Bending Behavior of Fiber Metal Laminate Plates Under Thermo-Mechanical Loads

Abstract

1. Introduction

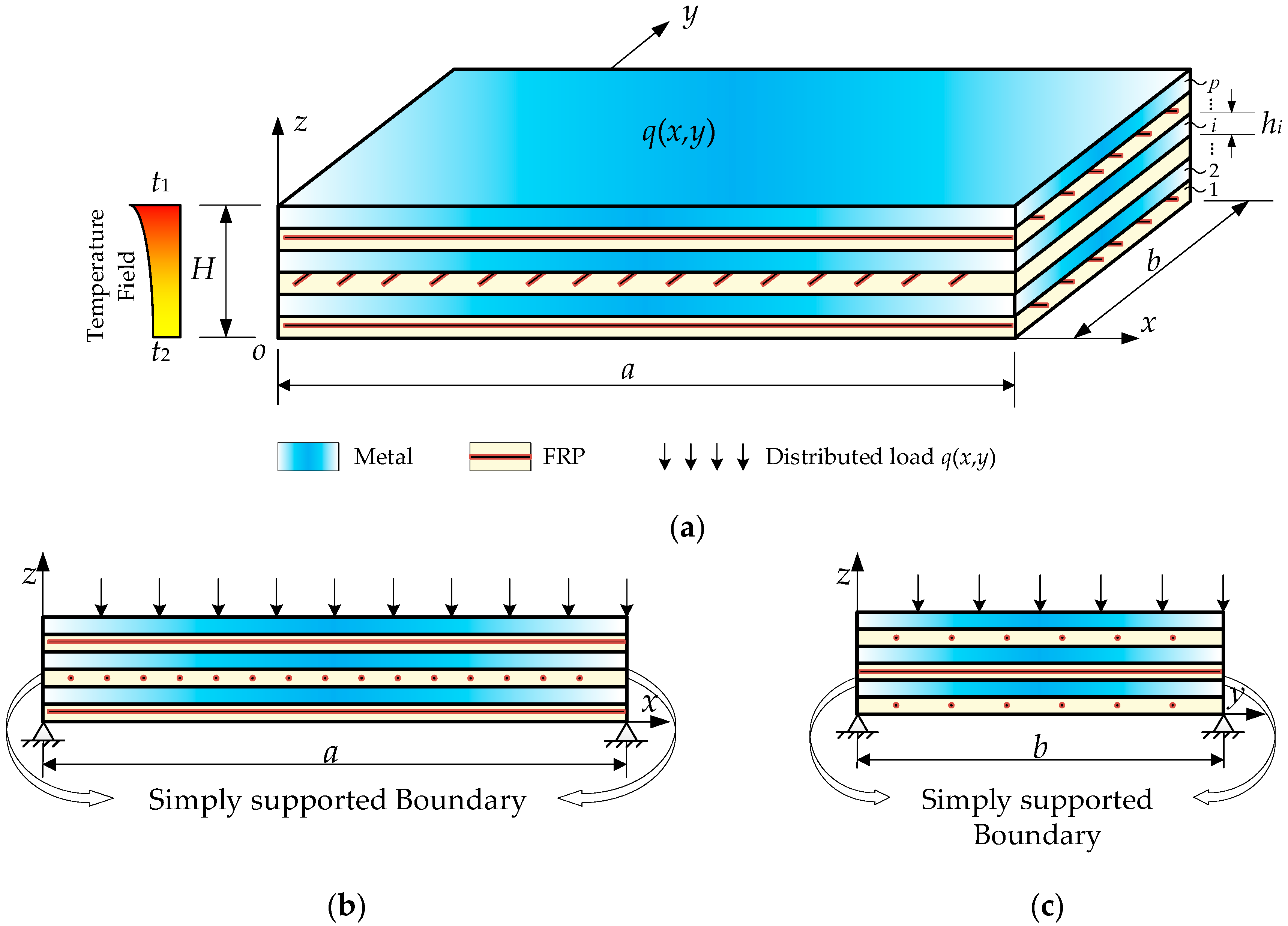

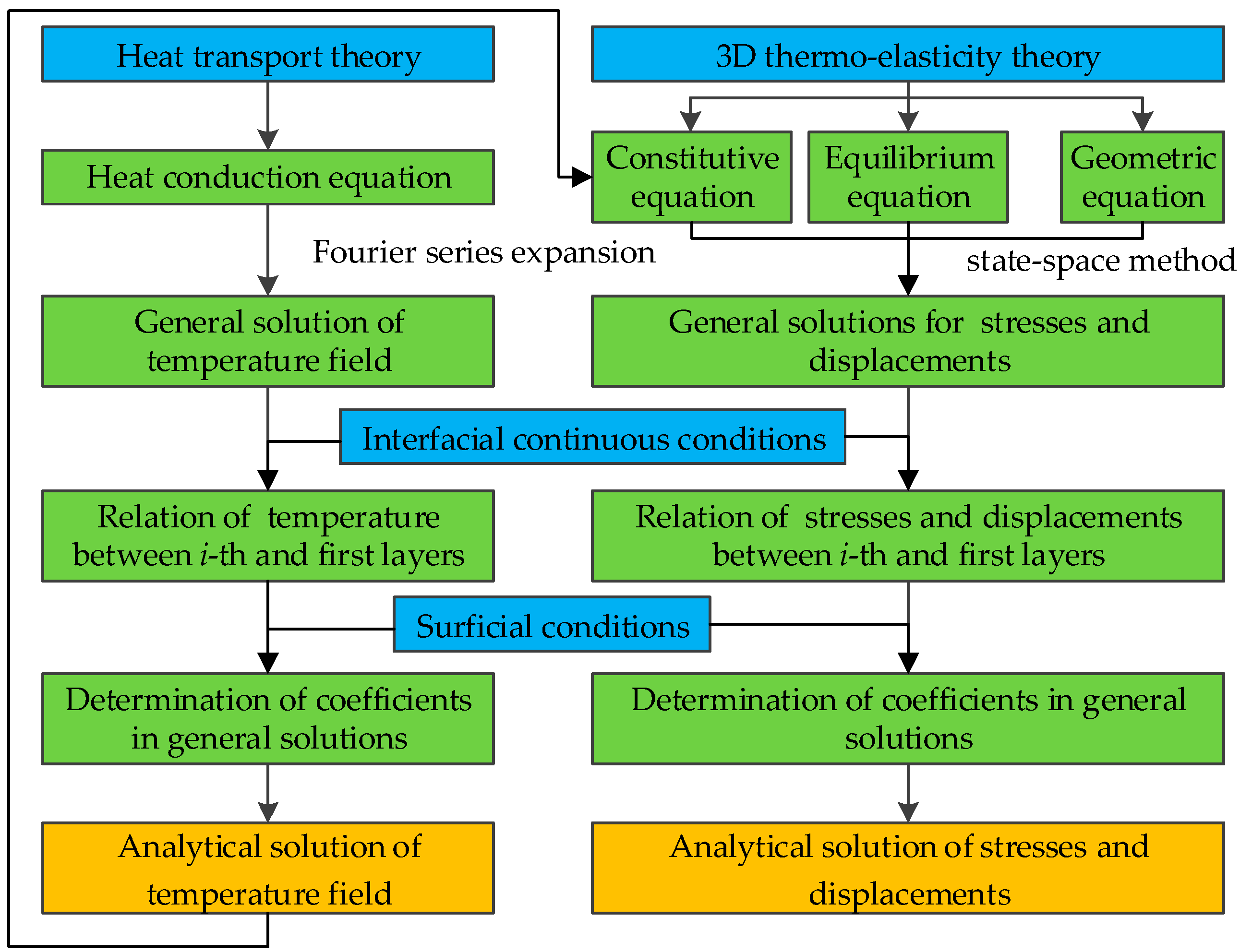

2. Thermo-Mechanical Analytical Model of FML Plate

2.1. Basic Assumptions and Applicability Scope

- (1)

- There is no internal heat generation, and that convective and radiative heat losses are neglected;

- (2)

- The temperature analysis considers only steady-state heat conduction;

- (3)

- The FML plate deforms within the linear range;

- (4)

- The adjacent laminae are well-bonded, and the interfacial slip is beyond the scope of consideration.

