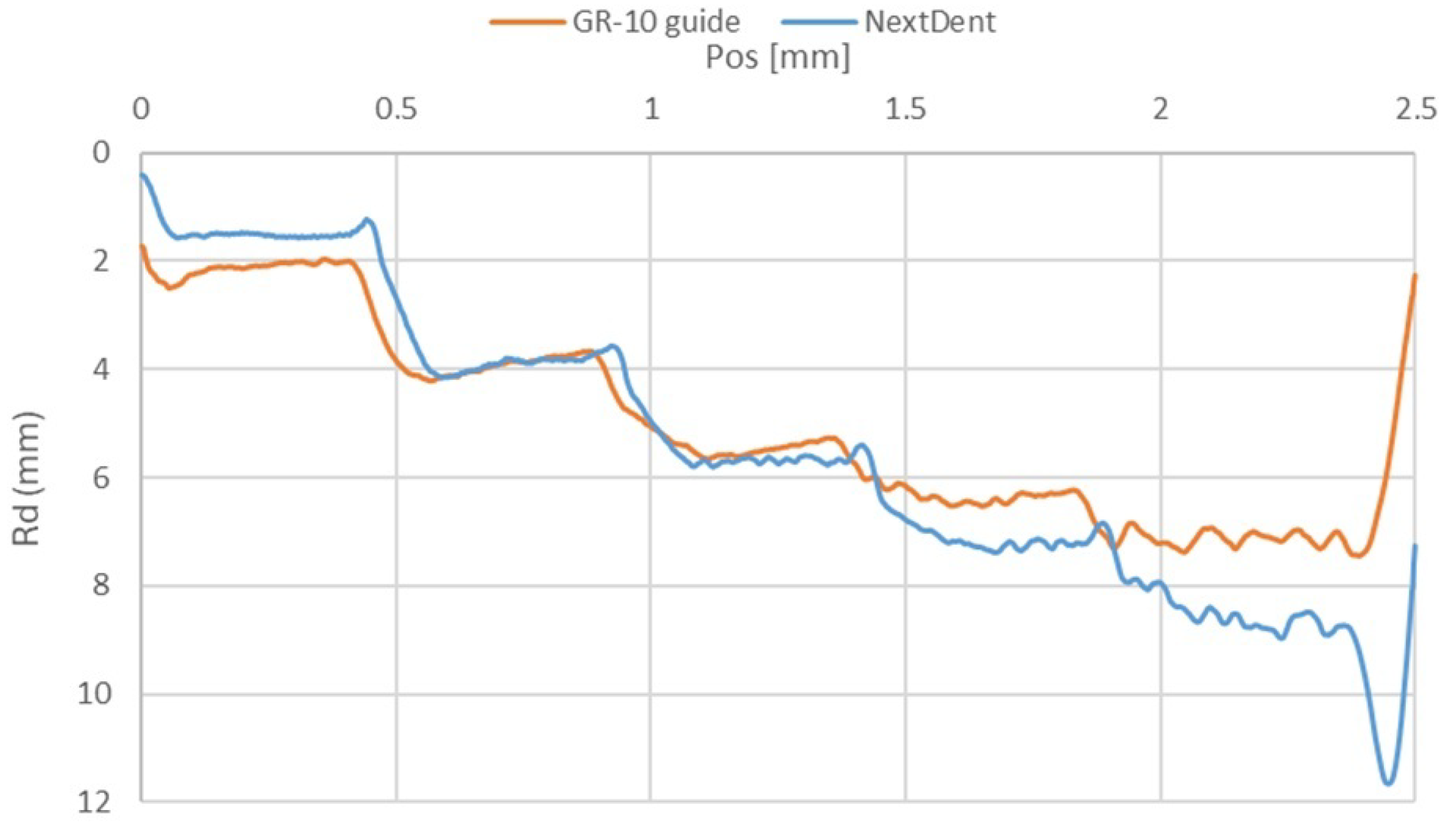

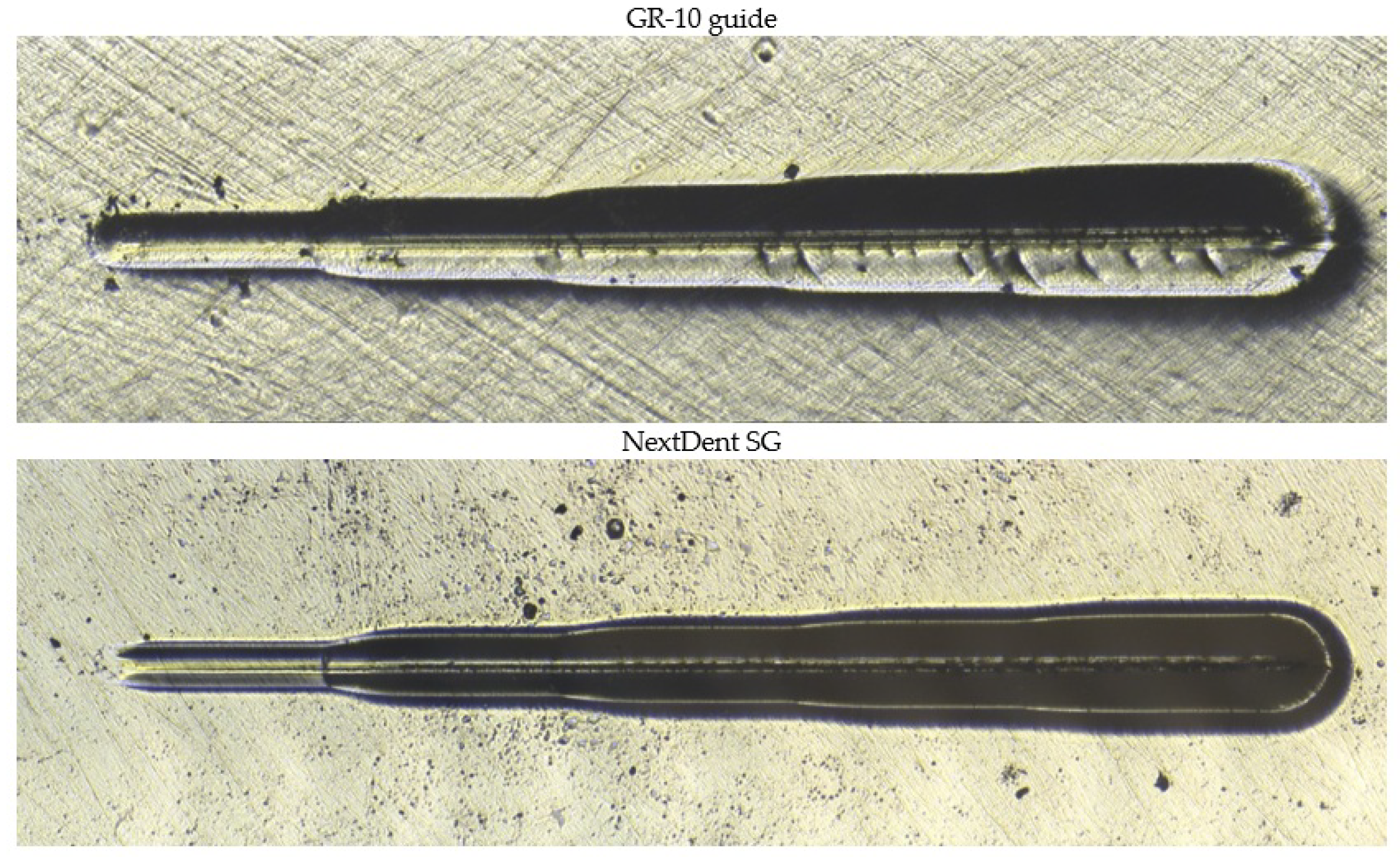

2.4. Scratch Test

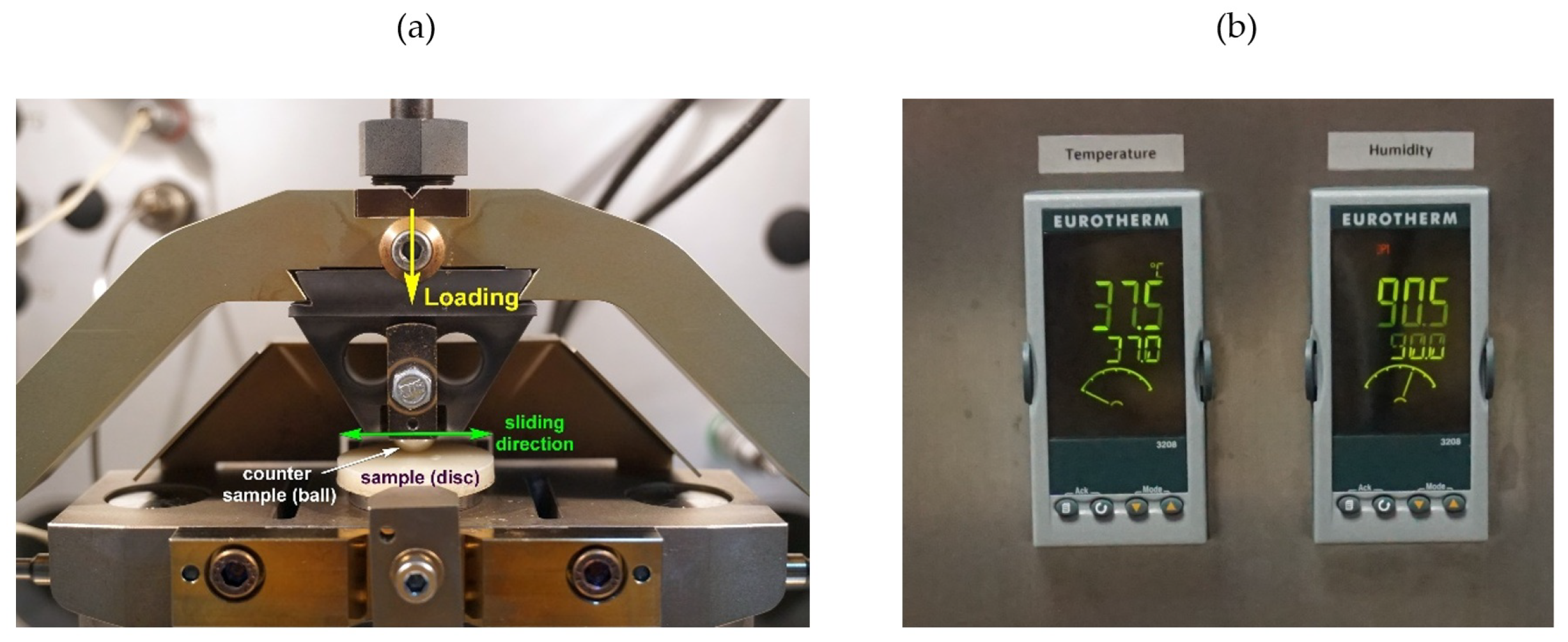

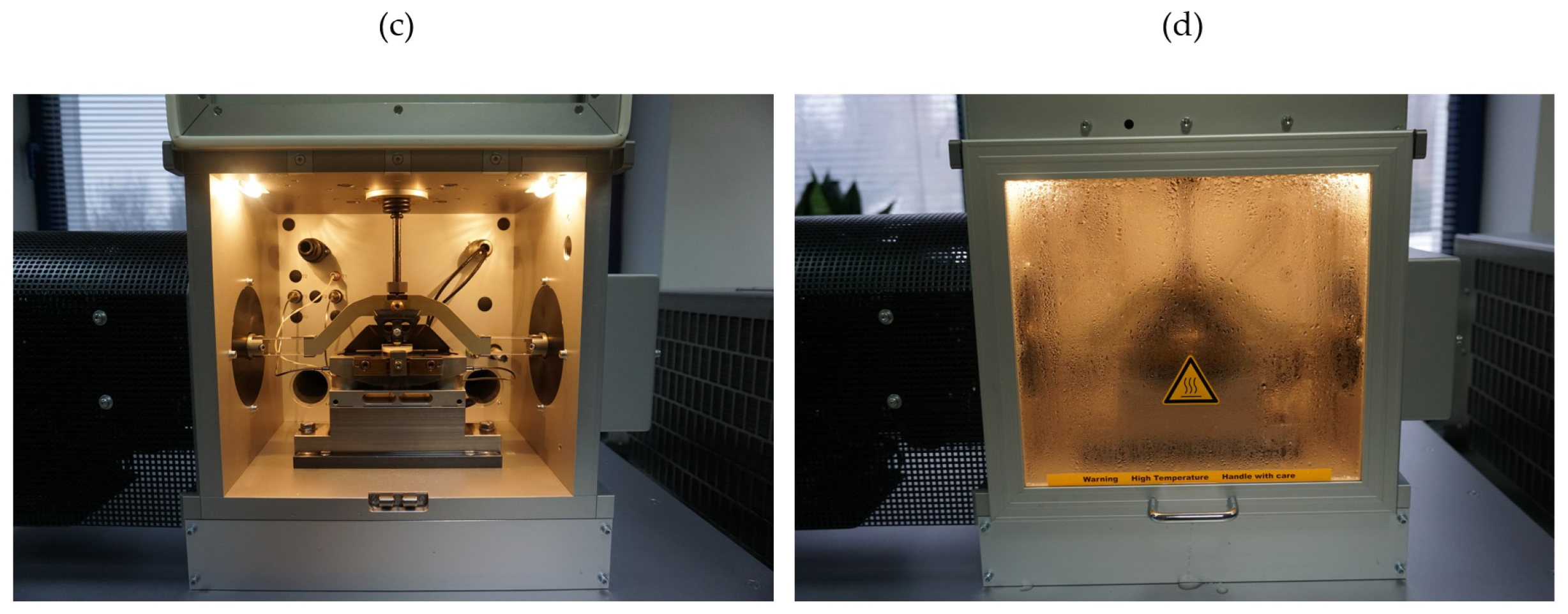

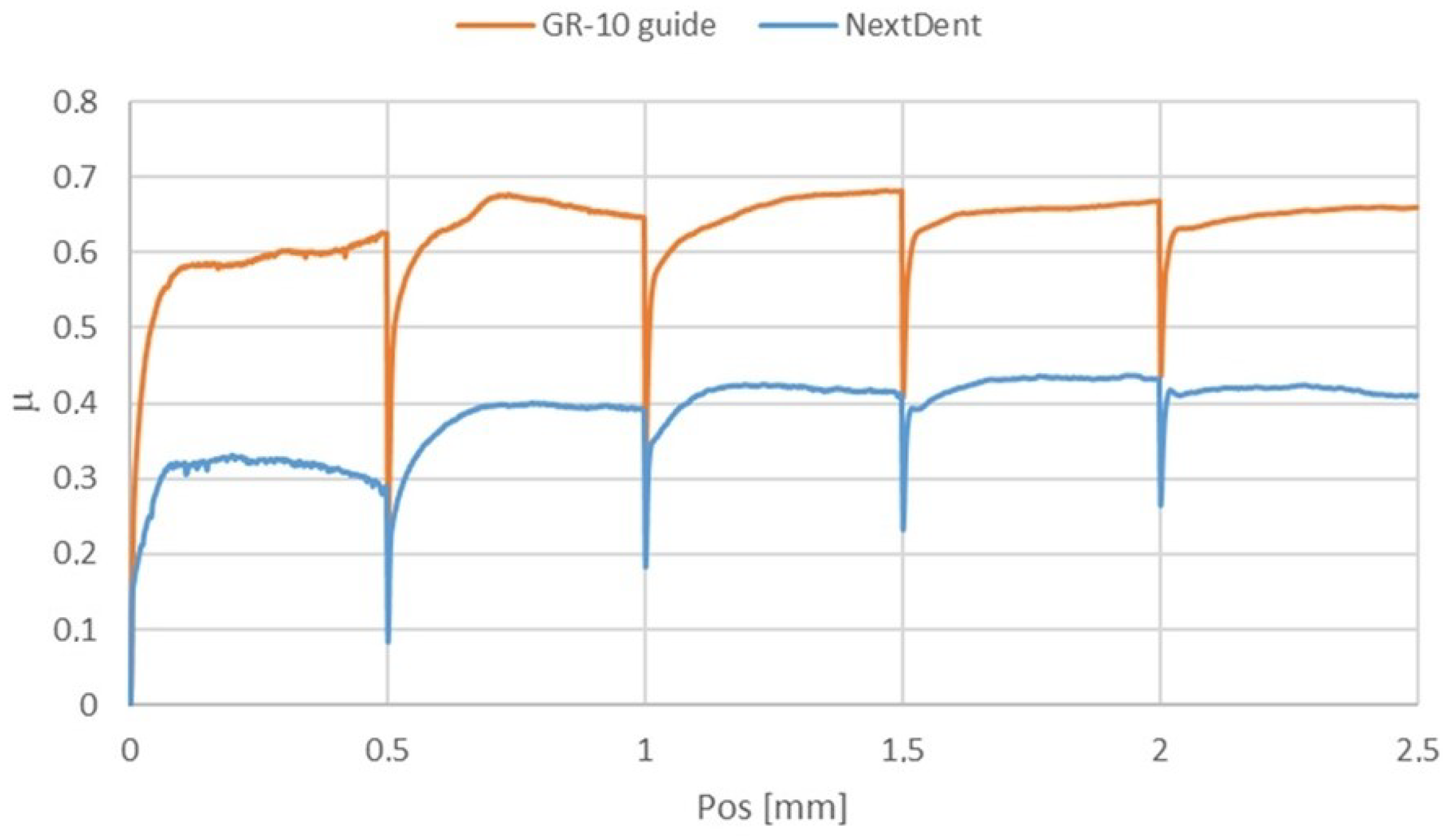

2.5. Sliding Friction

3. Results

3.1. Surface Topography

3.2. Indentation Properties

3.3. Scratch Test Results

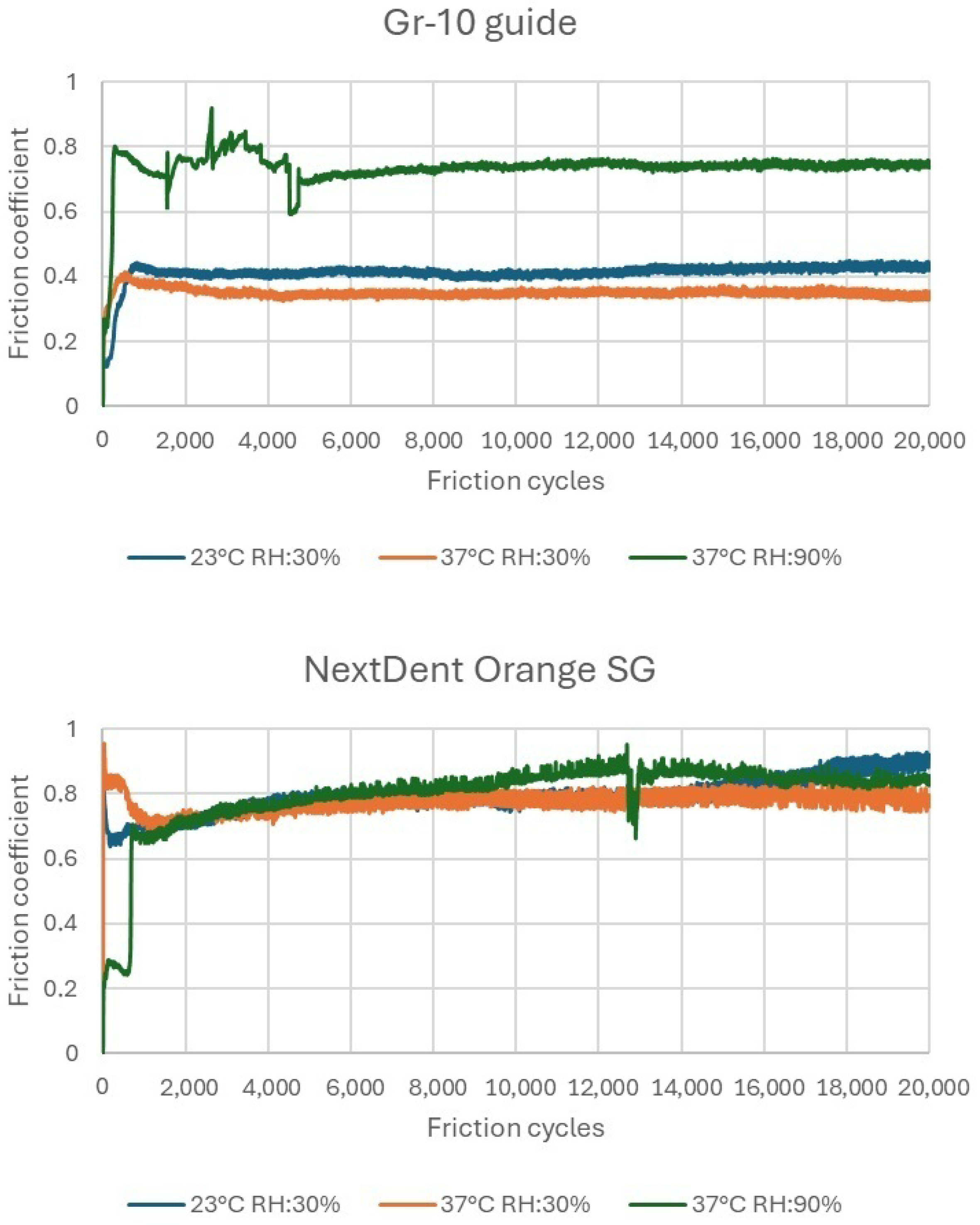

3.4. Sliding Friction and Wear Results

4. Discussion

5. Conclusions

- 1.

- Key Findings:

- (a)

- This study revealed that the mechanical and tribological properties of 3D-printed materials used in orthodontics, specifically NextDent