Analysis of the Influence of Parameters on Rz Surface Roughness and Selection of the Most Effective Conditions

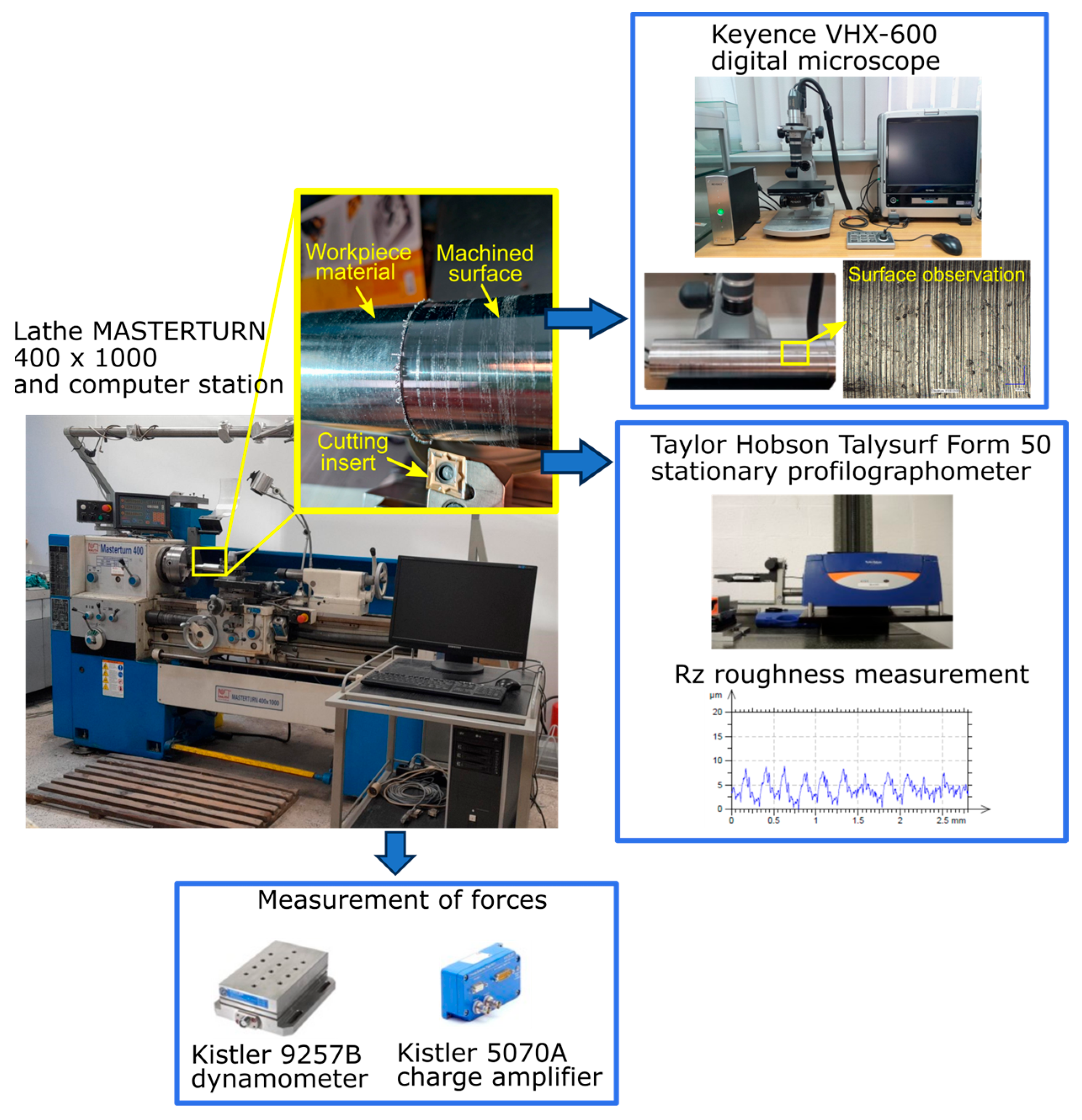

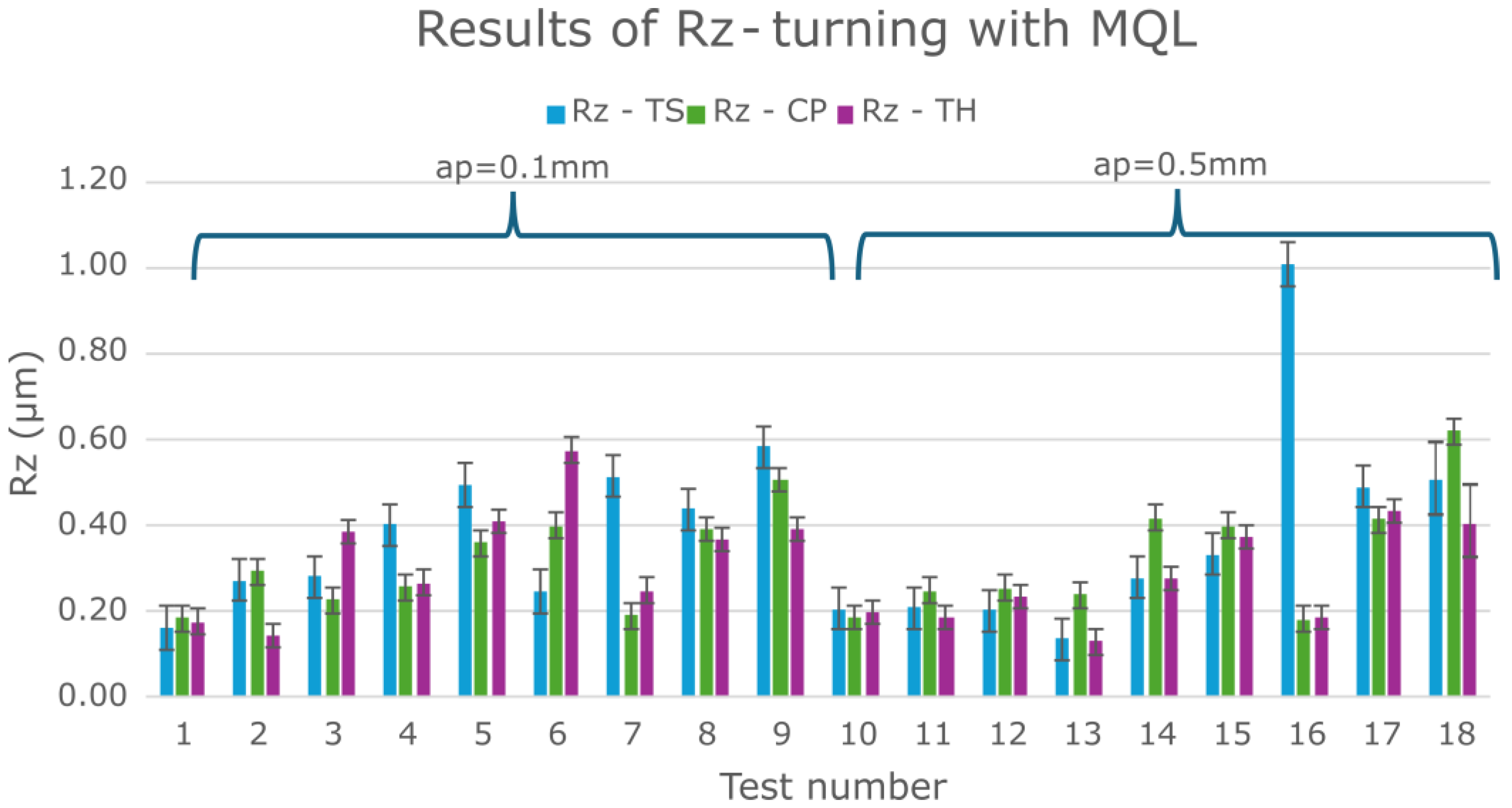

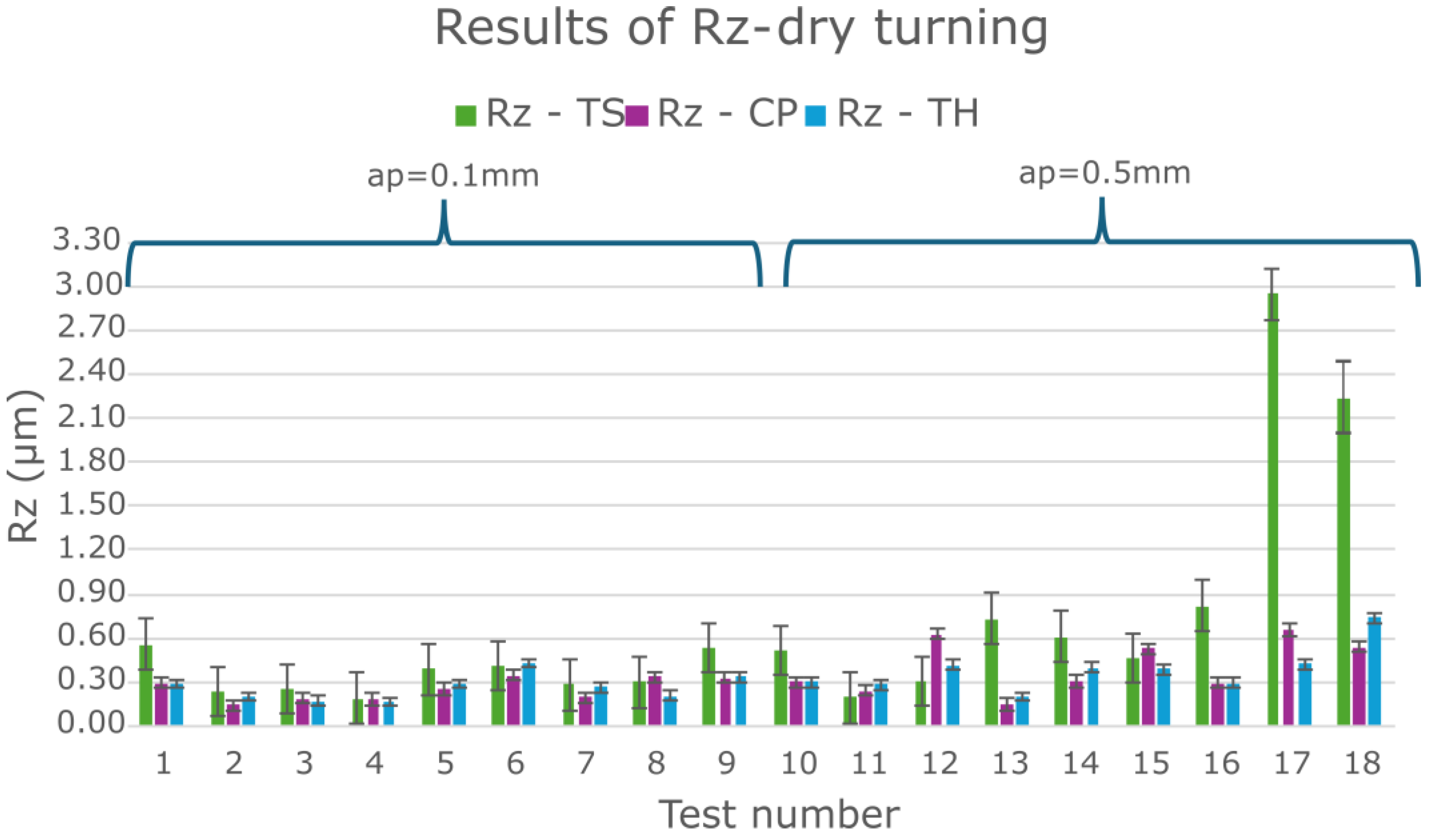

Initially, all results obtained from the Taguchi experimental plan for the three cutting inserts (TS, CP, TH) under MQL were analyzed (

Figure 3). Surface roughness values of Rz ≤ 0.4 µm were considered acceptable. For turning with a depth of cut of 0.1 mm (tests 1–9) and 0.5 mm (tests 10–18), most Rz values were below 0.6 µm.

