Sustainable Bio-Gelatin Fiber-Reinforced Composites with Ionic Coordination: Mechanical and Thermal Properties

Abstract

1. Introduction

2. Experimental Programs

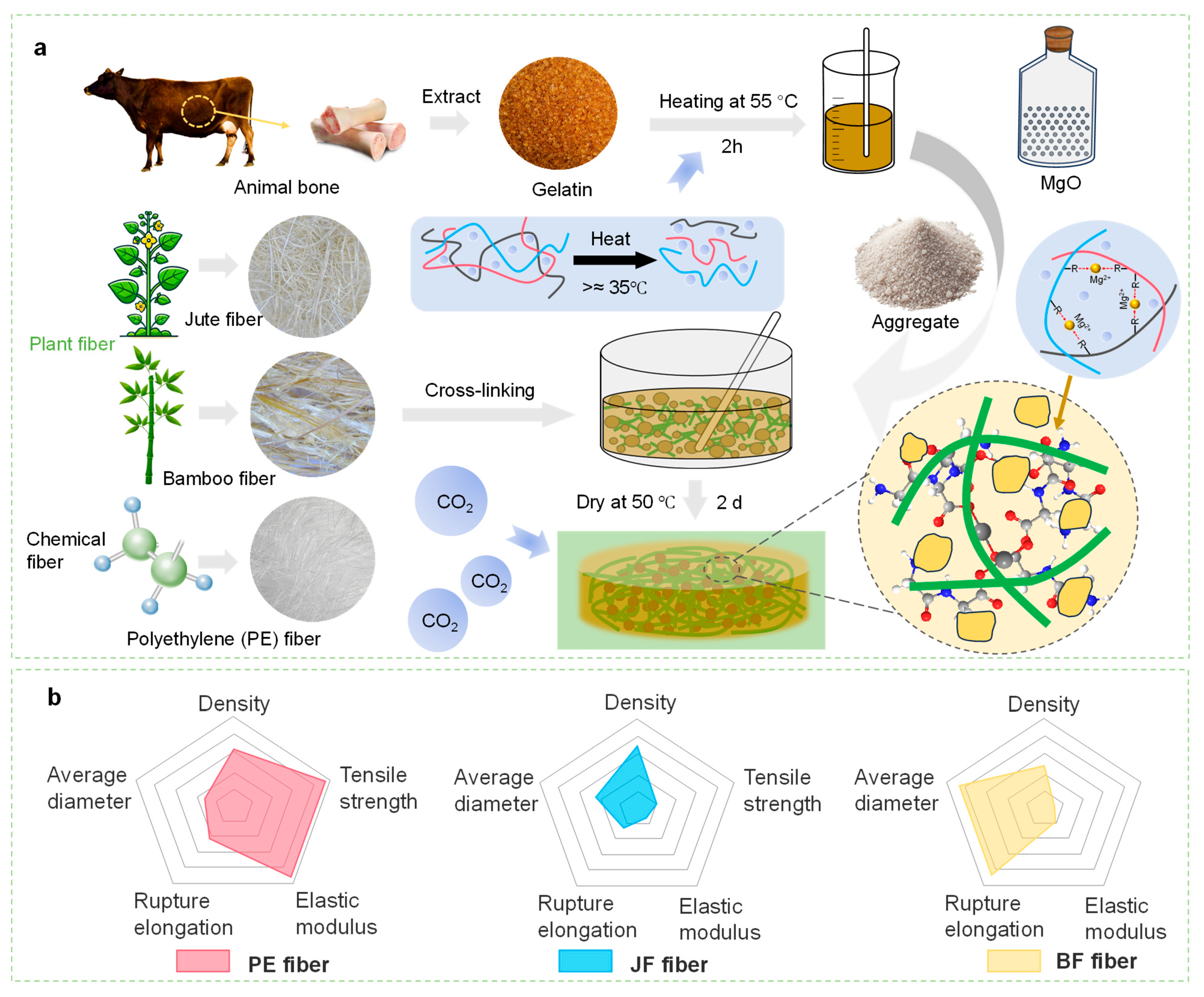

2.1. Raw Materials

2.2. Fabrication of BFRC

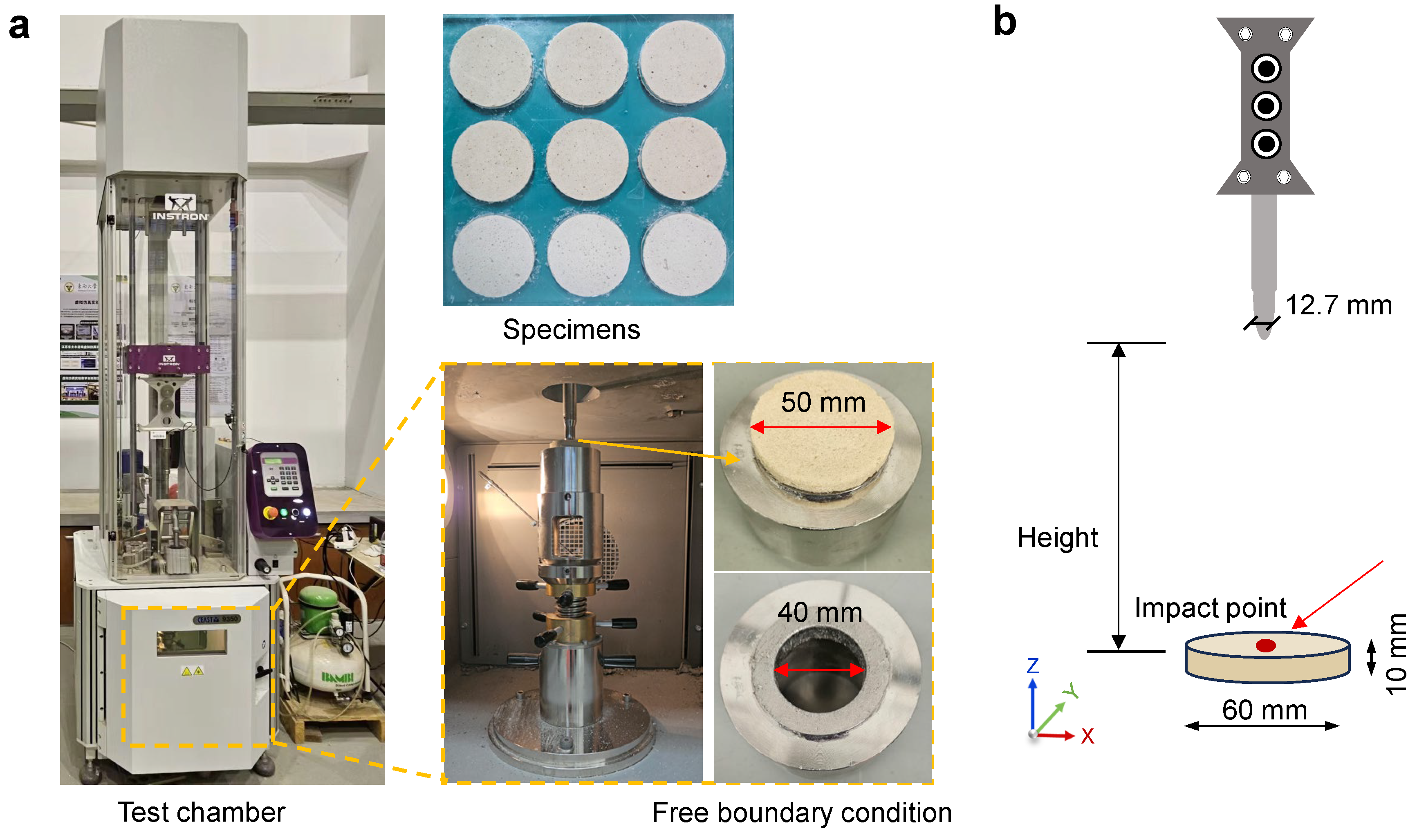

2.3. Mechanical Properties Testing Procedure