SG and GR-10, are significantly affected by environmental conditions such as temperature and humidity.

- (b)

- Elevated temperature (37 °C) and high humidity (90%) were shown to have a substantial impact on the friction coefficients and wear behaviors of these materials.

- (c)

- Notably, the GR-10 material exhibited an unexpected increase in the friction coefficient under high humidity, which did not correlate with increased wear, indicating complex interactions between environmental factors and material properties.

- 2.

- Implications and Future Work:

- (a)

- The findings underscore the importance of conducting experimental evaluations to accurately assess the wear and performance of 3D-printed orthodontic materials.

- (b)

- Due to the limited number of studies and the diversity of available 3D printing technologies and materials, there is a pressing need for additional research in this area [71].

- (c)

- Future studies should focus on developing standardized testing methods to enable reliable comparisons across different materials and technologies.

- 3.

- Challenges in Comparative Analysis:

- (a)

- The ability to compare our results with those of other researchers was constrained by the scarcity of relevant studies and the significant variability in research methodologies.

- (b)

- This highlights the necessity for a more unified approach in testing and reporting, to advance the collective knowledge in this field.

- 4.

- Environmental Effects on Material Properties:

- (a)

- The pronounced impact of elevated temperature and humidity on the tribological properties of the tested materials suggests that in vivo conditions can considerably influence material performance.

- (b)

- The unexpected behavior of the GR-10 material under high humidity conditions warrants further investigation, to understand the underlying mechanisms.

