Fabrication and Oxidation Resistance of Metallic Ta-Reinforced High-Entropy (Ti,Zr,Hf,Nb,Ta)B2 Ceramics

Abstract

1. Introduction

2. Experimental Details

2.1. Preparation

2.2. Characterization and Measurement

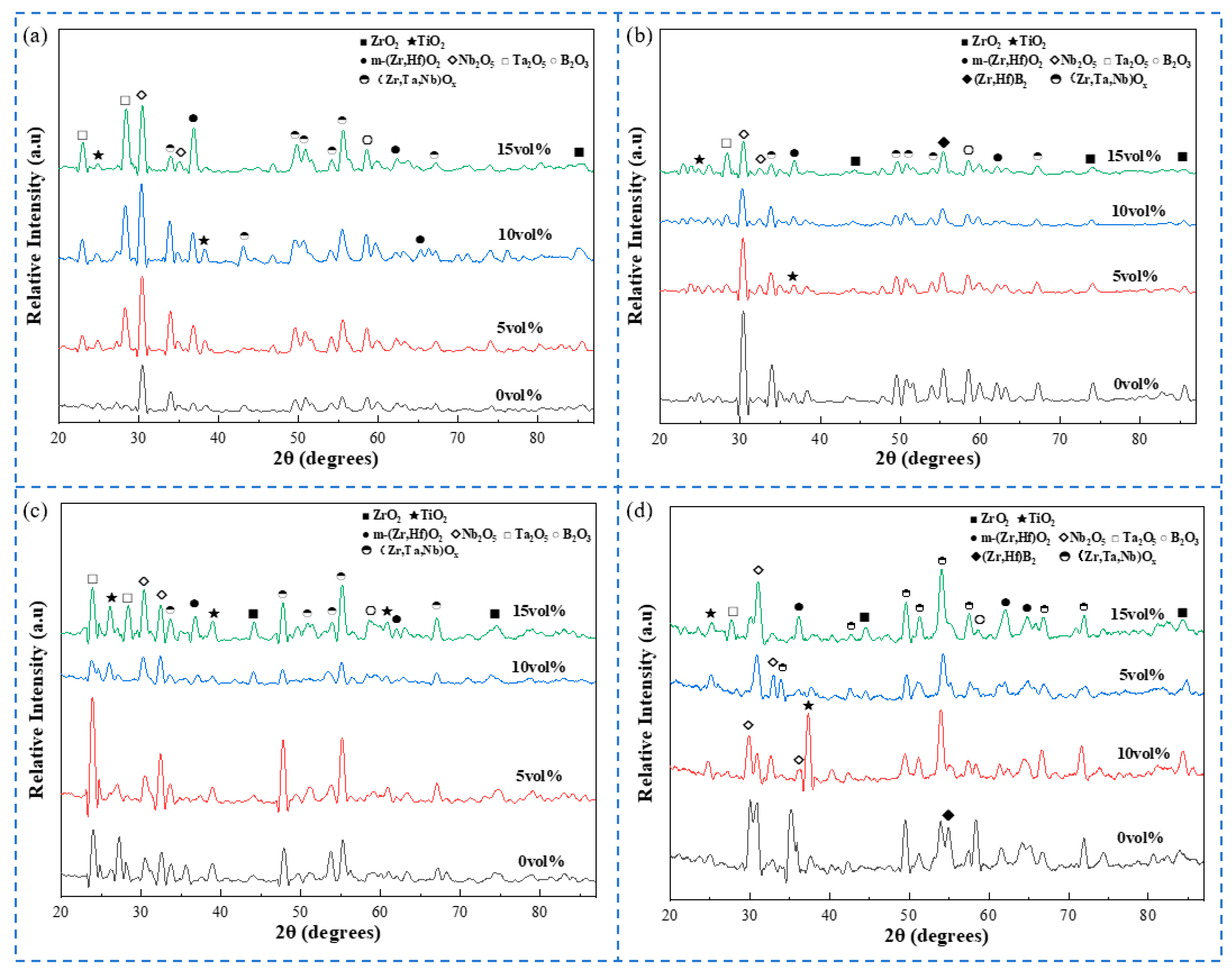

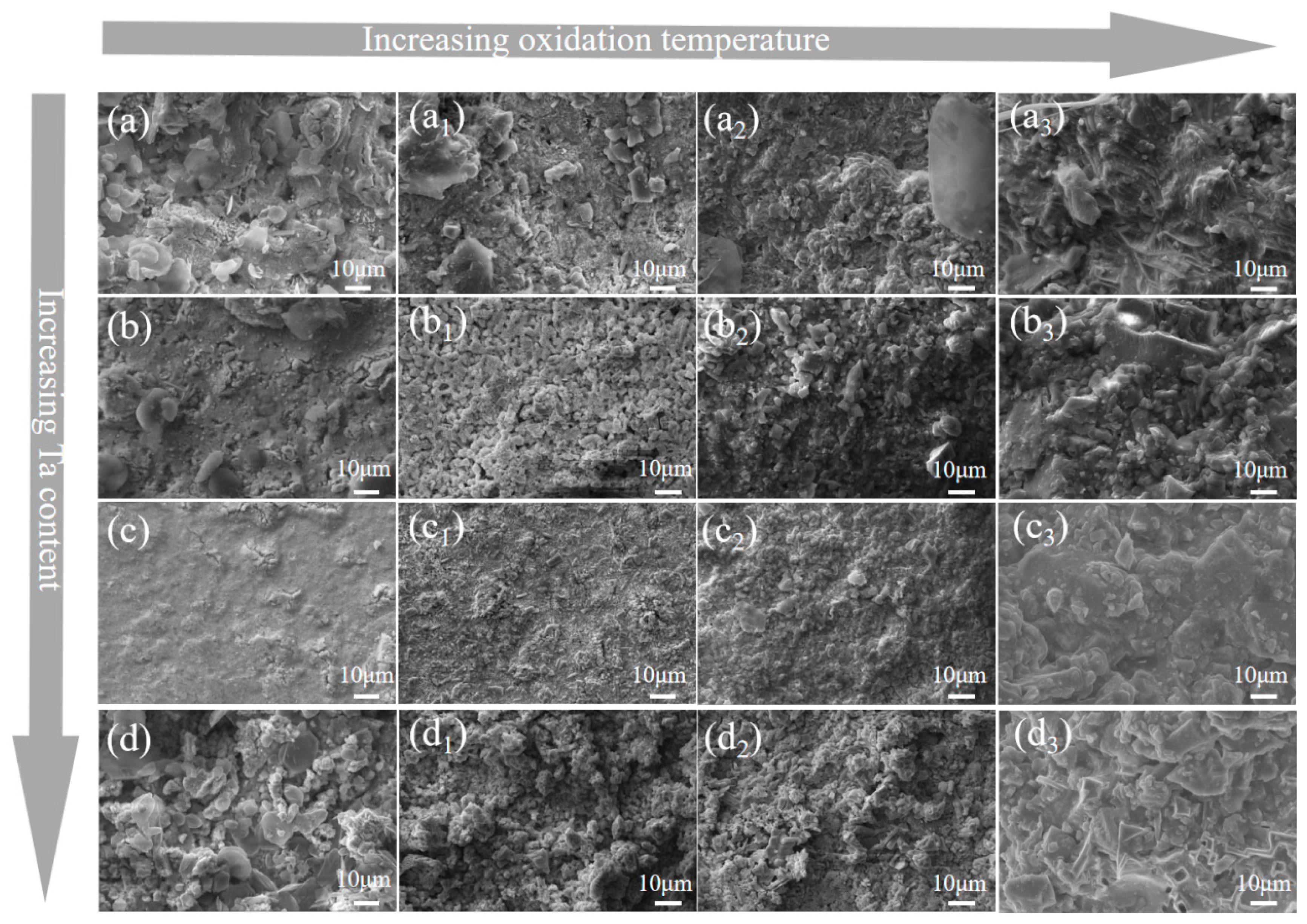

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yu, H.; Zhao, Q.; Fu, J.; Hu, Y.; Liang, J.; Li, J.; Xu, W. The design of oxidation resistant Ni superalloys for additive manufacturing. Addit. Manuf. 2025, 97, 104616. [Google Scholar] [CrossRef]

- Rost, C.M.; Sachet, E.; Borman, T.; Moballegh, A.; Dickey, E.C.; Hou, D.; Jones, J.L.; Curtarolo, S.; Maria, J.-P. Entropy-stabilized oxides. Nat. Commun. 2015, 6, 8485. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, D.; Nagaumi, H.; Wu, Z.; Zhang, M.; Wang, R.; Zou, J.; Chen, H.; Wang, P.; Zhou, P. Unveiling the growth mechanism of Fe-containing intermetallics in Al-Si alloy in the perspective of surface stability and atom adsorption. J. Mater. Res. Technol. 2025, 35, 2458–2470. [Google Scholar] [CrossRef]

- Wang, C.; Hao, J.; Duan, L.; Zhao, D.; Ma, Y.; Zhang, J.; Ma, P.; Han, D.; Meng, F. Energy storage performance with ultrahigh energy density and power density of Ba0.85Ca0.15Zr0.1Ti0.9O3-based lead-free ceramics through synergistic optimization. Ceram. Int. 2025, 51, 35133–35143. [Google Scholar] [CrossRef]

- Shen, C.; Wang, C.; Wei, X.; Li, Y.; van der Zwaag, S.; Xu, W. Physical metallurgy-guided machine learning and artificial intelligent design of ultrahigh-strength stainless steel. Acta Mater. 2019, 179, 201–214. [Google Scholar] [CrossRef]

- Xu, J.; Li, D.; Song, J.; Du, D.; Zhang, X. Hydrolysis behavior and mechanism of AlON powders. Mater. Des. 2025, 256, 114338. [Google Scholar] [CrossRef]

- Oses, C.; Toher, C.; Curtarolo, S. High-entropy ceramics. Nat. Rev. Mater. 2020, 5, 295–309. [Google Scholar] [CrossRef]

- Akrami, S.; Edalati, P.; Fuji, M.; Edalati, K. High-entropy ceramics: Review of principles, production and applications. Mater. Sci. Eng. R: Rep. 2021, 146, 100644. [Google Scholar] [CrossRef]

- Jiao, Y.; Dai, J.; Fan, Z.; Cheng, J.; Zheng, G.; Lawan, G.; Zhong, J.; Li, H.; Wang, D. Overview of high-entropy oxide ceramics. Mater. Today 2024, 77, 92–117. [Google Scholar] [CrossRef]

- Gild, J.; Zhang, Y.; Harrington, T.; Jiang, S.; Hu, T.; Quinn, M.C.; Mellor, W.M.; Zhou, N.; Vecchio, K.S.; Luo, J. High-Entropy Metal Diborides: A New Class of High-Entropy Materials and a New Type of Ultrahigh Temperature Ceramics. Sci. Rep. 2018, 8, 8609. [Google Scholar] [CrossRef]

