The Influence of Terfenol-D Content on the Structure and Properties of Multiferroic Composites Obtained Based on PZT-Type Material and Terfenol-D

Abstract

1. Introduction

2. Materials and Methods

2.1. Technology Process

2.2. Measurements Methods

3. Results and Discussion

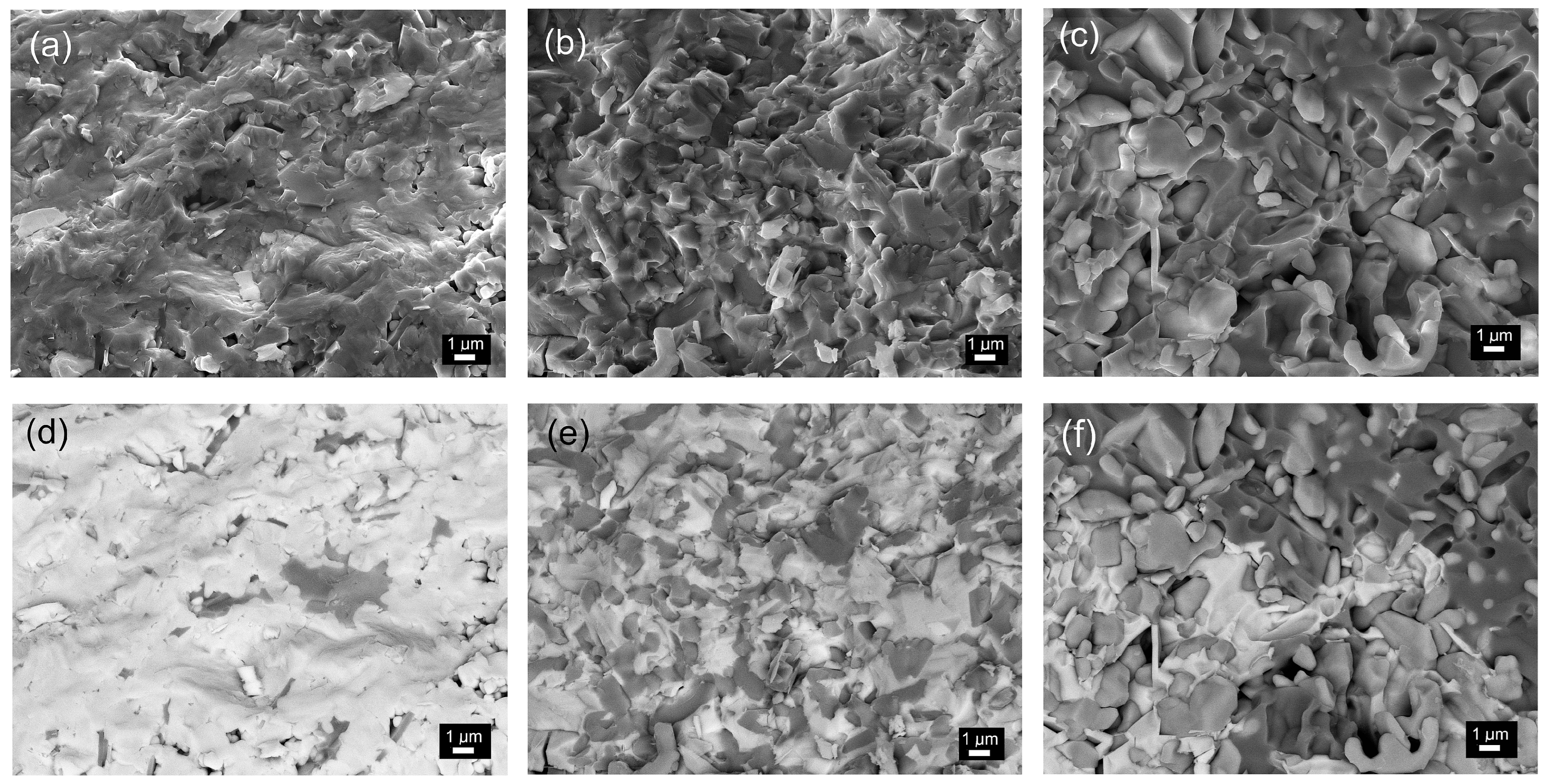

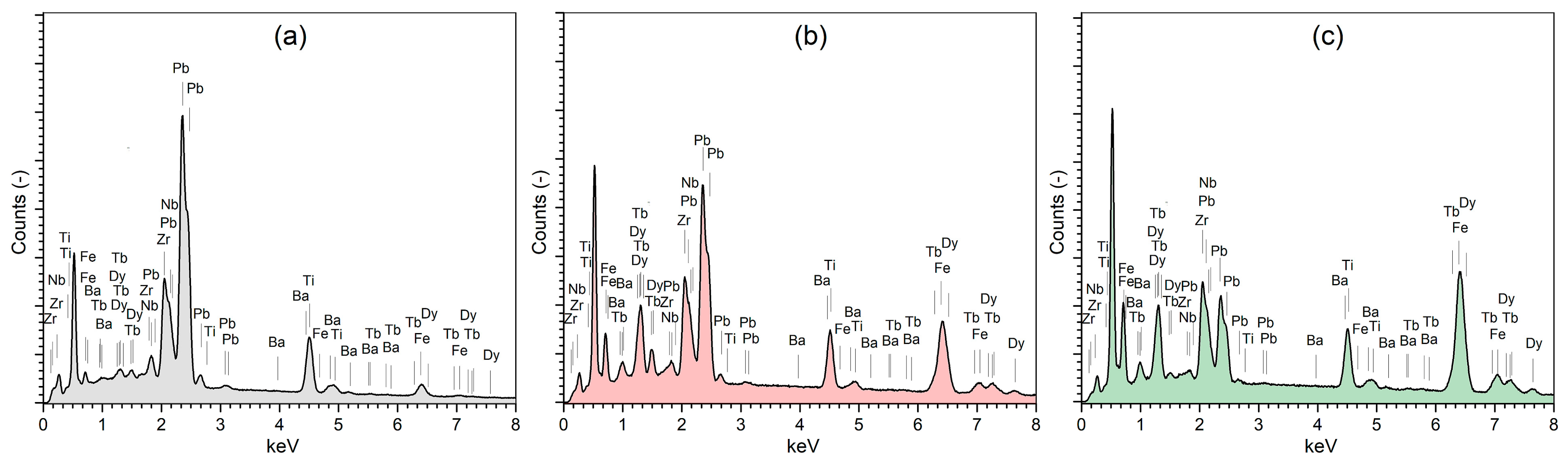

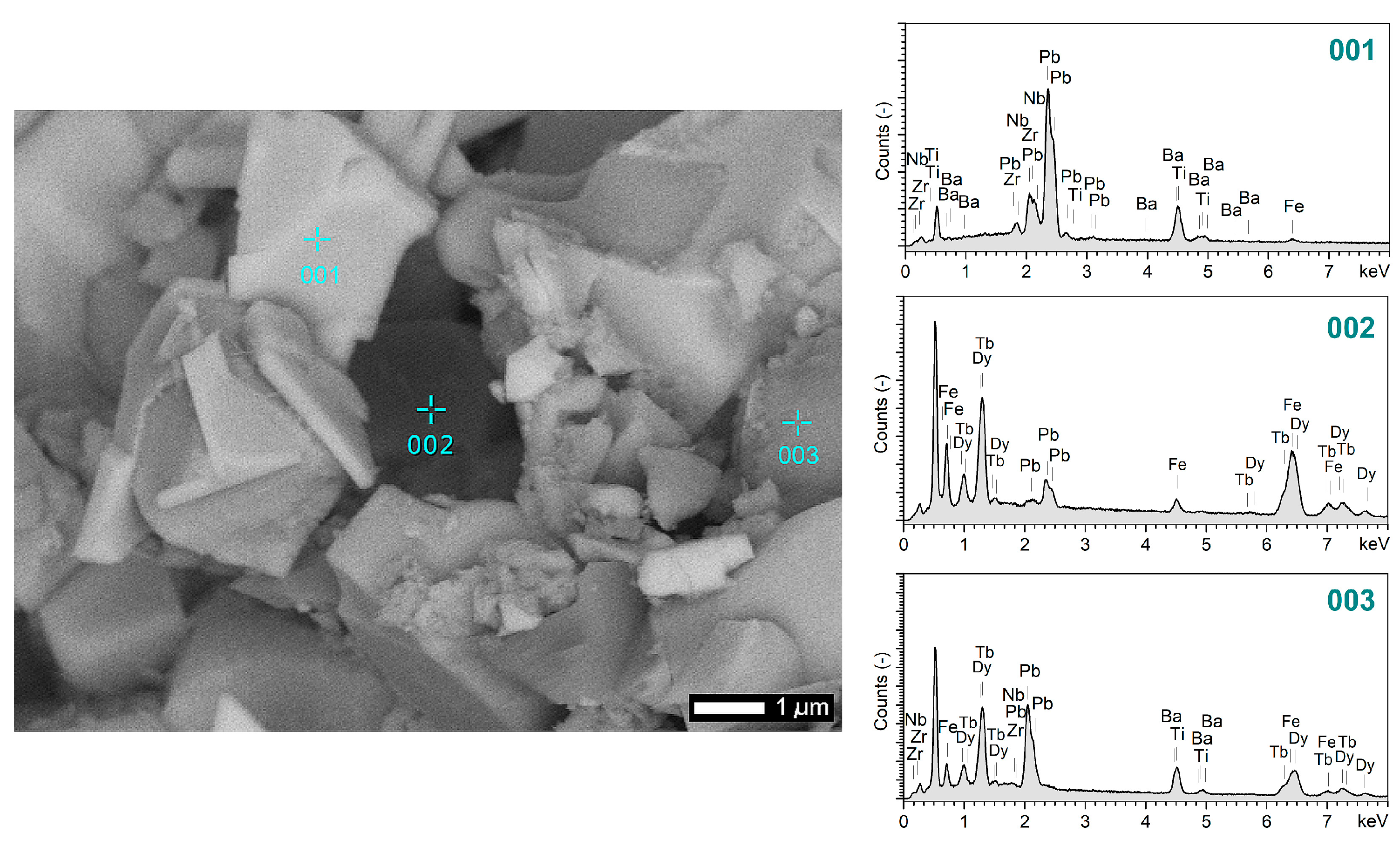

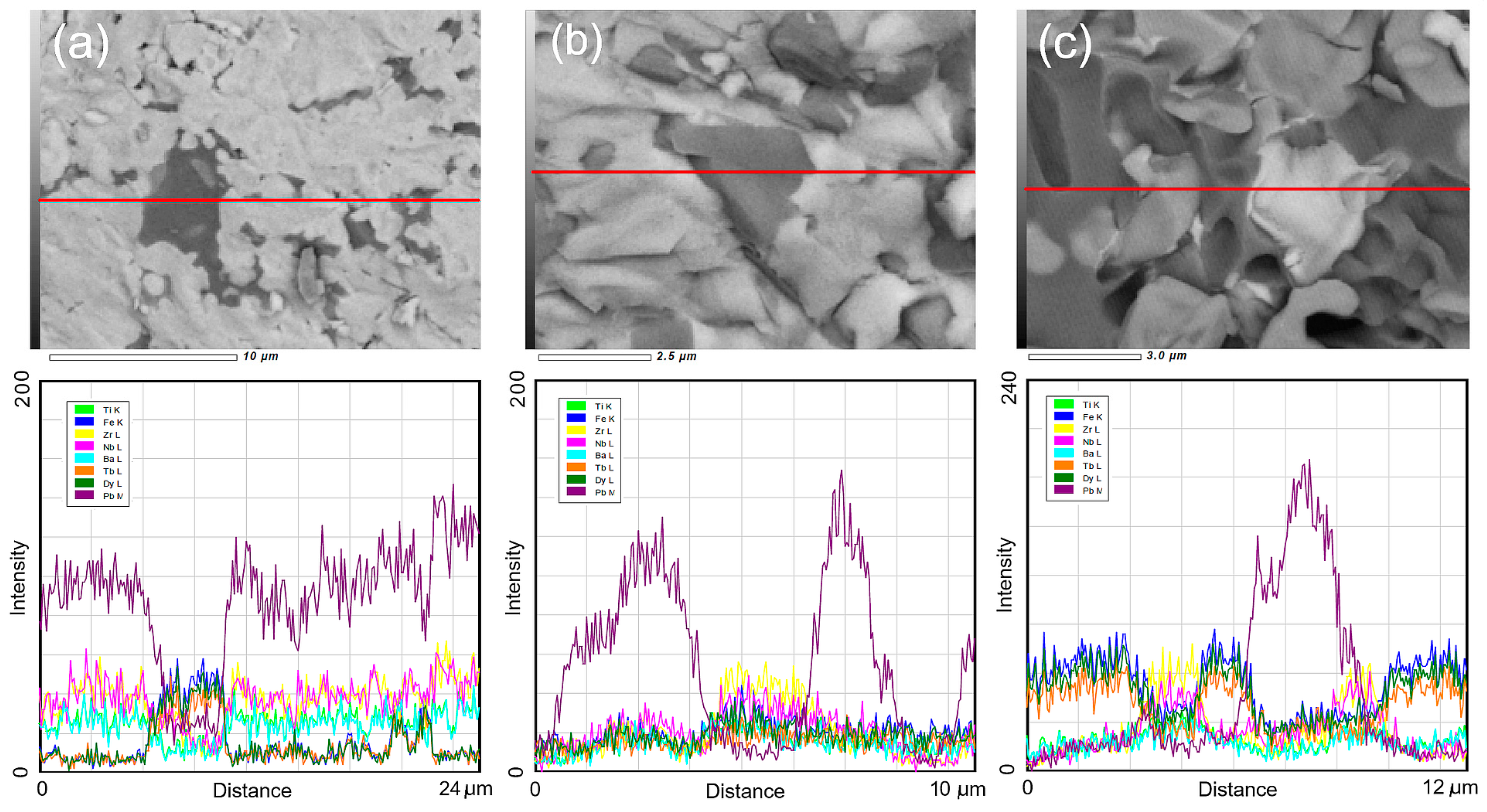

3.1. Microstructure and EDS Analysis

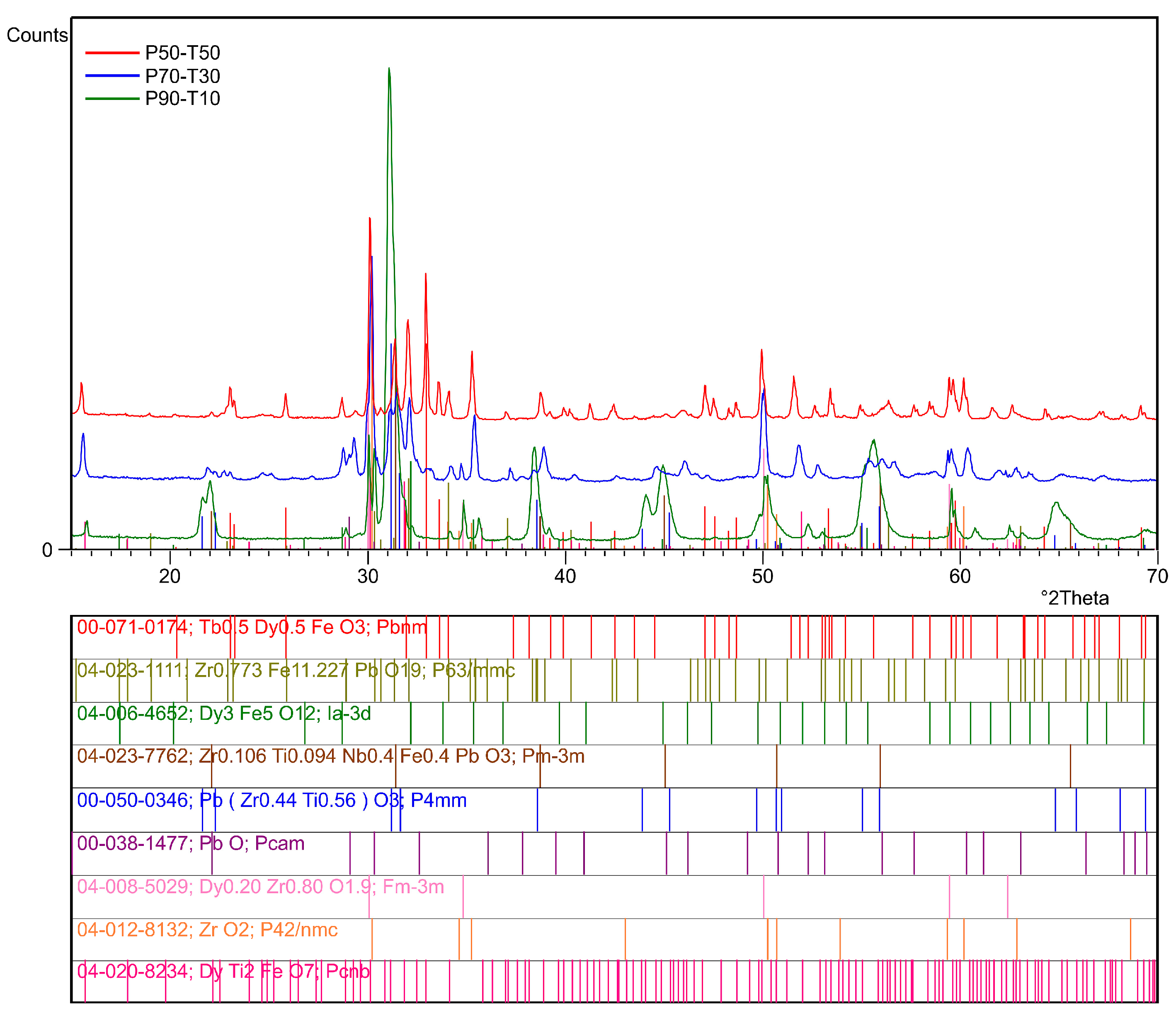

3.2. Crystal Structure