- 5.

- Recommendations for Future Research:

- (a)

- Conducting cyclic tests is essential, as the properties of the tested materials were observed to change significantly after just a few dozen indentation cycles.

- (b)

- Long-term studies that simulate the actual oral environment over extended periods are recommended, to evaluate the durability and reliability of these materials in clinical applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mayer, J.; Kessler, A.; Wöstmann, B.; Ernst, C.-P. Influence of Cleaning Methods after 3D Printing on Two-Body Wear and Fracture Load of Resin-Based Temporary Crown and Bridge Material. Clin. Oral Investig. 2021, 25, 5987–5996. [Google Scholar] [CrossRef] [PubMed]

- Kessler, A.; Hedderich, J.; Ernst, C.-P.; Hassel, A.J. Three-Body Wear of 3D Printed Temporary Materials. Dent. Mater. 2019, 35, 1805–1812. [Google Scholar] [CrossRef] [PubMed]

- Tahayeri, A.; Morgan, M.C.; Fugolin, A.P.P.; Bompolaki, D.; Athirasala, A.; Pfeifer, C.S.; Ferracane, J.L.; Bertassoni, L.E. 3D Printed versus Conventionally Cured Provisional Crown and Bridge Dental Materials. Dent. Mater. 2018, 34, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Firlej, M.; Pieniak, D.; Niewczas, A.M.; Walczak, A.; Domagała, I.; Borucka, A.; Przystupa, K.; Igielska-Kalwat, J.; Jarosz, W.; Biedziak, B. Effect of Artificial Aging on Mechanical and Tribological Properties of CAD/CAM Composite Materials Used in Dentistry. Materials 2021, 14, 4678. [Google Scholar] [CrossRef]

- Domagała, I.; Przystupa, K.; Firlej, M.; Pieniak, D.; Niewczas, A.; Biedziak, B. Bending Behaviour of Polymeric Materials Used on Biomechanics Orthodontic Appliances. Materials 2020, 13, 5579. [Google Scholar] [CrossRef]

- Kroma, A.; Adamczak, O.; Sika, R.; Górski, F.; Kuczko, W.; Grześkowiak, K. Modern Reverse Engineering Methods Used to Modification of Jewelry. Adv. Sci. Technol. Res. J. 2020, 14, 298–306. [Google Scholar] [CrossRef]

- Jabłońska, M.; Jurczak, W.; Ozimina, D.; Adamiak, M. Increasing the Operational Reliability of a Ship by Using a Composite Impeller in the Event of Hydrophore Pump Failure. Eksploat. Niezawodn. Maint. Reliab. 2023, 25, 18. [Google Scholar] [CrossRef]

- Prause, E.; Hey, J.; Beuer, F.; Schmidt, F. Wear Resistance of 3D-Printed Materials: A Systematic Review. Dent. Rev. 2022, 2, 100051. [Google Scholar] [CrossRef]

- Gómez-Mascaraque, L.G.; Aguilar, M.R.; San Román, J. The Use of Smart Polymers in Medical Devices for Minimally Invasive Surgery, Diagnosis, and Other Applications. In Smart Polymers and Their Applications; Aguilar, M.R., San Román, J., Eds.; Woodhead Publishing: Cambridge, UK, 2014; pp. 481–531. [Google Scholar] [CrossRef]

- Kilikevičius, A.; Maciūnas, K.; Strazdaitė, V.; Niaura, G.; Rutkūnas, V.; Ostrauskaite, J. Modelling of Silk-Reinforced PDMS Properties for Soft Tissue Engineering Applications. Technol. Health Care 2018, 26, 679–688. [Google Scholar] [CrossRef]

- Lamprou, D.A.; Narayan, R. Polymeric Coatings and Their Fabrication for Medical Devices. In Encyclopedia of Biomedical Engineering; Narayan, R., Ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 177–187. [Google Scholar] [CrossRef]

- Chopra, A.M.; Reddy, A.S.; Muliya, V.S.; Weisz, G.; Ternus, B.; Khheria, B.K. Polymer Coating Embolism from Intravascular Medical Devices: A Clinical Literature Review. Cardiovasc. Pathol. 2017, 30, 45–54. [Google Scholar] [CrossRef]

- Piedra-Cascón, W.; Álvarez-Quintana, J.; López-Álvarez, M.; Rodríguez-Urrego, F.; Martínez-González, J. 3D Printing Parameters, Supporting Structures, Slicing, and Postprocessing Procedures of Vat-Polymerization Additive Manufacturing Technologies: A Narrative Review. J. Dent. 2021, 110, 103630. [Google Scholar] [CrossRef] [PubMed]

- International Organization for Standardization ISO 17296-2:2015; Additive Manufacturing—General Principles—Part 2: Overview of Process Categories and Feedstock. ISO: Geneva, Switzerland, 2015.

- Bagheri, A.; Jin, J. Photopolymerization in 3D Printing. ACS Appl. Polym. Mater. 2019, 1, 593–611. [Google Scholar] [CrossRef]

- Dikova, T.D.; Dzhendov, D.A.; Ivanov, D.; Bliznakova, K. Dimensional Accuracy and Surface Roughness of Polymeric Dental Bridges Produced by Different 3D Printing Processes. Arch. Mater. Sci. Eng. 2018, 94, 49–56. [Google Scholar] [CrossRef]

- Hirai, K.; Ikawa, T.; Shigeta, Y.; Shigemoto, S.; Ogawa, T. Evaluation of Sleep Bruxism with a Novel Designed Occlusal Splint. J. Prosthodont. Res. 2017, 61, 333–343. [Google Scholar] [CrossRef]

- Jańczuk, Z. Stomatologia Zachowawcza: Zarys Kliniczny; PZWL: Warsaw, Poland, 2008. [Google Scholar]

- Luty, W. Badania Empiryczne. Wybrane Zagadnienia Metodyczne; ITeE: Radom, Poland, 1997. [Google Scholar]

- ISO 25178; Geometrical Product Specifications (GPS)—Surface Texture: Areal. ISO: Geneva, Switzerland, 2012.