- Liu, J.; Yang, Q.Q.; Zou, J.; Wang, W.M.; Wang, X.G.; Fu, Z.Y. Strong high-entropy diboride ceramics with oxide impurities at 1800 °C. Sci. China Mater. 2023, 66, 2061–2070. [Google Scholar] [CrossRef]

- Han, X.; Girman, V.; Sedlak, R.; Dusza, J.; Castle, E.G.; Wang, Y.; Reece, M.; Zhang, C. Improved creep resistance of high entropy transition metal carbides. J. Eur. Ceram. Soc. 2020, 40, 2709–2715. [Google Scholar] [CrossRef]

- Hu, J.; Yang, Q.; Zhu, S.; Zhang, Y.; Yan, D.; Gan, K.; Li, Z. Superhard bulk high-entropy carbides with enhanced toughness via metastable in-situ particles. Nat. Commun. 2023, 14, 5717. [Google Scholar] [CrossRef]

- Nayak, G.K.; Kretschmer, A.; Mayrhofer, P.H.; Holec, D. On correlations between local chemistry, distortions and kinetics in high entropy nitrides: An ab initio study. Acta Mater. 2023, 255, 118951. [Google Scholar] [CrossRef]

- Yuan, M.; Gao, X.; Gu, X.; Dong, C.; Wang, S.; Wen, M.; Zhang, K. Simultaneous enhancement of hardness and wear and corrosion resistance of high-entropy transition-metal nitride. J. Am. Ceram. Soc. 2023, 106, 1356–1368. [Google Scholar] [CrossRef]

- Tao, Q.; Ma, S.-L.; Cui, T.; Zhu, P.-W. Structures and properties of functional transition metal borides. Acta Phys. Sin. 2017, 66, 036103. [Google Scholar] [CrossRef]

- Yang, Y.; Bi, J.; Qiao, L.; Liang, G.; Liang, S.; Liu, S.; Wang, S.; Gong, H.; Qian, Z.; Shi, J.; et al. Effect of grain size on mechanical properties and tribological behavior of size-tunable high entropy diboride ceramics obtained by two-step SPS sintering. J. Adv. Ceram. 2024, 13, 1835–1843. [Google Scholar] [CrossRef]

- Su, Y.; Jiang, F.; Long, M.; Wu, F.; Xiao, Z.; Wu, M. Microstructure and frictional properties of copper-tin composites containing graphite and MoS2 by rapid hot-press sintering. Tribol. Int. 2023, 183, 108392. [Google Scholar] [CrossRef]

- Zhu, N.; Zhu, L.; Zhang, B.; Feng, P.; Li, S.; Kiryukhantsev-Korneev, P.V.; Levashov, E.A.; Ren, X.; Wang, X. Microstructural evolution and 1500 °C oxidation resistance of Mo (Al, Si) 2 fabricated via an innovative two-step SHS-SPS technique. Mater. Des. 2024, 247, 113397. [Google Scholar] [CrossRef]

- Ying, H.; Guo, Q.; Yuan, B.; Fan, H.; Yan, W.; Zheng, X.; Zhang, J.; Wu, J.; Liu, R. Preparation and properties of Ta foil toughened high entropy (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2) B2-SiC layered structure composites. Mater. Today Commun. 2025, 42, 111466. [Google Scholar] [CrossRef]