2.4. Low-Velocity Impact Test of BFRC

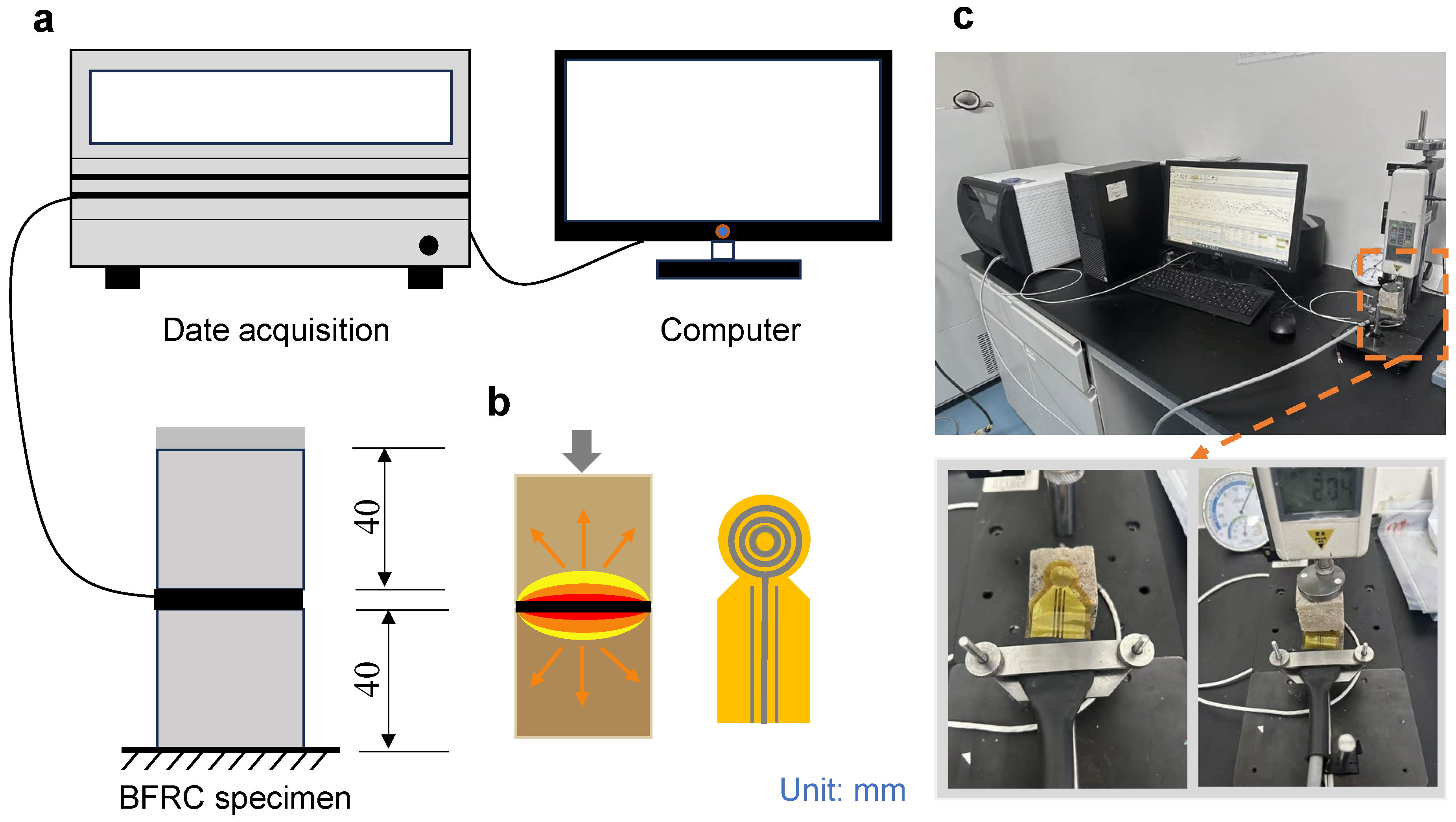

2.5. Thermal Performance Measurement

2.6. Infrared Spectroscopy Testing

2.7. X-Ray Diffraction (XRD) Characterization

2.8. Scanning Electron Microscopy (SEM)

3. Results

3.1. Mechanical Properties Test Results

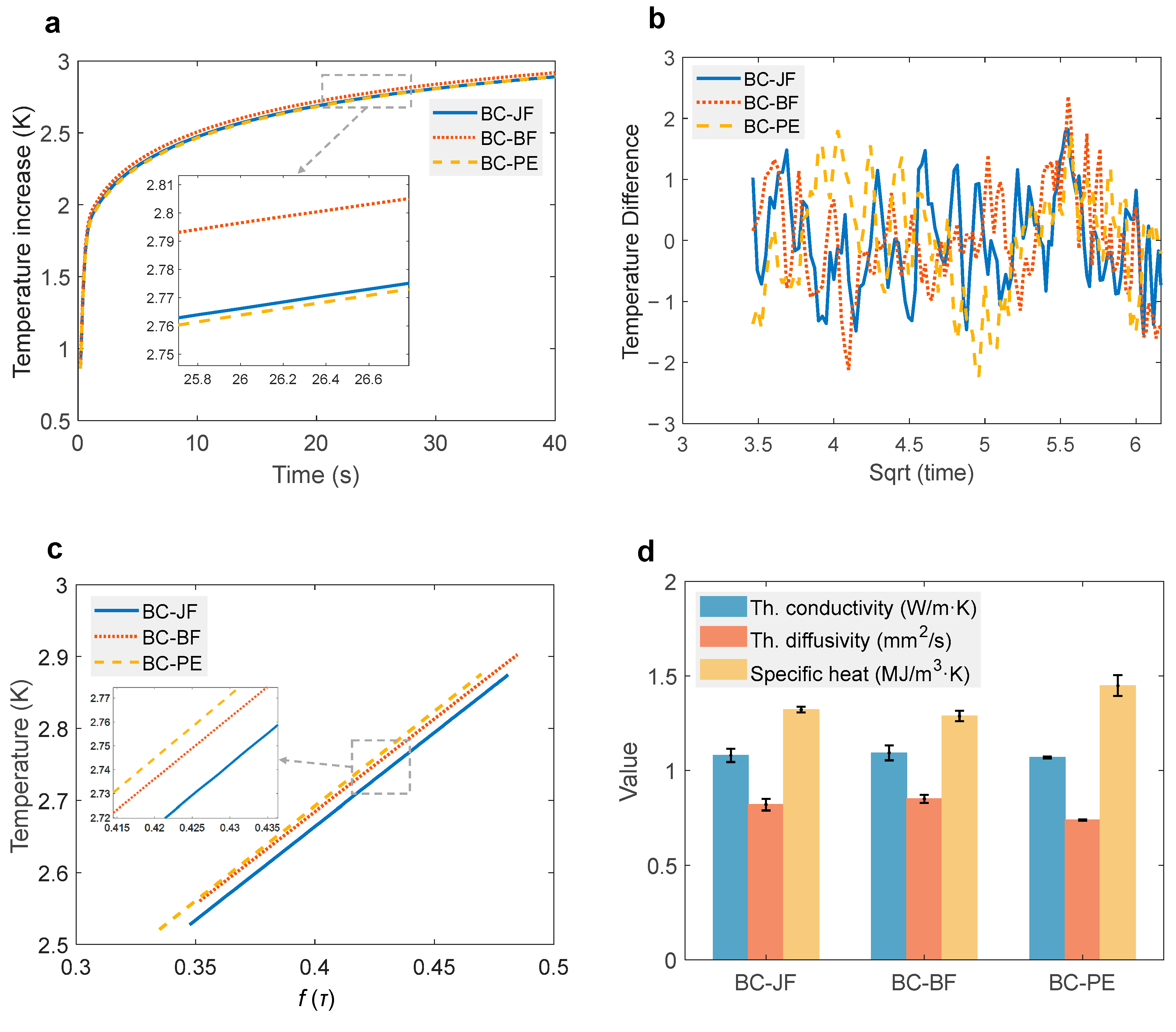

3.2. Thermal Performance