- Oliver, W.C.; Pharr, G.M. Measurement of Hardness and Elastic Modulus by Instrumented Indentation: Advances in Understanding and Refinements to Methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Sneddon, I.N. The Relation between Load and Penetration in the Axisymmetric Boussinesq Problem for a Punch of Arbitrary Profile. Int. J. Eng. Sci. 1965, 3, 47–57. [Google Scholar] [CrossRef]

- Hardiman, M.; Vaughan, T.J.; McCarthy, C.T. The Effects of Pile-Up, Viscoelasticity and Hydrostatic Stress on Polymer Matrix Nanoindentation. Polym. Test. 2016, 52, 157–166. [Google Scholar] [CrossRef]

- Maeda, N.; Chen, N.; Tirrell, M.; Israelachvili, J.N. Adhesion and Friction Mechanisms of Polymer-on-Polymer Surfaces. Science 2002, 297, 379–382. [Google Scholar] [CrossRef]

- Ferracane, J.L. Hygroscopic and Hydrolytic Effects in Dental Polymer Networks. Dent. Mater. 2006, 22, 211–222. [Google Scholar] [CrossRef]

- Hebda, M. Procesy Tarcia, Smarowania i Zużywania Maszyn; ITeE: Radom, Poland, 2007. [Google Scholar]

- Barbosa, L.M.; da Silva, W.M.; de Mello, J.D.B. Orthomicrotribometer. Wear 2019, 426–427, 1729–1739. [Google Scholar] [CrossRef]

- Zhang, R.; Han, B.; Liu, X. Functional Surface Coatings on Orthodontic Appliances: Reviews of Friction Reduction, Antibacterial Properties, and Corrosion Resistance. Int. J. Mol. Sci. 2023, 24, 6919. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Zheng, J. Tribology of Dental Materials: A Review. J. Phys. D Appl. Phys. 2008, 41, 113001. [Google Scholar] [CrossRef]

- Every, R.G.; Kühne, W.G. Biomodal Wear of Mammalian Teeth. In Early Mammals; Kermack, D.M., Kermack, K.A., Eds.; Academic Press: London, UK, 1971; pp. 23–27. [Google Scholar]

- Mair, L.H.; Duxbury, A.J.; Dorr, P.K.; Beech, I.D.; Gilmour, W.J.; Jones, S.S. Wear: Mechanisms, Manifestations and Measurement. Report of a Workshop. J. Dent. 1996, 24, 141–148. [Google Scholar] [CrossRef]

- Peterson, L.J. Peterson’s Principles of Oral and Maxillofacial Surgery, 3rd ed.; PMPH-USA: Shelton, CT, USA, 2012. [Google Scholar]

- Ferendiuk, E.; Zajdel, K.; Pihut, M. Incidence of Otolaryngological Symptoms in Patients with Temporomandibular Joint Dysfunctions. Biomed Res. Int. 2014, 2014, 824684. [Google Scholar] [CrossRef][Green Version]

- Beddis, H.; Pemberton, M.; Davies, S. Sleep Bruxism: An Overview for Clinicians. Br. Dent. J. 2018, 225, 497–501. [Google Scholar] [CrossRef]

- Wieleba, W. Bezobsługowe Łożyska Ślizgowe z Polimerów Termoplastycznych; Oficyna Wydawnicza Politechniki Wrocławskiej: Wrocław, Poland, 2013. [Google Scholar]

- Slapnik, J.; Stiller, T.; Wilhelm, T.; Hausberger, A. Influence of Solid Lubricants on the Tribological Performance of Photocurable Resins for Vat Photopolymerization. Lubricants 2020, 8, 104. [Google Scholar] [CrossRef]

- Chernets, M. Method of Calculation of Tribotechnical Characteristics of the Metal-Polymer Gear, Reinforced with Glass Fiber, Taking into Account the Correction of Tooth. Eksploat. Niezawodn. Maint. Reliab. 2019, 21, 546–552. [Google Scholar] [CrossRef]

- Mangal, U.; Min, Y.J.; Seo, J.-Y.; Kim, D.-E.; Cha, J.-Y.; Lee, K.-J.; Kwon, J.-S.; Choi, S.-H. Changes in Tribological and Antibacterial Properties of Poly(Methyl Methacrylate)-Based 3D-Printed Intraoral Appliances by Incorporating Nanodiamonds. J. Mech. Behav. Biomed. Mater. 2020, 110, 103992. [Google Scholar] [CrossRef]

- Albo Hassan, A.F.; Jameel, A.; Nahidh, M.; Hamid, D. Wear Resistance of Occlusal Splint Materials. J. Stomatol. 2019, 72, 215–221. [Google Scholar]

- Chun, K.J.; Choi, H.H.; Lee, J.Y. Comparison of Mechanical Property and Role between Enamel and Dentin in the Human Teeth. J. Dent. Biomech. 2014, 5, 1758736014520809. [Google Scholar] [CrossRef]

- Niewczas, A.M.; Pieniak, D.; Ogrodnik, P. Reliability Analysis of Strength of Dental Composites Subjected to Different Photopolymerization Procedures. Eksploat. Niezawodn. Maint. Reliab. 2012, 14, 249–255. [Google Scholar]

- Pieniak, D.; Niewczas, A.; Kordos, P. Influence of Thermal Fatigue and Ageing on the Microhardness of Polymer-Ceramic Composites for Biomedical Applications. Eksploat. Niezawodn. Maint. Reliab. 2012, 14, 181–188. [Google Scholar]

- Dulebová, Ľ.; Garbacz, T. The Effect of Particulate Fillers on Hardness of Polymer Composite. Adv. Sci. Technol. Res. J. 2017, 11, 66–71. [Google Scholar] [CrossRef]

