1. Introduction

Cellular solids represent a significant category of engineering materials. Due to their superior properties, these structures are a promising solution for various industrial applications [

1]. They offer a unique combination of lightweight design and mechanical strength, making them particularly beneficial in fields that demand high performance with reduced weight, such as the aerospace and automotive industries [

2]. As reported in [

3], cellular solids can be divided into two categories: foams and lattice structures, both characterized by their lightweight properties. Foams, which can also be metallic, possess excellent heat dissipation, thermal and electrical conductivity [

4]. On the other hand, lattice structures possess high specific strength and stiffness, and optimal structural properties [

2,

4]. As reported in [

5], within the macro area of lattice structures, three additional categories can be identified: disordered, periodic, and pseudo-periodic lattice structures. Specifically, the first category is characterized by unit cells that are arranged randomly with varying cell sizes. The second category, periodic lattice structures, refers to the periodic repetition of lattice cells that have specific shapes and topology within three-dimensional Euclidean space. Conversely, the third category, pseudo-periodic or conformal lattice structures [

2], is characterized by each unit cell maintaining a consistent topology while varying in size. Furthermore, among periodic lattice structures, there are various types, such as Diamond [

6], Face-Centered Cubic and Body-Centered Cubic lattices (BCC) [

7]. However, BCC ones represent one of the most common configurations and are the focus of the present study, not only for their well-defined geometry but also for their extensively studied mechanical behavior. In detail, BCC lattices are typically bending-dominated [

8], a behavior resulting from the limited number of struts per unit cell, which leads to load transfer primarily through bending rather than axial forces. This results in a relatively higher specific energy absorption (

) [

9] under deformation. Furthermore, to estimate their effective mechanical properties based on the bulk material and relative density, the Gibson–Ashby model [

3] is commonly adopted, providing a theoretical framework widely used in the analysis of lattice materials.

From a manufacturing standpoint, various techniques can be employed. Noteworthy methods include the creation of perforated sheets [

10], and selective laser melting [

11], with comprehensive reviews available in [

12,

13].

The industrial application of lattice structures is especially esteemed due to the capability to incorporate advanced production technologies such as additive manufacturing (AM). According to [

14,

15], AM technologies provide the capability to create custom-designed components with complex geometries while minimizing material waste. It allows the use of a wide range of materials, including metals [

16,

17], and composites [

18,

19]. Furthermore, numerous studies in the literature have explored the application of polymeric materials. Among these, particular attention is given to those in which polylactic acid (PLA) is used, as in the present study. In particular, BCC lattices manufactured with PLA have been widely adopted in energy absorption (

) applications, due to their ability to sustain large deformations while maintaining general structural integrity. For instance, in [

20] the authors investigated the low-velocity impact behavior of bi-material structures composed of 3D-printed PLA lattice frames impregnated with polyurethane foams. The use of PLA provided a lightweight yet sufficiently strong structural framework for evaluating the effect of different foam reinforcements. Similarly, [

21] employs PLA as the base material for additively manufactured lattice structures tested under low-velocity impact. Three different core configurations were investigated—honeycomb, tubular, and truss—with the truss design exhibiting the highest specific

under identical impact conditions. Furthermore, Hedayati et al. [

22] employed PLA as the base material for AM-fabricated lattice sandwich panels subjected to low-velocity impact. The study highlights PLA’s suitability for lightweight energy-absorbing structures, while also addressing its sensitivity to environmental degradation affecting impact performance.

Based on the above, the use of PLA in this study represents a consistent choice with the current state of the art, which highlights this material for its lightweight nature and good printability. Moreover, PLA was selected due to its wide commercial availability, low cost, ease of processing, and mechanical properties suitable for the impact conditions investigated. Thus, AM represents a significant advancement in the field of production and, as already mentioned, offers numerous advantages. To this end, the present study investigates two additively-manufactured PLA-BCC lattice configurations, differing only in strut diameter (1.5 mm and 2 mm). Since the local impact response of lattice structures depends on the specific point of impact, this research addresses a gap in the literature by proposing a method to quantify localized deformation under low-velocity impacts—an aspect that conventional global metrics such as , , or mean crushing force () fail to capture. In this regard, a novel dimensionless index, , capable of capturing the interplay between local plastic indentation and global displacement, is introduced. In each configuration, the independent variable is the strut diameter, while the dependent properties include , , , and the newly proposed index. Both experimental drop-weight impact tests and finite element simulations were conducted, allowing for a comprehensive comparison and validation of the proposed metric across physical and numerical domains. This dual approach provides a robust framework to evaluate how geometry-driven local effects influence global capacity in lattice structures.