4. Discussions

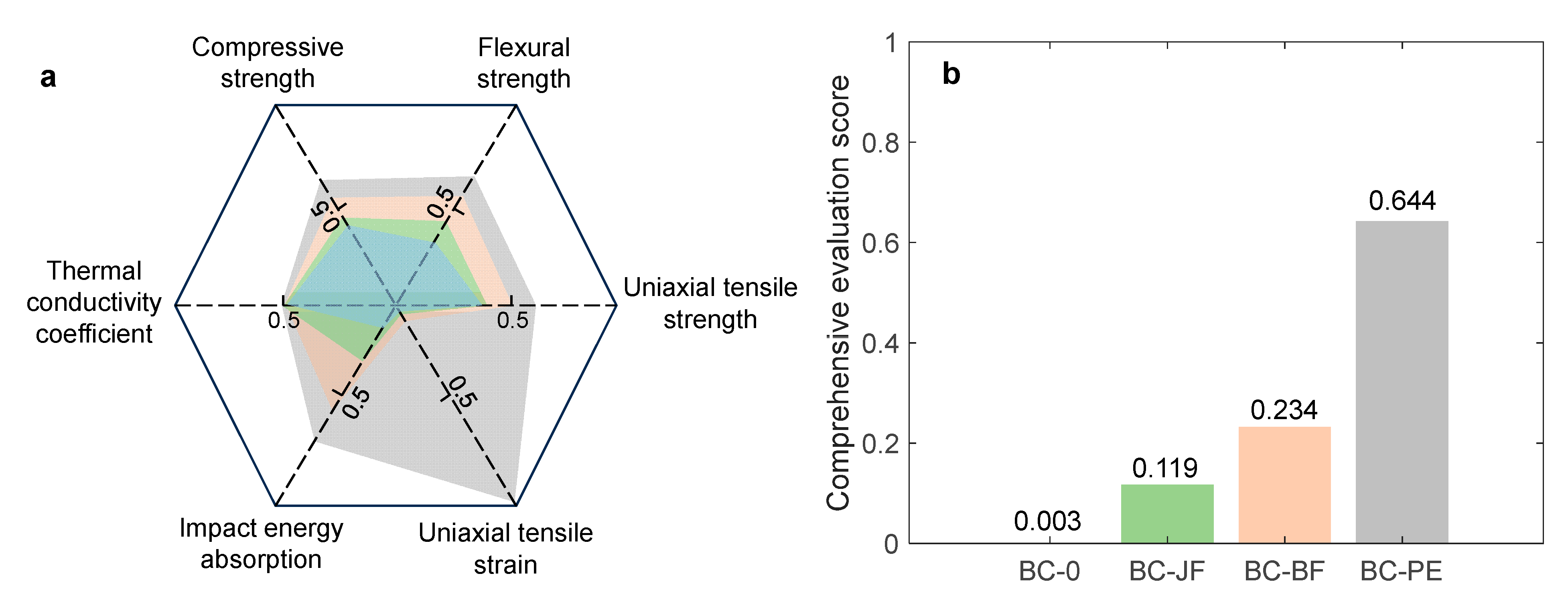

5. Multi-Criteria Performance Evaluation

6. Conclusions

- (1)

- Fiber incorporation markedly enhanced BFRC performance. Bamboo fiber (BC-BF) improved compressive and flexural strength, whereas PE fiber (BC-PE) showed the best overall results, with compressive, flexural, and tensile strengths of 22.8, 10.6, and 3.40 MPa, respectively, and a tensile strain of 10.77%. The superior crack-bridging ability of PE fibers promoted multiple microcracks, improving toughness and load capacity. Impact tests confirmed that BC-PE exhibited the highest peak impact force and energy absorption, outperforming all other fiber types.

- (2)