- Świderski, A.; Borucka, A.; Jacyna-Gołda, I.; Szczepański, E. Wear of Brake System Components in Various Operating Conditions of Vehicle in the Transport Company. Eksploat. Niezawodn. Maint. Reliab. 2019, 21, 1–9. [Google Scholar] [CrossRef]

- Nowakowska-Toporowska, A.; Małecka, K.; Raszewski, Z.; Wieckiewicz, W. Changes in Hardness of Addition-Polymerizing Silicone-Resilient Denture Liners after Storage in Artificial Saliva. J. Prosthet. Dent. 2019, 121, 317–321. [Google Scholar] [CrossRef] [PubMed]

- Mystkowska, J.; Dąbrowski, J.R. Tribological Characteristics of the Kinematic Couple: Tooth–Composite Material for Permanent Dental Fillings. Eksploat. Niezawodn. Maint. Reliab. 2010, 12, 123–133. [Google Scholar]

- Pieniak, D.; Walczak, A.; Walczak, M.; Przystupa, K.; Niewczas, A.M. Hardness and Wear Resistance of Dental Biomedical Nanomaterials in a Humid Environment with Non-Stationary Temperatures. Materials 2020, 13, 1255. [Google Scholar] [CrossRef]

- Matthews, A.; Leyland, A. The Role of Nanocomposite Coatings in Surface Engineering. In Surface Engineering—Proceedings of the 5th International Surface Engineering Conference; ASM International: Materials Park, OH, USA, 2006. [Google Scholar]

- Łępicka, M.; Grądzka-Dahlke, M.; Pieniak, D.; Pasierbiewicz, K.; Kryńska, K.; Niewczas, A. Tribological Performance of Titanium Nitride Coatings: A Comparative Study on TiN-Coated Stainless Steel and Titanium Alloy. Wear 2019, 422–423, 68–77. [Google Scholar] [CrossRef]

- Myshkin, N.K.; Petrokovets, M.I.; Kovalev, A.V. Tribology of Polymers: Adhesion, Friction, Wear, and Mass-Transfer. Tribol. Int. 2005, 38, 910–921. [Google Scholar] [CrossRef]

- Krzyżak, A.; Racinowski, D.; Szczepaniak, R.; Kosicka, E. An Assessment of the Reliability of CFRP Composites Used in Nodes of Friction after Impact of UV-A Impacts and Thermal Shocks. Eksploat. Niezawodn. Maint. Reliab. 2023, 25, 174221. [Google Scholar] [CrossRef]

- Bhushan, B. Principles and Applications of Tribology, 2nd ed.; John Wiley & Sons, Ltd.: Chichester, UK, 2013. [Google Scholar]

- Hanon, M.M.; Ghaly, A.; Zsidai, L.; Klébert, S. Tribological Characteristics of Digital Light Processing (DLP) 3D Printed Graphene/Resin Composite: Influence of Graphene Presence and Process Settings. Mater. Des. 2022, 218, 110718. [Google Scholar] [CrossRef]

- Abdelbary, A. Wear of Polymer Composites. In Wear of Polymers and Composites; Abdelbary, A., Ed.; Woodhead Publishing: Cambridge, UK, 2014; pp. 133–158. [Google Scholar]

- Pieniak, D.; Kubiak, A.; Firlej, M.; Pieniak, K.; Niewczas, A.M. Testing Methods for Determining the Scratch Resistance of Firefighter’s Helmets. Przemysł Chem. 2019, 98, 1313–1316. [Google Scholar]

- Niewczas, A.; Pieniak, D.; Bachanek, T.; Surowska, B.; Bieniaś, J.; Pałka, K. Prognosing of Functional Degradation of Bio-Mechanical Systems Exemplified by the Tooth-Composite Filling System. Eksploat. Niezawodn. Maint. Reliab. 2010, 12, 24–32. [Google Scholar]

- Chen, Z.; Wu, L.Y. Tribology of Polymeric Nanocomposites. In Tribology of Polymeric Nanocomposites, 2nd ed.; Friedrich, K., Schlarb, A.K., Eds.; Butterworth-Heinemann: Oxford, UK, 2013; pp. 467–505. [Google Scholar]

- Bora, M.O.; Coban, O.; Sinmazçelik, T. Mechanical Properties and Performance of Polymer Matrix Composites. J. Reinf. Plast. Compos. 2010, 29, 1467–1480. [Google Scholar]

- Palaniappan, S.; Celis, J.P.; Van Meerbeek, B.; Peumans, M.; Lambrechts, P. Correlating In Vitro Scratch Test with In Vivo Contact Free Occlusal Area Wear of Contemporary Dental Composites. Dent. Mater. 2013, 29, 259–268. [Google Scholar] [CrossRef]

- Andena, L.; Chiarot, G. Scratch Hardness as a Quasi-Intrinsic Parameter to Measure the Scratch Resistance of Polymers. Wear 2022, 514–515, 204562. [Google Scholar] [CrossRef]

- Firlej, M.; Pieniak, D.; Kubiak, A.; Niewczas, A.; Pieniak, K. Analysis of Indentation Hardness, Scratch Resistance, and Sliding Wear of Polymeric Materials from 3D DLP UV Resin. Przemysł Chem. 2021, 100, 35–39. [Google Scholar] [CrossRef]

- Potewiratnanond, P.; Ekrojanakul, C.; Harikul, T. Wear Effects between Polymethyl Methacrylate Occlusal Splints and Opposing Dentin Surfaces during Bruxism Mimicking Events. BDJ Open 2023, 9, 21. [Google Scholar] [CrossRef]

- Olszewski, A. Łożyska Ślizgowe Smarowane Wodą. In Eksploatacja Systemów Tribologicznych; Ozimina, D., Ed.; Politechnika Świętokrzyska: Kielce, Poland, 2013; Volume 2, pp. 75–90. [Google Scholar]