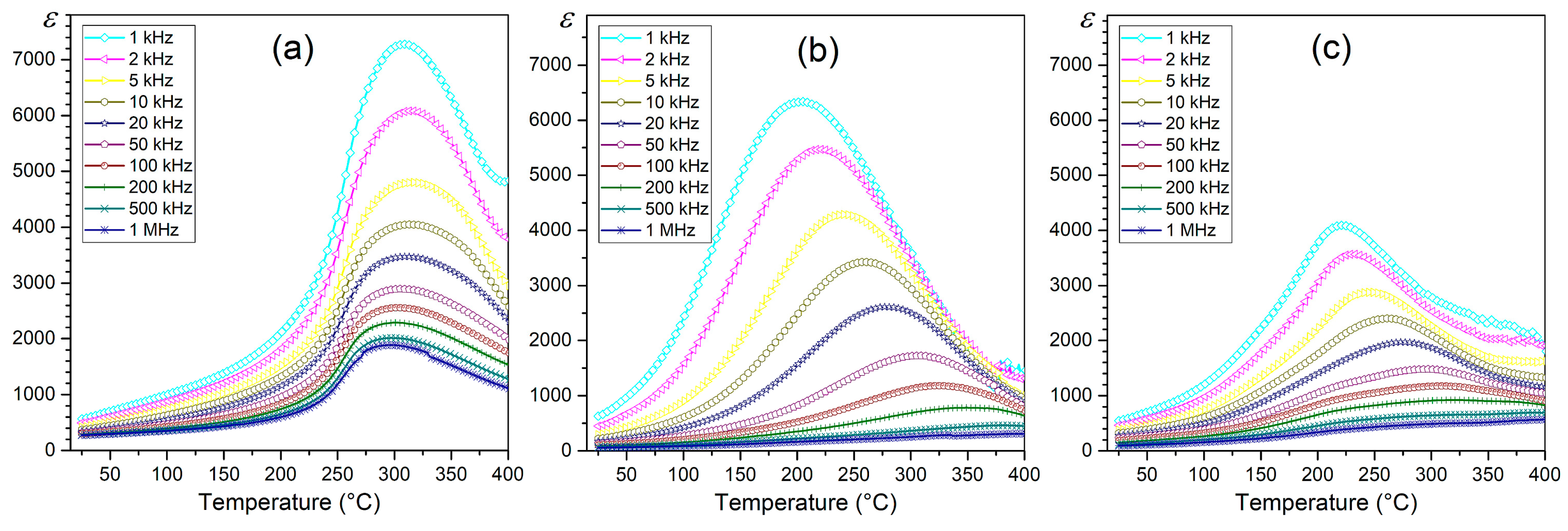

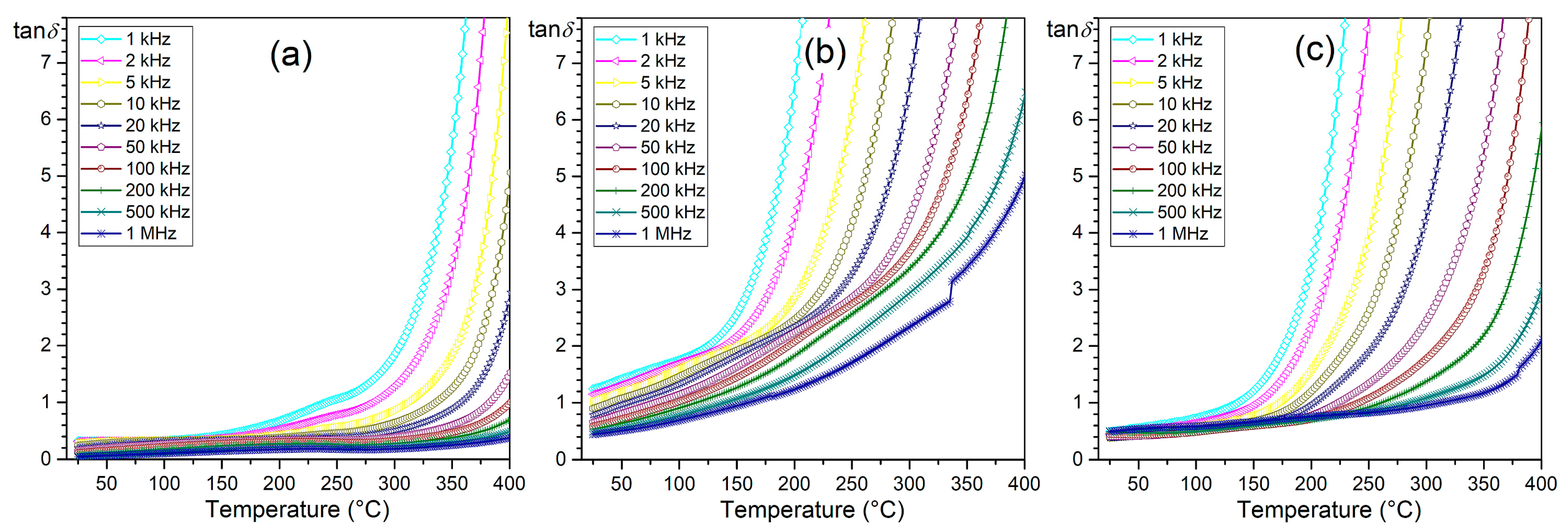

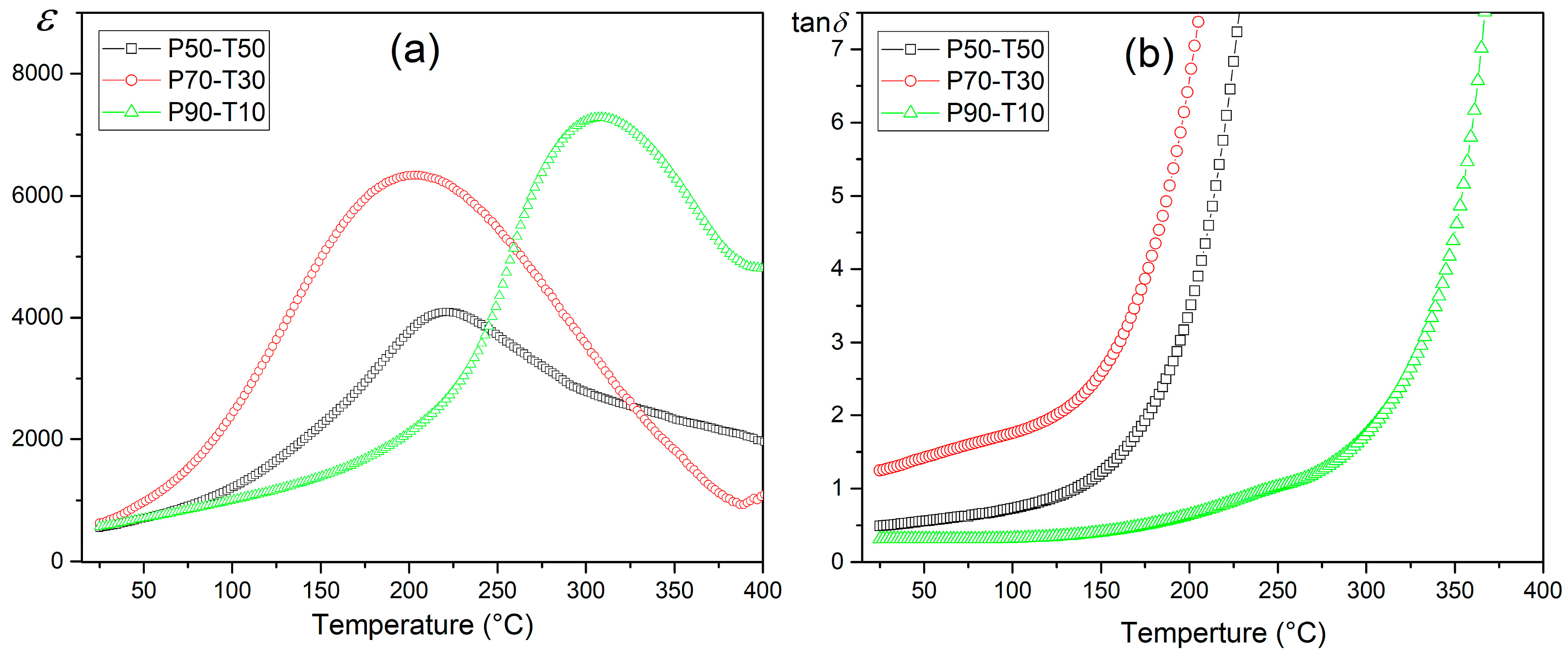

3.3. Dielectric Properties

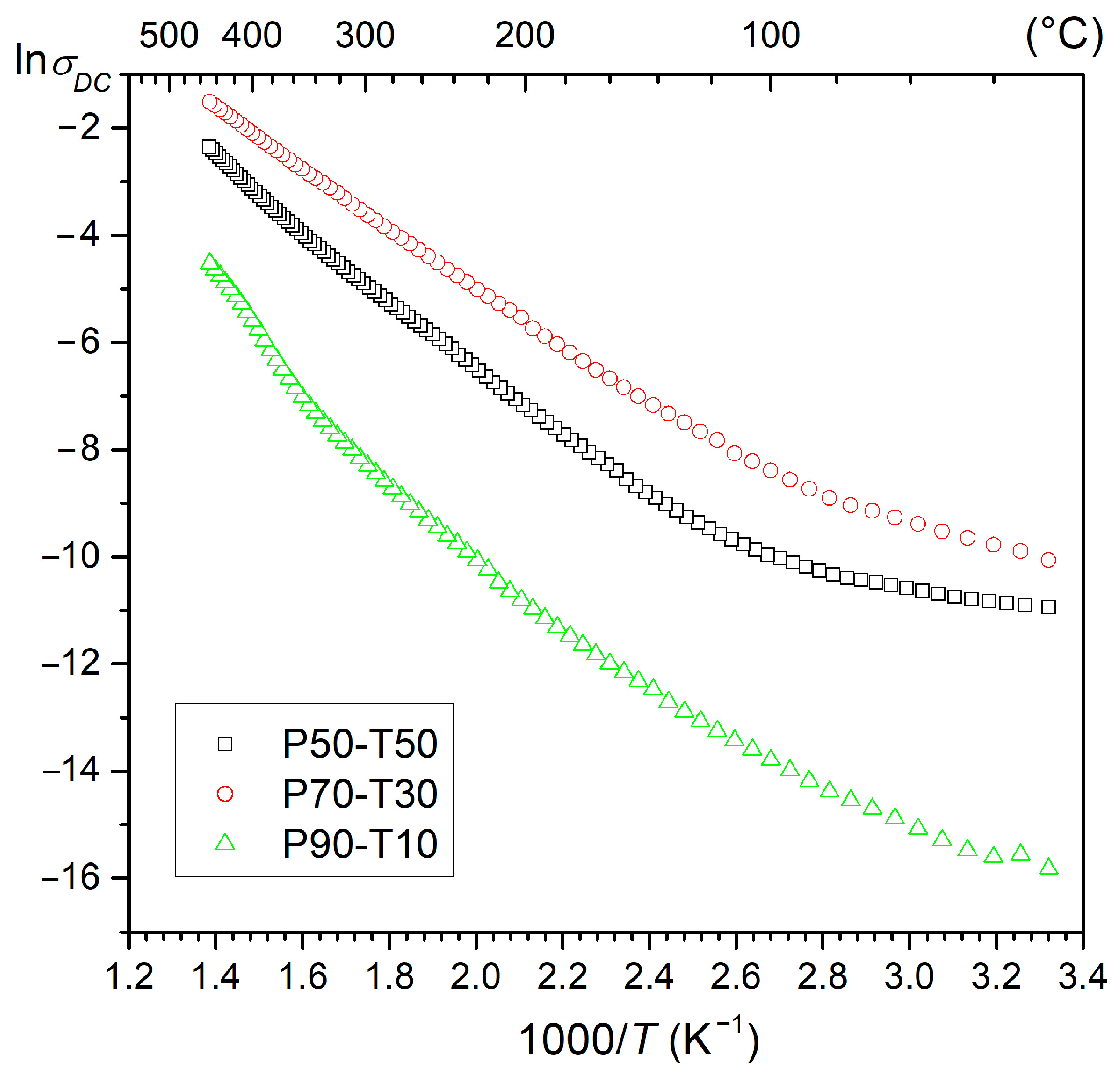

3.4. DC Electric Conductivity

3.5. Magnetic Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ramesh, R.; Spaldin, N.A. Multiferroics: Progress and prospects in thin films. Nat. Mater. 2007, 6, 21–29. [Google Scholar] [CrossRef] [PubMed]

- Van Suchtelen, J. Product properties: A new application of composite materials. Philips Res. Rep. 1972, 27, 28–37. [Google Scholar]

- He, H.C.; Zhou, J.P.; Wang, J.; Nan, C.W. Ferroelectric and ferromagnetic behavior of Pb(Zr0.52Ti0.48)O3–Co0.9Zn0.1Fe2O4 multilayered thins films prepared via solution processing. Adv. Funct. Mater. 2007, 17, 1333–1338. [Google Scholar] [CrossRef]