Table 4 shows the results of the mean values of Rz and the standard deviation values.

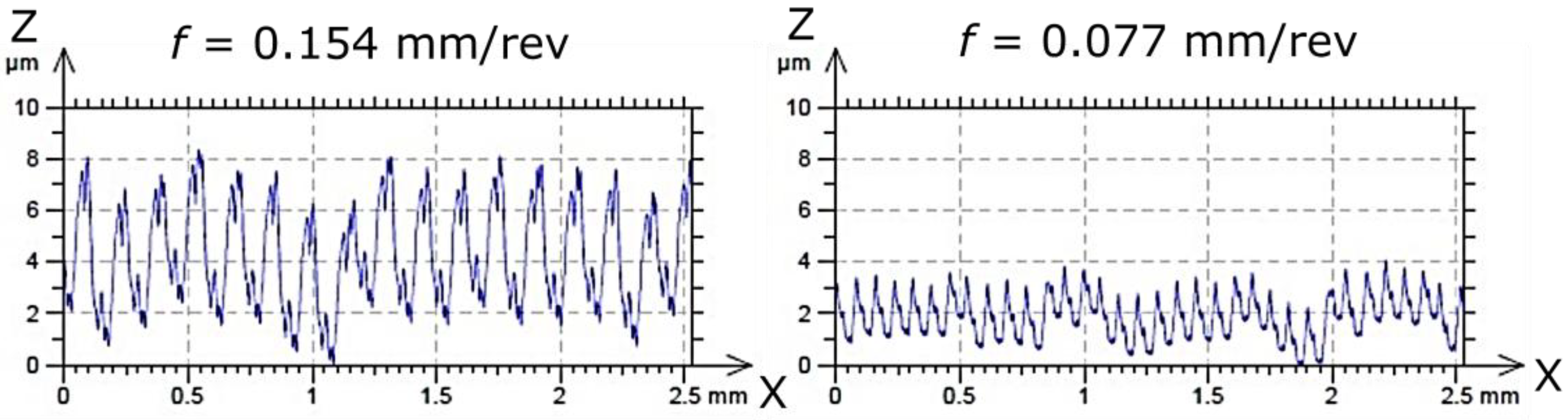

A clear effect of feed per revolution (

f) was observed: smaller feed values resulted in better surface quality. Additionally, the TS cutting insert in test 16 exhibited a significantly higher Rz (≈1 µm), and, in several other experimental tests (4, 5, 7, 8, 9, 17), Rz values were higher compared to the CP and TH cutting inserts. These tests were conducted at the smallest feed per revolution (0.077 mm/rev). It should be emphasized that lower feed rates improve surface quality.

