Fatigue-Limit Assessment via Infrared Thermography for a High-Strength Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Specimens

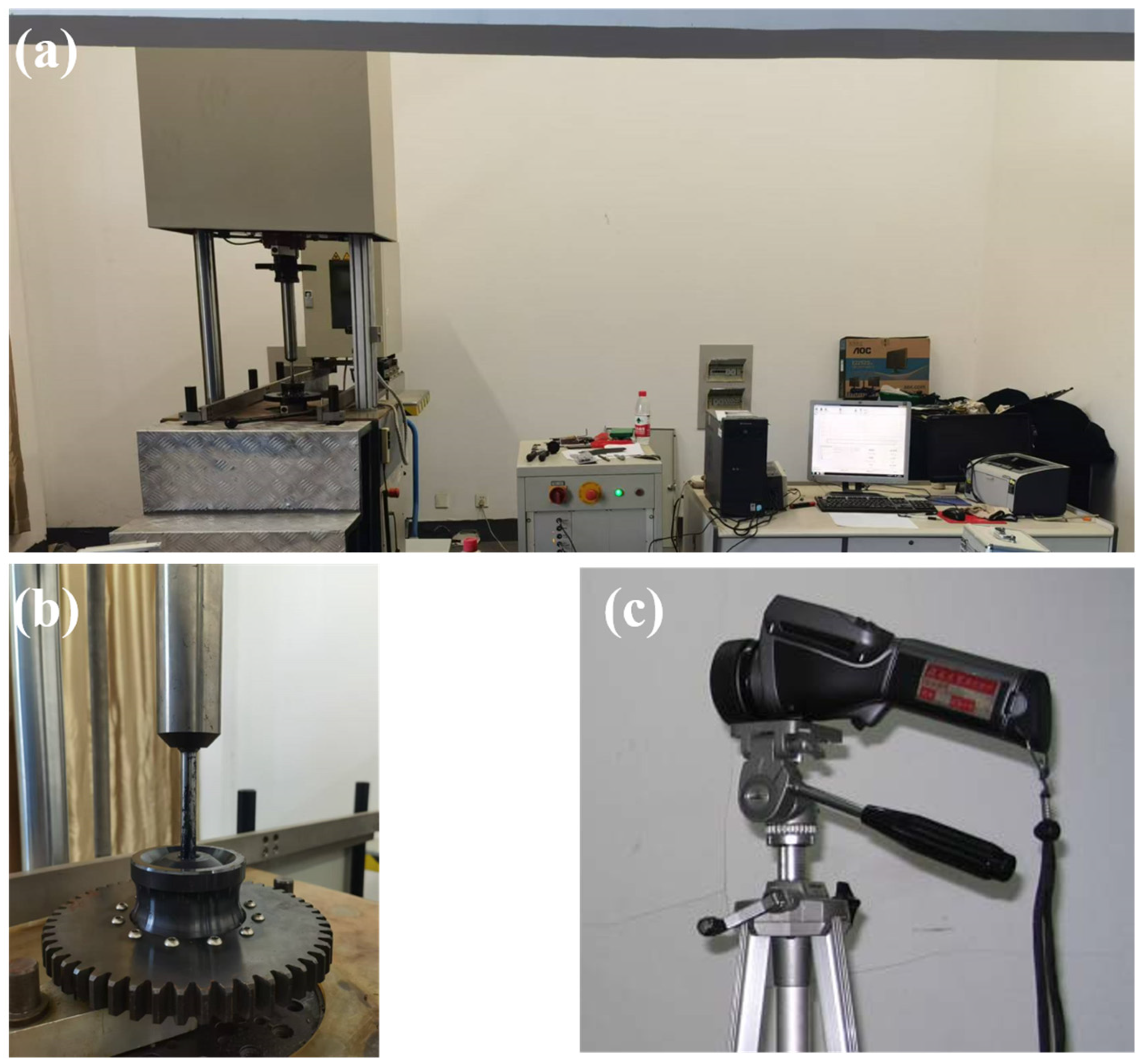

2.2. Experimental Methods

2.3. Theory of Fatigue Intrinsic Damping During Fatigue Loading