This work is organized into the following sections:

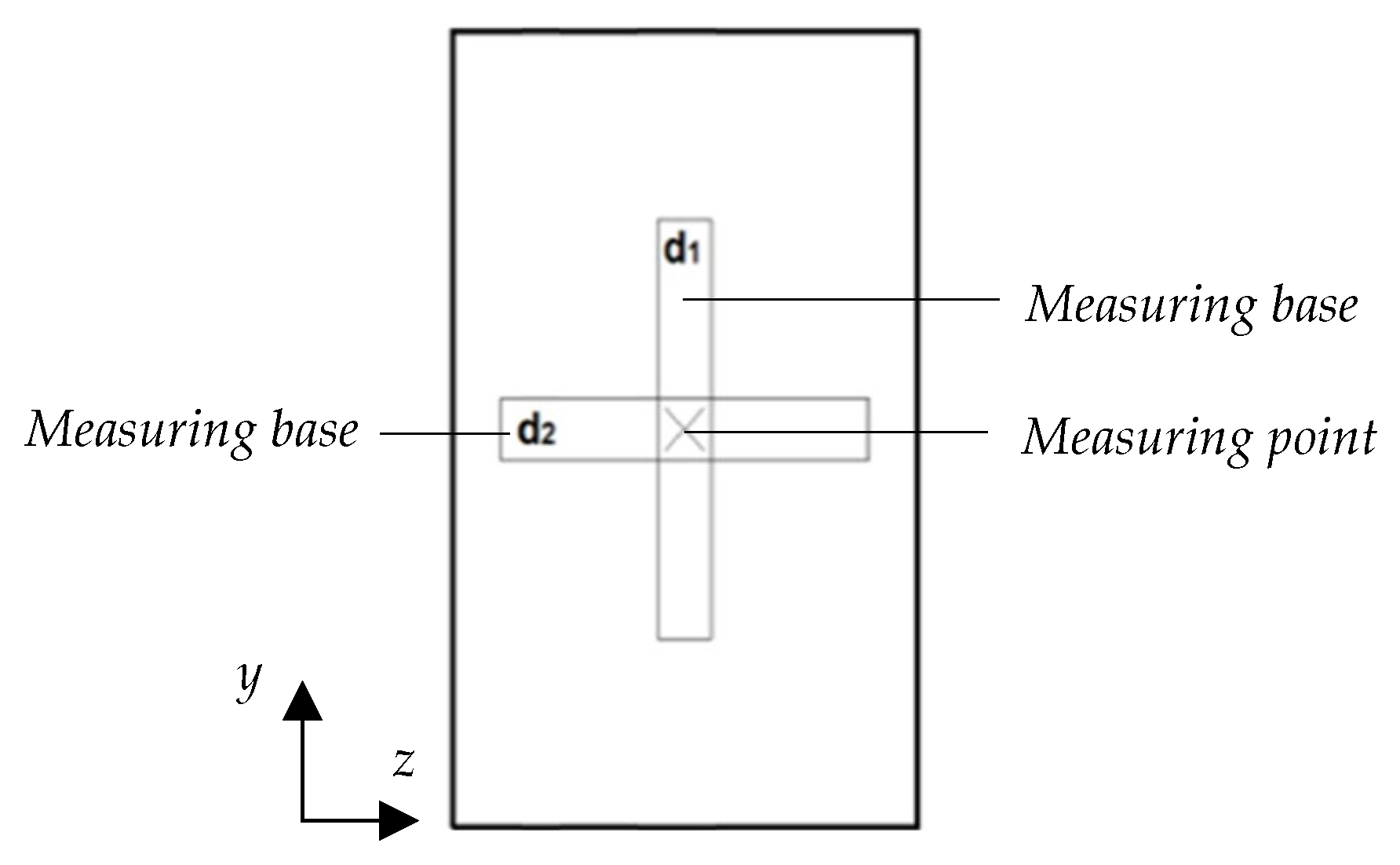

Section 2 introduces the theoretical background and defines the aforementioned index for both experimental and numerical cases.

Section 3 describes the experimental and numerical setup.

Section 4 presents the results.