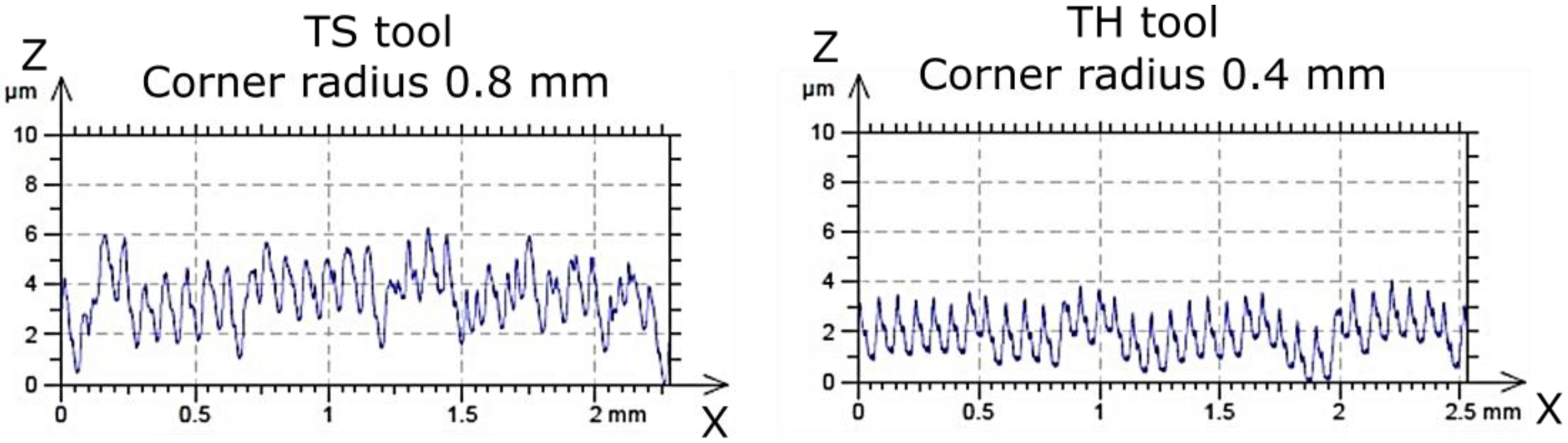

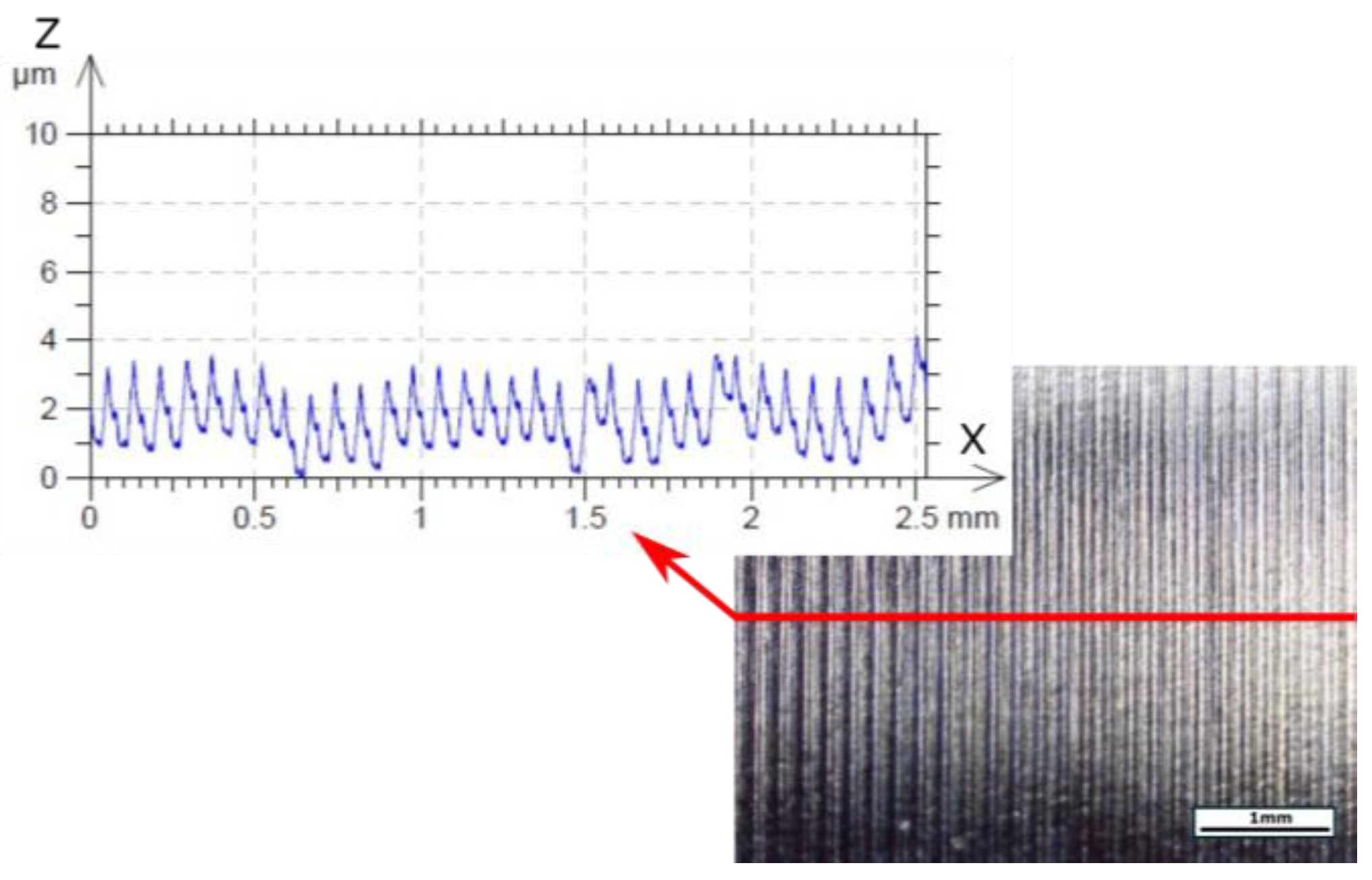

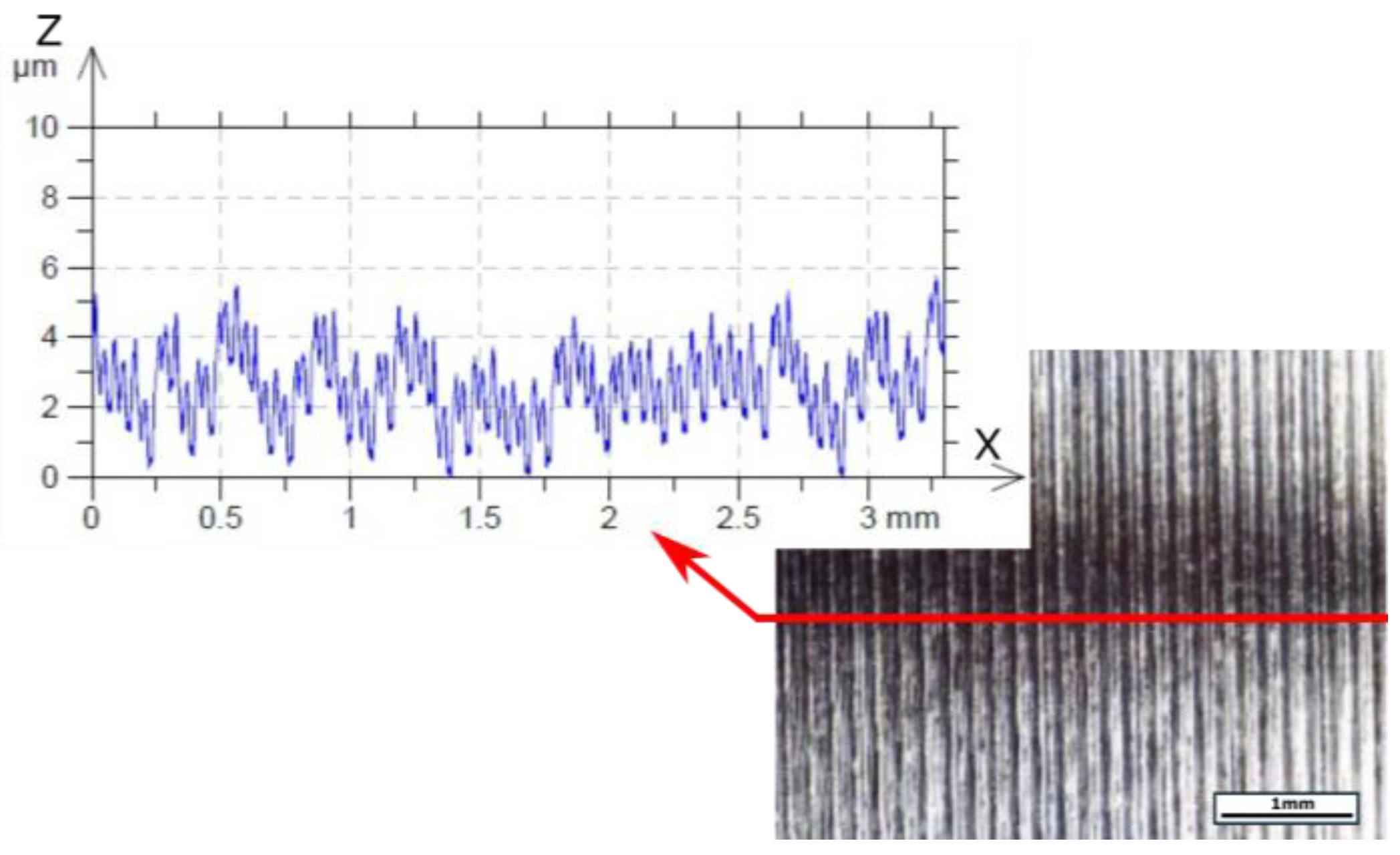

Figure 4 shows the surface profiles after the turning process with extreme values of feed per revolution to illustrate the difference in the obtained surface quality.

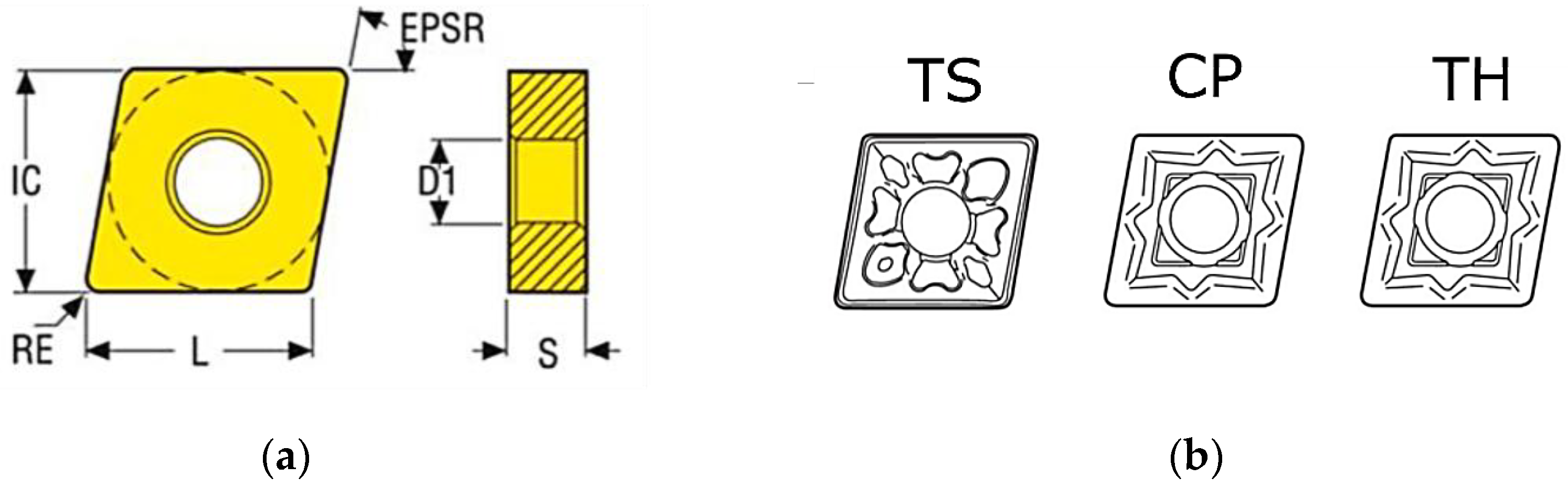

Moreover, the TS cutting insert has a larger corner radius (0.8 mm) compared to CP and TH (0.4 mm) and features a different chip breaker design. This analysis demonstrates that the type and geometry of the cutting insert significantly influence the resulting surface roughness. To illustrate the difference in the quality of the machined surface obtained after turning with a cutting insert with a corner radius of 0.4 mm and 0.8 mm, the corresponding surface profiles are presented in

Figure 5.

Therefore, the test results show that cutting insert geometry (specifically, its nose radius) significantly improves surface roughness. A lower feed rate also improves surface roughness; in these tests,

f = 0.077 mm/rev. Summarizing this part of the analysis, we can conclude that cutting insert geometry, nose radius, and feed per revolution strongly determine surface roughness. Similar conclusions were drawn based on other research results included in the

Section 1.

In order to better analyze the influence of insert type on Rz surface roughness, the MQL turning results were compared with the dry turning results under the same experimental plan (

Figure 6). Analysis of these results also shows that the TS tool produced some Rz roughness results that deviated significantly from the corresponding Rz results for the CP and TH tools.

Table 5 presents the average Rz values along with their corresponding standard deviations.

It can be concluded that certain features of the cutting insert significantly influence surface roughness. Therefore, turning of Inconel 625 is more effective when using CP and TH inserts, which have a 0.4 mm corner radius and a manufacturer-designated MF1 chip breaker. This conclusion is primarily based on the observation that the TS insert produced higher surface roughness values even at the lowest feed per revolution. Consequently, further analysis focused on the results obtained with the CP and TH cutting inserts.

