Effect of Silane Surface Treatments on the Interfacial Shear Strength Between Cotton Yarn and Poly(Lactic Acid) Resin

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

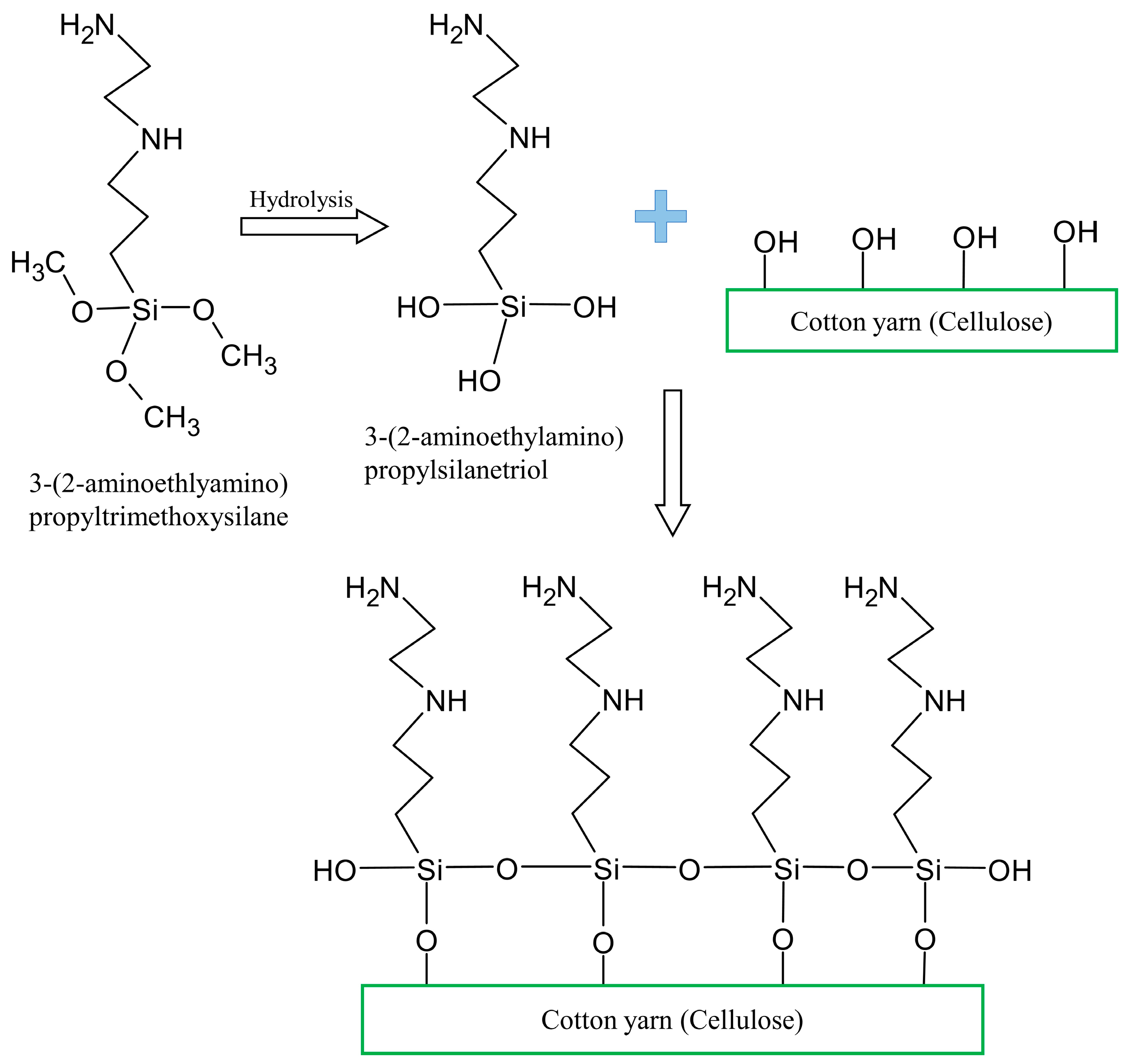

2.2. Surface Modification of Cotton Yarn

2.3. Analysis of Cotton Yarn

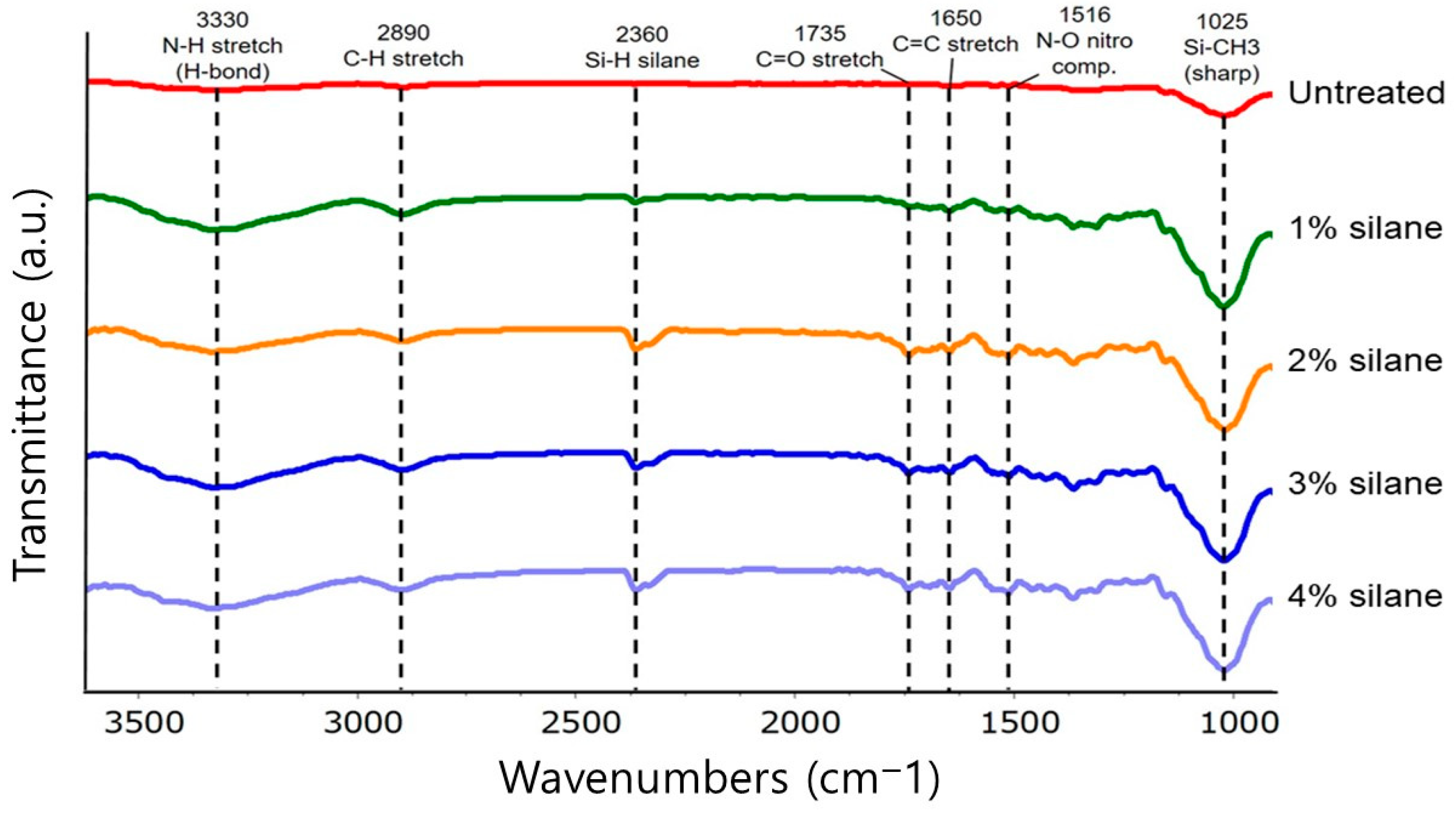

2.3.1. Fourier-Transform Infrared Spectroscopy (FTIR)

