Study on Erosion Wear Resistance of 18Ni300 Maraging Steel Remanufactured by Underwater Laser Direct Metal Deposition

Highlights

- 18Ni300 maraging steel has been successfully repaired by underwater additive manufacturing.

- The repaired 18Ni300 steel presents high hardness, owing to its fine microstructure.

- The erosion wear resistance of repaired 18Ni300 steel has been systematically investigated.

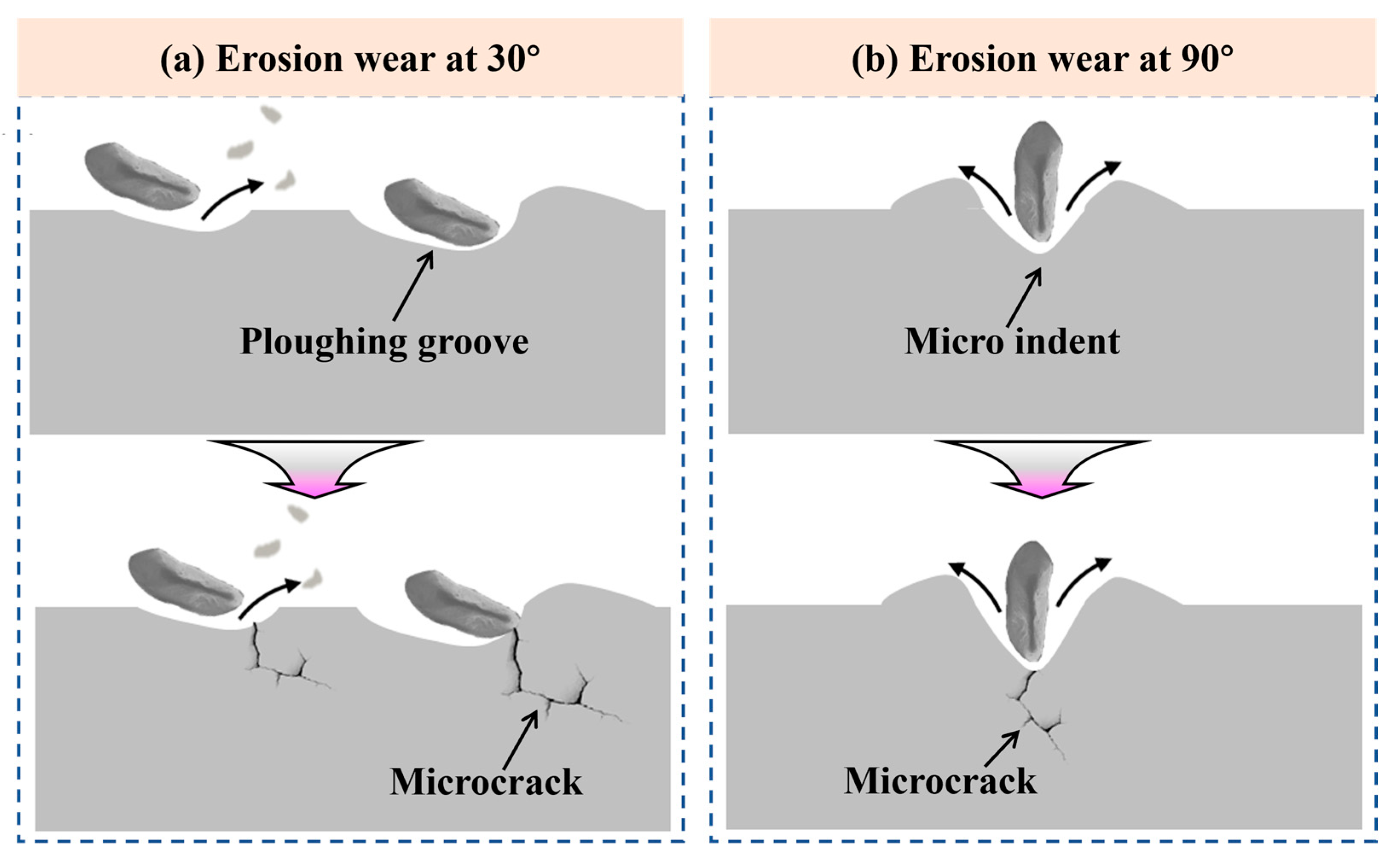

- The mechanisms for erosion wear at 30° and 90° impingement angles were different.

- The surface was hardened during the erosion wear test due to severe plastic deformation.