3. Results and Discussions

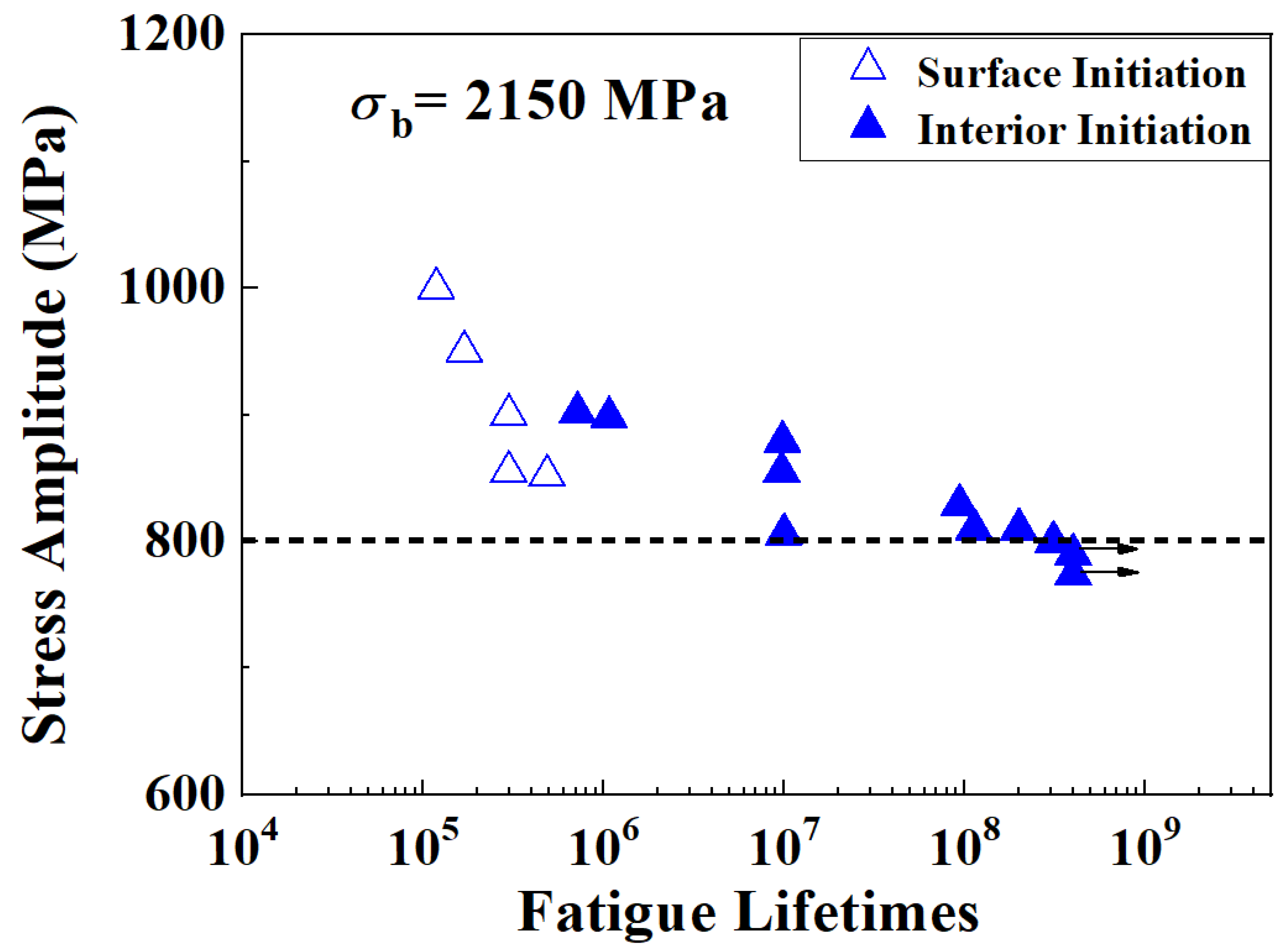

3.1. Traditional Fatigue-Testing Results

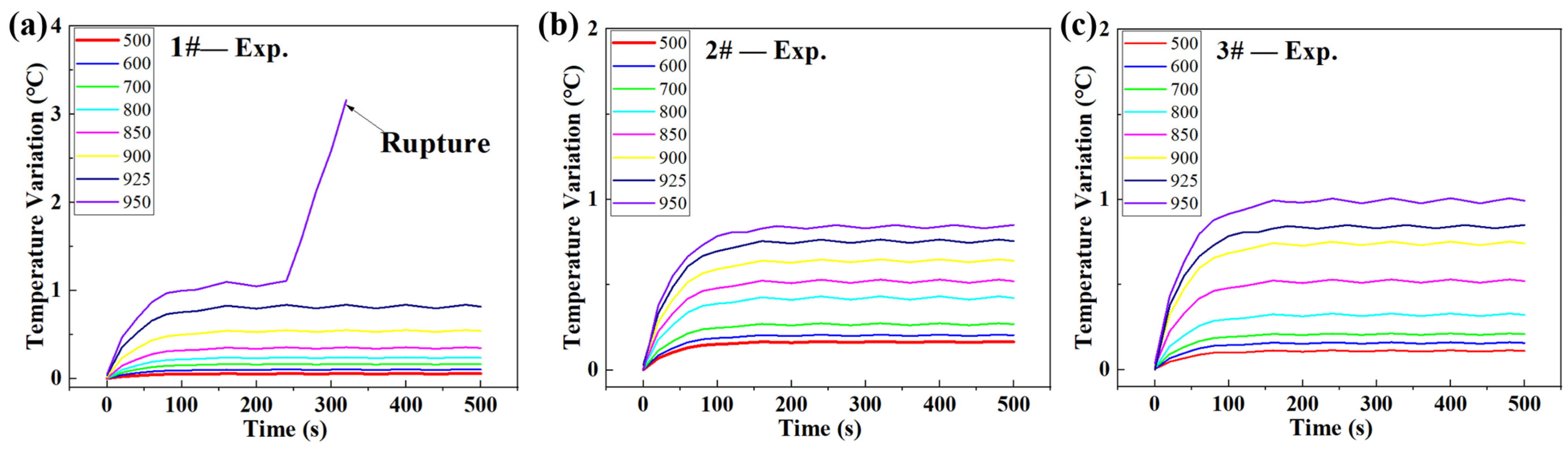

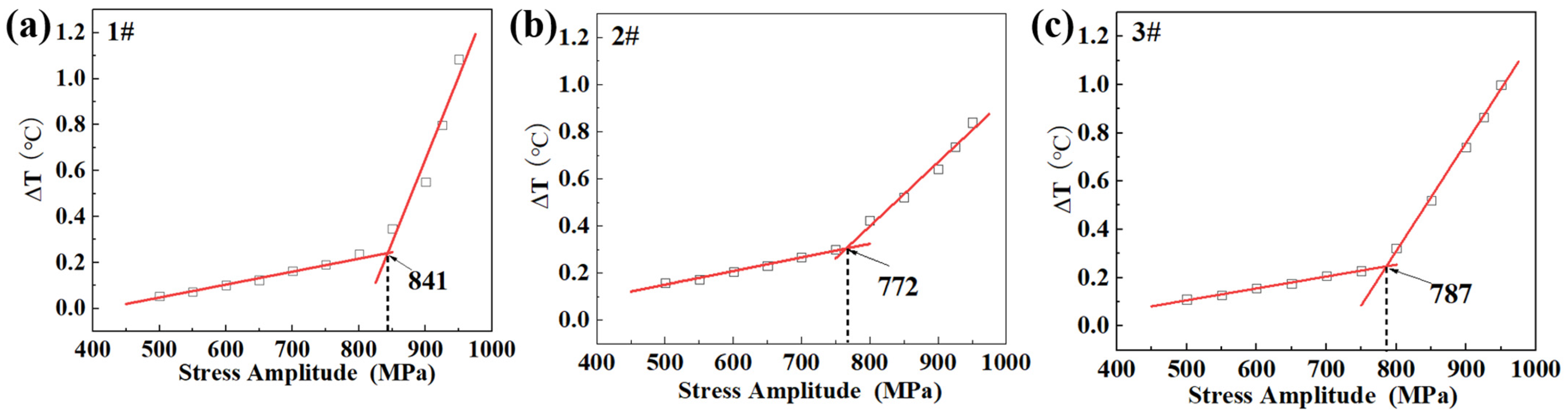