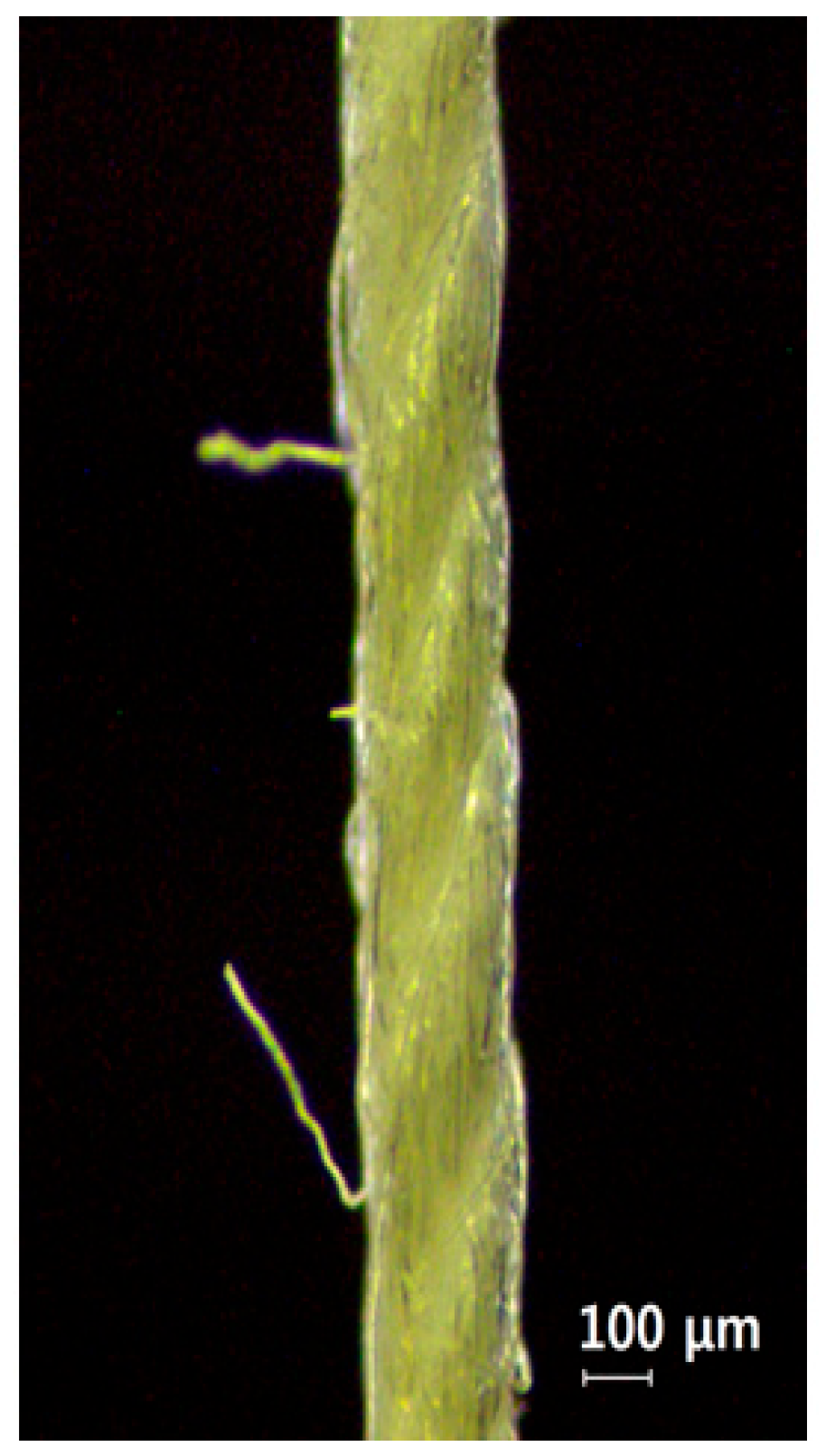

2.3.2. Optical Microscopy

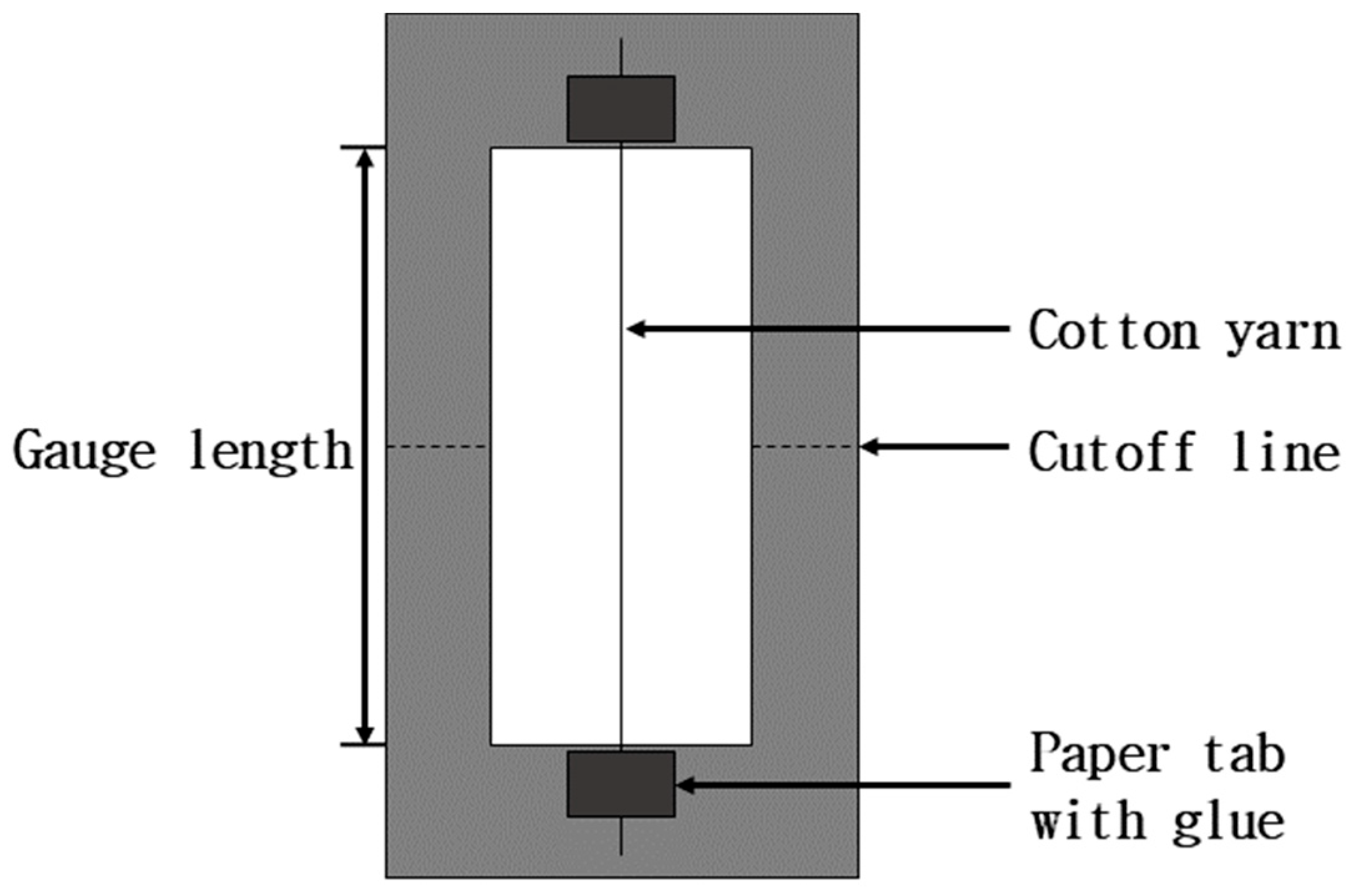

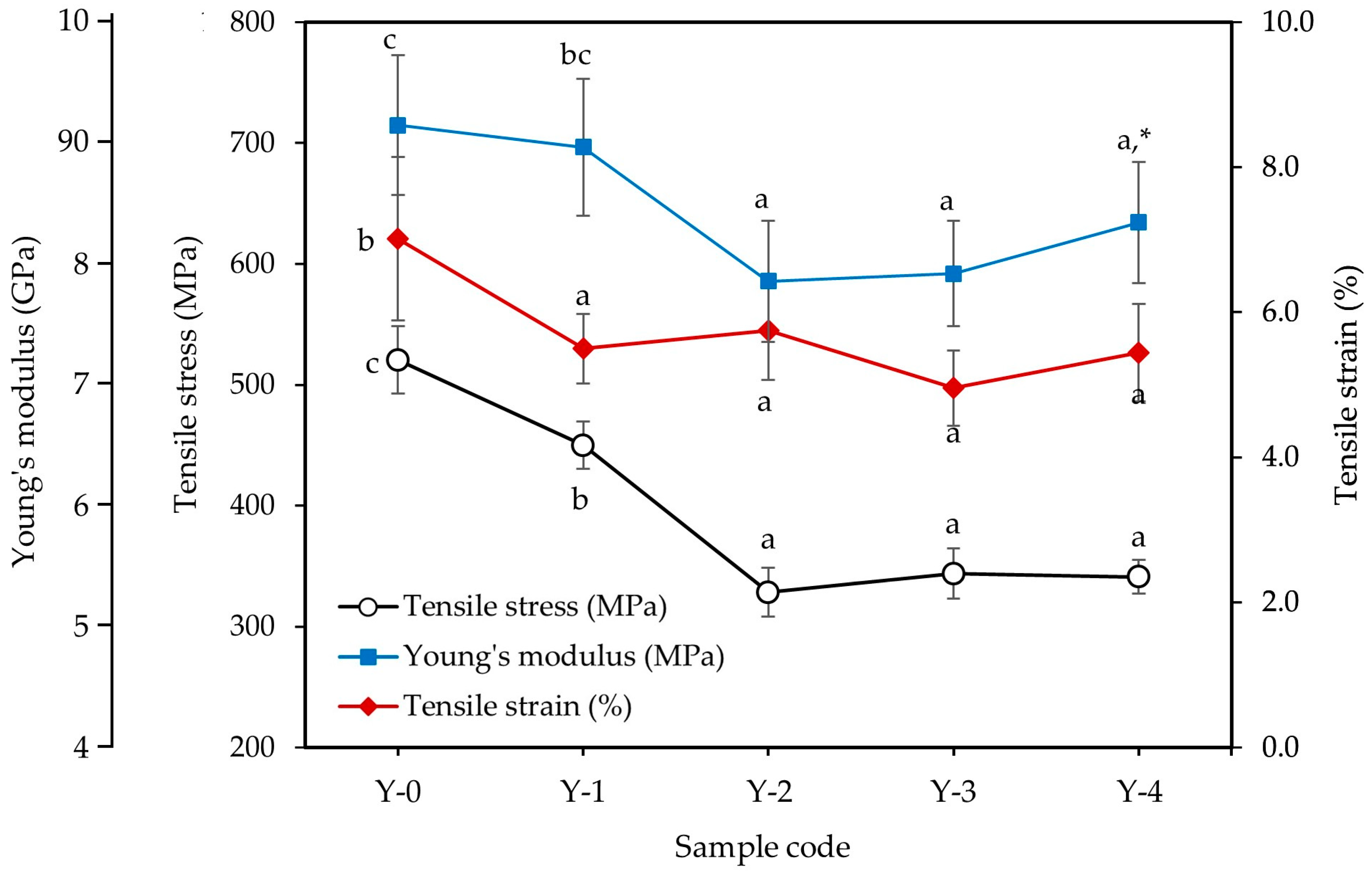

2.3.3. Tensile Properties of Cotton Yarn

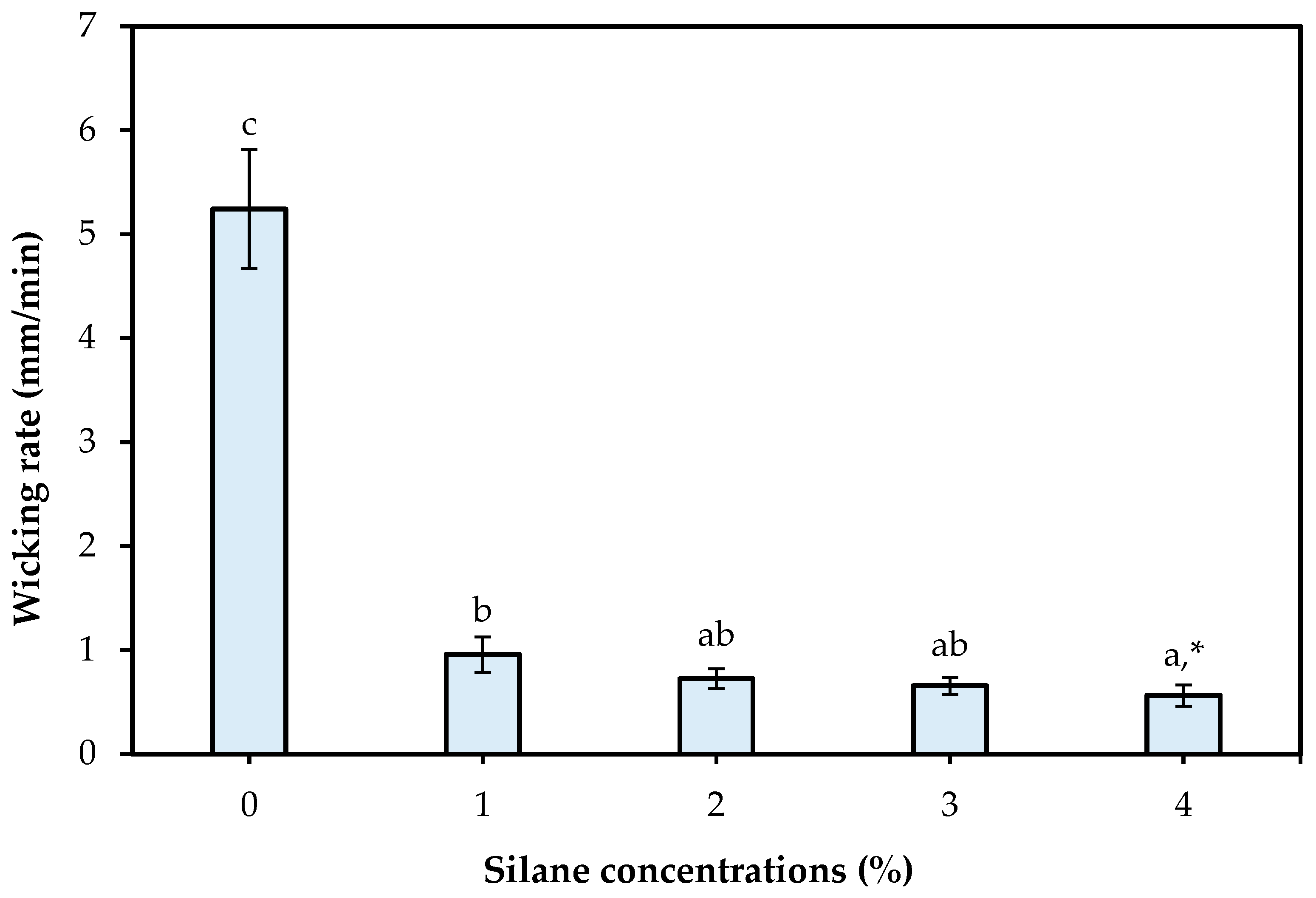

2.3.4. Liquid Wicking Rate

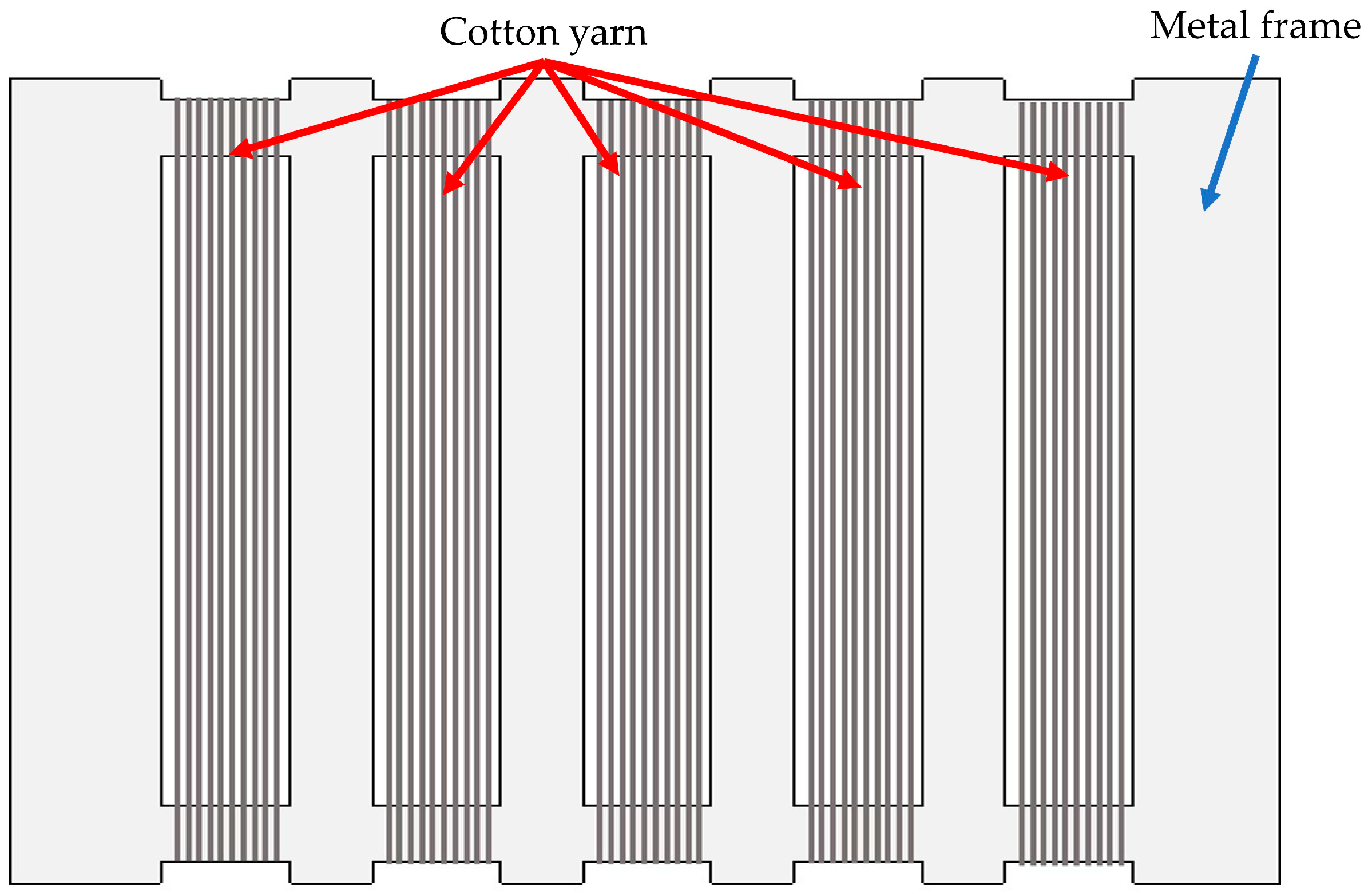