For turning tests with the CP and TH cutting inserts, an analysis of variance (ANOVA) was performed using the Minitab statistical software 22. Resulting approximation functions are listed below:

A general linear model was selected for the regression analysis. The generated coefficients were considered significant at

p-value ≤ 0.05. Regression results indicated that the depth of cut has a minimal effect on Rz surface roughness.

Table 6 presents the ANOVA results (DF—total degrees of freedom, Adj SS—adjusted sums of squares, Adj MS—adjusted mean squares). Moreover, the fitted functional models have statistical coefficients R-sq (R-squared) and R-sq(adj) (adjusted R-squared) at a high level above 70% and above 60%, respectively (see

Table 7).

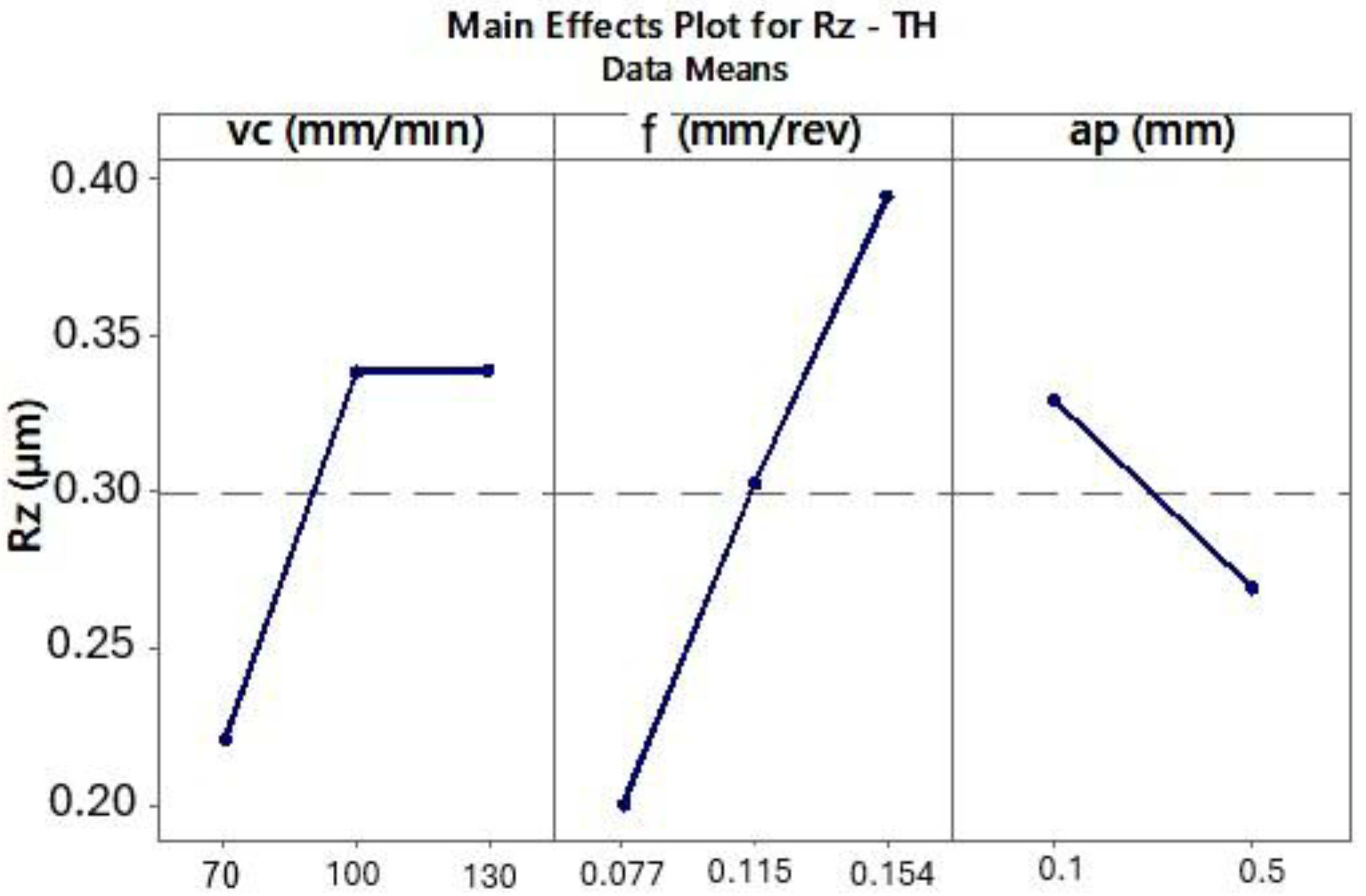

The ANOVA results for the CP and TH cutting inserts showed that surface roughness Rz decreases with decreasing cutting speed (

vc) and lower feed per revolution (

f) (

Figure 7 and

Figure 8).

Inconel 625 exhibits specific thermal properties that complicate its machining. The material heats up more slowly due to its low thermal conductivity and high temperature resistance [

27]. Consequently, higher cutting speeds can generate more heat, which is dissipated into both the cutting tool and the chips. The hotter chips tend to adhere more easily to the insert contact surface. In tests at a cutting speed of 130 m/min, the chips were more twisted, reflecting their intense heating during turning (

Figure 9). At higher cutting speeds, some chips adhered to the tool and required mechanical removal from the cutting insert, confirming that a significant portion of the heat generated in the cutting zone is absorbed by the chips.

Other studies [

22] recommend using lower cutting speeds (

vc), preferably below 100 m/min, for machining this superalloy. Due to the specific thermophysical properties of Inconel 625, the experimental results also showed that lower cutting speeds led to reduced Rz surface roughness values. Moreover, decreasing the feed per revolution resulted in lower surface roughness, which is a typical relationship in turning processes.