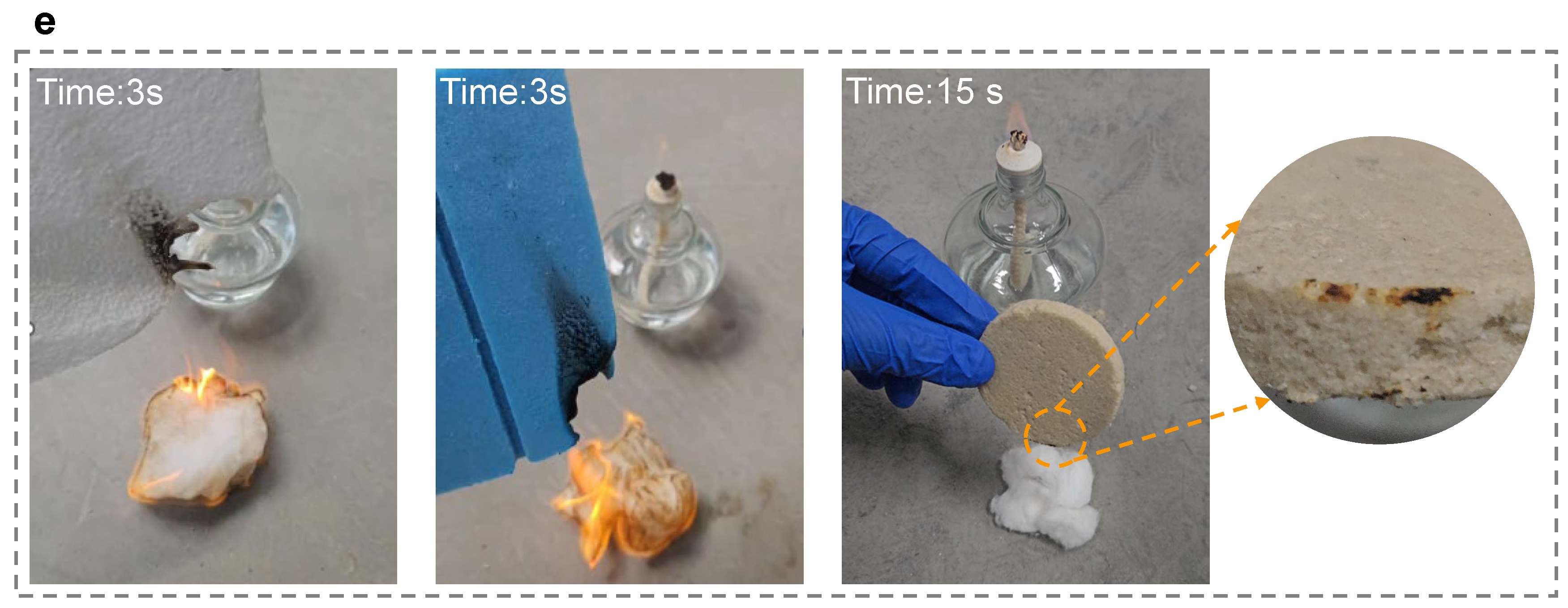

- Thermal conductivities of fiber-reinforced composites were comparable, but thermal diffusivity and specific heat capacity differed. BC-BF showed higher thermal conductivity, while BC-PE demonstrated superior heat storage and buffering capacity. Flame exposure tests further confirmed the excellent flame-retardant behavior of BFRCs, indicating favorable thermal safety.

- (3)

- Microstructural analysis showed that gelatin formed a stable triple-helix structure upon heating and coordination with Mg2+, enhancing matrix compactness and integrity. FTIR and XRD confirmed gelatin–Mg2+ coordination and the synergistic effect of quartz sand, which together improved thermal stability and strength. A porous honeycomb structure facilitated stress distribution and energy dissipation, while the fiber pull-out mechanism of PE under impact provided strong interfacial bonding and toughening effects.

- (4)

- Multi-criteria evaluation using the TOPSIS model identified BC-PE as the best-performing composite, with optimal tensile properties, impact resistance, and thermal regulation. This work provides insights and theoretical support for advancing bio-based composites in impact-resistant and functional insulation applications.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- York, I.N.; Europe, I. Concrete needs to lose its colossal carbon footprint. Nature 2021, 597, 593–594. [Google Scholar] [CrossRef]

- Xiao, J.; Zou, S.; Poon, C.S.; Sham, M.L.; Li, Z.; Shah, S.P. We use 30 billion tonnes of concrete each year—here’s how to make it sustainable. Nature 2025, 638, 888–890. [Google Scholar] [PubMed]

- Smirnova, M.; Nething, C.; Stolz, A.; Gröning, J.A.; Funaro, D.P.; Eppinger, E.; Reichert, M.; Frick, J.; Blandini, L. High strength bio-concrete for the production of building components. NPJ Mater. Sustain. 2023, 1, 4. [Google Scholar] [CrossRef]

- Lee, T.; Choi, J. Mycelium-composite panels for atmospheric particulate matter adsorption. Results Mater. 2021, 11, 100208. [Google Scholar] [CrossRef]

- Chan, X.Y.; Saeidi, N.; Javadian, A.; Hebel, D.E.; Gupta, M. Mechanical properties of dense mycelium-bound composites under accelerated tropical weathering conditions. Sci. Rep. 2021, 11, 22112. [Google Scholar] [CrossRef]

- Al-Sabaeei, A.M.; Al-Fakih, A.; Noura, S.; Yaghoubi, E.; Alaloul, W.; Al-Mansob, R.A.; Khan, M.I.; Yaro, N.S.A. Utilization of palm oil and its by-products in bio-asphalt and bio-concrete mixtures: A review. Constr. Build. Mater. 2022, 337, 127552. [Google Scholar] [CrossRef]

- Jiyoon, P.; Chongku, Y. Material Properties of Eco-friendly Composite Using Gelatin as an Organic Binder according to the Mix Proposition. J. Archit. Inst. Korea 2023, 39, 279–285. [Google Scholar]

- Wang, X.; Wang, X.; Yin, J.; Li, N.; Zhang, Z.; Xu, Y.; Zhang, L.; Qin, Z.; Jiao, T. Mechanically robust, degradable and conductive MXene-composited gelatin organohydrogel with environmental stability and self-adhesiveness for multifunctional sensor. Compos. Part B Eng. 2022, 241, 110052. [Google Scholar] [CrossRef]

- Hematibahar, M.; Esparham, A.; Vatin, N.I.; Kharun, M.I.; Gebre, T.H. Effect of gelatin powder, almond shell, and recycled aggregates on chemical and mechanical properties of conventional concrete. Struct. Mech. Eng. Constr. Build. 2023, 19, 233–250. [Google Scholar] [CrossRef]