3.2. Temperature Variation of Specimens and Determination of Fatigue Limits

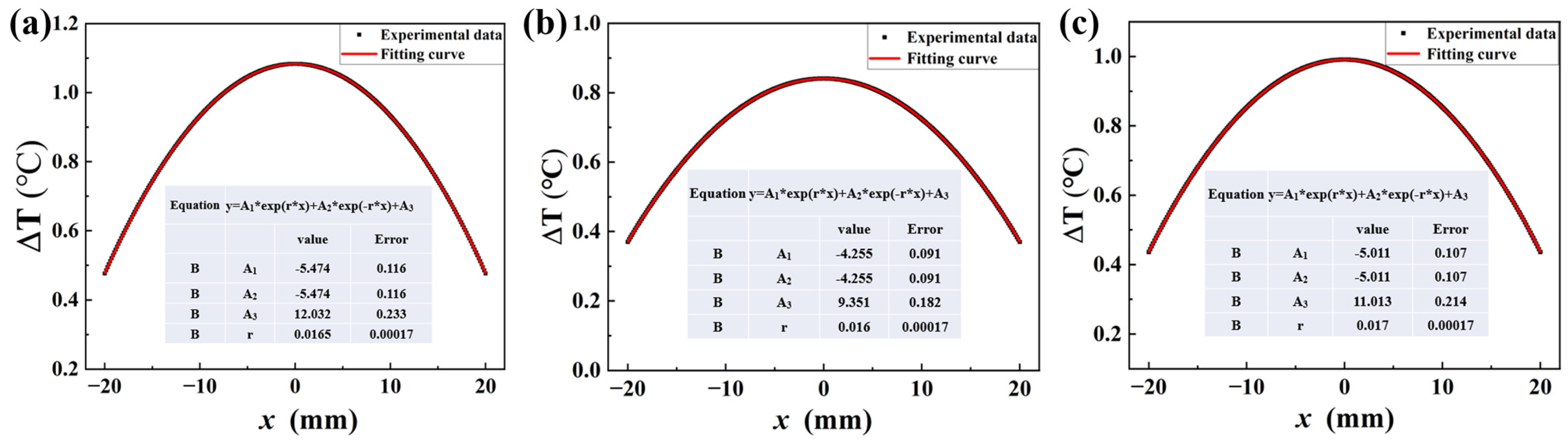

3.3. The Derivation of Intrinsic Dissipation Based on Temperature Distribution

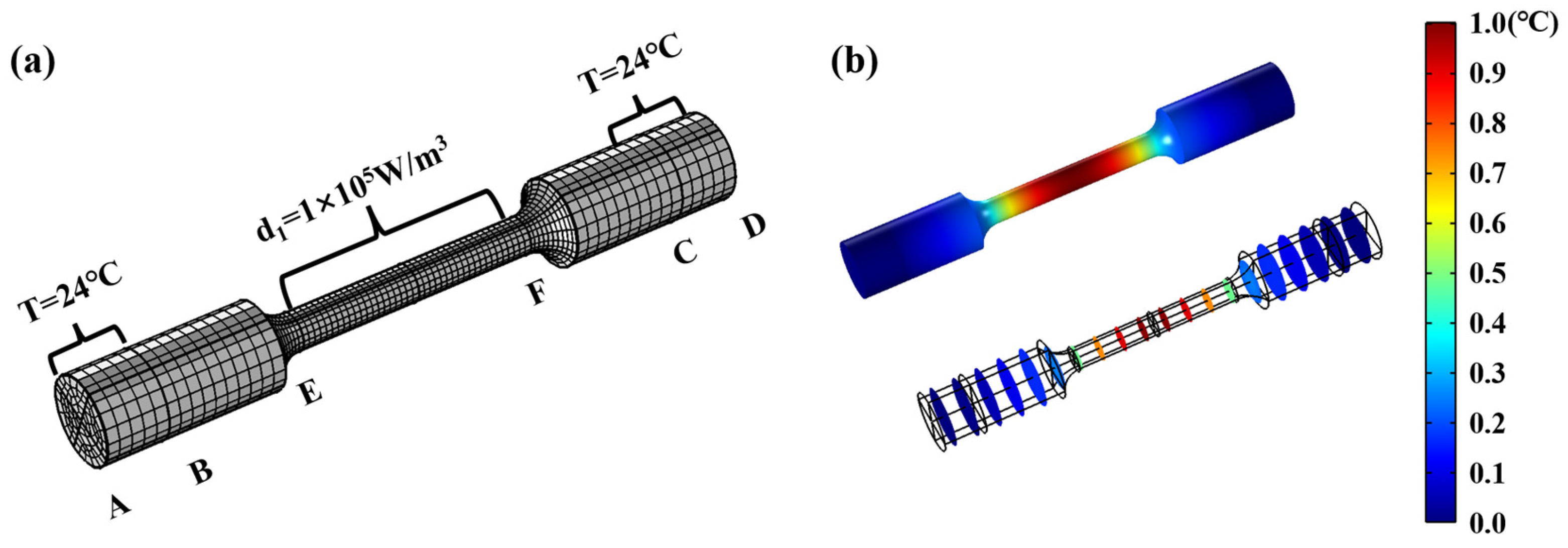