Abstract

1. Introduction

2. Experimental Procedure

2.1. Materials

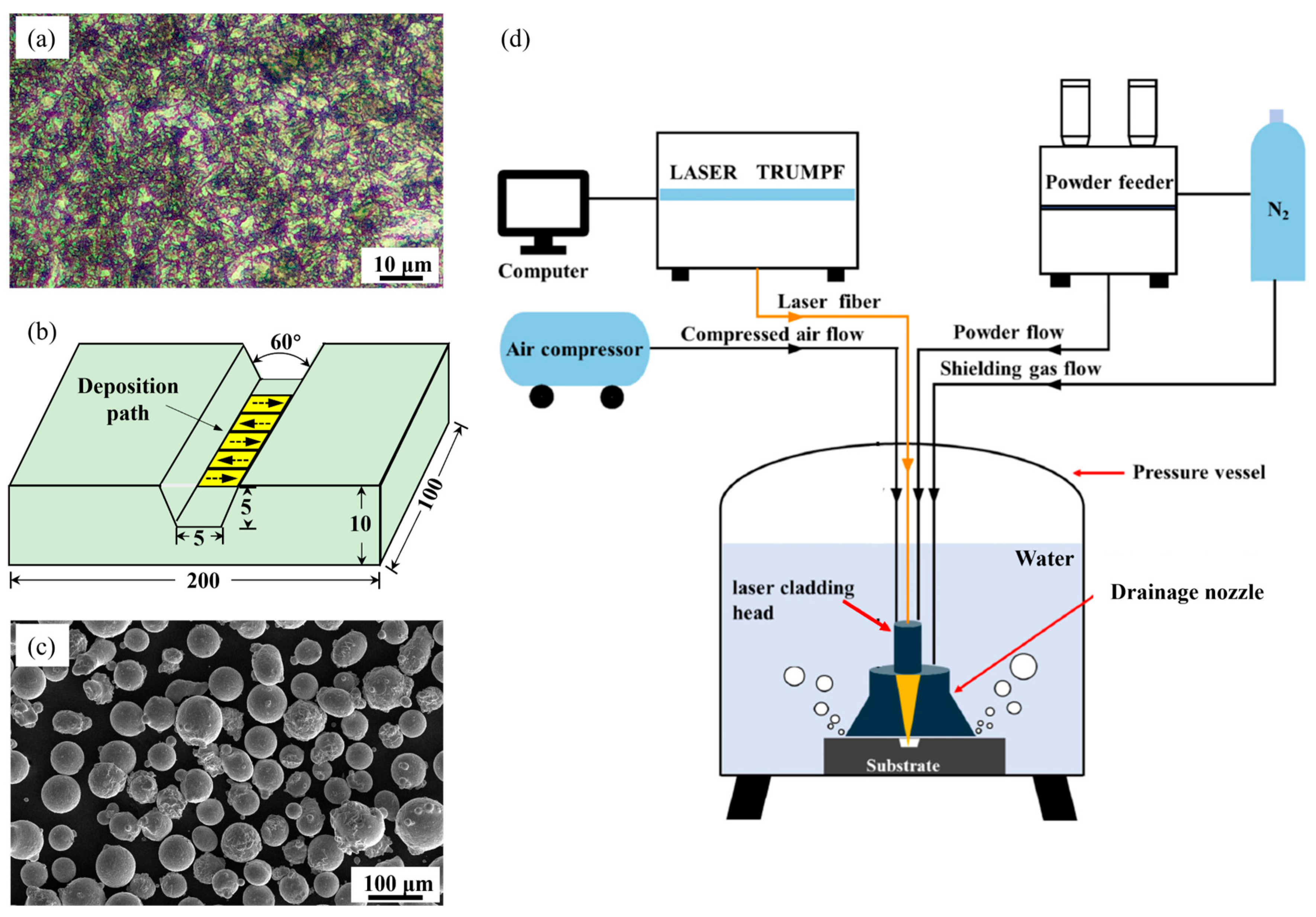

2.2. UDMD Set-Up

2.3. UDMD Process Parameters

2.4. Microstructure Characterization

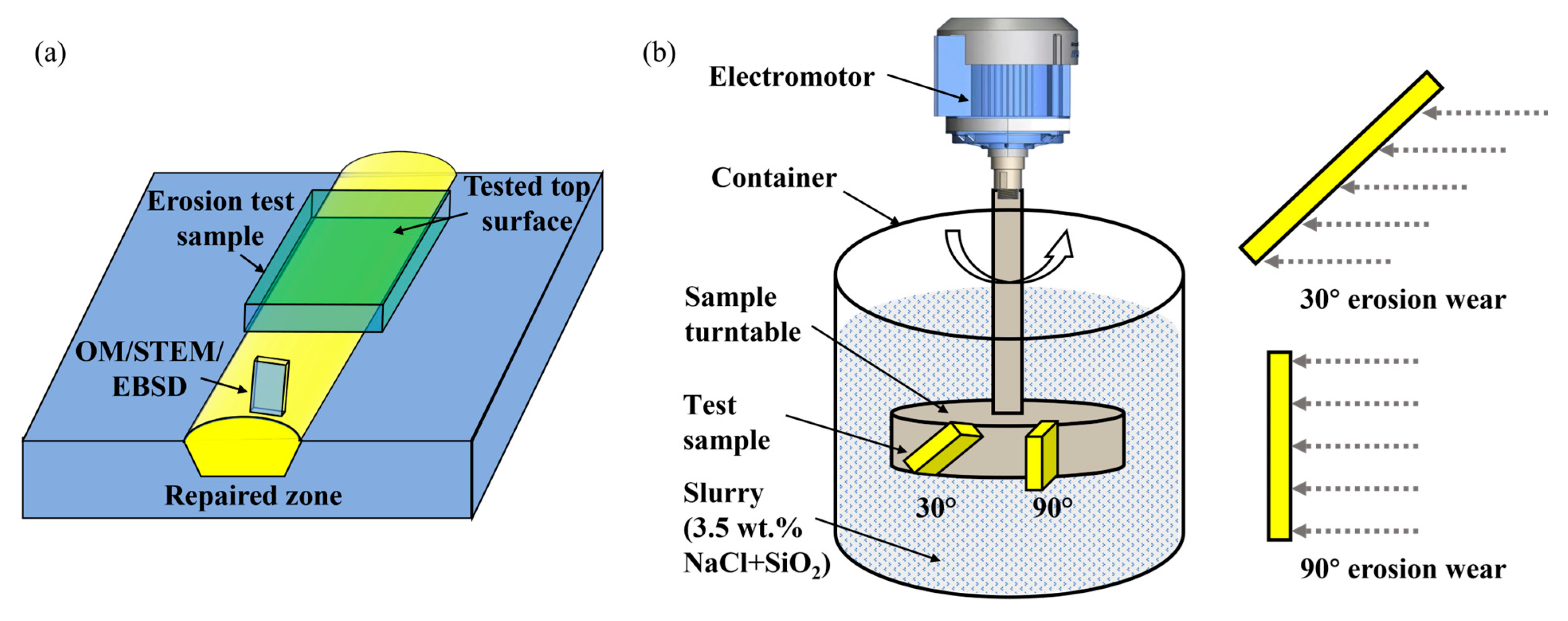

2.5. Erosion Wear Test

2.6. Surface Contour Characterization

2.7. Microhardness Test

3. Results and Discussion

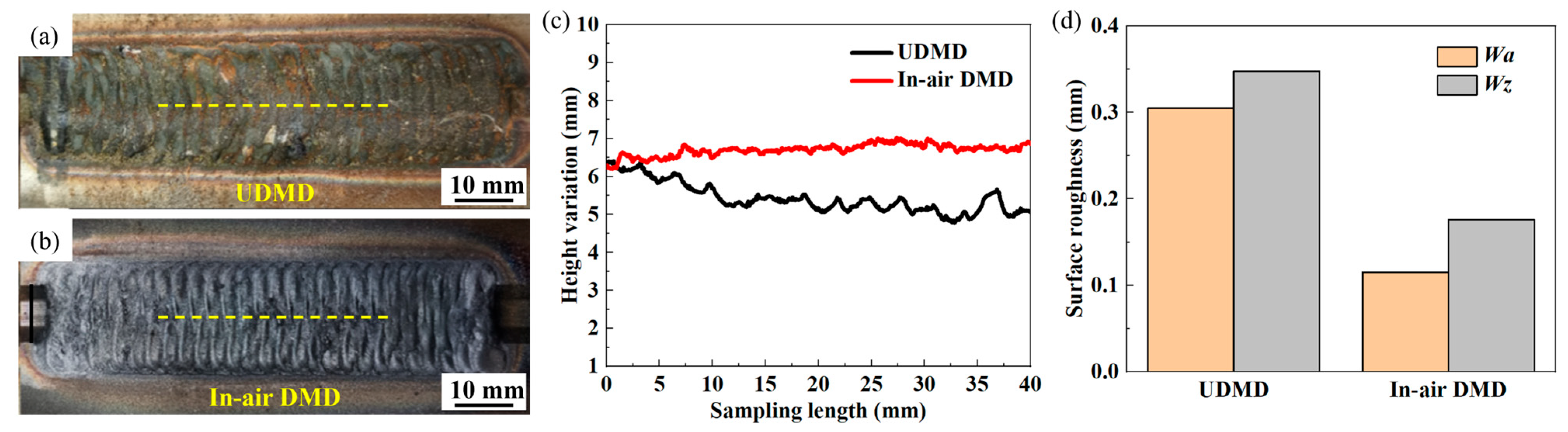

3.1. Surface Morphology

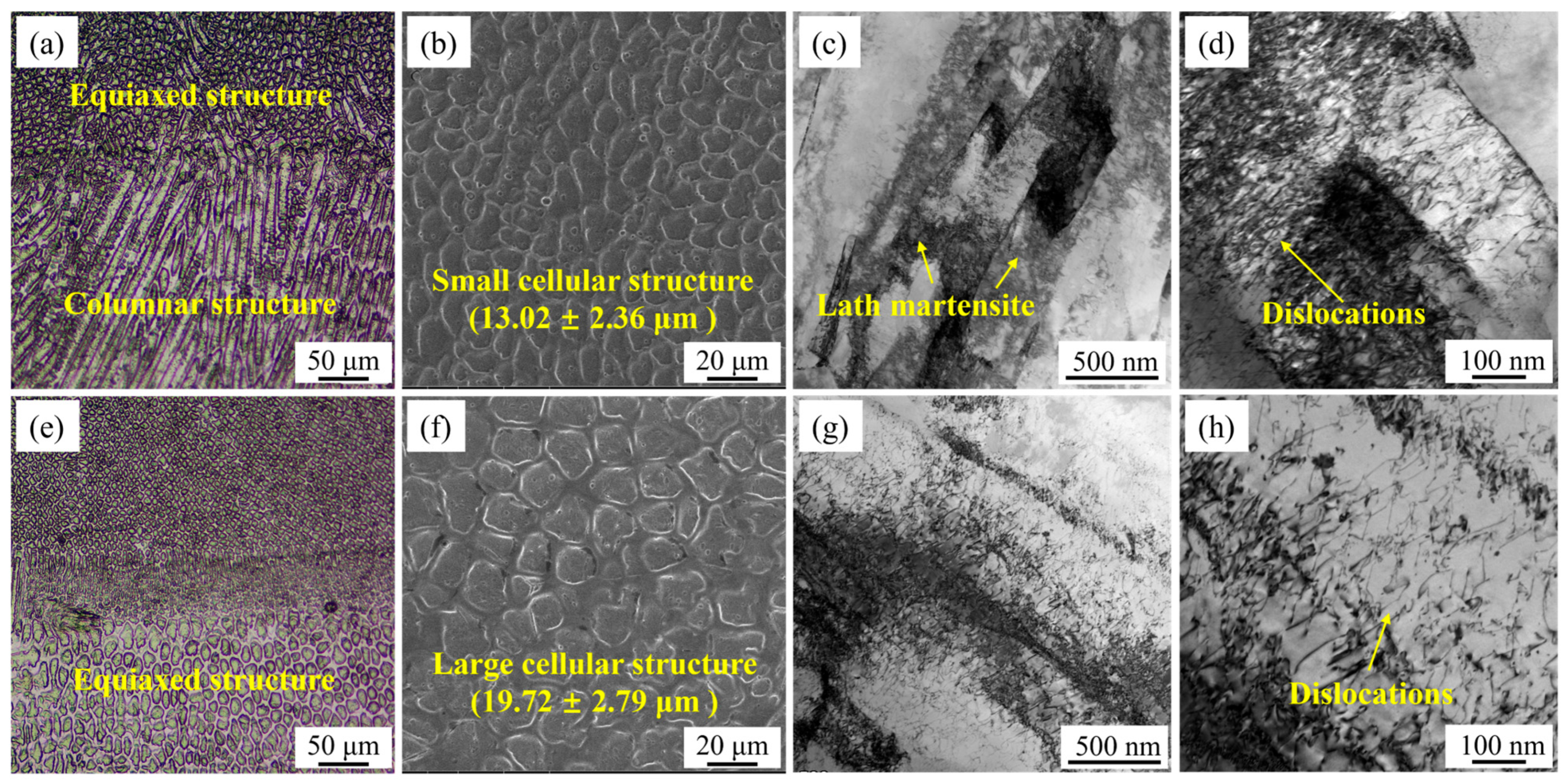

3.2. Microstructure of Repaired Zone

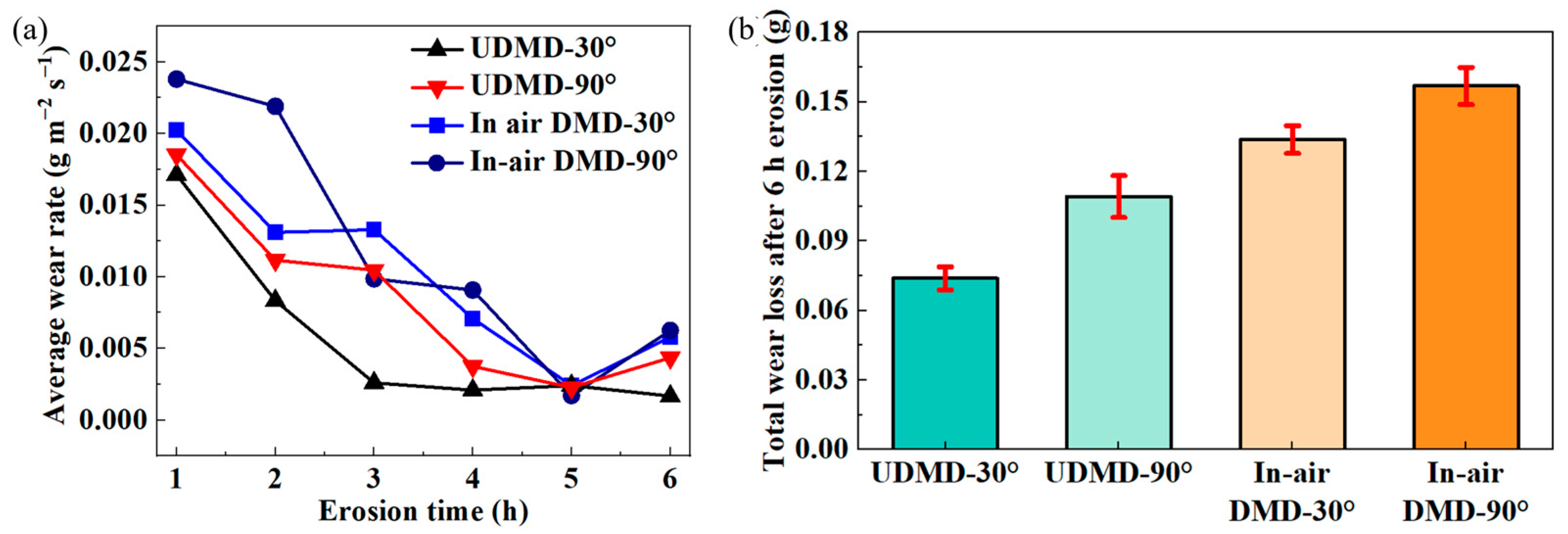

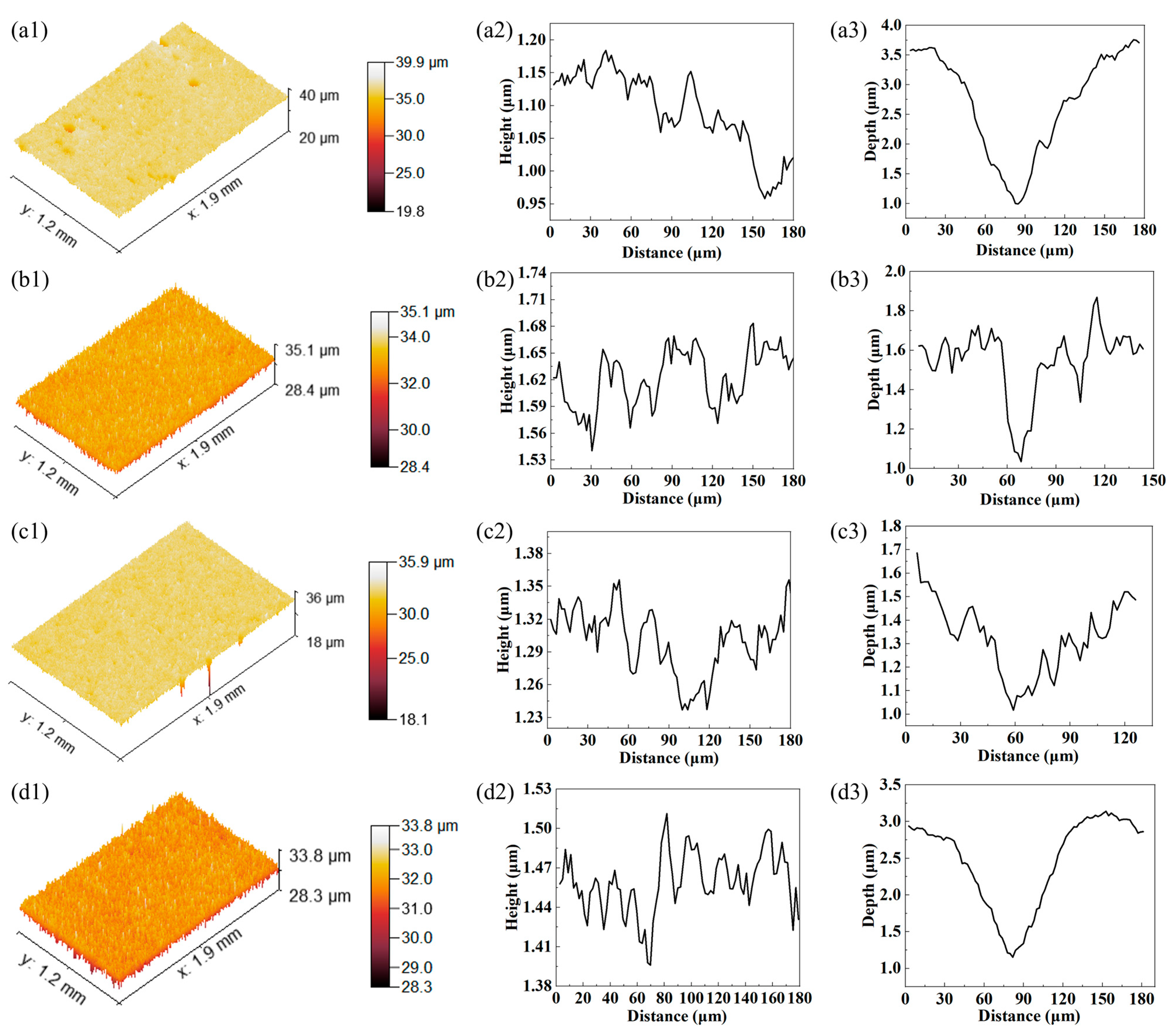

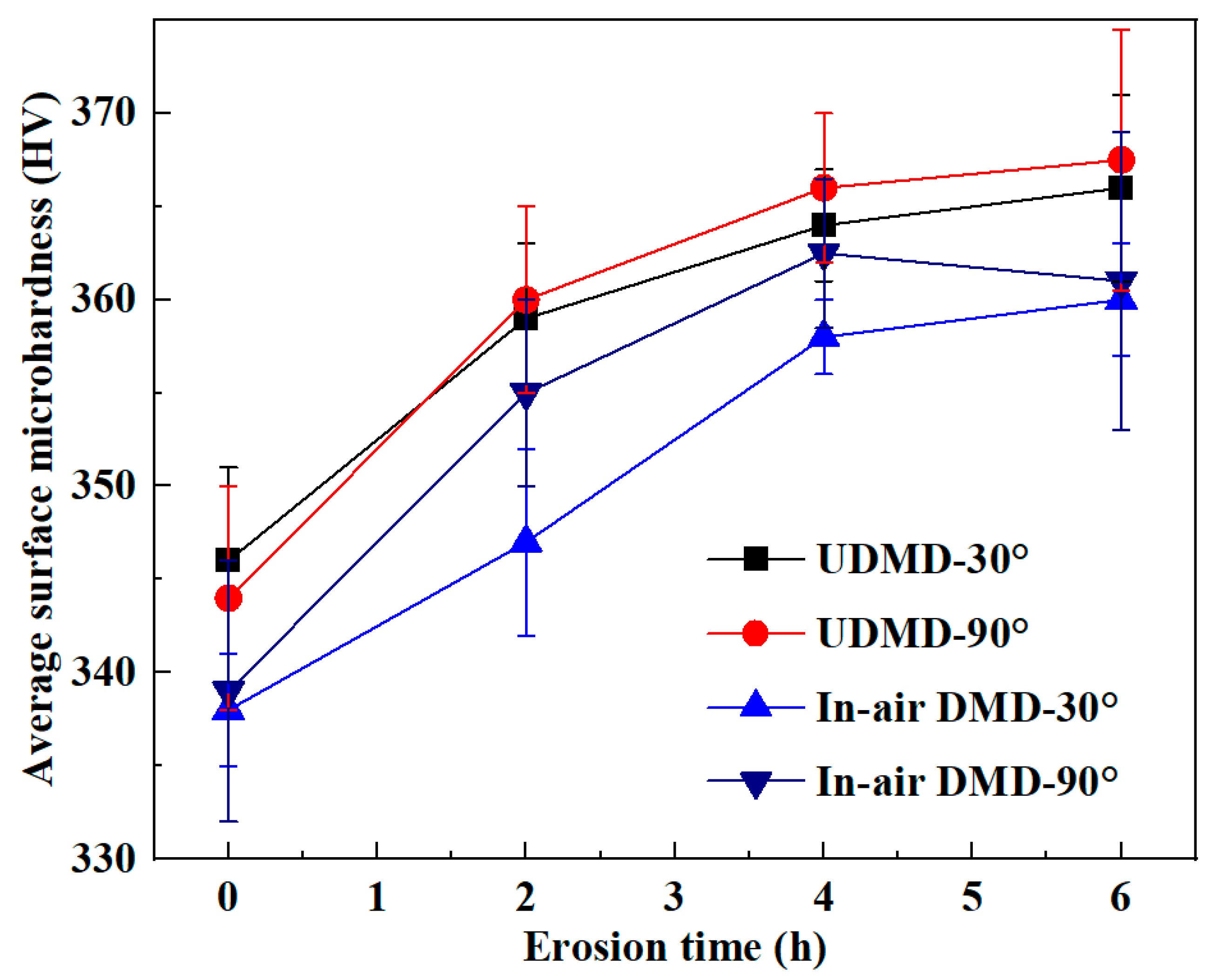