Section 5 presents a comparison between numerical and experimental results and discusses the effectiveness of the proposed index, while the conclusions are reported in

Section 6.

5. Discussion

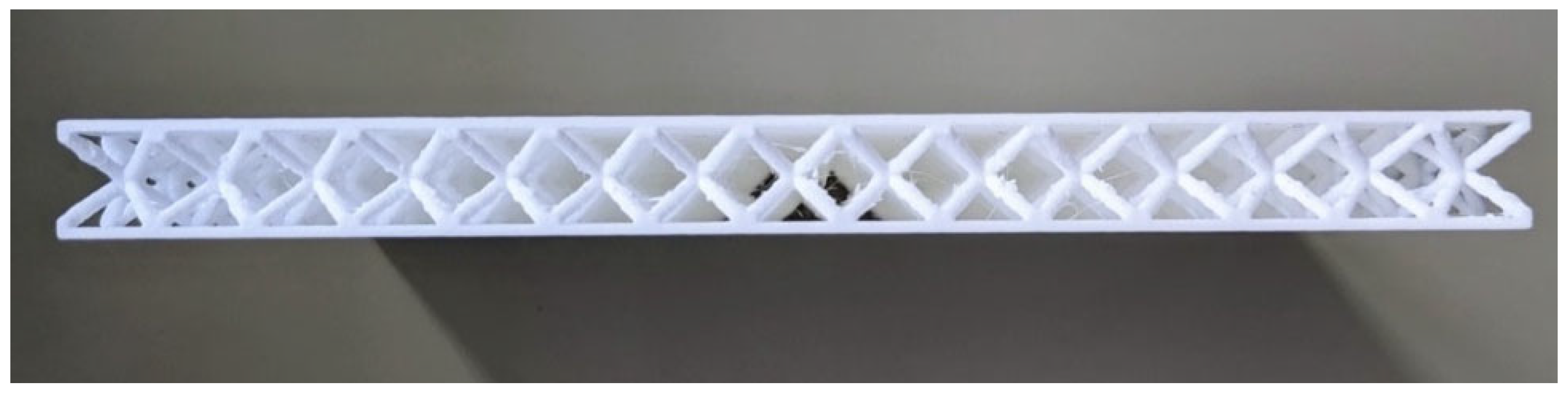

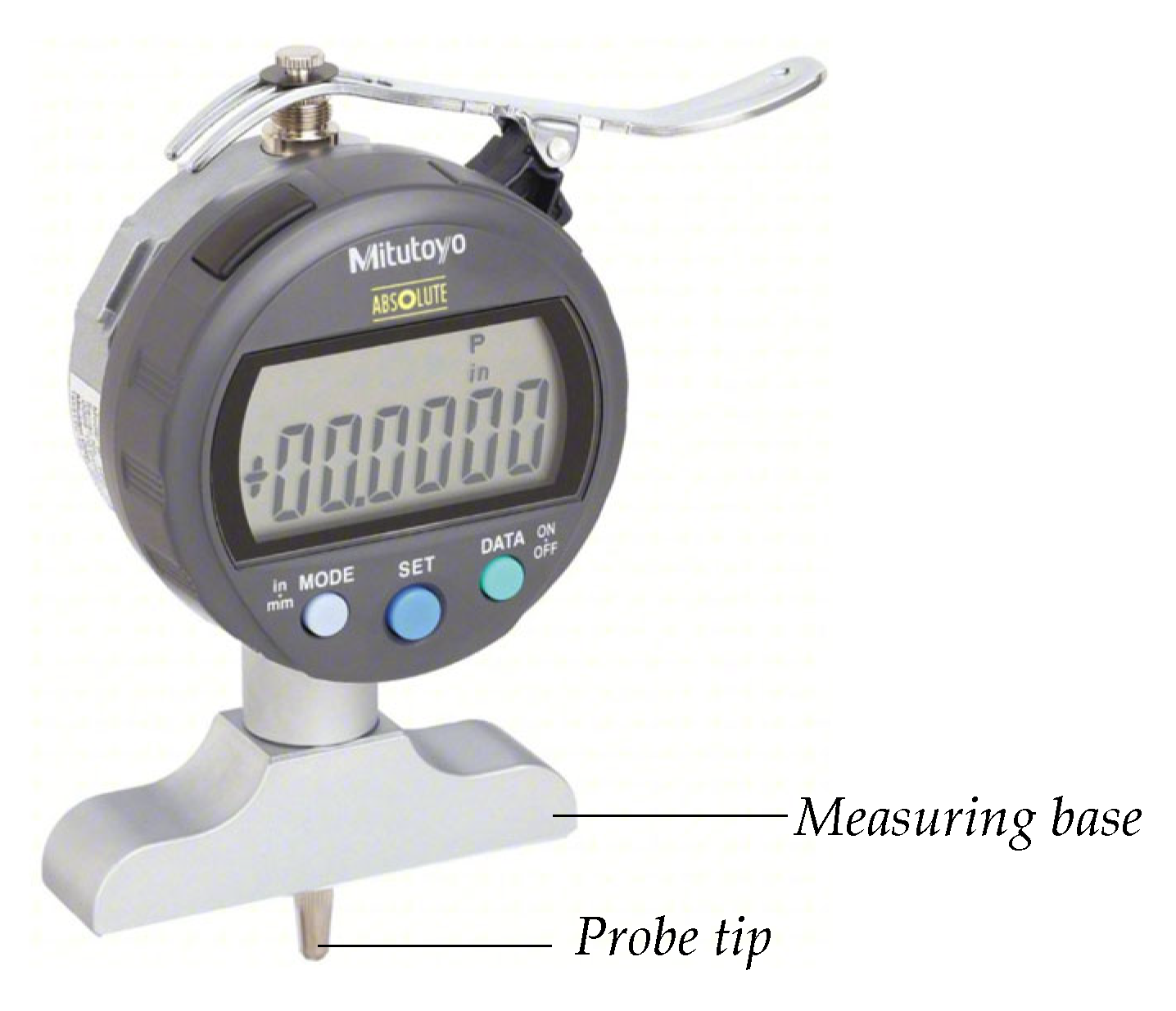