- Zheng, H.; Wang, J.; Lofland, S.E.; Ma, Z.; Mohaddes-Ardabili, L.; Zhao, T.; Salamanca-Riba, L.; Shinde, S.R.; Ogale, S.B.; Bai, F.; et al. Multiferroic BaTiO3-CoFe2O4 nanostructures. Science 2004, 303, 661–663. [Google Scholar] [CrossRef] [PubMed]

- Dong, S.; Bai, J.G.; Zhai, J.; Li, J.-F.; Lu, G.-Q.; Viehland, D. Circumferential-mode, quasi-ring-type, magnetoelectric laminate composite—A highly sensitive electric current and/or vortex magnetic field sensor. Appl. Phys. Lett. 2005, 86, 182506-1–182506-3. [Google Scholar] [CrossRef]

- Shastry, S.; Srinivasan, G.; Bichurin, M.I.; Petrov, V.M.; Tatarenko, A.S. Microwave magnetoelectric effects in single crystal bilayers of yttrium iron garnet and lead magnesium niobate-lead titanate. Phys. Rev. B 2004, 70, 064416-1–064416-6. [Google Scholar] [CrossRef]

- Semenov, A.A.; Karmanenko, S.F.; Demidow, V.E.; Kalinikos, B.A.; Srinivasan, G.; Slavin, A.N.; Mantese, J.V. Ferrite-ferroelectric layered structures for electrically and magnetically tunable microwave resonators. Appl. Phys. Lett. 2006, 88, 033503-1–033503-3. [Google Scholar] [CrossRef]

- Khomskii, D. Classifying multiferroics: Mechanisms and effects. Physics 2009, 2, 20. Available online: https://physics.aps.org/articles/v2/20?referer=rss (accessed on 18 November 2024). [CrossRef]

- D’Souza, N.; Atulasimha, J.; Bandyopadhyay, S. Four-state nanomagnetic logic using multiferroics. J. Phys. D-Appl. Phys. 2011, 44, 265001-1–265001-7. [Google Scholar] [CrossRef]

- Fetisov, Y.K.; Burdin, D.A.; Chashin, D.V.; Ekonomov, N.A. High-sensitivity wideband magnetic field sensor using nonlinear resonance magnetoelectric effect. IEEE Sens. J. 2014, 14, 2252–2256. [Google Scholar] [CrossRef]

- Bibes, M.; Barthélémy, A. Towards a magnetoelectric memory. Nature Mater. 2008, 7, 425–426. [Google Scholar] [CrossRef] [PubMed]

- Srinivasan, G. Magnetoelectric composites. Ann. Rev. Mater. Res. 2010, 40, 153–178. [Google Scholar] [CrossRef]

- Kozielski, L.; Bochenek, D.; Clemens, F.; Tutu, S. Magnetoelectric composites: Engineering for tunable filters and energy harvesting applications. Appl. Sci. 2023, 13, 8854. [Google Scholar] [CrossRef]

- Fetisov, Y.K.; Srinivasan, G. Electric field tuning characteristics of a ferrite-piezoelectric microwave resonator. Appl. Phys. Lett. 2006, 88, 143503. [Google Scholar] [CrossRef]

- Lee, J.H.; Fang, L.; Vlahos, E.; Ke, X.L.; Jung, Y.W.; Kourkoutis, L.F.; Kim, J.W.; Ryan, P.J.; Heeg, T.; Roeckerath, M.; et al. A strong ferroelectric ferromagnet created by means of spin–lattice coupling. Nature 2011, 476, 114. [Google Scholar] [CrossRef]

- Liu, M.; Li, S.D.; Obi, O.; Lou, J.; Rand, S.; Sun, N.X. Electric field modulation of magnetoresistance in multiferroic heterostructures for ultralow power electronics. Appl. Phys. Lett. 2011, 98, 222509. [Google Scholar] [CrossRef]

- Hu, J.-M.; Nan, C.W. Electric-field-induced magnetic easy-axis reorientation in ferromagnetic/ferroelectric layered heterostructures. Phys. Rev. B 2009, 80, 224416. [Google Scholar] [CrossRef]

- Wu, T.; Bur, A.; Wong, K.; Hockel, J.L.; Hsu, C.-J.; Kim, H.K.D.; Wang, K.L.; Carman, G.P. Electric-poling-induced magnetic anisotropy and electric-field-induced magnetization reorientation in magnetoelectric Ni/(011) [Pb(Mg1/3Nb2/3)O3](1−x)-[PbTiO3]x heterostructure. J. Appl. Phys. 2011, 109, 07D732. [Google Scholar] [CrossRef]

- Dong, S.X.; Zhai, J.Y.; Li, J.F.; Viehland, D. Small dc magnetic field response of magnetoelectric laminate composites. Appl. Phys. Lett. 2006, 88, 082907. [Google Scholar] [CrossRef]

- Das, J.; Song, Y.Y.; Mo, N.; Krivosik, P.; Patton, C.E. Electric-field-tunable low loss multiferroic ferrimagnetic–ferroelectric heterostructures. Adv. Mater. 2009, 21, 2045. [Google Scholar] [CrossRef]

- Zhao, P.; Zhao, Z.L.; Hunter, D.; Suchoski, R.; Gao, C.; Mathews, S.; Wuttig, M.; Takeuchi, I. Fabrication and characterization of all-thin-film magnetoelectric sensors. Appl. Phys. Lett. 2009, 94, 243507. [Google Scholar] [CrossRef]

- Filippov, D.A.; Srinivasan, G.; Gupta, A. Magnetoelectric effects in ferromagnetic films on ferroelectric substrates. J. Phys. Condens. Matter 2008, 20, 425206. [Google Scholar] [CrossRef]

- Petrov, V.M.; Srinivasan, G.; Bichurin, M.I.; Gupta, A. Theory of magnetoelectric effects in ferrite piezoelectric nanocomposites. Phys. Rev. B 2007, 75, 224407. [Google Scholar] [CrossRef]

- Elhajjar, R.; Law, C.-T.; Pegoretti, A. Magnetostrictive polymer composites: Recent advances in materials, structures and properties. Prog. Mater. Sci. 2018, 97, 204–229. [Google Scholar] [CrossRef]