3.3. Erosion Wear Performance

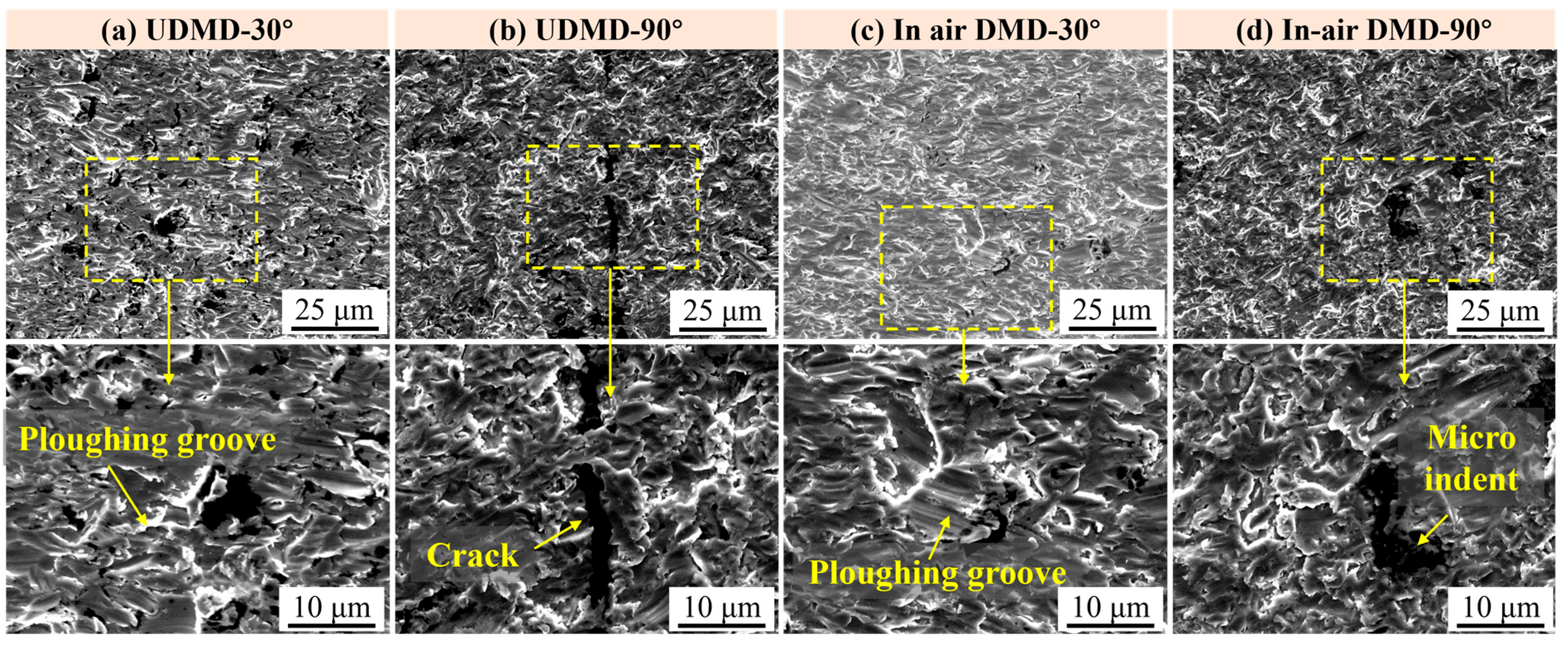

3.4. Erosion Wear Mechanism

4. Conclusions

- (1)

- UDMD can effectively restore damaged components with full groove filling and sound metallurgical bonding, confirming its technical feasibility for underwater structural repair in marine engineering applications.

- (2)

- Microstructural analysis revealed that the UDMD process, under rapid water cooling and gas shielding, produces finer cellular structures and denser lath martensite with higher dislocation density compared to in-air DMD. This refined microstructure is attributed to accelerated solidification rates, which enhance the microhardness and contribute to improved surface integrity.