- Christ, J.; Leusink, S.; Koss, H. Multi-axial 3D printing of biopolymer-based concrete composites in construction. Mater. Des. 2023, 235, 112410. [Google Scholar] [CrossRef]

- Qu, Z.; Yu, Q.; Ong, G.P.; Cardinaels, R.; Ke, L.; Long, Y.; Geng, G. 3D printing concrete containing thermal responsive gelatin: Towards cold environment applications. Cem. Concr. Compos. 2023, 140, 105029. [Google Scholar] [CrossRef]

- Gao, X.; Tang, P.; Gu, T.; Zhuang, J.; Zhang, H. Gelatin-based air-entraining agents for ordinary portland cement: Chelate Ca2+ and reduce surface tension. J. Appl. Polym. Sci. 2024, 141, e55282. [Google Scholar] [CrossRef]

- Cai, G.; Wang, R.; Liu, T.; Liu, H.; Guo, Z.; Wang, J. Wetting–Drying Durability and Microscopic Mechanism of MgO-GGBS and Sisal Fiber-Reinforced Carbonation-Stabilized Silty Clay. Iran. J. Sci. Technol. Trans. Civ. Eng. 2025. [Google Scholar] [CrossRef]

- Aduwenye, P.; Chong, B.W.; Gujar, P.; Shi, X. Mechanical properties and durability of carbon fiber reinforced cementitious composites: A review. Constr. Build. Mater. 2024, 452, 138822. [Google Scholar] [CrossRef]

- Wang, J.; Xiong, Y.; Li, Q.; Jin, D.; Hu, Y.; Che, T. Experimental investigation on the preparation and surface treatment of biomass fibers for stone mastic asphalt mixtures modification. Constr. Build. Mater. 2023, 408, 133667. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, C.; Li, Q.; Song, G.; Hu, Y. The synergistic effect of recycled steel fibers and rubber aggregates from waste tires on the basic properties, drying shrinkage, and pore structures of cement concrete. Constr. Build. Mater. 2025, 470, 140574. [Google Scholar] [CrossRef]

- Gao, S.; Chu, H.; Jiang, J.; Zhang, W. Optimizing high-performance lightweight concrete with hybrid fiber: Enhancing mechanical and thermal properties. Constr. Build. Mater. 2025, 458, 139598. [Google Scholar] [CrossRef]

- Sridhar, J.; Gobinath, R.; Kırgız, M.S. Comparative study for efficacy of chemically treated jute fiber and bamboo fiber on the properties of reinforced concrete beams. J. Nat. Fibers 2022, 19, 12224–12234. [Google Scholar] [CrossRef]

- Zhao, H.; Tang, J.; Li, Z.; Zhou, T.; Xiong, T. Experimental study on the static properties of bamboo fiber reinforced ultra-high performance concrete (UHPC). Constr. Build. Mater. 2024, 453, 138974. [Google Scholar] [CrossRef]

- Yu, K.; Ding, Y.; Liu, J.; Bai, Y. Energy dissipation characteristics of all-grade polyethylene fiber-reinforced engineered cementitious composites (PE-ECC). Cem. Concr. Compos. 2020, 106, 103459. [Google Scholar] [CrossRef]

- Liu, L.; Xiao, J.; Wu, Z. The effect of fiber content on the static and dynamic performance of PE-ECC. Case Stud. Constr. Mater. 2024, 20, e03041. [Google Scholar] [CrossRef]

- Huo, Y.; Liu, T.; Lu, D.; Han, X.; Sun, H.; Huang, J.; Ye, X.; Zhang, C.; Chen, Z.; Yang, Y. Dynamic tensile properties of steel fiber reinforced polyethylene fiber-engineered/strain-hardening cementitious composites (PE-ECC/SHCC) at high strain rate. Cem. Concr. Compos. 2023, 143, 105234. [Google Scholar] [CrossRef]

- Wang, J.; Fan, X.; Liu, H.; Tang, K. Self-assembly and metal ions-assisted one step fabrication of recoverable gelatin hydrogel with high mechanical strength. Polym.-Plast. Technol. Mater. 2020, 59, 1899–1909. [Google Scholar] [CrossRef]

- Zan, X.; Yang, D.; Xiao, Y.; Zhu, Y.; Chen, H.; Ni, S.; Zheng, S.; Zhu, L.; Shen, J.; Zhang, X. Facile general injectable gelatin/metal/tea polyphenol double nanonetworks remodel wound microenvironment and accelerate healing. Adv. Sci. 2024, 11, 2305405. [Google Scholar] [CrossRef]

- Zhang, M.; Feng, Q.; Zhang, G.; Wang, R.; Zhang, H.; Li, M.; Zhou, Y.; Jiang, C.; Li, J.; Nie, Y. Calcium-capturing hydrogel with self-reinforced multi-dynamic networks for effective periodontal bone regeneration in three-dimension. Adv. Funct. Mater. 2025, 35, 2415185. [Google Scholar] [CrossRef]

- Wen, M.; Wang, T.; Li, N.; Wu, Y.; Zhang, L.; Xue, Y.; Shang, L. Polyphenol-Copper Derived Self-Cascade Nanozyme Hydrogel in Boosting Oxygenation and Robust Revascularization for Tissue Regeneration. Adv. Funct. Mater. 2024, 34, 2403634. [Google Scholar] [CrossRef]