- Guo, Q.; Hou, H.; Wang, K.; Li, M.; Liaw, P.K.; Zhao, Y. Coalescence of Al0.3CoCrFeNi polycrystalline high-entropy alloy in hot-pressed sintering: A molecular dynamics and phase-field study. NPJ Comput. Mater. 2023, 9, 185. [Google Scholar] [CrossRef]

- Yang, Y.; Zhu, T.; Liang, X.; Liao, N.; Li, Y.; Sang, S.; Xie, Z.; Dai, J. Mechanical and tribological properties of SiC-GNPs composites prepared by oscillatory pressure sintering. Ceram. Int. 2022, 48, 34769–34779. [Google Scholar] [CrossRef]

- Li, M.; Zhao, X.; Shao, G.; Zhang, R. Oscillatory pressure sintering of high entropy (Zr0.2Ta0.2Nb0.2Hf0.2Mo0.2) B2 ceramic. Ceram. Int. 2021, 47, 8707–8710. [Google Scholar] [CrossRef]

- Liang, H.; Peng, F.; Chen, H.; Tan, L.; Zhang, Q.; Fan, C.; Guan, S.; Ni, X.; Liang, A.; Yan, X.; et al. High-pressure sintering of bulk MoSi2: Microstructural, physical properties and mechanical behavior. Mater. Sci. Eng. A 2018, 711, 389–396. [Google Scholar] [CrossRef]

- Gild, J.; Kaufmann, K.; Vecchio, K.; Luo, J. Reactive flash spark plasma sintering of high-entropy ultrahigh temperature ceramics. Scr. Mater. 2019, 170, 106–110. [Google Scholar] [CrossRef]

- Velappan, S.; Sellappan, R. Influence of ferrosilicon sintering aid on microstructure and mechanical properties of silicon nitride bonded SiC refractories. Mater. Today Commun. 2022, 33, 104575. [Google Scholar] [CrossRef]

- Xu, L.; Guo, W.-M.; Zou, J.; Zhou, Y.-Z.; Liang, H.-Y.; Qiu, S.-H.; Lin, H.-T.; Fu, Z. Low-temperature densification of high entropy diboride based composites with fine grains and excellent mechanical properties. Compos. Part B Eng. 2022, 247, 1359–8368. [Google Scholar] [CrossRef]

- Huang, Z.J.; Su, L.F.; Xu, L.; Zhou, Y.Z.; Guo, W.M.; Lin, H.T. Dense(Hf0.2Mo0.2Ta0.2Nb0.2Ti0.2)B2 ceramics prepared by pressureless sintering with Ni additives. Ceram. Int. 2023, 49, 27651–27656. [Google Scholar] [CrossRef]

- Wong, L.W.; Yang, K.; Han, W.; Zheng, X.; Wong, H.Y.; Tsang, C.S.; Lee, C.-S.; Lau, S.P.; Ly, T.H.; Yang, M.; et al. Deciphering the ultra-high plasticity in metal monochalcogenides. Nat. Mater. 2024, 23, 196–204. [Google Scholar] [CrossRef]

- Li, B.; Sun, J.; Ning, S.; Li, X.; Zhao, J. Densification and mechanical properties of high-entropy diboride ceramics sintered using Ni activation. Ceram. Int. 2025, 51, 25332–25339. [Google Scholar] [CrossRef]

- Ida, S.; Yonemura, K.; Nan, X.; Sekido, N.; Yoshimi, K. Toughening and strengthening by off-stoichiometric TiC in equilibrium with Mo solid solution. Sci. Rep. 2025, 15, 20842. [Google Scholar] [CrossRef]

- Wang, L.; Ma, B.; Ren, X.; Yu, C.; Tian, J.; Liu, C.; Deng, C.; Hu, C.; Liu, Z.; Yu, J.; et al. Phase-engineering strategy of ZrO2 for enhancing the mechanical properties of porous cordierite ceramics. Mater. Today Commun. 2022, 30, 103032. [Google Scholar] [CrossRef]

- Li, K.; Huang, Z.; Yuan, J.; Li, X.; Wang, Z.; Hu, M.; Wang, T.; Li, W.; Wang, X.; Wang, Q.; et al. Synthesis and growth mechanism of highly crystalized multi-branched HfB2 microrods with self-toughening effect. Mater. Des. 2024, 244, 113196. [Google Scholar] [CrossRef]

- Guo, R.; Li, Z.; Li, L.; Zheng, R.; Ma, C. Toughening mechanism and oxidation resistance of SiC whisker-toughened SiAlCN ceramics. Ceram. Int. 2024, 50, 8853–8864. [Google Scholar] [CrossRef]

- Greenfeld, I.; Wagner, H.D. Two natural toughening strategies may inspire sustainable structures. Sci. Rep. 2023, 13, 20416. [Google Scholar] [CrossRef]

- Anwer, Z.; Huang, S.; Vleugels, J. Liquid phase assisted synthesis of (Ti,V,Nb,Ta,W)C-Ni high entropy carbide cermets by conventional pressureless sintering. Int. J. Refract. Met. Hard Mater. 2022, 107, 105914. [Google Scholar] [CrossRef]

- Liu, J.; Xiong, J.; Guo, Z.; Zhou, H.; Yang, T.E.; Yang, L.; Zhao, W. Preparation of high-entropy (Zr0.25Hf0.25Ta0.25Ti0.25)C-Ni-Co composite by spark plasma sintering. Metall. Mater. Trans. A 2020, 51, 6706–6713. [Google Scholar] [CrossRef]

- Ma, J.; Ma, S.; Wang, X.; Xue, Z.; Li, B.; Wang, T.; Liu, Y. Preparation and mechanical properties of (Ti0.2Zr0.2V0.2Nb0.2Ta0.2)(C0.6N0.4)-Co high-entropy cermets. Mater. Charact. 2022, 192, 112213. [Google Scholar] [CrossRef]

- Mohapatra, B.D.; Sulka, G.D. Review of anodic tantalum oxide nanostructures: From morphological design to emerging applications. ACS Appl. Nano Mater. 2024, 7, 13865–13892. [Google Scholar] [CrossRef] [PubMed]

- Cardonne, S.M.; Kumar, P.; Michaluk, C.A.; Schwartz, H.D. Tantalum and its alloys. Int. J. Refract. Met. Hard Mater. 1995, 13, 187–194. [Google Scholar] [CrossRef]

- Roy, A.; Munagala, V.N.V.; Patel, P.; Sharifi, N.; Alidokht, S.; Makowiec, M.; Chromik, R.; Moreau, C.; Stoyanov, P. Friction and wear behavior of suspension plasma sprayed tantalum oxide coatings at elevated temperatures. Surf. Coat. Technol. 2023, 452, 129097. [Google Scholar] [CrossRef]

- Gül, C.; Albayrak, S.; Cinici, H.; Aytac, A. Improvement in corrosion resistance of tantalum oxide and tantalum oxide with diethanolamine sol–gel coated magnesium alloys. Prot. Met. Phys. Chem. Surf. 2022, 58, 603–614. [Google Scholar] [CrossRef]