- (3)

- Erosion wear tests at 30° and 90° impingement angles reveal distinct wear mechanisms: oblique impacts cause cutting and plowing, while normal impacts induce indentation, cracking, and spallation. The UDMD samples exhibit lower volumetric wear rates and total mass loss, particularly at 30°, indicating superior erosion resistance due to their finer microstructure and higher hardness.

- (4)

- Surface hardening occurs progressively during erosion due to severe plastic deformation and dislocation accumulation, leading to reduced wear rates over time. The combination of microstructural refinement, high dislocation density, and work hardening in UDMD-repaired 18Ni300 steel provides excellent resistance to erosive wear in harsh marine environments, making it a promising solution for long-term underwater structural integrity.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| UDMD | Underwater direct metal deposition |

| In-air DMD | In-air direct metal deposition |

| RZ | Repaired zone |

| EDM | Electrical discharge machine |

| SEM | Scanning electron microscope |

| OM | Optical microscope |

| STEM | Scanning-transmission electron microscope |

| EBSD | Electron backscatter diffraction |

| CLSM | Confocal laser scanning microscope |

| HAGBs | High-angle grain boundaries |

| LAGBs | Low-angle grain boundaries |

References

- Yao, Y.; Huang, Y.; Chen, B.; Tan, C.; Su, Y.; Feng, J. Influence of processing parameters and heat treatment on the mechanical properties of 18Ni300 manufactured by laser based directed energy deposition. Opt. Laser Technol. 2018, 105, 171–179. [Google Scholar] [CrossRef]

- Mei, X.; Qiao, L.; Su, Y.; Yan, Y. The role of cell structures in hydrogen embrittlement of L-PBF 18Ni(300) maraging steel. Corros. Sci. 2024, 236, 112276. [Google Scholar] [CrossRef]