- Yu, Y.; Li, P.; Bao, L.; Liu, F.; Zeng, Z.; Li, Z.; Wang, L.; Liu, F.; Jiang, M.; Xie, M.; et al. An Injectable, Self-Adaptive Hydrogel with Metallic-Functionalized Metal Organic Frameworks for Enhanced Wound Healing in Dynamic Infectious and Inflammatory Microenvironment. Small Methods 2025, 9, 2500015. [Google Scholar] [CrossRef]

- Chen, Y.; Cai, J.; Liu, D.; Liu, S.; Lei, D.; Zheng, L.; Wei, Q.; Gao, M. Zinc-based metal organic framework with antibacterial and anti-inflammatory properties for promoting wound healing. Regen. Biomater. 2022, 9, rbac019. [Google Scholar] [CrossRef]

- Geng, H.; Zhong, Q.Z.; Li, J.; Lin, Z.; Cui, J.; Caruso, F.; Hao, J. Metal ion-directed functional metal–phenolic materials. Chem. Rev. 2022, 122, 11432–11473. [Google Scholar] [CrossRef]

- Dai, Y.; Wu, J.; Wang, J.; Wang, H.; Guo, B.; Jiang, T.; Cai, Z.; Han, J.; Zhang, H.; Xu, B.; et al. Magnesium Ions Promote the Induction of Immunosuppressive Bone Microenvironment and Bone Repair through HIF-1α-TGF-β Axis in Dendritic Cells. Small 2024, 20, 2311344. [Google Scholar] [CrossRef]

- Mikhailov, O.V. Gelatin matrix as functional biomaterial for immobilization of nanoparticles of metal-containing compounds. J. Funct. Biomater. 2023, 14, 92. [Google Scholar] [CrossRef]

- Ruan, S.; Unluer, C. Comparative life cycle assessment of reactive MgO and Portland cement production. J. Clean. Prod. 2016, 137, 258–273. [Google Scholar] [CrossRef]

- Alipal, J.; Pu’AD, N.M.; Lee, T.C.; Nayan, N.H.M.; Sahari, N.; Basri, H.; Idris, M.; Abdullah, H.Z. A review of gelatin: Properties, sources, process, applications, and commercialisation. Mater. Today Proc. 2021, 42, 240–250. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, Y.; Zhang, Z.; Zhang, Y.; Li, L. Recent advances in amino acid-metal coordinated nanomaterials for biomedical applications. Chin. J. Chem. Eng. 2021, 38, 30–42. [Google Scholar] [CrossRef]

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). State Market Regulatory Administration: Beijing, China, 2021.

- Yokota, H.; Rokugo, K.; Sakata, N. JSCE Recommendations for Design and Construction of High Performance Fiber Reinforced Cement Composite with Multiple Fine Cracks. In High Performance Fiber Reinforced Cement Composites; Springer: Tokyo, Japan, 2008; Volume 2. [Google Scholar]

- ASTM D7136; Standard Test Method for Measuring the Damage Resistance of a Fiber-Reinforced Polymer Matrix Composite to a Drop-Weight Impact Event. ASTM International: West Conshohocken, PA, USA, 2005.

- ISO 22007-2:2015; Plastics—Determination of Thermal Conductivity and Diffusivity—Part 2: Transient Plane Source (Hot Disk) Method. International Organization for Standardization: Geneva, Switzerland, 2015.

- Elkholy, A.; Sadek, H.; Kempers, R. An improved transient plane source technique and methodology for measuring the thermal properties of anisotropic materials. Int. J. Therm. Sci. 2019, 135, 362–374. [Google Scholar] [CrossRef]

- Ye, H.; Zhu, B.; Pan, J.; Chen, X.; Qu, G. Solid waste-based low-carbon autoclaved aerated concrete: Relationship between engineering properties and microstructure. J. Build. Eng. 2024, 91, 109691. [Google Scholar] [CrossRef]

- Ahmad, J.; Arbili, M.M.; Majdi, A.; Althoey, F.; Farouk Deifalla, A.; Rahmawati, C. Performance of concrete reinforced with jute fibers (natural fibers): A review. J. Eng. Fibers Fabr. 2022, 17, 15589250221121871. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z.; Deifalla, A.F. Structural properties of concrete reinforced with bamboo fibers: A review. J. Mater. Res. Technol. 2023, 24, 844–865. [Google Scholar] [CrossRef]

- Ye, H.; Pan, J.; Zhu, B.; Lin, Y.; Cai, J. Dynamic splitting tensile properties of crumb rubber modified ultra-high performance engineered cementitious composites (UHP-ECC). Constr. Build. Mater. 2024, 455, 139183. [Google Scholar] [CrossRef]

- Zhu, B.; Pan, J.; Li, J.; Wang, P.; Zhang, M. Relationship between microstructure and strain-hardening behaviour of 3D printed engineered cementitious composites. Cem. Concr. Compos. 2022, 133, 104677. [Google Scholar] [CrossRef]

- Ye, H.; Zhu, B.; Ping, P.; Lin, Y.; Cai, J.; Pan, J. Mechanical performance, impact behavior and environmental assessment of coal furnace slag based low-carbon ultra-high performance engineered cementitious composites (UHP-ECC). J. Clean. Prod. 2024, 450, 141921. [Google Scholar] [CrossRef]