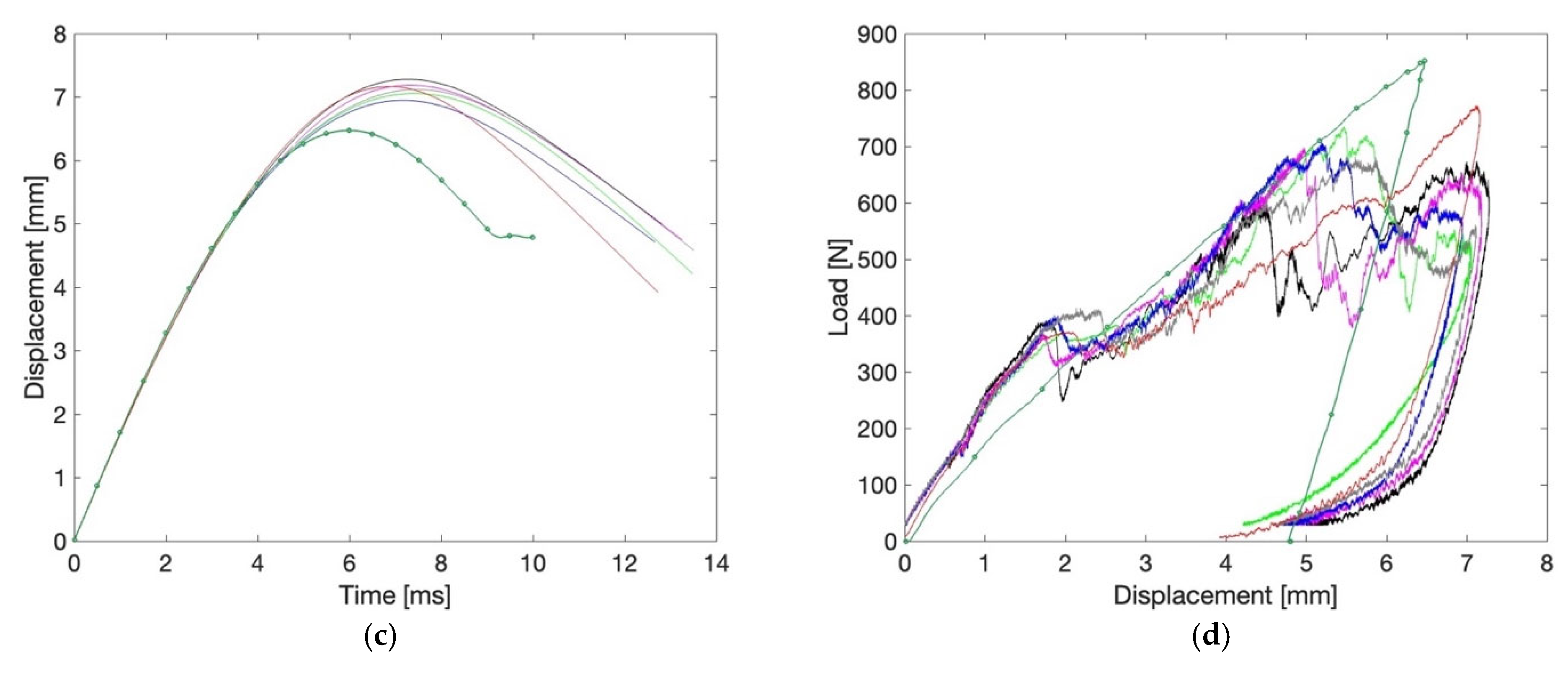

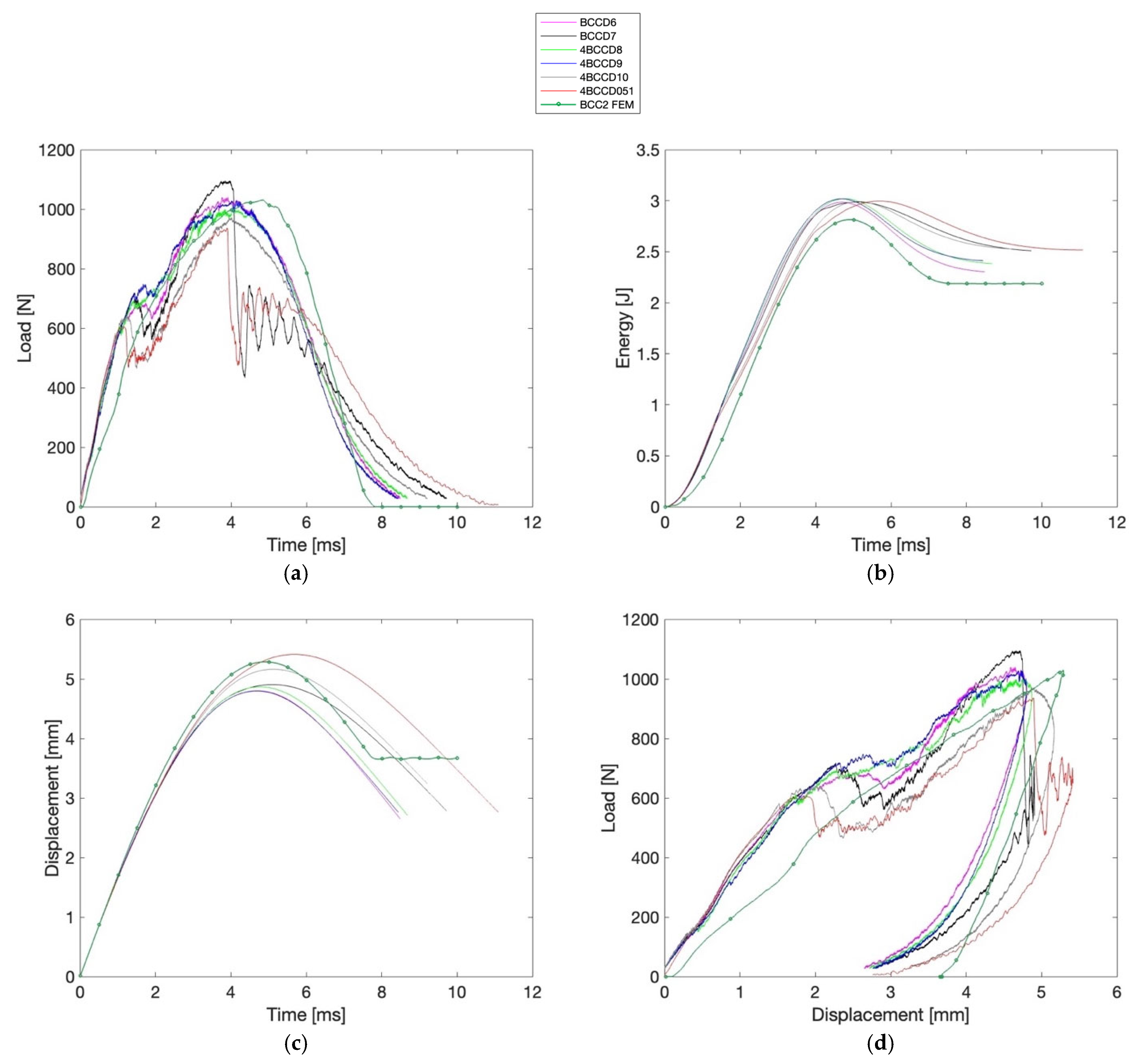

In this work, the dimensional characterization of the PLA-based BCC lattice specimens, manufactured via 3D printing, confirmed high fidelity to the nominal design specifications. Both