2.4. Preparation of Cotton Yarn/PLA Biocomposites

2.5. Analysis of Cotton Yarn/PLA Biocomposites

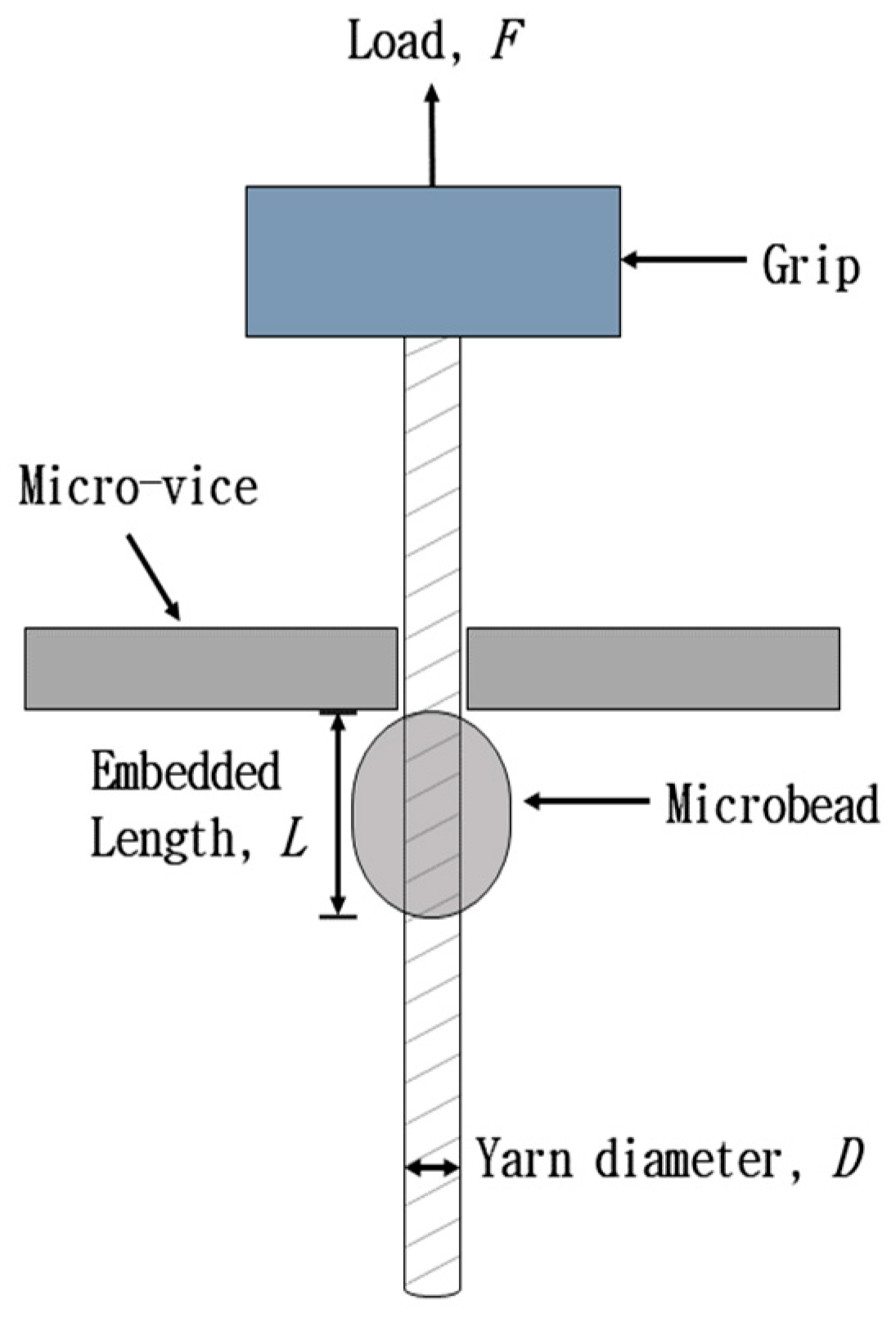

2.5.1. Interfacial Shear Strength (IFSS) Between Cotton Yarn and PLA Resin

2.5.2. Tensile Properties of Cotton Yarn/PLA Biocomposites

2.5.3. Scanning Electron Microscopy (SEM)

2.6. Statistical Analysis

3. Results and Discussion