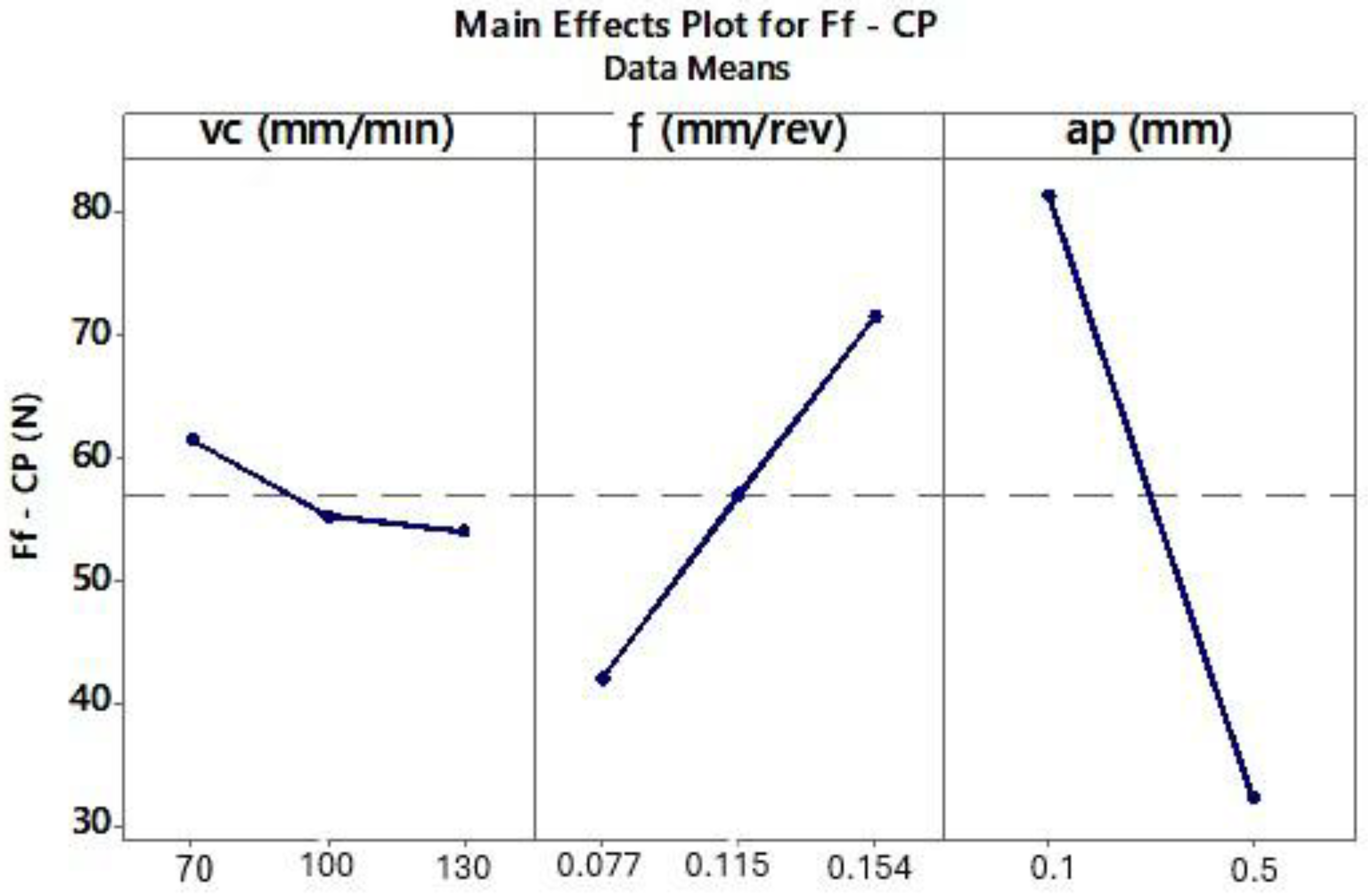

Next, the influence of turning parameters on the feed force component Ff was analyzed for the CP and TH cutting inserts, also using ANOVA. For the analyzed Ff force and the selected inserts, the following approximating functions were obtained:

A linear model was adopted for the regression analysis. The generated coefficients were considered significant at

p ≤ 0.05. Regression results indicated that cutting speed has a minimal effect on the feed force component

Ff for both inserts.

Table 8 presents the ANOVA results. Furthermore, the fitted regression models exhibited high statistical reliability, with R-sq and adjusted R-sq values exceeding 90% (

Table 9).

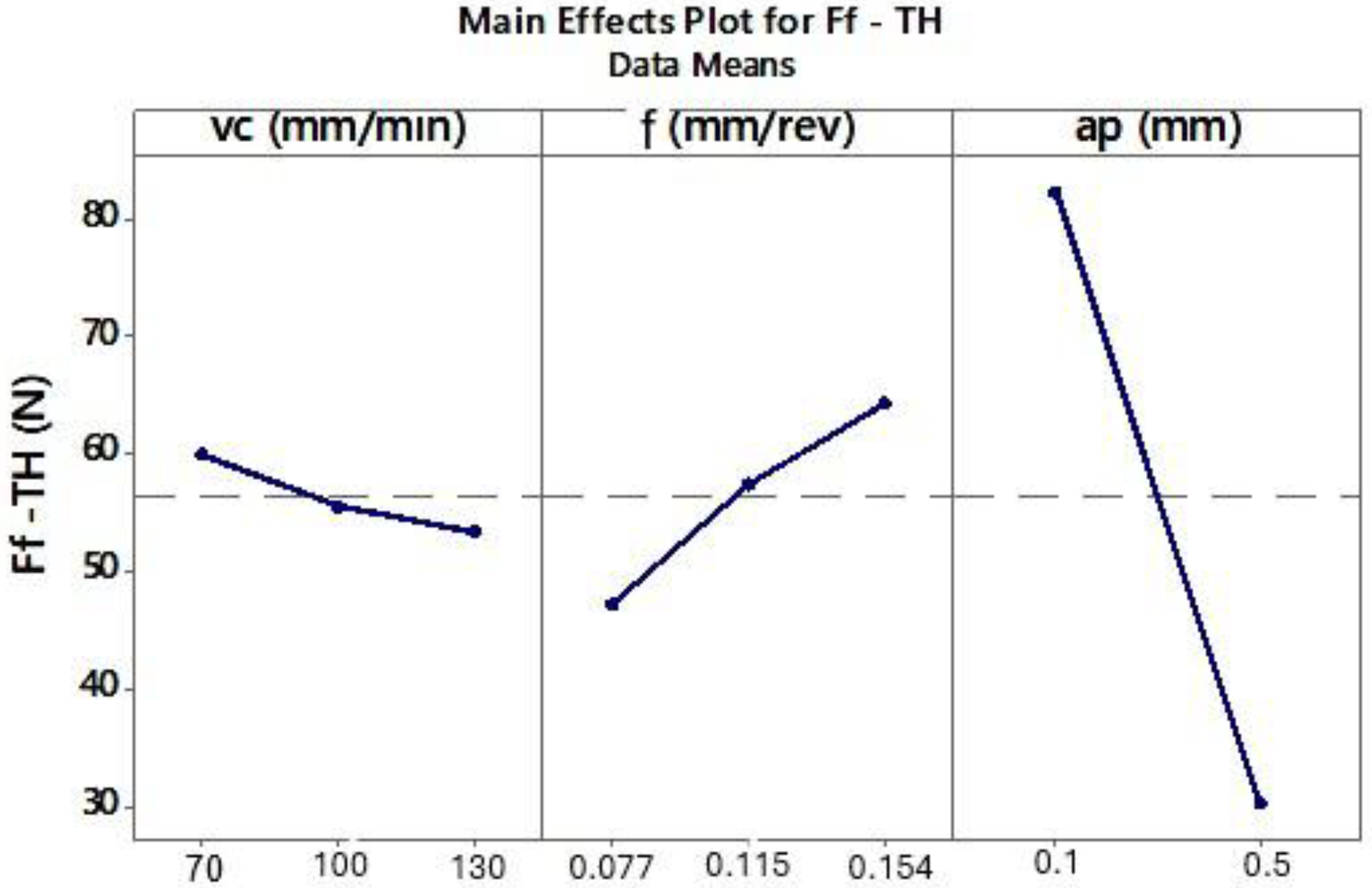

Analyzing the effect of cutting parameters on the feed force component Ff during turning of Inconel 625 (

Figure 10 and

Figure 11), lower Ff values were observed at lower feed rates. Previous analysis also showed that smaller feeds resulted in improved surface roughness. ANOVA results indicated that lower Ff forces occurred at a depth of cut of 0.5 mm. However, the surface roughness values for depths of 0.1 mm and 0.5 mm were similar for the corresponding tests (

Figure 3). Therefore, to determine the most effective depth of cut, the chips produced during turning were analyzed. The shape and type of chips influence machining efficiency, ease of chip separation from the tool–workpiece interface, and the quality of the machined surface.