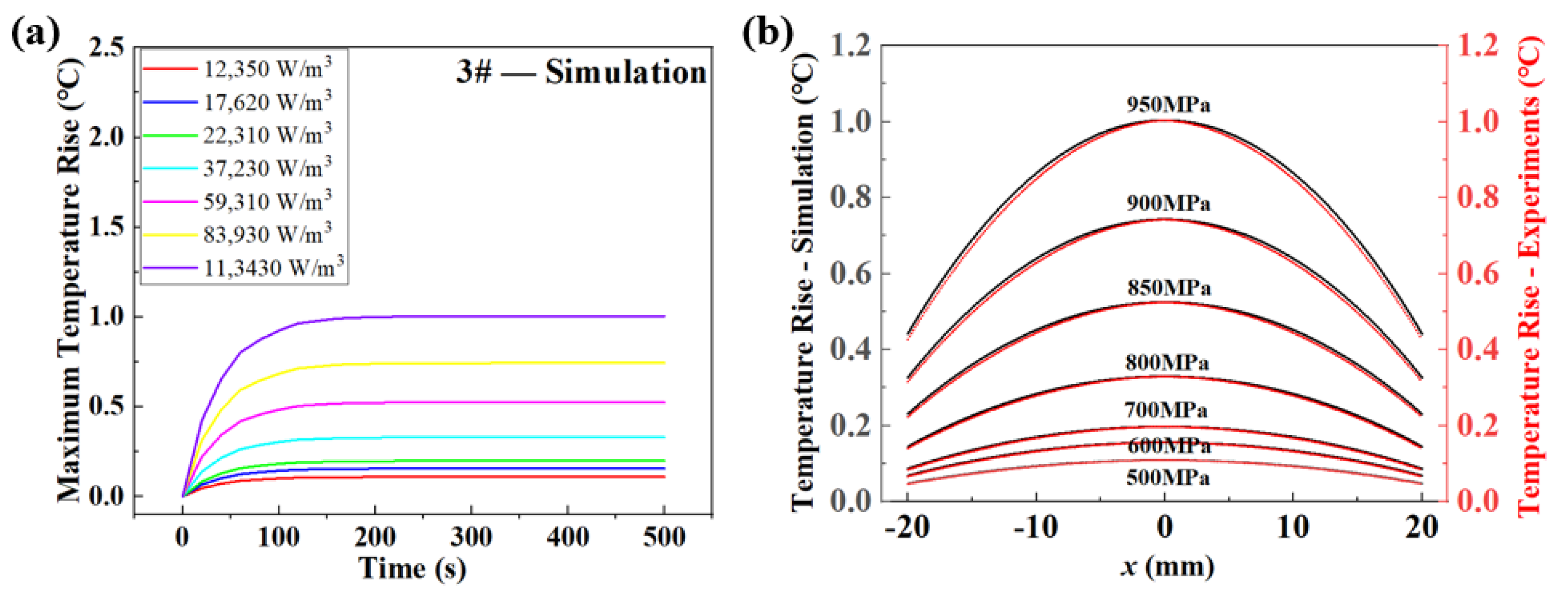

3.4. The Simulation of Self-Heating in Fatigue Loading

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Suresh, S. (Ed.) Fatigue of Materials; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Pan, X.; Hong, Y. High-cycle and very-high-cycle fatigue behaviour of a titanium alloy with equiaxed microstructure under different mean stresses. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 1950–1964. [Google Scholar] [CrossRef]