- McLellan, R.A.; Dutta, A.; Zhou, C.; Jia, Y.; Weiland, C.; Gui, X.; Place, A.P.M.; Crowley, K.D.; Le, X.H.; Madhavan, T.; et al. Chemical profiles of the oxides on tantalum in state of the art superconducting circuits. Adv. Sci. 2023, 10, 2300921. [Google Scholar] [CrossRef]

- Silvestroni, L.; Kleebe, H.J. Critical oxidation behavior of Ta-containing ZrB2 composites in the 1500–1650 °C temperature range. J. Eur. Ceram. Soc. 2017, 37, 1899–1908. [Google Scholar] [CrossRef]

- Hu, P.; Zhang, X.H.; Han, J.C.; Luo, X.G.; Du, S.Y. Effect of various additives on the oxidation behavior of ZrB2-based ultra-high-temperature ceramics at 1800 °C. J. Am. Ceram. Soc. 2010, 93, 345–349. [Google Scholar] [CrossRef]

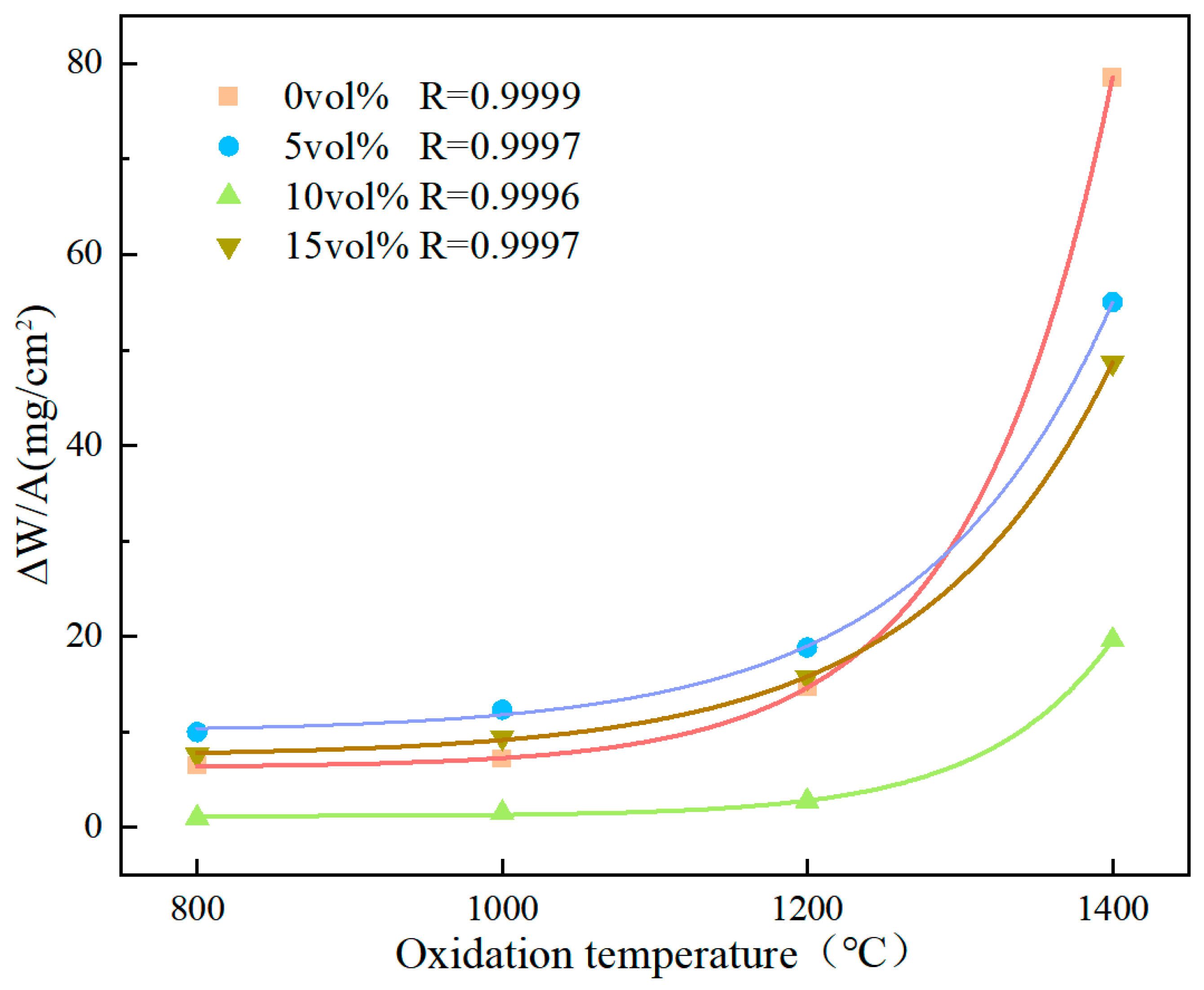

- Liu, G.; Fang, C.; Li, M.; Huang, F.; Xie, W.; Zhou, Y.; Wang, H. Breaking conventional understanding: Superior oxidation resistance of a novel Ta and Mo containing high-entropy transition metal diboride. J. Mater. Sci. Technol. 2025, 252, 313–327. [Google Scholar] [CrossRef]