- Zhu, B.; Wei, Y.; Chu, H.; Ye, H.; Cai, J.; Pan, J. Dynamic response of ultra-high performance engineered cementitious composites (UHP-ECC) under low-velocity impact: Effect of waste rubber incorporation and low temperatures. Cem. Concr. Compos. 2024, 151, 105576. [Google Scholar] [CrossRef]

- Rathore, P.K.S.; Kumar Shukla, S. Improvement in thermal properties of PCM/Expanded vermiculite/expanded graphite shape stabilized composite PCM for building energy applications. Renew. Energy 2021, 176, 295–304. [Google Scholar] [CrossRef]

- Thakur, S.; Govender, P.P.; Mamo, M.A.; Tamulevicius, S.; Thakur, V.K. Recent progress in gelatin hydrogel nanocomposites for water purification and beyond. Vacuum 2017, 146, 396–408. [Google Scholar] [CrossRef]

- Gharibshahian, M.; Salehi, M.; Kamalabadi-Farahani, M.; Alizadeh, M. Magnesium-oxide-enhanced bone regeneration: 3D-printing of gelatin-coated composite scaffolds with sustained Rosuvastatin release. Int. J. Biol. Macromol. 2024, 266, 130995. [Google Scholar] [CrossRef]

- Wang, J.; Ma, Y.; Dai, X.; Gong, B.; Chen, P.; Shao, Z.; Huang, X. Stiffened and toughened polyacrylamide/polyanionic cellulose physical hydrogels mediated by ferric ions. Colloid Polym. Sci. 2021, 299, 999–1009. [Google Scholar] [CrossRef]

- Ding, J.; Yu, C.; Lu, J.; Wei, X.; Wang, W.; Pan, G. Enhanced CO2 adsorption of MgO with alkali metal nitrates and carbonates. Appl. Energy 2020, 263, 114681. [Google Scholar] [CrossRef]

- Wang, J.; Liu, C.; Chen, G.; Yu, J. Insight into solvent effects on growth morphology of MgCO3·3H2O in CO2 mineralization: Molecular dynamics simulations and DFT studies. J. Mol. Struct. 2025, 1319, 139422. [Google Scholar] [CrossRef]

- Ye, H.; He, Q.; Ping, P.; Pan, J.; Zhu, B. Anisotropic flexural behavior and energy absorption of 3D printed engineered cementitious composites (3DP-ECC) beams under low-velocity impact. Cem. Concr. Compos. 2025, 163, 106183. [Google Scholar] [CrossRef]

| Fiber Type | Length (mm) | Diameter (μm) | Density (g/cm3) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Rupture Elongation (%) |

|---|---|---|---|---|---|---|

| Jute fiber | 12~15 | 60 | 1.4 | 400 | 10 | 0.5 |

| Bamboo fiber | 12~15 | 120 | 1.1 | 350 | 22 | 5.8 |

| PE fiber | 12 | 24 | 0.97 | 3000 | 110 | 2.7 |

| Mix ID | By Weight (kg/m3) | By Volume (%) | |||||

|---|---|---|---|---|---|---|---|

| Gelatin | Water | QS | MgO | JF | BF | PE | |

| BC-0 | 154.6 | 120.5 | 1125 | 35 | 0 | 0 | 0 |

| BC-LF | 154.6 | 120.5 | 1125 | 35 | 1.5 | 0 | 0 |

| BC-BF | 154.6 | 120.5 | 1125 | 35 | 0 | 1.5 | 0 |

| BC-PE | 154.6 | 120.5 | 1125 | 35 | 0 | 0 | 1.5 |

| Specimens | Temperature (°C) | Ave. Th. Conductivity (W/mK) | Ave. Th. Diffusivity (mm2/s) | Ave. Specific Heat (MJ/m3K) |

|---|---|---|---|---|

| BC-JF | 22.8 °C | 1.080 | 0.82 | 1.3215 |

| BC-BF | 22.8 °C | 1.093 | 0.85 | 1.2879 |

| BC-PE | 23.0 °C | 1.069 | 0.74 | 1.4487 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, B.; Wang, Q.; Wei, Y.; Pan, J.; Ye, H. Sustainable Bio-Gelatin Fiber-Reinforced Composites with Ionic Coordination: Mechanical and Thermal Properties. Materials 2025, 18, 4584. https://doi.org/10.3390/ma18194584

Zhu B, Wang Q, Wei Y, Pan J, Ye H. Sustainable Bio-Gelatin Fiber-Reinforced Composites with Ionic Coordination: Mechanical and Thermal Properties. Materials. 2025; 18(19):4584. https://doi.org/10.3390/ma18194584

Chicago/Turabian StyleZhu, Binrong, Qiancheng Wang, Yang Wei, Jinlong Pan, and Huzi Ye. 2025. "Sustainable Bio-Gelatin Fiber-Reinforced Composites with Ionic Coordination: Mechanical and Thermal Properties" Materials 18, no. 19: 4584. https://doi.org/10.3390/ma18194584

APA StyleZhu, B., Wang, Q., Wei, Y., Pan, J., & Ye, H. (2025). Sustainable Bio-Gelatin Fiber-Reinforced Composites with Ionic Coordination: Mechanical and Thermal Properties. Materials, 18(19), 4584. https://doi.org/10.3390/ma18194584