- Yu, C.; Huang, Z.; Zhang, Z.; Wang, J.; Shen, J.; Xu, Z. Effects of sandblasting and HIP on very high cycle fatigue performance of SLM-fabricated IN718 superalloy. J. Mater. Res. Technol. 2022, 18, 29–43. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, P.; Wang, B.; Zhu, Y.; Xu, Z.; Zhang, Z. Fatigue cracking criterion of high-strength steels induced by inclusions under high-cycle fatigue. J. Mater. Sci. Technol. 2023, 154, 114–128. [Google Scholar] [CrossRef]

- Cheng, G.; Li, H.; Dai, H.; Gao, H.; Pang, J. Investigation of High-Cycle Fatigue Properties of Wire Arc Additive Manufacturing 13Cr4Ni Martensitic Stainless Steel. Metals 2023, 13, 1210. [Google Scholar] [CrossRef]

- Wells, J.M.; Buck, O.; Roth, L.D.; Tien, J.K. Ultrasonic Fatigue, Proceedings of the First International Conference on Fatigue and Corrosion Fatigue Up to Ultrasonic Frequencies, Champion, PA, USA, 25–30 October 1981; The Metallurgical Society of AIME: San Ramon, CA, USA, 1982. [Google Scholar]

- Mayer, H. Fatigue crack growth and threshold measurements at very high frequencies. Int. Met. Rev. 1999, 44, 1–34. [Google Scholar] [CrossRef]

- Fitzka, M.; Schönbauer, B.M.; Rhein, R.K.; Sanaei, N.; Zekriardehani, S.; Tekalur, S.A.; Carroll, J.W.; Mayer, H. Usability of ultrasonic frequency testing for rapid generation of high and very high cycle fatigue data. Materials 2021, 14, 2245. [Google Scholar] [CrossRef]

- Furuya, Y.; Shimamura, Y.; Takanashi, M.; Ogawa, T. Standardization of an ultrasonic fatigue testing method in Japan. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 2415–2420. [Google Scholar] [CrossRef]

- Mayer, H. Recent developments in ultrasonic fatigue. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 3–29. [Google Scholar] [CrossRef]

- Jeddi, D.; Palin-Luc, T. A review about the effects of structural and operational factors on the gigacycle fatigue of steels. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 969–990. [Google Scholar] [CrossRef]

- Hong, Y.; Hu, Y.; Zhao, A. Effects of loading frequency on fatigue behavior of metallic materials—A literature review. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 3077–3098. [Google Scholar] [CrossRef]

- Zhao, A.; Xie, J.; Sun, C.; Lei, Z.; Hong, Y. Effects of strength level and loading frequency on very-high-cycle fatigue behavior for a bearing steel. Int. J. Fatigue 2012, 38, 46–56. [Google Scholar] [CrossRef]

- Guennec, B.; Ueno, A.; Sakai, T.; Takanashi, M.; Itabashi, Y. Effect of the loading frequency on fatigue properties of JIS S15C low carbon steel and some discussions based on micro-plasticity behavior. Int. J. Fatigue 2014, 66, 29–38. [Google Scholar] [CrossRef]

- Guennec, B.; Ueno, A.; Sakai, T.; Takanashi, M.; Itabashi, Y.; Ota, M. Dislocation-based interpretation on the effect of the loading frequency on the fatigue properties of JIS S15C low carbon steel. Int. J. Fatigue 2015, 70, 328–341. [Google Scholar] [CrossRef]

- Schneider, N.; Bödecker, J.; Berger, C.; Oechsner, M. Frequency effect and influence of testing technique on the fatigue behaviour of quenched and tempered steel and aluminium alloy. Int. J. Fatigue 2016, 93, 224–231. [Google Scholar] [CrossRef]

- Fatemi, A.; Yang, L. Cumulative fatigue damage and life prediction theories: A survey of the state of the art for homogeneous materials. Int. J. Fatigue 1998, 20, 9–34. [Google Scholar] [CrossRef]

- Chrysochoos, A.; Louche, H. An infrared image processing to analyze the calorific effects accompanying strain localization. Int. J. Eng. Sci. 2000, 38, 1759–1788. [Google Scholar] [CrossRef]