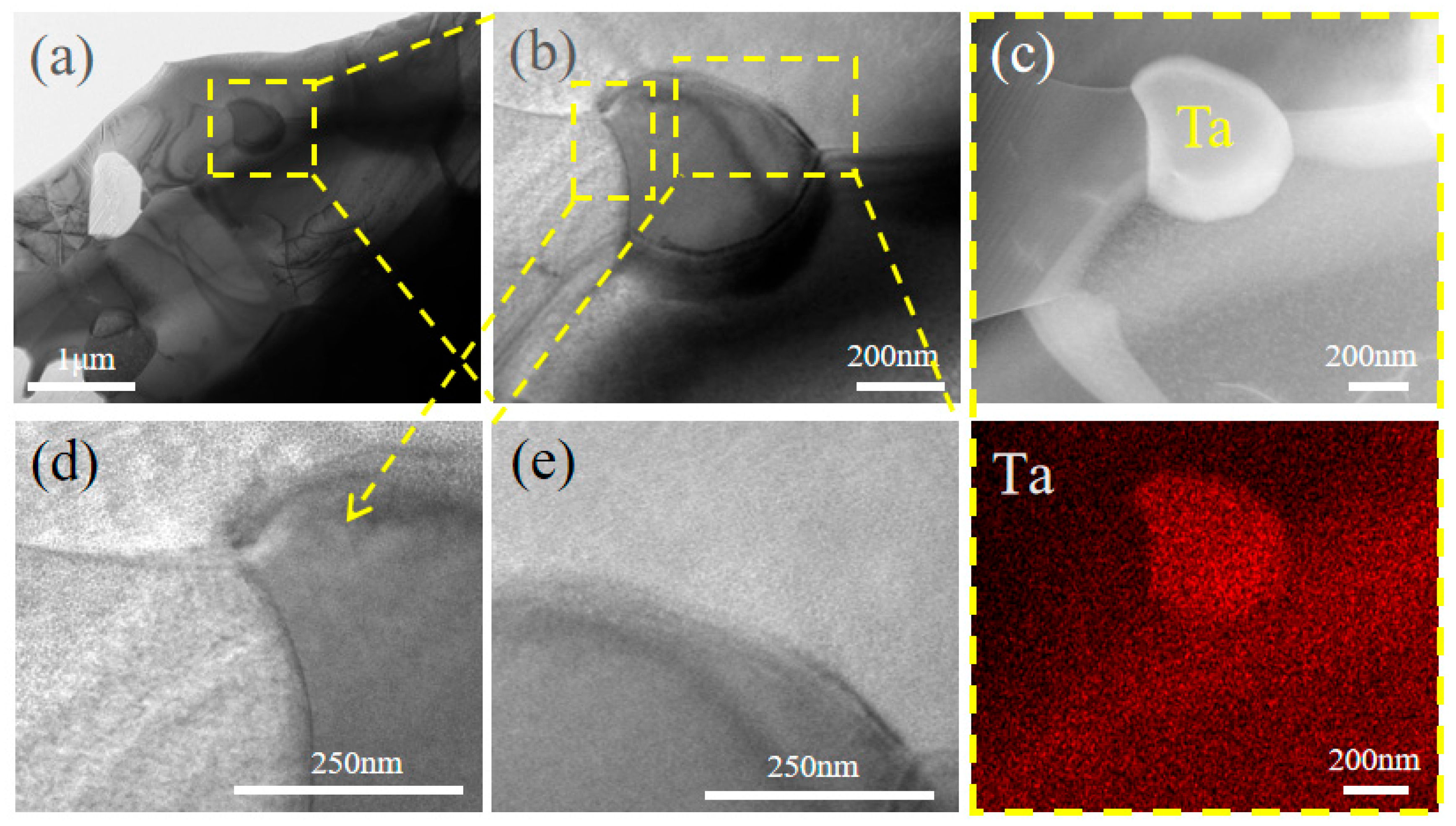

- Guo, Q.; Ying, H.; Yuan, B.; Fan, H.; Hua, L.; Liu, R.; Wang, J. Preparation and properties of Ta fiber reinforced high-entropy (Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2) B2-SiC composite ceramics. Ceram. Int. 2024, 50, 56070–56085. [Google Scholar] [CrossRef]

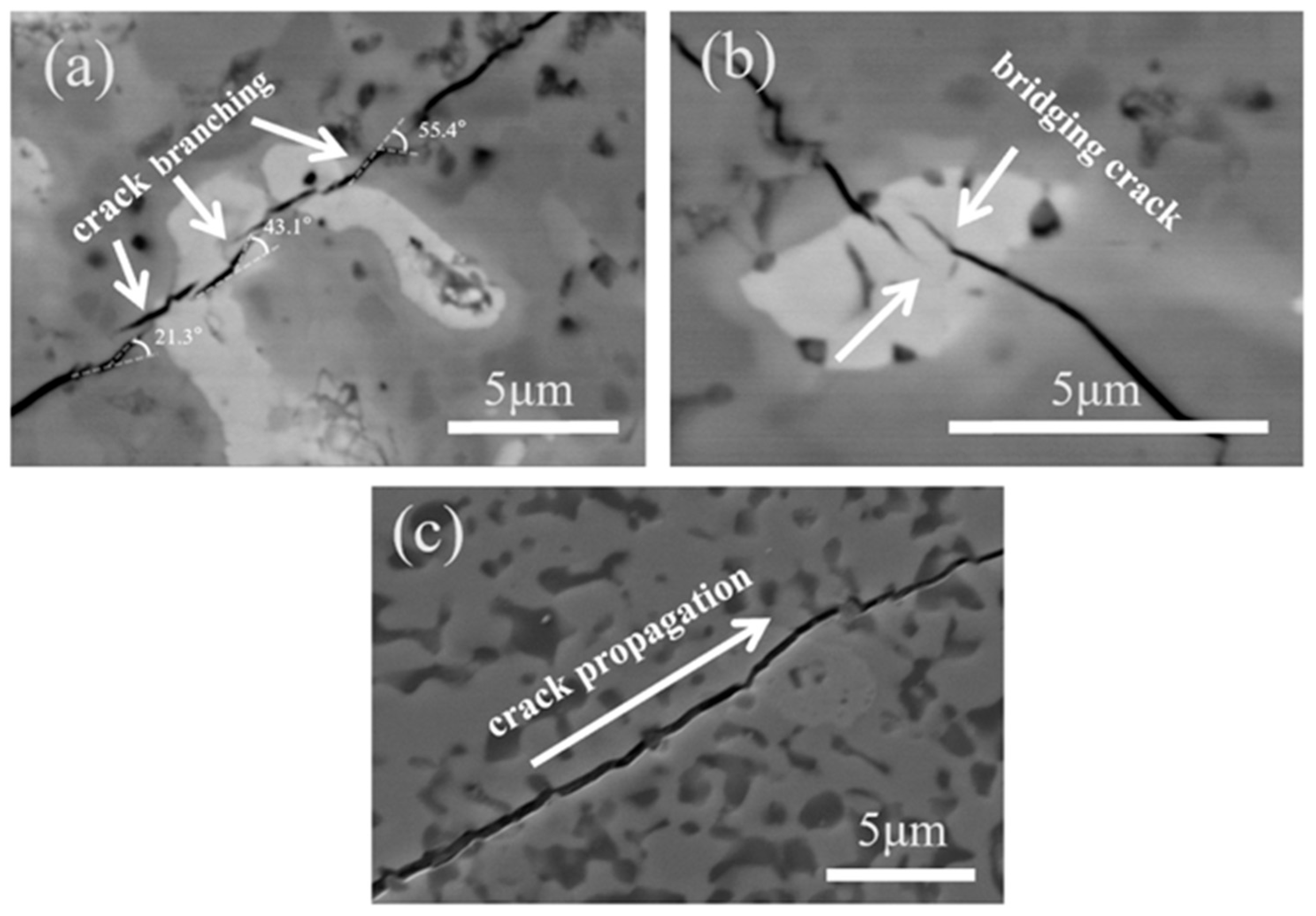

- Rödel, J. Interaction between crack deflection and crack bridging. J. Eur. Ceram. Soc. 1992, 10, 143–150. [Google Scholar] [CrossRef]

- Chen, S.; Wang, J.; Chen, Z.; Song, W.; Zeng, Y.; Li, X.; Li, T.; Xiong, X. Nb-and Ta-doped (Hf, Zr, Ti) C multicomponent carbides with enhanced oxidation resistance at 2500 °C. J. Adv. Ceram. 2024, 13, 332–344. [Google Scholar] [CrossRef]

- Wen, Z.; Meng, H.; Jiang, S.; Tang, Z.; Liu, Y.; Chu, Y. Non-equimolar (Hf, Zr, Ta, W) B2 high-entropy diborides enable superior oxidation resistance. Sci. China Mater. 2023, 66, 3213–3222. [Google Scholar] [CrossRef]

- Tang, Z.; Wen, Z.; Liu, Y.; Zhuang, L.; Yu, H.; Chu, Y. Rapid experimental screening of high-entropy diborides for superior oxidation resistance. Adv. Funct. Mater. 2024, 34, 2312239. [Google Scholar] [CrossRef]