The analysis of chip shape and type was carried out under the following conditions:

The applied cutting speed;

The depths of cut of 0.1 mm and 0.5 mm;

The TS, CP, and TH inserts.

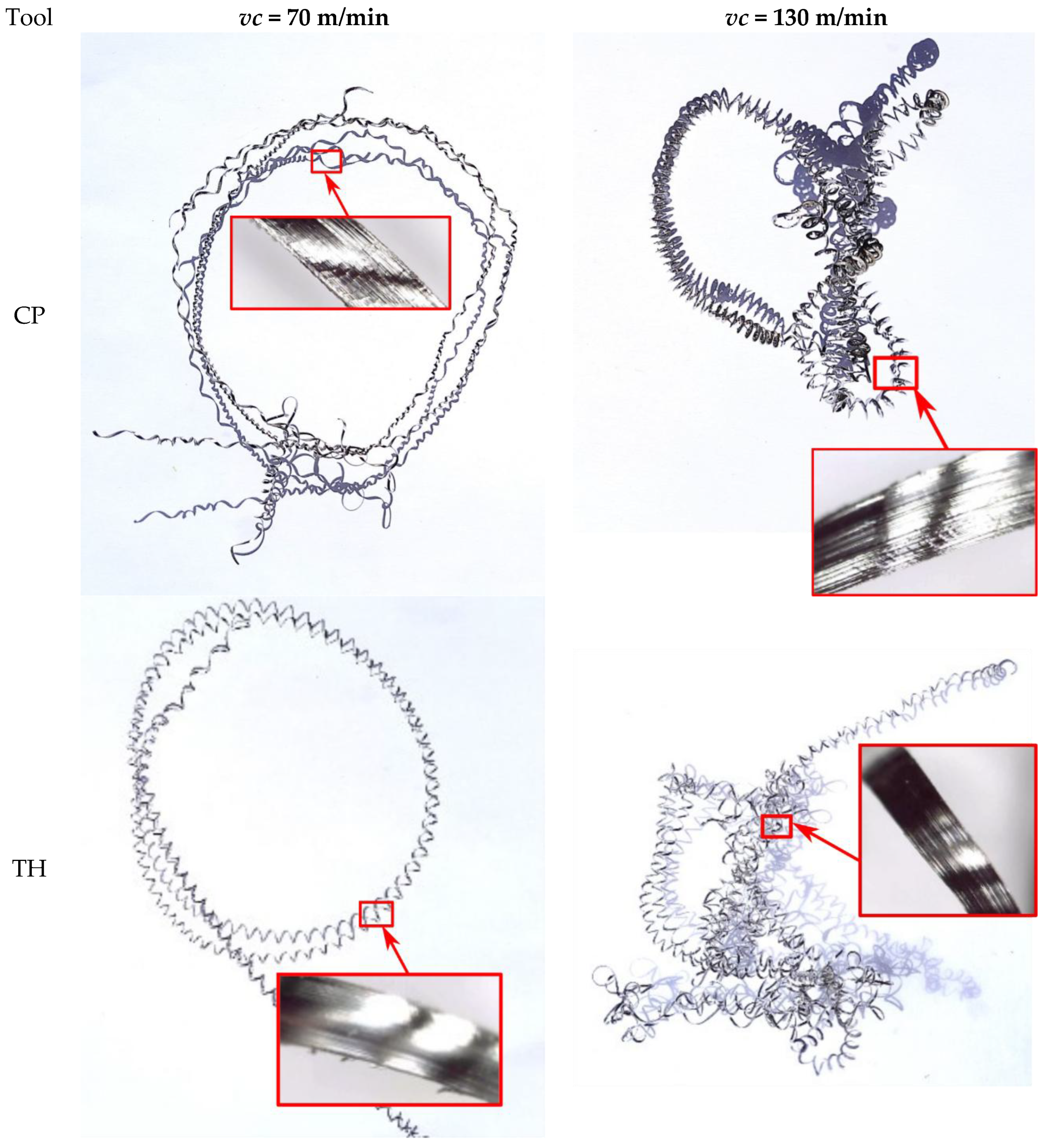

As shown in

Figure 12, the chips obtained at a depth of cut of 0.1 mm can be classified as long. At a cutting speed of

vc = 70 m/min, the chips were less spiral and less twisted compared to those produced at

vc = 130 m/min. Chips at

vc = 70 m/min remained more extended, facilitating their separation from the tool edge. In contrast, at

vc = 130 m/min, the chips were highly twisted and more spiral in shape. During turning, these chips twisted strongly at the tool–workpiece contact zone and rubbed against the machined surface, making them more difficult to detach, often requiring manual removal. Consequently, the Rz surface roughness parameter for the maximum cutting speed

vc = 130 m/min could be higher due to this effect.

It can be assumed that during turning of Inconel 625, long, less spiral chips favor improved surface quality and are easier to detach during machining. In this case, there is less chance of damaging the machined surface due to the formed chip.