- Guo, S.; Liu, X.; Zhang, H.; Yan, Z.; Zhang, Z.; Fang, H. Thermographic Study of AZ31B Magnesium Alloy under Cyclic Loading: Temperature Evolution Analysis and Fatigue Limit Estimation. Materials 2020, 13, 5209. [Google Scholar] [CrossRef] [PubMed]

- Risitano, A.; Risitano, G. Cumulative damage evaluation of steel using infrared thermography. Theor. Appl. Fract. Mech. 2010, 54, 82–90. [Google Scholar] [CrossRef]

- La Rosa, G.; Risitano, A. Thermographic methodology for rapid determination of the fatigue limit of materials and mechanical components. Int. J. Fatigue 2000, 22, 65–73. [Google Scholar] [CrossRef]

- Luong, M.P. Fatigue limit evaluation of metals using an infrared thermographic technique. Mech. Mater. 1998, 28, 155–163. [Google Scholar] [CrossRef]

- Żaba, K.; Trzepieciński, T.; Puchlerska, S.; Noga, P.; Balcerzak, M. Coupled Thermomechanical Response Measurement of Deformation of Nickel-Based Superalloys Using Full-Field Digital Image Correlation and Infrared Thermography. Materials 2021, 14, 2163. [Google Scholar] [CrossRef] [PubMed]

- Golasiński, K.M.; Staszczak, M.; Pieczyska, E.A. Energy Storage and Dissipation in Consecutive Tensile Load-Unload Cycles of Gum Metal. Materials 2023, 16, 3288. [Google Scholar] [CrossRef]

- Morabito, A.; Chrysochoos, A.; Dattoma, V.; Galietti, U. Analysis of heat sources accompanying the fatigue of 2024 T3 aluminum alloys. Int. J. Fatigue 2007, 29, 977–984. [Google Scholar] [CrossRef]

- Maquin, F.; Pierron, F. Heat dissipation measurements in low stress cyclic loading of metallic materials: From internal friction to micro-plasticity. Mech. Mater. 2009, 41, 928–942. [Google Scholar] [CrossRef]

- Pan, P.; Zhang, R.; Zhang, Y.; Li, H. Detecting Internal Defects in FRP-Reinforced Concrete Structures through the Integration of Infrared Thermography and Deep Learning. Materials 2024, 17, 3350. [Google Scholar] [CrossRef] [PubMed]

- Grodzki, W.; Oliferuk, W.; Doroszko, M.; Szusta, J.; Urbański, L. Prediction of Crack Initiation Based on Energy Storage Rate during Low-Cycle Fatigue of Austenitic Stainless Steel. Materials 2021, 14, 5526. [Google Scholar] [CrossRef] [PubMed]

- Pierron, Q.; Maitournam, H.; Raoult, I. Thermographic approach for high cycle fatigue of seam welded steel joints under variable amplitude loadings. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 2966–2983. [Google Scholar] [CrossRef]

- Yan, Z.; Zhang, H.; Wang, W.; He, X.; Liu, X.; Wu, G. Temperature evolution mechanism of AZ31B magnesium alloy during high-cycle fatigue process. Theor. Appl. Fract. Mech. 2014, 70, 30–38. [Google Scholar] [CrossRef]

- Wang, X.; Ran, H.R.; Jiang, C.; Fang, Q. An energy dissipation-based fatigue crack growth model. Int. J. Fatigue 2018, 114, 167–176. [Google Scholar] [CrossRef]

- Fan, G.D.; Zheng, M.Y.; Hu, X.S.; Wu, K.; Gan, W.M.; Brokmeier, H.G. Internal friction and microplastic deformation behavior of pure magnesium processed by equal channel angular pressing. Mater. Sci. Eng. A 2013, 561, 100–108. [Google Scholar] [CrossRef]

- Vinogradov, A.; Yasnikov, I.S. On the nature of acoustic emission and internal friction during cyclic deformation of metals. Acta Mater. 2014, 70, 8–18. [Google Scholar] [CrossRef]

- Meneghetti, G.; Ricotta, M. Estimating the intrinsic dissipation using the second harmonic of the temperature signal in tension-compression fatigue: Part I. Theory. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 2168–2185. [Google Scholar] [CrossRef]