2.2. Temperature Field

2.3. Stress and Displacement

3. Results and Discussion

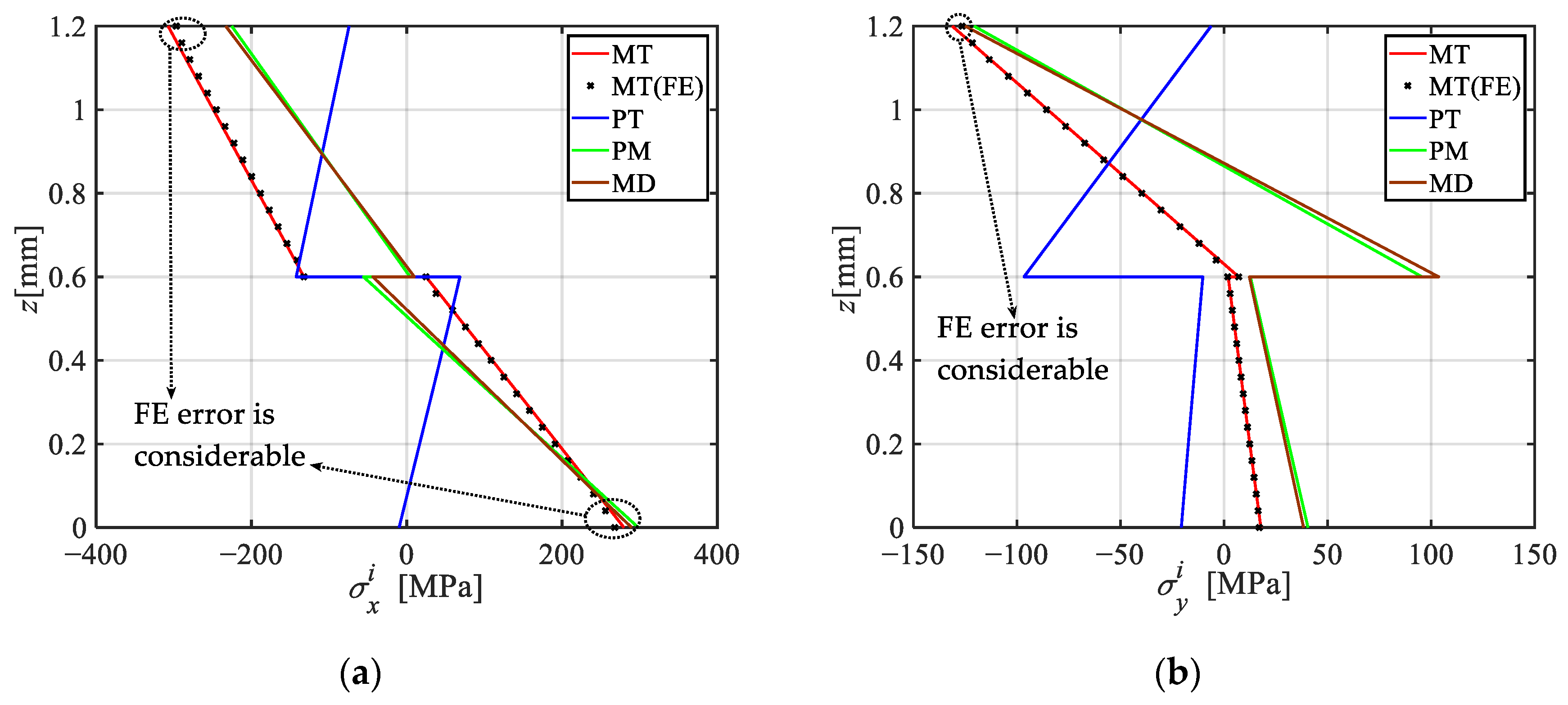

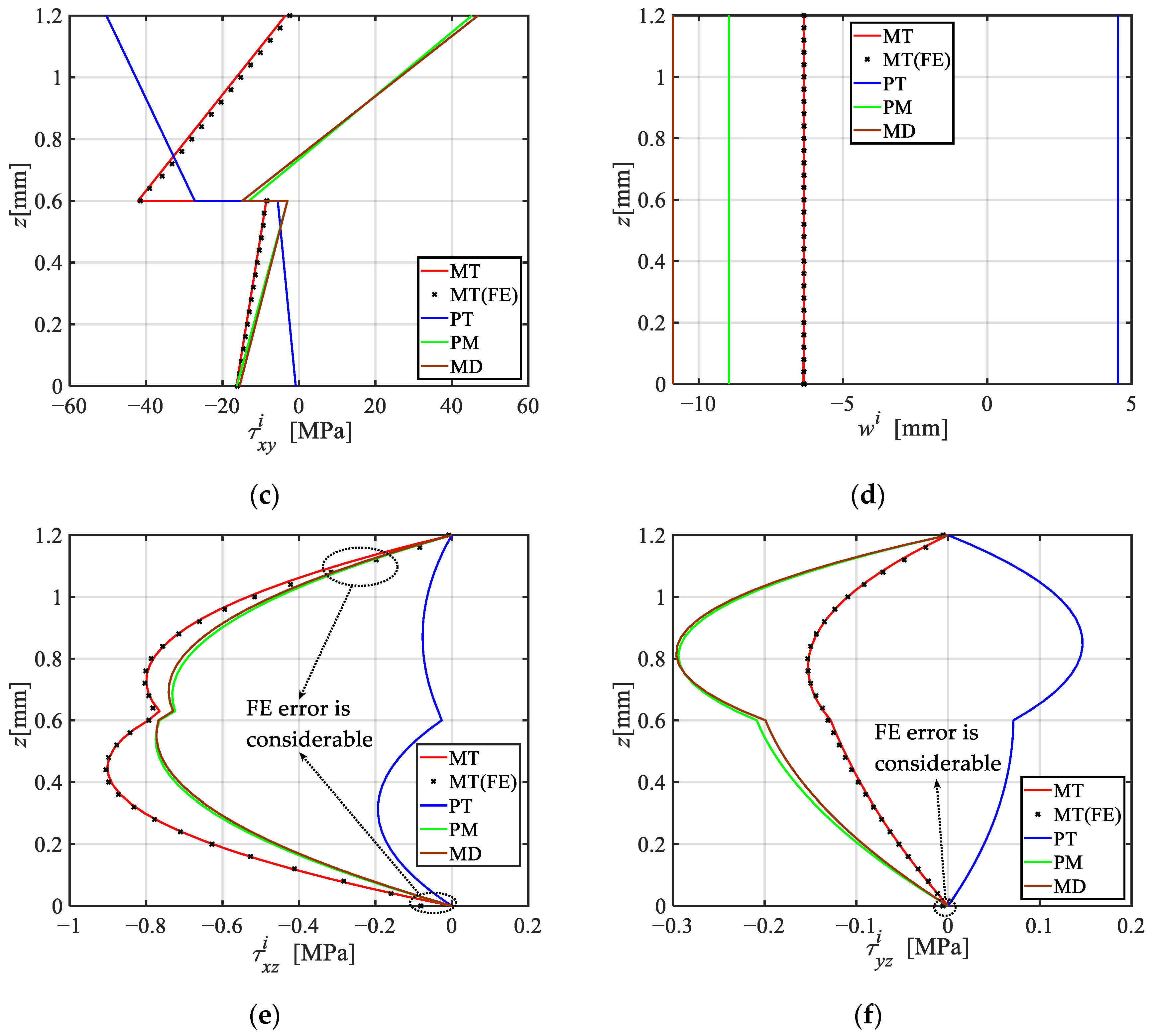

3.1. Comparison and Decoupling Analyses

3.2. Effect of Surficial Temperature Difference

3.3. Combined Effects of Temperature and Lamina Number

4. Conclusions

- The finite element results generally agree well with the present analytical solutions, with relative errors below 2%, except in regions adjacent to the top and bottom surfaces. In addition, the present solution agrees well with the experimental values for the laminated plate within the linear range, with errors below 10%.