BCC1.5 and BCC2 samples exhibited deviations below 0.2% for width and length, and thickness increases within acceptable tolerances (+1.2% and +1.9%, respectively). Furthermore, the low coefficient of variation (below 1%) across all measured dimensions highlights the good overall repeatability of the manufacturing process. From a data analysis perspective,

Table 4 and

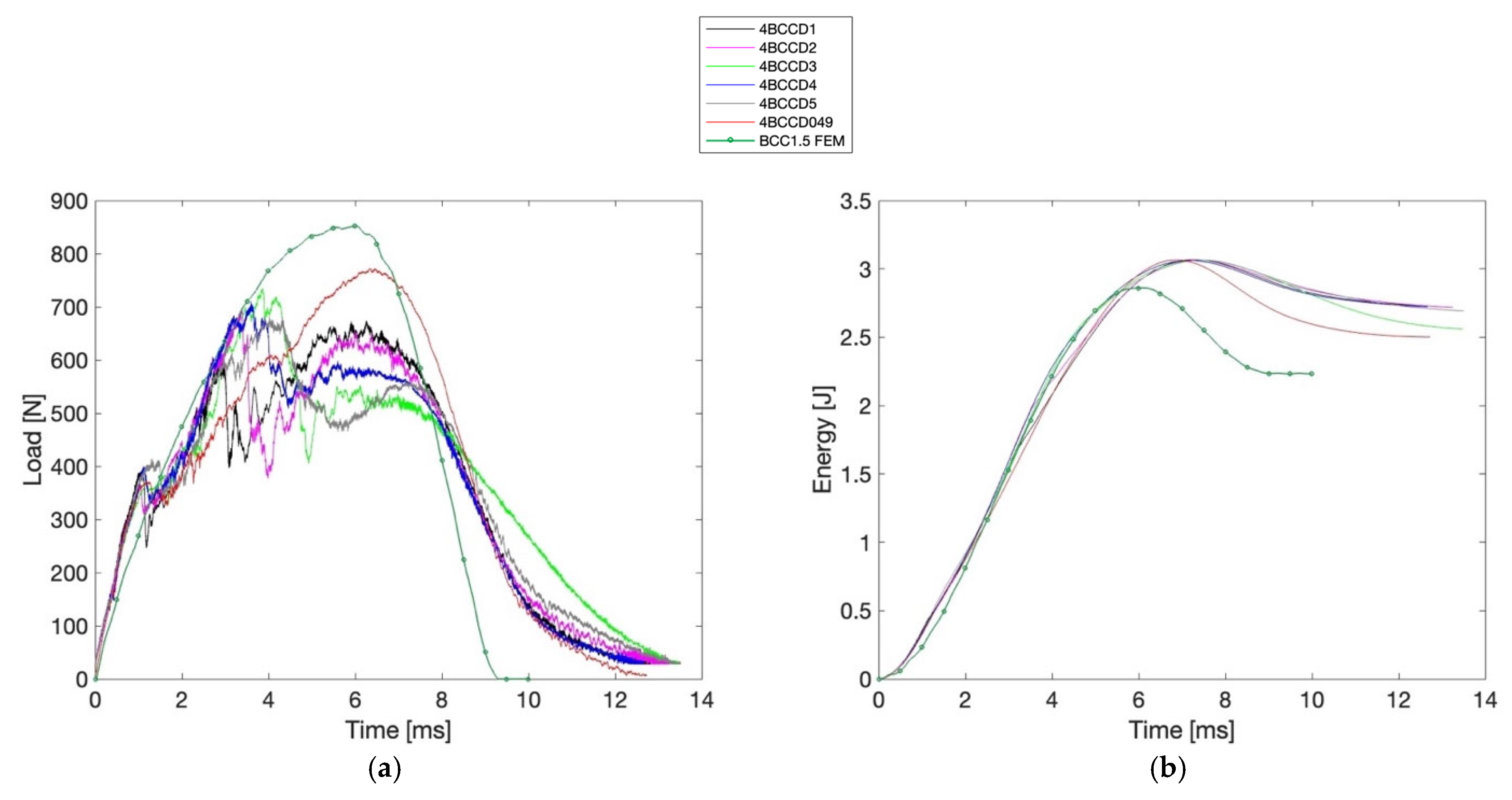

Table 5, together with the time–load, time–energy, time–displacement, and displacement–load diagrams presented in