- Tropp, M.; Lukáč, M.; Benko, M.; Brumerčík, F.; Krzysiak, Z.; Nieoczym, A. Sealing Technology for Vacuum Applications Working by Increased Temperatures. In Advances in Mechanisms Design; Springer: Cham, Switzerland, 2020; pp. 185–192. [Google Scholar] [CrossRef]

- Lohbauer, U.; Belli, R.; Ferracane, J.L. Factors Involved in Mechanical Fatigue Degradation of Dental Resin Composites. J. Dent. Res. 2013, 92, 584–591. [Google Scholar] [CrossRef]

- Finer, Y.; Santerre, J.P. The Influence of Resin Chemistry on a Dental Composite’s Biodegradation. J. Biomed. Mater. Res. Part A 2004, 69A, 233–246. [Google Scholar] [CrossRef]

- Ammar-Khodja, I.; Picard, C.; Fois, M.; Marais, C.; Netchitailo, P. Preliminary Results on Thermo-Oxidative Ageing of Multi-Hole Carbon/Epoxy Composites. Compos. Sci. Technol. 2009, 69, 1427–1431. [Google Scholar] [CrossRef]

- Sobków, D.; Barton, J.; Czaja, K.; Sudoł, M.; Mazoń, B. Studies on the Resistance of Materials to the Impact of Natural Environmental Factors. Chemik 2014, 68, 347–354. [Google Scholar]

- Merdas, I.; Thominette, F.; Tcharkhtchi, A.; Verdu, J. Factors Governing Water Absorption by Composite Matrices. Compos. Sci. Technol. 2002, 62, 487–492. [Google Scholar] [CrossRef]

- Xian, G.; Bai, Y.; Qi, X.; Wang, J.; Tian, J.; Xiao, H. Hygrothermal Aging on the Mechanical Property and Degradation Mechanism of Carbon Fiber Reinforced Epoxy Composites Modified by Nylon 6. J. Mater. Res. Technol. 2021, 13, 236–246. [Google Scholar] [CrossRef]

- Rouf, S.; Raina, A.; Haq, M.I.U.; Naveed, N.; Jeganmohan, S.; Kichloo, A.F. 3D Printed Parts and Mechanical Properties: Influencing Parameters, Sustainability Aspects, Global Market Scenario, Challenges, and Applications. Adv. Ind. Eng. Polym. Res. 2022, 5, 143–158. [Google Scholar] [CrossRef]

| Parameter [µm] | NextDent SG Orange | GR-10 Guide | ||

|---|---|---|---|---|

| Stan | * | ** | * | ** |

| Sq | 6.615 | 0.020 | 4.113 | 0.034 |

| Ssk | 1.479 | −0.532 | 0.943 | −0.376 |

| Sku | 7.814 | 6.453 | 4.679 | 4.076 |

| Sp | 39.180 | 0.250 | 25.554 | 0.305 |

| Sv | 28.840 | 0.407 | 9.719 | 0.396 |

| Sz | 68.020 | 0.657 | 35.273 | 0.701 |

| Sa | 4.772 | 0.016 | 3.178 | 0.027 |

| Parameters | N (Number of Measurements) = 15 (3 × 5), n (Number of Samples) = 3 | Gr 10 Guide | NextDent SG |

|---|---|---|---|

| HIT [MPa] | Mean | 57.605 | 118.664 |

| Std Dev | 5.025 | 6.640 | |

| Min | 51.804 | 111.854 | |

| Max | 69.489 | 136.399 | |

| EIT [MPa] | Mean | 1489.947 | 2954.660 |

| Std Dev | 140.118 | 93.034 | |

| Min | 1288.765 | 2796.381 | |

| Max | 1725.304 | 3152.841 | |

| S [N/µm] | Mean | 0.256 | 0.352 |

| Std Dev | 0.026 | 0.008 | |

| Min | 0.201 | 0.342 | |

| Max | 0.310 | 0.369 |

| Material | GR-10 Guide | NextDent SG | ||||

|---|---|---|---|---|---|---|

| Temperature | 23 °C RH:30% | 37 °C RH:30% | 37 °C RH:90% | 23 °C RH:30% | 37 °C RH:30% | 37 °C RH:90% |

| Maximum depth [m] | 58.84 | 82.16 | 88.218 | 88.518 | 131.354 | 87.895 |

| Volume [] | 0.081 | 0.175 | 0.128 | 0.221 | 0.440 | 0.161 |

| Cross section area [] | 3.758 | 5.169 | 5.047 | 6.770 | 8.864 | 4.658 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Snarski-Adamski, A.; Pieniak, D.; Krzysiak, Z.; Firlej, M.; Brumerčík, F. Evaluation of the Tribological Behavior of Materials Used for the Production of Orthodontic Devices in 3D DLP Printing Technology, Due to Oral Cavity Environmental Factors. Materials 2025, 18, 301. https://doi.org/10.3390/ma18020301

Snarski-Adamski A, Pieniak D, Krzysiak Z, Firlej M, Brumerčík F. Evaluation of the Tribological Behavior of Materials Used for the Production of Orthodontic Devices in 3D DLP Printing Technology, Due to Oral Cavity Environmental Factors. Materials. 2025; 18(2):301. https://doi.org/10.3390/ma18020301

Chicago/Turabian StyleSnarski-Adamski, Andrzej, Daniel Pieniak, Zbigniew Krzysiak, Marcel Firlej, and František Brumerčík. 2025. "Evaluation of the Tribological Behavior of Materials Used for the Production of Orthodontic Devices in 3D DLP Printing Technology, Due to Oral Cavity Environmental Factors" Materials 18, no. 2: 301. https://doi.org/10.3390/ma18020301

APA StyleSnarski-Adamski, A., Pieniak, D., Krzysiak, Z., Firlej, M., & Brumerčík, F. (2025). Evaluation of the Tribological Behavior of Materials Used for the Production of Orthodontic Devices in 3D DLP Printing Technology, Due to Oral Cavity Environmental Factors. Materials, 18(2), 301. https://doi.org/10.3390/ma18020301