- The traditional superposition principle proves inaccurate in predicting the thermo-mechanical bending behavior of FML plates, with maximum errors reaching up to 30.39%. To address this, a modified superposition principle incorporating temperature-induced modulus reduction is proposed.

- Under a uniform temperature field, normal stress remains constant and shear stress varies linearly across each lamina. A non-uniform temperature field causes differential thermal expansion, leading to bending deformation; the normal stress slope increases with the temperature gradient, amplifying the bending effect.

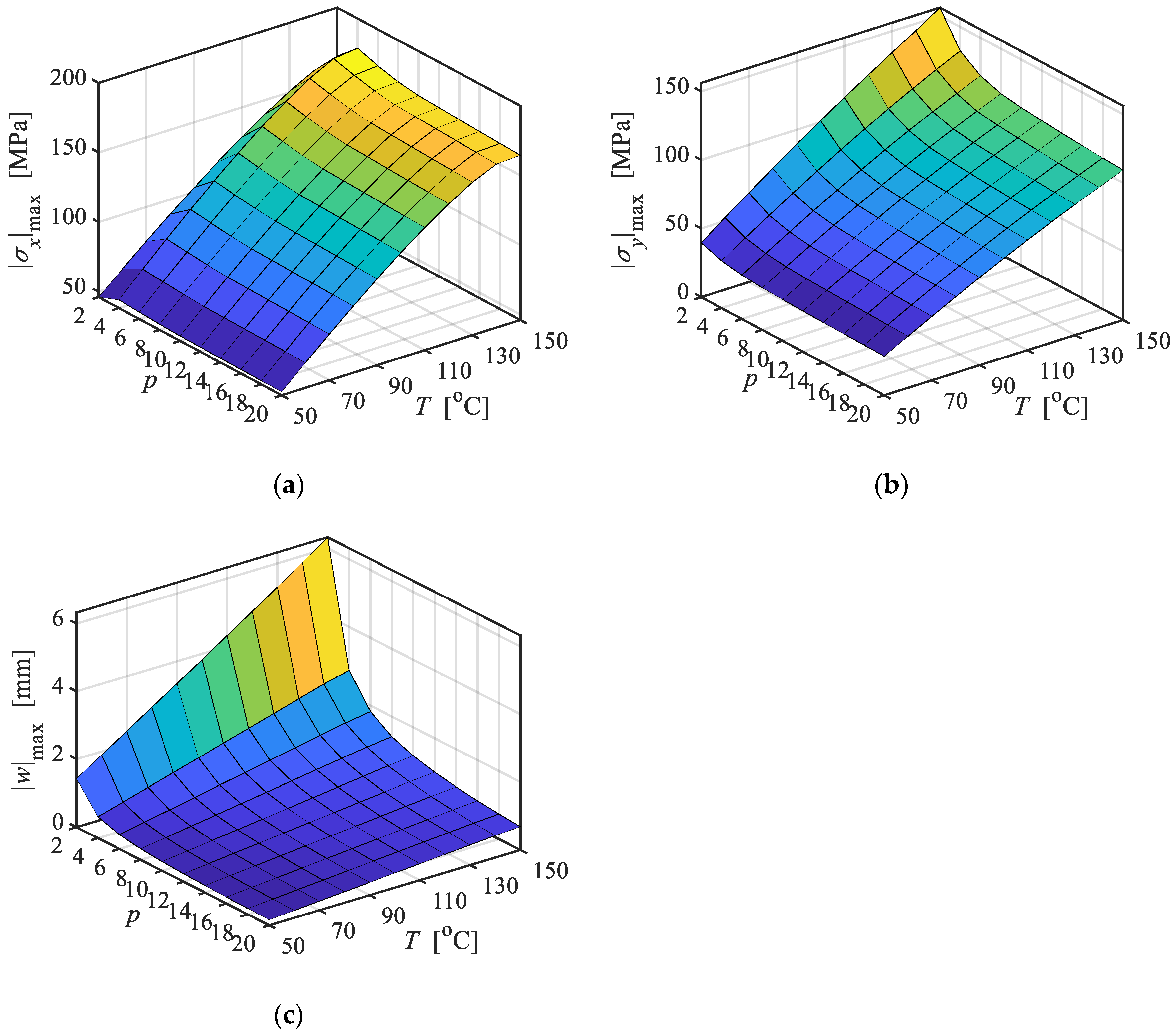

- The combined effect of temperature and lamina number shows that increasing temperature leads to nonlinear stress growth due to modulus degradation, while increasing the number of laminae contributes to stress distribution homogenization. For small lamina counts, displacements decrease rapidly with increasing lamina number, whereas beyond a certain threshold, the benefits of additional laminae diminish and the response approaches a stable value.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Múgica, J.I.; Aretxabaleta, L.; Ulacia, I.; Aurrekoetxea, J. Impact Characterization of Thermoformable Fibre Metal Laminates of 2024-T3 Aluminium and AZ31B-H24 Magnesium Based on Self-Reinforced Polypropylene. Compos. Part A Appl. Sci. Manuf. 2014, 61, 67–75. [Google Scholar] [CrossRef]

- Blala, H.; Lang, L.; Khan, S.; Li, L.; Sijia, S.; Guelailia, A.; Slimane, S.A.; Alexandrov, S. Forming Challenges of Small and Complex Fiber Metal Laminate Parts in Aerospace Applications—A Review. Int. J. Adv. Manuf. Technol. 2023, 126, 2509–2543. [Google Scholar] [CrossRef]