Figure 7 and

Figure 8, highlight the fundamental influence of strut diameter on the mechanical response of BCC lattice structures under low-velocity impact. The BCC2 configuration, characterized by thicker struts, exhibits significantly higher

—ranging from 937.20 N to 1096.00 N—reflecting an overall stiffer and more rigid structural behavior. However, this increased stiffness limits the structure’s ability to deform, as shown by the lower

observed in BCC2 samples, all below 5.41 mm. In contrast, the BCC1.5 specimens, with thinner struts, reach

values consistently above 7 mm on average, and display a more extended displacement–load curve. These longer deformation paths correspond to higher

values, calculated according to Equation (1), with BCC1.5 samples averaging 2.65 J compared to 2.44 J for BCC2. This allows the BCC1.5 structures to absorb energy gradually across a larger displacement range according to

Table 6. As shown,

SD is identical for both BCC1.5 and BCC2 (0.09 J), indicating a comparable repeatability of the global structural response. The

and

dent depth measures further support this interpretation. BCC1.5 specimens exhibit deeper indentations, indicating more significant local plastic deformation. In contrast, BCC2 samples show shallower dents, generally below 3 mm, confirming a more localized and limited response to impact.

Furthermore, a dimensionless index

, defined in Equations (4) and (5), was introduced by providing a simple and physically interpretable metric that quantifies the ratio between local plastic indentation and global displacement. The correlation between

and

, also reported in

Table 6, suggests that the

mechanism is not solely governed by

but is also influenced by localized indentation effects. Specifically, this trend can be observed when comparing samples such as 4BCCD2 and 4BCCD5, both belonging to the BCC1.5 category. Despite exhibiting comparable maximum global displacements (

≈ 7.18 mm and 7.11 mm, respectively), they present different values of

due to the significantly deeper dent, indicating that localized deformation contributes differently to the overall absorption process. Furthermore, it can be observed that 0.31

for the BCC1.5 specimens, whereas BCC2 sample cluster 0.33

. SD

is markedly higher for BCC1.5 (0.19 vs. 0.07), suggesting a greater variability in the localization of plastic deformation, likely due to local instabilities. Moreover, as shown in

Table 4,

, calculated according to Equation (2), ranges narrowly between 0.04 and 0.05 J/g, and

, determined based on Equation (3), between 0.34 and 0.40 J/mm indicating similar

and average resistance across samples. However,

spans a wider interval, effectively differentiating between specimens exhibiting distributed versus localized deformation. In our experimental data, values approaching

are not generally associated with a reduction in

; nonetheless, according to Equation (4),

flags pronounced perforation for sample 4BCCD5, despite its

and

values falling within the expected range. This behavior is also evident in the time–load diagrams in

Figure 7. Specifically, specimen 4BCCD5 (gray line) clearly stands apart from the others: while all samples display a marked peak between 4 and 8 ms, the response of 4BCCD5 exhibits a pronounced dip in the same time range. A similar pattern holds for BCC2 specimens. Here too,

and

show little variation (

= 0.03 J/g;

≈ 0.48–0.51 J/mm). Yet, specimen 4BCCD051 stands out with a

of 0.53, indicating a potential early shift toward localization that is not clearly reflected in the global indices. In the time–load diagram, 4BCCD051 corresponds to the red line and displays a curve like that of 4BCCD7 (black line), although it exhibits the lowest peak load among all tested samples.