3.1. Characterization of Cotton Yarn

3.1.1. Effect of Silane Surface Treatment on FTIR Spectra of Cotton Yarn

3.1.2. Effect of Silane Surface Treatment on Yarn Diameter and Twist Angle of Cotton Yarns

3.1.3. Effect of Silane Surface Treatment on Tensile Properties of Cotton Yarns

3.1.4. Effect of Silane Surface Treatment on the Liquid Wicking Rate of Cotton Yarns

3.2. Characterization of Cotton Yarn/PLA Biocomposites

3.2.1. Effect of Silane Surface Treatment on FTIR Spectra of Cotton Yarn

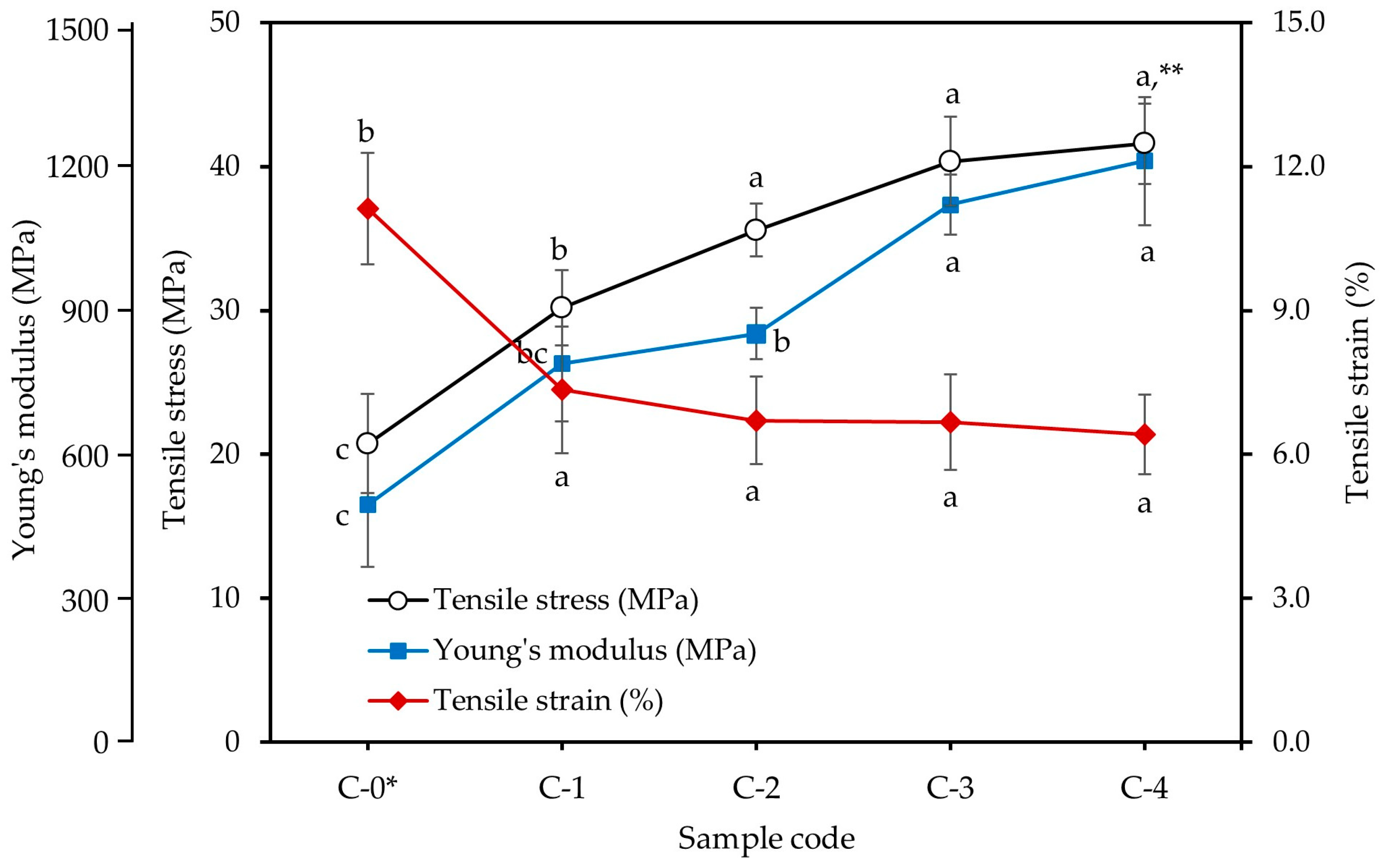

3.2.2. Effect of Silane Treatment on Tensile Properties of Cotton Yarn/PLA Biocomposites

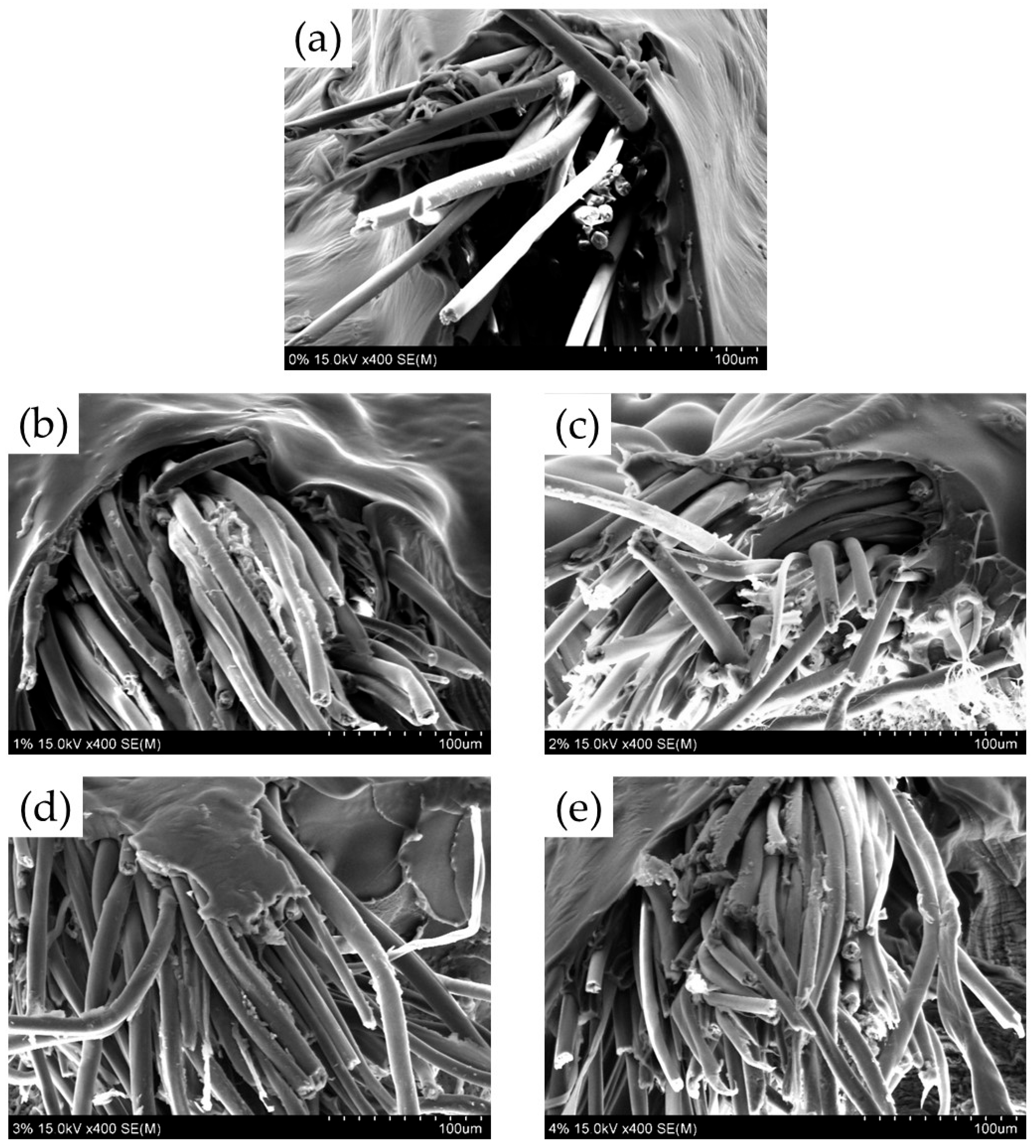

3.2.3. Effect of Silane Surface Treatment on the Morphology of Cotton Yarn/PLA Biocomposites

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Walter, L.; Ulla, S.; Mariia, F.; Arvo, I.; Harri, M.; Marija, K.; Viktoria, V. An overview of the problems posed by plastic products and the role of extended producer responsibility in Europe. J. Clean. Prod. 2019, 214, 550–558. [Google Scholar] [CrossRef]