- Li, H.; Hu, Y.; Liu, C.; Zheng, X.; Liu, H.; Tao, J. The Effect of Thermal Fatigue on the Mechanical Properties of the Novel Fiber Metal Laminates Based on Aluminum–Lithium Alloy. Compos. Part A Appl. Sci. Manuf. 2016, 84, 36–42. [Google Scholar] [CrossRef]

- Wang, J.; Anderson, A. Flexural Behavior of Al–Epoxy/(Basalt–Glass) Fiber Composites. JOM 2025, 77, 6314–6324. [Google Scholar] [CrossRef]

- Li, L.; Lang, L.; Khan, S.; Wang, Y. Investigation into Effect of the Graphene Oxide Addition on the Mechanical Properties of the Fiber Metal Laminates. Polym. Test. 2020, 91, 106766. [Google Scholar] [CrossRef]

- Hussain, M.; Zaki, W.; Umer, R. Flexural Performance of Shape Memory Alloy/CF-PEKK Fiber Metal Laminates for Aircraft Morphing under Varied Temperature Conditions. Sci. Rep. 2025, 15, 14093. [Google Scholar] [CrossRef]

- Hu, Y.; Zhang, Y.; Fu, X.; Hao, G.; Jiang, W. Mechanical Properties of Ti/CF/PMR Polyimide Fiber Metal Laminates with Various Layup Configurations. Compos. Struct. 2019, 229, 111408. [Google Scholar] [CrossRef]

- Logesh, K.; Bupesh Raja, V.K. Evaluation of Mechanical Properties of Mg-Al Layered Double Hydroxide as a Filler in Epoxy-Based FML Composites. Int. J. Adv. Manuf. Technol. 2019, 104, 3267–3285. [Google Scholar] [CrossRef]

- Vasudevan, B.; Nagarajan, L.; Nachippan, N.M.; Durvasulu, R.; Ansari, M.A. Unlocking the Potential of Copper-Reinforced Fibre Metal Laminates: The Influence of Stacking Sequences. J. Mater. Res. Technol. 2024, 33, 6546–6558. [Google Scholar] [CrossRef]

- Hu, Y.; Li, H.; Tao, J.; Pan, L.; Xu, J. The Effects of Temperature Variation on Mechanical Behaviors of Polyetheretherketone-based Fiber Metal Laminates. Polym. Compos. 2018, 39, 1447–1454. [Google Scholar] [CrossRef]

- Sang, L.; Xing, J.; Lv, J.; Gao, S.; Hou, W. Investigation of Structure–Flexural Response Relations in Thermoplastic Carbon/Glass Fiber-metal Laminates. Polym. Compos. 2024, 45, 5619–5632. [Google Scholar] [CrossRef]