The numerical data presented in this study show a reasonable agreement with the experimental findings. As reported in

Table 7, for the BCC1.5 specimens, the numerical simulation yielded an

of 2.30 J, an

of 0.35 J/mm, and a

of 0.04 J/g. These values can be compared to the

of 2.65 J,

of 0.37 J/mm, and

of 0.04 J/g, with a percentage error of 13.21% for the

. Similarly, the BCC2 model returned an

of 2.25 J,

of 0.42 J/mm, and

of 0.03 J/g, compared to the

values of 2.44 J, 0.49 J/mm, and 0.03 J/g, respectively, corresponding to a percentage error of 7.79% in

. Nonetheless, the simulations resulted in a

value of 0.74 for BCC1.5 and 0.70 for BCC2; these can be compared to the

of 0.46 for BCC1.5, and 0.38 for BCC2.

Because fracture/damage is not explicitly modeled, also serves as a potential diagnostic of the deformation pathway—indicating how the computation progressed and the extent to which the model captures expected localization mechanisms. The observed behavior of in both experimental and numerical results suggests its relevance not only for interpreting impact responses but also for identifying samples with deformation modes that may compromise structural integrity despite acceptable global metrics.

Undoubtedly, the results obtained depend exclusively on the impact point. This reveals a strong sensitivity of the outcomes to the location of the impact. Therefore, the collected data are valid only when the impactor strikes the standard reference point. In general, for a BCC-type lattice structure, the possible impact scenarios include the impactor striking (i) a node, (ii) between two nodes, or (iii) barycentric among four nodes.

When the impact occurs at one location or another, the global response may remain mostly unaffected, but local variations arise. In particular, the scenario (iii), which corresponds to the configuration adopted in this study, tends to exhibit greater compliance. Impacts in scenario (iii) produce deeper indentations, and thus higher values. This is due to the absence of direct energy transfer to the nodes, as most of the impact energy is absorbed by the upper skin. Hence, the findings are not generalizable but rather specific to the analyzed configuration. Consistently with this observation, statistical analysis revealed that is not significantly different between the two configurations (). The lack of significance for can be attributed to scenario (iii). Under this configuration, does not effectively capture the influence of strut diameter differences between BCC1.5 and BCC2. However, could become statistically significant when the impact occurs directly on a node, where local deformation is more pronounced. In such cases, the parameter should indeed be able to reflect differences in structural configuration. Furthermore, when parameters such as skin thickness are varied, could also prove to be effective in distinguishing structural responses.

Although the current experimental campaign is still at an early stage, future work will quantify response heterogeneity, also by incorporating a damage model. For better understanding the potentiality of the index, a possible approach involves conducting both numerical and experimental campaigns where the impactor hits a single node or between two nodes, also varying the skin thickness. This would enable a deeper understanding of the local non-uniform behavior of the specimen, while the variation in skin thickness would further highlight the sensitivity of the index to stiffness. Furthermore, given that the heterogeneity also depends on the relationship between the impactor and the cell dimensions, future investigations will serve to emphasize these relationships. In this regard, when the cell size approaches zero, the specimen behaves as a homogeneous material. On the contrary, when the cell size is much larger than the strut diameter, pronounced heterogeneities emerge. In this context, the index appears to be the most sensitive indicator of structural heterogeneity.

6. Conclusions

This study aimed to investigate the low-velocity impact behavior of PLA-based BCC lattice structures, focusing on the influence of strut diameter and the role of local deformation mechanisms. Two configurations, differing solely in strut diameter (1.5 mm and 2 mm), were examined through a combined experimental and numerical approach. Drop-weight impact tests were carried out alongside finite element simulations using Ansys LS-DYNA (version 2023 R1).

To overcome the limitations of traditional global metrics (, , ) in capturing localized deformation, a novel dimensionless index, , was proposed. This index quantifies the ratio between local plastic indentation and global displacement, providing a more nuanced understanding of structural response. Moreover, by definition, the index proved to be an effective metric to capture the heterogeneity of the lattice structures. The results showed that the BCC structure with thinner struts, although characterized by lower stiffness, absorbed more energy, making it more suitable for non-structural applications—e.g., protective frames, battery housings, or sensor mounts in Unmanned Aerial Vehicles—where its reduced initial stiffness is offset by a more progressive deformation and a more stable , thus minimizing the risk of sudden failure.

Although the index shows limited generalizability in two separate scenarios—specifically, when the impactor strikes between four nodes, and when the configurations being compared share the same skin thickness—it still proves to be a promising tool under alternative impact conditions.

In conclusion, these results highlight the importance of integrating both global and local metrics when evaluating the impact performance of lattice structures, and demonstrate the potential of as a complementary tool for structural engineering assessment.