- Mei, X.; Yan, Y.; Qiao, L. Research on hydrogen embrittlement behavior of L-PBF 18Ni(300) maraging steel by experiments and numerical simulations. Acta Mater. 2023, 256, 119141. [Google Scholar] [CrossRef]

- Moinuddin, S.Q.; Chamarthi, A.; Khan, M.F.; Niaz, A.; Arif, S.; Cheepu, M.; Dewangan, A.K.; Goka, S. Research progress in underwater welding: Techniques, materials, advancements, and challenges. Weld. World 2025, 69, 2805–2825. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, B.; Zhang, W.; Liao, H.; Wang, X.; Zhang, Y.; Zhang, Q. Effect of laser line energy on the microstructure, mechanical properties and corrosion resistance of Q355B welded by local dry underwater laser welding. Opt. Laser Technol. 2025, 183, 112370. [Google Scholar] [CrossRef]

- Vaccari, L.; Scheithauer, T.; Lendiel, I.; Klett, J.; Hassel, T.; Maier, H.J. Corrosion behavior of austenitic stainless steel and nickel-based welded joints in underwater wet welding. npj Mater. Degrad. 2024, 8, 51. [Google Scholar] [CrossRef]

- Guo, W.; Wang, L.; Su, L.; Ma, X.; Wang, J.; Hou, S.; He, B. Microstructure evolution and mechanical properties of Q690D steel repaired by wire based laser directed energy deposition. Virtual Phys. Prototyp. 2024, 19, e2375108. [Google Scholar] [CrossRef]

- Hamilton, J.D.; Sorondo, S.; Greeley, A.; Zhang, X.; Cormier, D.; Li, B.; Qin, H.; Rivero, I.V. Property-structure-process relationships in dissimilar material repair with directed energy deposition: Repairing gray cast iron using stainless steel 316L. J. Manuf. Process. 2022, 81, 27–34. [Google Scholar] [CrossRef]

- Balit, Y.; Joly, L.-R.; Szmytka, F.; Durbecq, S.; Charkaluk, E.; Constantinescu, A. Self-heating behavior during cyclic loadings of 316L stainless steel specimens manufactured or repaired by Directed Energy Deposition. Mater. Sci. Eng. A 2020, 786, 139476. [Google Scholar] [CrossRef]

- Li, C.; Wang, C.; Deng, C.; Cui, L.; Zhang, X.; Zhao, C.; Jiao, X. Microstructure and properties of underwater in-situ wire-based laser additive manufactured duplex stainless steel. Virtual Phys. Prototyp. 2024, 19, e2401925. [Google Scholar] [CrossRef]

- Fu, Y.; Yu, M.; Wu, D.; Zhao, Z.; Wang, D.; Guo, N. Fundamental investigation into mass transfer process and microstructural transformation pathways in Ti-6Al-4V via underwater wire-laser directed energy deposition. Virtual Phys. Prototyp. 2024, 19, e2374051. [Google Scholar] [CrossRef]

- Cheng, Q.; Guo, N.; Xue, Z.; Chen, H.; Tong, J.; Ding, Y.; Fu, Y.; Zhou, G. Effects of heat input on microstructure evolution and corrosion resistance of underwater laser cladding high-strength low-alloy steel coating. Mater. Charact. 2024, 218, 114498. [Google Scholar] [CrossRef]

- Liao, H.; Wang, Z.; Chi, P.; Zhang, B.; Ding, T.; Zhang, Q. Evolutions of microstructure and mechanical property of 308L stainless steel repaired by the local dry underwater wire arc additive manufacturing. Mater. Sci. Eng. A 2024, 898, 146365. [Google Scholar] [CrossRef]

- Telfer, C.G.; Stack, M.M.; Jana, B.D. Particle concentration and size effects on the erosion-corrosion of pure metals in aqueous slurries. Tribol. Int. 2012, 53, 35–44. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, L.; Zhou, Q.; Wang, X.; Tan, M.Y.; Huang, Y. An overview of major experimental methods and apparatus for measuring and investigating erosion corrosion of ferrous-based steels. Metals 2020, 10, 180. [Google Scholar] [CrossRef]

- Wang, T.; Wang, M.S.; Xu, T.Z.; Wu, C.L.; Zhang, C.H.; Zhang, S.; Chen, H.T.; Chen, J. Enhancing wear resistance and erosion wear performance of laser additive manufactured 17-4PH stainless steel through solution aging treatment. J. Therm. Spray Technol. 2024, 33, 2350–2366. [Google Scholar] [CrossRef]

- Kumar, N.; Arora, N.; Goel, S.K. Slurry erosion study on nitrogen-alloyed austenitic stainless steel and weld beads. Tribol. Lett. 2020, 68, 92. [Google Scholar] [CrossRef]

- Liu, X.; Meng, L.; Zeng, X.; Zhu, B.; Cao, J.; Wei, K.; Hu, Q. Study on cavitation erosion and slurry erosion resistance of martensitic precipitation hardening stainless steel coatings fabricated by high power laser cladding. Wear 2024, 558, 205562. [Google Scholar] [CrossRef]

- Zhao, T.Y.; Wang, Z.Y.; Wu, H.; Xu, T.Z.; Wu, C.L.; Zhang, C.H.; Zhang, S.; Chen, H.T.; Chen, J. Effect of aging treatment on cavitation erosion resistance and slurry erosion resistance of laser directed energy deposition martensitic aging steel. Mater. Today Commun. 2025, 46, 112588. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Z.; Yang, K.; Chen, M.; Wu, E.; Ni, Z.; Sun, G. Investigation of on-site repair of 18Ni300 by underwater laser direct metal deposition technique. J. Manuf. Process. 2022, 80, 909–919. [Google Scholar] [CrossRef]

- YB/T 6177; Metallic Materials-Wear Testing-Slurry Erosion Method. Ministry of Industry and Information Technology: Beijing, China, 2024.