- Jin, K.; Xuan, S.; Tao, J.; Chen, Y. The Synergistic Effect of Temperature and Loading Rate on Deformation for Thermoplastic Fiber Metal Laminates. Materials 2021, 14, 4210. [Google Scholar] [CrossRef]

- Jin, K.; Wang, H.; Tao, J.; Du, D. Mechanical Analysis and Progressive Failure Prediction for Fibre Metal Laminates Using a 3D Constitutive Model. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105490. [Google Scholar] [CrossRef]

- Abouhamzeh, M.; Sinke, J.; Jansen, K.M.B.; Benedictus, R. A New Procedure for Thermo-Viscoelastic Modelling of Composites with General Orthotropy and Geometry. Compos. Struct. 2015, 133, 871–877. [Google Scholar] [CrossRef]

- Aydogdu, M. A New Shear Deformation Theory for Laminated Composite Plates. Compos. Struct. 2009, 89, 94–101. [Google Scholar] [CrossRef]

- Ghomshei, M.M.M.; Mahmoudi, A. Thermal Buckling Analysis of Cross-Ply Laminated Rectangular Plates under Nonuniform Temperature Distribution: A Differential Quadrature Approach. J. Mech. Sci. Technol. 2010, 24, 2519–2527. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Z.; Lin, Y.; Wang, H.; Hua, L. Theoretical Modeling and Experimental Verification of the Bending Deformation of Fiber Metal Laminates. Materials 2023, 16, 3486. [Google Scholar] [CrossRef]

- Ali, J.S.M.; Bhaskar, K.; Varadan, T.K. A New Theory for Accurate Thermal/Mechanical Flexural Analysis of Symmetric Laminated Plates. Compos. Struct. 1999, 45, 227–232. [Google Scholar] [CrossRef]

- Wang, X.; Shi, G. A Refined Laminated Plate Theory Accounting for the Third-Order Shear Deformation and Interlaminar Transverse Stress Continuity. Appl. Math. Model. 2015, 39, 5659–5680. [Google Scholar] [CrossRef]

- Jiang, H.J.; Liang, L.H.; Ma, L.; Guo, J.; Dai, H.L.; Wang, X.G. An Analytical Solution of Three-Dimensional Steady Thermodynamic Analysis for a Piezoelectric Laminated Plate Using Refined Plate Theory. Compos. Struct. 2017, 162, 194–209. [Google Scholar] [CrossRef]

- Han, J.W.; Kim, J.S.; Cho, M. New Enhanced First-Order Shear Deformation Theory for Thermo-Mechanical Analysis of Laminated Composite and Sandwich Plates. Compos. Part B Eng. 2017, 116, 422–450. [Google Scholar] [CrossRef]

- Brischetto, S.; Carrera, E. Heat Conduction and Thermal Analysis in Multilayered Plates and Shells. Mech. Res. Commun. 2011, 38, 449–455. [Google Scholar] [CrossRef]

- Grigoriou, K.; Mouritz, A.P. Modelling and Testing of Fibre Metal Laminates and Their Constituent Materials in Fire. Compos. Struct. 2018, 200, 25–35. [Google Scholar] [CrossRef]

- Feih, S.; Mathys, Z.; Gibson, A.G.; Mouritz, A.P. Modelling the Tension and Compression Strengths of Polymer Laminates in Fire. Compos. Sci. Technol. 2007, 67, 551–564. [Google Scholar] [CrossRef]

- Asaro, R.J.; Lattimer, B.; Ramroth, W. Structural Response of FRP Composites during Fire. Compos. Struct. 2009, 87, 382–393. [Google Scholar] [CrossRef]

- Carslaw, H.S.; Jaeger, J.C. Conduction of Heat in Solids, 2nd ed.; Oxford University Press: Oxford, UK, 1959. [Google Scholar]

- Pinsky, M.A. Partial Differential Equations and Boundary-Value Problems with Applications, 3rd ed.; McGraw-Hill: New York, NY, USA, 1991. [Google Scholar]