- Guo, R.; Li, Z.; Li, L.; Liu, Y.; Zheng, R.; Ma, C. Microstructures and oxidation mechanisms of (Zr0.2Hf0.2Ta0.2Nb0.2Ti0.2) B2 high-entropy ceramic. J. Eur. Ceram. Soc. 2022, 42, 2127–2134. [Google Scholar] [CrossRef]

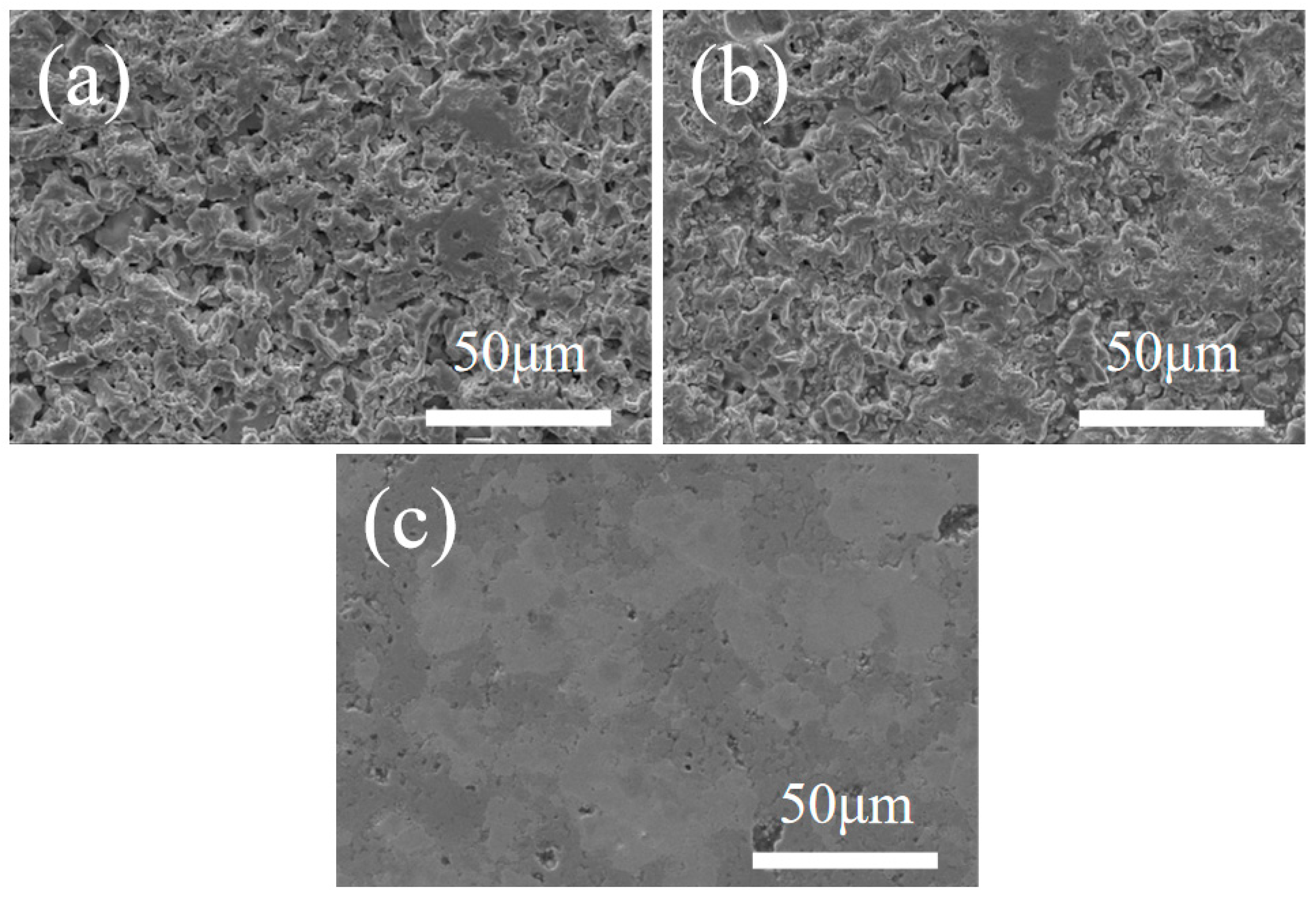

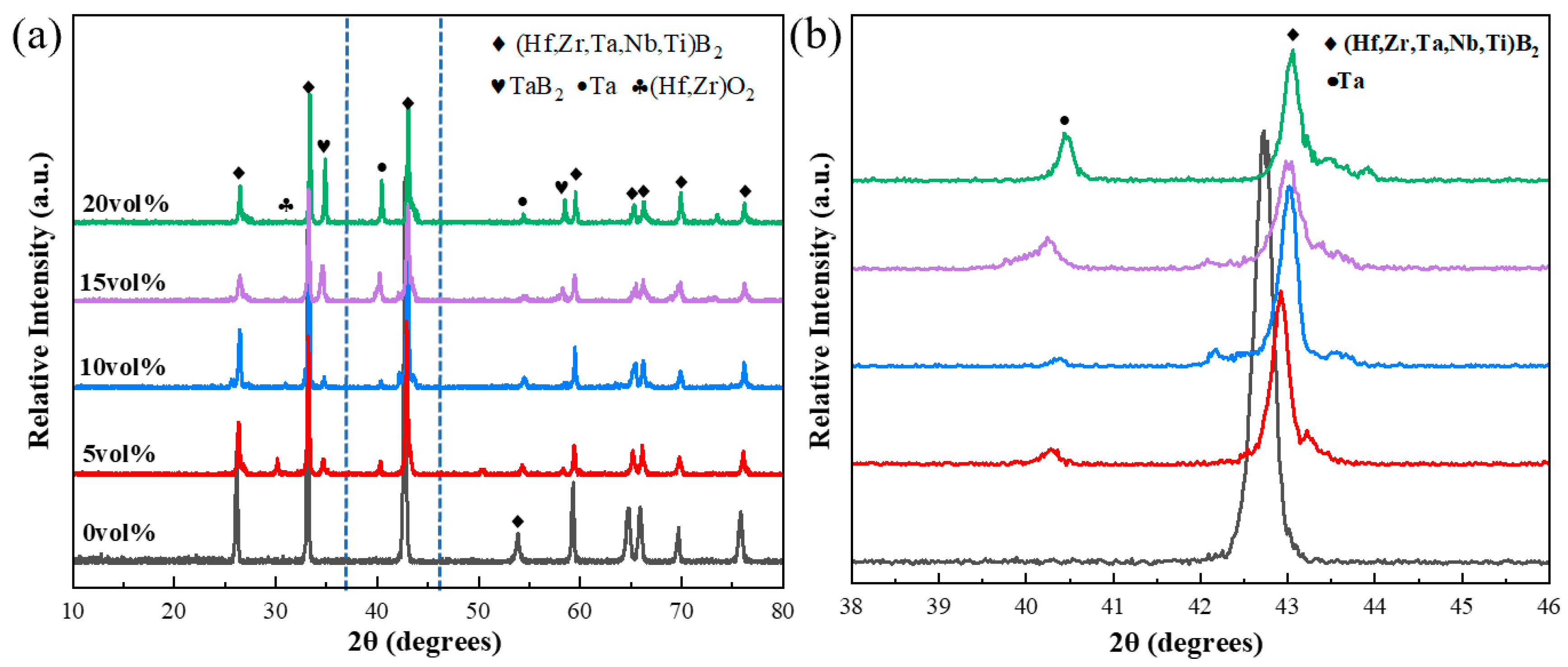

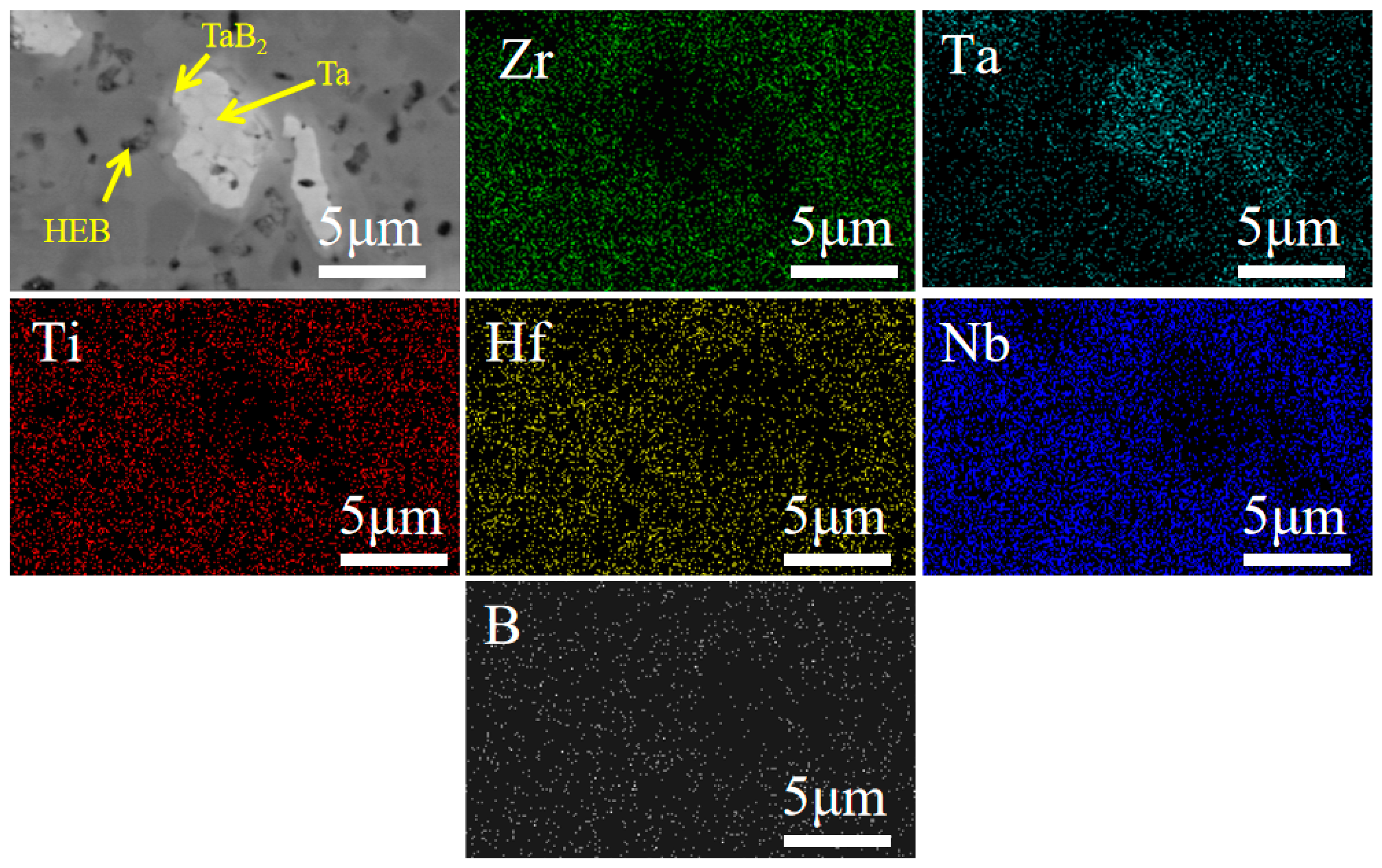

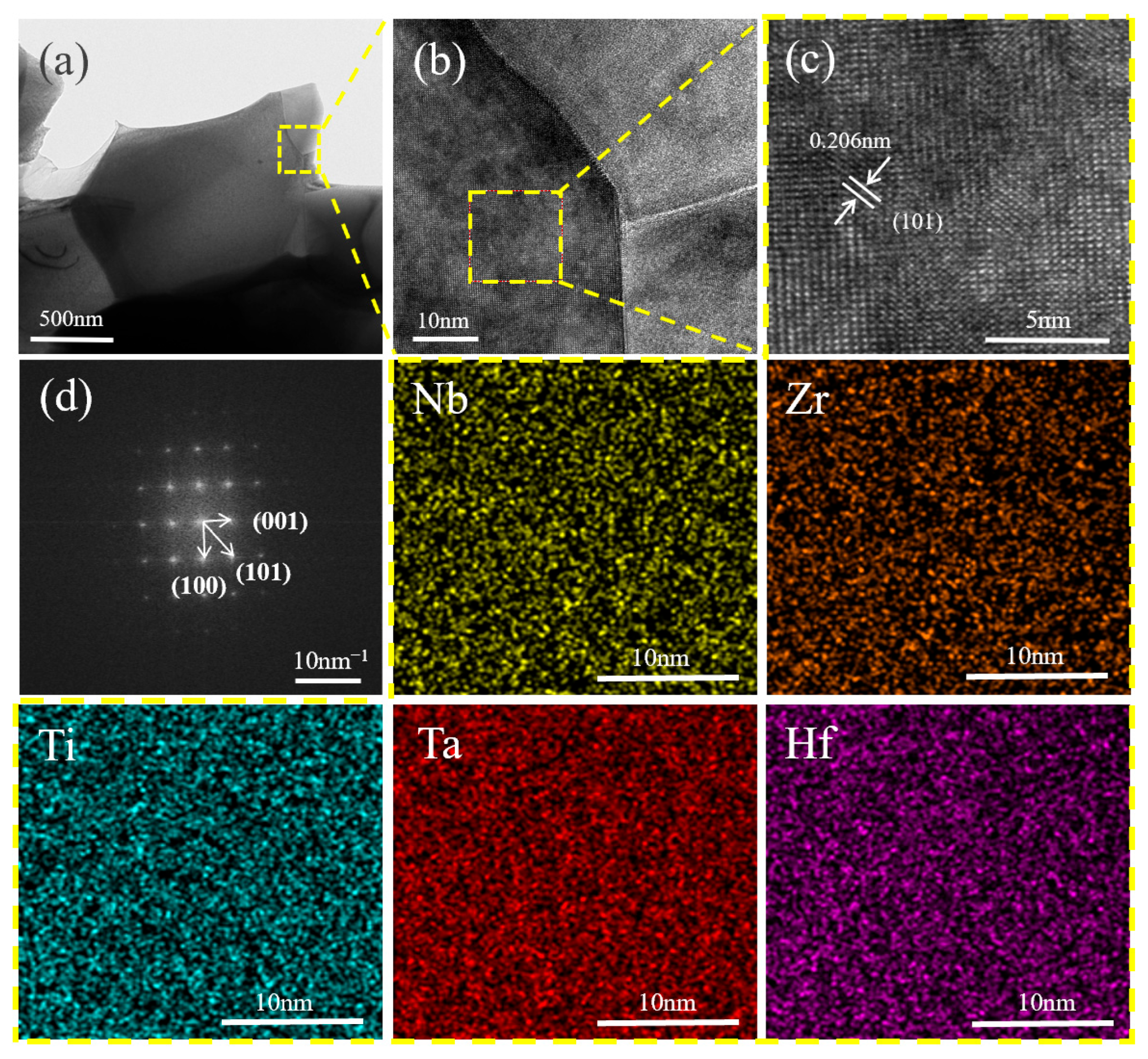

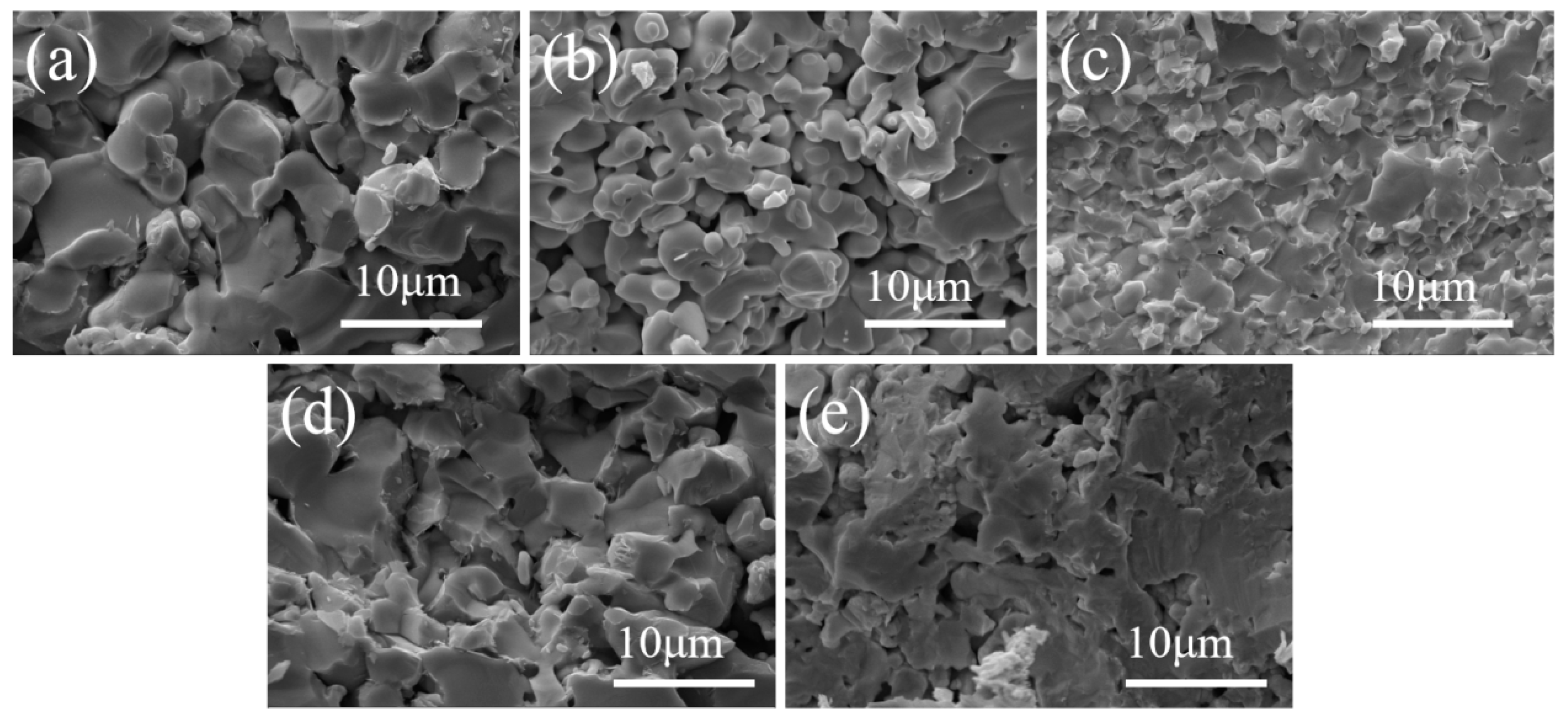

| Group | Open Porosity (%) | Density (g/cm3) | Grain Size of HEB (μm) | Hardness (GPa) | Fracture Toughness (MPa·m1/2) |

|---|---|---|---|---|---|

| HEB-0Ta | 7.28 | 7.55 | 7.85 ± 0.09 | 17.02 ± 0.24 | 3.17 ± 0.15 |