- Gao, Z.; Qian, H.; Cui, T.; Ren, Z.; Wang, X. Comprehensive meta-analysis reveals the impact of non-biodegradable plastic pollution on methane production in anaerobic digestion. Chem. Eng. J. 2024, 484, 149703. [Google Scholar] [CrossRef]

- Orue, A.; Jauregi, A.; Peña-Rodriguez, C.; Labidi, J.; Eceiza, A.; Arbelaiz, A. The effect of surface modifications on sisal fiber properties and sisal/poly(lactic acid) interface adhesion. Compos. B Eng. 2015, 73, 132–138. [Google Scholar] [CrossRef]

- Schutz, G.F.; de Ávila Gonçalves, S.; Alves, R.M.V.; Vieira, R.P. A review of starch-based biocomposites reinforced with plant fibers. Int. J. Biol. Macromol. 2024, 261, 129916. [Google Scholar] [CrossRef]

- Kim, J.T.; Netravali, A.N. Development of aligned-hemp yarn-reinforced green composites with soy protein resin: Effect of pH on mechanical and interfacial properties. Compos. Sci. Technol. 2011, 71, 541–547. [Google Scholar] [CrossRef]

- Khouri, N.G.; Bahú, J.O.; Blanco-Llamero, C.; Severino, P.; Concha, V.O.C.; Souto, E.B. Polylactic acid (PLA): Properties, synthesis, and biomedical applications—A review of the literature. J. Mol. Struct. 2024, 1309, 138243. [Google Scholar] [CrossRef]

- Auras, R.; Harte, B.; Selke, S. Effect of water on the oxygen barrier properties of poly(ethylene terephthalate) and polylactide films. J. Appl. Polym. Sci. 2004, 92, 1790–1803. [Google Scholar] [CrossRef]

- Auras, R.A.; Singh, S.P.; Singh, J.J. Evaluation of oriented poly(lactide) polymers vs. existing PET and oriented PS for fresh food service containers. Packag. Technol. Sci. 2005, 18, 207–216. [Google Scholar] [CrossRef]

- Zhou, Z.; Wang, Y.; Dong, T.; Song, L.; Pan, P.; Sun, T.; Bai, J.; Yun, X. Poly(lactic acid)-based materials with enhanced gas permeability for modified atmosphere packaging of Chinese bayberry. Int. J. Biol. Macromol. 2025, 299, 140202. [Google Scholar] [CrossRef] [PubMed]

- Gamiz-Conde, A.K.; Burelo, M.; Franco-Urquiza, E.A.; Martínez-Franco, E.; Luna-Barcenas, G.; Bravo-Alfaro, D.A.; Trevino-Quintanilla, C.D. Development and properties of bio-based polymer composites using PLA and untreated agro-industrial residues. Polym. Test. 2024, 139, 108576. [Google Scholar] [CrossRef]

- Datta, R.; Henry, M. Lactic acid: Recent advances in products, processes and technologies—A review. J. Chem. Technol. Biotechnol. 2006, 81, 1119–1129. [Google Scholar] [CrossRef]

- Swetha, T.A.; Bora, A.; Mohanrasu, K.; Balaji, P.; Raja, R.; Ponnuchamy, K.; Muthusamy, G.; Arun, A. A comprehensive review on polylactic acid (PLA)—Synthesis, processing and application in food packaging. Int. J. Biol. Macromol. 2023, 234, 123715. [Google Scholar] [CrossRef]

- Weber, C.J.; Haugaard, V.; Festersen, R.; Bertelsen, G. Production and applications of biobased packaging materials for the food industry. Food Addit. Contam. 2002, 19, 172–177. [Google Scholar] [CrossRef]

- Kim, J.T.; Netravali, A.N. Mercerization of sisal fibers: Effect of tension on mechanical properties of sisal fiber and fiber-reinforced composites. Compos. A Appl. Sci. Manuf. 2010, 41, 1245–1252. [Google Scholar] [CrossRef]

- Kim, J.T.; Netravali, A.N. Effect of protein content in soy protein resins on their interfacial shear strength with ramie fibers. J. Adhes. Sci. Technol. 2010, 24, 203–215. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G. Biofibres, biodegradable polymers and biocomposites: A review. Macromol. Mater. Eng. 2000, 276–277, 1–24. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Effect of fibre treatments on interfacial shear strength of hemp fibre reinforced polylactide and unsaturated polyester composites. Compos. A Appl. Sci. Manuf. 2011, 42, 1189–1196. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, J.; Wo, N.; Wang, L.; Ma, Y.; Tong, J. Influence of silane treatment on the mechanical, tribological and morphological properties of corn stalk fiber reinforced polymer composites. Tribol. Int. 2019, 131, 398–405. [Google Scholar] [CrossRef]

- Liu, F.P.; Wolcott, M.P.; Gardner, D.J.; Rials, T.G. Characterization of the interface between cellulosic fibers and a thermoplastic matrix. Compos. Interface 1994, 2, 419–432. [Google Scholar] [CrossRef]

- Zhandarov, S.F.; Mäder, E.; Yurkevich, O.R. Indirect estimation of fiber/polymer bond strength and interfacial friction from maximum load values recorded in the microbond and pull-out tests. Part 1: Local bond strength. J. Adhes. Sci. Technol. 2002, 16, 1171–1200. [Google Scholar] [CrossRef]

- Abdelmouleh, M.; Boufi, S.; Salah, A.B.; Belgacem, M.N.; Gandini, A. Interaction of silane coupling agents with cellulose. Langmuir 2002, 18, 3203–3208. [Google Scholar] [CrossRef]

- Abdelmouleh, M.; Boufi, S.; Belgacem, M.N.; Dufresne, A. Short natural-fibre reinforced polyethylene and natural rubber composites: Effect of silane coupling agents and fibres loading. Compos. Sci. Technol. 2007, 67, 1627–1639. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Lau, K.T.; Cardona, F. Chemical treatments on plant-based natural fibre reinforced polymer composites: An overview. Compos. B Eng. 2012, 43, 2883–2892. [Google Scholar] [CrossRef]

- DIN 53924; Testing of Textiles—Velocity of Soaking Water of Textile Fabrics (Method by Determining the Rising Height). Deutsches Institut für Normung: Berlin, Germany, 2020.