- Bochenek, D.; Niemiec, P.; Brzezińska, D. Electrophysical properties of the multiferroic BFN-ferrite composites obtained by spark plasma sintering and classical technology. Arch. Metall. Mater. 2020, 65, 799–804. [Google Scholar] [CrossRef]

- Bochenek, D.; Niemiec, P.; Brzezińska, D.; Dercz, D.; Ziółkowski, G.; Jartych, E.; Grotel, J.; Suchanicz, J. Magnetoelectric properties of multiferroic composites based on BaTiO3 and nickel-zinc ferrite material. Materials 2024, 17, 1905. [Google Scholar] [CrossRef] [PubMed]

- Bochenek, D.; Niemiec, P.; Brzezińska, D.; Dercz, D.; Wąs, M. Electrophysical properties of the three-component multiferroic ceramic composites. Materials 2024, 17, 49. [Google Scholar] [CrossRef]

- Bochenek, D.; Chrobak, A.; Dercz, G. Strengthening the ferroelectric properties in the three-component multiferroic ceramic composites. Appl. Mater. Today 2023, 32, 101847. [Google Scholar] [CrossRef]

- Bochenek, D.; Niemiec, P.; Dercz, G.; Chrobak, A. Electrophysical properties of multiferroic PMN-PT-Ferrite composites sintered by spark plasma sintering. J. Magn. Magn. Mater. 2022, 563, 169909. [Google Scholar] [CrossRef]

- Nan, C.W.; Bichurin, M.I.; Dong, S.; Viehland, D.; Srinivasan, G. Multiferroic magnetoelectric composites: Historical perspective, status, and future directions. J. Appl. Phys. 2008, 103, 031101-1–031101-35. [Google Scholar] [CrossRef]

- Newnham, R.E.; Skinner, D.P.; Cross, L.E. Connectivity and piezoelectric-pyroelectric composites. Mater. Res. Bull. 1978, 13, 525–536. [Google Scholar] [CrossRef]

- Hilczer, B.; Małecki, J. Elektrety i Piezopolimery; PWN: Warszawa, Poland, 1992. [Google Scholar]

- Liu, M.; Li, S.; Zhou, Z.; Beguhn, S.; Lou, J.; Xu, F.; Lu, T.J.; Sun, N.X. Electrically induced enormous magnetic anisotropy in Terfenol-D/lead zinc niobate-lead titanate multiferroic heterostructures. J. Appl. Phys. 2012, 112, 063917. [Google Scholar] [CrossRef]

- Williams, P.I.; Lord, D.G.; Grundy, P.J. Magnetostriction in polycrystalline sputter-deposited TbDyFe films. J. Appl. Phys. 1994, 75, 5257. [Google Scholar] [CrossRef]

- Speliotis, A.; Kalogirou, O.; Niarchos, D. Magnetostrictive properties of amorphous and partially crystalline TbDyFe thin films. J. Appl. Phys. 1997, 81, 5696. [Google Scholar] [CrossRef]

- Liang, Y.; Zheng, X. Experimental researches on magneto-thermo-mechanical characterization of TERFENOL-D. Acta Mech. Solida Sin. 2007, 20, 283–288. [Google Scholar] [CrossRef]

- Satpathi, D.; Moore, J.A.; Ennis, M.G. Design of a Terfenol-D based fiber-optic current transducer. IEEE Sens. J. 2005, 5, 1057–1065. [Google Scholar] [CrossRef]

- Cremonezi, A.O.; Ferreira, E.C.; Biazon Filho, A.J.; Dias, J.A.S. A fiber Bragg grating RMS current transducer based on the magnetostriction effect using a Terfenol-D toroidal-shaped modulator. IEEE Sens. J. 2013, 13, 683–690. [Google Scholar] [CrossRef]

- Verhoeven, J.D.; Gibson, E.D.; McMasters, O.D.; Baker, H.H. The growth of single crystal Terfenol-D crystals. Metall. Trans. A 1987, 18, 223–231. [Google Scholar] [CrossRef]

- Kendall, D.; Piercy, A.R. Magnetisation processes and temperature dependence of the magnetomechanical properties of Tb0.27Dy0.73Fe1.9. IEEE T. Mag. 1990, 26, 1837–1839. [Google Scholar] [CrossRef]

- Moffett, M.B.; Clark, A.E.; Wun-Fogle, M.; Linberg, J.; Teter, J.P.; McLaughlin, E.A. Characterization of Terfenol-D for magnetostrictive transducers. J. Acoust. Soc. Am. 1991, 89, 1448–1455. [Google Scholar] [CrossRef]

- García-Miquel, H.; Barrera, D.; Amat, R.; Kurlyandskaya, G.V.; Sales, S. Magnetic actuator based on giant magnetostrictive material Terfenol-D with strain and temperature monitoring using FBG optical sensor. Measurement 2016, 80, 201–206. [Google Scholar] [CrossRef]

- Lin, C.-H.; Lin, Y.-Z. Analysis of nonlinear piezomagnetism for magnetostrictive terfenol-D composites. J. Magn. Magn. Mater. 2021, 540, 168490. [Google Scholar] [CrossRef]

- Du, T.; Zhang, T.; Meng, H.; Zhou, X.; Jiang, C. A study on laminated structures in terfenol-D/epoxy particulate composite with enhanced magnetostriction. J. Appl. Phys. 2014, 115, 243909. [Google Scholar] [CrossRef]

- Palneedi, H.; Annapureddy, V.; Priya, S.; Ryu, J. Status and perspectives of multiferroic magnetoelectric composite materials and applications. Actuators 2016, 5, 9. [Google Scholar] [CrossRef]

- Harshe, G.; Dougherty, J.P.; Newnham, R.E. Theoretical modelling of multilayer magnetoelectric composites. Int. J. Appl. Electrom. 1993, 4, 145–159. [Google Scholar]

- Bichurin, M.I.; Kornev, I.A.; Petrov, V.M.; Lisnevskaya, I.V. Investigation of magnetoelectric interaction in composite. Ferroelectrics 1997, 204, 289–297. [Google Scholar] [CrossRef]

- Patankar, K.K.; Patil, S.A.; Sivakumar, K.V.; Mahajan, R.P.; Kolekar, Y.D.; Kothale, M.B. AC conductivity and magnetoelectric effect in CuFe1.6Cr0.4O4–BaTiO3 composite ceramics. Mater. Chem. Phys. 2000, 65, 97–102. [Google Scholar] [CrossRef]