- Luo, M.; Wei, P.; Li, Q.; Hu, R.; Huang, A.; Pang, S. Underwater laser welding of pure Ti: Oxidation and hardening behaviors. Metals 2021, 11, 610. [Google Scholar] [CrossRef]

- Li, S.; Chen, B.; Tan, C.; Song, X. Effects of oxygen content on microstructure and mechanical properties of 18Ni300 maraging steel manufactured by laser directed energy deposition. Opt. Laser Technol. 2022, 153, 108281. [Google Scholar] [CrossRef]

- Cheng, Q.; Guo, N.; Fu, Y.; Gao, Y.; Zhang, X.; Zhou, G. Underwater additive manufacturing of 10CrNi3MoV high-strength low-alloy steel by wire-feed laser melting deposition: Effect of microstructure evolution on mechanical properties. J. Mater. Res. Technol. 2024, 31, 2864–2875. [Google Scholar] [CrossRef]

- Zhang, S.; Zhou, N.; Ma, C.; Liu, J.; Liu, S.; Misra, R.D.K. Simultaneous enhancement of strength and hydrogen embrittlement resistance of laser-powder bed fusion maraging steel via long-term low-temperature aging. Corros. Sci. 2023, 223, 111440. [Google Scholar] [CrossRef]

- Allam, T.; Pradeep, K.G.; Köhnen, P.; Marshal, A.; Schleifenbaum, J.H.; Haase, C. Tailoring the nanostructure of laser powder bed fusion additively manufactured maraging steel. Addit. Manuf. 2020, 36, 101561. [Google Scholar] [CrossRef]

- Amirabdollahian, S.; Deirmina, F.; Harris, L.; Pellizzari, M.; Bosetti, P.; Molinari, A. Towards controlling intrinsic heat treatment of maraging steel during laser directed energy deposition. Scr. Mater. 2021, 201, 113973. [Google Scholar] [CrossRef]

- Aguirre, J.; Walczak, M. Multifactorial study of erosion-corrosion wear of a X65 steel by slurry of simulated copper tailing. Tribol. Int. 2018, 126, 177–185. [Google Scholar] [CrossRef]

- Selvam, K.; Ayyagari, A.; Grewal, H.S.; Mukherjee, S.; Arora, H.S. Enhancing the erosion-corrosion resistance of steel through friction stir processing. Wear 2017, 386–387, 129–138. [Google Scholar] [CrossRef]

- Ojala, N.; Valtonen, K.; Antikainen, A.; Kemppainen, A.; Minkkinen, J.; Oja, O.; Kuokkala, V. Wear performance of quenched wear resistant steels in abrasive slurry erosion. Wear 2016, 354–355, 21–31. [Google Scholar] [CrossRef]

- Zheng, Y.G.; Luo, S.Z.; Ke, W. Cavitation erosion-corrosion behaviour of CrMnB stainless overlay and 0Cr13Ni5Mo stainless steel in 0.5 M NaCl and 0.5 M HCl solutions. Tribol. Int. 2008, 41, 1181–1189. [Google Scholar] [CrossRef]

- Yao, C.; He, S.; Shin, K.; Lee, K.; Shim, D. Outstanding cavitation erosion resistance in Cu-Al alloys synthesized in situ by directed energy deposition. J. Mater. Res. Technol. 2025, 37, 5387–5395. [Google Scholar] [CrossRef]

- Javaheri, V.; Porter, D.; Kuokkala, V.T. Slurry erosion of steel—Review of tests, mechanisms and materials. Wear 2018, 408–409, 248–273. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhou, F.; Yao, J.; Dong, S.; Li, N. Erosion-corrosion behavior and corrosion resistance of AISI 316 stainless steel in flow jet impingement. Wear 2015, 328–329, 464–474. [Google Scholar] [CrossRef]

| Element | C | Ni | Co | Mo | Al | Ti | Si | Fe |

| 18Ni300 substrate | 0.023 | 18.1 | 8.6 | 5.5 | 0.13 | 0.49 | 0.04 | Bal. |

| 18Ni300 powder | 0.005 | 17.9 | 9.1 | 5.0 | 0.11 | 0.80 | 0.03 | Bal. |

| Parameter | Value |

| Erosion angle | 30° and 90° |

| Erosion particles | 5 wt.% quartz sand |

| Particle size | 125–700 μm |

| Erosion solution | 3.5 wt.% NaCl solution |

| Erosion time | 2 h, 4 h and 6 h |

| Erosion velocity | 10 m/s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Wu, L.; Wang, S.; Wang, C. Study on Erosion Wear Resistance of 18Ni300 Maraging Steel Remanufactured by Underwater Laser Direct Metal Deposition. Materials 2025, 18, 4583. https://doi.org/10.3390/ma18194583

Wang Z, Wu L, Wang S, Wang C. Study on Erosion Wear Resistance of 18Ni300 Maraging Steel Remanufactured by Underwater Laser Direct Metal Deposition. Materials. 2025; 18(19):4583. https://doi.org/10.3390/ma18194583

Chicago/Turabian StyleWang, Zhandong, Linzhong Wu, Shibin Wang, and Chunke Wang. 2025. "Study on Erosion Wear Resistance of 18Ni300 Maraging Steel Remanufactured by Underwater Laser Direct Metal Deposition" Materials 18, no. 19: 4583. https://doi.org/10.3390/ma18194583

APA StyleWang, Z., Wu, L., Wang, S., & Wang, C. (2025). Study on Erosion Wear Resistance of 18Ni300 Maraging Steel Remanufactured by Underwater Laser Direct Metal Deposition. Materials, 18(19), 4583. https://doi.org/10.3390/ma18194583