- Guo, Q.; Guo, X.; Fan, J.; Syed, R.; Wu, C. An energy method for rapid evaluation of high-cycle fatigue parameters based on intrinsic dissipation. Int. J. Fatigue 2015, 80, 136–144. [Google Scholar] [CrossRef]

- Wang, X.; Feng, E.; Jiang, C. A microplasticity evaluation method in very high cycle fatigue. Int. J. Fatigue 2017, 94, 6–15. [Google Scholar] [CrossRef]

- Mehdizadeh, M.; Khonsari, M. On the role of internal friction in low-and high-cycle fatigue. Int. J. Fatigue 2018, 128, 159–166. [Google Scholar] [CrossRef]

- Guo, Q.; Zaïri, F.; Yang, W. Evaluation of intrinsic dissipation based on self-heating effect in high-cycle metal fatigue. Int. J. Fatigue 2020, 139, 105653. [Google Scholar] [CrossRef]

- Fan, J.; Guo, X.; Zhao, Y. An energetic method to evaluate the macro and micro high-cycle fatigue behavior of the aluminum alloy. J. Mech. Eng. Sci. 2017, 232, 1456–1469. [Google Scholar] [CrossRef]

- Fan, J.; Zhao, Y.; Guo, X. A unifying energy approach for high cycle fatigue behavior evaluation. Mech. Mater. 2018, 120, 15–25. [Google Scholar] [CrossRef]

- Yang, W.; Guo, X.; Guo, Q.; Fan, J. Rapid evaluation for high-cycle fatigue reliability of metallic materials through quantitative thermography methodology. Int. J. Fatigue 2019, 124, 461–472. [Google Scholar] [CrossRef]

- Salimia, H.; Pourgol-Mohammada, M.; Yazdanib, M. Metal fatigue assessment based on temperature evolution and thermodynamic entropy generation. Int. J. Fatigue 2019, 127, 403–416. [Google Scholar] [CrossRef]

- Teng, Z.; Wu, H.; Boller, C.; Starke, P. Thermography in high cycle fatigue short-term evaluation procedures applied to a medium carbon steel. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 515–526. [Google Scholar] [CrossRef]

- Teng, Z.; Wu, H.; Boller, C.; Starke, P. A unified fatigue life calculation based on intrinsic thermal dissipation and microplasticity evolution. Int. J. Fatigue 2020, 131, 105370. [Google Scholar] [CrossRef]

- Zhao, A.; Xie, J.; Zhao, Y.; Liu, C.; Zhu, J.; Qian, G.; Wang, S.; Hong, Y. Fatigue limit evaluation via infrared thermography for a high strength steel with two strength levels. Eng. Fract. Mech. 2022, 268, 108460. [Google Scholar] [CrossRef]

- GB_T 228.1-2010; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Available online: https://www.chinesestandard.net/PDF/English.aspx/GBT228.1-2021?Redirect (accessed on 2 January 2025).

| C | Cr | Mn | Si | P | S | Fe |

|---|---|---|---|---|---|---|

| 1.01 | 1.45 | 0.35 | 0.28 | 0.015 | 0.01 | Balance |

| Micro-Hardness Hv (kgf/mm2) | Young’s Modulus (GPa) | Yield Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|---|

| 801 | 207.2 | 2032 | 2272 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Lin, Z.; Xia, Y.; Chen, L.; Gu, G.; Pan, L. Fatigue-Limit Assessment via Infrared Thermography for a High-Strength Steel. Materials 2025, 18, 279. https://doi.org/10.3390/ma18020279

Zhao Y, Lin Z, Xia Y, Chen L, Gu G, Pan L. Fatigue-Limit Assessment via Infrared Thermography for a High-Strength Steel. Materials. 2025; 18(2):279. https://doi.org/10.3390/ma18020279

Chicago/Turabian StyleZhao, Yingxin, Zhaodong Lin, Yu Xia, Liming Chen, Guoqing Gu, and Like Pan. 2025. "Fatigue-Limit Assessment via Infrared Thermography for a High-Strength Steel" Materials 18, no. 2: 279. https://doi.org/10.3390/ma18020279

APA StyleZhao, Y., Lin, Z., Xia, Y., Chen, L., Gu, G., & Pan, L. (2025). Fatigue-Limit Assessment via Infrared Thermography for a High-Strength Steel. Materials, 18(2), 279. https://doi.org/10.3390/ma18020279