- Bochenek, D.; Niemiec, P.; Chrobak, A.; Guzdek, P. Magnetoelectric properties of multiferroic ceramic composites. Appl. Phys. A 2023, 129, 642. [Google Scholar] [CrossRef]

- Ryu, J.; Carazo, A.V.; Uchino, K.; Kim, H.E. Piezoelectric and magnetoelectric properties of lead zirconate titanate/Ni-ferrite particulate composites. J. Electroceram. 2001, 7, 17–24. [Google Scholar] [CrossRef]

- Lou, J.; Liu, M.; Reed, D.; Ren, Y.H.; Sun, N.X. Giant electric field tuning of magnetism in novel multiferroic FeGaB/lead zinc niobate–lead titanate (PZN-PT) heterostructures. Adv. Mater. 2009, 21, 4711. [Google Scholar] [CrossRef]

- Liu, M.; Obi, O.; Lou, J.; Chen, Y.J.; Cai, Z.H.; Stoute, S.; Espanol, M.; Lew, M.; Situ, X.; Ziemer, K.S.; et al. Giant electric field tuning of magnetic properties in multiferroic ferrite/ferroelectric heterostructures. Adv. Funct. Mater. 2009, 19, 1826. [Google Scholar] [CrossRef]

- Yang, P.; Peng, S.; Wu, X.B.; Wan, J.G.; Lu, X.M.; Yan, F.; Zhu, J.S. Magnetoelectricity in laminate composites of Terfenol-D and 0.52Pb(Fe1/2Nb1/2)O3–0.48PbTiO3 with different orientations. J. Phys. D Appl. Phys. 2009, 42, 015005. [Google Scholar] [CrossRef]

- Ryu, J.; Priya, S.; Carazo, A.V.; Uchino, K. Effect of the magnetostrictive layer on magnetoelectric properties in lead zirconate titanate/Terfenol-D laminate composites. J. Am. Ceram. Soc. 2001, 84, 2905–2908. [Google Scholar] [CrossRef]

- Dong, S.; Li, J.-F.; Viehland, D. Ultrahigh magnetic field sensitivity in laminates of TERFENOL-D and PbMg1/3Nb2/3O3–PbTiO3 crystals. Appl. Phys. Lett. 2003, 83, 2265–2267. [Google Scholar] [CrossRef]

- Dong, S.X.; Cheng, J.R.; Li, J.F.; Viehland, D. Enhanced magnetoelectric effects in laminate composites of Terfenol-D/Pb(Zr,Ti)O3 under resonant drive. Appl. Phys. Lett. 2003, 83, 4812. [Google Scholar] [CrossRef]

- Dai, X.; Wen, Y.; Li, P.; Yang, J.; Zhang, G. Modeling, characterization and fabrication of vibration energy harvester using, Terfenol-D/PZT/Terfenol-D composite transducer. Sens. Actuators A Phys. 2009, 156, 350–358. [Google Scholar] [CrossRef]

- Jia, Y.; Or, S.W.; Chan, H.L.W.; Zhao, X.; Luo, H. Converse magnetoelectric effect in laminated composites of PMN–PT single crystal and Terfenol-D alloy. Appl. Phys. Lett. 2006, 88, 242902. [Google Scholar] [CrossRef]

- Zhao, C.P.; Fang, F.; Yang, W. A dual-peak phenomenon of magnetoelectric coupling in laminated Terfenol-D/PZT/Terfenol-D composites. Smart Mater. Struct. 2010, 19, 125004. [Google Scholar] [CrossRef]

- Dong, S.; Li, J.-F.; Viehland, D. A longitudinal-longitudinal mode TERFENOL-/Pb(Mg1/3Nb2/3O3–PbTiO3 laminate composite. Appl. Phys. Lett. 2004, 85, 5305–5306. [Google Scholar] [CrossRef]

- Dong, S.; Zhai, J.; Li, J.-F.; Viehland, D. Magnetoelectric effect in Terfenol-D/Pb(Zr,Ti)O3/μ-metal laminate composites. Appl. Phys. Lett. 2006, 89, 122903. [Google Scholar] [CrossRef]

- Bochenek, D.; Chrobak, A.; Dercz, G. Influence of the sintering method on the properties of a multiferroic ceramic composite based on PZT-type ferroelectric material and Ni-Zn ferrite. Materials 2022, 15, 8461. [Google Scholar] [CrossRef] [PubMed]

- Bobić, J.D.; Ivanov, M.; Ilić, N.I.; Dzunuzović, A.S.; Vijatović Petrović, M.M.; Banys, J.; Ribic, A.; Despotovic, Z.; Stojanovic, B.D. PZT-nickel ferrite and PZT-cobalt ferrite comparative study: Structural, dielectric, ferroelectric and magnetic properties of composite ceramics. Ceram. Int. 2018, 44, 6551–6557. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bochenek, D.; Chrobak, A.; Dercz, G.; Niemiec, P.; Brzezińska, D.; Czaja, P. The Influence of Terfenol-D Content on the Structure and Properties of Multiferroic Composites Obtained Based on PZT-Type Material and Terfenol-D. Materials 2025, 18, 235. https://doi.org/10.3390/ma18020235

Bochenek D, Chrobak A, Dercz G, Niemiec P, Brzezińska D, Czaja P. The Influence of Terfenol-D Content on the Structure and Properties of Multiferroic Composites Obtained Based on PZT-Type Material and Terfenol-D. Materials. 2025; 18(2):235. https://doi.org/10.3390/ma18020235

Chicago/Turabian StyleBochenek, Dariusz, Artur Chrobak, Grzegorz Dercz, Przemysław Niemiec, Dagmara Brzezińska, and Piotr Czaja. 2025. "The Influence of Terfenol-D Content on the Structure and Properties of Multiferroic Composites Obtained Based on PZT-Type Material and Terfenol-D" Materials 18, no. 2: 235. https://doi.org/10.3390/ma18020235

APA StyleBochenek, D., Chrobak, A., Dercz, G., Niemiec, P., Brzezińska, D., & Czaja, P. (2025). The Influence of Terfenol-D Content on the Structure and Properties of Multiferroic Composites Obtained Based on PZT-Type Material and Terfenol-D. Materials, 18(2), 235. https://doi.org/10.3390/ma18020235