| HEB-5Ta | 4.40 | 8.27 | 4.37 ± 0.10 | 18.37 ± 0.31 | 3.94 ± 0.21 |

| HEB-10Ta | 0.15 | 9.04 | 2.33 ± 0.14 | 20.63 ± 0.22 | 4.24 ± 0.13 |

| HEB-15Ta | 0.43 | 9.42 | 3.57 ± 0.25 | 20.79 ± 0.17 | 4.31 ± 0.12 |

| HEB-20Ta | 0.22 | 9.87 | 5.43 ± 0.12 | 16.22 ± 0.11 | 3.67 ± 0.26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, B.; Guo, Q.; Ying, H.; Hua, L.; Shi, Z.; Yang, S.; Wang, J.; Wang, X. Fabrication and Oxidation Resistance of Metallic Ta-Reinforced High-Entropy (Ti,Zr,Hf,Nb,Ta)B2 Ceramics. Materials 2025, 18, 4642. https://doi.org/10.3390/ma18194642

Yuan B, Guo Q, Ying H, Hua L, Shi Z, Yang S, Wang J, Wang X. Fabrication and Oxidation Resistance of Metallic Ta-Reinforced High-Entropy (Ti,Zr,Hf,Nb,Ta)B2 Ceramics. Materials. 2025; 18(19):4642. https://doi.org/10.3390/ma18194642

Chicago/Turabian StyleYuan, Bowen, Qilong Guo, Hao Ying, Liang Hua, Ziqiu Shi, Shengcai Yang, Jing Wang, and Xiufang Wang. 2025. "Fabrication and Oxidation Resistance of Metallic Ta-Reinforced High-Entropy (Ti,Zr,Hf,Nb,Ta)B2 Ceramics" Materials 18, no. 19: 4642. https://doi.org/10.3390/ma18194642

APA StyleYuan, B., Guo, Q., Ying, H., Hua, L., Shi, Z., Yang, S., Wang, J., & Wang, X. (2025). Fabrication and Oxidation Resistance of Metallic Ta-Reinforced High-Entropy (Ti,Zr,Hf,Nb,Ta)B2 Ceramics. Materials, 18(19), 4642. https://doi.org/10.3390/ma18194642