- Nyoni, A.B.; Brook, D. Wicking mechanisms in yarns—The key to fabric wicking performance. J. Text. Inst. 2006, 97, 119–128. [Google Scholar] [CrossRef]

- Temmerman, E.; Leys, C. Surface modification of cotton yarn with a DC glow discharge in ambient air. Surf. Coat. Technol. 2005, 200, 686–689. [Google Scholar] [CrossRef]

- ASTM D882-10; Standard Test Method for Tensile Properties of Thin Plastic Sheeting. American Society for Testing and Materials: West Conshohocken, PA, USA, 2020.

- Shirgholami, M.A.; Khalil-Abad, M.S.; Khajavi, R.; Yazdanshenas, M.E. Fabrication of superhydrophobic polymethylsilsesquioxane nanostructures on cotton textiles by a solution-immersion process. J. Colloid Interface Sci. 2011, 359, 530–535. [Google Scholar] [CrossRef]

- Yu, S.W.; Oh, K.W.; Hwang, J.Y.; Hong, S.H. The effect of amino-silane coupling agents having different molecular structures on the mechanical properties of basalt fiber-reinforced polyamide 6,6 composites. Compos. B Eng. 2019, 163, 511–521. [Google Scholar] [CrossRef]

- Li, S.; Zhang, S.; Wang, X. Fabrication of superhydrophobic cellulose-based materials through a solution-immersion process. Langmuir 2008, 24, 5585–5590. [Google Scholar] [CrossRef]

- Sreekala, M.S.; Thomas, S. Effect of fibre surface modification on water-sorption characteristics of oil palm fibres. Compos. Sci. Technol. 2003, 63, 861–869. [Google Scholar] [CrossRef]

- Kissa, E. Wetting and wicking. Text. Res. J. 1996, 66, 660–668. [Google Scholar] [CrossRef]

- George, J.; Sreekala, M.S.; Thomas, S. A review on interface modification and characterization of natural fiber reinforced plastic composites. Polym. Eng. Sci. 2001, 41, 1471–1485. [Google Scholar] [CrossRef]

- Orue, A.; Jauregi, A.; Unsuain, U.; Labidi, J.; Eceiza, A.; Arbelaiz, A. The effect of alkaline and silane treatments on mechanical properties and breakage of sisal fibers and poly(lactic acid)/sisal fiber composites. Compos. A Appl. Sci. Manuf. 2016, 84, 186–195. [Google Scholar] [CrossRef]

- Sever, K.; Sarikanat, M.; Seki, Y.; Erkan, G.; Erdoğan, Ü.H. The mechanical properties of γ-methacryloxypropyltrimethoxysilane-treated jute/polyester composites. J. Compos. Mater. 2010, 44, 1913–1924. [Google Scholar] [CrossRef]

- Valadez-Gonzalez, A.; Cervantes-Uc, J.M.; Olayo, R.; Herrera-Franco, P.J. Chemical modification of henequén fibers with an organosilane coupling agent. Compos. B Eng. 1999, 30, 321–331. [Google Scholar] [CrossRef]

- Musa, A.A.; Park, J.; Hong, G.; Yoon, S.H.; Onwualu, A.P.; Kim, M. Development of high-performance basalt fiber-reinforced polymer composite using a nanocellulose-based surface modification strategy. Compos. A 2025, 199, 109191. [Google Scholar] [CrossRef]

| Sample Code | |||||

|---|---|---|---|---|---|

| Y-0 * | Y-1 | Y-2 | Y-3 | Y-4 | |

| Yarn diameter (μm) | 186.6 ± 16.9 b | 177.9 ± 7.4 a | 173.6 ± 6.3 a | 175.6 ± 7.7 a | 173.5 ± 8.7 a |

| Twist angle (°) | 27.3 ± 3.7 c | 23.8 ± 2.5 b | 23.1 ± 2.6 b | 23.1 ± 2.6 b | 22.5 ± 2.5 a |

| Samples | Silane Conc. | Volume Fraction of PLA | Young’s Modulus (MPa) | Tensile Stress (MPa) | ||

|---|---|---|---|---|---|---|

| Theoretical | Experimental | Theoretical | Experimental | |||

| PLA resin | - | 100 | - | 495.51 ± 67.00 | - | 11.39 ± 2.53 |

| Cotton yarn/PLA biocomposites | 0% | 92.96 | 1064.59 | 496.01 ± 140.46 | 47.22 | 20.74 ± 3.81 |

| 1% | 89.06 | 1346.75 | 788.77 ± 129.77 | 59.38 | 30.19 ± 2.63 | |

| 2% | 90.10 | 1082.52 | 851.76 ± 58.47 | 42.76 | 35.53 ± 1.92 | |

| 3% | 91.45 | 1012.06 | 1120.30 ± 52.39 | 39.81 | 40.35 ± 3.51 | |

| 4% | 90.54 | 1133.48 | 1211.14 ± 129.63 | 42.57 | 41.58 ± 3.22 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, G.H.; Cho, Y.S.; Shin, G.H.; Kim, J.T. Effect of Silane Surface Treatments on the Interfacial Shear Strength Between Cotton Yarn and Poly(Lactic Acid) Resin. Materials 2025, 18, 4582. https://doi.org/10.3390/ma18194582

Kim GH, Cho YS, Shin GH, Kim JT. Effect of Silane Surface Treatments on the Interfacial Shear Strength Between Cotton Yarn and Poly(Lactic Acid) Resin. Materials. 2025; 18(19):4582. https://doi.org/10.3390/ma18194582

Chicago/Turabian StyleKim, Gyu Hyeon, Young Soo Cho, Gye Hwa Shin, and Jun Tae Kim. 2025. "Effect of Silane Surface Treatments on the Interfacial Shear Strength Between Cotton Yarn and Poly(Lactic Acid) Resin" Materials 18, no. 19: 4582. https://doi.org/10.3390/ma18194582

APA StyleKim, G. H., Cho, Y. S., Shin, G. H., & Kim, J. T. (2025). Effect of Silane Surface Treatments on the Interfacial Shear Strength Between Cotton Yarn and Poly(Lactic Acid) Resin. Materials, 18(19), 4582. https://doi.org/10.3390/ma18194582