- Li, X.; Yu, J.; Fang, H.; Wu, P. Modified State Space Method for Bending Creep and Recovery Behaviors of Viscoelastic Orthotropic Laminated Plate. Eur. J. Mech. A/Solids 2024, 105, 105235. [Google Scholar] [CrossRef]

- Yu, J.; Guan, B.; Sun, B.; Zhang, Y.; Yue, K.; Hu, C.; Wu, P. Modified State Space Method for Long-Term Behavior of Viscoelastic Laminated Angle-Ply Plate. Compos. Struct. 2024, 339, 118151. [Google Scholar] [CrossRef]

- Mivehchi, H.; Varvani-Farahani, A. The Effect of Temperature on Fatigue Damage of FRP Composites. J. Mater. Sci. 2010, 45, 3757–3767. [Google Scholar] [CrossRef]

- Afaghi Khatibi, A.; Kandare, E.; Feih, S.; Lattimer, B.Y.; Case, S.W.; Mouritz, A.P. Finite Element Modelling of Tensile Deformation and Failure of Aluminium Plate Exposed to Fire. Comput. Mater. Sci. 2014, 95, 242–249. [Google Scholar] [CrossRef]

- Zhou, J.; Wen, P.; Wang, S. Numerical Investigation on the Repeated Low-Velocity Impact Behavior of Composite Laminates. Compos. Part B Eng. 2020, 185, 107771. [Google Scholar] [CrossRef]

- He, M.J.; Sun, X.F.; Li, Z.; Feng, W. Bending, shear, and compressive properties of three- and five-layer cross-laminated timber fabricated with black spruce. J. Wood Sci. 2020, 66, 38. [Google Scholar] [CrossRef]

| Material Type | Values of Material Property |

|---|---|

| CFRP | = 6, = 0.4 = 30 × 10−6, = 0.8 |

| AA | = 0.33 = 23.6 × 10−6, k = 121 |

| Conditions | Load Effect | Thermal Stresses and Deformation | Temperature-Induced Modulus Degradation |

|---|---|---|---|

| PM | √ | ||

| PT | √ | √ | |

| MD | √ | √ | |

| MT | √ | √ | √ |

| Conditions | (MPa) | (MPa) | (MPa) | (MPa) | (MPa) | (mm) |

|---|---|---|---|---|---|---|

| TSP (PM + PT) | 299.4 | 126.83 | 40.33 | 0.9094 | 0.1527 | 4.430 |

| MSP (MT) | 307.2 | 131.2 | 42.10 | 0.9012 | 0.1516 | 6.364 |

| errors | 2.54% | 3.33% | 4.20% | 0.91% | 0.73% | 30.39% |

| Solution | Displacement in Linear Rage (mm) | |

|---|---|---|

| Three-Layer | Five-Layer | |

| Present | 62.49 | 83.77 |

| Test 1 | 59.5 | 85.76 |

| Test 2 | 69.47 | 87.19 |

| Test 3 | 75.12 | 104 |

| Test average | 68.03 | 92.32 |

| Errors | 8.14% | 9.26% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, L.; Xing, T.; Zhao, Y.; Yuan, Y.; Yang, C. Bending Behavior of Fiber Metal Laminate Plates Under Thermo-Mechanical Loads. Materials 2025, 18, 4640. https://doi.org/10.3390/ma18194640

Pan L, Xing T, Zhao Y, Yuan Y, Yang C. Bending Behavior of Fiber Metal Laminate Plates Under Thermo-Mechanical Loads. Materials. 2025; 18(19):4640. https://doi.org/10.3390/ma18194640

Chicago/Turabian StylePan, Like, Tong Xing, Yingxin Zhao, Yuan Yuan, and Caizhi Yang. 2025. "Bending Behavior of Fiber Metal Laminate Plates Under Thermo-Mechanical Loads" Materials 18, no. 19: 4640. https://doi.org/10.3390/ma18194640

APA StylePan, L., Xing, T., Zhao, Y., Yuan, Y., & Yang, C. (2025). Bending Behavior of Fiber Metal Laminate Plates Under Thermo-Mechanical Loads. Materials, 18(19), 4640. https://doi.org/10.3390/ma18194640