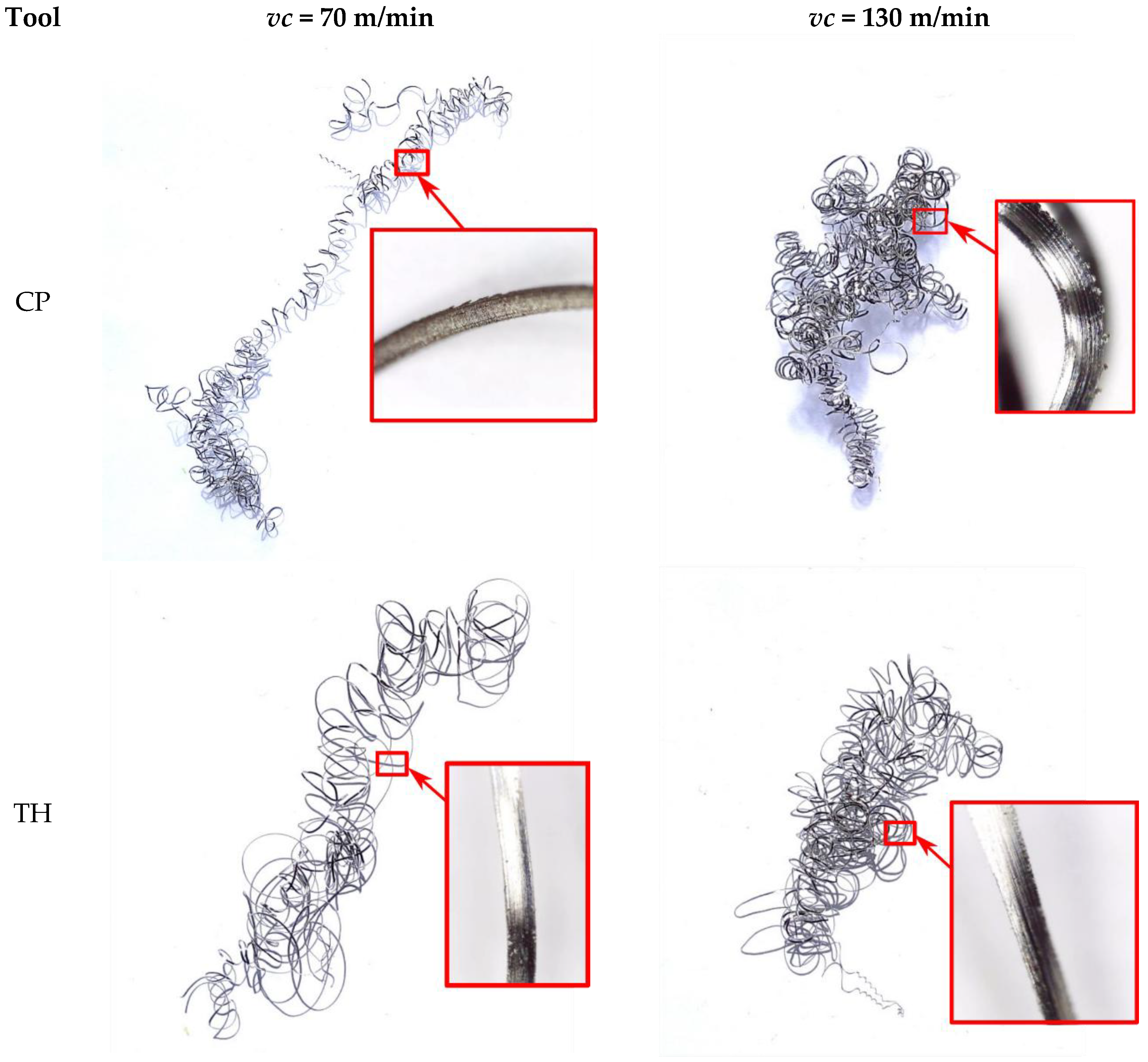

Analyzing the chips produced at a depth of cut of 0.5 mm for the CP and TH cutting inserts, the chip shape was similar for both extreme cutting speeds (70 m/min and 130 m/min) (

Figure 13). These chips were highly twisted, leading to accumulation in the tool zone and making them difficult to detach from the tool–workpiece interface. Additionally, at a cutting speed of 130 m/min, some chips adhered to the insert in several tests. The low thermal conductivity of Inconel 625 significantly influenced the cutting conditions in these experiments. The strong twisting of chips at

vc = 130 m/min could result from their increased heating during turning. One potential solution in future tests could be more intensive cooling of the cutting zone to reduce heat transfer to both the chips and the cutting tool material.

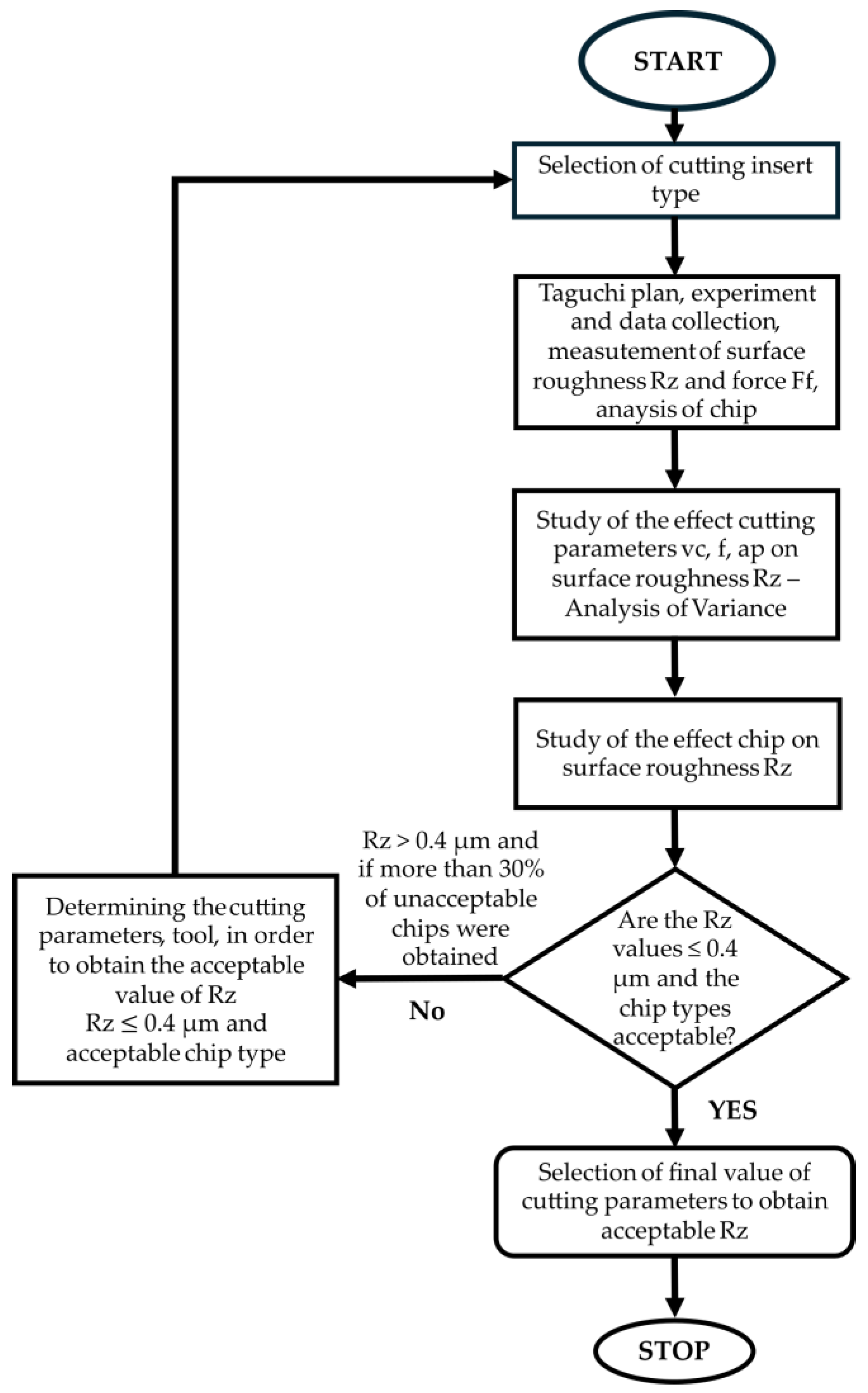

Based on the previous analysis of the Rz roughness results and the analysis of the shape and type of chips for both cutting depths, it was assumed that a cutting depth of

ap = 0.1 mm provides more efficient machining. The algorithm for the results analysis and the sequence of selecting the turning process parameters to obtain a surface roughness of Rz ≤ 0.4 µm are presented below (

Figure 14).

The surface topography of the obtained surface with the most effective parameters of this turning process selected (

vc = 70 m/min,

f = 0.077 mm/rev,

ap = 0.1 mm) is presented below (

Figure 15). For comparison, the surface obtained at the maximum cutting speed is also presented (

Figure 16).